SprayTECH CAPspray AirCoat 0508074 Owner's Manual

EnglishFrançaisEspañol

AirCoat Spray System

Owner’s Manual • Manuel de l'utilisateur • Manual del propietario

1203 © 2003 SprayTECH. All rights reserved. Form No. 0551366A

CAPSpray

1770 Fernbrook Lane

Minneapolis, MN 55447

Technical Assistance: 1-800-292-4637

Order Entry: 1-800-443-4500

Fax: 1-800-525-9501

www.spraytechinc.com

Model Number 0508074

English

2©SprayTECH. All rights reserved.

Table of Contents

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Grounding Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Priming the Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Painting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Pressure Relief Procedure. . . . . . . . . . . . . . . . . . . . . . . . . 6

Spraying Technique . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Cleanup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Overnight Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Long Term Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Removing and Cleaning the Inlet Valve . . . . . . . . . . . . . . . 8

Removing and Cleaning the Outlet Valve. . . . . . . . . . . . . . 8

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Parts List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Safety Precautions

This manual contains information that must be read and

understood before using the equipment. When you come to an

area that has one of the following symbols, pay particular

attention and make certain to heed the safeguard.

This symbol indicates a potential hazard that may cause

serious injury or loss of life. Important safety information will

follow.

This symbol indicates a potential hazard to you or to the

equipment. Important information that tells how to prevent

damage to the equipment or how to avoid causes of minor

injuries will follow.

The diaphragm pump is provided with a thermally

protected automatic reset. If an overload occurs the

thermally protected automatic reset disconnects the motor

from the power supply.

• The motor will restart without warning when the protector

automatically resets.

• Always disconnect the motor from the power supply

before working on the equipment.

• When the thermally protected automatic reset disconnects

the motor from the power supply, relieve pressure by

turning the PRIME/SPRAY valve to PRIME.

•Turn the pump ON/OFF switch to OFF.

NOTE: The cause of the overload should be corrected

before restarting. Refer to the Troubleshooting

section.

CAUTION

NOTE: Notes give important information which should

be given special attention.

CAUTION

WARNING

HAZARD: Injection injury - A high pressure fluid stream

produced by this equipment can pierce the skin

and underlying tissues, leading to serious

injury and possible amputation. See a

physician immediately.

DO NOT TREAT AN INJECTION INJURY AS A SIMPLE CUT!

Injection can lead to amputation. See a physician

immediately.

The maximum operating range of the unit is 2800 PSI / 19

MPa fluid pressure.

PREVENTION:

• NEVER aim the gun at any part of the body.

• NEVER allow any part of the body to touch the fluid stream.

DO NOT allow body to touch a leak in the fluid hose.

• NEVER put hand in front of the gun. Gloves will not

provide protection against an injection injury.

•ALWAYS lock gun trigger, shut pump off, and release all

pressure before servicing, cleaning tip or guard, changing

tip, or leaving unattended. Pressure will not be released

by turning off the motor. The PRIME/SPRAY valve handle

must be turned to PRIME to relieve the pressure. Refer to

the PRESSURE RELIEF PRESSURE described in the

pump manual.

•ALWAYS keep tip guard in place while spraying. The tip

guard provides some protection but is mainly a warning

device.

•ALWAYS remove the spray tip before flushing or cleaning

the system.

• Paint hose can develop leaks from wear, kinking and

abuse. A leak can inject material into the skin. Inspect

the hose before each use.

• NEVER use a spray gun without a working trigger lock

and trigger guard in place.

• All accessories must be rated at or above 2800 PSI / 19

MPa. This includes spray tips, guns, extensions, and hose.

HAZARD: EXPLOSION AND FIRE - Solvent and paint

fumes can explode or ignite. Severe injury

and/or property damage can occur.

PREVENTION:

• Provide extensive exhaust and fresh air introduction to

keep the air within the spray area free from accumulation

of flammable vapors.

•Avoid all ignition sources such as static electricity sparks,

electrical appliances, flames, pilot lights, hot objects, and

sparks from connecting and disconnecting power cords or

working light switches.

•Do not smoke in spray area.

• Fire extinguisher must be present and in good working

order.

• Place pump at least 20 feet (6.1 m) from the spray object

in a well ventilated area (add more hose if necessary).

Flammable vapors are often heavier than air. Floor area

must be extremely well ventilated. The pump contains

arcing parts that emit sparks and can ignite vapors.

• The equipment and objects in and around the spray area

must be properly grounded to prevent static sparks.

• Use only conductive or grounded high-pressure fluid hose.

Gun must be grounded through hose connections.

• Power cord must be connected to a grounded circuit.

NOTE TO PHYSICIAN:

Injection into the skin is a traumatic injury. It is

important to treat the injury as soon as possible. DO

NOT delay treatment to research toxicity. Toxicity is a

concern with some coatings injected directly into the

blood stream. Consultation with a plastic surgeon or

reconstructive hand surgeon may be advisable.

WARNING

• Always flush unit into separate metal container, at low

pump pressure, with spray tip removed. Hold gun firmly

against side of container to ground container and prevent

static sparks.

• Follow material and solvent manufacturer's warnings and

instructions.

• Use extreme caution when using materials with a

flashpoint below 70° F (21° C). Flashpoint is the

temperature at which a fluid can produce enough vapors

to ignite.

• Plastic can cause static sparks. Never hang plastic to

enclose spray area. Do not use plastic drop cloths when

spraying flammable materials.

• Use lowest possible pressure to flush equipment.

GAS ENGINE (WHERE APPLICABLE)

Always place unit outside of structure in fresh air. Keep all

solvents away from engine exhaust. Never fill fuel tank with a

running or hot engine. Hot surface can ignite spilled fuel.

Always attach ground wire from pump to a grounded object.

Refer to engine owner’s manual for complete safety

information.

HAZARD: EXPLOSION HAZARD DUE TO INCOMPATIBLE

MATERIALS - will cause severe injury or

property damage.

PREVENTION:

• Do not use materials containing bleach or chlorine.

• Do not use halogenated hydrocarbon solvents such as

bleach, mildewcide, methylene chloride and 1,1,1 trichloroethane. They are not compatible with aluminum.

• Contact your coating supplier about the compatibility of

material with aluminum.

HAZARD: HAZARDOUS VAPORS - Paints, solvents,

insecticides, and other materials can be

harmful if inhaled or come in contact with body.

Vapors can cause severe nausea, fainting, or

poisoning.

PREVENTION:

• Use a respirator or mask if vapors can be inhaled. Read

all instructions supplied with the mask to be sure it will

provide the necessary protection.

•Wear protective eyewear.

•Wear protective clothing as required by coating

manufacturer.

HAZARD: GENERAL - Can cause severe injury or

property damage.

PREVENTION:

• Read all instructions and safety precautions before

operating equipment.

• Follow all appropriate local, state, and national codes

governing ventilation, fire prevention, and operation.

• The United States Government Safety Standards have

been adopted under the Occupational Safety and Health

Act (OSHA). These standards, particularly part 1910 of

the General Standards and part 1926 of the Construction

Standards, should be consulted.

• Use only manufacturer authorized parts. User assumes

all risks and liabilities when using parts that do not meet

the minimum specifications and safety devices of the

pump manufacturer.

• Before each use, check all hoses for cuts, leaks, abrasion

or bulging of cover. Check for damage or movement of

couplings. Immediately replace hose if any of those

conditions exist. Never repair a paint hose. Replace with

a grounded high-pressure hose.

• All hoses, swivels, guns, and accessories must be

pressure rated at or above 2800 PSI / 19 MPa.

• Do not spray outdoors on windy days.

•Wear clothing to keep paint off skin and hair.

• Always unplug cord from outlet before working on

equipment.

