Spring Air Systems Dynaflow, Dynaflow FN-B-MB, Dynaflow Series, Dynaflow FN-B-MJ Installation And Maintenance Manual

Dynaflow

Hood

Installation and Maintenance

Manual

___________________________

Spring Air Systems Inc., Oakville, Ontario

Phone (905) 338-2999, Fax (905) 338-0179, info@springairsystems.com

2010 Revision 1.0

Dynaflow Installation and Maintenance

Manual

Table of Contents

Introduction 1

Spring Air Systems Hood Model Number Designations 2

Dynaflow MB Hood Principle of Operation 2

Three Fresh Air Boundary Regions 3

Standard Dynaflow MB hood specification 3

Dynaflow MJ Hood Principle of Operation 4

Standard Dynaflow MJ hood specification 5

Dynaflow Installation 5

Arrangement “D” Exhaust Fire Damper Assemblies 7

Link/Cable Assemblies for various exhaust duct collar sizes. 7

Adjusting the Fire Damper Blade Position 9

Grease Filter for Dynaflow Hoods 10

MJ Blower assembly for all MJ hoods 13

Dynaflow Maintenance Schedule 14

Trouble Shooting and Cleaning 15

Measuring Exhaust Air flow with VE, HE, EC and Sa Filters 16

Measure Exhaust Air Flow with CA Filters 20

Measuring Dynaflow MB Supply 22

A. Measuring the Appliance Region 22

B. Adjusting the MB Blade to change velocity at the appliance region. 23

C. Adjusting the air velocity to the Chef Region. 23

C. Measuring the Supply Discharge velocity from the MB Blade. 23

Measuring Dynaflow MJ Plenum Air 25

A. Measuring the Appliance Region 25

B. Adjusting the MJ Blower to change the appliance region velocity 26

C. Adjusting the air velocity to the Chef Region 26

T

Dynaflow Hood Installation and Maintenance Manual

INTRODUCTION

Thank you for selecting a SPRING AIR SYSTEMS INC. Dynaflow commercial kitchen exhaust hood. The Dynaflow

hood is an innovative idea in commercial kitchen ventilator design that provides for the total kitchen comfort, particulate

capture and energy efficiency.

People comfort. The fresh air introduced through the make up air plenum utilizes the Comfort Tuning Blade to provide

a comforting breeze for the people working under the kitchen hood.

Balanced air flow design: The kitchen hood exhaust air and fresh air introduced into the kitchen space are always

balanced, reducing drafts, hot and cold spots and improving particulate capture.

Low exhaust volumes: The exhaust volume is minimized with dynaflow technology to maximize your energy

savings.

The Spring Air Systems Inc. Dynaflow hood was

selected to best meet the design requirements of

your commercial kitchen application.

The Dynaflow hood is a NFPA-96 Type 1 listed for

use with all temperature ranges on single row; wall

mounted, island double row cooking or island

single row cooking equipment lineups, The hood is

MAXIMUM 87"

MOUNTING HEIGH

Typical Dynaflow FN-B-MB Hood

Figure 1

• VE - standard grease extraction efficiency Stainless steel baffles.

• CA - Medium grease extraction efficiency cartridges with adjustable flow baffles.

• HE - High grease extraction Efficiency Cascade baffles for Enviro applications and reducing grease discharge

from buildings.

• EC - Easy Clean Teflon – standard grease extraction efficiency baffles for hot, heavy grease laden appliances.

• SA - Spark Arrestor – standard grease extraction efficiency, for solid fuel appliances.

ceiling hung with a maximum mounting height of

87” (2209 mm) from the lower front edge of the

canopy to the floor and (52” (1320mm) from the

surface of the cooking equipment to the lower edge

of the grease extractor). The box canopy can be

tapered to 11” (279 mm) at the front. The hood is

finished with a number 4 finish on exposed sides.

The Dynaflow hood is available with fluorescent,

incandescent, recessed incandescent or LED lights

wired to a J-box.

The Dynaflow hood is equipped with UL/ULC listed

grease filters or cartridges. Five extraction types are

available with Dynaflow.

1

Model Number Designation

Sample Model Number

F N B MB (VE)

F= Filter Hood

N= Exhaust duct collar with no fire damper, listed under

D= Exhaust duct collar with fusible link fire damper

B = box canopy

DS= double box canopy single row appliance

DB= double box canopy double row appliance

MB= Dynaflow type hood with Tri-Zone control System

MJ= Dynaflow type hood with Perimeter Defense control System

VE= standard grease extraction efficiency Stainless steel baffles.

CA= Medium grease extraction efficiency cartridges with adjustable flow baffles.

HE= High grease extraction Efficiency Cascade baffles for Enviro applications and reducing grease

discharge from buildings.

EC= Easy Clean Teflon – standard grease extraction efficiency baffles for hot, heavy grease laden

appliances.

SA= Spark Arrestor – standard grease extraction efficiency, for solid fuel appliances.

Dynaflow MB hood

8.00

6.00

3.00

2.00

1

54.00

5.25

APPLIANCE

2

5.50

3

23.00

MAXIMUM

87"

MINIMUM DOOR

WIDTH TO CLEAR 27"

Dynaflow FN-B-MB Hood Section

View with standard VE filters.

Figure 2

Principle of Operation

The Dynaflow design provides the lowest minimum exhaust. The Dynaflow hood exhaust volume is based on the

appliances below the hood. It’s a simple adjustment to fine-tune your ventilator to provide excellent smoke capture with

maximum grease extraction.

2

Fig

Heated and/or cooled fresh air ducting is connected to the supply duct collar(s) on the top, front of the hood. The fresh air

enters the fire damper in each supply duct connection and then discharges into the Dynaflow plenum. Within the plenum

the fresh air is routed to three (3) regions within the boundaries of the appliances.

Three Fresh Air Boundary Regions

1. Appliance Region: Fresh air discharges down through a full length S/S perforated panel, creating an air curtain

around the perimeter of the hood within the boundary of the kitchen appliances for excellent smoke capture with

maximum grease extraction and to reduce each appliance net exhaust requirement.

2. Chef Region: Fresh air discharges down through a full length S/S perforated panel towards the chef for a more

comfortable work environment in front of the hood.

3. Kitchen Ambient Region: The horizontal fresh air discharges through a s/s perforated panel out the front of the hood

into the kitchen to provide the exact amount of air to balance the kitchen and ensure optimum capture

HOOD CANOPY

END VIEW

Internal Blade (IB)

Comfort Tuning Blade(CTB)

BLADE FULL OPEN

1 Appliance Region Chef Region2 Kitchen Ambient Region3

3

HOOD CANOPY

END VIEW

BLADE FULL CLOSED

12 21

3

HOOD CANOPY

END VIEW

BLADE HALF OPEN

3

21

Fresh Air Regions

ure 3

The internal blade (IB) is adjusted to direct fresh air between the Kitchen Ambient (3) Region, the Appliance (1) Region,

and Chef (2) Region. The Comfort Tuning Blade (CTB) is adjusted to direct fresh air between the Appliance (1) Region

and the Chef (2) Region. The complete kitchen ventilation system is always balanced. The IB and CTB are adjustable

every 24” (610mm) along the length of the Dynaflow hood to match the appliances underneath. Dynaflow operates with

the lowest minimum exhaust. After your kitchen is complete, appliances can be Relocated, Added, or Removed from

under the hood while maintaining maximum capture and chef comfort within the commercial kitchen.

Standard Dynaflow MB hood Specification

The unit casing shall be a minimum 18 GA. stainless steel, with No. 4 finish on all exposed surfaces. The hood shall include UL/ULC

listed grease filters mounted in an integral stainless steel rack inclined at 45 degrees. The filter rack shall include a full length stainless

steel grease gutter and grease cup.

The optional exhaust fire damper shall be an arrangement "D", butterfly type, constructed of stainless steel with blade and edge seals.

The fire damper shall be activated by a fusible link and dead weight arrangement.

