Spreadmaster SQ 404 F, SQ 600 F, SQ 800 F, SQ 1000 F Operating Instructions And Spare Parts List

OPERATING INSTRUCTIONS AND SPARE PARTS

R

EADCAREFULLYBEFOREOPERATINGMACHINE

July 2006

SQ/TF Series

IMPORTANT

Maximum PTO Speed is 500 RPM

Technical Data

SERIES "SQ/TF”

Model SQ/TF 404 F SQ/TF 600 F SQ/TF 800 F SQ/TF 1000 F

Capacity 400 li/480 kg 530 li/636 kg 820 li/984 kg 1000 li/1200 kg

Empty weight 104 kg. 146 kg 146 kg. 154 kg.

Loading height 0.93 m 0.97 m 1.09 m 1.19 m

Width 1.10 m 1.51 m 1.51 m 1.51 m

Spreading Width 5 – 6 *

12 – 14 **

5 – 6 *

12 – 14 **

5 – 6 *

12 – 14 **

5 – 6 *

12 – 14 **

P.T.O. r.p.m. 500 500 500 500

Working speed 4/15 kph 4/12 kph 4/15 kph 4/15 kph

* Powdered fertilisers ** Granulated fertilisers

The technical data are approximate and not binding. The Manufacturer reserves the rightto modifythem without notice.

ACCESSORIES AVAILABLE

Agitator for powdered fertilisers

Stainless steel distribution unit

Hydraulic remote control (600/1000)

Flywheel protection

Filter grate

Rubber insert tube

You have selected our spreader and we thank you for the confidence placed in our machine. For proper

use and to get the best capacities from the machine, we ask you to carefully read these instructions.

Please return the completed warranty card promptly

!

SAFETY REGULATION - take notice of this sign

1 - HOW TO USE THE MACHINE

The spreader cannot be used for purposes other than those for which it has been designed.

The liability is null and void in case of damage occurred if the machine is used for applications different

than those specified by the manufacturer.

Correctly operating the machine also implies:

- Following the operating, maintenance and repair instructions given by the manufacturer

- Using original parts and accessories approved by the manufacturer.

The spreader must be operated and repaired by skilled operators who are familiar with correctly

operating the machine. The operators must be also aware of the dangers that can arise with the use of

the machine.

The operator is requested to strictly follow the rules concerning:

- accident prevention

- labour safety rules

- travelling on public roads.

The operator must strictly obey the warning labels on the machine.

Any liability arising from modifications made on the machine by the user or any other person without

the express written consent of the manufacturer is born by the machine's owner.

The spreader does not exceed under normal working conditions a sound level of 80 dB.

Prior to operating the machine/tractor combination ensure that they conform with all safety rules and the

traffic code.

2 – GENERAL INSTRUCTIONS

1. Strictly adhere to all safety and accident prevention rules, regulations and OSH guidelines in addition

to the instructions contained in this manual.

2. The warnings placed on the machine show safety measures to be taken to prevent accidents.

3. When travelling on public roads strictly follow the traffic rules.

4. Prior to starting work the operator must become familiar with the controls and operating devices on

the machine and their respective functions.

5. Wear appropriate clothing. Loose clothing can become entangled in moving parts.

6. It is advisable to operate on tractors provided with a cabin and with a safety frame according to the

local regulations.

7. Prior to commencing operations check for people or livestock in the vicinity of the machine. Only

operate the equipment if you have good visibility. Move any animal or person away from the

dangerous area of the machine (spreading area).

8. Do not carry animals or allow other persons to ride on the machine during operation.

9. The connection of the machine to the tractor must be made to all the available engagement points.

10. Take caution attaching or removing the machine onto/from the tractor.

11. Prior connecting the machine, be sure that the ballasting of the front axle of the tractor is suitable.

The ballasting must be attached to the proper approved brackets in accordance to the tractor

manufacturer’s specifications.

12. Be sure that the tractor front axle loading does not exceed permitted limits.

13. When travelling on the public roads ensure to comply with all rules concerning clearances,

overhangs and maximum dimensions.

14. Prior to travelling on a public road ensure that all guards and signalling devices (lights, reflectors,

etc.) required are fitted.

15. All remote control devices (cables, ropes, rods, flexible lines, etc.) must be positioned in such a way

as to prevent to movements which could lead to accidents or damages.

16. Do not leave the operating seat while the tractor is still moving.

17. The speed and the way of driving must be appropriate to the nature of the ground. In all cases do

not perform sudden direction changes.

18. The steering uniformity, tractor adhesion, road holding and the efficiency of the braking devices are

influenced by the following factors: weight and nature of the connected machine, ballasting of the

front axle and the state of the ground or paving. It is important then, to follow exercise caution

appropriate to each situation.

19. Take care when steering taking into consideration the trim, length, height and weight of the machine.

20. Prior using the machine check that all the guard devices are applied and be in good state. Damaged

guards must be immediately replaced.