Grounding Instructions

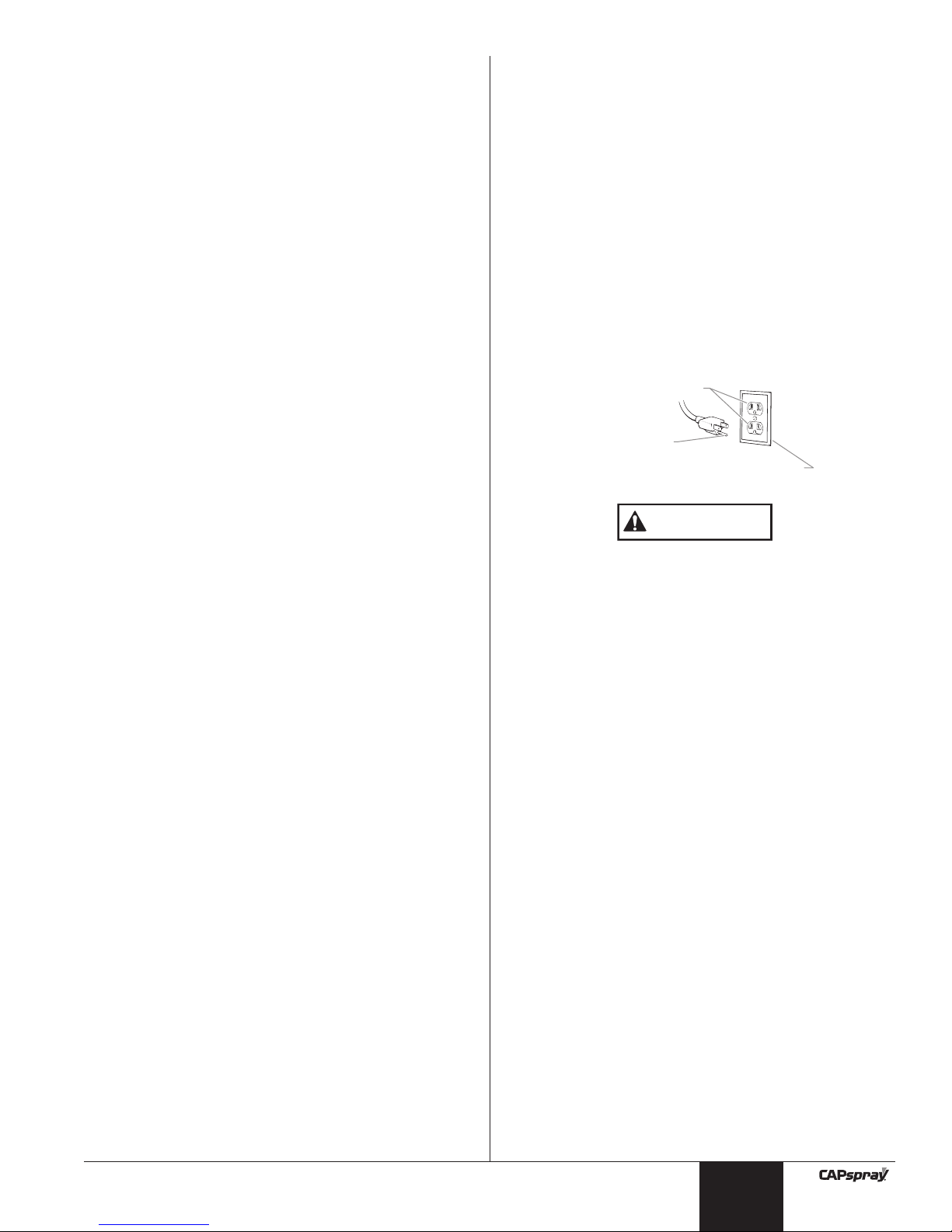

This product must be grounded. In the event of an electrical

short circuit, grounding reduces the risk of electric shock by

providing an escape wire for the electric current. This product

is equipped with a cord having a grounding wire with an

appropriate grounding plug. The plug must be plugged into an

outlet that is properly installed and grounded in accordance

with all local codes and ordinances.

DANGER — Improper installation of the grounding plug can

result in a risk of electric shock. If repair or replacement of the

cord or plug is necessary, do not connect the green grounding

wire to either flat blade terminal. The wire with insulation

having a green outer surface with or without yellow stripes is

the grounding wire and must be connected to the grounding

pin.

Check with a qualified electrician or serviceman if the

grounding instructions are not completely understood, or if you

are in doubt as to whether the product is properly grounded.

Do not modify the plug provided. If the plug will not fit the

outlet, have the proper outlet installed by a qualified

electrician.

Use only a 3-wire extension cord that has a 3-blade

grounding plug and a 3-slot receptacle that will accept the

plug on the product. Make sure your extension cord is in

good condition. When using an extension cord, be sure

to use one heavy enough to carry the current your

product will draw. An undersized cord will cause a drop

in line voltage resulting in loss of power and overheating.

A 12 gauge cord is recommended. If an extension cord is

to be used outdoors, it must be marked with the suffix WA after the cord type designation. For example, a

designation of SJTW-A would indicate that the cord would

be appropriate for outdoor use.

CAUTION

© SprayTECH. All rights reserved. 3

English

Grounded Outlet

Grounding Pin

Cover for grounded outlet box

General Description

This fine finish spray system is versatile enough to use for low

pressure fine finish work as well as high pressure airless

spraying. The system includes a diaphragm paint pump and

an air compressor that work together to provide this versatility.

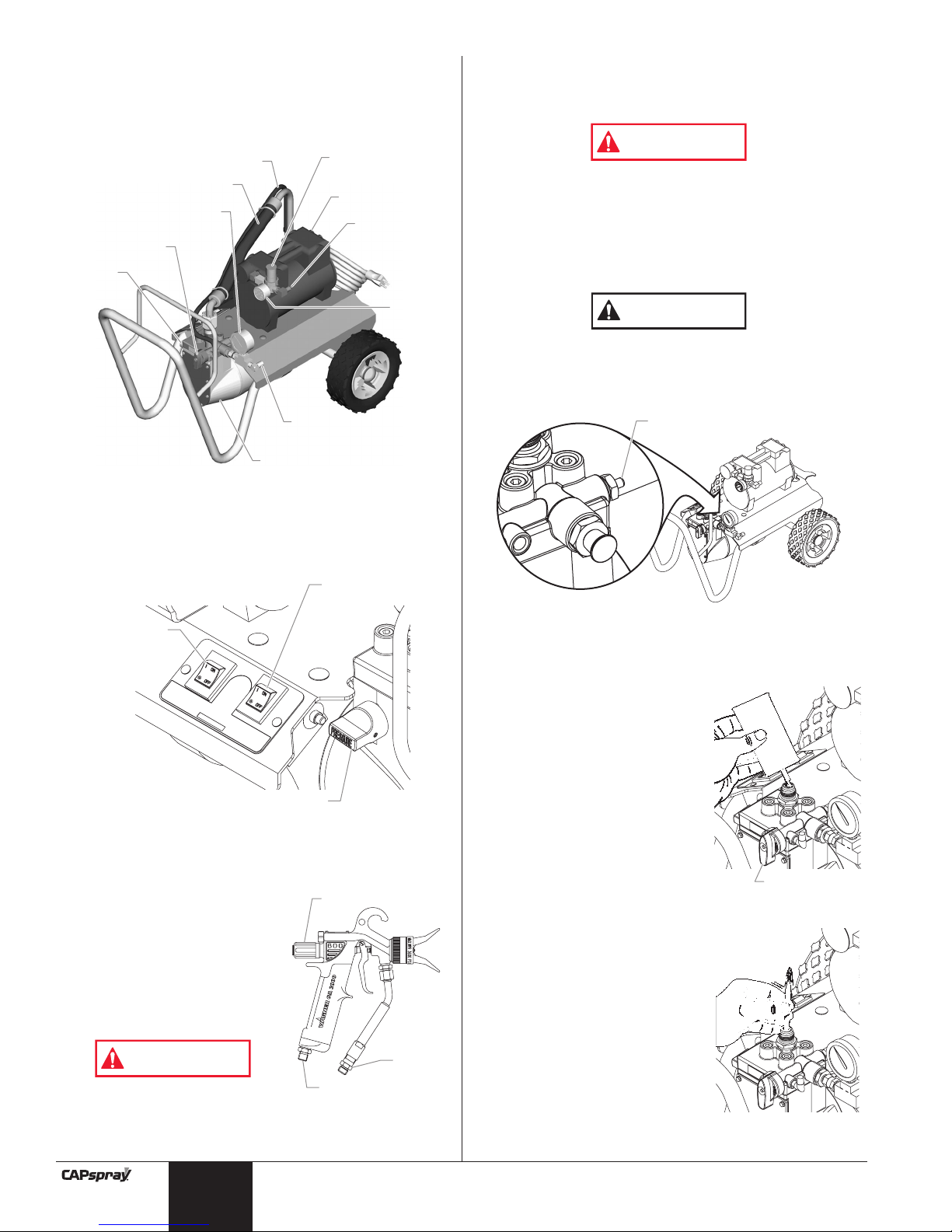

Setup

Use this procedure to set up the spray system.

