SportsArt Fitness 8300, E8300 Mechanical Repair Manual

8300 and E8300 Elliptical Trainer – Mechanical Repair Guide

Version 2.1. Revised 03-18-05

E8300 and 8300 Elliptical Trainer Mechanical Repair Manual

This troubleshooting manual was made through the cooperation of SportsArt personnel in the USA and Taiwan.

Our goal is to provide clear, useful troubleshooting information for technicians in the field. If you have questions, comments or suggestions,

please contact Bob Baumgartner at SportsArt America. Thank you.

E-mail: bob@sportsartamerica.com

Tel: 866 709 1750 ext. 115

E8300 and 8300 Elliptical Trainer Mechanical Repair Manual

Version 1: December 31, 2003

Version 2: September 28, 2004 - Minor organizational changes were made

Version 2.1: March 18, 2005 – Part list removed due. Please see product blowups and part lists on our web site.

Notes:

(1) Some parts of this manual refer to the 8300 Elliptical Trainer and no reference to the E8300 is made.

Mechanically, the 8300 and E8300 are the same. No effort was made to include the word E8300 on every page.

(2) Part numbers listed in this manual are factory part numbers – not part numbers used by SportsArt America –

and are subject to change. Please see the website, www.sportsartamerica.com, for updates.

8300 and E8300 Elliptical Trainer – Mechanical Repair Guide - Contents

Chapter 1 – Blowup Diagram and Part List

1-1-1Blowup Diagram and Part List – CONTENTS REMOVED 03-18-05; SEE BLOWUP DIAGRAM.

Chapter 2 - Component Removal and Installation Procedures

2-1-1 Access Cover Removal and Installation

2-2-1 Stride Motor Removal and Installation

2-3-1 Flywheel Removal and Installation

2-4-1 Flywheel Washer Removal and Installation

Chapter 3 - Troubleshooting

3-1-1 Pulsating Vibration

Chapter 4 – Design Change Record

4-1-1 Changes Due to Rust Issue

4-2-1 Change to Prevent Foam from Sliding Down

Version 2.1, Revised 03-18-05

8300 and E8300 Elliptical Trainer – Mechanical Repair Guide

Chapter 1 – Blowup Diagram and Part List

1-1-1 Blowup Diagram and Part List

CONTENTS REMOVED 03-18-05;

PLEASE REFER TO BLOWUP DIAGRAMS AVAILABLE ON THE WEB SITE.