21. Prior beginning the job check the tightness of nuts and screws, particularly those which are securing

the implements (discs, firms, deflectors, etc.). Tighten them if necessary.

22. Do not enter the operating area of the machine (spreading area).

23. Caution! Check for cracks and shearing which may occur on the remote control devices,

particularly those hydraulically controlled.

24. Switch off the engine prior to leaving the tractor seat or working on the machine, removing the key

and waiting until all the moving parts have stopped.

2 – GENERAL INSTRUCTIONS (continued)

25. Do not move between the machine and the tractor without having previously engaged the hand

brake, or having securely chocked the wheels.

26. Prior to performing any work on the machine be sure that it cannot be inadvertently moved.

27. Read carefully the instructions printed on the bags of fertiliser concerning the toxicity or

corrosiveness of the product. Follow any precautions to be taken. Prior to loading the fertiliser into

the hopper disengage the power take off, switch off the engine and remove the starting key.

28. Caution! Do not operate on a grade over 1 in 10 because of the danger of rolling over.

3 - CONNECTION

1. When connecting or disconnecting the machine to/from the tractor, place the 3-point linkage lever in

such a position as to prevent it to be operated or accidentally moved.

2. When connecting the machine onto the three points of the tractor, be sure that the forks and pins

match the diameter of the tractor's joints.

3. Caution! Check around the three connection points for cracks or breaks.

4. Do not stand between the machine and the tractor when operating the hoisting control lever.

5. During transportation the hoisting arms must be secured by means of stiffening rods to prevent

oscillations and lateral movement of the machine.

6. When the machine is not to be transported in hoisted position, block the booster controlling lever.

4 - MOVING PARTS (P.T.O. and P.T.O. shaft)

7. Only use the power take off shaft delivered with the machine or those approved by the

manufacturer.

8. Always use the guards on the P.T.O. and power take off shaft and ensure they are in a good state.

9. Check the tubes of the power take off shaft are correctly overlapped and positioned while operating

and during transportation.

10. Prior connecting or disconnecting a power take off shaft, disengage the power take off and remove

the starting key.

11. If the power take off shaft is equipped with a torque limiting device or with a back stop, the back

stop must be firmly mounted on the power take off of the machine.

12. Be careful when assembling to correctly position the power take off shaft.

13. Be sure that the guards of the power take off shaft are secured by means of the chains provided for

this purpose.

14. Prior to engaging the power take off be sure that the selected speed and direction of rotation re in

accordance with the specifications of the manufacturer. Only engage the power take off at low

engine speed.

15. Prior to engaging the power take off be certain that no persons or animals are around the machine.

16. Disengage the power take off when the angle of the power take off shaft is going to exceed 25°.

17. Caution! After disengaging the power take off, the moving parts will continue to rotate for a

period. Stay clear until they have come to a complete standstill.

18. When storing the machine, the power take off shaft must be supported by a suitable chain.

19. After removing the power take off shaft from the power take off ensure the guards are replaced

immediately.

5 - MAINTENANCE

20. Before performing any maintenance or repairs, disengage the power take off, switch off the engine

and remove the starting key from the panel.

21. Periodically check the tightness of nuts and screws. Tighten where necessary.

22. Before performing any maintenance on the machine in a raised position, prop it securely with

appropriate props.

23. When replacing parts, wear gloves and use the correct equipment.

24. To preserve the environment do not burn or dump oils, greases and filters of any kind. Take them

to an approved agent for their recycling or disposal.

25. Check all guards devices for wear. Replace them if necessary.

26. Spare parts must be in accordance with the specifications given by the manufacturer. Only use

manufacturer’s originals spare parts.

27. Before welding when the machine is connected to the tractor, remove the alternator and battery

cables.

6 – BEFORE OPERATING

A - On Delivery

28. Check to see that no parts are missing.

29. Be sure that the hopper is free from foreign matter.

30. The spreader must be used for the designed purpose only.

31. Check for any damage that occurred during transportation and that no bags or parts are missing.

These claims will only be considered if reported on delivery.

32. Note any damage on the carrier’s consignment note.

33. In case of queries or disputes refer the matter to the supplier.

B - Maintenance

34. Clean all parts ensuring that you do not use any solvent or materials that will damage the gear box,

or other parts of the machine.