1. Make sure the pump ON/OFF switch and the compressor

ON/OFF switch are in the OFF position.

2. Make sure the pressure control knob is turned fully

counterclockwise to its lowest pressure setting.

3. Lock the gun by turning the gun lock nut clockwise (when

looking from the back of the gun) until it stops. This

closes the material valve in the gun.

4. Using a wrench, attach a

minimum of 50’ of 1/4” nylon

airless spray hose to the

material outlet fitting on the

pump. Tighten securely.

5. Attach the spray hose to the

material inlet fitting on the spray

gun. Using two wrenches (one

on the gun and one on the

hose), tighten securely.

Make sure all airless hoses and

spray guns are electrically

grounded and rated for at least

2800 PSI (19 MPa) fluid pressure.

WARNING

4©SprayTECH. All rights reserved.

6. Attach the air hose to the air outlet fitting on the

compressor. Tighten securely.

7. Attach the air hose to the air inlet fitting on the spray gun.

Tighten securely.

Reversing the hose connections could result in serious

injury. Make sure the airless spray hose is connected

from the diaphragm pump to the material inlet fitting on

the gun and the air hose is connected from the

compressor to the air inlet fitting on the gun.

8. Make sure the electrical service is 120V, 15 amp minimum.

9. Plug the power cord into a properly grounded outlet at

least 25’ from the spray area.

Always use a minimum 12 gauge, three-wire extension

cord with a grounded plug. Never remove the third prong

or use an adapter.

10. Firmly press the pusher valve button on the side of the pump

housing to make sure the outlet ball valve moves freely.

Operation

Use the following procedures to operate the spray system.

Priming the Pump

Preparing to Prime

1. Fill the inlet valve with water or

with a light household oil.

2. Make sure that the

PRIME/SPRAY valve is set to

PRIME and that the pressure

control knob is turned

counterclockwise to its lowest

pressure setting.

3. Turn on the pump by moving the

pump ON/OFF switch to the ON

position.

4. Increase the pressure by turning

the pressure control knob

clockwise 1/2 turn.

5. Force the inlet valve to open and

close by pushing on it with a

screwdriver or the eraser end of

a pencil. It should move up and

down about 1/16 of an inch.

Continue until water or oil is

sucked into the pump. This will

wet the moving parts and break

loose any old paint residue.

6. Put the palm of your hand over

the inlet. Turn the pressure

control knob clockwise to its

maximum setting. You should

feel suction coming from the inlet

valve. If you do not, refer to the “Removing and Cleaning

the Outlet Valve” procedure in the Maintenance section.

PRIME/SPRAY

Val ve

CAUTION

WARNING

English

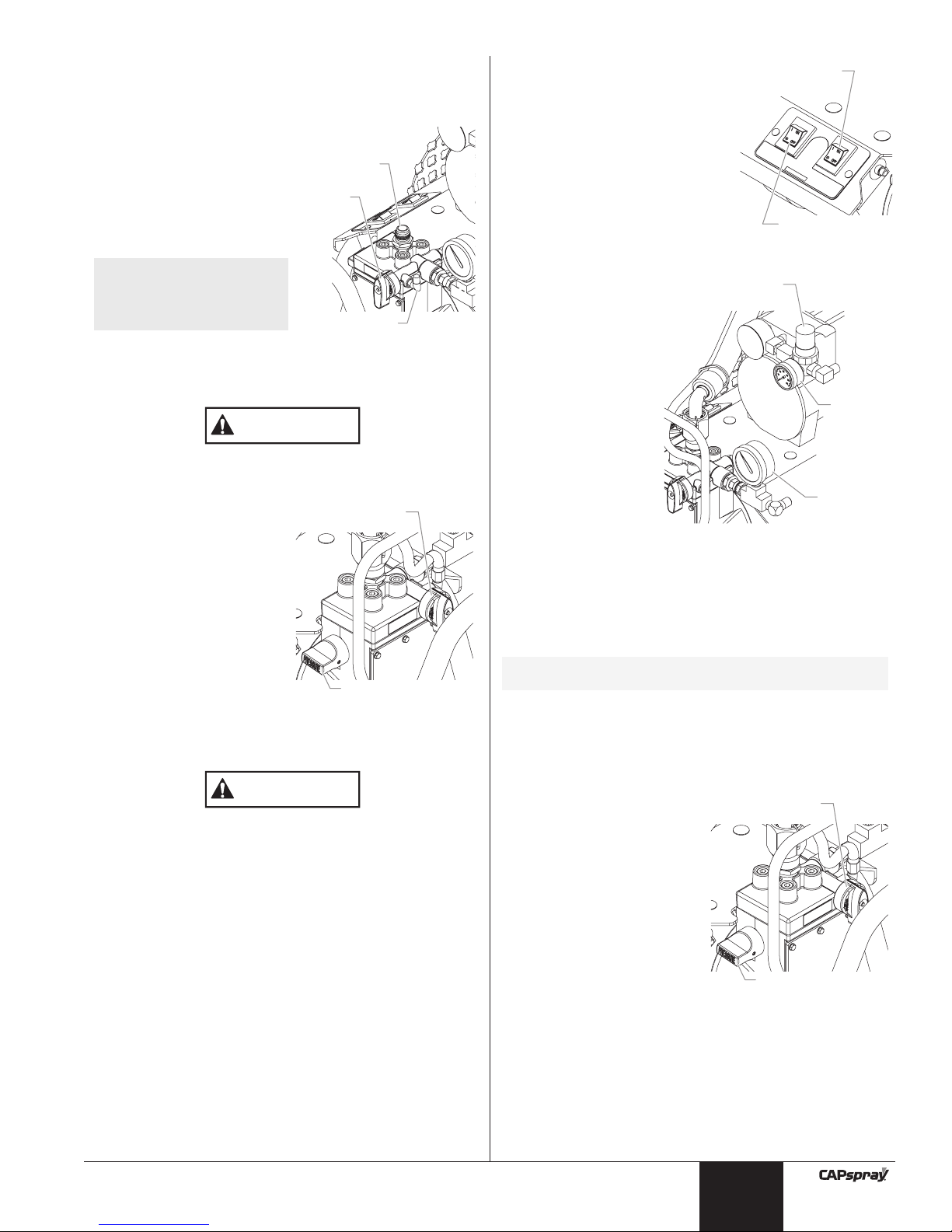

Air Pressure

Regulator

Air Compressor

Air

Outlet

Fitting

Air

Pressure

Gauge

Material

Outlet Fitting

Material Pressure

PRIME/SPRAY

Pressure

Control

Knob

Val ve

Return Hose

Suction Hose

Gauge

Diaphragm Pump

Pump ON/OFF

Switch

Pusher Valve Button

Compressor

ON/OFF

Switch

Pressure Control Knob

Gun Lock Nut

Air Inlet

Fitting

Material

Inlet

Fitting

7. Turn the pressure control knob counterclockwise to the

minimum pressure setting.

8. Turn the pump ON/OFF switch to OFF.

Priming

1. Attach the suction set to the

pump.

a. Thread the suction hose

nut onto the inlet valve on

the pump.

b. Thread the return hose

onto the return hose fitting

on the pump.

2. Place the suction set into a

container of paint.

3. Turn the pressure control knob counterclockwise to the

minimum pressure setting.

Always reduce the pressure to zero before changing the

position of the PRIME/SPRAY valve. Failure to do so may

cause damage to the paint pump diaphragm.

4. Turn the PRIME/SPRAY

valve to PRIME.

5. Move the pump ON/OFF

switch to the ON position.

6. Turn the pressure control

knob clockwise to between

half and full pressure. Let

the unit prime 1 to 2

minutes after paint begins

to flow through the return

hose until no bubbles are

present.

7. Turn the pressure control

knob counterclockwise to

the minimum pressure

setting.

8. Move the pump ON/OFF switch to the OFF position.

If the pressure control knob is reduced to zero and the

PRIME/SPRAY valve is still on SPRAY while the pump is

operating, there will be high pressure in the hose and

spray gun until the PRIME/SPRAY valve is turned to

PRIME or until the spray gun is triggered to relieve the

pressure.

Painting

The AirCoat spray system has two different painting modes.

The AirCoat mode is used for fine finish work with low to

medium viscosity materials (oil, stains, lacquers, etc...). The

airless mode is used for general painting with high viscosity

materials (latex).

Painting in AirCoat Mode

Use the AirCoat mode for low-pressure fine finish work (pump

pressure up to 1000 PSI).