Version 2.1

Revised 03-18-05

8300 Elliptical Trainer – Mechanical Repair Guide

Chapter 2 - Component Removal and Installation Procedures

2-1-1 Access Cover Removal and Installation

2-2-1 Stride Motor Removal and Installation

2-3-1 Flywheel Removal and Installation

2-4-1 Flywheel Washer Removal and Installation

Version 2

Revised 09-28-04

SportsArt America

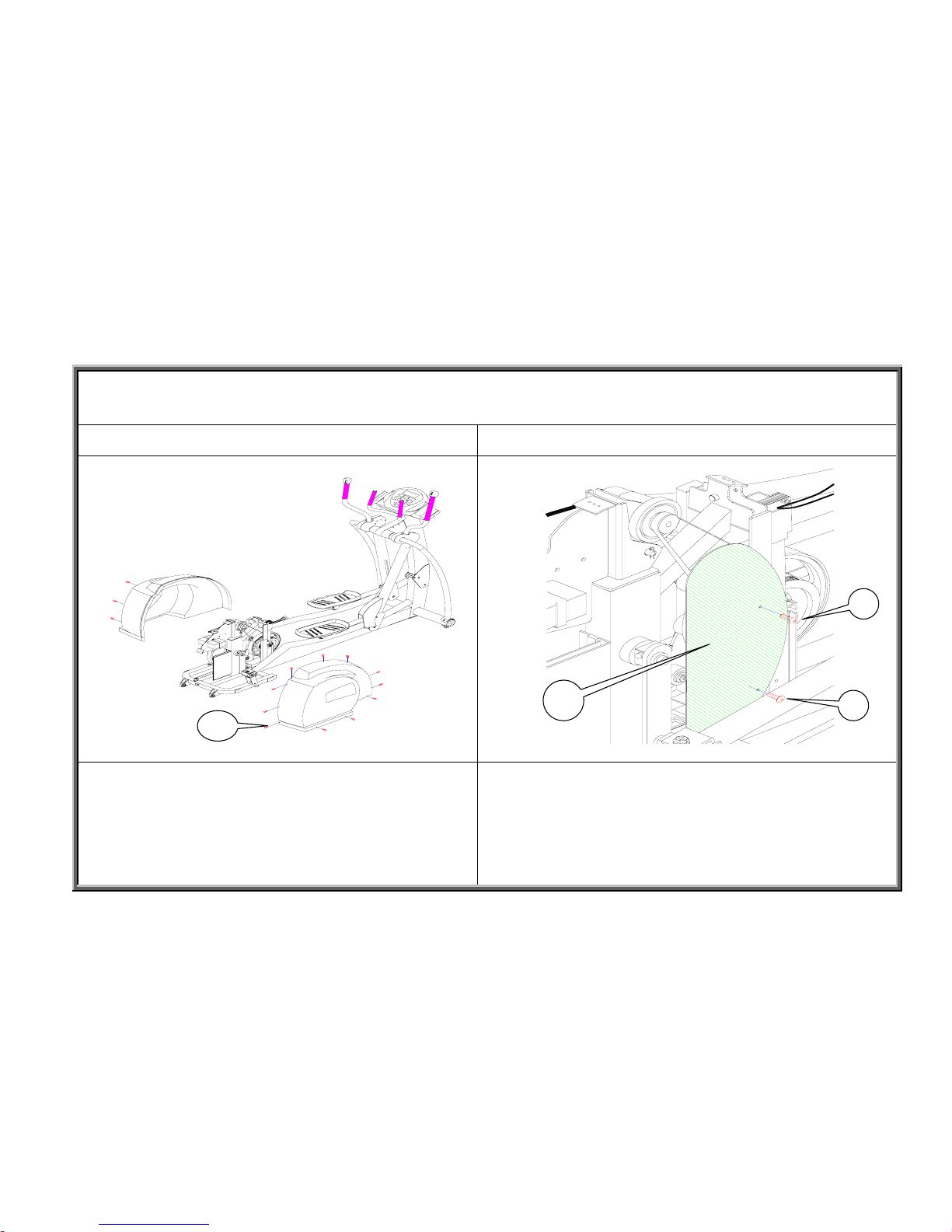

8300 Component Removal and Installation Procedures

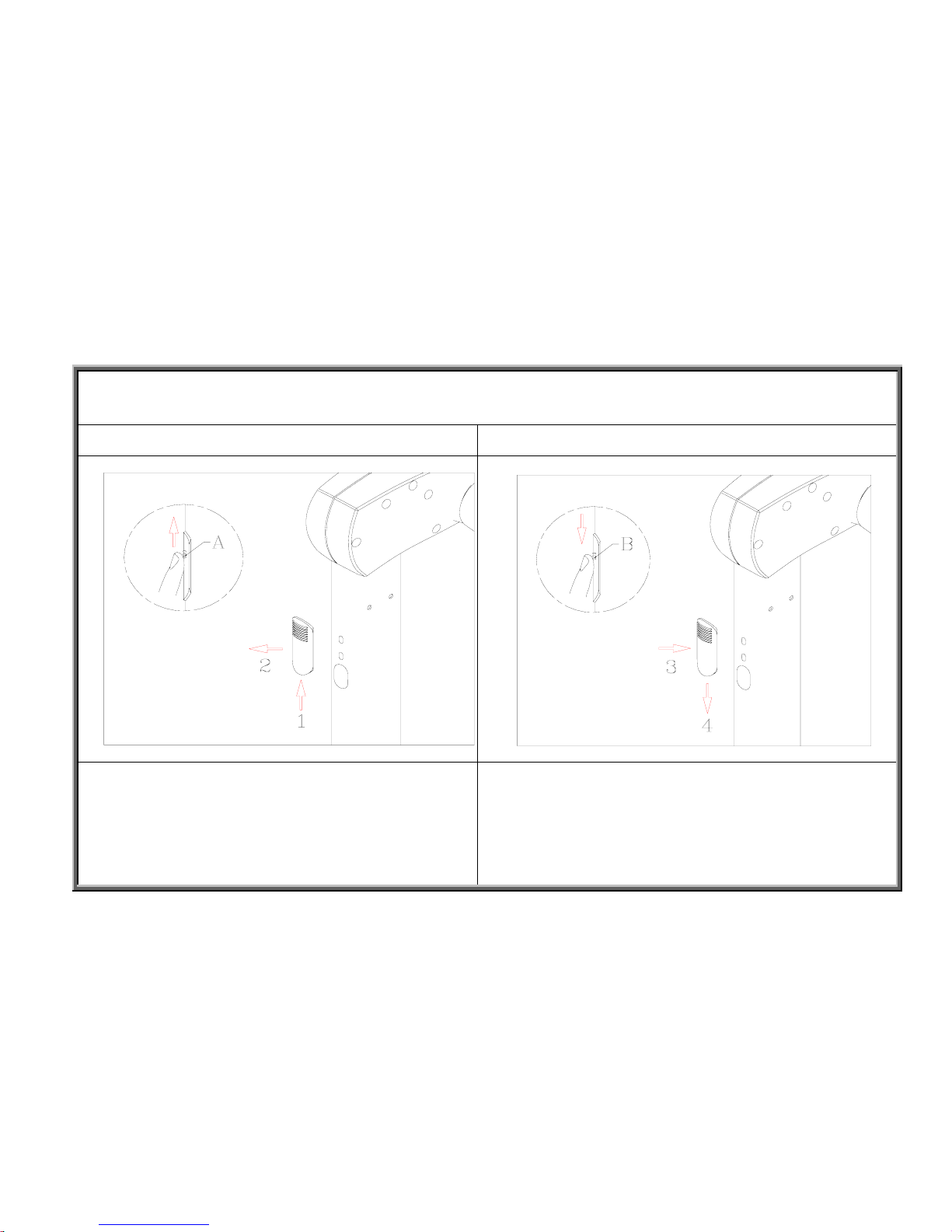

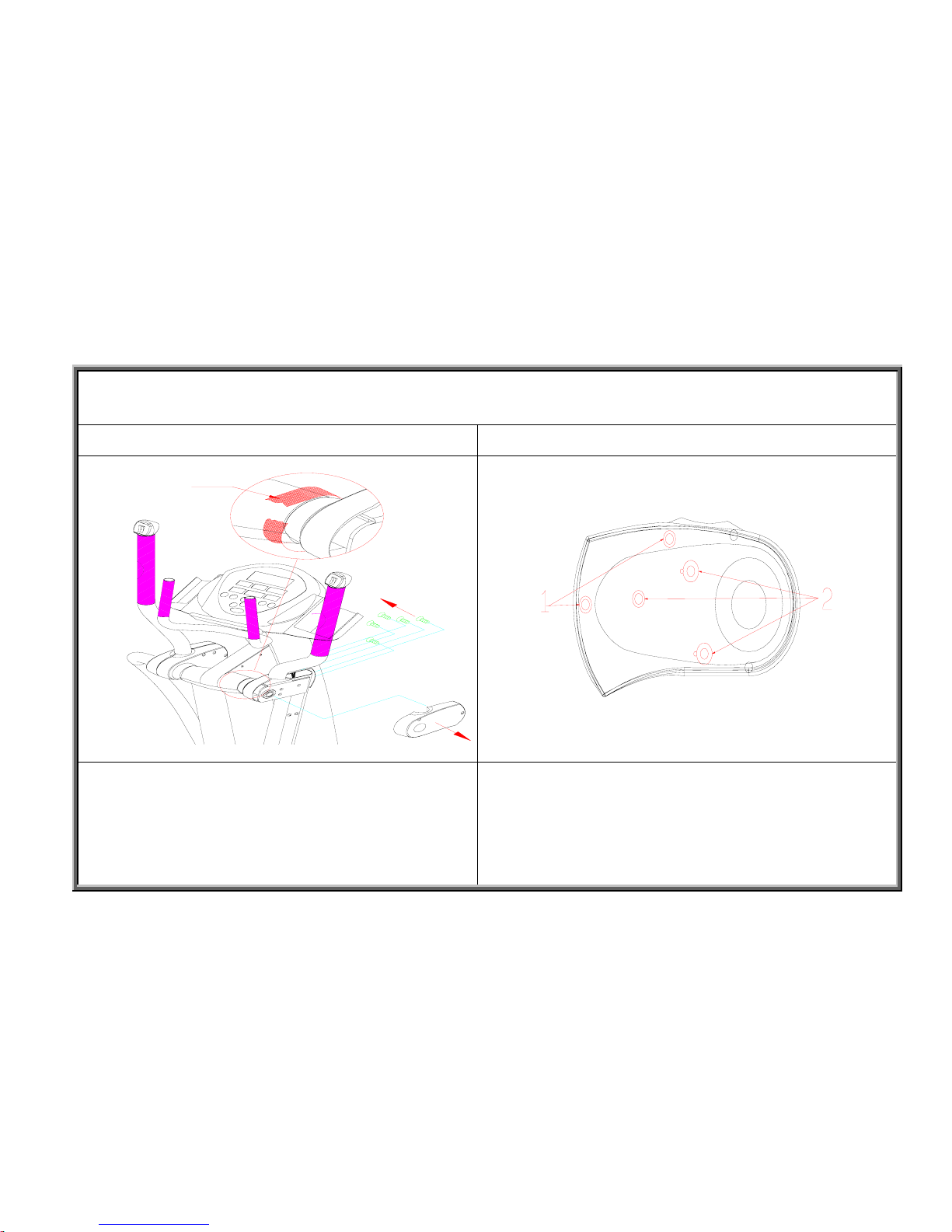

Access Cover Removal and Installation

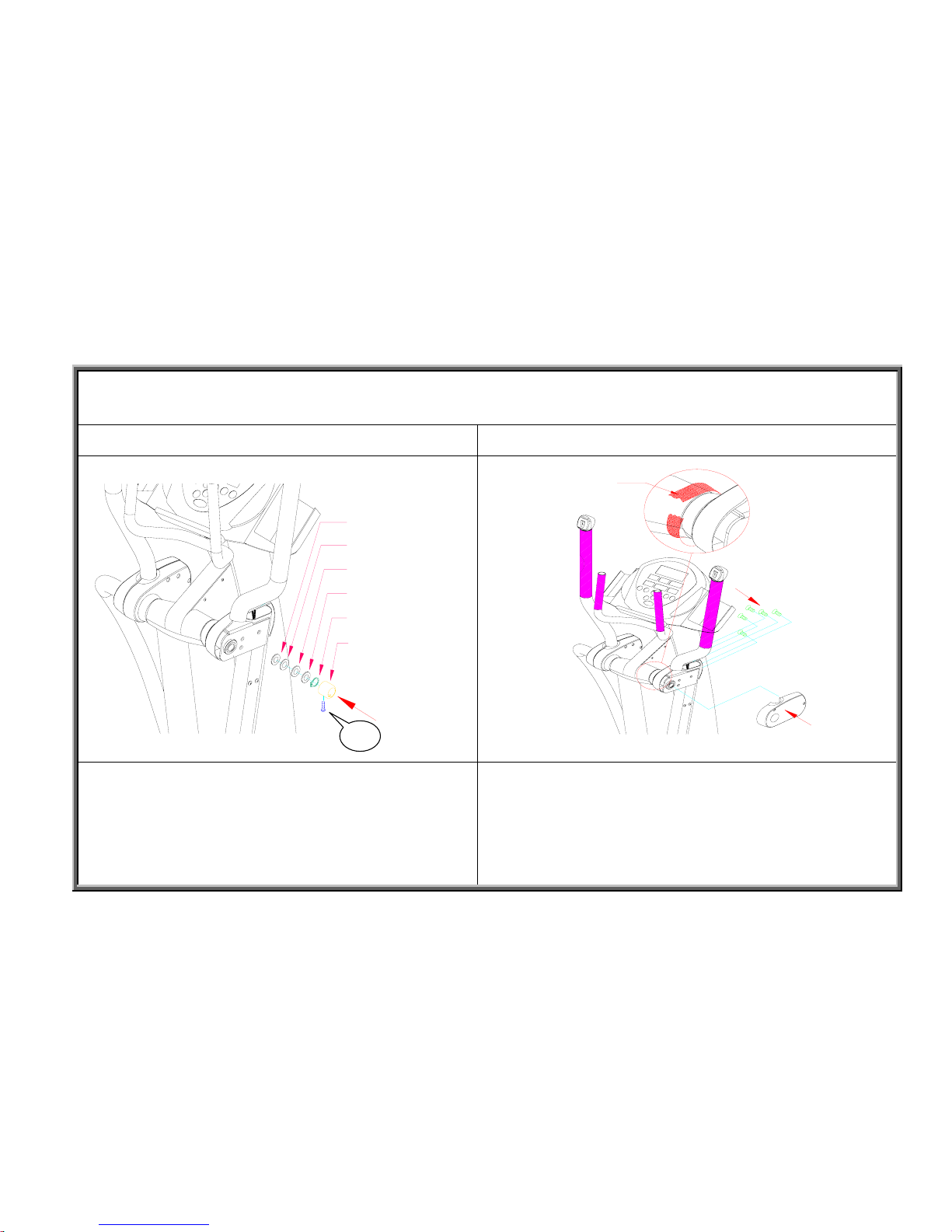

Step 1 - Removal Step 2 - Installation

2-1-1

Step 4 Step 1

Remove the access cover by pressing up (1), then

pulling out (2) as shown above.

Reinstall the access cover by pressing in (3), then

pushing down (4).