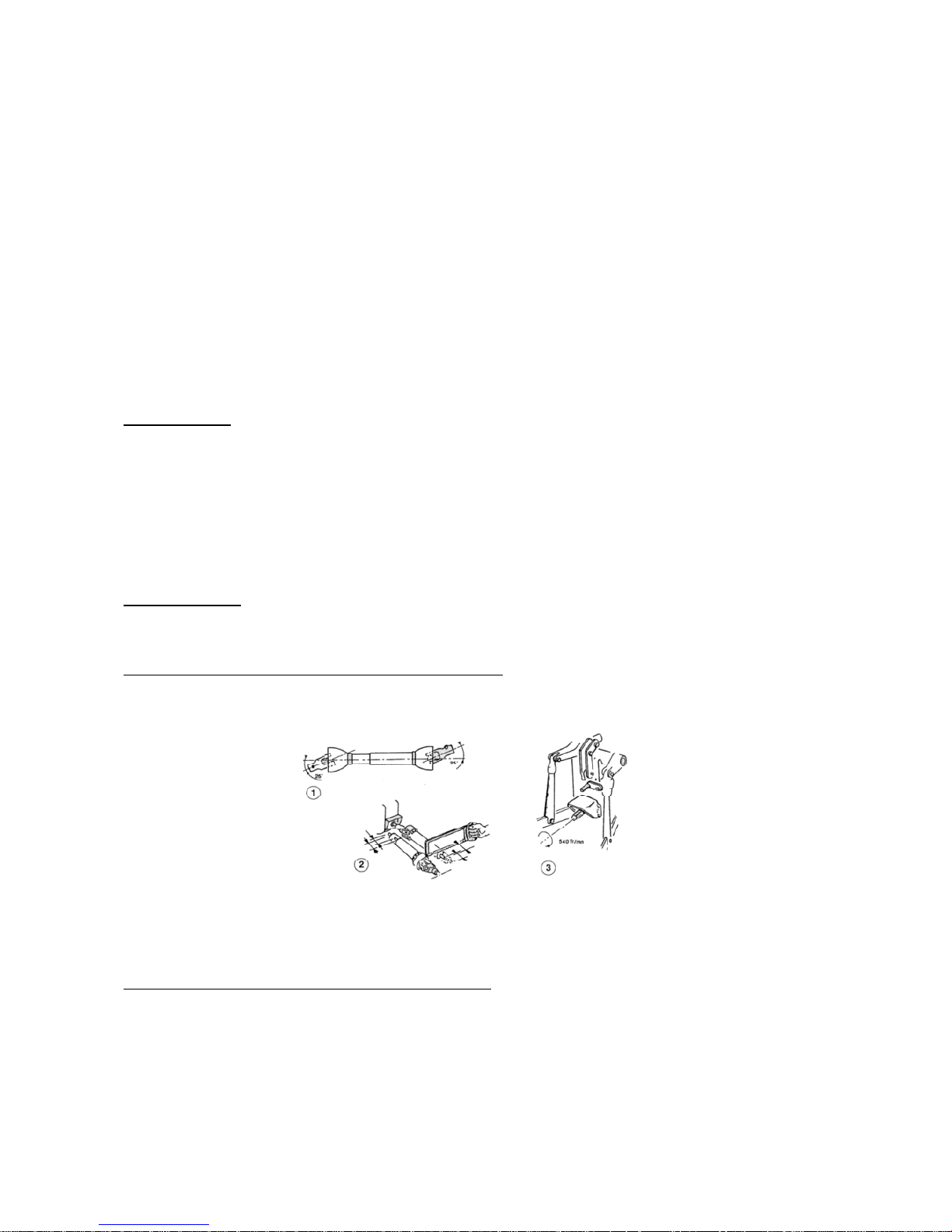

C - Transmission (for models with a power take off shaft)

35. Before using the machine grease the power take off shaft.

36. To preserve the power take off shaft in a good working state (see figure)

Do not exceed the power take off working angle of 25°. Check that the length of the power

take off shaft suits your tractor.

Leave a clearance of 3 cm at each end.

The rotational speed must be 500 r.p.m..

D - Connection (for models with a power take off shaft)

1. The spreader must be connected to the three point linkage.

2. The position of the lugs on the machine and the tractor must match.

3. Place the spreading disc or the oscillating tube parallel and 70 – 80cm above the ground level.

7 - ADJUSTMENTS

A - Capacity adjustment

1. Adjust the position of lever opening the port according to: the quantity to be spread, the tractor

speed and the fertiliser used by placing the index from 0 to 10 for models working with spreading

disc and from 0 to 9 for models working with an oscillating tube.

2. To achieve a uniform capacity keep a constant forward speed.

3. Adjustment rules (see diagram or table).

Example of how to achieve correct spreading adjustment.

Spreading Table

Numbered Rac kPositionTypeof

Fertiliser

Spreadi ng Width

(m)

Workin g Speed

(kph)

1R 1S 1T 2R 2S 2T 3R 3S 3T 4R 4S 4T 5R 5S 5T

6 / / / 36 58 82 104 146 186 228 280 354 416 488 560

8 / / / 27 43 61 78 109 139 171 217 265 311 366 420

10 / / / 22 35 49 62 88 112 137 174 202 249 293 336

12 / / / 18 30 41 52 76 93 114 145 177 208 244 280

Complex 12.12.12

ps = 1kg/l 12

14 / / / 15 25 35 46 63 80 96 124 152 179 209 240

Table For Oscillating Bar Type Models

The graded scale comprises three lines of holes marked with the letters R, S and T.Each line consist of 9 holes, which are out of line with the

holes of the previous line by half a diameter. This system allows simple but effective adjustment with 27 different fertiliser quantity settings.