1. Make sure that the airless spray hose is free of kinks and

clear of objects with sharp cutting edges.

2. Turn the pressure control knob counterclockwise to its

lowest setting.

3. Turn the compressor air pressure regulator

counterclockwise to its lowest setting.

CAUTION

CAUTION

NOTE: The pump can be

used with the

optional hopper

accessory instead

of the suction set.

Inlet

Val ve

PRIME/

SPRAY

Val ve

Return

Hose Fitting

4. Move the compressor ON/OFF

switch to the ON position.

5. Move the pump ON/OFF switch

to the ON position.

6. Turn the PRIME/SPRAY valve to

SPRAY.

7. Turn the pressure control knob

clockwise until the material

pressure gauge reads 400 PSI.

The paint hose should stiffen as

paint begins to flow through it.

8. Turn the air pressure regulator

clockwise until the air pressure

gauge reads 20 PSI.

9. Unlock the gun by

turning the gun lock

nut counterclockwise (when

looking from the

back of the gun)

three full turns. This

opens the material

valve in the gun.

10. Trigger the spray gun

to bleed air out of the

material hose.

11. When material

reaches the spray

tip, spray a test area

to check the spray

pattern.

12. Adjust the spray

pattern to the desired size and atomization.

a. Use the pressure control knob to control the flow of

paint to the gun.

b. Use the air pressure regulator to control the amount of

atomization air available to the gun.

c. Use the pattern adjustment knob on the gun to fine

tune the spray pattern.

Painting in Airless Mode

Use the airless mode for general high-pressure spraying

(pump pressure from 500 to 2000 PSI).

1. Make sure that the airless spray hose is free of kinks and

clear of objects with sharp cutting edges.

2. Turn the pressure control

knob counterclockwise to its

lowest setting.

3. Turn the PRIME/SPRAY

valve to SPRAY.

4. Move the pump ON/OFF

switch to the ON position.

5. Turn the pressure control

knob clockwise to its

highest setting. The paint

hose should stiffen as paint

begins to flow through it.

6. Unlock the gun by turning

the gun lock nut counterclockwise (when looking from the back of the gun) three

full turns. This opens the material valve in the gun.

7. Trigger the spray gun to bleed air out of the material hose.

8. When material reaches the spray tip, spray a test area to

check the spray pattern.

PRIME/SPRAY

Val ve

Pressure

Control Knob

NOTE: Refer to the spray gun Owner’s Manual for

information on the operation of the gun.

Air

Pressure

Gauge

Material

Pressure

Gauge

Compressor

ON/OFF Switch

Pump ON/OFF

Switch

© SprayTECH. All rights reserved. 5

English

PRIME/SPRAY

Val ve

Pressure

Control Knob

Air Pressure

Regulator

Air

Air

Pressure

Pressure

Gauge

Gauge

Material

Material

Pressure

Pressure

Gauge

Gauge

9. Use the lowest pressure setting necessary to get a good

spray pattern. If the pressure is set too high, the spray

pattern will be too light. If the pressure is set too low,

tailing will appear or the paint will spatter out in “gobs”

rather than in a fine spray.

Pressure Relief Procedure

Follow this procedure after the unit is assembled and before

any operation that involves the spray gun such as cleaning

and maintenance or changing tips or accessories.

1. Turn the pressure control

knob counterclockwise to its

lowest setting.

2. Turn the PRIME/SPRAY

valve to the PRIME

position.

3. Trigger the gun to remove

any pressure that still may

be in the hose.

4. Lock the gun by turning the

gun lock nut clockwise

(when looking from the back

of the gun) until it stops.

This closes the material

valve in the gun.

Injection hazard. Do not spray without the tip guard in

place. NEVER trigger the gun unless the tip is completely

turned to either the spray or the unclog position. ALWAYS

engage the gun trigger lock before removing, replacing or

cleaning tip.

WARNING

PRIME/SPRAY

Val ve

Pressure

Control Knob

Good spray pattern

Paint tailing pattern

6©SprayTECH. All rights reserved.

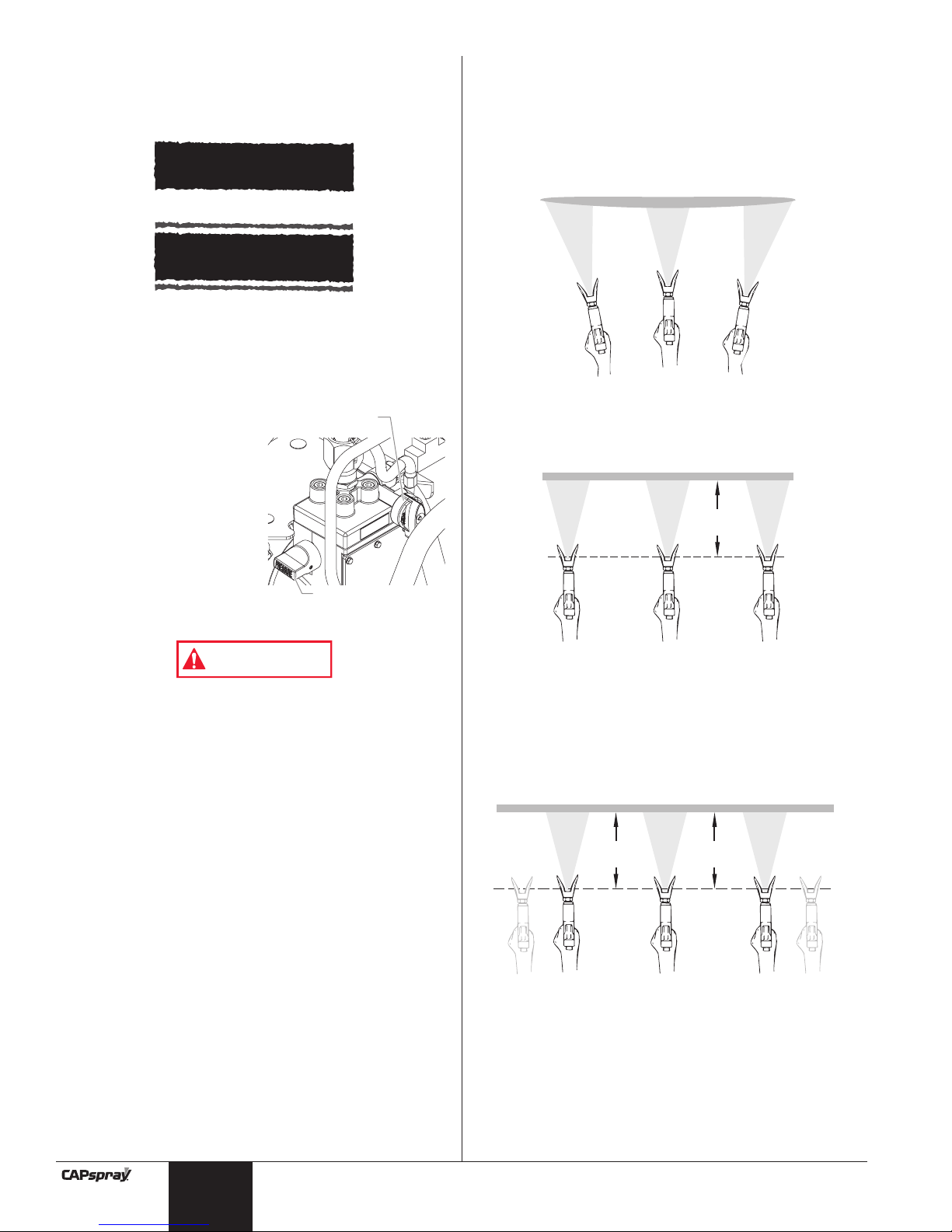

Spraying Technique

The key to a good paint job is an even coating over the entire

surface. This is done by using even strokes. Keep your arm

moving at a constant speed and keep the spray gun at a

constant distance from the surface. The best spraying

distance is 10 to 12 inches between the spray tip and the

surface.

Keep the spray gun at right angles to the surface. This means

moving your entire arm back and forth rather than just flexing

your wrist.

Keep the spray gun perpendicular to the surface, otherwise

one end of the pattern will be thicker than the other.

The spray gun should be triggered by turning it on and off with

each stroke. This will save paint and avoid paint buildup at the

end of the stroke. Do not trigger the gun during the middle of

a stroke. This will result in an uneven spray and splotchy

coverage.

Overlap each stroke by about 30%. This will ensure an even

coating.