SportsArt America

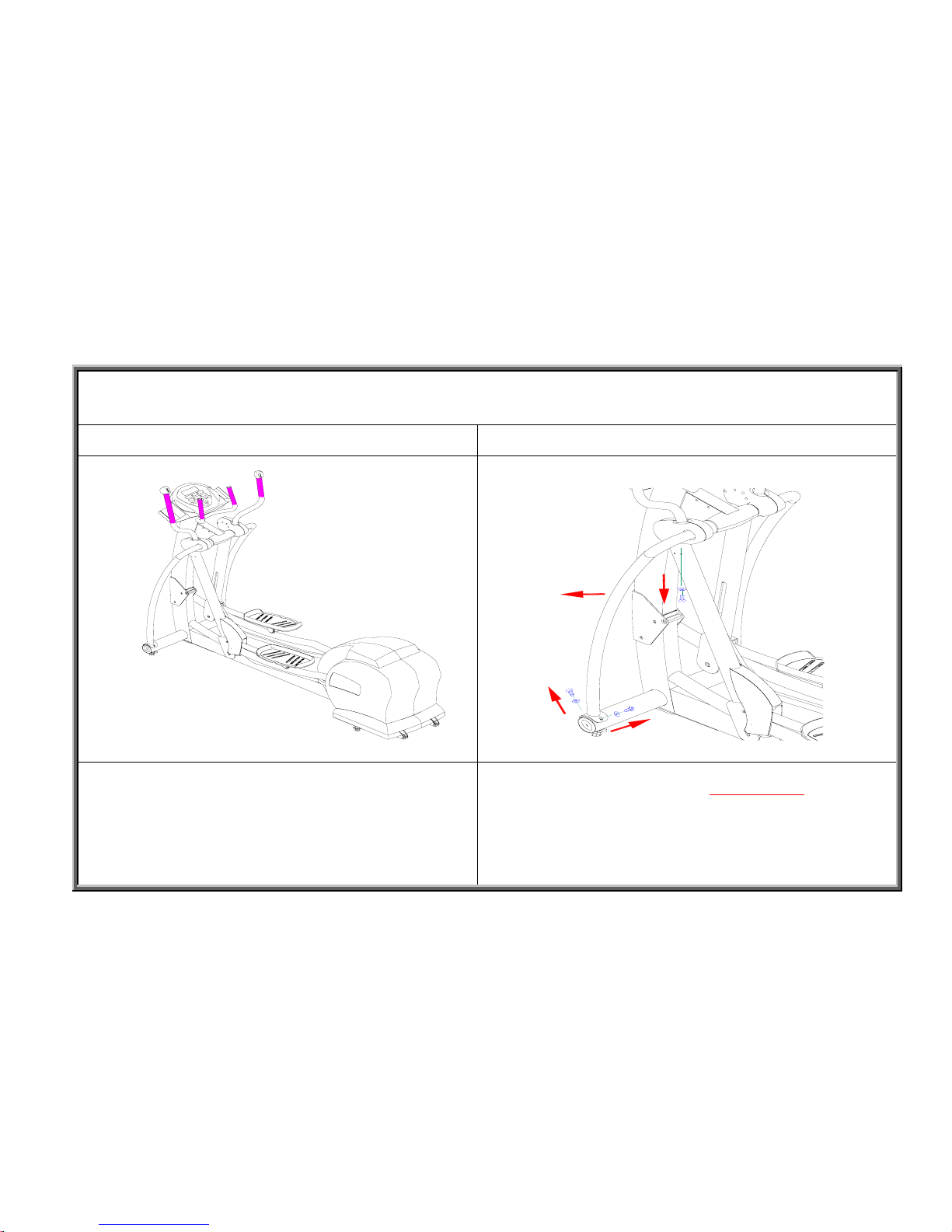

8300 Component Removal and Installation Procedures

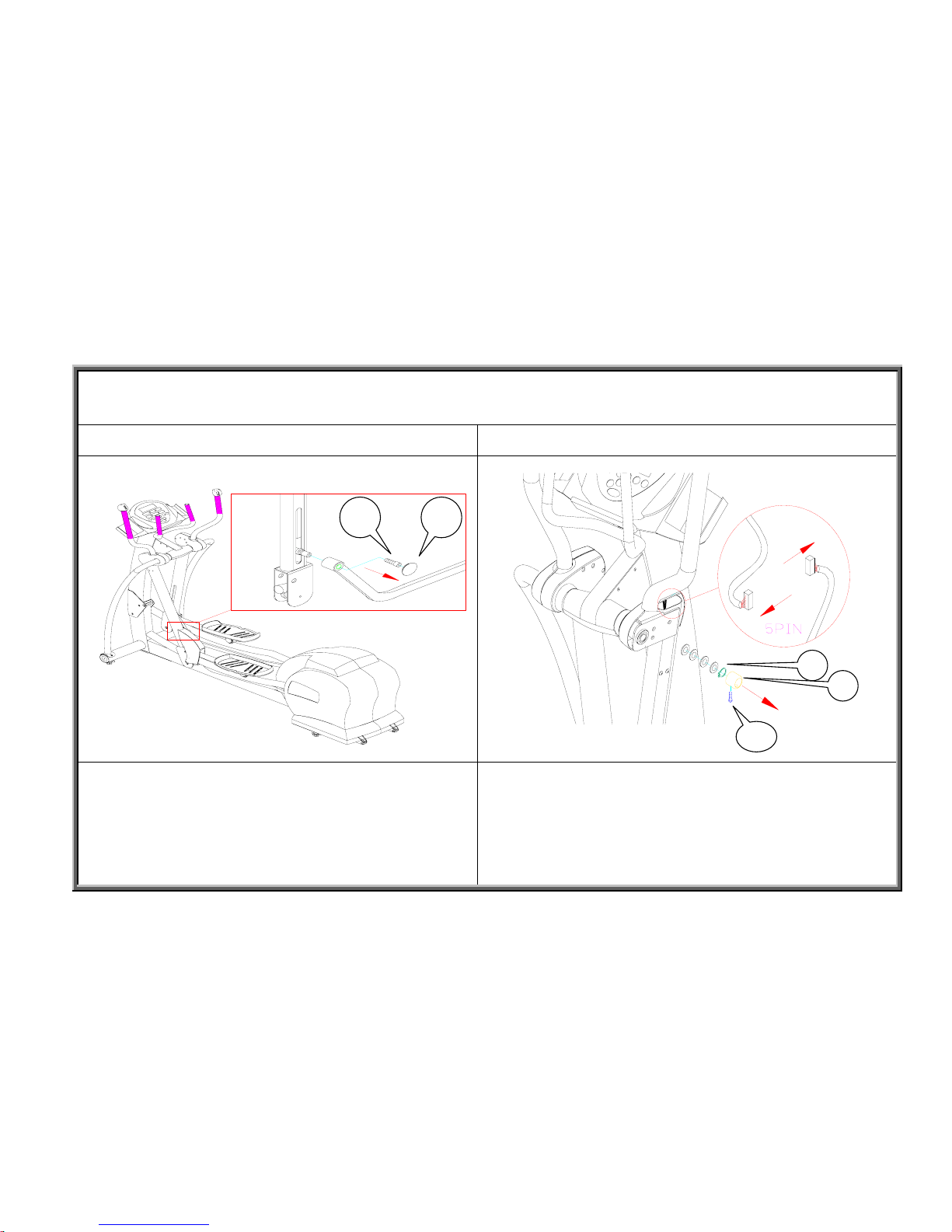

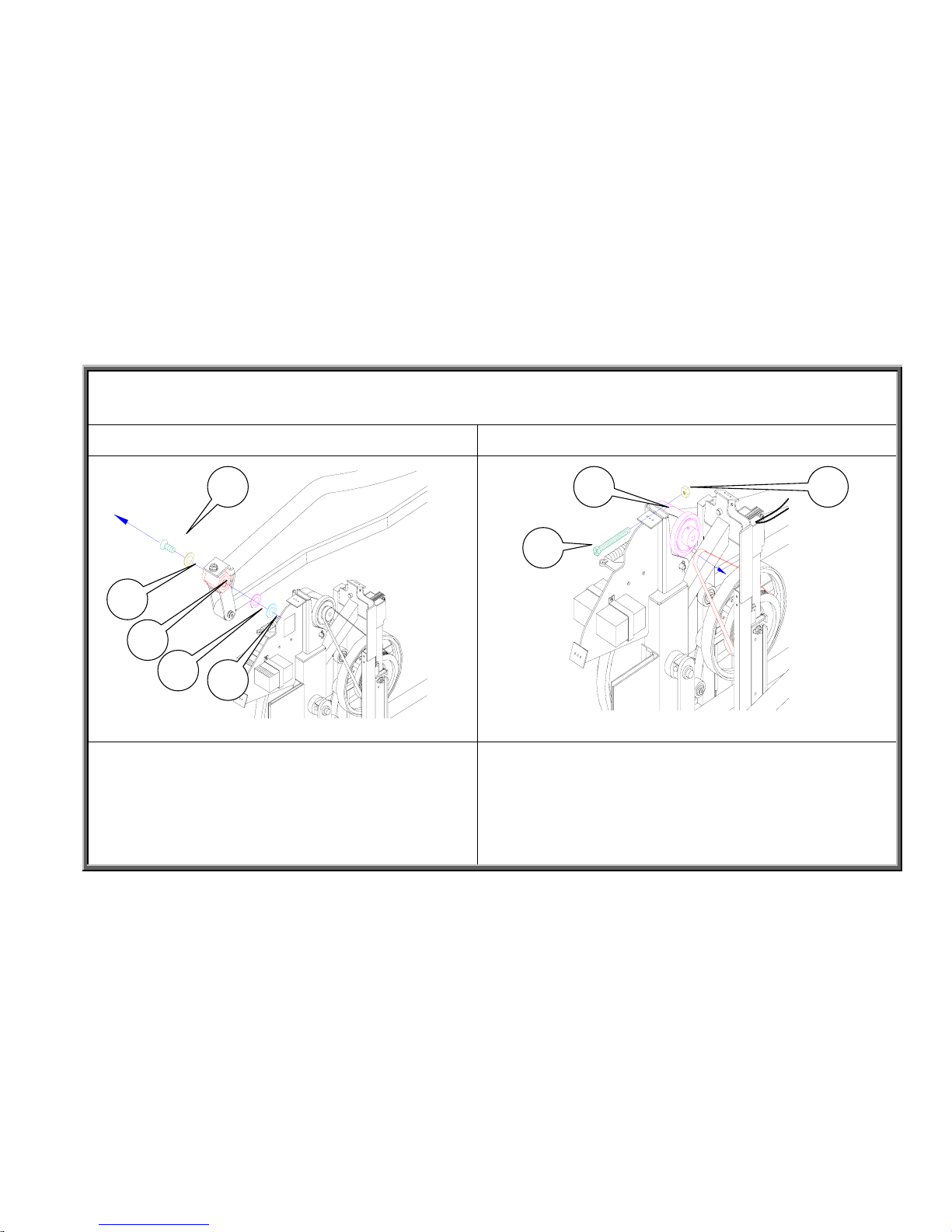

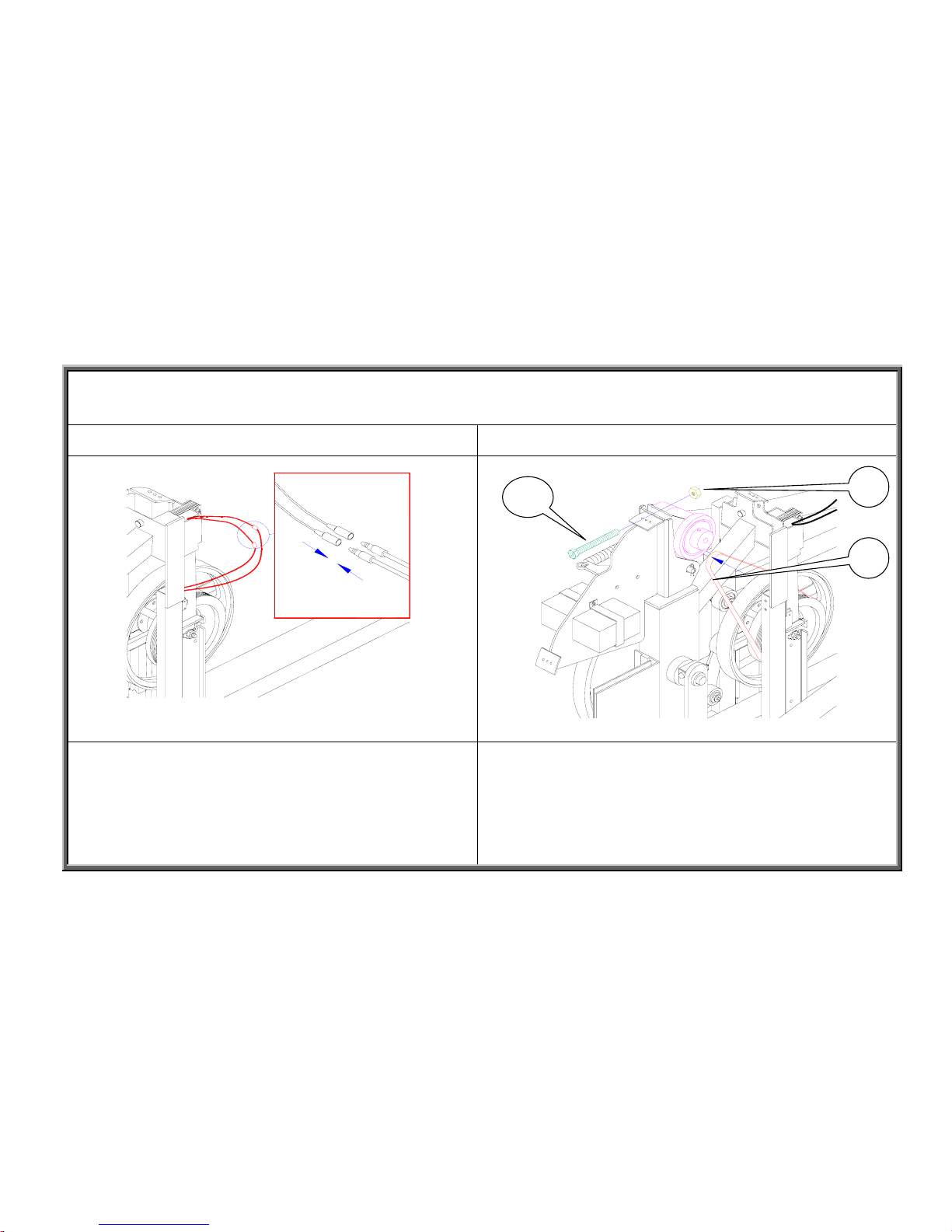

Stride Motor Removal and Installation

Step 1 Step 2

Use these instructions when calibrating or replacing the

stride motor sets.

Press the stride key on the display or the stride switch until

the display stride window shows 650mm (26in).

Continue to

exercise on the unit. After the stride linkage reaches its

destination, remove the stabilizing arms by removing the

mushroom-head hex screws.

2-2-1

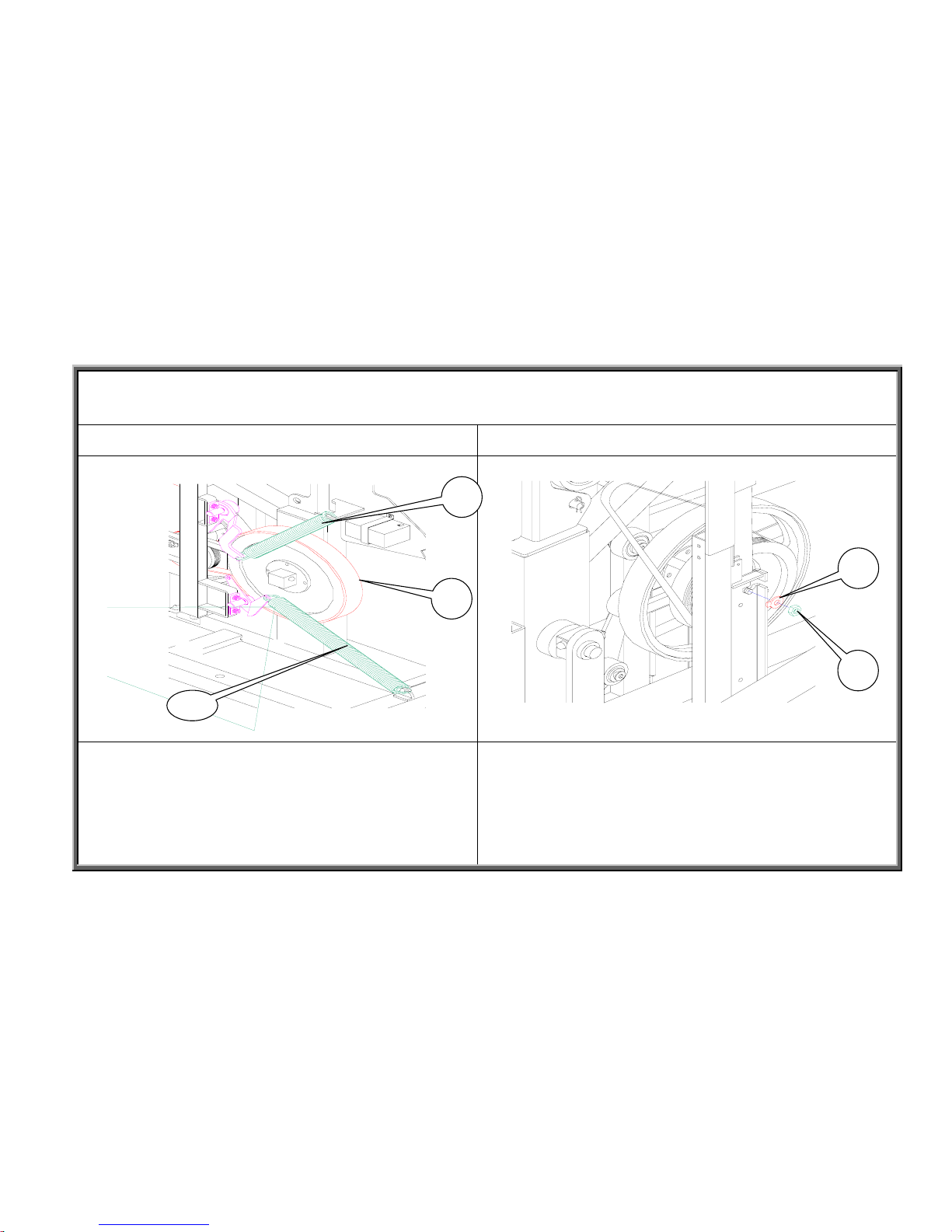

SportsArt America

8300 Component Removal and Installation Procedures

Stride Motor Removal and Installation

Step 3 Screw Types in the Shoulder Cover

Use tape to secure the inner cover (A). Remove the six

screws that secure the outer cover (B).

