SportsArt Fitness 6100, 6100E, 6150, 6150E Repair Manual

6100/E/6150/E Treadmill Repair Guide

SPORTS ART INDUSTRIAL CO., LTD.

SPORTS ART INDUSTRIAL CO., LTD.

6100/E/6150/E Series Treadmill Repair Guide

Chapter 1. Treadmill Configuration and Wiring Diagrams

Chapter 2. Operation

Chapter 3. Error Message Definitions

Chapter 4. Measuring and Testing

0-0-1

6100/E/6150/E

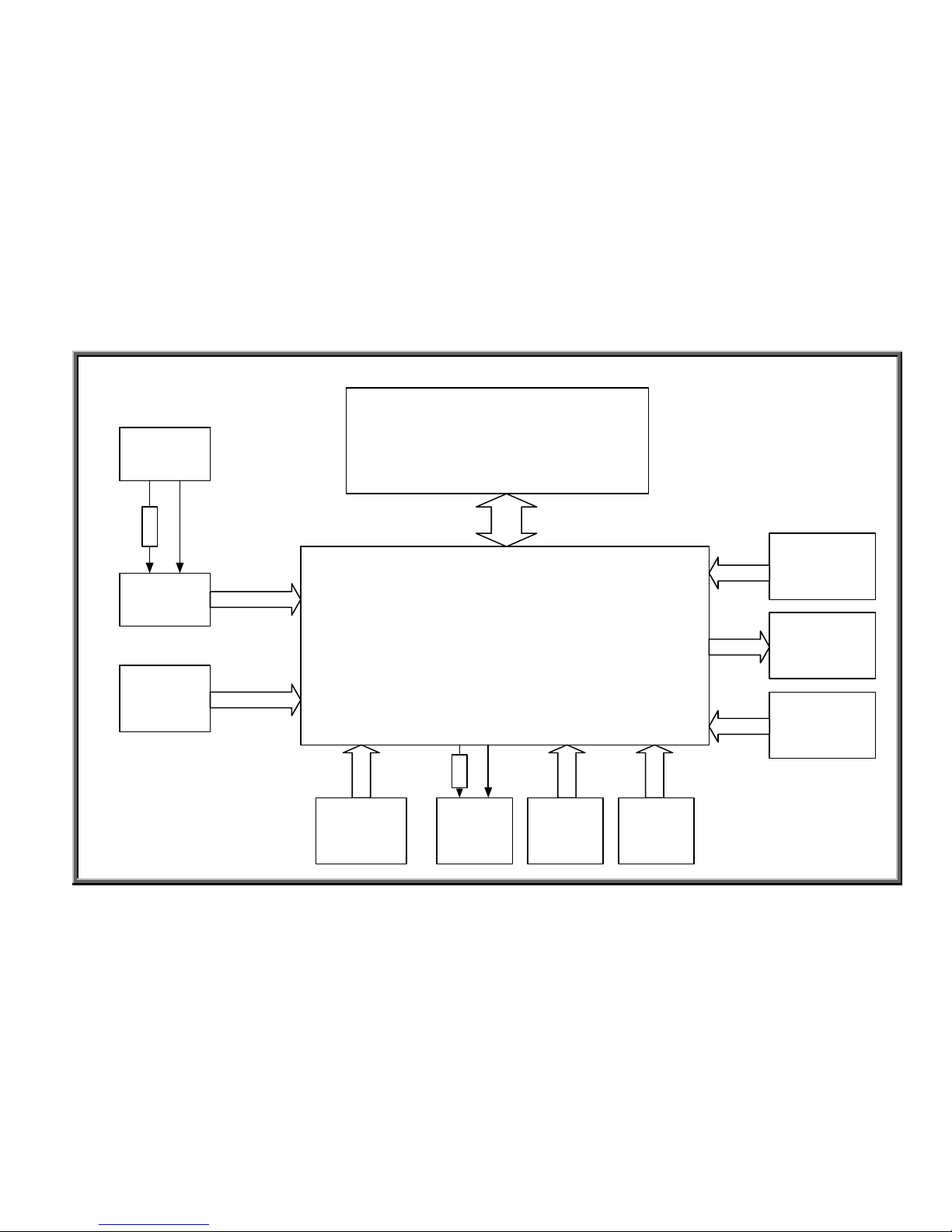

1. Treadmill Configuration and Wiring Diagram

SPOR TS AR T INDUSTRIAL CO., L TD.

SPORTS ART INDUSTRIAL CO., LTD.

6150E/6100E Treadmill

1-1-1

SPORTS ART INDUSTRIAL CO., LTD.