When you stop painting, lock the gun trigger lock, turn the

pressure control knob counterclockwise to its lowest setting

and set the priming knob to PRIME. Turn the motor switch to

OFF and unplug the sprayer.

If you expect to be gone more than 1 hour, follow the short

term clean up procedure described in the Cleanup section of

this manual.

Keep stroke smooth and at an even speed.

Even coat throughout

Approximately

10 to 12 inches

Heavy Coat

Do not flex wrist while spraying.

Light Coat Light Coat

English

Proper way to trigger the spray gun

Keep stroke

even

Start stroke End strokePull trigger Release triggerKeep steady

Aproximately

10 to 12 inches

Cleanup

Overnight Storage

Shutdown

1. Turn the pressure control

knob counterclockwise to

the minimum setting.

2. Turn the PRIME/SPRAY

valve to PRIME.

3. Move the pump ON/OFF

switch to the OFF position.

4. Move the compressor

ON/OFF switch to the OFF

position.

5. Wait a couple seconds, then

trigger the gun into the

material container to

release built up fluid

pressure from the pump and air pressure from the

compressor.

6. Lock the gun by turning the gun lock nut clockwise (when

looking from the back of the gun) until it stops. This

closes the material valve in the gun.

7. Unplug the unit.

8. For latex materials only, pour 1/2 cup water slowly on the

top of the paint to prevent the paint from drying. For other

materials, seal the material container keeping the return

hose in the paint.

9. Wrap the spray gun assembly in a damp cloth and place it

in a plastic bag. Seal the bag shut.

10. Place the unit in a safe place out of the sun for short-term

storage.

Startup

1. Remove the gun from the plastic bag.

2. Stir the water into the paint for latex materials. Remove

the cover from the material container and stir the paint for

all other materials.

3. Perform the appropriate procedure in the “Painting”

section of this manual for the type of spraying that will be

performed.

Long-Term Storage

Do not allow paint to build up on the motor or the motor

will overheat. Do not allow flammable solvents to come in

contact with the motor or they could ignite.

Do not use mineral spirits or paint thinner on latex paint,

or the mixture will turn into a jelly-like substance which is

difficult to remove.

CAUTION

NOTE: If spraying with latex paint, use warm soapy

water for cleaning. If using oil or alkyd-based

paints, use mineral spirits or paint thinner.

WARNING

PRIME/SPRAY

Val ve

Pressure

Control Knob

Clearing the Suction Tube

1. Turn the pressure control knob

counterclockwise to the minimum

setting.

2. Turn the PRIME/SPRAY valve to

PRIME.

3. Move the pump ON/OFF switch

to the OFF position.

4. Move the compressor ON/OFF

switch to the OFF position.

5. Wait a couple seconds, then

trigger the gun into the material

container to release built up fluid

pressure from the pump and air

pressure from the compressor.

6. Lock the gun by turning the gun lock nut clockwise (when

looking from the back of the gun) until it stops. This

closes the material valve in the gun.

7. Remove the suction hose from the material and hold it

above a bucket of water or solvent. Leave the return hose

in the material bucket.

Do not use mineral spirits or paint thinner on latex paint,

the mixture will turn into a jelly-like substance that is

difficult to remove.

8. Move the pump ON/OFF switch to the ON position.

9. Turn the pressure control knob to 1/2 maximum pressure.

This will draw the remaining material in the suction hose

through the pump, down the return hose and into the

material bucket.

10. Turn the pressure control knob counterclockwise to the

minimum setting.

11. Remove the spray tip and guard and place them into a

container of the appropriate solvent.

12. Place the attached suction hose and return hose into the

container of water or appropriate solvent.

13. Increase the pressure to 1/2 the maximum pressure. Let

the water or solvent circulate for 2-3 minutes to flush paint

out of the pump, the suction hose and the return hose.

Clearing the Paint Hose

1. Turn the pressure control knob counterclockwise to the

minimum pressure setting.

2. Turn the PRIME/SPRAY

valve to SPRAY.

3. Unlock the gun by turning

the gun lock nut counterclockwise (when looking

from the back of the gun)

three full turns. This opens

the material valve in the gun.

4. Carefully trigger the gun

with the spray tip removed

against the inside of the

material container.

5. Turn the pressure control

knob slowly clockwise until

material starts to flow into the container. As soon as the

water or solvent starts to come into the container, release

the trigger.

6. Change to clean water or solvent and continue circulating

for another 5 minutes to thoroughly clean the hose, pump

and spray gun.

7. Turn the pressure control knob counterclockwise to its

lowest setting.

8. Turn the PRIME/SPRAY valve to PRIME.

9. Trigger the gun into the water or solvent container to

release built up fluid pressure from the pump.

PRIME/SPRAY

Val ve

Pressure

Control Knob

CAUTION

Compressor

ON/OFF Switch

Pump ON/OFF

Switch

© SprayTECH. All rights reserved. 7

English

10. Lock the gun by turning the gun lock nut clockwise (when

looking from the back of the gun) until it stops. This

closes the material valve in the gun.

11. Move the pump ON/OFF switch to the OFF position.

Final Cleanup

1. Remove the suction set from the inlet valve.

2. Clean the threads of the inlet valve with a damp cloth.

3. Fill the inlet valve with water or

with a light household oil.

4. Make sure that the

PRIME/SPRAY valve is set to

PRIME and that the pressure

control knob is turned

counterclockwise to its lowest

pressure setting.

5. Turn on the pump by moving the

pump ON/OFF switch to the ON

position.

6. Increase the pressure by turning

the pressure control knob

clockwise 1/2 turn.

7. Turn the PRIME/SPRAY valve to

SPRAY to distribute the oil.

8. Turn the pressure control knob counterclockwise to its

lowest setting.

9. Turn the PRIME/SPRAY valve to PRIME.

10. Unlock and trigger the gun to remove any pressure that

may still be in the hose.

11. Lock the gun by turning the gun lock nut clockwise (when

looking from the back of the gun) until it stops. This

closes the material valve in the gun.

12. Turn off the pump by moving the pump ON/OFF switch to

the OFF position

13. Remove the material hose and air hose from the spray

gun using two adjustable wrenches. Refer to the spray

gun Owner’s Manual for gun cleaning instructions.

14. Wipe the entire unit, hose, and gun with a damp cloth to

remove accumulated paint.

Maintenance

Follow these procedures when encountering problems

indicated in the troubleshooting section.