The Dynaflow plenum provides all the fresh air required for the commercial kitchen. The fresh air is routed to three (3) regions within

the boundaries of the appliances. Each region includes an aerodynamically designed s/s perforated discharge panel.

The first (1) region discharges through a full length s/s panel located at the bottom of the Dynaflow plenum. Fresh air is directed through

the Comfort Tuning Blade (CTB) towards the appliances providing maximum exhaust air reduction. The second (2) Region discharges

through a full length s/s angular panel located at the bottom front of the Dynaflow plenum. The fresh air is directed towards the chef to

provide a more comfortable work environment in front of the hood. The third (3) region provides horizontal discharge of fresh air

through a s/s perforated panel out the front of the hood into the kitchen. The third region provides the exact amount of fresh air to

balance the kitchen and ensure optimum capture.

The s/s front discharge shall include multiple s/s perforated panels for the full length of the hood. A manually operated Internal Blade

(IB) damper shall be located behind each front s/s discharge panel. The CTB and IB dampers are field adjustable through the lower s/s

discharge panel. The hood shall have ______ incandescent/fluorescent/recessed/incandescent/LED lights evenly spaced along the length

of the hood. Optional Sideflow right and/or left MJ blower assemblies are available.

3

Fig

Fig

Dynaflow MJ hood

Principle of Operation

The MJ Perimeter Defense design exhaust volume is based on the appliances under the hood. It’s a simple calculation to

determine your best exhaust volume for any commercial kitchen lineup. The MJ Perimeter Defense hood can be fine-tuned

to provide excellent smoke capture with maximum grease extraction. A MJ tangential blower is mounted on top of the

plenum. Return air from the ceiling is drawn into the blower inlet through removable washable aluminum mesh filters.

The tangential MJ blower discharges air through a fusible link fire damper into the MJ plenum. The air is then discharged

from the bottom through a two way adjustable perforated grill. The air is then proportioned between the appliances and the

chef aria by adjusting the comfort tuning dial. This is not fresh air from outside the building. Fresh supply air must still be

introduced somewhere else in the commercial kitchen.

MESH FILTERS

RHEOSTAT

MJ BLOWER

FIRE DAMPER

MESH FILTERS

RHEOSTAT

MJ BLOWER

FIRE DAMPER

SIDEFLOW

MJ PLENUM

S/S PERFORATED

DISCHARGE

HOOD CANOPY

END VIEW

INTERNAL APPLIANCE DISCHARGE

FRONTFLOW

MJ PLENUM

S/S PERFORATED

DISCHARGE

HOOD CANOPY

FRONT RIGHT VIEW

SIDEFLOW DISCHARGE

MJ Perimeter Defense Operation

ure 4

Introducing supply air back into the kitchen is good engineering practice. An adequate supply of fresh air eliminates cold

drafts, and hot spots, enhances the capture capability of the hood and results in a more comfortable kitchen environment. A

supply air volume of at least 80% of the total exhaust is recommended. The fresh air should be tempered to between 55 and

75F (13 to 24C). Direct the fresh air to separate diffusers surrounding the hood located in the finished ceiling. The diffusers

must be located to eliminate short circuiting the exhaust and drafting. Consult with factory for recommended kitchen

diffuser locations. If the hood is required to supply the fresh air directly refer to the Spring Air MB DYNAFLOW

specification sheet

6.00

10.00

3.00

4.63

23.00

3.00

47.00

APPLIANCE

Dynaflow FN-B-MJ Hood Section View with standard VE filters.

5.25

87.00

ure 5

6.63

2.25

4.63

5.25

4

Fig

7

Fig

Standard

Dynaflow MJ hood Specification

The unit casing shall be a minimum 18 GA. stainless steel, with No. 4 finish on all exposed surfaces. The hood shall include UL/ULC

listed grease filters mounted in an integral stainless steel rack inclined at 45 degrees. The filter rack shall include a full length stainless

steel grease gutter and grease cup.

The MJ blowers provides ceiling return air to the MJ plenum which discharges out the bottom of the plenum through a s/s perforated

plate along the length of the MJ plenum. The return air is directed through the MJ plenum towards the appliances. MJ blower(s) mounted

on top of the plenum shall be complete with adjustable Triacs, washable filters and wired to a common J-box on top of the hood. A

fusible link fire damper is located below each MJ blower.

The hood shall have ______ incandescent/fluorescent/recessed/incandescent/LED lights evenly spaced along the length of the hood.

Optional Sideflow right and/or left MJ blower assemblies are available.

