Page 1

Diaphragm Pumps

1150

Piston Pumps

EP2105

EP2205

EP2300

EP2300se

EP2400

EP2510

GP2605

GP2905

HVLP

CS5100

CS8100

CS9100

Maxum II Gun

Diaphragm Pumps

1150

Piston Pumps

EP2105

EP2205

EP2300

EP2300se

EP2400

EP2510

GP2605

GP2905

HVLP

CS5100

CS8100

CS9100

Maxum II Gun

Page 2

Page 3

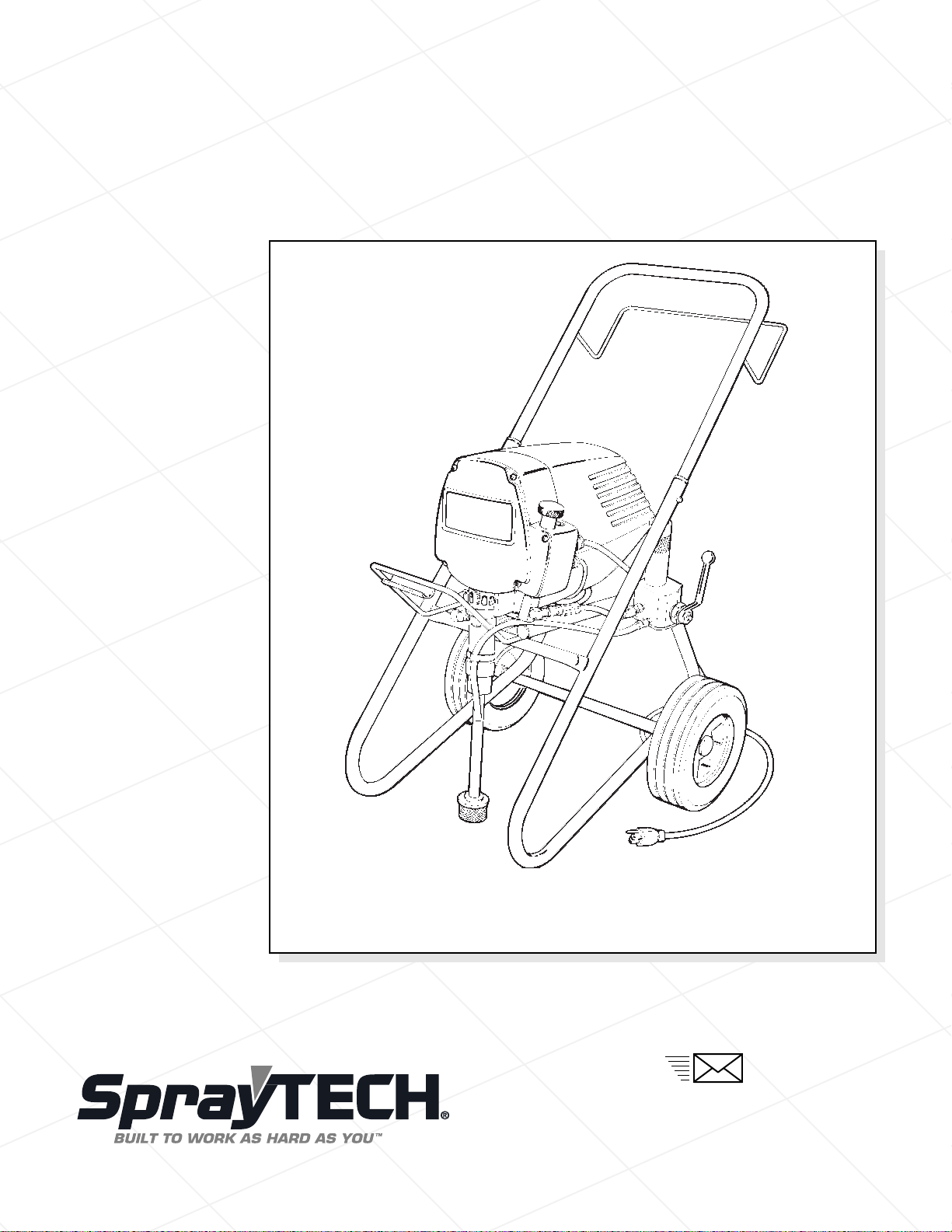

EP2300 Piston Pump

Owner's Manual

Model Numbers:

0294006 Cart Mount

0294036 Low Boy

SprayTECH

1770 Fernbrook Lane

Minneapolis, MN 55447

1297 © 1997 Wagner Spray Tech. All rights reserved. Form No. 0294724E

1

Page 4

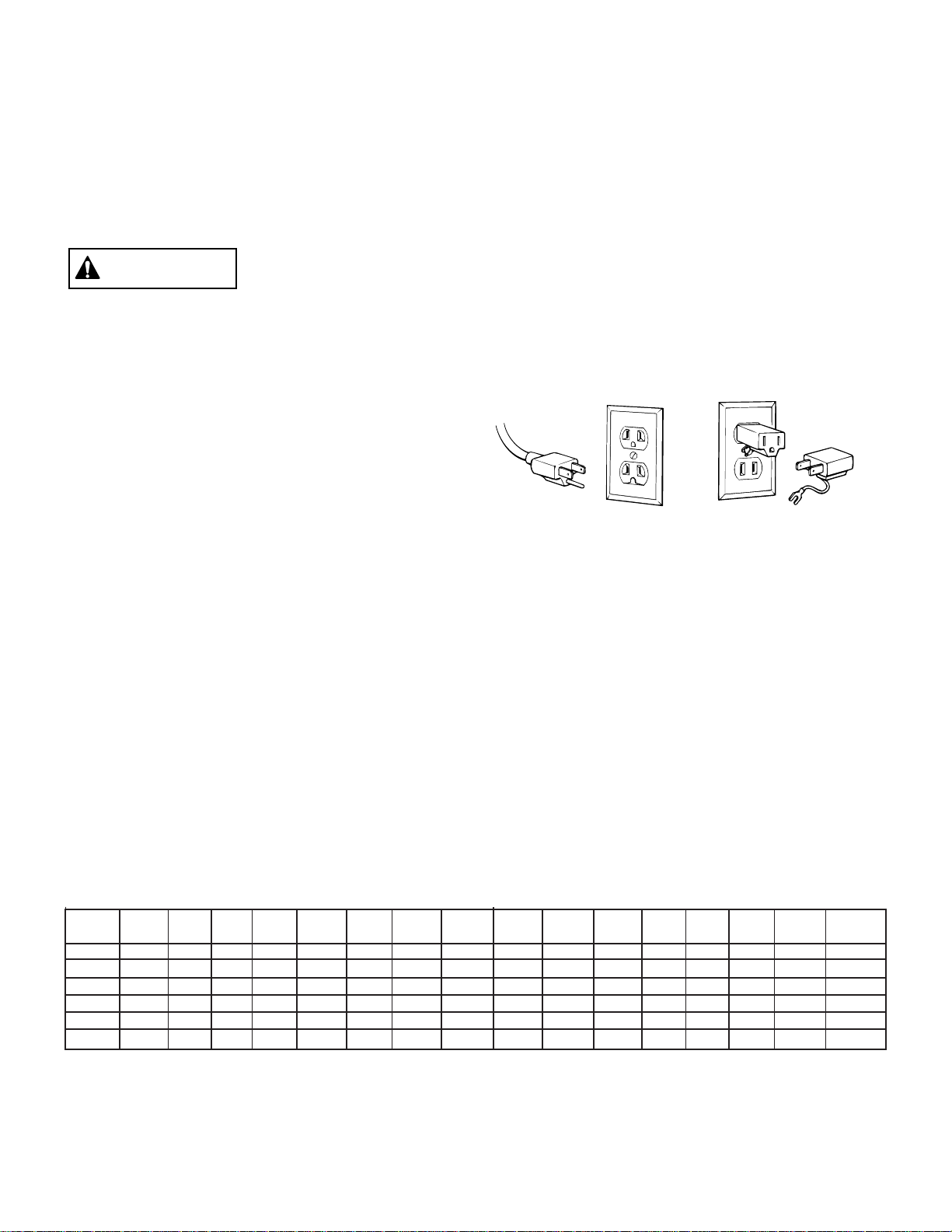

GROUNDING INSTRUCTIONS

This product must be grounded. In the event of an electrical

short circuit, grounding reduces the risk of electric shock by

providing an escape wire for the electric current. This

product is equipped with a cord having a grounding wire

with an appropriate grounding plug. The plug must be

plugged into an outlet that is properly installed and grounded

in accordance with all local codes and ordinances.

Improper installation of the

WARNING

If repair or replacement of the cord or plug is necessary, do

not connect the green grounding wire to either flat blade

terminal. The wire with insulation having an outer surface

that is green with or without yellow stripes is the grounding

wire and must be connected to grounding pin.