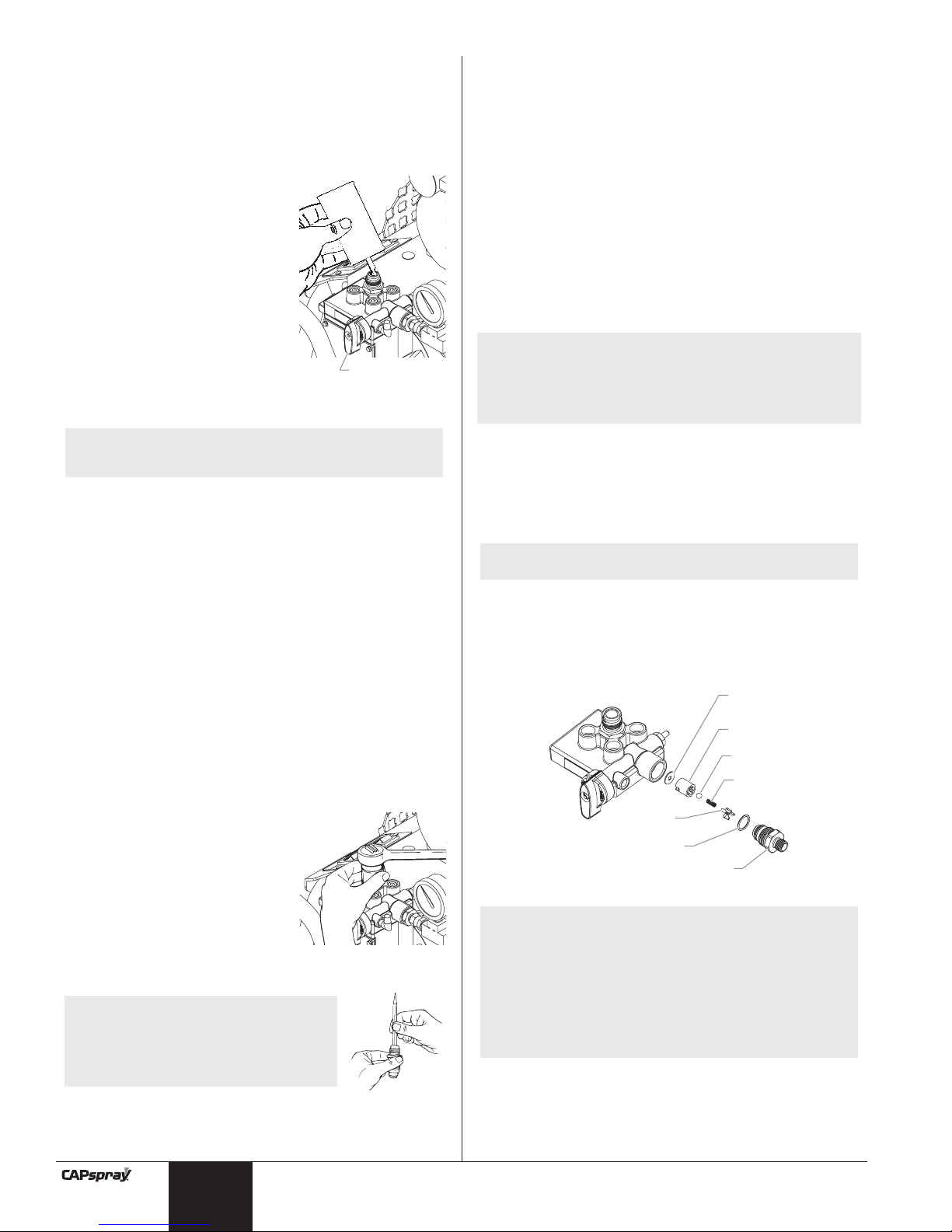

Removing and Cleaning the Inlet Valve

1. Perform the Pressure Relief

Procedure, turn off and unplug

the unit.

2. Remove the inlet valve assembly

using a 27 millimeter socket or

box end wrench.

3. Test movement of the valve by

pushing on it from the open end

of the valve housing with a

screwdriver or the eraser end of

a pencil. It should move about 1/16 of an inch. If it does

not move, it should be cleaned or replaced.

NOTE: The inlet valve must be oiled

after every job. This will

reduce or eliminate priming

problems the next time the

unit is used as well as extend

the life of the valve.

NOTE: Proper cleaning and oiling of the pump after

use are the most important steps to perform

to insure proper operation after storage.

PRIME/SPRAY

Val ve

8©SprayTECH. All rights reserved.

4. Thoroughly clean the valve assembly with water or the

appropriate solvent. Use a small brush.

5. If the valve has been properly cleaned and water drips out

of the bottom, the valve is worn and needs to be replaced.

A properly seated valve filled with water and held vertically

will not drip.

6. Install a new or cleaned valve in the pump block and then

fill the valve with light oil or solvent.

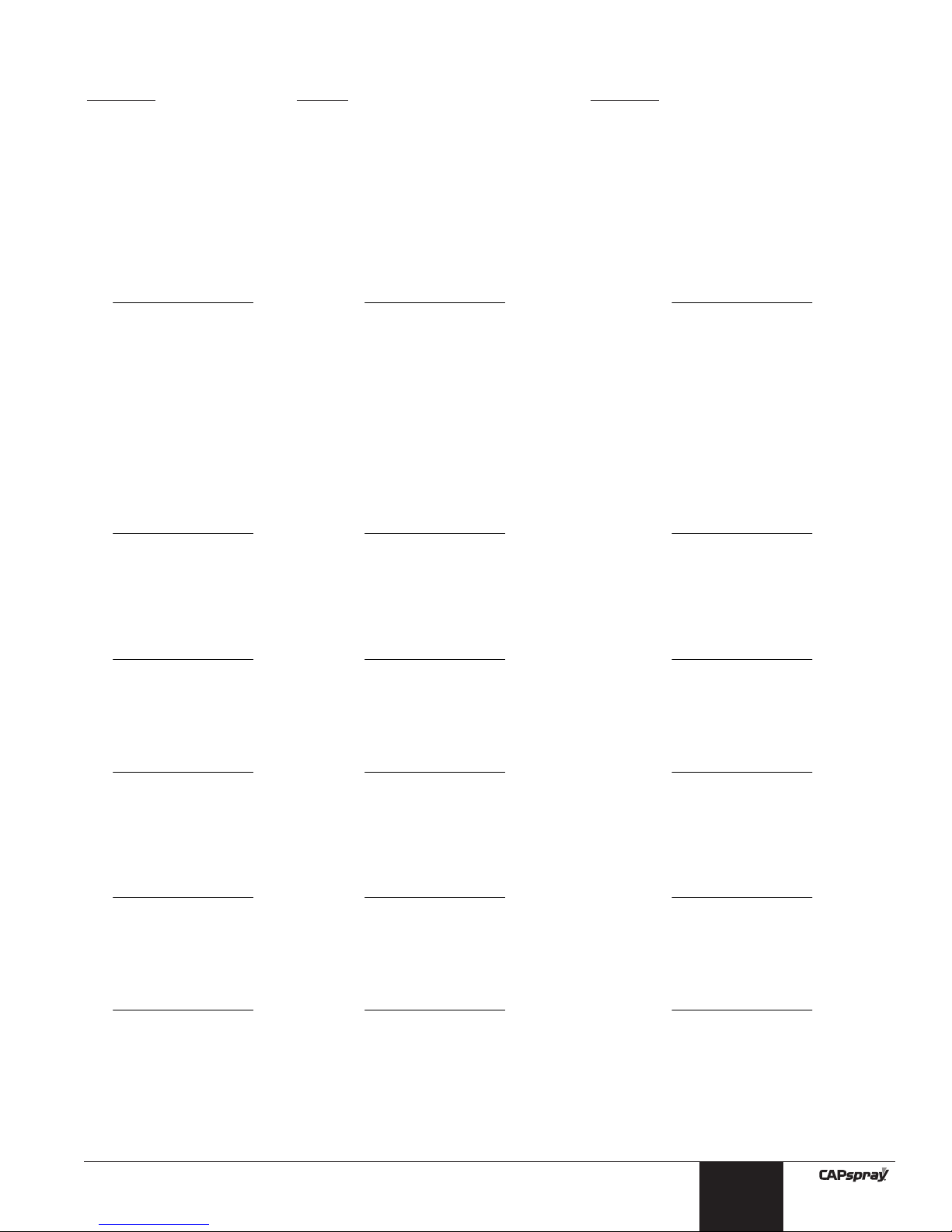

Removing and Cleaning the Outlet

Valve

It may be necessary to remove and clean the outlet valve or to

replace parts inside the valve worn out through normal use.

1. Remove the outlet valve body with a wrench.

2. Remove and clean the ball stop and small spring inside

the valve using a wire hook or tweezers. Replace the

spring if it is broken or worn.

3. Remove the seat and ball assembly.

4. Clean all parts thoroughly. If the ball or seat show any

sign of wear or damage, replace them with new parts.

This carbide ball must seal tightly against its seat for the

valve to function properly.

5. Cover all parts with a thin coat of light oil before

reassembling.

6. Drop in the valve ball.

7. Insert the protector and spring and replace the valve body.

Be sure that the O-ring is positioned properly and that the

tongue on the cap fits inside the spring.

8. Tighten the valve body securely with an adjustable

wrench. Do not over-tighten.

NOTE: Wear on the ball is almost impossible to

detect visually. To test for a worn outlet valve

assembly, turn the pressure control knob

clockwise to its highest setting and run water

only through the pump for 10 to 15 minutes

without triggering the gun.

If the valve is defective, the end cap will get

very hot to the touch. If it is functioning

properly, it will stay approximately the same

temperature as the water running through it.

NOTE: Align the ridge on the seat with the groove in

the pump housing when reassembling.

NOTE: This spring is manufactured to a very specific

tension. Do not stretch the spring. Do not put in

an unauthorized substitute. See the paint pump

assembly parts diagram for the proper

replacement part number. An extra spring is

included in the literature set.

English

Seal

Seat

Ball

Spring

Ball Stop

O-ring

Valve Body

English

© SprayTECH. All rights reserved. 9

Troubleshooting

Solution

1. Plug the unit in.

2. Turn the ON/OFF switch to ON.

3. Replace the blown fuse with the proper

replacement.

4. Properly test the power supply voltage.

5. Turn the PRIME/SPRAY knob to PRIME.

6. Replace the extension cord.

7. Allow the motor to cool and move the unit to a

cooler spot.