The exact hole into which the pin should be inserted can he obtainedfrom the spreading table used as shown inthe example.

Diagram Reading Example: Spreading Width

Trailing Speed= 2 kph

Lever Opening Position = 5

Spreading Width= 8 – 13 – 18 m

Fertiliser = 1350 – 832 – 600 kg/Hectare approx kg/Ha

18 m 13 m 8 m

10 9 8 7 6 5 4 3 2 1 0

2 k ph 4 kph 8 kph 12 kph

LEVER OPENING POSITION

1600

1400

1200

1000

800

600

400

200

0

2216

1939

1662

1385

1108

832

554

278

0

3600

3150

2700

2250

1800

1350

900

450

0

For Models with Discs made of Steel

Diagram Reading Example: Spreading Width

Trailing Speed= 2 kph

Lever Opening Position = 5

Spreading Width= 8 – 13 – 18 m

Fertiliser = 1350 – 832 – 600 gm/m² approx gm/m²

18 m 13 m 8 m

10 9 8 7 6 5 4 3 2 1 0

2 k ph 4 kph 8 kph 12 kph

LEVER OPENING POSITION

1600

1400

1200

1000

800

600

400

200

0

2216

1939

1662

1385

1108

832

554

278

0

3600

3150

2700

2250

1800

1350

900

450

0

For Models with Discs made of Steel

B – Width Adjustment

The spreader had been designed to get a good fertiliser distribution on the ground. To get good results it

is necessary to reach the following conditions:

1. Keep the power take off rotational speed at 540 r.p.m. (the spreading width is strongly influenced

by rotational speed).

2. Keep the machine in the horizontal position and the centrifugal disc or oscillating tube at 70 to 80cm

above the ground level.

3. Keep the spreading fins and the oscillating tube in a good state.

4. Replace the hopper agitator if worn.

5. Other factors influencing the fertiliser distribution:

The unit weight of the product and its dimension.

The specific humidity and the wind.

B – Width Adjustment (continued)

6. To obtain the desired distribution, adjust the position of the disc fins:

Move them back if the fertiliser is mainly spreading towards the left side.

Move them forward if the fertiliser is mainly spreading towards the right side.

8 - MAINTENANCE AND PRESERVATION

The spreader is an agricultural implement whose maintenance is difficult to perform. It is constantly

submitted to the worst conditions:

- Chemical etching: potassium, phosphoric acid, nitrogen.

- Mechanicaldamages: granulated abrasion, shocks and scoring.

- Weather damages from rain and the inclemency of the weather, closeness to the sea.

- High pressure washing: high pressure too close to the machine.

1. Before Starting Work:

Spray a mixture of fuel and oil on the implement, especiallyon concealed parts and corners. Do

not forget to do this in a ventilated room or in the open air.

Apply, by means of a brush or greaser, a thick grease onto the moving parts such as power take

off shaft and spiders.

2. After Each Working Session:

Wash the implement after without excessive pressure and without directing the jet into the

moving parts such as bearings.

Carefully dry the implement (Water + fertiliser = liquid fertiliser = corrosion).

Spray a mixture of fuel and vegetable oil on to the implement. Do not forget to do this in a

ventilated room or in the open air.

Grease the moving parts with a brush or greaser.

37. At the End of Each Season:

After washing, drying, spraying and greasing store the implement out of the weather. The

corrosion causes serious damage when the implement is not used.

If cracks an scoring have taken place, brush them using a wire brush and smear them with a rust

proof preventer.

Store the implement on wooden boards.

38. To be checked:

Check all nuts, bolts and screws after 10 hours of operation. Tighten them if necessary.

Check the state of the moving/wearing parts. Replace them if necessary.

The oil level for models equipped with an oil-filled gear box. Replace the oil after the first 30

hours of operation and then after each 150 hours of operation using an SAE 85 W6140 oil.

In the models fitted with pendulum spreaders

remove the sealing plug on the transmission unit

and replace with the supplied oil level dipstick.