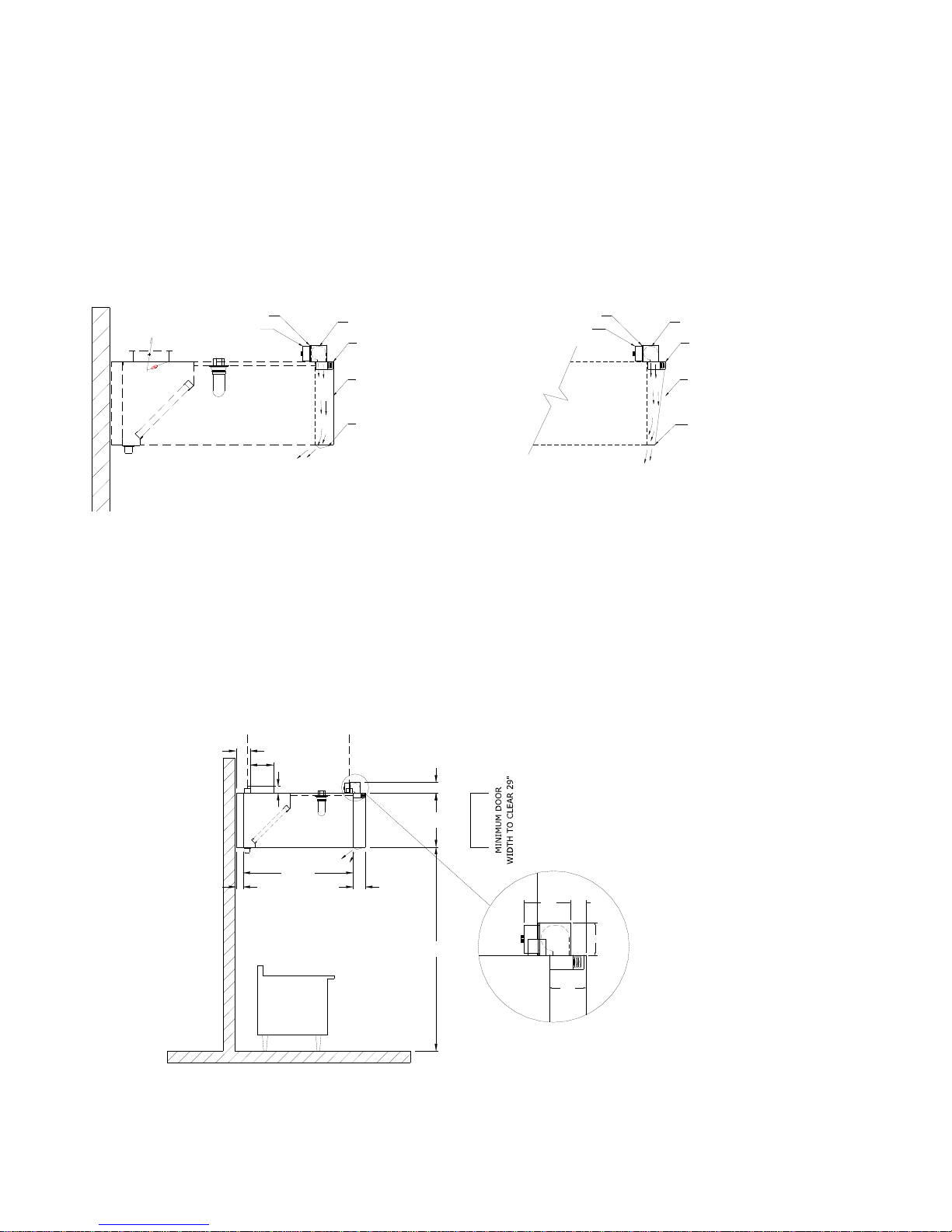

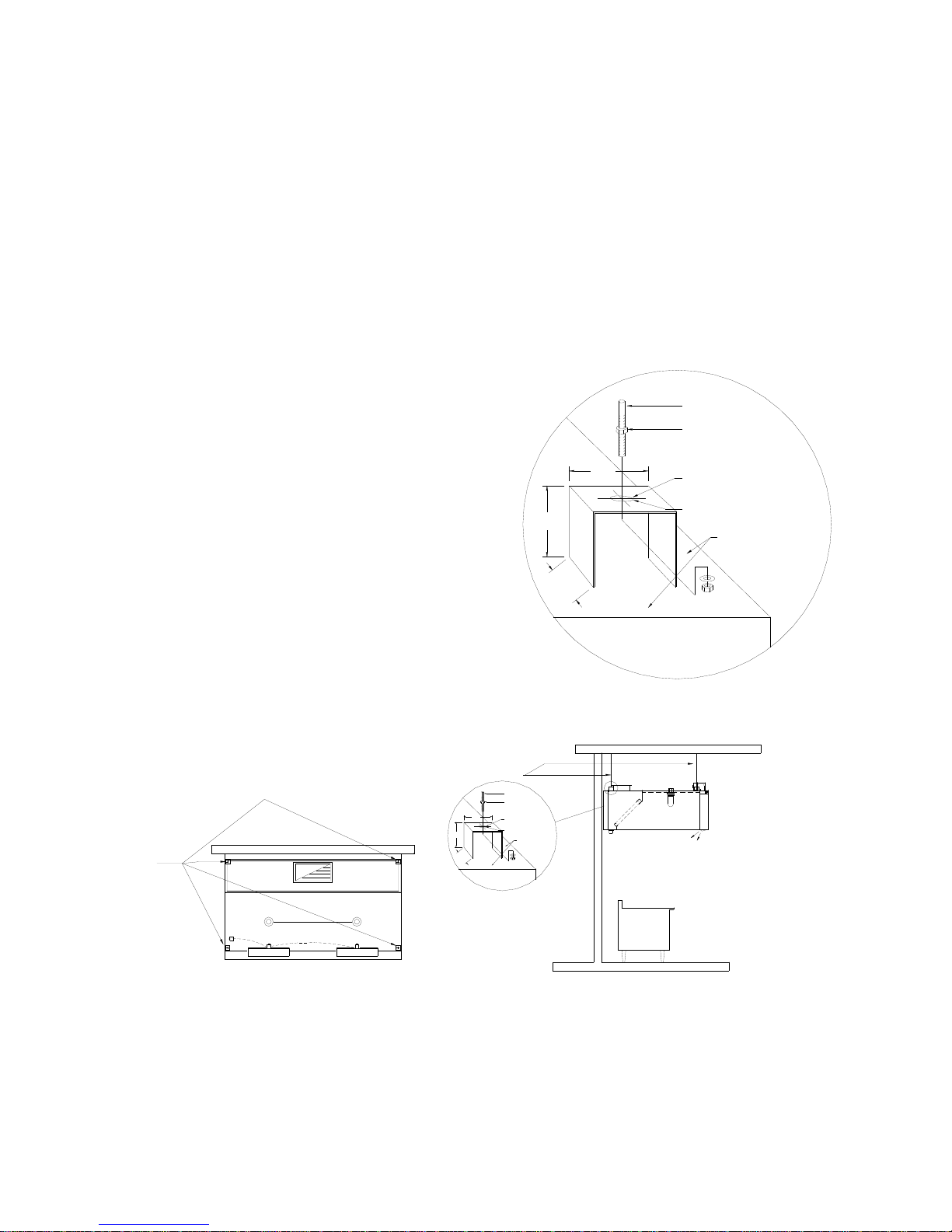

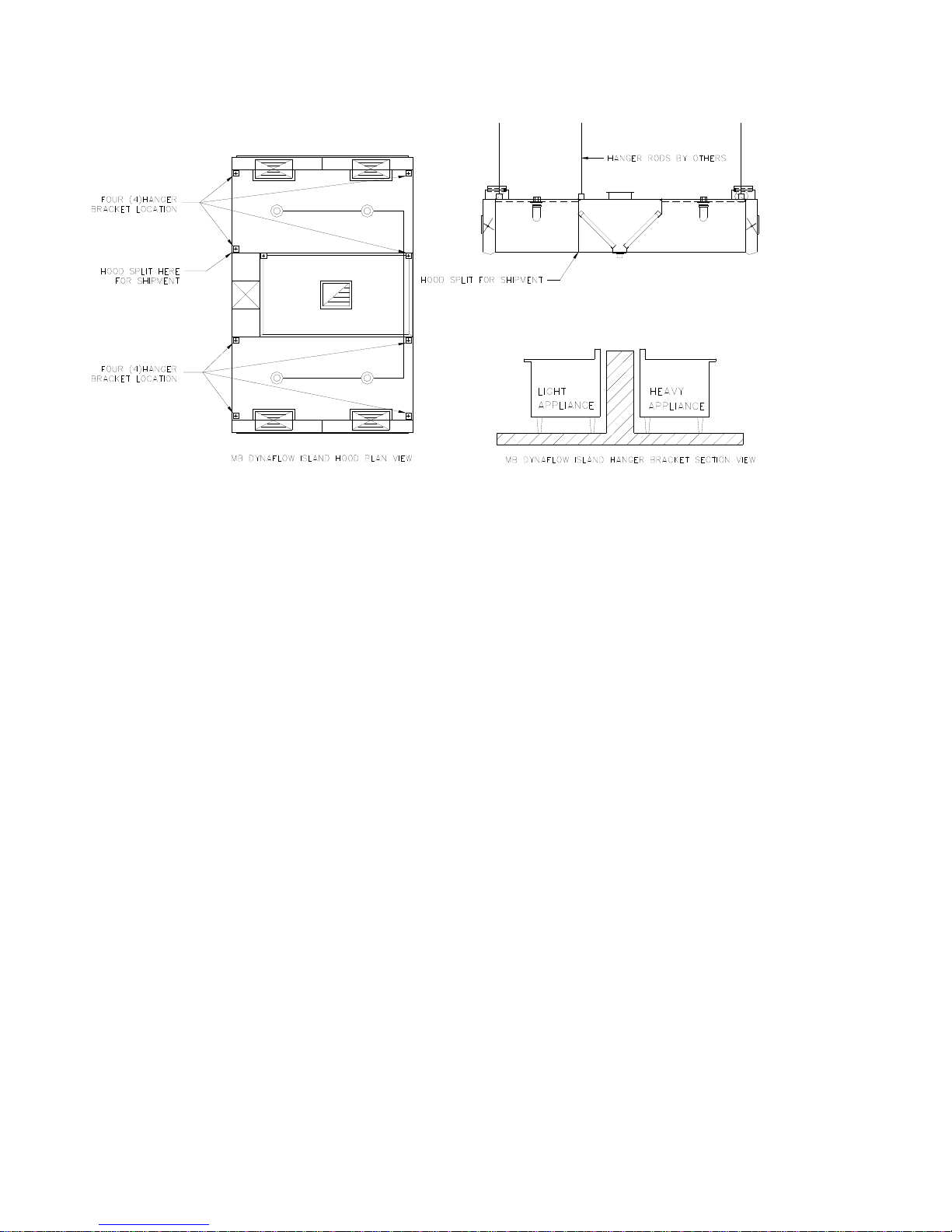

Dynaflow Installation

The Dynaflow hoods are hung from 4 or more hanging brackets

(depending on the model) mounted on top of the hoods as

indicated on the engineering drawings. The engineering

drawings indicate number and location of the hanger bracket.

All hanger brackets shown on the Spring Air Systems

drawings must be used to support the hood. Spring Air

Systems assumes no responsibility for the field installation

of the any hood.

A typical schematic is shown to the right with recommend

method on installing the hanger rods to the hanger brackets.

