Spreadmaster SQ 404 F, SQ 600 F, SQ 800 F, SQ 1000 F Operating Instructions And Spare Parts List

OPERATING INSTRUCTIONS AND SPARE PARTS

R

EADCAREFULLYBEFOREOPERATINGMACHINE

July 2006

SQ/TF Series

IMPORTANT

Maximum PTO Speed is 500 RPM

Technical Data

SERIES "SQ/TF”

Model SQ/TF 404 F SQ/TF 600 F SQ/TF 800 F SQ/TF 1000 F

Capacity 400 li/480 kg 530 li/636 kg 820 li/984 kg 1000 li/1200 kg

Empty weight 104 kg. 146 kg 146 kg. 154 kg.

Loading height 0.93 m 0.97 m 1.09 m 1.19 m

Width 1.10 m 1.51 m 1.51 m 1.51 m

Spreading Width 5 – 6 *

12 – 14 **

5 – 6 *

12 – 14 **

5 – 6 *

12 – 14 **

5 – 6 *

12 – 14 **

P.T.O. r.p.m. 500 500 500 500

Working speed 4/15 kph 4/12 kph 4/15 kph 4/15 kph

* Powdered fertilisers ** Granulated fertilisers

The technical data are approximate and not binding. The Manufacturer reserves the rightto modifythem without notice.

ACCESSORIES AVAILABLE

Agitator for powdered fertilisers

Stainless steel distribution unit

Hydraulic remote control (600/1000)

Flywheel protection

Filter grate

Rubber insert tube

You have selected our spreader and we thank you for the confidence placed in our machine. For proper

use and to get the best capacities from the machine, we ask you to carefully read these instructions.

Please return the completed warranty card promptly

!

SAFETY REGULATION - take notice of this sign

1 - HOW TO USE THE MACHINE

The spreader cannot be used for purposes other than those for which it has been designed.

The liability is null and void in case of damage occurred if the machine is used for applications different

than those specified by the manufacturer.

Correctly operating the machine also implies:

- Following the operating, maintenance and repair instructions given by the manufacturer

- Using original parts and accessories approved by the manufacturer.

The spreader must be operated and repaired by skilled operators who are familiar with correctly

operating the machine. The operators must be also aware of the dangers that can arise with the use of

the machine.

The operator is requested to strictly follow the rules concerning:

- accident prevention

- labour safety rules

- travelling on public roads.

The operator must strictly obey the warning labels on the machine.

Any liability arising from modifications made on the machine by the user or any other person without

the express written consent of the manufacturer is born by the machine's owner.

The spreader does not exceed under normal working conditions a sound level of 80 dB.

Prior to operating the machine/tractor combination ensure that they conform with all safety rules and the

traffic code.

2 – GENERAL INSTRUCTIONS

1. Strictly adhere to all safety and accident prevention rules, regulations and OSH guidelines in addition

to the instructions contained in this manual.

2. The warnings placed on the machine show safety measures to be taken to prevent accidents.

3. When travelling on public roads strictly follow the traffic rules.

4. Prior to starting work the operator must become familiar with the controls and operating devices on

the machine and their respective functions.

5. Wear appropriate clothing. Loose clothing can become entangled in moving parts.

6. It is advisable to operate on tractors provided with a cabin and with a safety frame according to the

local regulations.

7. Prior to commencing operations check for people or livestock in the vicinity of the machine. Only

operate the equipment if you have good visibility. Move any animal or person away from the

dangerous area of the machine (spreading area).

8. Do not carry animals or allow other persons to ride on the machine during operation.

9. The connection of the machine to the tractor must be made to all the available engagement points.

10. Take caution attaching or removing the machine onto/from the tractor.

11. Prior connecting the machine, be sure that the ballasting of the front axle of the tractor is suitable.

The ballasting must be attached to the proper approved brackets in accordance to the tractor

manufacturer’s specifications.

12. Be sure that the tractor front axle loading does not exceed permitted limits.

13. When travelling on the public roads ensure to comply with all rules concerning clearances,

overhangs and maximum dimensions.

14. Prior to travelling on a public road ensure that all guards and signalling devices (lights, reflectors,

etc.) required are fitted.

15. All remote control devices (cables, ropes, rods, flexible lines, etc.) must be positioned in such a way

as to prevent to movements which could lead to accidents or damages.

16. Do not leave the operating seat while the tractor is still moving.

17. The speed and the way of driving must be appropriate to the nature of the ground. In all cases do

not perform sudden direction changes.