Spreading Table (Kg/Ha)

PTO Speed: 540rpm

Numbered Rack Position

Type of Fertiliser

Spreading

Width (m)

Working

Speed (kph) 1R 1S 1T 2R 2S 2T 3R 3S 3T 4R 4S 4T 5R 5S 5T

6 / / / 38 58 82 104 146 186 228 290 354 416 488 580

8 / / / 27 43 61 78 109 139 171 217 265 311 366 420

10 / / / 22 35 49 62 88 112 137 174 212 249 293 338

12 / / / 18 19 41 52 73 93 114 145 177 208 244 280

Complex 12-12-12

SG = 1 Kg/L

12

14 / / / 15 25 35 46 63 80 98 124 152 179 209 240

6 / / / 20 42 64 86 122 160 196 252 306 362 426 492

8 / / / 15 31 48 64 91 120 147 189 229 271 319 369

10 / / / 12 25 38 51 73 96 118 151 184 217 256 295

12 / / / 10 21 32 43 61 80 98 126 153 181 213 246

Superphosphate

SG = 1.1 Kg/L

12

14 / / / 9 18 27 36 52 69 84 108 131 155 183 211

6 / / / 56 92 128 164 218 270 324 404 484 564 652 742

8 / / / 42 69 96 122 163 202 243 303 363 423 489 556

10 / / / 34 55 77 98 131 162 194 242 290 338 391 445

12 / / / 28 46 64 82 109 135 162 202 242 282 326 371

Ammonium Nitrate

SG = 1.05 Kg/L

12

14 / / / 24 39 55 70 93 116 139 173 207 242 279 318

6 / / / / / / 78 114 152 190 246 300 356 424 492

8 / / / / / / 59 85 114 142 184 225 266 318 369

10 / / / / / / 47 68 91 113 148 180 213 254 295

12 / / / / / / 39 57 76 95 123 150 178 212 246

Calcium Nitrate

SG = 1.03 Kg/L

10

14 / / / / / / 33 49 65 81 105 129 152 182 211

6 / / / 66 124 182 240 322 404 486 620 752 886 1028 1172

8 / / / 49 93 136 180 241 303 364 465 564 664 771 879

10 / / / 40 74 109 144 193 242 291 372 451 531 617 703

12 / / / 33 62 91 120 161 202 243 310 376 443 514 586

Ammonium Sulfate

SG = 1.03 Kg/L

7

14 / / / 38 53 78 103 138 173 208 266 322 279 440 502

6 / / / 28 56 86 114 162 212 260 326 390 456 520 582

8 / / / 21 42 64 86 121 159 194 244 292 341 390 436

10 / / / 17 34 52 68 97 127 155 196 234 273 312 349

12 / / / 14 28 43 57 81 106 130 163 195 228 260 291

Magnesic

Potassium Sulfate

SG = 1.14 Kg/L

11

14 / / / 12 24 37 49 69 91 111 140 167 195 223 249

6 / / / 26 62 100 136 192 250 306 380 456 530 628 724

8 / / / 19 46 75 101 144 187 229 285 342 397 469 543

10 / / / 16 37 60 81 115 150 183 228 274 318 378 434

12 / / / 13 31 50 68 96 125 153 190 228 265 313 362

Granulated

Potassium Chloride

SG = 1.06 Kg/L

10

14 / / / 11 27 43 58 82 107 130 163 195 227 268 310

6 / / / 38 64 90 116 170 222 278 336 396 456 530 606

8 / / / 28 48 67 87 127 166 206 252 297 341 397 454

10 / / / 23 38 54 69 102 133 165 142 238 273 318 364

12 / / / 19 32 45 58 85 111 138 168 196 228 265 303

Urea

SG = 0.75 Kg/L

10

14 / / / 16 27 39 50 73 95 118 144 170 195 227 260

6 / / / 68 124 178 234 316 396 478 596 714 832 966 1098

8 / / / 51 93 133 175 237 297 358 447 535 624 724 832

10 / / / 41 74 107 140 190 238 266 358 428 499 580 659

12 / / / 34 62 89 117 158 198 239 298 357 416 483 549

Calcium Cyanomide

SG = 1.04 Kg/L

9

14 / / / 29 53 76 100 135 170 204 205 229 357 414 471

6 / / / 32 64 94 126 182 238 294 362 432 500 598 696

8 / / / 24 48 70 94 136 178 220 271 324 375 488 522

10 / / / 19 38 56 76 109 143 176 217 259 300 359 418

12 / / / 16 32 47 63 91 119 147 181 216 250 299 348

Granulated

Thomas Scoria

SG = 1.48 Kg/L

14

14 / / / 14 37 40 54 78 102 126 155 185 214 256 298

6 / / / 50 122 194 266 538 808 1080 1528 1976 2424 2696 2966

8 / / / -38 162 145 200 403 606 809 1146 1482 1817 2022 2224

10 / / / 30 73 116 160 323 485 647 917 1186 1454 1618 1780

12 / / / 25 61 97 133 269 404 540 764 988 1212 1348 1483

Powdered

Thomas Scoria

SG = 1.55 Kg/L

6

14 / / / 21 52 83 114 231 346 462 655 847 1038 1155 1271

Spreading Table (Kg/Ha) (continued)

PTO Speed: 540rpm

Numbered Rack Position

Type of Fertiliser

Spreading

Width (m)