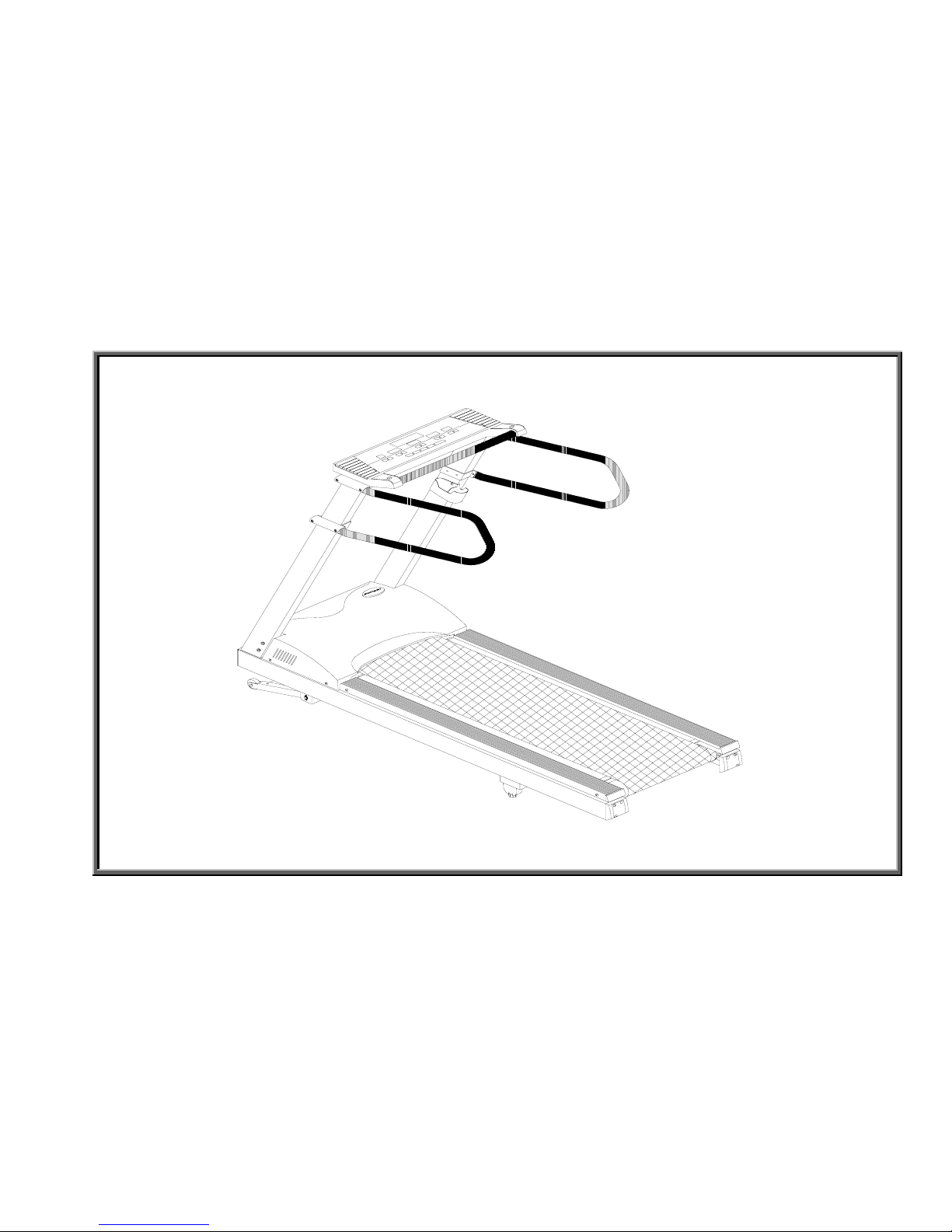

6150E/6100E Treadmill Electronic Component Placement Diagram

1-2-1

Display Window

HTR Handlebar

Motor

Optic Sensor

+Tachometer

Incline VR

Fuse Socket

On/off Switch

Inductor

(220V)

Resistance Resistor

Transformer

Drive Board

Incline Motor Set

Power Filter

SPORTS ART INDUSTRIAL CO., LTD.

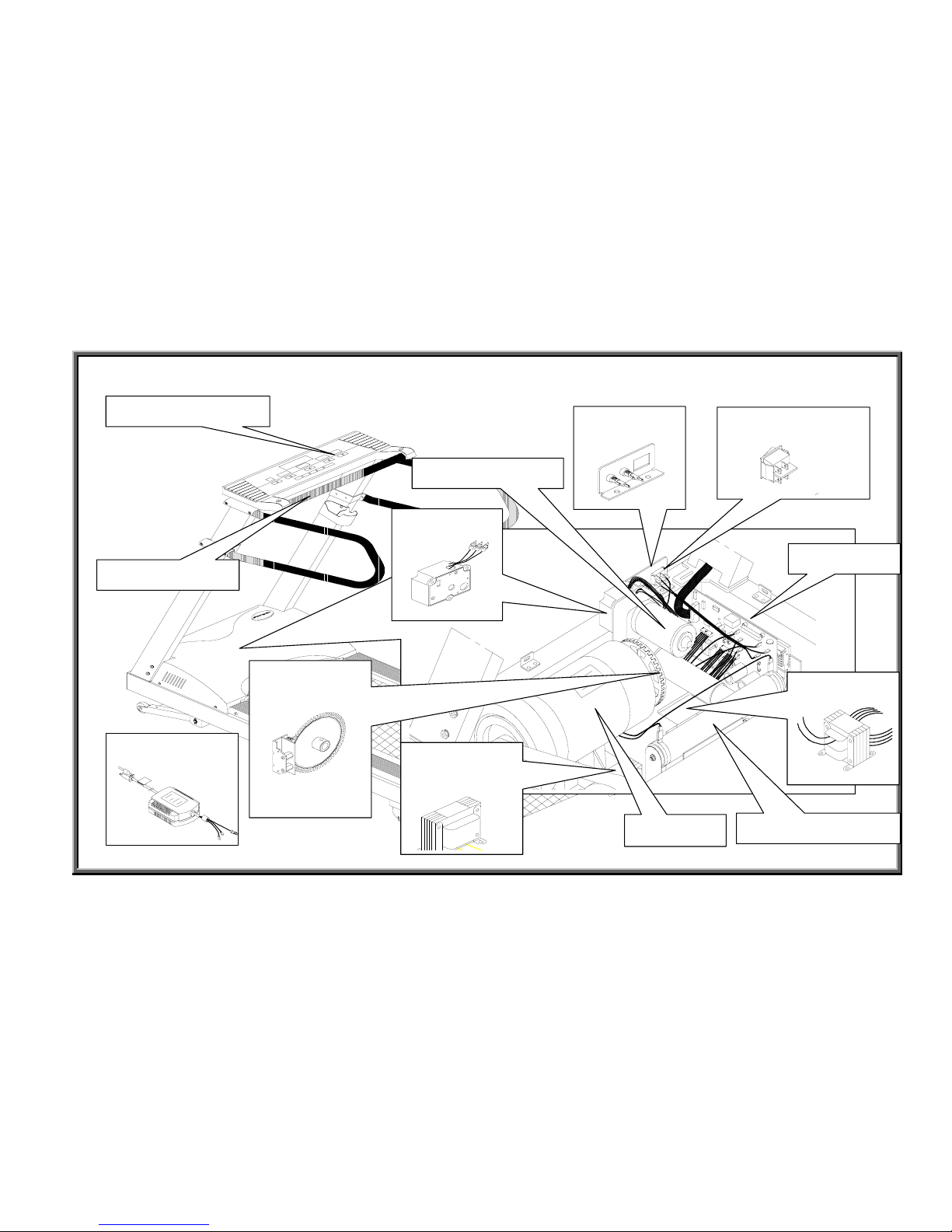

6150/E/6100/E Treadmill Configuration

Display

Drive Board

Motor

Optic Sensor

Large

Resistor

(FUSE)