The size of the hanger rods, washers and nuts must be

determined by a structural engineer based on hood weight and

site conditions. All hood weight is shown on the Spring Air

Systems section view drawing. The hanger rods must be size to

safely hold the weight of the hood from the structure above.

The structure above must be designed to hold the weight of the

hood. Structural engineers will be required to determine what is

acceptable. The hanger bracket diagram indicates how the rod

is attached to the hood. All hanger rods must be installed

perpendicular to the roof of the hood.

2.25"

2.5

TOP OF

2.5"

HOOD

TYPICAL HANGER ROD

BRACKET ISOMETRIC

(FROM FRONT OF HOOD)

Hanger Rod Schematic

HANGER ROD

HANGER ROD NUT

PRE DRILLED HOLE,

ACCEPTS UP TO

1/2" Ø ROD

Ø 17/32"

HANGER BRACKET

OFFSET 1/2" FROM

EDGE OF HOOD

ure 6

FOUR (4)HANGER

BRACKET LOCATION

MJ DYNAFLOW PLAN VIEW

Wall mounted Dynaflow model FN-B-MJ Hood in Plan and Section View showing hanger rod locations.

HANGER ROD BY INSTALLER

HANGER ROD

HANGER ROD NUT

PRE DRILLED HOLE,

2.5

ACCEPTS UP TO

1/2" Ø ROD

2.25"

2.5"

MJ BLOWERMJ BLOWER

Ø17/32"

TOP OF

HOOD

TYPICAL HANGER ROD

BRACKET ISOMETRIC

(FROM FRONT OF HOOD)

HANGER BRACKET

OFFSET 1/2" FROM

EDGE OF HOOD

MJ DYNAFLOW HANGER BRACKET SECTION VIEW

APPLIANCE

ure

5

Fig

Typical Island Dynaflow model FN-DB-MB in Plan and Section View showing hanger rod locations.

ure 8

Your Dynaflow hood must be installed in accordance with the building permit issued for the commercial kitchen. The

hood may be mounted against a wall or in an island configuration.

The Dynaflow hood must be installed in accordance with the current edition of the NFPA-96, all local building codes, all

state or provincial building codes, all national building codes, and the authority having jurisdiction.

A commercial kitchen exhaust fan must be installed on the roof or wall mounted and connected to the hood by liquid tight

all welded duct in accordance to the current edition of the NFPA-96. A dedicated fresh air unit may also be installed

depending on the local code requirements for your area. Place the hood on the ground in the position it will hang below

the hanger rods. The hood must rest on wood 2”x 4” or some other soft material to prevent damages to the bottom edges.

When lifting the hood, support from the underside at the four corners. Otherwise the hood ends or sides may buckle. Lift

the hood straight up. Do not remove the lifting device until the hood is secure. After the hood is securely hung the exhaust

and supply ductwork can be connected.

Welding the Exhaust Duct to the Hood Exhaust Duct Collar

A “FD” Dynaflow hood is supplied with an Exhaust duct collar fire damper in the hood exhaust duct collar. The fire

damper must be closed before welding the hood duct collar to the exhaust duct. We recommend the exhaust duct be

continuously welded to the exhaust duct collar of the hood per the current edition of the NFPA-96. The fire damper is

closed by removing the link/cable assembly from the hook on the inside of the hood exhaust duct collar. Check to ensure

the damper moves freely open and closed within the exhaust duct collar after installation of the exhaust duct. Once the

welding is complete the link/cable assembly mu st be connected to the hook to open the fire damper. See the next section

for details on the cable/link assembly.

Supply ductwork, electrical wiring and plumbing must be installed in accordance with all applicable municipal, state,

provincial and national codes.

6

Fig

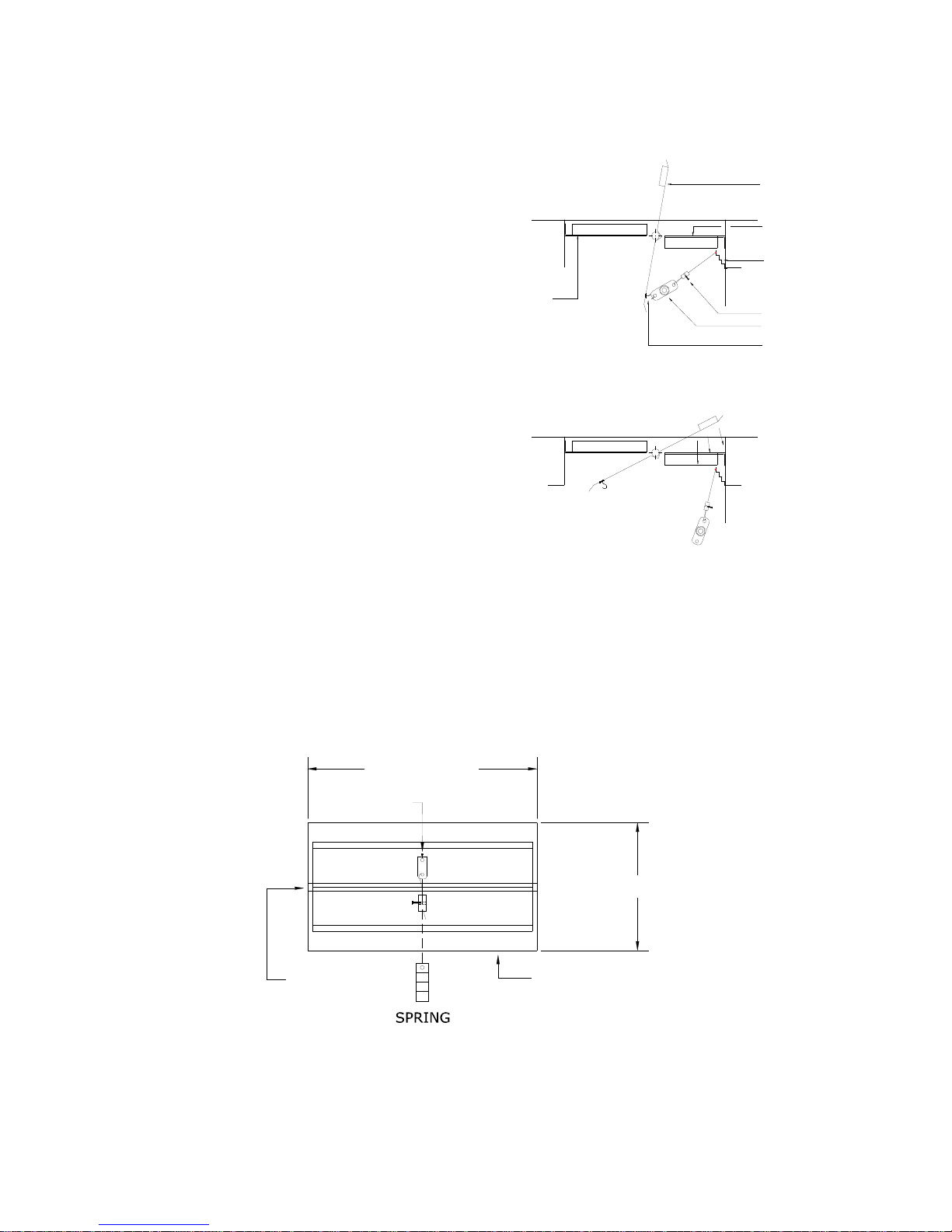

ARRANGEMENT “D” FIRE DAMPER ASSEMBLIES:

Provide on all FD Dynaflow Hoods.

(FN Hoods do not have a fire damper in the exhaust

duct collar)

Description:

The section view of the exhaust fire damper to the right

shows a cross section of the exhaust duct collar, fire

damper blade, fusible link, adjustable cable block, spring,

and stainless steel cable when the damper is in the set

position.

In the event of a fire in the exhaust duct collar, th e fusible

link melts, releasing the fire damper, which closes tight

on the damper blade stops and seals. The second drawing

shows the damper as the fusible link has been removed.

The damper will rotate clockwise against the damper bar

weight and close.