18. The steering uniformity, tractor adhesion, road holding and the efficiency of the braking devices are

influenced by the following factors: weight and nature of the connected machine, ballasting of the

front axle and the state of the ground or paving. It is important then, to follow exercise caution

appropriate to each situation.

19. Take care when steering taking into consideration the trim, length, height and weight of the machine.

20. Prior using the machine check that all the guard devices are applied and be in good state. Damaged

guards must be immediately replaced.

21. Prior beginning the job check the tightness of nuts and screws, particularly those which are securing

the implements (discs, firms, deflectors, etc.). Tighten them if necessary.

22. Do not enter the operating area of the machine (spreading area).

23. Caution! Check for cracks and shearing which may occur on the remote control devices,

particularly those hydraulically controlled.

24. Switch off the engine prior to leaving the tractor seat or working on the machine, removing the key

and waiting until all the moving parts have stopped.

2 – GENERAL INSTRUCTIONS (continued)

25. Do not move between the machine and the tractor without having previously engaged the hand

brake, or having securely chocked the wheels.

26. Prior to performing any work on the machine be sure that it cannot be inadvertently moved.

27. Read carefully the instructions printed on the bags of fertiliser concerning the toxicity or

corrosiveness of the product. Follow any precautions to be taken. Prior to loading the fertiliser into

the hopper disengage the power take off, switch off the engine and remove the starting key.

28. Caution! Do not operate on a grade over 1 in 10 because of the danger of rolling over.

3 - CONNECTION

1. When connecting or disconnecting the machine to/from the tractor, place the 3-point linkage lever in

such a position as to prevent it to be operated or accidentally moved.

2. When connecting the machine onto the three points of the tractor, be sure that the forks and pins

match the diameter of the tractor's joints.

3. Caution! Check around the three connection points for cracks or breaks.

4. Do not stand between the machine and the tractor when operating the hoisting control lever.

5. During transportation the hoisting arms must be secured by means of stiffening rods to prevent

oscillations and lateral movement of the machine.

6. When the machine is not to be transported in hoisted position, block the booster controlling lever.

4 - MOVING PARTS (P.T.O. and P.T.O. shaft)

7. Only use the power take off shaft delivered with the machine or those approved by the

manufacturer.

8. Always use the guards on the P.T.O. and power take off shaft and ensure they are in a good state.

9. Check the tubes of the power take off shaft are correctly overlapped and positioned while operating

and during transportation.

10. Prior connecting or disconnecting a power take off shaft, disengage the power take off and remove

the starting key.

11. If the power take off shaft is equipped with a torque limiting device or with a back stop, the back

stop must be firmly mounted on the power take off of the machine.

12. Be careful when assembling to correctly position the power take off shaft.

13. Be sure that the guards of the power take off shaft are secured by means of the chains provided for

this purpose.

14. Prior to engaging the power take off be sure that the selected speed and direction of rotation re in

accordance with the specifications of the manufacturer. Only engage the power take off at low

engine speed.

15. Prior to engaging the power take off be certain that no persons or animals are around the machine.

16. Disengage the power take off when the angle of the power take off shaft is going to exceed 25°.

17. Caution! After disengaging the power take off, the moving parts will continue to rotate for a

period. Stay clear until they have come to a complete standstill.

18. When storing the machine, the power take off shaft must be supported by a suitable chain.

19. After removing the power take off shaft from the power take off ensure the guards are replaced

immediately.

5 - MAINTENANCE

20. Before performing any maintenance or repairs, disengage the power take off, switch off the engine

and remove the starting key from the panel.

21. Periodically check the tightness of nuts and screws. Tighten where necessary.

22. Before performing any maintenance on the machine in a raised position, prop it securely with

appropriate props.

23. When replacing parts, wear gloves and use the correct equipment.

24. To preserve the environment do not burn or dump oils, greases and filters of any kind. Take them

to an approved agent for their recycling or disposal.

25. Check all guards devices for wear. Replace them if necessary.

26. Spare parts must be in accordance with the specifications given by the manufacturer. Only use

manufacturer’s originals spare parts.

27. Before welding when the machine is connected to the tractor, remove the alternator and battery

cables.

6 – BEFORE OPERATING

A - On Delivery

28. Check to see that no parts are missing.

29. Be sure that the hopper is free from foreign matter.

30. The spreader must be used for the designed purpose only.

31. Check for any damage that occurred during transportation and that no bags or parts are missing.

These claims will only be considered if reported on delivery.