Transformer

Incline

Motor

Incline

VR Set

Inductor

(220V)

Incline

LIMIT

Switch

Power Cord

(Filter)

On/Off

Switch

2-PIN

3-PIN

2-PIN

16- PIN

Cable

2-PIN

2-PIN

3-PIN

FUSE

2-PIN

10-PIN

FUSE

1-3-1

SPORTS ART INDUSTRIAL CO., LTD.

6150/E/6100/E Display Board Wiring Connection Diagram

6150 Soft Keys

HTR BOARD

HTR HANDLEBAR HTR HANDLEBAR

STOP

Board

STOP

Board

POLAR Receiver

K1K2

STOP

1

STOP2

CNT3

CNT1

CN1

CN2

CN3

6150 Display Board Backside

POLAR RECEIVER

TO Drive

Board

16-PIN

1-4-1

SPORTS ART INDUSTRIAL CO., LTD.

6150/E/6100/E Drive Board Wiring Connection Diagram

Large

Capacitor

Power

Switch

Inductor

(

220V)

Incline Set

(Motor

,VR,

LIMIT Switch)

Transformer

Display

Board

Motor

Optic

Sensor

1

6

P

I

N

7 pin

7 pin

Power Cor

d

and Filter

FUSE

4

p

i

n

1-5-1

SPORTS ART INDUSTRIAL CO., LTD.

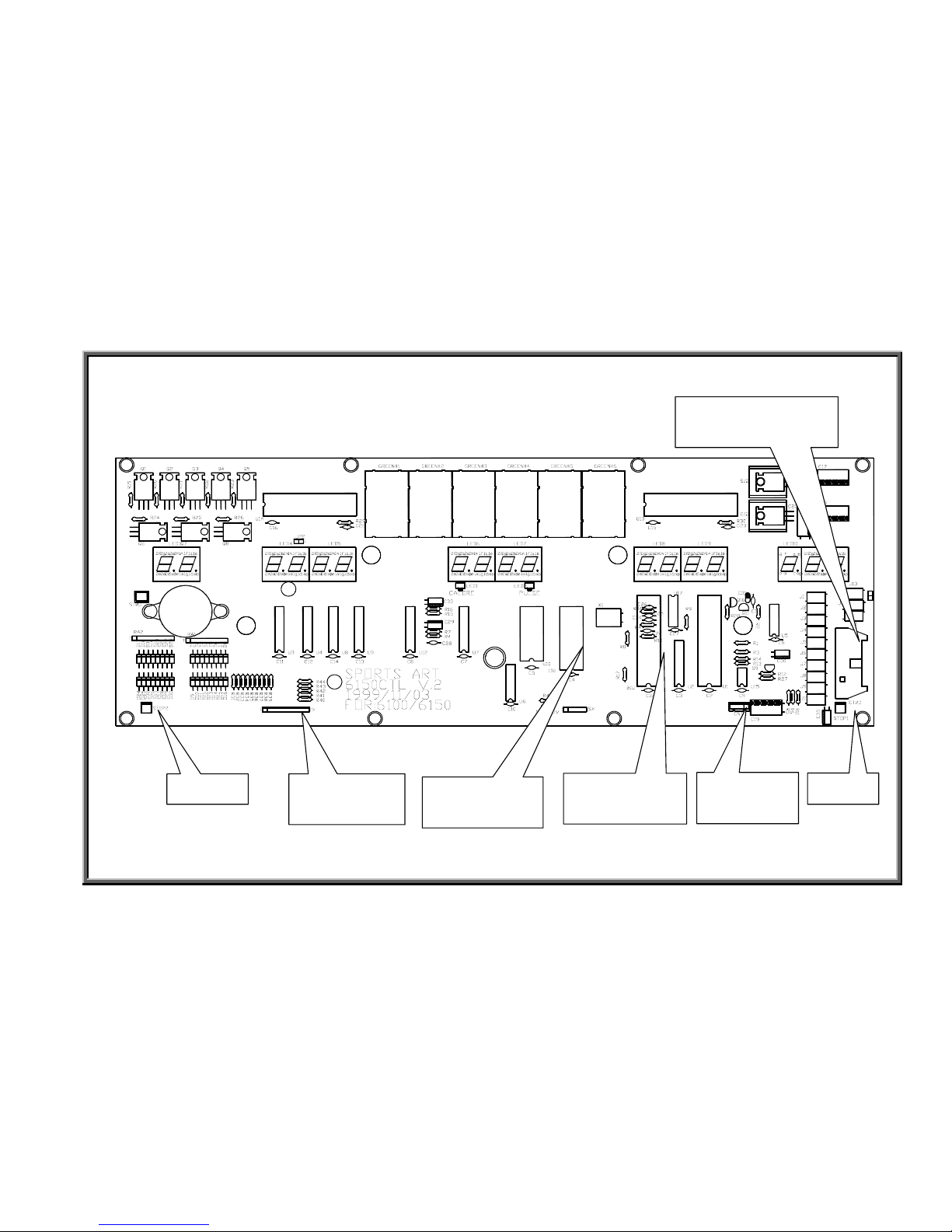

6150/E/6100/E Display Board Component Placement Diagram

1-6-1

CNT3 16-PIN

Cable Connector

STOP1

CNT1

Heart Rate

U16

Motor Program

U11

Main Program

K1, K2

Soft Keys

STOP2

SPORTS ART INDUSTRIAL CO., LTD.