Working

Speed (kph) 6R 6S 6T 7R 7S 7T 8R 8S 8T 9R 9S 9T

6 632 698 764 830 944 1056 1170 1207 1244 1282 1296 1320

8 473 523 573 623 708 792 878 905 933 962 972 990

10 379 419 458 498 566 634 702 724 746 769 778 792

12 316 349 382 415 472 528 585 603 622 641 648 660

Complex 12-12-12

SG = 1 Kg/L

12

14 270 299 327 356 405 452 5001 517 533 549 555 566

6 556 636 718 798 888 980 1070 1136 1204 1270 1290 1310

8 417 477 538 596 666 735 803 852 903 963 967 982

10 334 382 431 478 538 588 642 682 722 762 744 786

12 278 318 359 399 444 490 535 588 602 635 645 655

Superphosphate

SG = 1.1 Kg/L

12

14 238 273 308 342 380 420 459 487 516 544 553 561

6 830 956 1082 1208 1274 1340 1407 1448 1480 1532 1544 1556

8 623 717 811 906 955 1005 1055 1086 1117 1148 1158 1167

10 498 574 649 725 762 804 844 869 894 919 926 934

12 415 478 541 604 637 670 704 724 745 766 772 778

Ammonium Nitrate

SG = 1.05 Kg/L

12

14 356 410 464 518 546 574 603 621 638 656 662 667

6 560 634 706 780 870 960 1050 1154 1256 1360 1400 1435

8 420 475 529 585 625 720 788 865 942 1020 1050 1076

10 336 380 424 468 522 576 630 692 754 812 840 861

12 280 317 353 390 435 480 525 577 628 690 700 717

Calcium Nitrate

SG = 1.03 Kg/L

10

14 240 272 303 334 373 411 450 495 538 583 600 615

6 1314 1490 1666 1842 2050 2256 2464 2490 2514 2540 2570 2585

8 986 1117 1249 1381 1537 1692 1847 1867 1885 1905 1927 1939

10 788 894 999 1105 1230 1354 1478 1494 1508 1525 1542 1551

12 657 745 833 921 1025 1128 1232 1245 1257 1270 1285 1292

Ammonium Sulfate

SG = 1.03 Kg/L

7

14 563 639 714 789 878 967 1056 1067 1077 1089 1101 1108

6 616 736 828 918 1034 1152 1268 1327 1386 1445 1486 1500

8 484 552 621 689 775 864 951 995 1039 1084 1115 1125

10 387 442 497 551 620 691 761 796 832 867 892 900

12 323 368 414 459 517 576 634 663 393 723 743 750

Magnesic

Potassium Sulfate

SG = 1.14 Kg/L

11

14 276 315 355 393 443 493 543 569 594 619 637 643

6 820 932 1144 1156 1238 1318 1400 1466 1534 1600 1660 1680

8 615 699 783 866 928 988 1050 1099 1150 1200 1245 1260

10 492 559 624 693 743 791 840 880 920 960 996 1008

12 410 466 522 578 619 659 700 733 767 800 830 840

Granulated

Potassium Chloride

SG = 1.06 Kg/L

10

14 351 389 447 495 531 585 600 628 657 688 711 720

6 680 768 858 946 1030 1116 1200 1234 1266 1300 1320 1335

8 510 576 643 709 772 837 900 925 949 975 990 1001

10 408 461 515 567 618 670 720 740 759 780 792 801

12 340 384 429 473 515 558 600 617 633 650 660 667

Urea

SG = 0.75 Kg/L

10

14 291 329 368 405 441 478 514 529 543 557 566 572

6 1232. 1346 1462 1576 1650 1728 1800 1834 1866 1900 1925 1940

8 924 1009 1096 1182 1237 1294 1350 1375 1399 1425 1444 1455

10 739 808 877 946 990 1035 1080 1100 1120 1140 1155 1164

12 616 673 731 788 825 863 900 917 933 950 962 970

Calcium Cyanomide

SG = 1.04 Kg/L

9

14 528 577 626 675 707 740 771 788 800 814 825 831

6 794 882 970 1058 1182 1304 1428 1502 1576 1650 1692 1714

8 595 661 727 793 886 978 1071 1128 1182 1237 1269 1285

10 476 529 582 634 709 782 857 901 946 989 1015 1028

12 397 441 485 529 591 652 717 761 788 825 846 857

Granulated

Thomas Scoria

SG = 1.48 Kg/L

14

14 340 378 416 453 507 559 612 644 675 707 725 735

6 3238 3586 3934 4282 4680 5080 5478 5578 5630 / / /

8 2428 2689 2950 3211 3510 3810 4108 4183 4222 / / /

10 1942 2152 2960 2569 2808 3048 3287 3347 3378 / / /

12 1619 1793 1967 2141 2340 2540 2739 2789 2815 / / /

Powdered

Thomas Scoria

SG = 1.55 Kg/L

6

14 1387 1537 1686 1835 2006 2177 2348 2391 2413 / / /

Spreading Table (Kg/Ha) (continued)