Check with a qualified electrician or serviceman if the

grounding instructions are not completely understood, or if

in doubt as to whether the product is properly grounded. Do

not modify the plug provided; if it will not fit the outlet, have

the proper outlet installed by a qualified electrician.

grounding plug can result in a

risk of electrical shock.

This product is for use on a nominal 120 volt circuit, and has

a grounding plug that looks like plug illustrated in sketch A.

A temporary adapter which looks like the adapter illustrated

in sketch B and C, may be used to connect this plug to a 2

pole receptacle as shown in sketch B if a properly grounded

outlet is not available. The temporary adapter should be

used only until a properly grounded outlet (sketch A) can be

installed by a qualified electrician. The green colored rigid

ear lug, or the like extending from the adapter must be

connected to a permanent ground such as a properly

grounded outlet box cover. Whenever the adapter is used,

it must be held in place by a metal, screw.

(B)

(A)

(C)

IMPORTANT

EXTENSION CORD SELECTION

If an extension cord is used, make sure it is of the three-conductor type with NEMA connectors so a continuous grounding circuit is

provided from tool to power circuit receptacle. Also, be sure that the conductor size is large enough to prevent excessive voltage drop

which will cause loss of power. A table of recommended extension cord sizes will be found below.

For nameplate ampere ratings which are between those given, use the extension cord recommended for the NEXT higher ampere

rating.

If an extension cord is to be used outdoors it must be marked with the suffixi W-A following the cord type designation. For example

— SJTW-A to indicate it is acceptable for outdoor use.

RECOMMENDED EXTENSION CORD SIZES FROM SERVICE ENTRANCE TO PUMP MOTOR.

NAMEPLATE AMPERE RATING

Cord

Lgth. 0 to 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

25Ft. 18 18 18 18 18 18 16 16 16 14 14 14 14 14 12 12

50Ft. 18 18 18 18 18 18 16 16 16 14 14 14 14 14 12 12I

25Ft. 18 18 18 18 18 18 16 16 16 14 14 14 14 14 12 12

100Ft. 18 18 18 16 16 16 16 16 14 14 14 14 14 14 12 12

125Ft. 18 18 16 16 16 14 14 14 14 14 14 12 12 12 12 12

150Ft. 18 16 16 16 14 14 14 14 14 12 12 12 12 12 12 12

2

Page 5

CONTENTS

Safety Warnings......................................................... 4-6

Specifications.................................................................7

Initial Set-up...................................................................7

Purging & Priming..........................................................8

Operation....................................................................... 9

Setting the Pressure...................................................... 9

Using the Spray Gun....................................................10

Pressure Relief Procedure...........................................10

Prime the Sprayer with Paint....................................... 10

Spraying Technique.....................................................11

Clean-up.......................................................................12

Maintenance.................................................................13

Daily Maintenance......................................................13

Repacking the Fluid Section.......................................14

Motor Brush Replacement..........................................16

Trouble Shooting...........................................................17

Parts List...............................................................19 - 29

Accessories..................................................................30

Warranty........................................................Back Cover

SAFETY PRECAUTIONS

This manual contains information which must be read and understood before using the equipment. When you come to an

area which has one of the following symbols, pay particular attention and make certain to heed the safeguard.

WARNING

Important safety information indicates a hazard which may cause serious injury or loss of life.

CAUTION

Important information that tells how to prevent damage to equipment or how to avoid causes of minor injuries.

Note: Gives important information which should be given special attention.

3

Page 6

WARNING

HAZARD

Injection Injury - A high pressure stream of paint pro-

duced by this equipment can pierce the skin and

underlying tissues, leading to serious injury and possible amputation.

PREVENTION

• Maximum operating range of the gun - 3000 PSI fluid

pressure.

• NEVER aim the gun at any part of the body.

• NEVER allow any part of the body to come in contact

with the fluid stream. DO NOT come in contact with a

fluid stream created by a leak in the fluid hose.

• NEVER put hand in front of the gun. Gloves will not

provide protection against an injection injury.

• ALWAYS lock the gun trigger,shut fluid pump off and

release all pressure before servicing, cleaning tip guard,

changing tips, or leaving unattended. Simply turning off

the motor will not release pressure in the system. The

Prime Spray Valve must be turned to the position to

relieve the pressure. See Pressure Relief Procedure,

Page 10.

• ALWAYS have the tip guard in place while spraying. The

tip guard provides some protection against injection

injuries but is mainly a warning device.

DO NOT TREAT AS A SIMPLE CUT! Injectioncan lead to amputation. See a physician immediately.

NOTE TO PHYSICIAN: Injection into the skin

is a traumatic injury. It is important to treat

the injury surgically as soon as possible. DO

NOT delay treatment to research toxicity.

Toxicity is a concern with some coatings

injected directly into the blood stream. Consultation with a plastic surgeon or reconstructive hand surgeon may be advisable.

•

ALWAYS remove spray tip before flushing or cleaning

the system.

• Paint hose can develop leaks from wear, kinking, abuse

etc. A leak is capable of injecting material into the skin.

The paint hose should be inspected before each use.

• NEVER use a spray gun which does not have a trigger

lock or trigger guard in place and in working order.

• All accessories must be rated at or above 3000 PSI

(Includes spray tips, guns, extensions, and hose).

• In case of skin injection, see physician immediately.

4

Page 7

WARNING

HAZARD

Explosion or fire - Solvent and paint fumes can explode or

ignite causing property damage and or severe injury.

PREVENTION

• Exhaust and fresh air introduction must be provided to

keep the air within the spray area free from accumulation

of flammable vapors.

• Avoid all ignition sources such as static electricity sparks,

open flames such as pilot lights, hot objects such as

cigarettes, and sparks from connecting and disconnecting power cords and working light switches.

• Fire extinguishing equipment must be present and in

working order.

• Keep the pump away from spray area to avoid solvent

and paint fumes.

• High velocity flow of material through equipment may

develop static electricity. The equipment being used,

and objects in and around the spray area must be

properly grounded to prevent static discharge and sparks.

• Use only conductive or grounded high pressure fluid

hoses for airless applications. Be sure that gun is

grounded through hose connections.

• Follow the material and solvent manufacturer's safety

precautions and warnings.

• WHEN FLUSHING EQUIPMENT use lowest possible

pressure.

5

Page 8

WARNING

HAZARD

Explosion hazard incompatible materials - May cause

property damage or severe injury.

Hazardous vapors - Paints, solvents, insecticides, and

other materials may be harmful if inhaled causing severe nausea, fainting, or poisoning.

PREVENTION

• Halogenated hydrocarbon solvents such as methylene

chloride and 1,1,1 - Trichlorethane are not compatible

with aluminum and may cause an explosion. If unsure of

a material’s compatibility with aluminum, contact your

coating's supplier.

• Some spray guns and accessories cannot be used with

halogenated hydrocarbon solvents. Be certain of compatibility before use with halogenated hydrocarbon solvents.

• The SprayTech EP2300 pump is NOT compatible for use

with halogenated hydrocarbon solvents. The SprayTech

G-05, G-09, and G-10 guns must not be used with

halogenated hydrocarbon solvents.

• Use a respirator or mask whenever there is a chance that

vapors may be inhaled. Read all instructions with the

mask to assure that it will provide the necessary protection against the inhalation of harmful vapors.

General - May cause property damage or severe injury.

• Read all instructions and safety precautions before operating.

• Comply with all appropriate local, state and national

codes governing ventilation, fire preventive, and operation.

• The United States Government Safety Standards have

been adopted under Occupational Safety and Health

Act. These standards, particularly the General Standards, Part 1910 and construction Standard, Part 1926,

should be consulted.

• This high- pressure airless pump is designed to be used

with authorized SprayTech parts only. When using this

pump with parts that do not comply with the minimum

specifications and safety devices of the pump manufacturer, the user assumes all risks and liabilities.

• Before each use, check all hoses for cuts, leaks, abrasion or bulging of cover or damage or movement of

couplings. If any of these conditions exist, replace the

hose immediately. Never repair a paint hose. Replace it

with another grounded hose.

• All hoses, swivels, guns, and accessories used with this

unit must be pressure rated at or above 3000 PSI.

6

Page 9

SPECIFICATIONS

MODEL EP2300

1. GPM----------------------------------------------------------2/3

2. Maximum pressure-------------------------------3000 PSI

3. Motor - electric ------------------------------------------1 HP

4. Amperage-------------------------------------------8.5 Amps

5. Cycle------------------------------------124 cycles per min.

6. Maximum Tip Size @2000 psi---------------------- .023"

(Latex paint)

7. Max. Hose Length @ 2000 PSI-----------------100 feet

8. Weight:

LowBoy--------------------------------------------------63 lbs.

Cart Mount---------------------------------------------64 lbs.

9. Dimensions:

Cart Mount -------------------------------30"Lx39''Hx21''W

LowBoy------------------------------------28L x 21H x 21W

(38H with Handle)

INITIAL SET-UP

The SprayTech EP2300 Piston Pump unit is fully assembled upon delivery. Follow these

simple steps for set-up:

LOWBOY

1. Remove the plug from the inlet elbow on the fluid

section.