The complete assembly is part of the UL/ULC listed

Spring Air Systems “Commercial Kitchen Exhaust Hood

with Fire Damper”.

DAMPER BLADE

STOPS

SECTION VIEW OF ASSEMBLE FUSIBLE LINK

SECTION VIEW OF DISASSEMBLE FUSIBLE LINK

Link/Cable Assembly

ure 9

Link/Cable Assemblies for various Exhaust Duct Collar Sizes.

Dampers up to 18” long:

UP TO 18"

DAMPER BLADE

DUCT FLANGE

DAMPER BLADE STOPS

SPRING

CABLE BLOCK

FUSIBLE LINK

PIN

FIRE DAMPER

SHAFT

Exhaust Fire Damper up to 18” long

FIRE DAMPER

BLADE

Figure 10

PIN

WIDTH

EXHAUST DUCT

COLLAR PERIMETER

7

Dampers up over 18” up to 32” long

OVER 18" UP TO 32"

FIRE DAMPER

SHAFT

Dampers up over 32” long

DAMPERS OVER 32"

PIN

FIRE DAMPER

BLADE

PIN

PIN

FIRE DAMPER

BLADE

SPRING

UNDERSIDE OF TOP OF HOOD

Exhaust Fire Damper up to 18” to 32” long

Figure 11

PIN

WIDTH

PIN

WIDTH

EXHAUST DUCT

COLLAR PERIMETER

LEGEND

CABLE BLOCK

FUSIBLE LINK

S/S FUSIBLE LINK CABLE

PIN WELDED TO FIRE DAMPER BLADE

FIRE DAMPER

SHAFT

SPRINGSPRING

UNDERSIDE OF TOP OF HOOD

Exhaust Fire Damper over 32” long

EXHAUST DUCT

COLLAR PERIMETER

Figure 12

SPRING WELDED TO DUCT COLLAR

8

ADJUSTING THE DAMPER BLADE POSITION:

The fire damper fusible links, springs and cable blocks are all accessible through the front on the hood. For filter hoods

remove the baffle filters under the opening of the duct collar(s) of the hood. For dry extractors and cartridge remove the

inserts under the opening of the duct collar(s) of the hood.

A single, double, and triple fusible link assembly is shown above. The blade

position is adjusted by removing the fusible link/cable and block assembly

from the damper pin. The fire damper will close and the complete assembly

will hang loose from the spring. Loosen the set-screw on the adjustable

block and pull the stainless steel cable through the block to open the damper

or release cable from the stainless steel block to close the fire damper.

Once the correct position is reached, re-tighten the set screw on the

adjustable block and re-ached the fusible links on the damper pins.

The single fusible link damper has one block to adjust. The

double fusible link damper has two blocks to just and the

three fusible link dampers have up to four blocks to adjust.

Single Fusible link Damper

Figure 14

Two fusible link Damper

9

Grease Filters for Dynaflow Hoods

VE- Stainless Steel Baffle Filters

The exhaust air accelerates through two 90

degree turns within the baffle filters. The

liquefied grease then drains down the vertical

length of the baffles to the grease trough and

into a grease cup.

Each grease baffle contains weeping holes to

allow the liquid grease to drain into the grease

trough.

EXHAUST AIR OUT OF BAFFLE FILTER

FILTER BAFFLES

FILTER FRAME

EXHAUST AIR INTO BAFFLE FILTER

Always ensure that the grease filters are

installed with the weeping holes down

toward the grease trough.

Put the Baffle Filter in a dishwasher or in a pot sink in a detergent and water mixture to soak or spray the inner surfaces

with hot water and detergent to clean.

Cross Section of Baffle Filter

Figure 15

CA- Stainless Steel Cartridge Filters

The Cartridge Filter provides high efficiency grease extraction at an

economical price. Unlike standard baffle filter grease extraction is carried out

inside the Cartridge Filter not on any visible surface. The Cartridge Filter is

always aesthetic pleasing because the smooth stainless steel surface does not

collect oil or grease. The Cartridge Filter can be removed for easy cleaning.

Each cartridge is also adjustable for various exhaust volume.

Easy Cleaning

Remove the Cartridge Filter Module from the hood rack and take note of the

location of each module if the settings vary across the hood. Remove the

Cartridge Filter Baffle from the Module by taking out two wing nuts; located

in module air inlet.

Put the Cartridge Baffle along with the Module up side down in a dishwasher

or just spray the inner surfaces with hot water and detergent.

Re-install the Cartridge Baffle in the Module with its proper initial air setting

number and tighten the two wing nuts from the air inlet of the Module.

CA Cartridge

Figure 16

10

HE- High Grease Extraction Efficiency Cascade Filtration

Cascade high efficiency hood filtration captures more grease

than standard filters, reduce grease damage, the hassle and

expense of duct cleaning, cost much less than other high

performance filters, and have lower static pressure.

Cascade is 270% more efficient (at 8 microns capture) then

standard filters and removes 33% more grease than standard

filters. This will result in less grease build up in the ducts and

exhaust fan.

The Cascade is environmentally friendly reducing air pollution

and odors. It reduces duct cleaning cut down on caustic

cleaning chemicals.

Environmentally Friendly

Easy Cleaning

Remove the Cascade Module from the hood rack. Rotate the Locking

Handles opposite the hinge on the Cascade to open the filter. Open

the hinged Cascade and put it in the dishwasher or just spray the inner

surfaces with hot water and detergent.

After cleaning just close the Cascade, lock the handles together and

put them back in the hood filter rack.

Cascade shown in the Open Position

HE Cascade

Figure 17

Figure 18

EC- Easy Clean Teflon Filters for Heavy Grease

Applications.

Grease laden air is drawn into the filter by the exhaust fan.

As the air starts through the aerodynamic “V” baffle system,

it undergoes a series of compressions, expansions and

pressure changes. the heavy grease is deposited safely and

quickly on the baffles while the grease-free air passes

through the filter and up the exhaust duct. The baffle’s

smooth surface enables the collected grease to run off into

collection troughs without dripping on food utensils or burner

surfaces. the ChG.

Because Flame Gard® removes grease aerosols from the air stream and drain them away instead of retaining them. there is

no build-up of grease in the path of the air Flame Gard® therefore, insures a constancy of air never before achievable with

mesh-type filters.

EC – Easy Clean Teflon

Figure 19

11

Flame Gard’s high rate of grease extraction is aided by our TEFLON® coated baffle. In the same manner that grease rolls

off a TEFLON coated pan, it rolls down our baffles, out of the filter and into the hood’s remote collection cup. Because

FlameGard’s filters retain only insignificant amounts of surface grease and do not load, you will have constancy of air flow

throughout your operating day.

The FlameGard’s filters can be easily cleaned in a pot sink or dishwasher with simple detergent and hot water.

SA- Spark Arrestor Filters for Solid Fuel Appliance.

CLASSIFIED BAFFLE GREASE FILTER MEETS

NFPA 96 REQUIREMENT FOR COOKING WITH

SOLID FUEL

SPARK ARRESTOR FRAME

The 3/8” X 1/2” SPARK ARRESTOR FRAME MEETS

NFPA 211REQUIREMENT FOR SOLID FUEL

BURNING APPLIANCES.

The filters are all steel construction, non-loading Teflon

coated. If airborne sparks and embers can be generated

by the solid fuel cooking operation, spark arrestor devices

shall be used prior to the grease removal device to

minimize the entrance of these sparks and embers into the

grease removal device and into the hood and duct system.

NFPA 211 CHAPTER 1.11.2 (B) STATES:

(b) The arrestor screen shall have heat and corrosion

resistance equivalent to 19 gauge (0.011 in.) galvanized steel or 24 gauge (0.024 in.) stainless steel.

(c) Opening shall not permit the passage of spheres having a diameter larger than 1/2 in. (12.7mm) nor block the passage of

spheres having a diameter of less than 3/8 in. (9.5mm).

94% EFFICIENT AT GREASE EXTRACTION!