6150/E/6100/E Drive Board Component Placement Diagram

1-7-1

EMG LED

Incline UP LED Incline DN LED

Incline ERR

LED

POWER LED

SPORTS ART INDUSTRIAL CO., LTD.

6150/E Display Panel

1-8-1

SPORTS ART INDUSTRIAL CO., LTD.

6100/E Display Panel

1-9-1

6100/E/6150/E

2. Operation

SPORTS ART INDUSTRIAL CO., LTD.

6100/E/6150/E

2. Operation

SPORTS ART INDUSTRIAL CO., LTD.

SPORTS ART INDUSTRIAL CO., LTD.

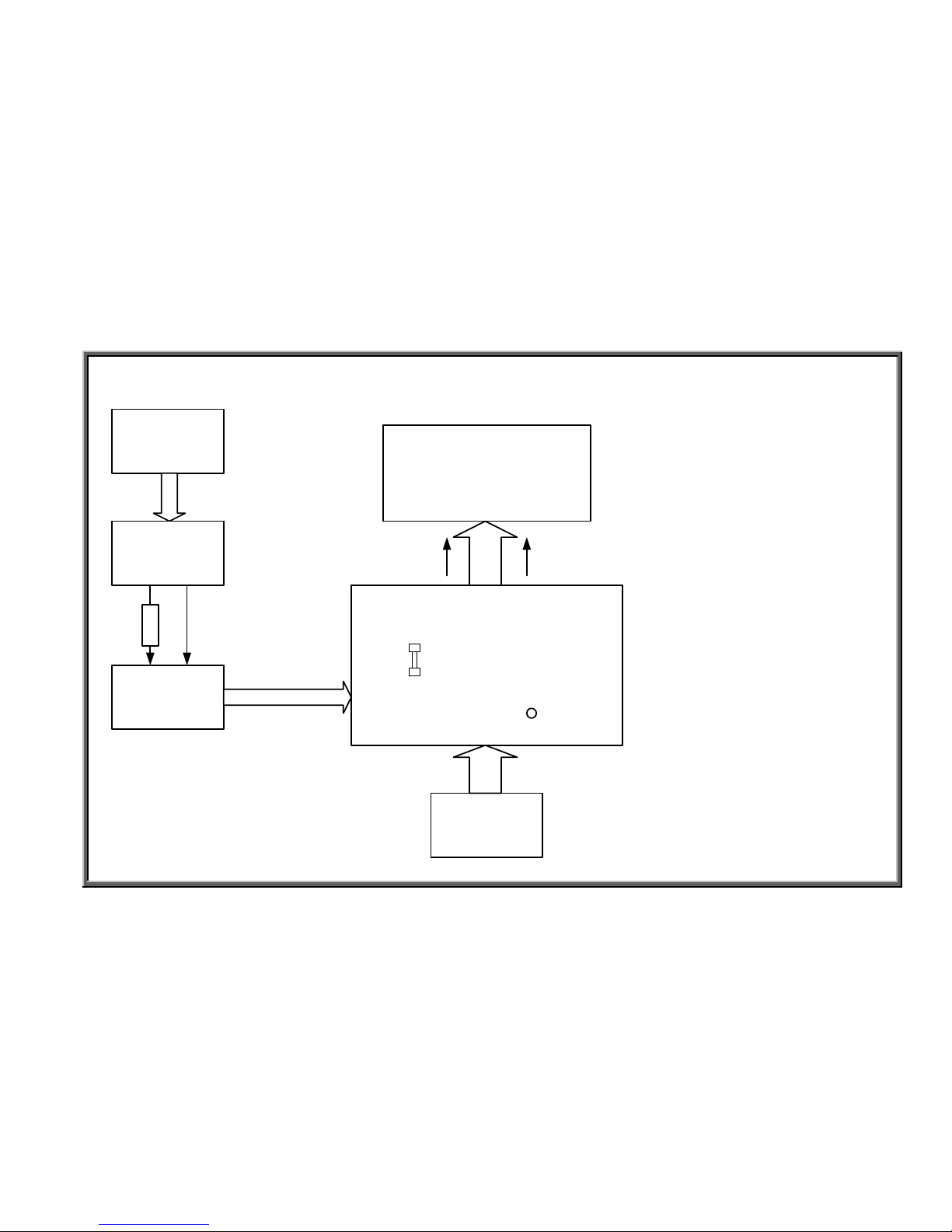

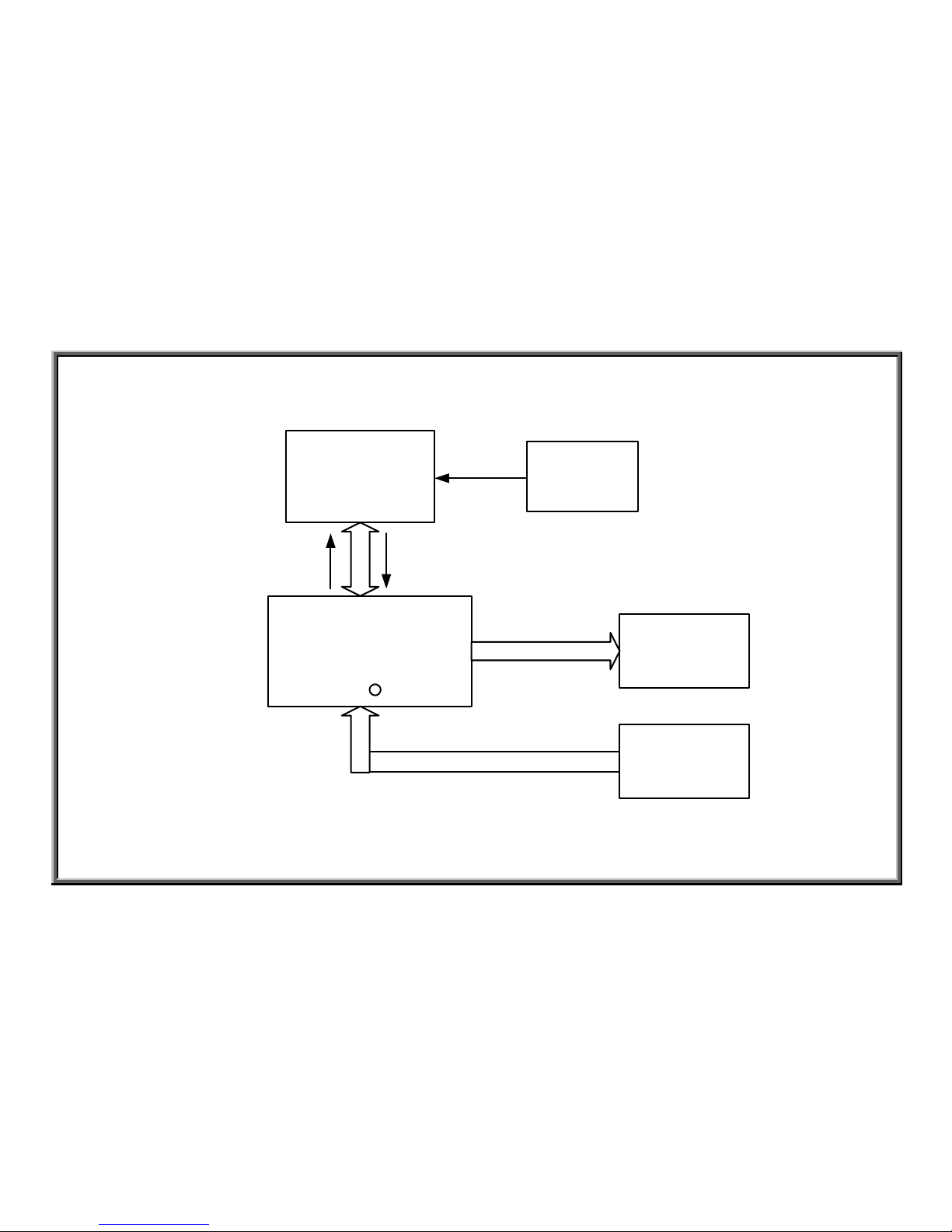

6150/E/6100/E Voltage Flow Chart

1. Configuration

DISPLAY BOARD

DRIVE BOARD

TRANSFORMER

POWER CORD

POWER

VBB 12VVCC 5V

FILTER

(CE)

ON/OFF

SWITCH

FUSE

AC1,AC2

VAC

F1

2-1-1

SPORTS ART INDUSTRIAL CO., LTD.