2. Attach the suction set fitting into the inlet elbow on the

fluid section.

3. Attach the return line to the tube fitting at the dump

valve.

CART MOUNT/LOW BOY

4. Remove protector cap on outlet fitting and install airless hose. DO NOT INSTALL SPRAY TIP(S) IN

GUN(S) AT THIS POINT.

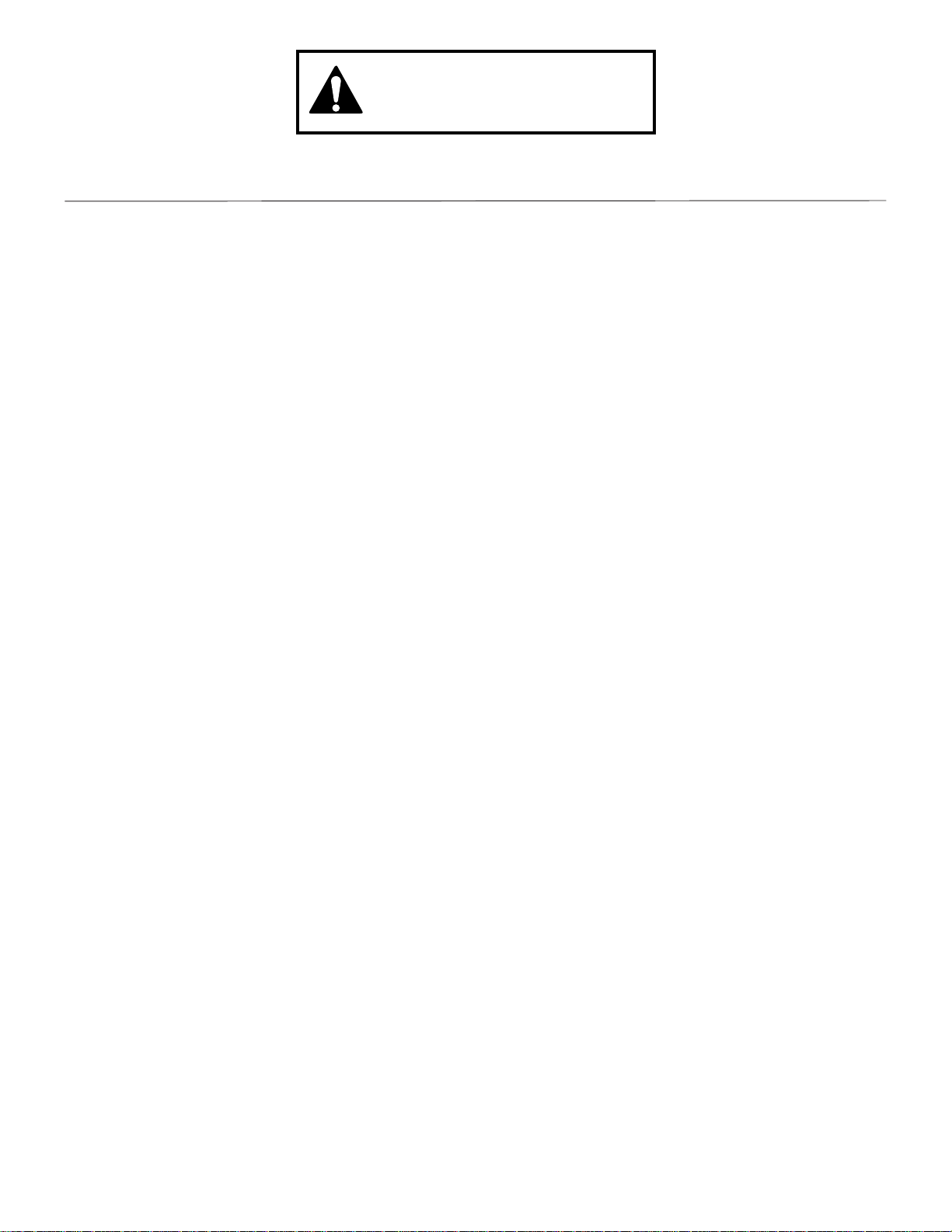

SprayTech EP2300 Low Boy Piston Pump

Figure 1. SprayTech EP2300 Cart Mounted Piston Pump

1. Attach handle to cart using bolts and knobs provided.

Insert bolt through square hole in handle and then

through hole in cart leg. Secure with knob. Repeat

other side.

2. Remove protector cap on outlet fitting and install airless hose. DO NOT INSTALL SPRAY TIP(S) IN GUN(S)

AT THIS POINT.

Figure 2. Install Siphon Tube

7

Page 10

PURGING AND PRIMING

This unit is shipped with test fluid in the fluid section to

prevent corrosion during shipment and storage.

For spraying with solvent-based paint, thorough flushing of

this material is not necessary.

If you are going to spray with LATEX paint, this fluid must

be thoroughly cleaned out of the system.

KEEP SPRAY GUN LOCKED AND IN THE OFF POSITON DURING ALL THESE STEPS.

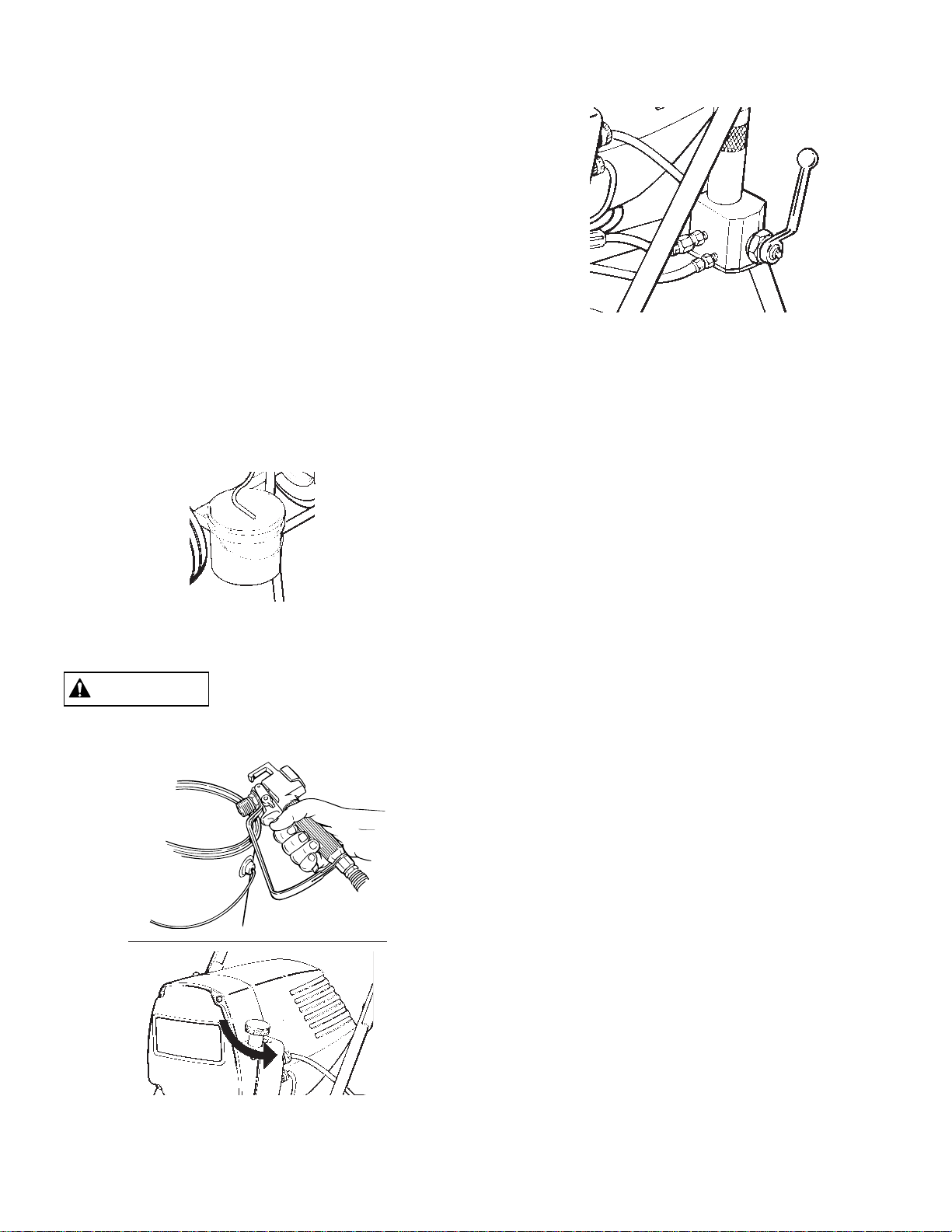

4. Set Prime/Spray Ball Valve to the Prime position.

Purging System for Latex Paint

1. Place a bucket of soapy water under the paint suction

tube. Also, have a waste container handy to catch the

purged fluid.