8. Take the unit to a SprayTECH Authorized Service

Center.

1. Try to prime the pump again.

2. Immerse the suction hose in paint.

3. Clean the suction set filter.

4. Clean the tube connection and tighten it securely.

5. Clean the inlet valve.

6. Clean the outlet valve and replace any worn

parts.

7. Take the unit to a SprayTECH Authorized Service

Center.

8. Replace the inlet valve.

9. Take the unit to a SprayTECH Authorized Service

Center.

10. Take the unit to a SprayTECH Authorized Service

Center.

1. Replace the spray tip with a new tip.

2. Clean the suction set filter.

3. Clean or replace the proper filter. Always keep

extra filters on hand.

4. Thin or strain the paint.

5. Clean or replace the outlet valve assembly.

6. Replace the inlet valve.

1. Increase the fluid pressure.

2. Increase the air pressure.

3. Clean the filters.

4. Tighten the suction hose fitting.

5. Replace the spray tip.

6. Thin the paint.

1. Allow to cool for 30 minutes.

2. Allow to cool for 30 minutes and replace the

extension cord with a shorter extension or a

thicker gauge cord.

3. Clean the paint from the motor.

4. Restart the unit in the PRIME mode.

5. Move the unit out of the sun.

1. Move the compressor ON/OFF switch to the ON

position.

2. Take the unit to a SprayTECH Authorized Service

Center.

3. Take the unit to a SprayTECH Authorized Service

Center.

4. Clean out the relief hole.

1. Increase the air regulator setting.

2. Thin the paint.

3. Open the gun air valve. Refer to gun Owner’s

Manual.

4. Install a new pressure relief valve.

Cause

1. The unit is not plugged in.

2. The ON/OFF switch is set to OFF.

3. A fuse is blown in the unit.

4. Low or no voltage is coming from the

wall plug.

5. The unit was turned off while still under

pressure.

6. The extension cord is damaged or has too

low a capacity.

7. The thermal overload on the unit is tripped.

8. There is a problem with the motor.

1. The pump will not prime properly or has lost

prime.

2. The paint bucket is empty or the suction

hose is not totally immersed in the paint.

3. The suction filter is clogged.

4. The suction hose is loose at the inlet valve.

5. The inlet valve is stuck.

6. The outlet valve is stuck.

7. The PRIME/SPRAY valve is plugged.

8. The inlet valve is worn or damage.

9. There is a problem with the diaphragm.

10. The hydraulic oil level is low or empty.

1. The spray tip is worn.

2. The suction set filter is clogged.

3. The gun or spray tip filter is plugged.

4. The paint is too heavy or coarse.

5. The outlet valve assembly is dirty or worn.

6. The inlet valve assembly is damaged or

worn.

1. The fluid pressure is set too low.

2. The air pressure is set too low.

3. The gun, the tip, or the suction filter is

plugged.

4. The suction hose is loose at the inlet valve.

5. The tip is worn.

6. The paint is too thick.

1. The motor overheated.

2. The extension cord is too long or is too

small a gauge.

3. Paint has built up on the motor.

4. The motor was started while the unit was

under pressure.

5. The unit was sitting in the hot sun.

1. The compressor ON/OFF switch is in the

OFF position.

2. Compressor ON/OFF switch is bad.

3. Compressor problem.

4. Relief hole under air regulator is blocked.

1. Air regulator setting is too low.

2. Paint is too thick.

3. Closed air valve on gun.

4. Bad pressure relief valve.

Problem

The unit does not start up.

The pump starts up but does not

draw in paint when the

PRIME/SPRAY valve is set to

PRIME.

The pump draws up paint but the

pressure drops when the gun is

triggered.

The paint pattern is tailing.

The thermal overload tripped and

shut off the pump.

Compressor does not start.

Compressor starts but not enough

air.

Table des matières

Consignes de sécurité . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Instructions de mise à la terre . . . . . . . . . . . . . . . . . . . . . 11

Description générale. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Fonctionnement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Amorçage de la pompe . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Peinture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Procédure de limitation de la pression . . . . . . . . . . . . . . . 14

Technique de pulvérisation . . . . . . . . . . . . . . . . . . . . . . . 15

Nettoyage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Rangement pour la nuit . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Rangement à long terme . . . . . . . . . . . . . . . . . . . . . . . . . 15

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Démontage et nettoyage de la soupape d'admission . . . . 17

Démontage et nettoyage de la soupape de sortie . . . . . . 17

Dépannage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Liste de pièces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Garantie Limitée . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Consignes de sécurité

Le présent manuel contient des renseignements à lire

attentivement et à bien comprendre avant d'utiliser l'appareil.

Lorsque l’un des symboles suivants apparaît, il est

recommandé d’être particulièrement attentif et de tenir compte

des mesures de sécurité indiquées.

Ce symbole indique un risque potentiel susceptible d'entraîner

des blessures graves, voire mortelles. Des renseignements sur

la sécurité sont également indiqués ci-après.

Ce symbole indique un risque potentiel pour l'utilisateur ou

l'équipement. Vous trouverez ci-après des renseignements

importants sur la manière d'éviter d'endommager l'équipement

ou de provoquer des blessures superficielles.

La pompe à diaphragme est dotée d’un dispositif de

remise en marche automatique avec protection thermique.

En cas de surcharge, ce dispositif débranche le moteur du

bloc d'alimentation.

• Le moteur se remet en marche sans avertissement

lorsque le protecteur est réarmé automatiquement.

• Débranchez toujours le moteur du bloc d’alimentation

avant d’utiliser l'équipement.

• Lorsque le dispositif de remise en marche automatique

débranche le moteur du bloc d'alimentation, libérez de la

pression en tournant la soupape d'AMORÇAGE/

PULVÉRISATION à la position AMORÇAGE.

• Placez l'interrupteur MARCHE/ARRÊT (ON/OFF) de la

pompe en position ARRÊT (OFF).

DANGER :Blessures résultant d’une injection – Le jet à

haute pression produit par cet équipement peut

transpercer la peau et les tissus sous-jacents

causant des blessures graves pouvant aller

jusqu’à l’amputation. Consultez

immédiatement un médecin.

AVERTISSEMENT

NOTA: Il faut remédier à la cause de la surcharge

avant de faire redémarrer la pompe. Voir la

section Dépannage.

ATTENTION

NOTA: Les remarques vous fournissent des

renseignements importants auxquels il faut

faire particulièrement attention.

ATTENTION

AVERTISSEMENT

10 © SprayTECH. Tous droits réservés.

N'ESSAYEZ PAS DE TRAITER UNE BLESSURE PAR

INJECTION COMME UNE SIMPLE COUPURE! Les

blessures par injection peuvent entraîner une amputation.

Consultez immédiatement un médecin.

La pression de liquide maximale de fonctionnement du

pistolet est de 2 800 PSI / 19 MPa.

PRÉVENTION :

• NE dirigez JAMAIS le pistolet vers une partie du corps,

quelle qu'elle soit.

• NE laissez JAMAIS une partie du corps entrer en contact

avec le jet de liquide ni une fuite provenant du tuyau à

fluide..

• NE placez JAMAIS vos mains devant le pistolet. Les

gants ne constituent pas une protection suffisante contre

les risques d’injection cutanée.

• Bloquez TOUJOURS la détente du pistolet, éteignez la

pompe et libérez toute la pression avant de procéder à

des opérations d'entretien, de nettoyage de la tête ou d’un

dispositif de protection, de remplacement de la tête ou si

vous laissez l'appareil sans surveillance. La pression ne

s'évacue pas simplement en éteignant le moteur. La

soupape d'AMORÇAGE/PULVÉRISATION doit être placée

en position AMORÇAGE pour libérer la pression.

Reportez-vous à la section intitulée Procédure limitation

de la pression du présent manuel.

• Conservez TOUJOURS l’embout de protection de la tête

lorsque vous pulvérisez. Ce dispositif fournit une certaine

protection, mais il agit principalement à titre

d’avertissement. • Enlevez TOUJOURS la

tête de pulvérisation avant de rincer ou de nettoyer le

système.

• Le tuyau à peinture peut présenter des fuites dues à

l'usure, aux pincements et aux mauvaises utilisations.

Toute fuite peut entraîner une injection de produit dans la

peau. Vérifiez soigneusement le tuyau avant chaque

utilisation.

• N'utilisez JAMAIS un pistolet pulvérisateur qui n’est pas

muni d’un dispositif de verrouillage ou d’un dispositif de

protection en place.