2. How the Unit Operates

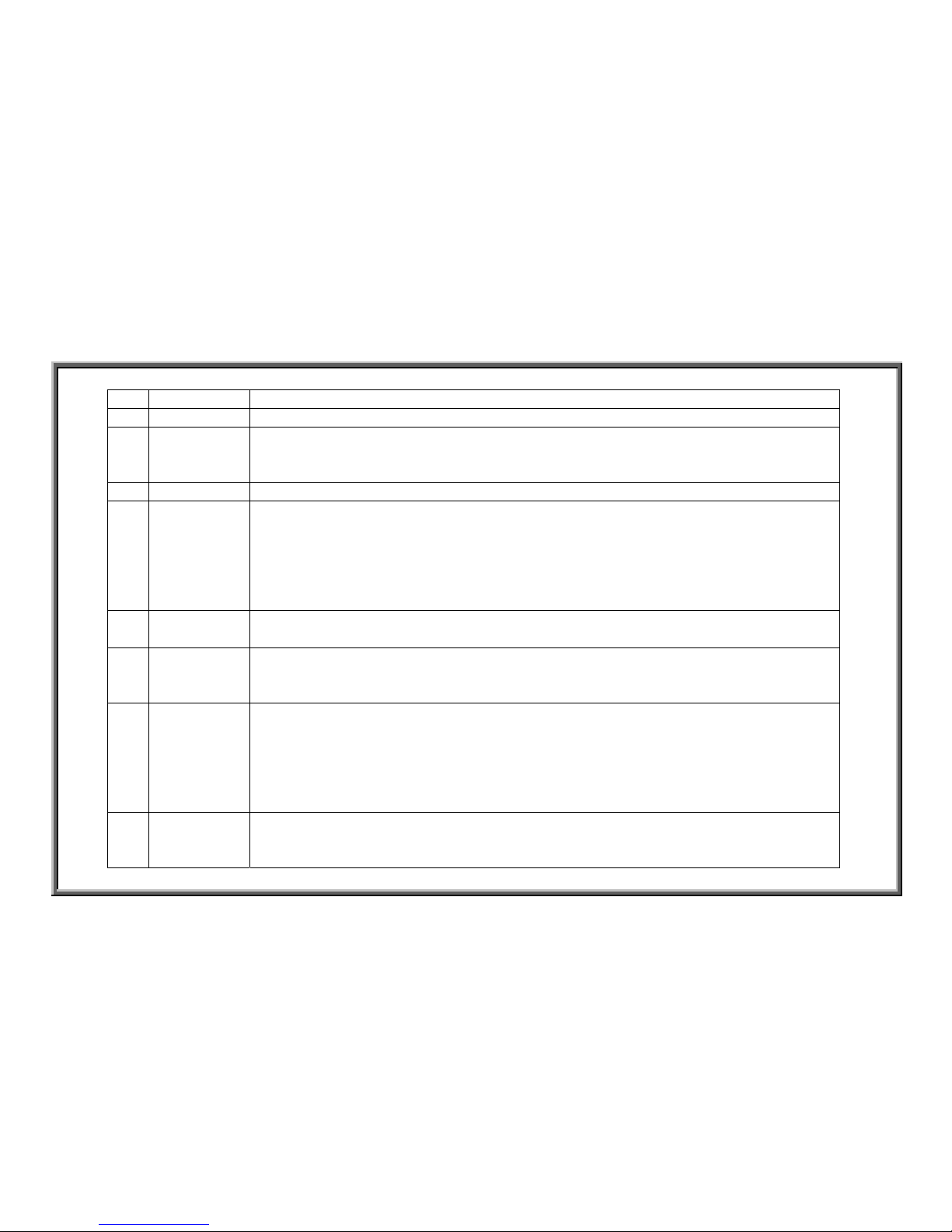

Order Name Operation

1 Power Cord 1. Brings power in from the power supply.

2 Filter 1. Filters power, preventing interference (220V CE products only).

3 Fuse 1. Prevents damage to components from high current.

4 Power Switch 1. Turn power on “1”; power switch lights; power comes from the

filter into the unit.

2. Turn power off “0”; power switch doesn’t light; power doesn’t

come from the filter into the unit.

5 Drive Board 1. Drive board has sent AC power through the fuse F1 to the

transformer connector.

2. After the transformer power enters the drive board, the power is

stabilized as VCC, VBB, which supplies drive and display board

power.