2. Place paint return hose into the waste container.

Figure 3. Place return hose so purged fluid goes into

waste container.

WARNING

edge of the container while flushing (As shown below).

Failure to do so may lead to static electric discharge, which

may cause a fire.

If a metal container is used, ground

the gun by holding it against the

Figure 5. Set Prime/Spray Ball Valve to Prime

5. Turn the ON-OFF switch to the ON position.

6. Gradually increase pressure by turning Pressure Control Knob clockwise.

7. Watch for fluid to start coming through return tube. Use

minimum pressure necessary to keep fluid flowing.

8. When test fluid is purged, soapy water will flow through

the return. Turn pressure down to minimum and

replace soapy water bucket with clear water.

9. Increase pressure again and let unit run until water

running through the return line is clear.

10. Decrease pressure. Replace clean water container

with bucket of latex paint.

11. Increase pressure slowly until paint comes through the

return tube. Place return hose back into operating

position above paint bucket. Keep recirculating until

the paint coming through the return tube is free of air

bubbles.

Figure 4. Turn Pressure Control Knob Counter-Clockwise to

Reduce Pressure

12. Decrease pressure to minimum setting (counter-clockwise). The unit is now ready to use. (See “Operating

the Sprayer, page 9.)

8

Page 11

Purging System for Solvent-Based

Paint

If you are going to spray solvent-based paint, all you need

to do is purge the fluid. Thorough cleaning is not necessary

as it is with latex paint.

NOTE: KEEP SPRAY GUN LOCKED OFF DURING

ALL THESE STEPS.

1. Put full paint bucket into position.

2. Place return hose over waste container. (See Figure

3.) Attach paint hose without tip and put into waste

container.

3. Set Pressure Control Knob full counter-clockwise (minimum pressure). (See Figure 4.)

4. Set Prime/Spray Ball Valve on Prime . (See Figure 5.)

5. Turn the ON-OFF switch to the ON position.

6. Turn Pressure Control Knob clockwise to increase

pressure until fluid starts to come through return tube

into waste container.

7. When paint starts to flow through return tube, decrease

pressure to minimum setting and place return tube over

paint bucket.

8. Continue recirculating until paint flowing through return

tube is free of bubbles.

9. Install spray tip.

10. You are now ready to spray.

OPERATION

For a new unit, follow purging and priming steps above. For

units already in service, also purge water or solvent from

the system as described above, depending on the type of

paint being used.

After pump is primed and ready to spray, it may also be

necessary to purge the hoses of water or solvent.

1. Set Pressure Control Knob to minimum setting (counterclockwise).

2. Set Prime/Spray Ball Valve to Spray .

3. Be sure spray gun still has no tip installed.

4. Unlock spray gun.

5. Increase pressure by turning Pressure Control Knob

clockwise.

6. Trigger gun into waste container until solvent or water

is purged from the hose.

7. Decrease pressure by turning Pressure Control Knob

counter-clockwise.

8. Set Prime/Spray Ball Valve to Prime, and trigger gun

to be sure no pressure is left in the hose.

9. Lock gun off.

10. Install spray tip appropriate for the material being

sprayed. (The thicker the paint, the larger the spray tip

required.)

11. Re-set Prime/Spray Ball valve to Spray.

12. Increase pressure to maximum setting (turn Pressure

Control Knob clockwise).

13. Release gun lock.

Before starting spraying every day, squirt upper packing

lubricant (Part No. 9992504) into slots in packing nut cover.

Do not apply so much that it overflows and drips into the

paint. This lubricant keeps the piston seals pliant, minimizing paint by-pass and piston wear. If unit is operated

several hours a day, repeat lubrication after about 4 hours.

Figure 6. Oil Upper Pump Packings

14. Trigger gun to test spray pattern. Spray against a scrap

piece of pasteboard or other test surface.

15. See Setting the Pressure, below.

Setting the Pressure

The best pressure setting will vary with the type of paint and

the size and type of nozzle. The thicker the paint, the higher

the pressure needed.

To find the optimum pressure setting, start with the Pressure Control Knob turned fully clockwise (maximum pressure). Gradually decrease the pressure by turning the knob

counter-clockwise to the minimum level necessary to maintain the desired spray pattern and atomization.

Until you are satisfied with the spray pattern, spray on a test

surface rather than on the surface to be painted.

9

Page 12

Using the Spray Gun

NOTE: FOLLOW THE INSTRUCTIONS THAT CAME

WITH YOUR GUN.

Prime the Sprayer with Paint

1. Turn the prime/spray ball valve to prime.

2. Put the suction tube into the paint container.

3. Turn the pressure control knob counterclockwise as far

as possible to the lowest pressure setting.

PRESSURE RELIEF PROCEDURE

WARNING

the unit down for any purpose, including servicing or

adjusting any part of the spray system, changing or

cleaning spray tips, or preparing for clean-up.

1. Engage the gun safety latch.

2. Shut off the motor and turn the pressure control knob

counterclockwise as far as possible.

3. Turn the prime/spray ball valve to prime, having a pail

ready to catch the drainage or return to the paint

container via the return hose.

4. Disengage the gun safety latch.

5. Hold metal part of the gun firmly to the side of a metal

pail to avoid a build up of static electricity, and trigger

the gun into the metal container to relieve the pressure.

6. Engage the gun safety latch.

7. Leave the prime/spray ball valve on prime, until you are

ready to operate the sprayer again.

Be sure to follow the Pressure

Relief Procedure when shutting

4. Start motor. Slowly increase pressure by turning the

pressure control knob clockwise until pump begins to

function. When paint begins to flow through return tube

decrease pressure by turning the pressure control

knob counterclockwise and then turn the prime/spray

ball valve to the spray position.

5. Disengage the gun safety latch.

6. Hold a metal part of the gun firmly against and aimed

into a metal waste container. Trigger the gun and hold

it open while slowly increasing the pressure setting by

turning the pressure control knob clockwise until the

sprayer starts. Keep the gun triggered until all the air

is forced out of the system and paint is flowing freely.

Release the trigger and engage the safety latch.

7. Check all fluid connections for leaks. If any are found,

follow the pressure relief procedure before tightening

the connection.

10

Page 13

Spraying Technique

You can learn to spray paint as easily as you can learn to

paint with a brush or roller. You can get a professional

looking job in a safe manner by following the spray painting

tips below.

1. Heed all WARNINGS and CAUTIONS that are listed

on pages 3 thru 6 at the front of this manual. Take time out

now to reread them.

2. Avoid sharp bending and kinking of the paint hose. All

paint hoses should be kept clear of traffic and sharp cutting

edges or objects.

3. Use the lowest pressure possible when spraying. Too

much pressure shortens equipment life. It also causes

faster than normal wear on the spray tip.

4. Determine the best spraying distance (distance from

spray tip on the spray gun to the work). If the spray gun is

held too close to the work, you will have paint buildup that

will cause sags and runs. If the spray gun is held too far

from the work,

"fogging"

will result.

Light

Coat

Figure 7. - Result of flexing wrist while spraying.

Even Coat on Work Throughout

Heavy

Coat

Wrong

Way to Spray

Approximatley

10 to 12 Inches

Light

Coat

Work

The correct distance should be about 10 to 12 inches. Keep

this distance for the entire length of the stroke. Of course,

the shape of some work surfaces will not permit this.

However, the same spraying distance should be kept

whenever possible.

5. Do not move the spray gun by flexing your wrist. The

result of this is shown in Figure 7. Rather, move the spray

gun with a smooth stroke of the entire arm and shoulder.

Maintain the same arm speed all the way through the

stroke. The result of this is shown in Figure 8.

NOTE:

WHEN SPRAYING BLOCK FILLER, MASTICS OR

HIGH SOLID COATING LEAVE OUT GUN FILTER

AND HIGH PRESSURE FILTER SCREENS.

Right

Way To Spray

Figure 8. - Result of smooth arm stroke and steady, even

speed while spraying.

Steady Arm

6. Keep the spray gun perpendicular to the work as shown

in Figure 9.

Approximately

10 to 12 inches

Right Way

Wrong Way

Figure 9. - Right and wrong ways to hold spray gun toward

work.

11

Page 14

7. The spray gun should be triggered (turned off and on)

on each stroke. This will save paint and avoid paint

buildup at the end of the stroke. However, do not trigger

during the middle of a stroke. This will result in an

uneven spray and splotchy work. See Figure 10 for

proper triggering on a left-to-right stroke. Reverse for

a right-to-left stroke.

CLEAN-UP

CAUTION

Failure to do so permits material to cake, seriously affecting

the performance of the unit.

The pump, hose and gun should be

cleaned thoroughly after daily use.