FlameGard’s high rate of grease extraction is aided by our TEFLON® coated baffle. In the same manner that grease rolls

off a TEFLON coated pan, it rolls down our baffles, out of the filter and into the hood’s remote collection cup. Because

FlameGard’s filters retain only insignificant amounts of surface grease and do not load, you will have constancy of air flow

throughout your operating day. In addition,

The Spark Arrestor FlameGard’s filters must be washed daily to ensure proper operation of your hood filter assembly.

They can be easily cleaned in a pot sink or dishwasher with simple detergent and hot water.

SA- Spark Arrestor Filter

Figure 20

12

MJ- Blower Assembly on Dynaflow MJ

hoods.

Every Dynaflow with MJ Perimeter Defense

control has one or more MJ Blower assemblies

mounted on the top of the MJ plenum. The MJ

blower assembly consists of a double shafted

120V/1/60 AC motor with one tangential blower

attached to each shaft. The motor/blower sub

assembly is inside a protective housing to

discharge the air down into the top of the MJ

plenum. The MJ blower assembly has two (2)

removable washable pre-filters, and a J-box with

rheostat mounted on the switch MTG plate. The

return air from above the hood enters the washable

filters, travels through the tangential blowers and

discharges into the MJ plenum through a fusible

line fire damper. Each MJ Blower assembly is

bolted to four (4) studs on the top of the hood.

The fire damper is accessed by removing the 4

bolts and lifting the MJ blower off the hood to

reveal the fusible link fire damper.

Complete MJ Blower assembly

Figure 22

Exploded View of MJ Blower assembly

Figure 21

The rheostat is used to adjust the air discharge from the MJ Grille. See the

air measurement section of the manual for more detail.

The filters should be removed and wash every two years in a pot sink or

dishwasher

13

DYNAFLOW MAINTENANCE SCHEDULE

DAILY:

1. At the end of the cooking day wipe off the interior and exterior of the Dynaflow hood canopy and the underside of the

grease trough with a damp cloth. Inspect the grease filters and clean if necessary.

2. Clean SA Spark Arrestor filter daily.

3. Inspect and clean HE High Efficiency filters daily as required.

WEEKLY:

1. Remove all the grease filters and wash in a mild detergent and water mixture.

WIPE UNDERSIDE OF

GREASE TROUGH

Cleaning the Hood Exterior

Wipe off the interior of the filter hood plenum behind the grease filters and the interior and exterior of the grease trough.

Remove the grease cup and clean if necessary.

WIPE INTERIOR OF CANOPY

AFTER DAILY COOKING

Figure 23

SIX MONTHS

1. Check the exhaust fan belts for alignment, tightness, and wear. Adjust and/or replace.

2. If the hood has an exhaust duct collar fire damper (Models “FD”) inspect the exhaust fusible link fire damper. Clean

and/or replace the fusible link if necessary.

ONE YEAR

1. Check the exhaust fan belts for alignment, tightness, and wear. Adjust and/or replace.

2. If the hood has an exhaust duct collar fire damper (Models “FD”) inspect the exhaust fusible link fire damper. Clean

and/or replace the fusible link if necessary.

3. MB Dynaflow hoods replaced the supply duct collar fusible link.

4. MJ Dynaflow hoods replace the MJ plenum fusible link under the MJ Blower assembly.

5. MJ Dynaflow hoods measure the MJ Grill discharge and adjust MJ Blower assembly rheostat to set correct appliance

velocity at the discharge.

14

CLEANING THE EXTERIOR

Normal soil can be removed with a mild detergent and water mixture applied to a cloth.

To remove baked on grease, apply a cleanser to a damp cloth or sponge and rub on the metal in the direction of the

polishing lines. DO NOT RUB IN A CIRCULAR MOTION.

Burnt deposits which do not respond can usually be removed by rubbing the surface with SCOTCH-BRITE Scouring pads

or Stainless scouring pads. Do not use ordinary steel wool.

Heat tint can be removed by a vigorous scouring in the direction of the polish lines using SCOTCH BRITE or STAINLESS

scouring pads in conjunction with a powdered cleanser.

TROUBLE SHOOTING

Low Exhaust air

1. Improper exhaust fan rotation.

2. Broken or slipping belt.

3. Exhaust ductwork inspection door open.

4. Obstruction in the ductwork.

No Exhaust air

1. Start/Stop station not turned on.

2. Broken belt exhaust fan belt.

3. Exhaust fan overload tripped. Inspect the magnetic starter or VFD overload.

4. Exhaust fan disconnect open on the roof.

5. Exhaust fan breaker open at the breaker panel

6. Exhaust fan motor or fuse or breaker blown.

7. “FD” type Dynaflow hoods Exhaust Fire damper closed. Check fusible link.

Poor Capture

1. Improper exhaust fan rotation.

2. Broken or slipping belt.

3. Exhaust ductwork inspection door open.

4. Obstruction in the ductwork.

5. “FD” type Dynaflow hoods Exhaust Fire damper closed. Check fusible link.

6. MB Dynaflow plenum fresh air supply fusible link fire damper closed.

7. MJ Dynaflow plenum fusible link fire damper closed.

8. MJ Dynaflow Blower not running. Not turned on, fuse blown, breaker open, motor burnt.

9. Dynaflow MB appliance air velocity too high. Adjust the MB Blade position to provide more fresh air out MB front

and less to the appliances.

10. Dynaflow MB appliance air velo city too low. Adj ust the MB Blade position to provide less fresh air out MB front and

more to the appliances.

11. Dynaflow MJ appliance air velocity too low. Adjust the MB MJ blower rheostat to provide more air to the appliances

region.

15

Measuring Exhaust Air Flow with VE, HE, EC, and SA Filters

VE= standard grease extraction efficiency Stainless steel baffles.

HE= High grease extraction Efficiency Cascade baffles for Enviro applications and reducing grease

discharge from buildings.

EC= Easy Clean Teflon – standard grease extraction efficiency baffles for hot, heavy grease laden

appliances.

SA= Spark Arrestor – standard grease extraction efficiency, for solid fuel appliances.

Measuring Instruments:

VANAXIAL VELOMETER

Follow the instruments instruction manual to measure the exhaust volume at each filter. The instrument will either measure

the total CFM or average velocity of each filter. Hold the instrument perpendicular to the face of each filter. The

Velometer should be within 1” of the filter face for best results. Once the each filter average exhaust velocity has been

measure use Chart No.1 to convert Average Filter Face Velocity to CFM.

The total exhaust volume is the sum total of each filter CFM.

2"

VELOMETER

INSIDE HOOD

CANOPY

BACK OF

HOOD

BAFFLE FILTER

GREASE CUP

Measuring Exhaust Air

Figure 24

Exhaust Air Flow VS Average Filter Face Velocity

Baffle Filter Average Filter Velocity

Size 100 fpm/0.5m/s 200 fpm/1.0m/s 300 fpm/1.5 m/s

in x in mm x mm CFM l/s CFM l/s CFM l/s

20 x 16 508 x 406 200 94 400 189 600 283

20 x 20 508 x 508 260 123 520 245 780 368

20 x 25 508 x 635 320 151 640 302 960 453

Chart No. 1

16

PITOT TUBE OR ANEMOMETER

Spring Air Systems has factory calibrated the average filter slot velocity VS filter CFM. Measure the average bottom slot

velocity of each filter and use Chart No. 2 to convert the slot velocity to total filter CFM.

Each filter has a series of open and closed slots across the face. Hold the instrument perpendicular to the open filter slot at

the bottom of the filter. Place the hot wire anemometer directly in the filter slot. Take one reading at the bottom of each

slot as shown in Figure 25 below. Calculate the average slot velocity for each filter. Refer to Chart No.2 below for the

corresponding filter exhaust volumes. Sum each filter CFM to determine the total hood exhaust volume.

BAFFLE FILTER

BACK OF

HOOD

1

2

PITOT

TUBE

INSIDE HOOD

CANOPY

Measure velocity here at

the bottom of the slot.