PTO Speed: 540rpm

Numbered Rack PositionType of

Seed

Spreading

Width (m)

Working

Speed (kph) 1R 1S 1T 2R 2S 2T 3R 3S 3T 4R 4S 4T 5R 5S 5T 6R 6S 6T

6 8 26 44 62 100 140 178 244 308 374 440 506 / / / / / /

8 6 19 33 46 75 105 133 183 231 280 330 379 / / / / / /

10 5 16 26 37 60 84 107 146 185 224 264 304 / / / / / /

12 4 13 22 31 50 70 89 122 154 187 220 253 / / / / / /

Clover 8

14 3 11 19 26 43 60 76 105 132 160 188 217 / / / / / /

6 8 22 36 52 84 116 148 202 258 312 368 422 / / / / / /

8 6 16 28 39 63 87 111 151 193 234 276 316 / / / / / /

10 5 13 23 31 50 70 89 121 155 187 221 253 / / / / / /

12 4 11 19 26 42 58 74 101 129 156 184 211 / / / / / /

Grass 8

14 3 9 16 22 36 50 63 87 110 134 158 181 / / / / / /

6 10 26 42 58 94 128 164 232 298 366 448 526 / / / / / /

8 8 19 31 43 70 96 123 174 223 274 334 394 / / / / / /

10 6 16 25 35 56 77 98 139 179 220 267 316 / / / / / /

12 5 13 21 29 47 64 82 116 149 183 223 263 / / / / / /

Lucerne 8

14 4 11 18 25 40 55 70 99 128 157 191 225 / / / / / /

6 / / / 16 46 78 108 156 202 250 316 384 450 528 606 684 776 866

8 / / / 12 34 58 81 117 151 187 237 288 337 296 454 513 582 649

10 / / / 10 27 47 65 94 121 150 190 230 270 317 364 410 466 520

12 / / / 8 23 39 54 78 101 125 158 192 225 264 303 342 388 433

Wheat 12

14 / / / 7 20 33 46 67 86 107 135 164 193 226 260 428 332 371

6 / / / 12 30 48 66 94 124 152 196 240 284 346 408 470 536 600

8 / / / 9 22 36 49 70 93 114 147 180 213 259 306 352 402 450

10 / / / 7 18 29 40 56 74 91 118 1444 1.70 207. 245 282 321 360

12 / / / 6 15 24 33 47 62 76 98 120 142 173 204 235 268 300

Barley 12

14 / / / 5 13 20 28 40 53 65 84 102 122 148 175 201 229 257

6 / / / 12 24 38 50 68 88 106 142 178 214 254 292 332 392 450

8 / / / 9 18 28 37 51 66 79 106 133 160 190 219 249 294 337

10 / / / 7 14 23 30 41 53 64 85 107 128 152 175 199 235 270

12 / / / 6 12 19 25 34 44 53 71 89 107 127 146 166 196 225

Oats 12

14 / / / 5 10 16 21 29 38 45 61 76 92 106 125 162 168 193

NOTES

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

Series SQ/TF

N° Code Quantity

404 600

Description

1 58.60.77 1 1 Handle

2 37.30.15 1 1 Lever

3 22.51.25 1 1 Screw

4 21.11.08 1 3 Nut

5 22.51.33 - 2 Screw

6 35.10.35 2 Spacer

7 20.23.08 2 Washer

8 61.17.05 1 1 Spring

9 22.15.84 - 1 Screw

10 21.30.06 - 1 Nut

11 37.32.07 - 1 Support 600

11 a 37.32.05 1 - Support 404

12 25.00.60 1 1 Cotter pin

13 58.38.22 1 1 Washer

14 58.30.53 1 1 Plug

15 20.19.16 1 1 Washer

16 61.01.43 1 1 Spring

17 20.10.13 1 1 Washer

18 21.30.12 2 3 Nut

19 25.00.60 1 1 Cott pin

20 37.34.07 - 1 Tie rod 600

20 a 37.34.05 1 - Tie rod 404

21 37.02.15 - 1 Fram e 600

21 a 37.02.11 1 - Frame 404

22 58.30.57 2 4 Plug

23 21.10.12 4 4 Nut

24 20.24.12 4 4 Washer

25 20.19.22 4 4 Washer

26 20.11.16 4 4 Washer

27 22.93.37 4 4 Screw

28 37.73.06 - 1 Half ring

29 58.04.06 - 1 Hopper600

29a 58.04.29 1 - Hopper 404

30 58.14.14 - 1 Extension 400x600

30 a 58.14.12 - 1 Extension 200x600

30 b 58.14.04 1 Extension 1 00x404

32 22.51.29 8 12 Screw

33 20.11.08 8 12 Washer

34 21.30.08 8 12 Nut

35 41.50.05 1 1 Agitator

36 41.52.05 1 1 Bracket

37 22.16.78 2 2 Screw

38 58.38.71 1 1 Washer

39 22.51.52 4 4 Screw

40 19.07.58 1 1 Gasket