8. Move the spray gun at a rate of speed that is comfortable for you. If you have to move your arm too fast in

order to prevent excessive paint buildup, either (1)

lower the pressure by turning the pressure control knob

counterclockwise, or (2) use a spray tip with a smaller

hole. If you have to move your arm too slow in order to

get a good coating, either (1) raise the pressure by

turning the pressure control knob clockwise, or (2) use

a spray tip with a larger orfice. You should always keep

the spray gun moving when making a stroke. Slowing

down in one place will cause sags or runs.

Approximatley

10 to 12 Inches

Start

Stroke

Pull

Trigger

Figure 10. - Proper way to trigger spray gun.

Work

Even Steady

Stroke

Release

Trigger

End

Stroke

WARNING

When cleaning the pump, hose

and gun with mineral spirits or any

other solvent, ALWAYS spray at minimum pressure with

the gun nozzle tip removed. Static electricity build-up may

result in a fire or explosion in the presence of flammable

vapors.

After daily use, paint should be flushed from the unit with

solvent compatible with the material applied, and then reflushed with mineral spirits.

1. Turn power switch to OFF.

2. Bleed off any pressure remaining in the pump by

opening the dump valve.

3. Remove gun tip and clean with solution compatible

with material applied.

4. Remove paint container from its position directly below

siphon hose and paint strainer. Replace with a container of solvent compatible with material being applied.

9. Overlap each stroke by about 40% to 50%. The

overlap will assure a paint coating that is uniform

across the work. One way to get good overlap is to

point the spray gun at the edge of the last stroke.

5. Turn the pressure control knob counter-clockwise to

the lowest pressure setting.

6. Turn power switch to ON.

7. Trigger spray gun(s) into container to flush pump, hose

and gun(s) clean.

8. Turn power switch to OFF.

9. Bleed off solvent.

10. Unplug unit and store in a clean dry area.

For long-term storage, be sure to flush unit with appropriate

oil before storing.

12

Page 15

MAINTENANCE

Routine operator maintenance on this unit is minimal. Only

three daily procedures are required: (1) lubricating the

upper packings, (2) cleaning the high pressure filter screen,

and (3) cleaning the intake screen.

Daily Maintenance

1. Squirt upper packing lubricant into slots in upper pump

housing. Do not over-lubricate, as this will result in oil

dripping into the paint. Oil approximately every four

hours of operation.

Filter

Support

O-Ring

Filter

Housing

Filter

Element

Figure 11. Squirt upper packing lubricant into upper cylinder

housing every four hours.

2. Clean high pressure filter, as needed. Remove filter

housing. (Filter canister is threaded into base with

right-hand threads.) Take out filter element and wash

thoroughly. Scrub gently with a fiber-bristle brush if

necessary (DO NOT use a wire brush). If spraying

block fillers, mastics, etc. leave filter element out.

Figure 12. Remove and clean High-Pressure Filter at

least daily, more often if needed.

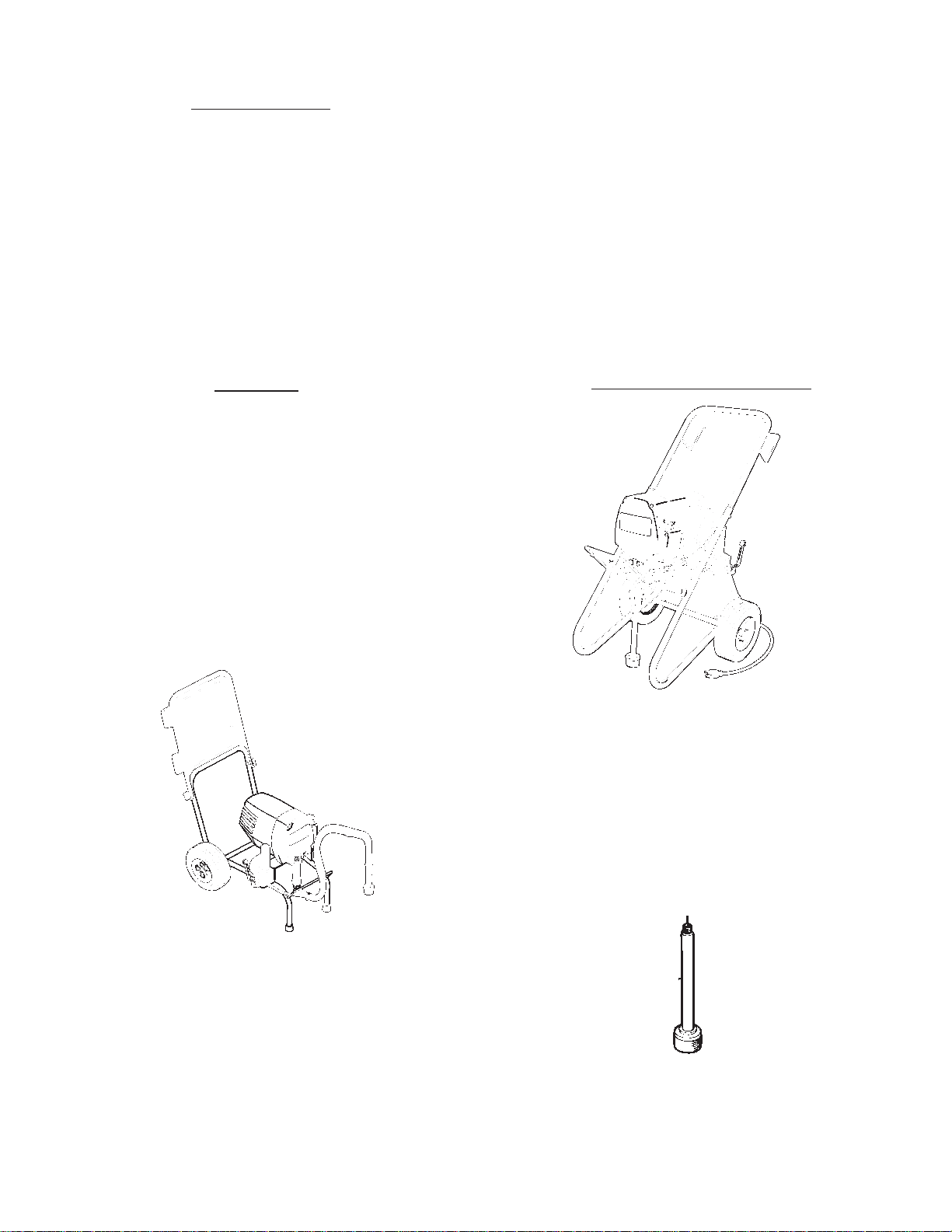

3. Inspect paint intake screen (at bottom of paint suction

tube) and wash if necessary. (Screen is threaded onto

suction tube. Remove by turning counter-clockwise.)

Teflon tape

Siphon tube

Screen

Figure 13. Clean paint intake screen daily, or more often if

needed.

13

Page 16

Repacking the Fluid Section

A small amount of paint by-passing the piston and coming

out of the slots in the upper piston housing is normal, but if

it becomes excessive, or if paint pressure drops, the piston

packings need to be replaced.

1

*2

*4

*3

*5

*6

7

8

*9

10

WARNING

before starting any troubleshooting, servicing, or cleaning.

Refer to Figure 14 (left).

1. Loosen and remove siphon tube assembly by turning

counterclockwise.

2. Remove front cover.

3. Remove packing nut cover.

4. Run the unit in short intervals until the connecting pin

is in front of the recessed area of the housing.

5. Disconnect the power cord from the electrical supply.

6. Remove the retainer clip on the yoke.

7. Remove the connecting pin by pushing it through the

yoke and piston rod.

8. Loosen and remove fluid hose.

9. Loosen large locknut (7) on upper end of fluid section.

10. Unscrew entire fluid section assembly by turning counterclockwise.

CAUTION

ALWAYS follow the Pressure

Relief Procedure (page 10)

Do not run motor with fluid section

removed.

*13

20

16

#18

*#24

*14

*#22

23

25

#26

*#27

*11

*12

15

*#17

*#19

28

* Included in Packing Kit

P/N 0294905.

# Included in Valve Kit

P/N 0294689.

21

11. Using wrench flats on inlet valve holder (28), position

fluid section vertically into vise. Tighten vise.

12. Locate wrench flats on cylinder (8). Turn cylinder

counterclockwise with large adjustable wrench until it is

removed from the inlet valve holder (28).

13. Remove and inspect upper O-Ring (22) in inlet valve

holder. If damaged, replace when re-installing.

14. Remove inlet valve holder (28) from vise. Tap out ball

stop disc (23), ball cage (25) and ball (24).

If any parts are difficult to disassemble, soak in

lacquer thinner until paint softens.

15. Remove lower ball seat (26). Inspect the ball and ball

seat for damage. If seat is worn or damaged it can be

flipped to the unused side. Ball must be replaced if

damaged or if the seat is flipped.

NOTE:

Inlet and Outlet Valve carbide seats are reversible.

If one side becomes worn or damaged, flip the seat

to the un-used side.

Figure 14 - Fluid Section

©1994, rev. 1995 Wagner Spray Tech Corporation. All rights reserved.