Measuring Exhaust Air

Figure 25

17

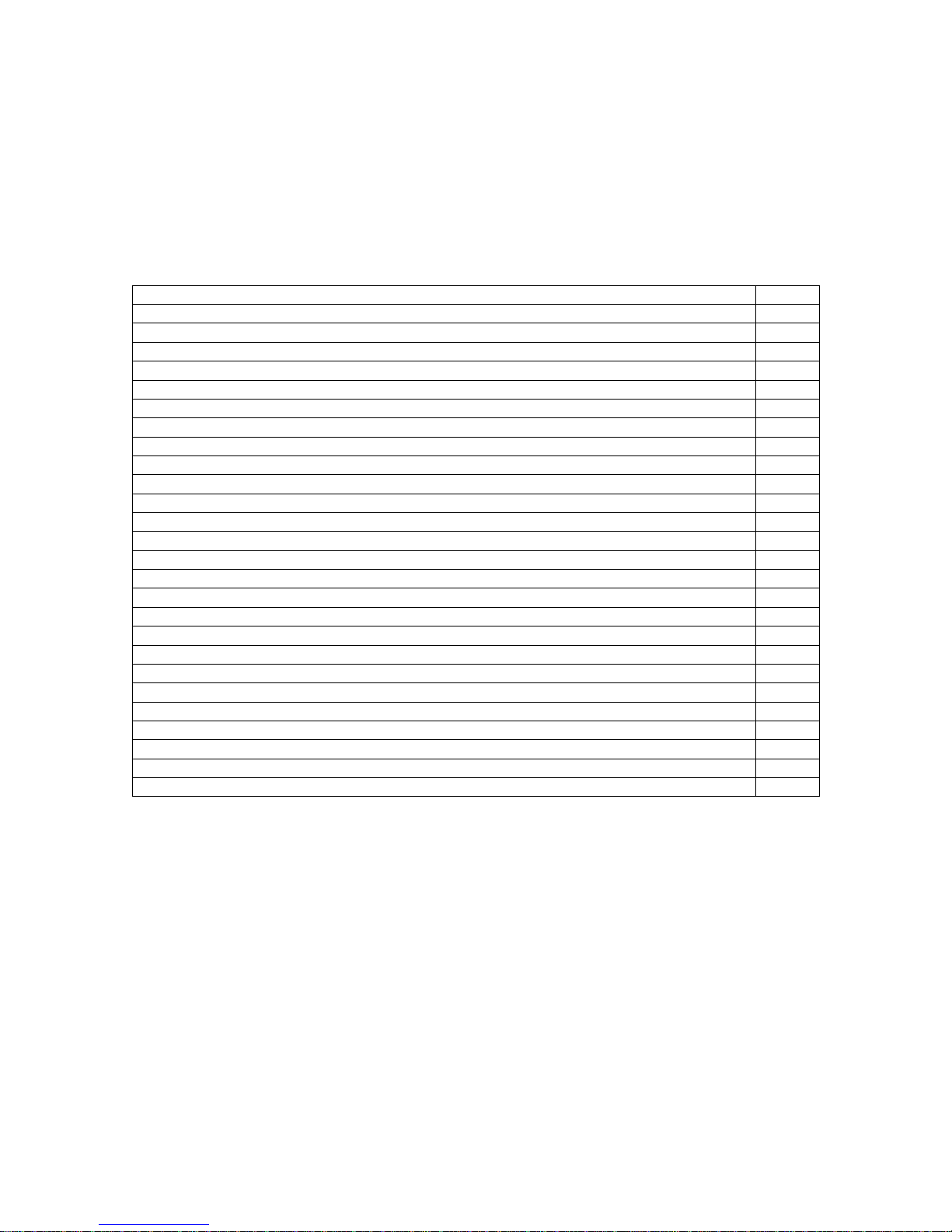

VE/EC/SA STAINLESS STEEL FILTERS

Average Slot Velocity vs CFM per Filter

Filter Slot Filter Size VS CFM per Filter

Velocity 16x16 20x16 20x20 20x25

(fpm) (CFM) (CFM) (CFM) (CFM)

100

200

300

400

500

600

700

800

900

1000

1100

1200

1300

1400

1500

1600

1700

1800

1900

2000

2100

2200

2300

2400

2500

2600

2700

2800

2900

3000

37 46 58 72

74 92 116 145

111 139 173 217

148 185 231 289

185 231 289 361

222 277 347 434

259 324 405 506

296 370 462 578

333 416 520 650

370 462 578 723

407 509 636 795

444 555 694 867

481 601 752 939

518 647 809 1012

555 694 867 1084

592 740 925 1156

629 786 983 1228

666 832 1041 1301

703 879 1098 1373

740 925 1156 1445

777 971 1214 1518

814 1017 1272 1590

851 1064 1330 1662

888 1110 1387 1734

925 1156 1445 1807

962 1202 1503 1879

999 1249 1561 1951

1036 1295 1619 2023

1073 1341 1676 2096

1110 1387 1734 2168

Chart No. 2

18

HE STAINLESS STEEL FILTERS

Average Slot Velocity vs CFM per Filter

Filter Slot Filter Size VS CFM per Filter

Velocity 16x16 20x16 20x20 20x25

(fpm) (CFM) (CFM) (CFM) (CFM)

100

200

300

400

500

600

700

800

900

1000

1100

1200

1300

1400

1500

1600

1700

1800

1900

2000

2100

2200

2300

2400

2500

2600

2700

2800

2900

3000

44 55 68 86

88 109 137 171

131 164 205 257

175 219 274 342

219 274 342 428

263 328 411 513

307 383 479 599

350 438 547 684

394 493 616 770

438 547 684 855

482 602 753 941

525 657 821 1026

569 712 889 1112

613 766 958 1197

657 821 1026 1283

701 876 1095 1368

744 931 1163 1454

788 985 1232 1540

832 1040 1300 1625

876 1095 1368 1711

920 1149 1437 1796

963 1204 1505 1882

1007 1259 1574 1967

1051 1314 1642 2053

1095 1368 1711 2138

1138 1423 1779 2224

1182 1478 1847 2309

1226 1533 1916 2395

1270 1587 1984 2480

1314 1642 2053 2566

Chart No. 3

19

Measuring Exhaust Air Flow with CA Cartridges

CA= medium efficiency cartridge with adjustable flow baffles.

Setting the Cartridge

Each cartridge is adjustable for various appliances. There are 6 settings.

Closed, 1, 2, 3, 4, 5 and Open. The Open setting is for the heaviest

appliance and the Closed setting is for the lightest appliances.

To adjust the setting to match the appliance:

A. Loosen the two wing nuts located in the middle of the air inlet.

B. Slide the baffle up or down so the top of the Cartridge coincides

with the number engraved on the side of the module.

C. Tighten the two wing nuts located in the module air inlet.

Cartridge Filter Exhaust

Figure 26

Cartridge Adjustment

Figure 27

20

Chart No. 4

21

Measuring Dynaflow MB Supply

Dynaflow type hood with Tri-Zone control System

MB Blade

MB HOOD CANOPY

END VIEW

MB Blade Threaded Rod

Comfort Tuning Dial

Comfort Tuning Dial

1 Appliance Region

Full Open

2 Chef Region 3 Kitchen Ambient Region

Dynaflow MB Three Regions

12

Figure 28

A. Measuring the Appliance Region

3

MB Blade Discharge perforated plate

The Appliance Region and Chef Region discharge is called a

MJGrill. The MJGrill is manufactured as a single component shown

on the left in Figure 28. The MJGrill includes the Ap pliance Region

discharge, Chef Region discharge, and a adjustable Comfort Tuning

Dial. The Comfort Tuning Dial proportions the amount of fresh air

to the Chef Region.

The Comfort Tuning Dial on the MJ Grill has two colored dots; red

and blue. The Comfort Tuning Dial

proportions the volume of air to the chef.

Turning the Comfort Tuning Dial towards the

red dot provides less air to the Chef Region

Each of the three regions must be

measured to ensure proper hood

operation. The Appliance Region, the

Chef Region and the Kitchen Ambient

Region as shown in the schematic

Figure 27

The Appliance region is measured

first.