Remove the screws in this order: (1) Remove the

mushroom-top Phillips-head pointed screws; (2) Remove the

mushroom-top Phillips-head metal screws.

2-2-2

Tape

SportsArt America

8300 Component Removal and Installation Procedures

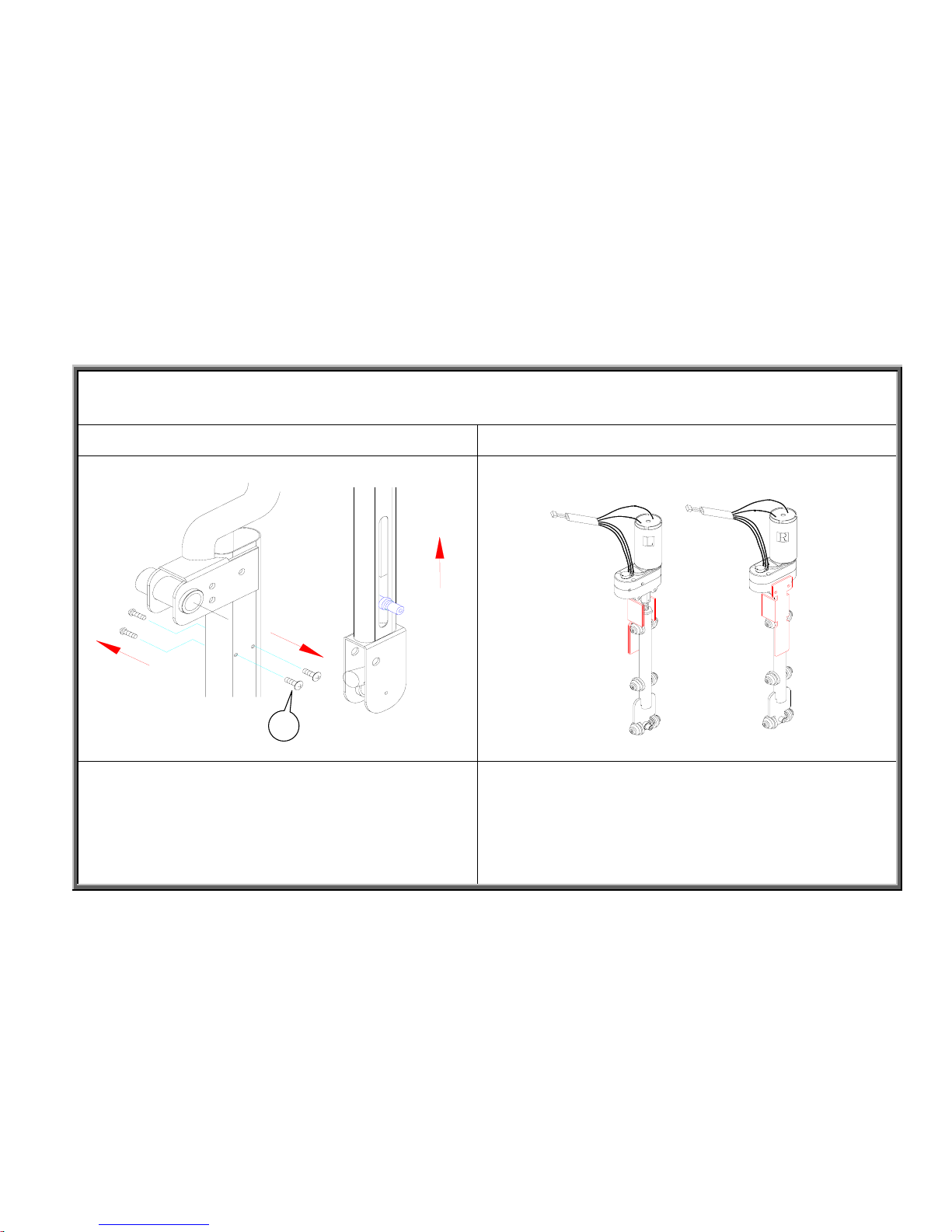

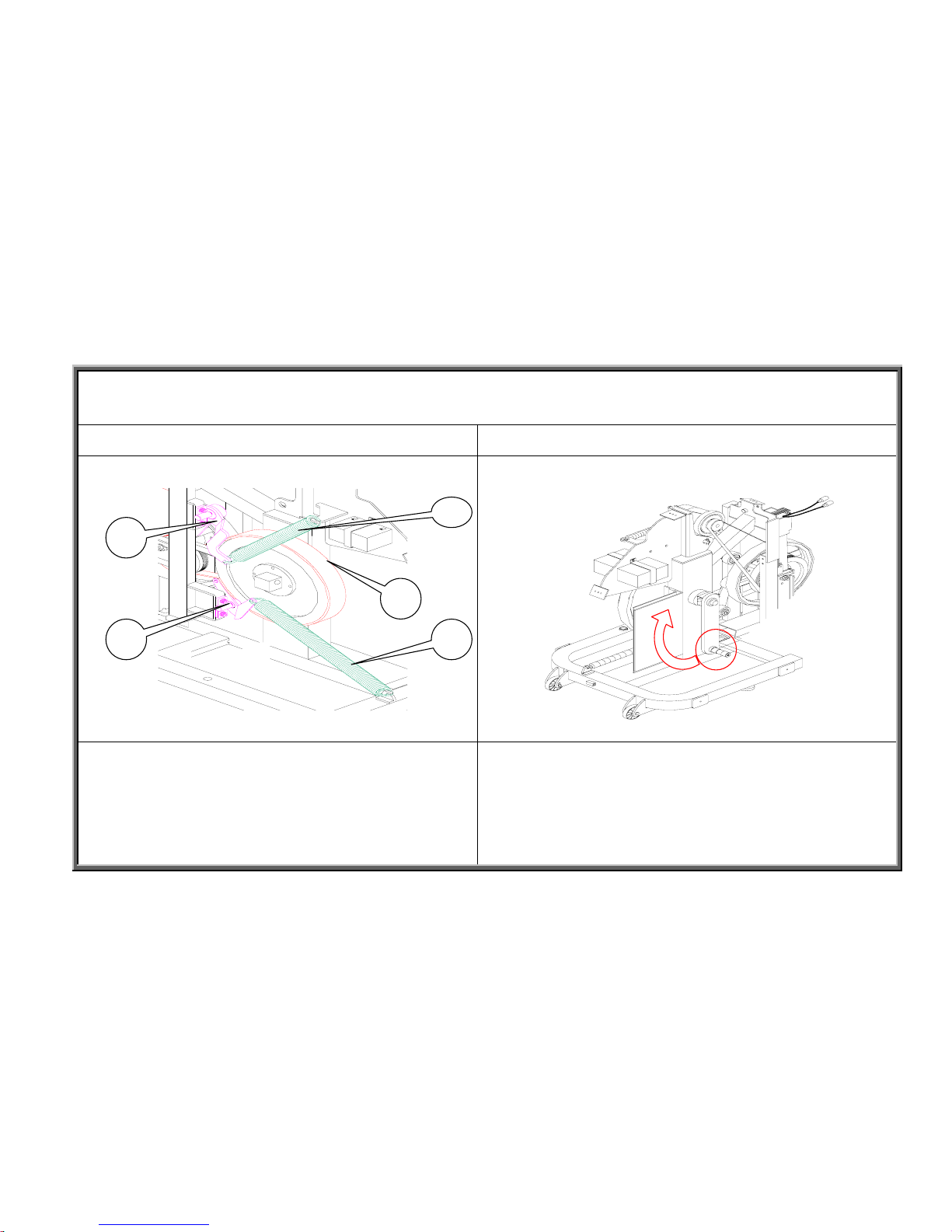

Stride Motor Removal and Installation

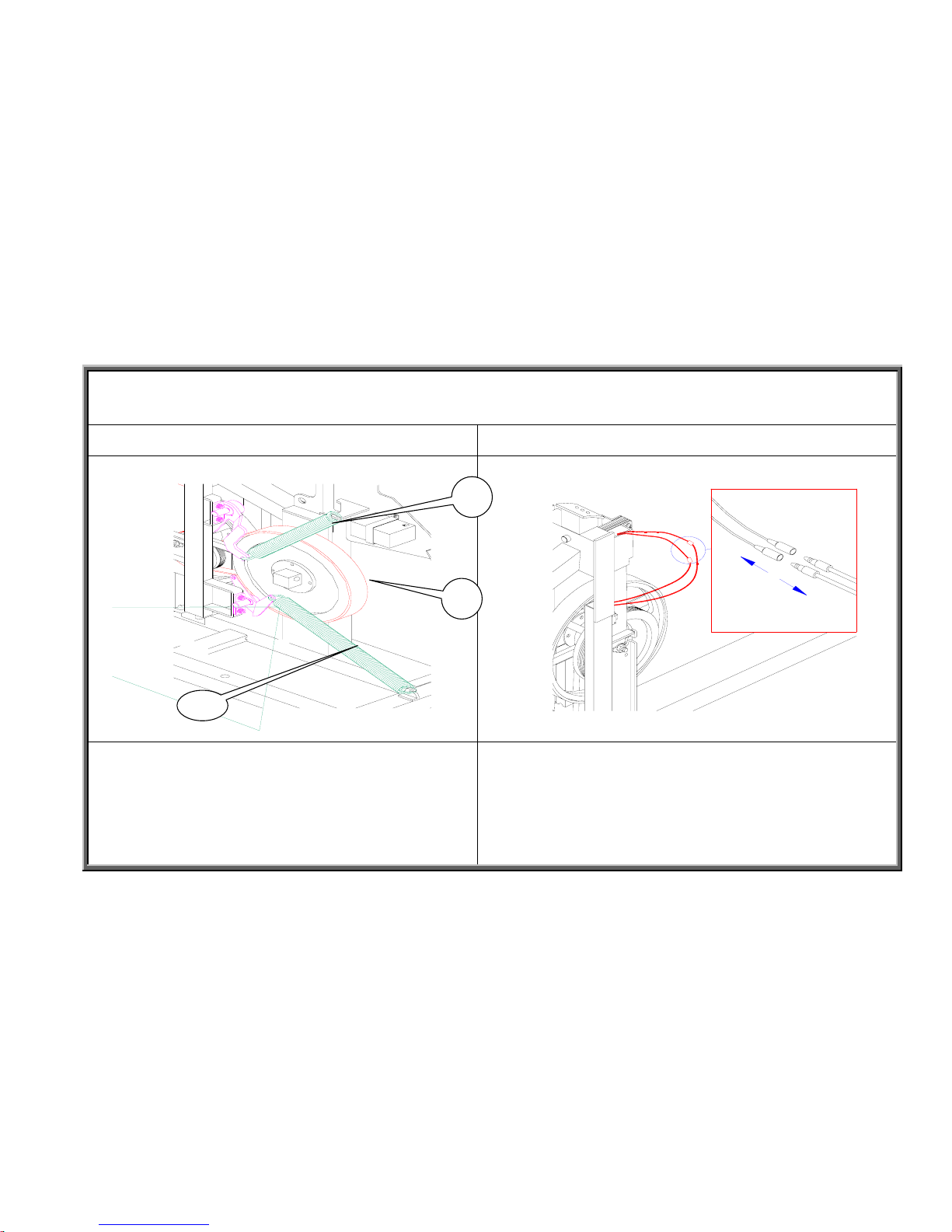

Step 4 Step 5

Remove the stride linkage bushing cover (B). Remove the

inner hex head bolt (A). Detach the stride linkage.