Continued on next page.

14

Page 17

Repacking Fluid Section

Continued from Page 14

(Refer to Figure 14, Page 14)

16. Remove lower O-Ring (27) from inlet valve holder.

17. Place cylinder (8) in vise (on wrench flats) and

tighten.

CAUTION

18. Remove packing nut (1).

19. Gently hammer piston assembly down with rubber

mallet. Piston assembly will come out.

CAUTION

falls to the floor. Lower packings may also fall out.

20. Remove lower packings (12, 13) and lower female

adapter (14) if they have not already fallen out.

21. Remove lower male adapter (11) and wave spring (9).

22. Remove upper packings (3, 4 ) and adapter (2, 5) and

wave spring (6).

23. Insert connecting pin through hole in piston rod (10).

Lock connecting pin in vise jaws so piston rod is

vertical. DO NOT put piston rod itself in vise. The vise

jaws will damage piston rod.

24. Remove jam nut (21).

25. Remove piston seat retainer (20) with 5/16'' allen

wrench.

26. Remove piston rod assembly from vise.

27. Remove washer (19), ball seat (18), ball (17), ball

cage(16) and ball stop disc (15) from lower end of

piston rod assembly.

28. Inspect ball, and ball seat for damage. If the seat is

worn or damaged it can be flipped to the un-used side.

Ball must be replaced if damaged or the seat is flipped.

Washer must be replaced.

29. Hold piston assembly in vice using same procedure as

step 23.

30. Insert upper ball stop disc (15), ball cage (16), ball (17),

ball seat (18), and washer (19) into piston assembly.

31. Put removable loctite on piston seat retainer (20).

Insert into piston assembly and tighten. Torque to 250

in./lbs.

32. Put removable loctite on jam nut (21). Tighten onto

piston seat retainer. Torque to 200 in./lbs. Remove

piston assembly from vice.

33. Place cylinder in vice using wrench flats and tighten.

Do not over tighten or damage to

cylinder may occur.

Hold hand under piston rod (10).

Damage can occur if piston rod

34. Soak new leather packings in linseed oil for 5 minutes.

Do not oversoak.

35. Insert wave spring (9) and lower male adapter (11) into

cylinder. Remove leather packings from oil. Install

leather packings (13) alternatively with UHMWPE

packings (12). Insert lower female adapter (14).

36. Insert piston assembly into bottom of cylinder (8). A

slight force may be required to push piston rod through

packings.

37. Place O-Ring (27), lower ball seat (26), ball cage (25),

ball (24) and lower ball stop disc (23) into inlet valve

holder (28).

38. Put anti-seize compound on lower threads of cylinder

(8). Put O-Ring (22) on cylinder. Loosen vise and tilt

cylinder assembly at about a 45 degree angle. Tighten

vise again.

39. Tighten foot valve holder assembly onto cylinder with

an appropriate adjustable wrench until cylinder bottoms

out in foot valve holder. Make sure to use wrench flats

on foot valve holder to tighten completely. Torque to 40

ft./lbs.

40. Soak remaining new leather packings in linseed oil for

5 minutes. Do not oversoak.

41. Insert wave spring (6), upper male adapter (5). Remove

leather packings from oil. Install leather packings (4)

alternatively with UHMWPE packings (3). A tool, Wagner

part #06009, may be required to compress packings

down. Insert female adapter (2).

42. Install packing nut (1) and tighten until the nut bottoms

out in cylinder. Torque to 25 ft./lbs. Do not overtighten.

43. Install large locknut (7) onto upper cylinder (8) and

turn until nut bottoms out on threaded section of

cylinder.

44. Put anti-seize compound on upper cylinder threads.

45. Remove fluid section from vice and install into main

pump housing. Piston rod (10) will align itself inside

yoke.

46. Rotate fluid section slightly to align hole in yoke and

hole in piston assembly. Insert connecting pin.

Replace spring retainer.

47. Thread fluid section into pump housing completely,

then unscrew up to 3/4 turn to align outlet elbow with

fluid hose.

48. Rotate large locknut (7) clockwise until tight against

drive housing.

15

Page 18

WARNING

NEVER OPERATE PUMP WITHOUT FRONT COVER IN

PLACE.

Motor Brush Replacement

Brushes should be inspected periodically to insure uninterrupted service. Their life depends on speed as well as load.

If one of the brushes measures less than 1/4'' or is worn

roughly or chipped, replace both motor brushes. It is also

recommended that brushes be checked when packings are

replaced.

1. Disconnect power cord from electrical supply.

2. Remove the four (4) motor shroud mounting screws

and remove the motor shroud.

3. Unscrew and remove brush caps holding brushes in

place.

4. Remove brushes.

5. Replace with new brushes.

Brush Cap

Motor Brush

Figure 15. Remove Brush Cap and Motor Brush

6. Replace brush caps.

7. Replace motor shroud and screws.

16

Page 19

TROUBLESHOOTING

PROBLEM CAUSE REMEDY

Unit will not run Blown panel fuse or tripped Check and replace/reset

breaker

Unit not plugged in Plug in

Pressure control knob set too low Turn knob to higher pressure

Faulty or loose wiring Inspect/Take to SprayTech Authorized Service

Center

Worn motor brushes Check and replace brushes

Clogged Tip or Filters Clean tip and filters.

Faulty On/Off switch fuse Take to SprayTech Authorized Service Center

Unit will not prime Dried out piston packings Remove siphon tube and feel lower ball check to

be sure it is free to move off its seat. Place full

cup of paint thinner over end of fluid section and

turn on pump.

Pump inlet screen plugged Remove and clean.

Air in pump or hose Hold gun trigger in open position and run unit

about 10 seconds until air is purged

Check for siphon tube leak

Packings worn Replace packings. (See page 14)

Fluid is too viscous Prime pump with compatible solvent. Bring pump

up to pressure. Carefully remove pump from

solvent container and immerse inlet tube in heavy

material to be sprayed. With nozzle tip removed,

trigger gun until heavy material appears at gun.

Replace nozzle tip.

Siphon tube clogged Remove and clean

Siphon tube air leak Check connection and seal

Clogged tip Relieve pressure, remove tip and clean.

Unit will not build or Pressure adjusting knob not Adjust to increase pressure

maintain pressure properly set

Pump inlet strainer dirty Clean

Valve balls or seals worn or dirty Replace or clean

Air in pump or hose Hold gun trigger in open position and run about 10

seconds until air is purged

Packings worn Replace (See Page 14)

Worn spray tip Replace (Follow direction supplied with gun)

Internal leakage With gun trigger closed, allow unit to pump up to

pressure and shut off if pump momentarily starts.

Internal leak is indicated and fluid section rebuild

is necessary. (See Page14)

Fluid leak Check for external leaks including hydraulic

fittings attached to pressure control housing

Fluid too viscous Consult manufacturers recommendations on paint

container label

Spray tip too large Change tip

Fluid leakage at upper Upper packing worn Relieve pressure and tighten packing take up nut

end of fluid section or replace packings. (See Page 14)

Piston rod worn Replace. (See Page 14)

17

Page 20

TROUBLESHOOTING CONTINUED

PROBLEM CAUSE REMEDY

Poor spray pattern Tip too large Change to smaller tip

Pressure adjustment wrong Adjust pressure control knob

Insufficient fluid delivery Clean all strainers and filters

Fluid too viscous Add solvent according to manufacturer's

recommendations

Unit lacks power Pressure adjustment low Increase pressure

Improper voltage supply Reconnect input voltage for 115 AC

Blow Fuses at Pump Excessive pressure Take to SprayTech Authorized Service

Circuit Breaker Center

Overtightened packings Repair/replace malfunctioning parts

gear box, linkage or motor

failures

18

Page 21

25

26

20

22

21

23

20

19

17

18

24

16

13

15

12

3

4

2

5

1

14

9

10

9

10

11

2

6

6

7

8

Figure 16- EP2300 Final Assembly

EP2300 FINAL ASSEMBLY - FIGURE 16

ITEM PART NO. DESCRIPTION QTY

1 0294611 Hose, Fluid,1/4 NPT 1

2 05045 Nipple 2

3 - - - - - - - - Cart Assembly 1

(See Figure 18)

4 0294220 Filter/Dump Valve Assembly 1

(See Figure 26)

0294229 Optional Filter Assembly

(Includes Items 2, 4, 5, 6 & 7)

5 02518 Nipple 1

6 51055 Plug, Pipe 2

7 9885563 Fitting, Tube 1

8 0294416 Tube, Return 1

9 51357 Washer, Lock 4

10 52183 Bolt, Hex. Head 4

11 13549 Hose, Fluid 1

12 12440 Elbow, 90° 1

13 0294415 Manifold 1

ITEM PART NO. DESCRIPTION QTY

14 9885547 Elbow 45° 1

15 02208 Transducer Assembly 1

(See Figure 22)

16 02975 Strainer 1

17 0279473 Siphon Tube Assembly 1

18 0294584 Return Tube Clamp 1

19 0294393 Cover, Packing Nut 1

20 9802515 Screw 6

21 0294425 Cover, Front 1

22 9802511 Screw 5

23 0294133 Fluid Section Assembly 1

(See Figure 21)

24 ------------ Drive Assembly, 23 Series 1

(See Figure 25)

25 0294344 Baffle 1

26 0294405 Shroud, Motor 1

19

Page 22

22

24

18

23

8

5

6

6

2

3

2

3

20

21

19

18

16

17

15

9

10

11

12

7

13

14

Figure 17- Low Boy Final Assembly

4

4

5

EP2300 LOW BOY FINAL ASSEMBLY - FIGURE 17

1

ITEM PART NO. DESCRIPTION QTY.