•Tous les accessoires doivent pouvoir fonctionner à des

pressions minimales de 2 800 PSI / 19 MPa. Cette

remarque s’applique aux têtes de pulvérisation, aux

pistolets, aux rallonges et aux tuyaux.

DANGER :EXPLOSION ET INCENDIE – Les émanations de

solvants et de peintures peuvent exploser ou

s'enflammer causant des dégâts ou des

blessures corporelles graves.

PRÉVENTION :

• Un approvisionnement en air frais et une évacuation des

gaz doivent être assurés afin que l’air entourant la zone

de pulvérisation soit libre de toute accumulation de

vapeurs inflammables.

• Évitez toutes les sources d'inflammation telles que les

étincelles d'électricité statique, les appareils électriques,

les flammes nues, les flammes pilotes, les objets chauds

et les étincelles pouvant se produire lors du branchement

ou du débranchement des cordons d’alimentation ou des

interrupteurs de lampes de travail.

• Ne fumez pas dans la zone de pulvérisation.

•Vous devez disposer d'un extincteur en bon état de

marche.

REMARQUE À L’INTENTION DU MÉDECIN :

L'injection de liquide dans la peau est une lésion

traumatique qu’il importe de traiter le plus tôt

possible. NE retardez PAS le traitement pour

rechercher la toxicité. La toxicité est à prendre en

compte lorsque certains enduits sont injectés

directement dans le sang. Il peut être recommandé de

consulter un chirurgien plastique ou un spécialiste de

chirurgie reconstructive de la main.

Français

• Placez la pompe à une distance minimale de 6,1 mètres

(20 pieds) de l'objet à pulvériser dans une pièce bien

ventilée (ajoutez une longueur de tuyau au besoin). Les

vapeurs inflammables sont souvent plus lourdes que l'air.

La zone proche du sol doit être extrêmement bien

ventilée. La pompe contient des parties susceptibles de

former un arc électrique qui peuvent provoquer des

étincelles et enflammer les vapeurs.

• L'équipement et les objets présents dans et autour de la

zone de pulvérisation doivent être correctement mis à la

terre pour éviter la formation d'étincelles statiques.

• N'utilisez qu'un tuyau de liquide à haute pression

conducteur ou relié à la terre. Le pistolet doit être relié à

la masse par les raccords de tuyaux.

• Le cordon d’alimentation doit être branché sur un circuit

relié à la terre.

•Vidangez toujours l'appareil dans un contenant en métal

isolé, à une faible pression de pompe et lorsque la tête de

pulvérisation a été enlevée. Tenez le pistolet fermement

contre le côté du contenant pour mettre le contenant à la

masse et éviter la formation d'étincelles statiques.

• Suivez les instructions et mises en garde du fabricant du

solvant.

• Redoublez de prudence lorsque vous utilisez des produits

dont le point d'éclair est inférieur à 21 °C (70 ºF)). Le point

d'éclair est la température à laquelle un liquide peut

produire assez de vapeurs pour s'enflammer.

• Les plastiques peuvent produire des étincelles statiques.

N'accrochez jamais de revêtement en plastique pour

circonscrire la zone de pulvérisation. N'utilisez pas de

vêtements en plastiques lorsque vous vaporisez des

produits inflammables.

• Utilisez la plus petite pression possible pour rincer

l'équipement.

MOTEUR À ESSENCE (LE CAS ÉCHÉANT)

Placez toujours l'appareil à l'extérieur à l'air libre. Éloignez tous

les solvants du conduit d'échappement du moteur. Ne

remplissez jamais le réservoir de carburant lorsque le moteur

est en marche ou chaud. Le carburant répandu sur le sol peut

s'enflammer au contact de surfaces chaudes. Reliez toujours

le câble de mise à la terre de la pompe à un objet mis à la

terre. Veuillez consulter le manuel d'utilisateur du moteur pour

de plus amples renseignements concernant les consignes de

sécurité.

DANGER :RISQUE D'EXPLOSION DÛ À DES MATÉRIAUX

INCOMPATIBLES – entraîne des blessures

graves ou des dégâts matériels.

PRÉVENTION :

• N'utilisez pas de produits contenant de l'eau de javel ou

du chlore.

• N'utilisez pas de solvants à base d'hydrocarbure halogéné

tels que l'eau de javel, les produits antimoisissure, le

chlorure de méthylène et le trichloro-éthane 1,1,1. Ils ne

sont pas compatibles avec l'aluminium.

• Renseignez-vous auprès de votre fournisseur de

revêtement pour obtenir plus de détails sur la compatibilité

des matériaux avec l'aluminium.

DANGER :ÉMANATIONS DANGEREUSES – Les peintures,

solvants, insecticides et autres matériaux

peuvent être dangereux en cas d'inhalation ou

de contact avec la peau. Les vapeurs peuvent

entraîner des nausées, des évanouissements

ou des empoisonnements.

PRÉVENTION :

• Utilisez un masque de protection si des vapeurs peuvent

être inhalées. Lisez attentivement toutes les instructions

fournies avec le masque pour vous assurer qu'il vous

procurera toute la protection nécessaire.

• Portez des lunettes de protection.

• Portez des vêtements de protection, selon les instructions

du fabricant de revêtement.

DANGER :GÉNÉRALITÉS – Ce produit peut provoquer

des blessures graves ou des dégâts matériels.

PRÉVENTION :

• Lisez attentivement toutes les instructions et les

consignes de sécurité avant d’utiliser l’appareil.

• Respectez attentivement toutes les réglementations

locales, provinciales et nationales régissant la ventilation,

la prévention des incendies et l’utilisation de l’appareil.

• Les normes de sécurité du gouvernement des États-Unis

ont été adoptées en vertu de la Occupational Safety and

Health Act (OSHA – Loi sur la sécurité et la santé au

travail). Il convient de prendre connaissance de ces

normes et surtout de la partie 1910 des Normes générales

et de la partie 1926 des Normes de construction.

• N'utilisez que des pièces de remplacement d'origine.

L'utilisateur sera tenu responsable de tous les dommages

s'il utilise des pièces non conformes aux caractéristiques

minimales et aux consignes de sécurité du fabricant de la

pompe.

•Avant chaque utilisation, assurez-vous qu’aucun tuyau ne

présente des signes de coupures, de fuites, d'abrasion ni

de renflement du revêtement. Vérifiez l'état et le

mouvement des raccords. Remplacez immédiatement les

tuyaux en présence d’une ou de plusieurs de ces

conditions. Ne réparez jamais un tuyau à peinture.

Remplacez-le par un tuyau à haute pression relié à la

masse.

•Tous les tuyaux, pivots, pistolets et autres accessoires

doivent pouvoir fonctionner à des pressions minimales de

2 800 PSI.

• Ne pulvérisez pas à l'air libre en présence de vent.

• Portez des vêtements de protection pour protéger votre

corps et vos cheveux des éclaboussures de peinture.

• Débranchez toujours les cordons électriques de la prise

avant d’utiliser l’appareil.

Instructions de mise à la terre

Cet outil doit être branché à la terre. En cas de court-circuit

électrique, la mise à la terre réduit les risques de choc

électrique en fournissant un fil d'échappement pour le courant

électrique. Ce produit est équipé d'un cordon ayant un fil de

mise à la terre et une fiche de mise à la terre adaptée. Le

branchement doit être effectué dans une prise correctement

installée et mise à la terre selon les codes et les règlements

locaux.

DANGER – Une installation incorrecte de la fiche de mise

à la terre peut conduire à une électrocution. Si vous devez

réparer ou remplacer le cordon ou la fiche d'alimentation,

ne branchez pas un fil de mise à la terre vert à une borne

à lame plate. Le fil isolé recouvert d’une gaine verte avec

ou sans bandes jaunes est le fil de mise à la terre. Il doit

être branché sur la fiche de mise à la terre.

Renseignez-vous auprès d’un électricien qualifié ou d’un

expert en réparations si vous n'avez pas entièrement compris

les instructions de mise à la terre ou si vous avez un doute

concernant le branchement de l'appareil à la terre. Ne modifiez

pas la prise fournie. Si la fiche d'alimentation n'entre pas dans

la prise murale, faites installer une prise murale par un

électricien qualifié.

© SprayTECH. Tous droits réservés. 11

Français

Prise reliée à la terre

Fiche de mise à la terre

Couvercle de boîtier de prise reliée à la terre

Loading...

Loading...