First, loosen the mushroom-head Phillips screw (C) that holds

the sleeve (A) in place. Remove the sleeve (A). Remove the

C-clip (B). Pull the stride support assembly out slightly. (Do

not pull it off the axle.) Disconnect the VR, motor, and switch

wires. Set them out of the way, and pull the stride motor up

and out of the stride support arm.

2-2-3

A B

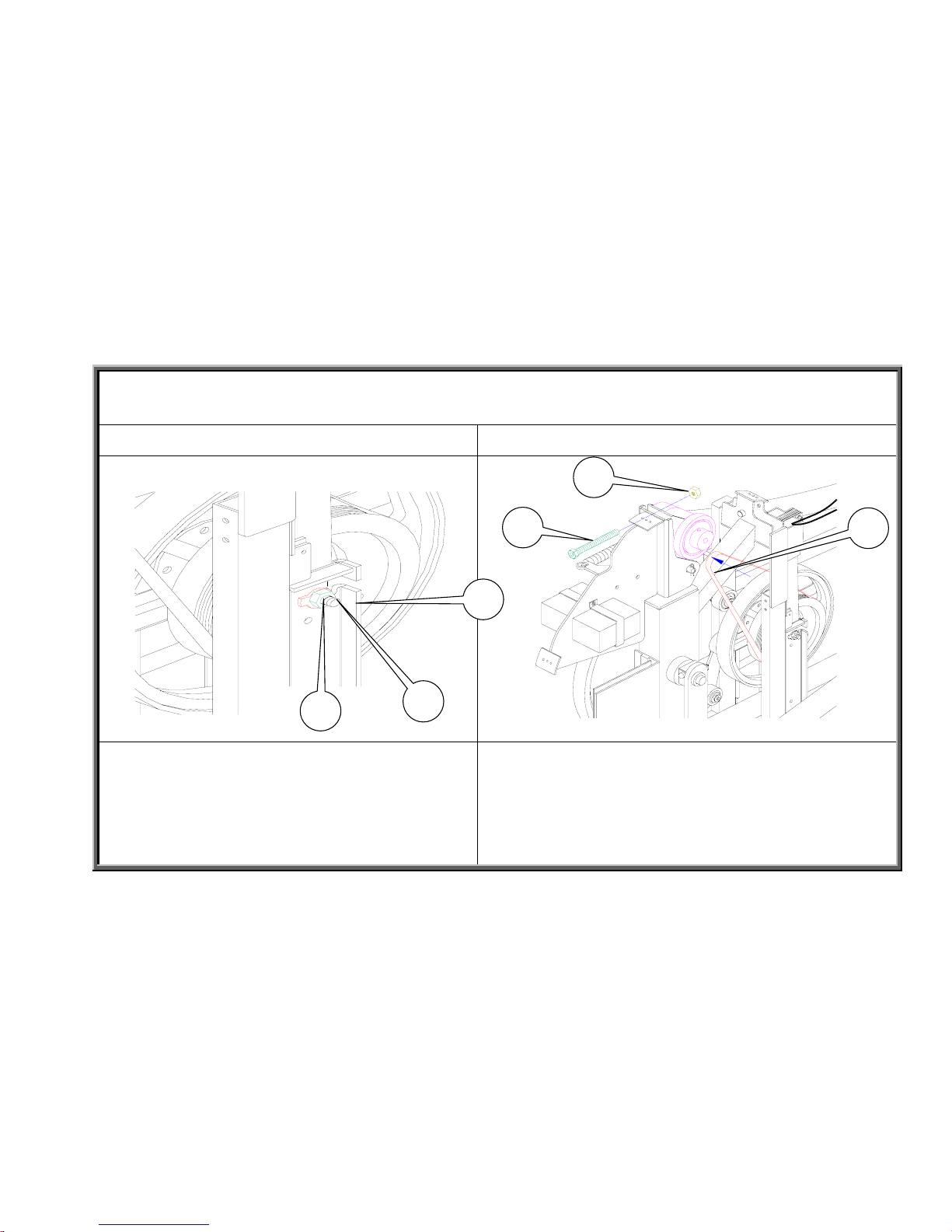

SportsArt America

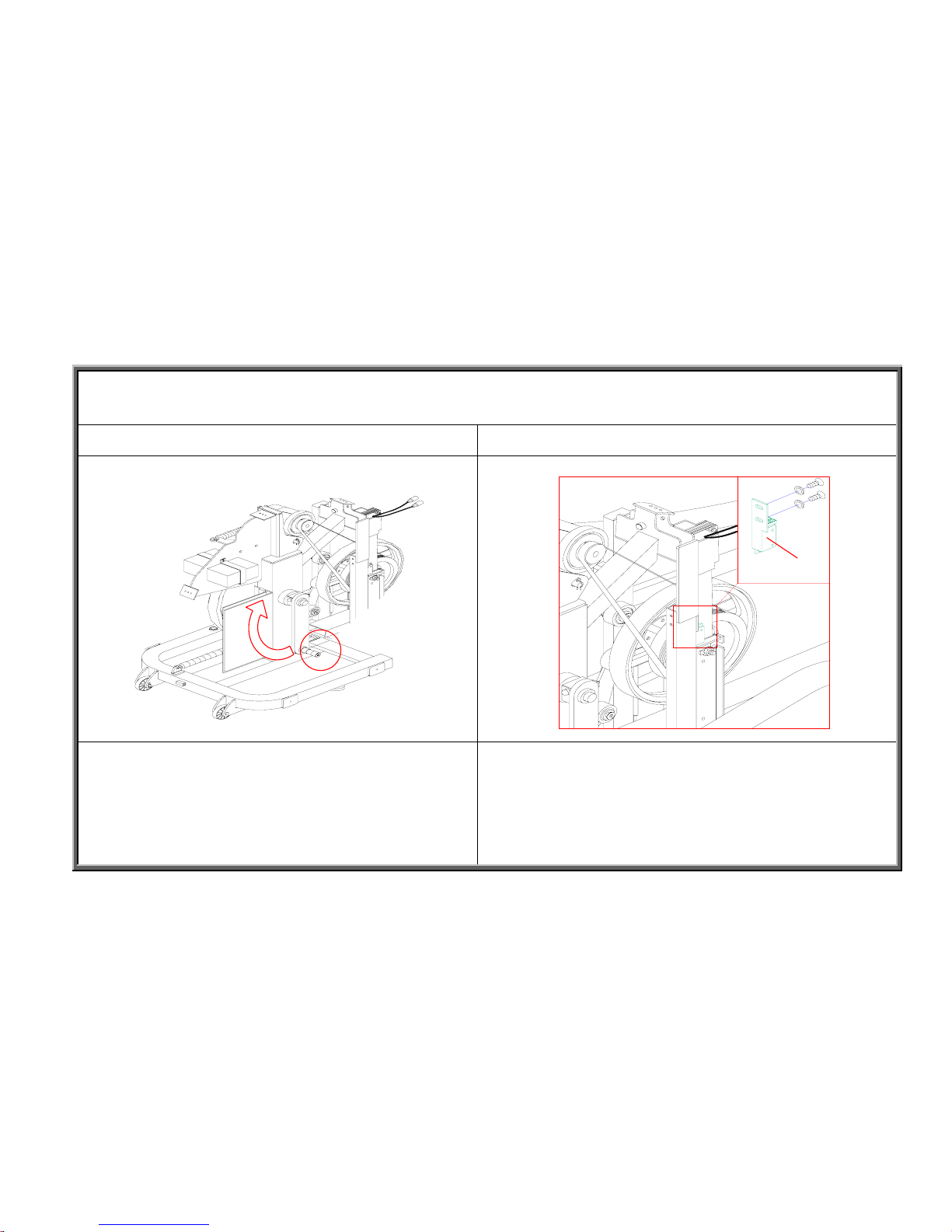

8300 Component Removal and Installation Procedures

Stride Motor Removal and Installation

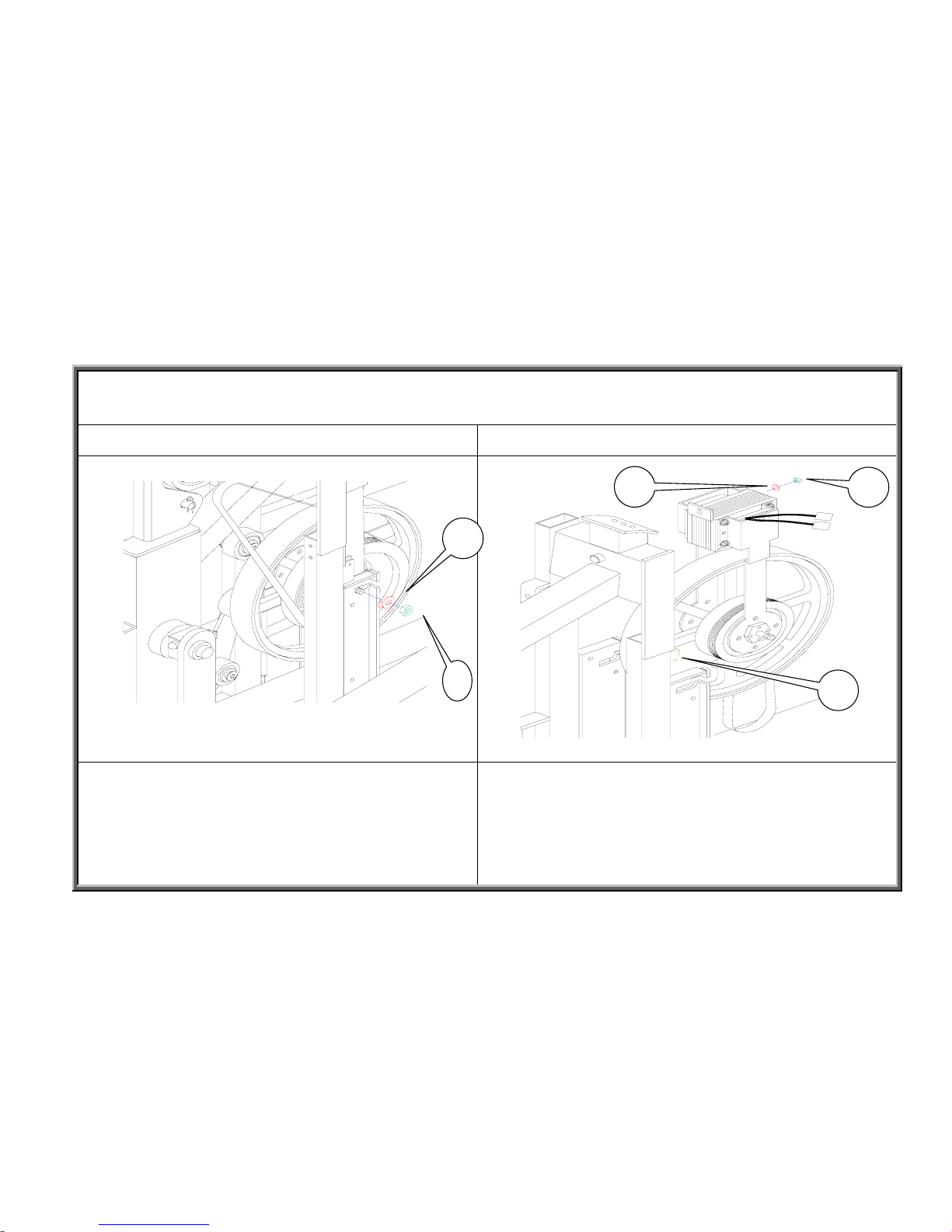

Step 6 Step 7

Remove the mushroom-head Phillips screws shown above

(A). Pull the stride motor set upward to remove it.

Note: In removing the stride motor set, push up on the

stride motor connection pin. Do not pull on the wires on

top.

First, remove the protective bracket on the stride motor set.

Apply bearing grease to the worm gear and rollers. Then

insert the stride set into the stride support arm.

Note: Do not change the relationship of the brass stem to the

motor; ERR7 may result. Also, do not change the worm gear

position; The stride height may become uneven or jam.