1 - - - - - - - - LowBoy Cart Assembly 1

(See Figure 19)

2 51357 Washer, Lock 4

3 52183 Bolt, Hex. Hex. 4

4 13549 Hose, Fluid 2

5 05045 Nipple 2

6 51055 Plug, Pipe 2

7 02518 Nipple 1

8 0294220 Filter/Dump Valve Assembly 1

(See Figure 26)

0294228 Optional Filter Assembly

( Includes Items 5, 6, 7, 8, & 9)

9 9885559 Elbow, 90°, Return Line 1

10 0294424 Tube, Return 1

11 9885547 Elbow, 45° 1

12 02208 Transducer Assembly 1

(See Figure 22)

ITEM PART NO. DESCRIPTION QTY.

13 12440 Elbow, 90° 1

14 0294415 Manifold 1

15 0090447 Elbow, 90° 1

16 0294133 Fluid Section Assembly 1

(See Figure 21)

17 0294393 Cover, Packing Nut 1

18 9802515 Screw 6

19 0294425 Cover, Front 1

20 0294185 Suction Set 1

(See Figure 23)

21 9802511 Screw 5

22 - - - - - - - Drive Assembly 23 Series 1

(See Figure 25)

23 0294344 Baffle 1

24 0294405 Shroud, Motor 1

20

Page 23

7

8

Figure 18 - Cart Assembly

1

2

3

4

5

6

CART ASSEMBLY - FIGURE 18

ITEM PART NO. DESCRIPTION QTY.

1 0279324 Handle 1

2 9802518 Bolt 2

3 0288661 Knob 2

4 0294558 Frame, Cart 1

5 0270318 Wheel

ITEM PART NO. DESCRIPTION QTY.

6 9890104 Cap, Axle 2

7 54458 Screw 2

8 13538 Bumper 2

0294534 Spacer, Wheel (NOT SHOWN) 4

21

Page 24

1

2

3

4

5

4

7

8

Figure 19- LowBoy Cart Assembly

6

LOWBOY CART ASSEMBLY - FIGURE 19

ITEM PART NO. DESCRIPTION QTY. ITEM PART NO. DESCRIPTION QTY.

1 0294445 Handle, Cart 1

2 9802518 Bolt, Carriage 2

3 0288661 Knob, Handle 2

4 0294534 Spacer, Wheel 4

5 0270318 Wheel 2

6 9890104 Cap, Hub 2

7 0294579 Cart 1

8 0270343 Foot, Rubber 2

22

Page 25

1

8

17

18

16

21

15

14

19

13

20

11

10

2

3

4

6

5

7

9

12

Figure 20 - Pressure Control Assembly

PRESSURE CONTROL ASSEMBLY - FIGURE 20

Item Part No. Description Qty.

1 0294837 Pressure Increase Label 1

2 0295426 Knob 1

3 02585 Toggle Boot 1

4 0089986 On/Off plate 1

5 0294349 Housing 1

6 0275703 Strain relief 1

9850630 Strain relief (CSA)

7 52671 Ring terminal 1

8 0294428 Cord set 1

02491 Cord Set (CSA) 1

9 9850629 Strain relief 1

10 02712 Spring 1

11 0294359 Plunger 1

Item Part No. Description Qty.

12 02208 Transducer assy. 1

(See Figure 23)

13 9822522 Retainer ring 1

14 03662 Switch spacer 1

15 0294132 Pressure Switch Assembly 1

16 9800604 Screw 2

17 9851311 Lead wire 1

18 53280 On/Off switch 1

19 53732 Fuse (10 amp) 1

20 18066 Relay (25 amp) 1

21 50520 Screw 3

23

Page 26

NOTE:

#20 Torque

250 IN. LBS.

*13

*4

20

16

#18

*#24

1

*2

*5

*6

7

8

*9

10

*14

*#19

*#22

23

25

# 26

*#27

#1 Torque

25 FT. LBS.

*3

*11

*12

15

*#17

21

NOTE:

NOTE:

#21 Torque

200 IN./LBS.

0294133 FLUID SECTION

ASSEMBLY FIGURE 21

ITEM PART NO DESCRIPTION QTY.

1 0294319 Packing nut 1

2 0294377 Adapter 1

3 08180 Packings, UHMWPE 3

4 00078 Packings, leather 2

5 0294376 Upper male adapter 1

6 0294379 Wave spring 1

7 00302 Locknut 1

8 0294318 Cylinder 1

9 13364 Wave spring 1

10 0294316 Piston rod 1

11 0294326 Lower male adapter 1

12 08070 Lower packings, UHMWPE 3

13 09091 Lower packings, leather 2

14 0294375 Lower female adapter 1

15 13458 Upper ball stop disc 1

16 13357 Upper ball cage 1

17 50164 Upper ball 1

18 13359 Upper ball seat 1

19 09446 Washer 1

20 13481 Piston seat retainer 1

21 13482 Jam nut 1

22 13381 O-ring 1

23 13380 Lower ball stop disc 1

24 51519 Lower ball 1

25 00311 Lower ball cage 1

26 00310 Lower ball seat 1

27 00203 O-ring 1

28 13403 Inlet valve holder 1

REPAIR KITS

KIT NO. DESCRIPTION

0294905 Packing Kit

(* Items Included)

0294689 Valve Kit

(# Items Included)

28

Figure 21 - Fluid Section

NOTE:

#28 Torque

40 FT. LBS.

24

Page 27

TRANSDUCER ASSEMBLY -

1

2

3

8

4

5

6

7

Figure 22 - Transducer Assembly

ITEM PART NO. DESCRIPTION QTY

1 50431 Retainer ring 1

2 50504 O-ring 1

3 02216 Transducer body 1

4 02232 Piston 1

5 50512 Back-up ring 1

6 50482 O-ring - Standard material 1

02305* O-Ring - Lacquer based

7 50423 Retainer ring 1

8 02283 Transducer Packing Kit

* Optional - for lacquer based material

NOTE: When paint begins to leak through the

weep hole on the transducer assembly, repack the

transducer assembly.

FIGURE 22

material 1

Includes Items 1, 2, and 4 through 7.

7

ASSEMBLY - FIGURE 23

ITEM PART NO. DESCRIPTION QTY

1 0090447 Elbow 1

0294185 SUCTION SET

2 13455 Fitting, Hose 1

3 53635 Clamp, Hose 1

4 0294426 Hose, Siphon 1

5 02975 Strainer 1

6 13463 Tube, Siphon 1

7 0294424 Hose, Return 1

6

5

43

Figure 23 - Suction Set Assembly

1

2

25

Page 28

EP2300 MOTOR ASSEMBLY - FIGURE 24

3

2

ITEM PART NO. DESCRIPTION QTY.

1

1 01678 Brush Holder 2

2 01694 Motor Brush 2

3 01686 Brush Cap 2

4 01783 Stud 2

5 19498 Stator Assy. 1

4

6 50148 #10 Lockwasher 4

7 50865 10-32 Nut 4

8 01791 Belleville Washer 4

9 50962 Bearing-Commutator End 2

10 *01961 Armature w/Bearings 1

5

6

6

7

8

7

8

9

10

* Includes #50962 Bearing

NOTE: Washers

must be stacked

as shown.

EP2300 Motor Assembly - Figure 24

9

6

7

26

Page 29

9

8

7

6

5

4

3

1

2

7

6

15

14

13

10

11

37

38

39

40

32

33

30

16

17

18

19

35

29

34

31

28

36

27

26

24

25

EP2300 Drive Assembly - Figure 25

23

22

21

20

EP2300 DRIVE ASSEMBLY - FIGURE 25

12

ITEM PART NO. DESCRIPTION QTY.

1 0294349 Housing 1

2 05304 Key 1

3 11177 Crankshaft 1

4 51837 Bearing 1

5 51845 Ring, Retainer 1

6 11843 Washer 2

7 53074 Screw 2

8 05282 Gear 1

9 50547 Bearing 1

10 0294154 Motor with Pinion 1

11 50318 Screw 13

50113 Washer 13

12 05208 Gear Set 1

13 05207 Pinion 1

14 50717 Spring Pin 1

15 19015 Gear Case 1

16 17183 Gasket 1

17 50989 Bearing 1

18 05223 High Speed Cluster 1

19 50997 Bearing 1

20 50008 Ball, Stainless 1

ITEM PART NO. DESCRIPTION QTY.