3. VCC and VBB power go through the 16-PIN cable to the display

board.

6 Transformer 1. Takes power voltage from high volt AC1, AC2 to low voltage,

supplying power to components.

7 Display Board 1. VCC and VBB power are supplied to the display board CPU to

activate the unit.

2. The display windows light up once it has power.

2-1-2

SPORTS ART INDUSTRIAL CO., LTD.

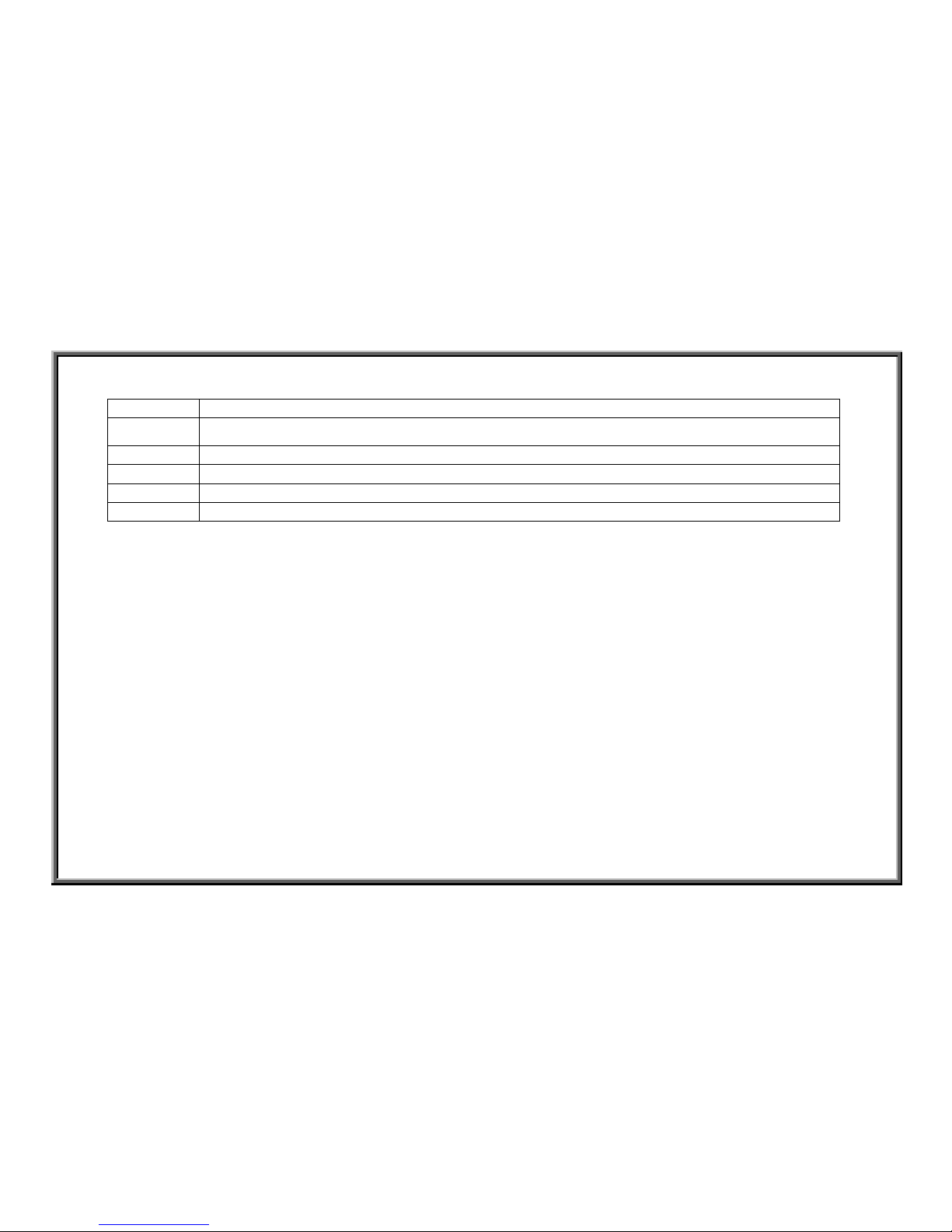

3. Operational Procedure

Step Operation

1

Plug unit into power supply.

2

Turn on power, flipping switch to ”1”; power light lights.

3

Drive board POWER LED lights.

4

Display board screen shows ”MAN’L”.

5

Turn off power switch, flipping switch to ”0”; power light doesn’t light; display

doesn’t light.