2-2-4

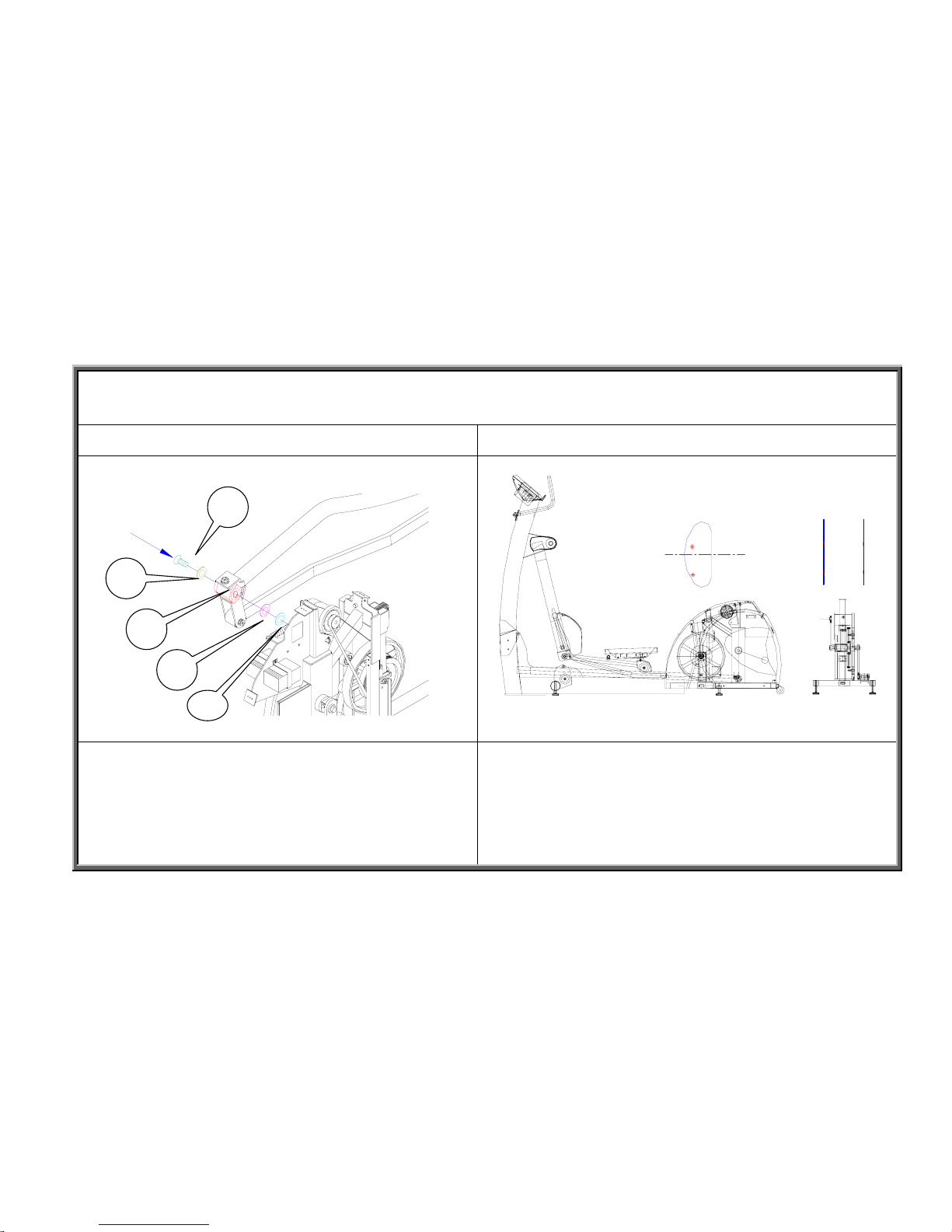

SportsArt America

8300 Component Removal and Installation Procedures

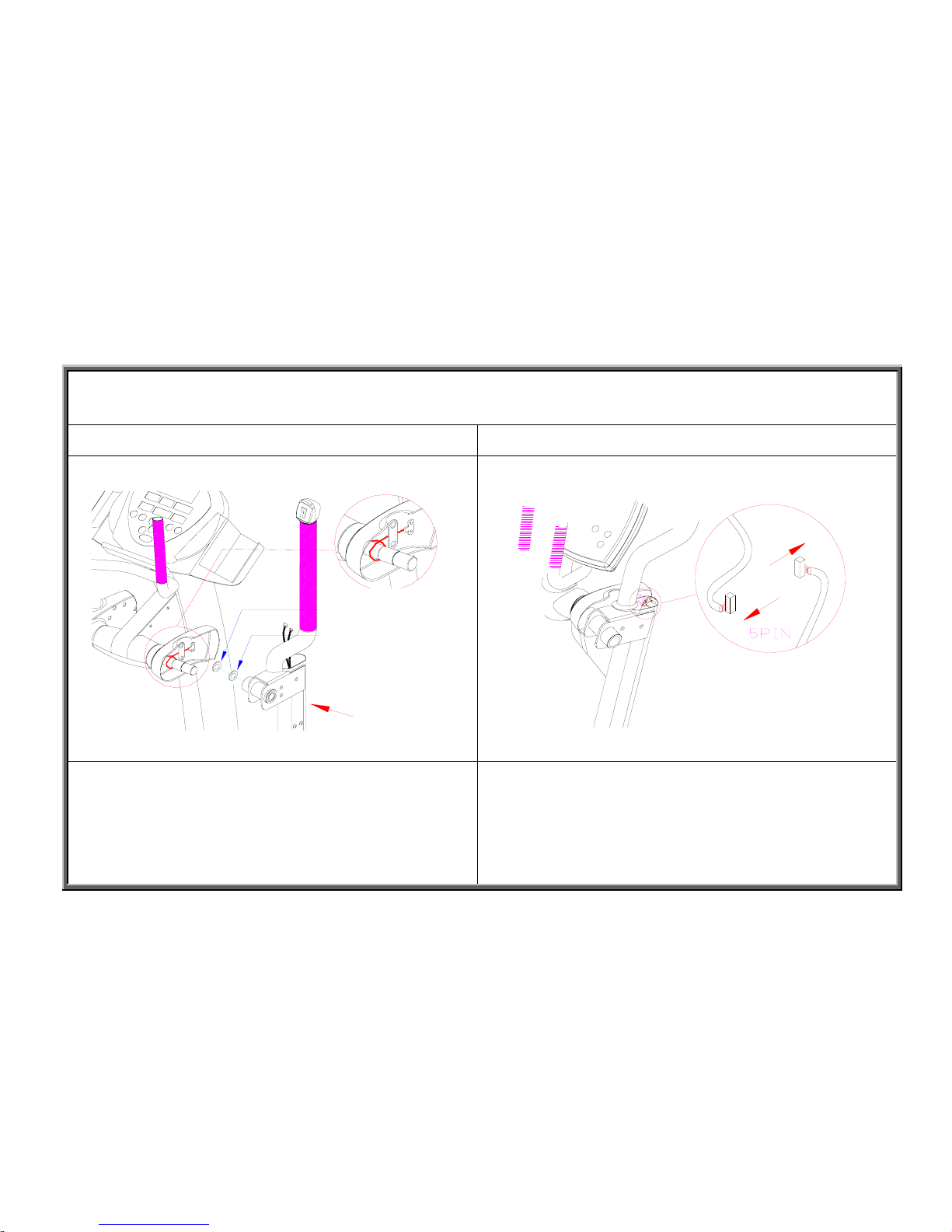

Stride Motor Removal and Installation

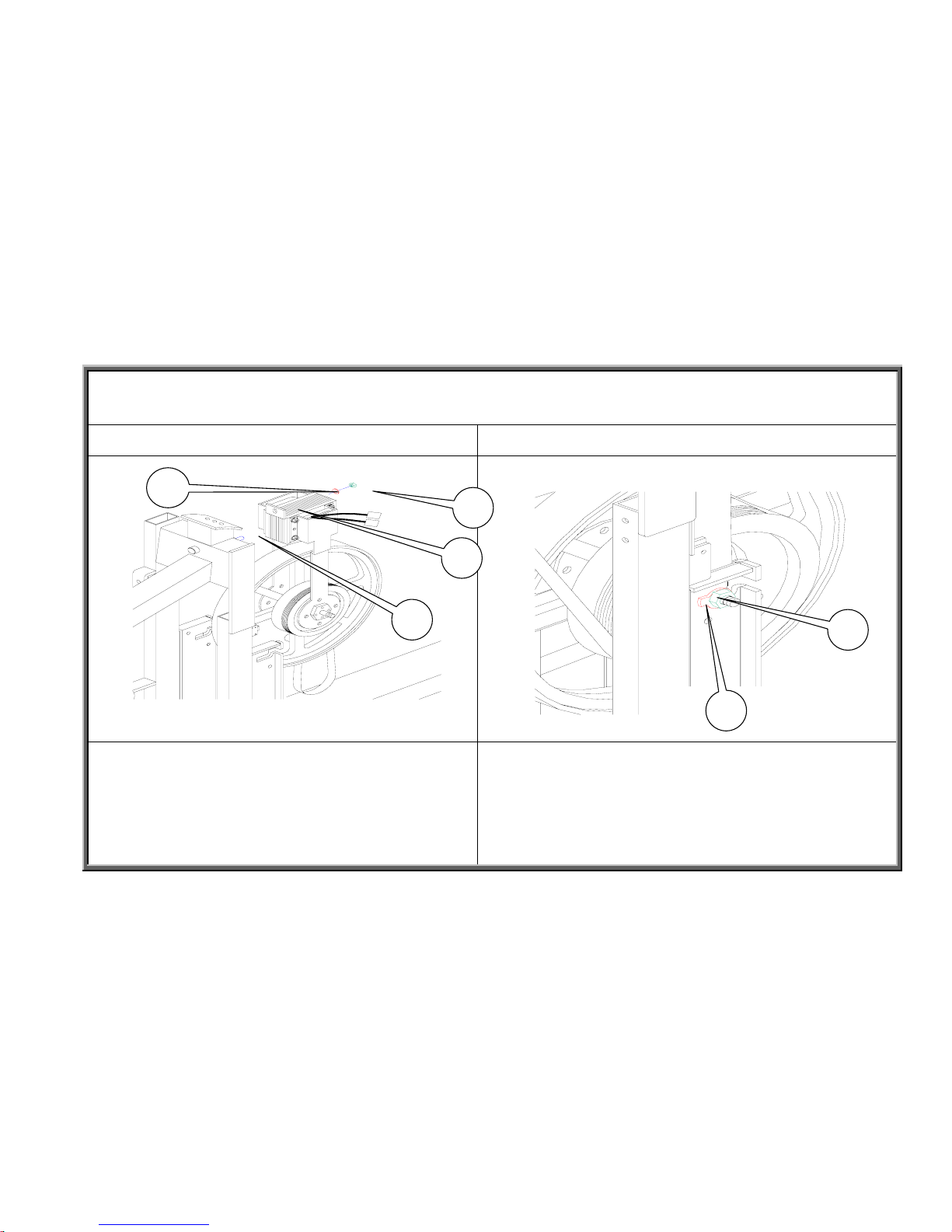

Step 8 Step 9

In installing the stride motor set, note that the stride linkage

connector must face the stride linkage.

Note on alignment: The zirc fitting faces forward and the

stride linkage connector faces inside.

Use the stride linkage connector to guide the stride motor

set into place in the stride support arm. Then attach the

mushroom-head Phillips screws as shown. (Hex head screws

were later used in this spot.)

Note: In adjusting the stride motor set position in the support

arm, do not pull the wires; the VR circuit board might break.