21 50962 Bearing 1

22 05274 Low Speed Cluster 1

23 50954 Bearing 1

24 53074 Screw 6

Washer, Lock 6

25 0294402 Plate, Adapter 1

26 0294365 Pin, Yoke 1

27 0294394 Gasket 1

28 0294301 Retainer. Spring 1

29 0294302 Pin, Connecting 1

30 51187 Ring, Retainer 2

31 0294606 Yoke 1

32 0294366 Bearing 1

33 0294367 Bearing 2

34 0294364 Bushing 1

35 50555 Bearing 1

36 0294604 Rod, Connecting 1

37 0294410 Bolt, Shoulder 1

38 0294368 Bearing 1

39 0294602 Drag Line 1

40 0294446 Washer 1

27

Page 30

1

2

3

4

1

∆

2

∆

Figure 26 - Dump Valve Assembly

5

6

7

8

9

0294220 DUMP VALVE ASSEMBLY - FIGURE 26

ITEM PART NO. DESCRIPTION QTY. ITEM PART NO. DESCRIPTION QTY.

1 0294194 Filter Body Assembly 1

2 14069 Filter Sieve (50 Mesh) 1

14068 Filter Sieve (100 Mesh)

(OPTIONAL)

3 9894245 Support, Filter 1

4 14072 O-Ring 1

5 0294555 Head, Filter/Dump Valve 1

6 0294499 Seal, Dump Valve 1

7 0294516 Seat, Valve 1

8 9841502 Ball, 10mm 1

9 0294214 Dump Valve Cartridge 1

NOTES:

1

Apply antisieze (P/N 0093930) to threads when reassembled.

∆

2

∆ Torque to 35 Ft./Lbs. CAUTION: Be sure the handle is turned all the way counterclockwise

when reassembled. Valve seat (item 6) will be

damaged if it is not.

28

Page 31

1

2

3

4

5

6

1

See Note Page 28

Figure 27 - Dump Valve Assembly

{

∆

2

∆

DUMP VALVE ASSEMBLY - FIGURE 27

Item Part No. Description Qty.

1 0294502 Housing, Dump Valve 1

2 0294966 Repair Kit 1

3 0294499 Seal, Dump Valve 1

Convex

Concave

Convex

8

Item Part No. Description Qty.

4 0294516 Seat, Valve 1 5 9841502 Ball, 10mm 1 6 0294214 Dump Valve Cartridge 1

1

2

3

4

5

6

7

Figure 28 - Dump Valve Cartridle

DUMP VALVE CARTRIDGE - FIGURE 28

Item Part No. Description Qty.

1 9871046 O-Ring 1

2 0294498 Body, Dump Valve 1

3 9871045 O-Ring 1

4 0294500 Stem, Dump Valve 1

Item Part No. Description Qty.

5 0294501 Washer, Dump Valve 1

6 9822516 Ring, Retainer 1

7 0294788 Washer, Kit, Bellville 4

8 0291512 Handle, Dump Valve 1

29

Page 32

ACCESSORIES

GUN FILTERS

Part

Number Description

0153—— Tungsten Carbide Flat Tips

0153003 Tip Guard, Flat Tip

0291004 Hose, Whip End, 3' x 3/16"

0291003 Hose, Whip End, 5’ x 3/16”

0291002 Hose, Wireless, 25’ x 1/4"

0291000 Hose, Wireless, 50’ x 1/4"

0093896 Hose Connector, 1/4” x 1/4”M

0088154 Pressure Gauge

0153043 Tip Extension, 6” (fits 11/16” diffuser)

0153042 Tip Extension, 12” (fits 11/16” diffuser)

0152001 Power Roller Gun Attachment

0152308 9" Roller Cover, 3/8” Nap

0152307 9" Roller Cover, 1/2” Nap

0152309 9" Roller Cover, 3/4” Nap

0152310 9" Roller Cover, 1-1/4” Nap

0152235 12" Roller Cover, 1/2" Nap

0152236 12" Roller Cover, 3/8" Nap

0152237 12" Roller Cover, 3/4" Nap

0152238 12" Roller Cover, 1-1/4" Nap

0152700 Adapter, Power Roller Extension

0149017 G-10 Four Finger Airless Spray Gun (no tip)

0093930 Anti-Seize Compound

0152909 R-10 Telescoping Roller, 9", 3/8" Nap

0152900 R-10 Telescoping 12" Roller, 3/8" Nap

0502007 G-10 Four Finger Airless Spray Gun with 517

Reversible Tip

0502008 G-10 Two Finger Airlesss Spray Gun (no tip)

0502009 G-10 Two Finger Airless Spray Gun with 517

Reversible TIp

0270214 G-10 Four Finger Spray Pack with 50’ x 1/4”

airless hose

0502012 G-10 Two Finger Spray Pack with 50” x 1/4”

Airless Hose

Part No.

0089960

0089959

0089958

0089957

Application

Synthetic resin

enamels, clean

varnishes, stains

azures

Base coat enamels

primer enamels

fillers, marking paints,

textujred enamesls

Emulsions

Latex-paints

acrylic-paints

Filler paints,

large area surface

s

Filter

Type

Extrafine

Fine

Medium

Coarse

Mesh

Number

0.084 mm

0.140 mm

0.315 mm

0.560 mm

Color of

Fiilter Body

Red

Yellow

Green

White

30

Page 33

Limited W arranty

Commercial Airless Spray Equipment

Two Year Warranty

Spray Tech, a division of Wagner Spray Tech Corporation ("Spray Tech"), warrants this product against defects in material and

workmanship for a period of two years following the date of purchase by the original purchaser. During that period, Spray Tech will repair

or replace any defective or worn-out component or, at Spray Tech’s option, refund to the original purchaser the full purchase price for

the product in exchange for the return of that product. However, Spray Tech will not replace or repair any fluid pump component on account

of wear more than twice during the two year warranty period. This warranty does not cover consumable products such as filters and tips.

Lifetime Warranty on Gear Trains, Electric Motors, and Gas Engines

Spray Tech warrants any gear train, electric motor (excluding brushes) and gas engine (excluding the clutch) in this product against

defects in material and workmanship for the lifetime of the original purchaser. If Spray Tech determines that the foregoing warranty has

been breached, Spray Tech will repair or replace the defective components without charge or, at Spray Tech’s option, refund to the original

purchaser the full purchase price for the product in exchange for the return of that product.

Warranty Claims

Any request for repair or replacement pursuant to the warranties above must be accompanied by the return of the applicable parts, with

transportation charges prepaid, to a service center authorized by Spray Tech or to Wagner Spray Tech Corporation, 1770 Fernbrook Lane,

Minneapolis, MN 55447.

Limitation of Remedies

THE REMEDIES SET FORTH ABOVE ARE THE EXCLUSIVE REMEDIES AVAILABLE FOR BREACH OF EXPRESS AND IMPLIED

WARRANTIES. These remedies shall not be deemed to have failed of their essential purpose so long as Spray Tech is willing to repair

or replace parts, or to refund the purchase price, as set forth above.

What Is Not Covered By This Warranty

This warranty does not cover defects or damages caused by:

• the use or installation of repair or replacement parts or accessories not manufactured by Spray Tech;

• repair performed by anyone other than a Spray Tech Authorized Service Center; or

• abuse, misuse, negligence, accident, faulty installation or tampering in a manner which impairs normal operation.

This warranty also does not cover equipment and accessories supplied to Spray Tech from an original equipment manufacturer, including

but not limited to hoses, tips, and accessories. Spray Tech will provide the purchaser with copies of the original equipment manufacturer’s

express warranties provided to Spray Tech along with the name and address of the appropriate manufacturer.

Limitation of Remedies

IN NO CASE SHALL SPRAY TECH BE LIABLE FOR ANY INCIDENTAL, SPECIAL OR CONSEQUENTIAL DAMAGES OR LOSS,

INCLUDING TRANSPORTATION COSTS, WHETHER SUCH DAMAGES ARE BASED UPON A BREACH OF EXPRESS OR IMPLIED

WARRANTIES, BREACH OF CONTRACT, NEGLIGENCE, STRICT TORT, OR ANY OTHER LEGAL THEORY.

Disclaimer Of Implied Warranties

THE FOREGOING WARRANTIES ARE IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT

LIMITED TO THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

No Ability To Transfer

This warranty is extended to the original purchaser only and is not transferable.

Patents

These products are covered by one or more of the following patents:

5,228,842 5,192,425 D344,832 5,318,314 5,282,722 5,099,183

5,346,037 5,494,199 5,472,318 5,435,697 4,992,633

1770 Fernbrook Lane

Minneapolis, Minnesota 55447

Telephone 1-800-292-4637

Printed in U.S.A.

32

Loading...

Loading...