41 39.40.05 - 1 Ring

41 a 39.40.10 1 - Ring

42 20.23.10 4 4 Washer

43 21.11.10 7 7 Nut

44 62.70.25 1 1 Distributor unit

46 35.40.27 1 1 Pawl

48 58.20.05 1 1 Tube

49 36.84.15 1 1 Ring

50 22.51.56 1 1 Screw

51 22.51.59 3 3 Screw

52 58.22.06 1 1 Deflector

63 20.21.12 4 4 Washer

64 22.46.83 4 4 Screw

79 25.11..92 2 2 Plug

80 25.12.65 2 2 Plug

90 41.60.05 1 1 Joint

91 58.80.05 1 1 Spring drive

93 25.61.59 1 1 Ring

110 22.11.79 1 - Screw

111 58.30.37 1

Optional

N° Code Quantity

404 600

Description

112 61.17.15 1 1 Spring

113 39.38.15 1 1 Agitator for powder

N° Code Quantity

404 600

Description

92 35.20.05 1 1 Fork

94 63.80.02 2 2 Cross

95 63.80.20 1 1 Ring nut

96 63.80.28 - 1 Fork

96a 63.80.24 1 - Fork

97 63.80.81 1 1 Ring nut

98 63.80.65 - 1 Protection

98a 63.80.69 1 - Protection

99 63.80.19. 1 1 Ring nut

100 63.80.52 - 1 Protection

1008 63.80.56 1 - Protection

101 63.80.80 1 1 Ring nut

102 63.80.12 - 1 Fork

102 a 63.80.08 1 - Fork

103 63.80.84 1 1 Chain

104 63.80.01 1 1 Fork

62.81.54 1 - Drive shaftLl =800

62.81.58 - 1 Drive shaftLl =1000

N° Code Quantity Description

47 51.05.05 1 Tank

54 25.81.03 1 Key

55 58.38.90 1 Washer

56 58.33.64 1 Plug

57 58.33.64 1 Plug

58 27.55.59 1 Ring

59 25.61.56 2 Ring

60 60.00.43 3 Bearing

61 35.10.07 1 Spacer

62 41.10.05 1 Box

65 60.00.31 1 Bearing

66 20.00.21 1 Washer

67 57.05.05 1 Gasket

68 41.13.30 1 Small lid

69 22.80.62 3 Screw

70 20.23.06 3 Washer

71 21.31.20 1 Nut

72 20.30.20 1 Washer

73 35.10.05 1 Spacer

74 26.16.77 1 Plug

75 26.16.77 1 Plug

76 41.20.05 1 Fork

77 51.45.05 1 Slide

78 31.05.05 1 Shaft

81 35.10.06 1 Spacer

82 25.60.35 1 Ring

83 57.05.10 1 Gasket

84 41.13.'05 1 Lid

85 27.52.40 1 Ring

86 41.30.05 1 Flywheel

87 22.46.54 4 Screw

88 20.23.10 4 Washer

Accessories

Code 99.15.59 99.12.56 99.12.52 99.12.05

m 2 3 5 7

1/4 2/4 3/4 4/4

1/4 m 1 2 1

2/4 m 1 3 1

3/4 m 1 5 1

4/4 m 1 7 1

The tapered spouts without end deflector are

used for spreading on rows of trees, etc. For

each shorter spout there is a corresponding

narrowed inter-row spout. This system

ensures that the fertiliser is spread almost

entirelyat the sides, over a band

approximately 3' wide, leaving a central strip

parallel to the tractor still to be spread – this

strip varies according to the length ofthe fitted

tapered spout.

Spreading Diagram

0

1

2

3

4

5

6

12 11 10 9 8 7 6 5 4 3 2 1 0 1 2 3 4 5 6 7 8 9 10 11 12

Code 58.21.05 99.12.27 99.12.29 99.12.31 99.12.33

m 12 10 8 6

4/4 3/4 2/4 1/4

The tapered spout (4/4) supplied is a standard modelallowing

a spreading width of about 39'4". If less width is required,

shorter tapered spouts should be fitted (eg. 3/4-2/4-1/4). The

rubber insert (code 58.21.05) is needed inside the tapered

spout for the distribution of damp fertilisers or peat. This is

available as a kit.

62.70.30 - Stainless steel distributor.

Power Take Off Cover.

99.42.01 (SPTO)

99.42.02 (SQTF 404)

99.42.03 (SQTF 600-800-1

99.30.30 - Hydraulic remote control (SQTF 600-800-1000).

NOTES

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

Imported and Distributed by:

P.O. Box 578 30 Hurlstone Drive New Plymouth

(06) 759 8402 NEW PLYMOUTH

Loading...

Loading...