2-2-5

馬達

軸心

油嘴

Motor

Connector

Zirc fitting

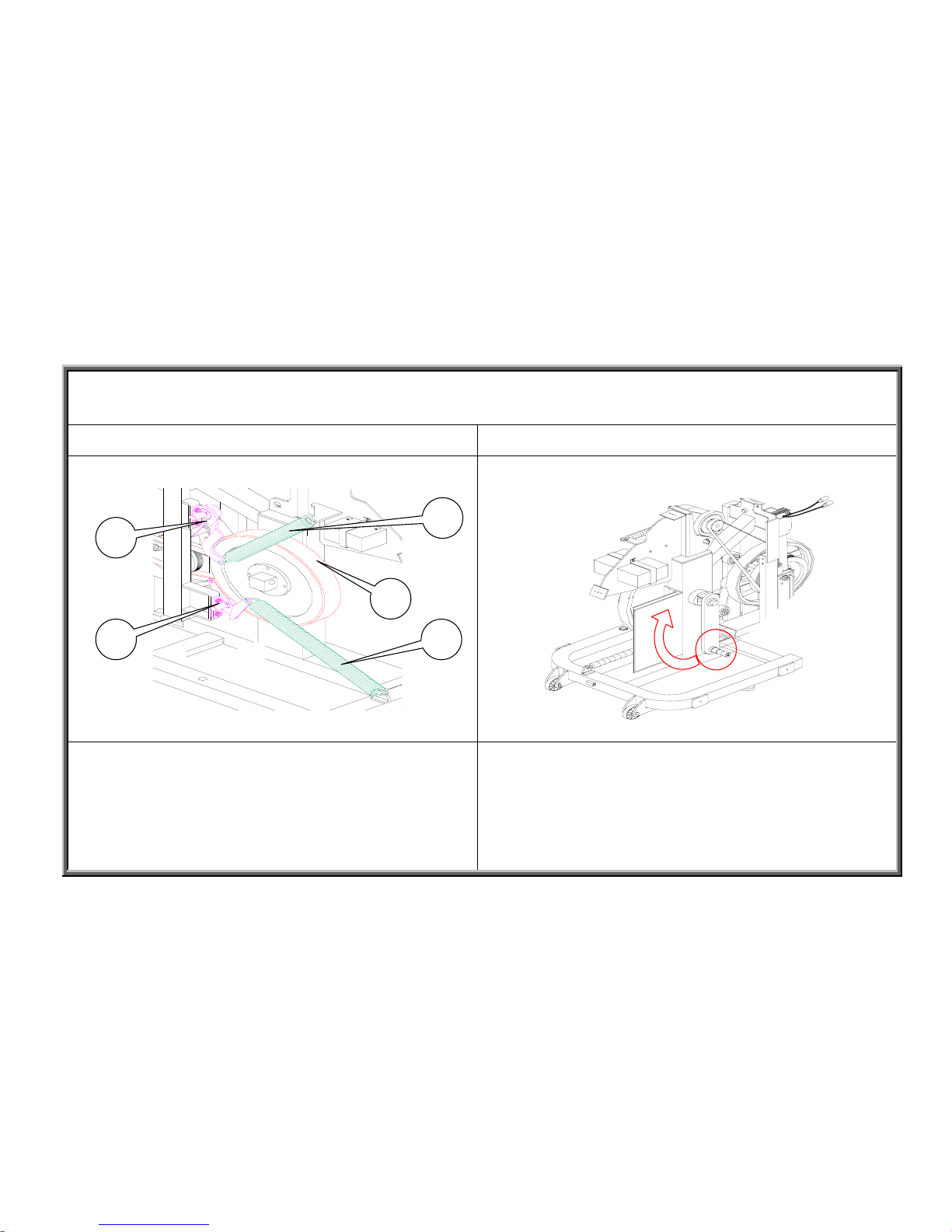

SportsArt America

8300 Component Removal and Installation Procedures

Stride Motor Removal and Installation

Step 10 Step 11

Before installing the stride support assembly, put the washers

in place on the pedestal shaft, with the regular washer on the

inside and the Teflon washer facing the stride support

assembly.

Note: Make the Teflon side face the stride support assembly.

Note: If the tape on the shoulder cover becomes detached, wrap the

wires around the shaft once, pushing them forward, then under and up.

Connect the VR, motor, and switch wires, then stuff the

connectors into the stride support arm.

2-2-6

A

B

SportsArt America

8300 Component Removal and Installation Procedures

Stride Motor Removal and Installation

Step 12 Step 13

Put the stride support assembly in place. Put on washers as

follows: Teflon washer (A), Teflon side facing the stride

support assembly, black washer (B), wave washer (C), black

washer (B), and C-clip (D). Finally, put the sleeve (E) in

place, then tighten the screw (F).

Put the outer cover in place. Screw in the five screws. An

d

remove the tape.

2-2-7

A

B

C

B

D

E

Tape

SportsArt America

8300 Component Removal and Installation Procedures

Stride Motor Removal and Installation

Outer Cover Screws Step 14

First screw in the metal screws (2), then the sharp screws (1). Install the stride linkage as shown. Put the flat washer (B) on

the stride linkage screw (A), and tighten down the screw.

Then put cover (C) in place.

2-2-8

C

B

SportsArt America

8300 Component Removal and Installation Procedures

8300 Stride Motor Removal and Installation

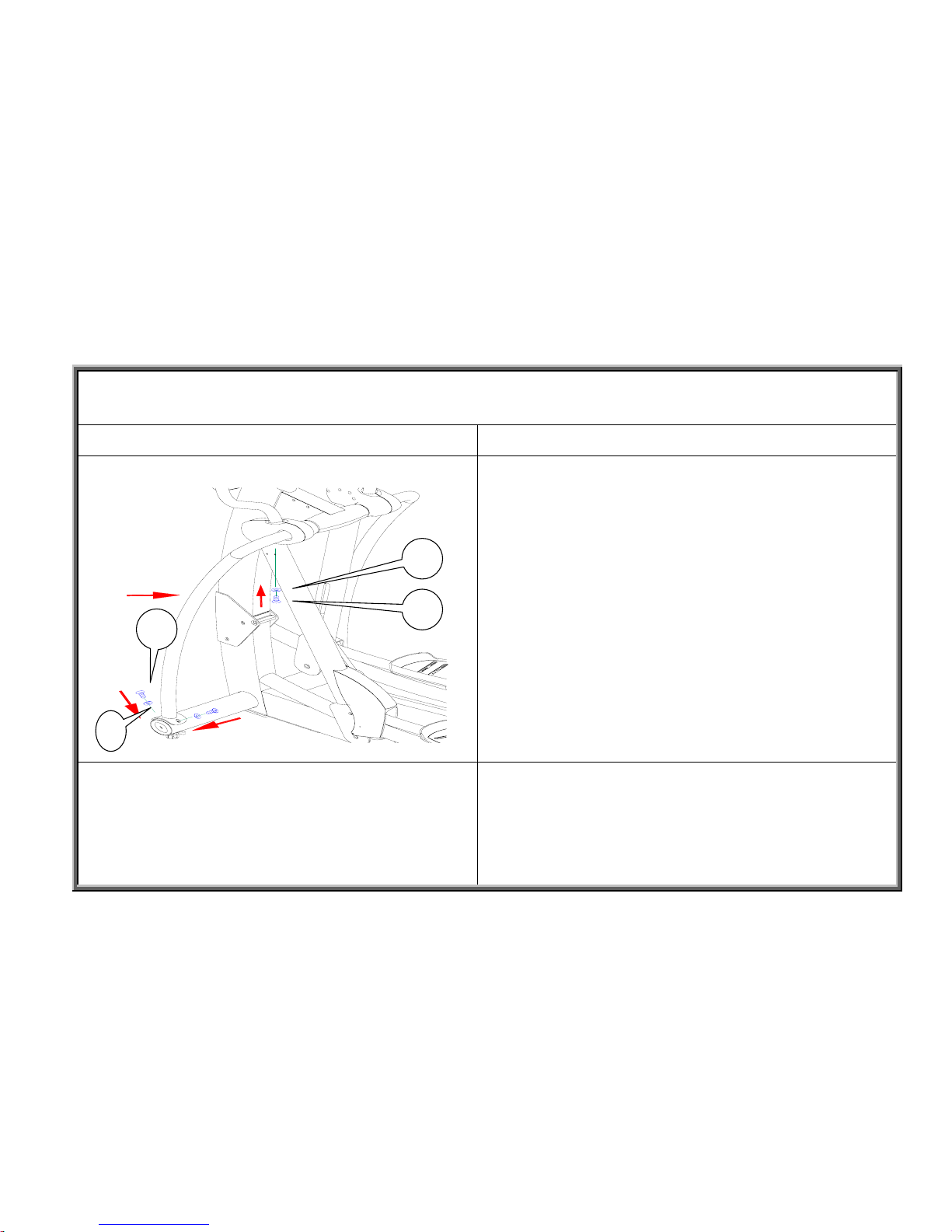

Step 15

Put support arms in place. Then tighten support arm screws

to complete the job.

A. Mushroom-head hex screws (5/16”*L19)

B. Support washer (D18*d8.5*t2); support washer

(D20*d7*t2.0)

C. Mushroom-head inner hex screw (1/4”*L3/4”)

2-2-9

A

B

C

D

SportsArt America

8300 Component Removal and Installation Procedures

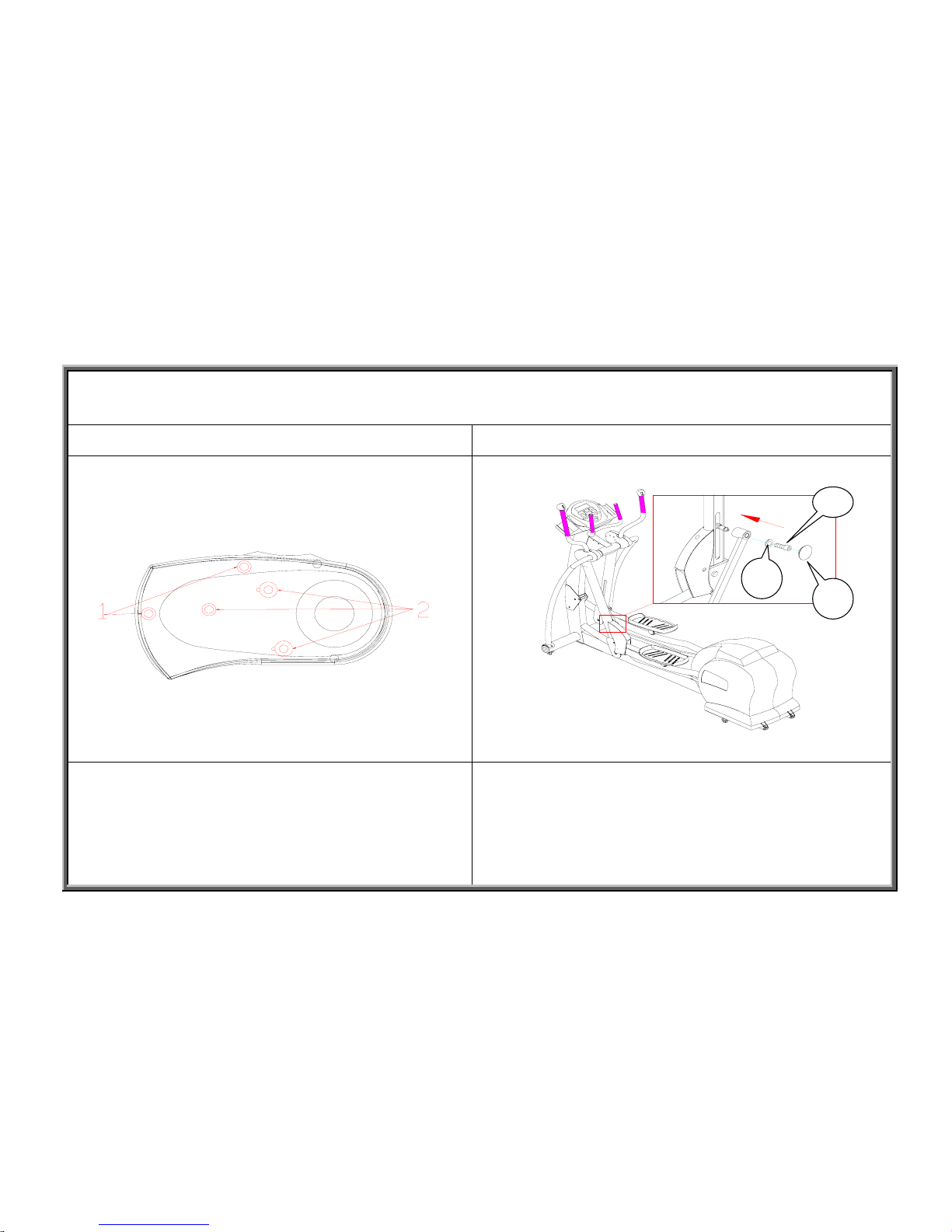

Flywheel Removal and Installation

Step 1 Step 2

Remove the 14 mushroom-top Phillips-head screws (A)

from the rear cover, and remove the cover from the unit as

shown.