MJGrill Discharge

Figure 29

COMFORT

MJGRILL

MEASURE

VELOCITY

APPLIANCE

REGION

TUNING

DIAL

CHEF

REGION

Measuring the Appliance Region

Figure 31

and turning the Comfort Tuning Dial

towards the blue dot provides more air to

the Chef Region.

Comfort Tuning Dial

Figure 30

To measure the Appliance Region air velocity rotate the Comfort Tuning Dial

towards the red dot, counterclockwise to shut off air to the Chef Region. Now

measure the velocity from the MJGrill perforated discharge towards the inside of

the hood in the Appliance Region. The measurement can be made with a Hot

Wire Anemometer or Vane Axial Velometer. The required air velocity is

indicated below in Chart No. 4. If the velocity is to o high or low the MB Blade

must be adjusted to increase or decrease the velocity to the Appliance Region.

22

Hood Appliances VS Appliance Region Face Velocity

APPLIANCES

Heavy

Medium/Light

Hood Length

(ft)

9 - 14 500 450

6 - 9 500 450

4 - 6 550 450

Up to 4 550 450

9 - 14 450 400

6 - 9 450 400

4 - 6 450 450

Up to 4 450 450

Discharge Velocity (fpm)

FRONT SIDE

FLOW

Set point Set point

Chart No.5

B. Adjusting the MB Blade to change velocity at the appliance region.

Open the MB Blade Face Discharge Grill on the front of the MB

plenum located above the MJGrill that requires adjustment. The MB

Blade perforated discharge grill is secured with four (4) Philips

screws. Once the MB Blade discharge grill is removed in the center

of the MB Blade is a threaded MB Blade adjustable Rod. To increase

the velocity to the MJGrill below, rotate th e threaded MB Blade Rod

clockwise. To decrease the velocity to the MJGrill b elow, rotate the

MB Blade Rod counter-clockwise. Measure the MJGrill discharge

velocity after each adjustment until the correct velocity as indicated in

Chart No. 4 is achieved.

Adjusting the MB Blade Threaded Rod

Figure 32

C. Adjusting the air velocity to the Chef Region

The amount of air directed to the Chef Region is a personal decision. When commissioning an

MB hood system we recommend the following:/

Heavy Appliances, Charbroilers, Woks: Rotate the Comfort Tuning Dial towards the blue dot to

fully for maximum Chef air.

Medium Appliances, Griddles, and Ranges: Rotate the Comfort Tuning Dial towards the blue

dot about three or four rotations clockwise.

Light Appliances, Ovens, and Kettles: Rotate the Comfort Tuning Dial towards the red d ot to

fully close the air to the Chef Region.

Comfort Tuning Dial

Figure 33

23

D. Measuring the Supply Discharge velocity from the MB Blade

MB Blade Discharge perforated plate

MB Blade Perforated Discharge

MB Blade

MB Blade Threaded Rod

MB Blade Assembly

Measuring MB Blade Perforated Discharge

Figure 34

There are two sizes of MB Blade Discharge Grills.

MBFront41x06 with a perforated discharge dimension of

41.5” wide x 6” high. The face area is 1.38sq feet

MBFront33x06 with a perforated discharge dimension of 33”

wide x 6” high. The face area is 1.1 sq feet

When using a hot wire anemometer take 12 velocity readings

at each discharge grill. Take 6 readings across the length and

2 rows. See Chart No5 below to convert the average velocity

reading per grille to CFM.

Hood Appliances VS Appliance Region Face Velocity

Average Velocity

(fpm)

50 69 55

75 104 83

100 138 110

125 173 138

150 207 165

175 242 193

200 276 220

225 311 248

250 345 275

275 380 303

300 414 330

325 449 358

350 483 385

375 518 413

400 552 440

425 587 468

450 621 495

475 656 523

500 690 550

525 725 578

550 759 605

600 828 660

625 863 688

650 897 715

675 932 743

700 966 770

725 1001 798

MBFront41x-6

(CFM)

MBFront33x06

(CFM)

Chart No. 6

24

Measuring Dynaflow MJ Plenum Air

Dynaflow type hood with Perimeter Defense control System

MESH FILTERS

RHEOSTAT

MJ BLOWER

FIRE DAMPER

MESH FILTERS

RHEOSTAT

MJ BLOWER

FIRE DAMPER

FRONTFLOW

MJ PLENUM

HOOD CANOPY

END VIEW

INTERNAL APPLIANCE DISCHARGE

S/S PERFORATED

DISCHARGE

Measuring MJGrill Appliance Region

A. Measuring the Appliance Region

MJGrill with Comfort Tuning Dial

Figure 36

To measure the Appliance Region air velocity

rotate the Comfort Tuning Dial towards the red dot, counterclockwise to shut

COMFORT

MJGRILL

MEASURE

VELOCITY

APPLIANCE

REGION

TUNING

DIAL

CHEF

REGION

Measuring the Appliance Region

Figure 38

off air to the Chef Region. Now measure the velocity from the MJGrill

perforated discharge towards the inside of the hood in the Appliance Region.

The measurement can be made with a Hot Wire Anemometer or Vane Axial

Velometer. The required air velocity is indicated below in Chart No. 4 . If

the velocity is too high or lo w the MJ Blo wer must be ad ju sted to in crease or

decrease the velocity to the Appliance Region.

SIDEFLOW

MJ PLENUM

HOOD CANOPY

FRONT RIGHT VIEW

SIDEFLOW DISCHARGE

S/S PERFORATED

DISCHARGE

Figure 35

The Appliance Region and Chef Region discharge is called the

MJGrill. The MJGrill is manufactured as a single component shown

on the left in Figure 28. The MJGrill includes the Ap pliance Region

discharge, Chef Region discharge, and a adjustable Comfort Tuning

Dial. The Comfort Tuning Dial proportions the amount of air to the

Chef Region.

The Comfort Tuning Dial on the MJ Grill has

two colored dots; red and blue. The Comfort

Tuning Dial proportions the volume of air to

the chef. Turning the Comfort Tuning Dial

towards the red dot provides less air to the

Chef Region and turning the Comfort Tuning

Dial towards the blue dot provides more air

to the Chef Region.

Comfort Tuning Dial

Figure 37

Hood Appliances VS Appliance Region Face Velocity

25

Fig

Heavy Appliances

Medium and Light Appliances

APPLIANCES

Hood

Length

(ft)

9 - 14 500 450

6 - 9 500 450

4 - 6 550 450

Up to 4 550 450

9 - 14 450 400

6 - 9 450 400

4 - 6 450 450

Up to 4 450 450

Discharge Velocity (fpm)

FRONT SIDE

FLOW

Set point Set point

Chart No.7

B. Adjusting the MJ Blower to change the appliance region velocity

The MJ blower assembly is located on top of the MJ

plenum. Each hood has one or more MJ Blower assemblies.

To adjust the air flow of the MJ blower rotate the rheostat in

the middle of the MJ blower assembly. Rotating the knob

clockwise increases the air flow and rotating the knob

counter clockwise decreases the amount of air into the

plenum. Adjust the know until the correct velocity is

measured one the MJ Grill appliance discharge.

Adjusting the MB Blade Threaded Rod

ure 39

C. Adjusting the air velocity to the Chef Region

The amount of air directed to the Chef Region is a personal decision. When commissioning an

MJ hood system we recommend the following:

Heavy Appliances, Charbroilers, Woks: Rotate the Comfort Tuning Dial towards the blue dot

three (3) rotations clockwise.

Medium Appliances, Griddles, and Ranges: Rotate the Comfort Tuning Dial towards the blue

dot one (1) rotations clockwise.

Light Appliances, Ovens, and Kettles: Rotate the Comfort Tuning Dial towards the red d ot to

fully close the air to the Chef Region.

Comfort Tuning Dial

Figure 40

NOTE: Check to make sure that the Appliance Region velocity does not

decrease below the required velocity after adjusting the Chef Region air with

Comfort Tuning Dial.

26

Loading...

Loading...