32. Note any damage on the carrier’s consignment note.

33. In case of queries or disputes refer the matter to the supplier.

B - Maintenance

34. Clean all parts ensuring that you do not use any solvent or materials that will damage the gear box,

or other parts of the machine.

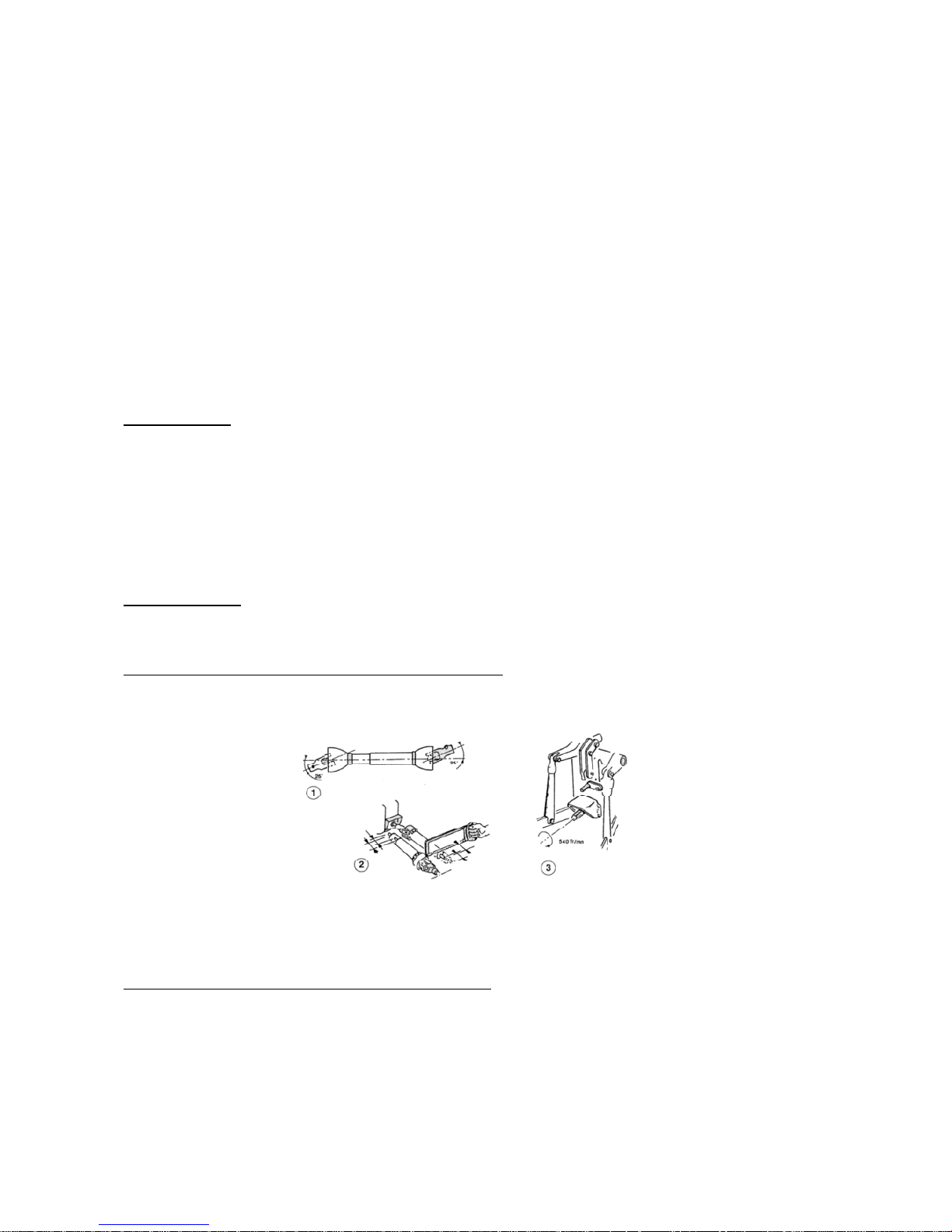

C - Transmission (for models with a power take off shaft)

35. Before using the machine grease the power take off shaft.

36. To preserve the power take off shaft in a good working state (see figure)

Do not exceed the power take off working angle of 25°. Check that the length of the power

take off shaft suits your tractor.

Leave a clearance of 3 cm at each end.

The rotational speed must be 500 r.p.m..

D - Connection (for models with a power take off shaft)

1. The spreader must be connected to the three point linkage.

2. The position of the lugs on the machine and the tractor must match.

3. Place the spreading disc or the oscillating tube parallel and 70 – 80cm above the ground level.

Loading...

Loading...