Remove the mushroom-top Phillips-head metal screws (A)

from the guard panel (A) and remove the finger guard as

shown.

2-3-1

B

SportsArt America

8300 Component Removal and Installation Procedures

Flywheel Removal and Installation

Step 3 Step 4

Remove the mushroom-top inner hex screw from the

left-side knuckle, and pull the knuckle off the crank.

Note: If necessary, adjust the knuckle so it slides out easily.

Parts: Spindle washer A; Wave washer B; Knuckle C; Flat

washer D; Mushroom-top inner hex screw

Loosen the nut (C) and screw (A) that attaches the generator

(B) to the unit frame. Then remove the drive belt (440J5).

Note: it is not necessary to totally remove the screw and nut as

shown in the picture. Just loosen them.

2-3-2

A

B

C

D

E B

A

C

SportsArt America

8300 Component Removal and Installation Procedures

Flywheel Removal and Installation

Step 5 Step 6

Detach the idler pulley springs (A), and remove the

multi-channel belt (B) (460J7).

Note: When removing idler pulley springs, pull from both

ends to maintain even pressure, preventing the springs

from loosing their flexibility and wearing out early.

Disconnect the magnet wires as shown.

2-3-3

A

B

SportsArt America

8300 Component Removal and Installation Procedures

Flywheel Removal and Installation

Step 7 Step 8

Remove the flywheel nut (B) and washer (A). Remove the nut (B) and washer (C) that secures the flywheel

in place. Then remove the flywheel.

Note: Be careful not to hit the optic sensor (A) when

removing the flywheel.

2-3-4

A

B

A

B

C

SportsArt America

8300 Component Removal and Installation Procedures

Flywheel Removal and Installation

Step 9 Step 10

Insert the axle of the new flywheel into the flywheel

bracket on the frame. Lift the magnet (D) up into the

flywheel attachment screw (C). Install flywheel washer (B)

and nut (A) to the screw.

Put the flywheel washer (B) in place on the axle, with the

washer protrusion facing back, then hand-tighten nut (A) into

place. Press the flywheel toward the back of the unit. Make

sure that the flywheel fits well at the attachment point by the

magnet and at the axle. Tighten the nuts on both sides of the

flywheel and at the attachment screw by the magnet.

2-3-5

A

B

A

B

C

D

SportsArt America

8300 Component Removal and Installation Procedure

Flywheel Removal and Installation

Step 11 Step 12

Connect magnet wires as shown. Put the drive belt (B) (440J5) in place, making sure that it

meshes well on the drive pulley. Then gradually tighten nut (C)

onto the generator screw (A).

Note: Tighten nut (C) just to the point that the belt doesn’t

jump or shudder when the flywheel rotates forward or

backward.

2-3-6

A

C

B

SportsArt America

8300 Component Removal and Installation Procedures

8300 Flywheel Removal and Installation

Step 13 Step 14.1

Put belt (C460J7) onto the wheel and adjust the idler pulleys

(A) so the belt sits well. Rotate the flywheel (C) so the belt

meshes, then put idler pulley springs (B) in place.

Note: Pull both ends of the spring to keep the pressure

even and prevent it from losing flexibility.

Inspect the Installation

1. Turn the crank arm: Inspect the flywheel movement.

If not normal, adjust the belt and idler pulleys.

2-3-7

A

A

B

C

SportsArt America

8300 Component Removal and Installation Procedures

Flywheel Removal and Installation

Step 14.2 Step 14.3

Inspect the Installation

2. Rotate the crank and press the LEVEL up key on the

display. Inspect whether resistance increases. If not, inspect

whether wires are properly installed and connected.

Inspect the Installation

3. Rotate the crank and inspect whether a steps-per-minute

value appears on the display. If not, adjust the distance

between the optic sensor and the sticker on the flywheel to

within 3 mm (1/4 inch).

2-3-8

A

SportsArt Industrial

8300 Component Removal and Installation Procedures

Flywheel Removal and Installation

Step 15 Step 16

Install washer (A) and wave washer (B) onto the crank

arm. Then install the left side of the knuckle (C) onto the

crank arm. Finally, put on the flat washer (D), and tighten

the mushroom-head inner hex screw (E).

Note: If the glide rail does not install easily, jiggle the

knuckle.

Put the guard panels in place and screw in their mushroom-top

Phillips-head metal screws.

Note: The flat surface faces the rear; The screw hole

protrusions face the inside of the unit; Screw holes are toward

the lower part of the panel. If installed incorrectly, the unit

covers cannot be installed.

2-3-9

B

C

D

E

SportsArt America

8300 Component Removal and Installation Procedures

Flywheel Removal and Installation

Step 17

Install rear covers onto unit. Tighten the mushroom-head

Phillips screws to complete the job.

Note: The cover attachment plate on the unit frame has

three holes in it, making it easy to screw the cover onto the

wrong hole. As a rule, use the screw hole on the right.

2-3-10

SportsArt America

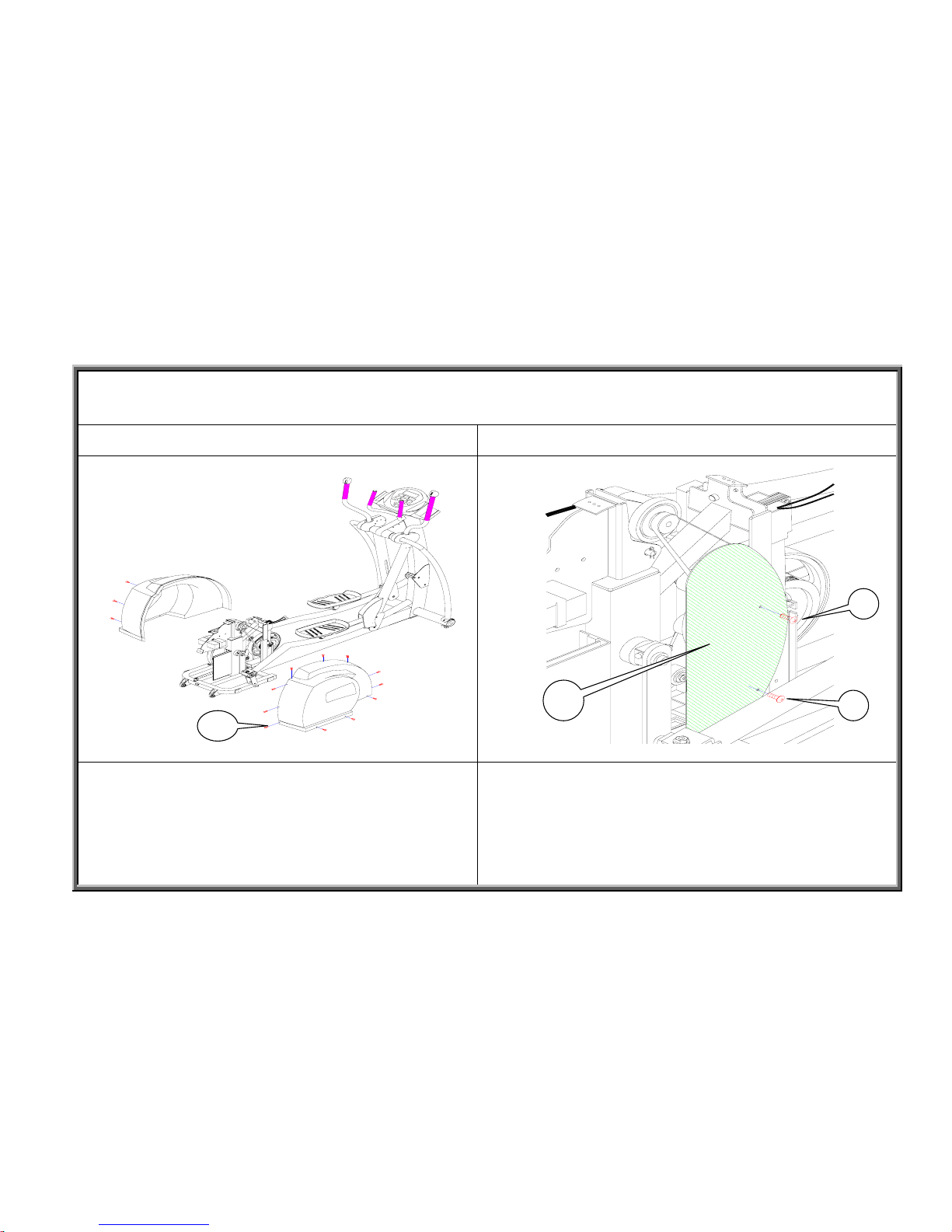

8300 Component Removal and Installation Procedures

8300 Flywheel Washer Removal and Installation

Step 1 Step 2

Remove the 14 mushroom-top, Phillips-head screws (A)

from the cover, then remove the cover as shown.

Remove the mushroom-top, Phillips-head metal screws (A)

from the finger guard (B). And remove finger guards from both

sides as shown.

2-4-1

B

SportsArt America

8300 Component Removal and Installation Procedures

Flywheel Removal and Installation

Step 3 Step 4

From the left side glide rail, remove the mushroom-top

inner hex screw. Then remove the glide rail.

Note: Adjust the knuckle to remove the glide rail easily.

A = Spindle washer: B=Wave washer; C=Knuckle

D=Flat washer; E=Mushroom-top inner hex screw.

Loosen the outer hex-head screw (A) and nut (C) from the

generator (B) bracket, then remove the drive belt (440J5).

P.S. Loosen the generator screw (A) and nut (C). There’s no

need to take them all the way off.

2-4-2

A

B

C

D

E B

A

C

SportsArt America

8300 Component Removal and Installation Procedures

Flywheel Washer Removal and Installation

Step 5 Step 6

From the left side, remove the idler pulley springs (A) and

the multi-channel belt B(460J7).

P.S. Pull springs from the ends to keep pressure even and

preserve spring life.

Remove the nut (B) and flywheel washer (A).

2-4-3

A

B

B

A

SportsArt America

8300 Component Removal and Installation Procedures

Flywheel Washer Removal and Installation

Step 7 Step 8

Put the flywheel washer (C) in place on the spindle

(B), inserting the protruding part of the washer

toward the rear of the unit. Then hand-screw the nut

(A) in place. Push the flywheel toward the rear of the

unit. Make sure that the washer meshes into the

bracket in the frame. Tighten the nut.

Put generator belt B(440J5) in place. Rotate the flywheel to

make sure that the belt channels mesh in the grooves.

Gradually tighten nylon lock washer (C) onto the bolt (A)

with an inner hex head.

Note: Tighten until the flywheel rotates smoothly in both

directions without jumping.

2-4-4

A

B

C

B

C

A

SportsArt America

8300 Component Removal and Installation Procedures

Flywheel Washer Removal and Installation

Step 9 Step 10.1

Install the multi-channel belt (C460J7) onto the flywheel.

Adjust the idler pulleys (A) so that the idler pulleys ride on

the outside of the belt. Rotate the flywheel to make sure that

the belt and flywheel mesh well. Then put springs (B) into

place.

Note: Pull springs from the ends to maintain even pressure

and prevent springs from wearing out.

Inspect the work:

1. Turn the crank. Inspect whether the multi-channel belt

rotates smoothly.

If not, adjust the multi-channel belt and idler pulleys.

2-4-5

A

A

B

B

C

Loading...

Loading...