2-1-3

SPORTS ART INDUSTRIAL CO., LTD.

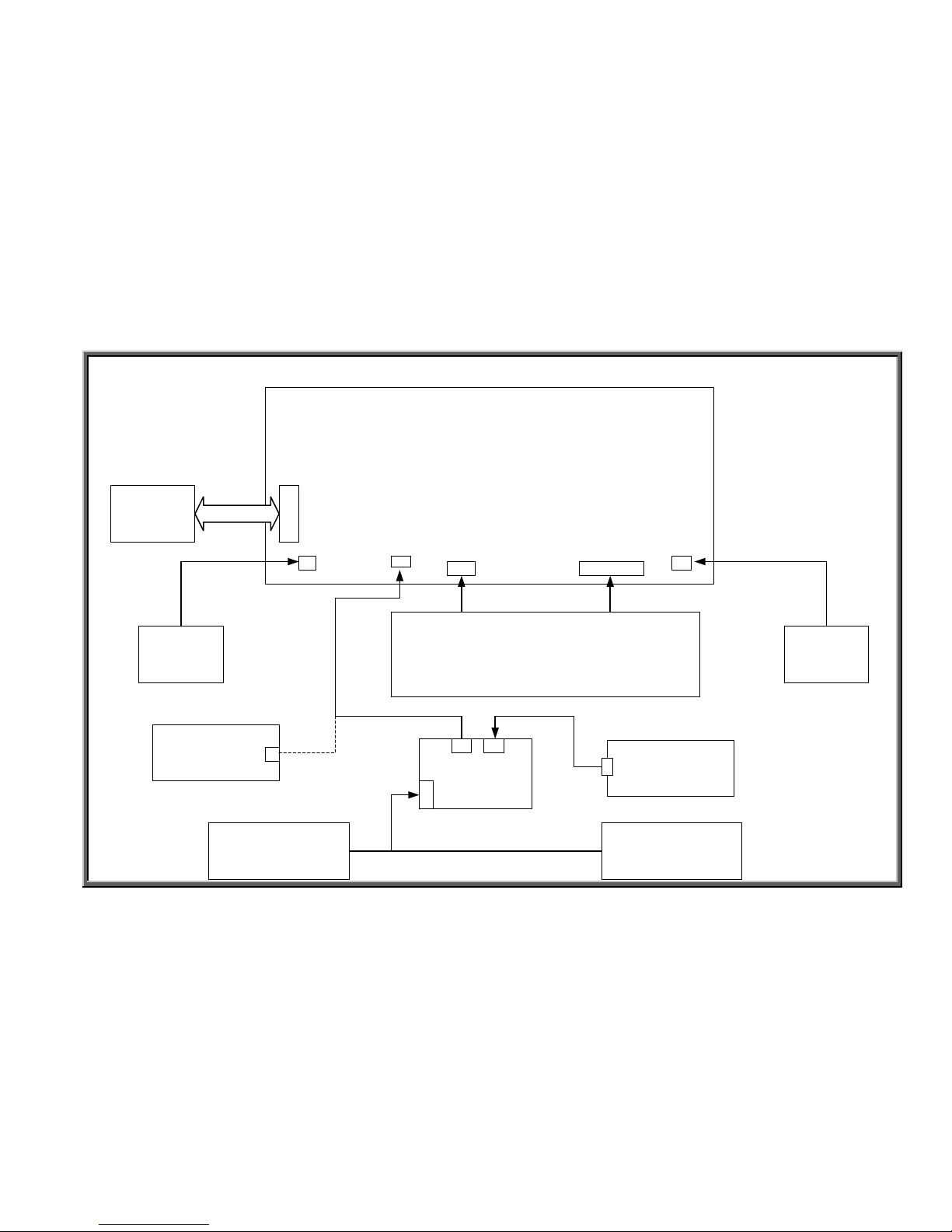

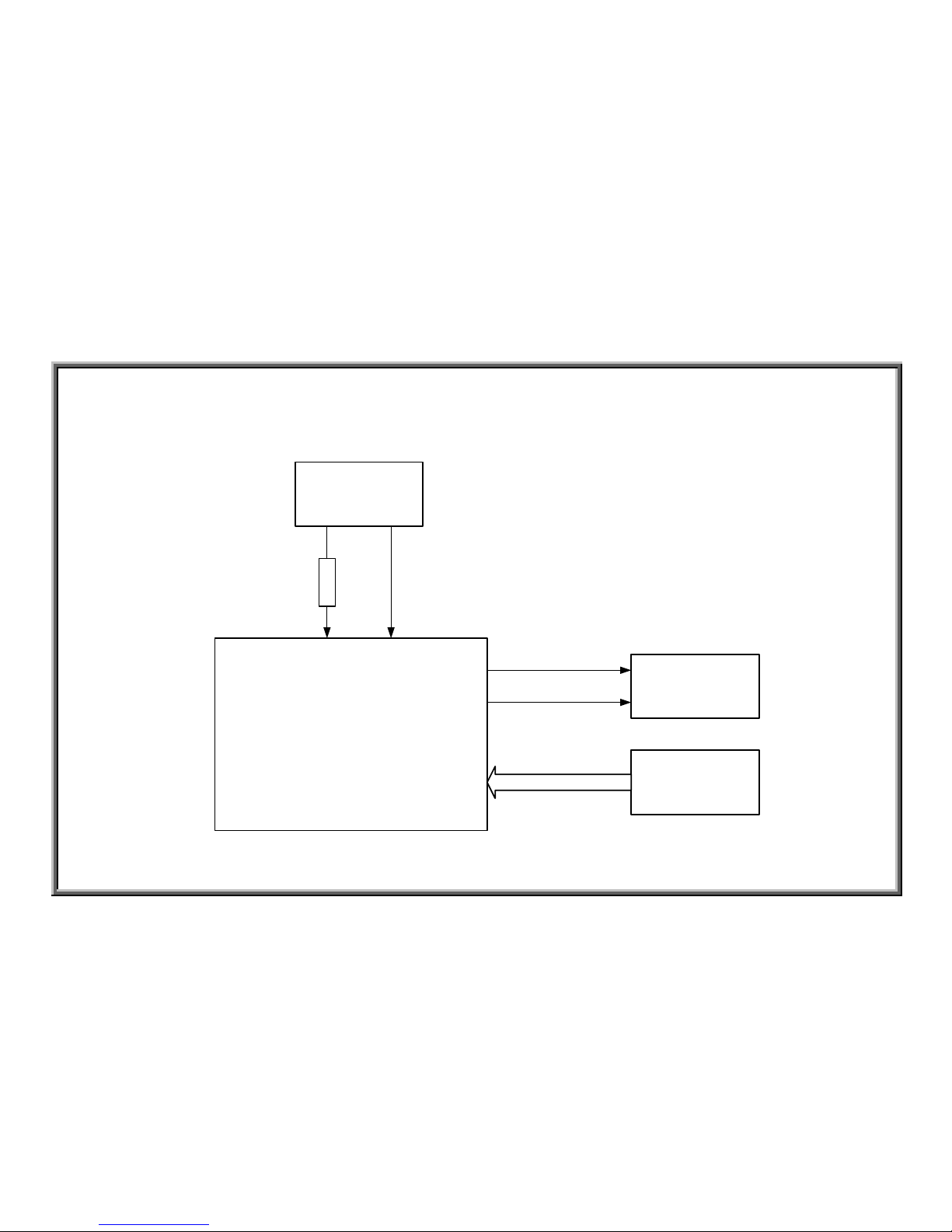

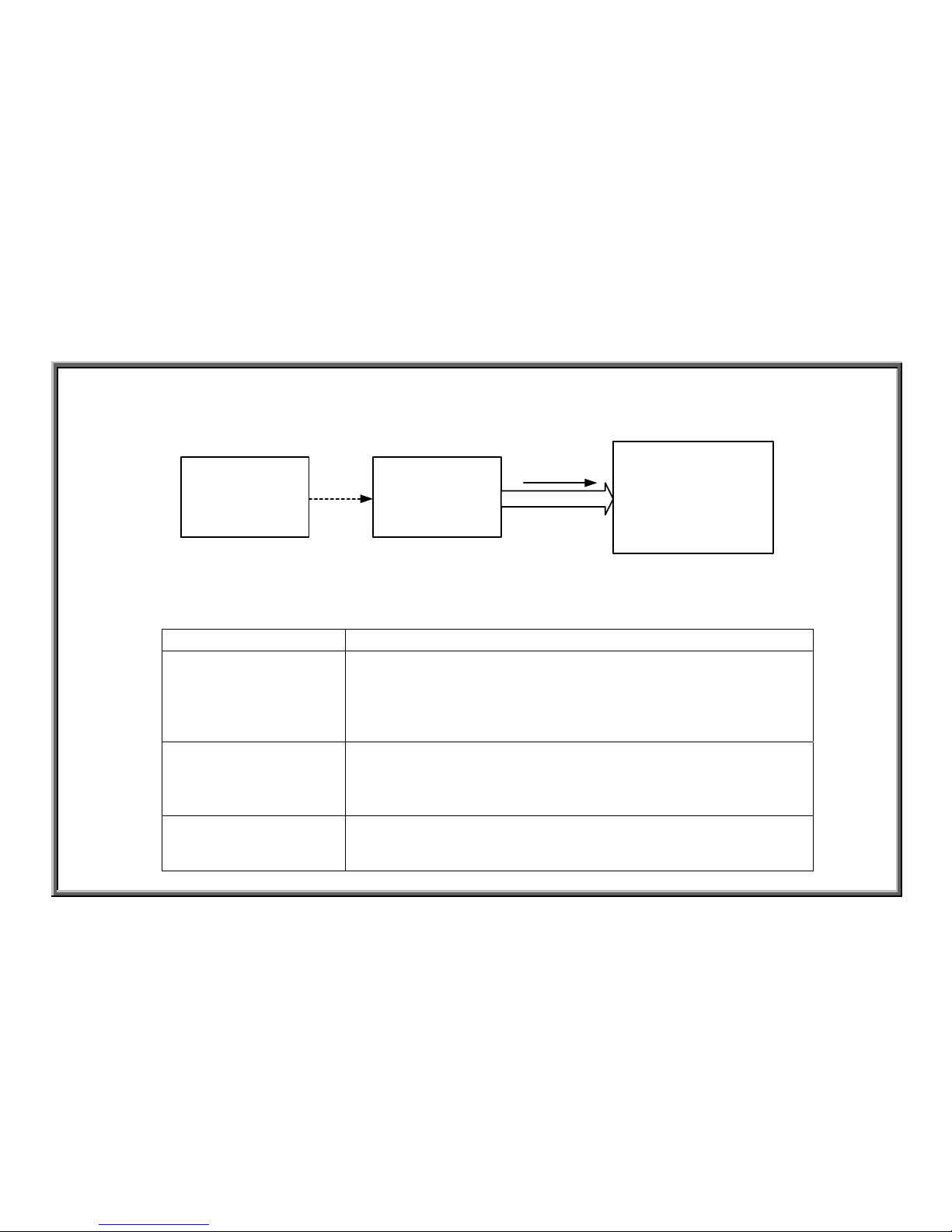

6150/E/6100/E Motor Operation Flow Chart

1. Configuration

4pin

Display Board

Drive Board Motor

Optic Sensor

2 pin

CLK

Motor Speed

Signal

Motor

Voltage

Optic Sensor Signal

Optic Sensor

Signal

Soft Keys

16 PIN

Key Signal

2-2-1

SPOR TS AR T INDUSTRIAL CO., L TD.

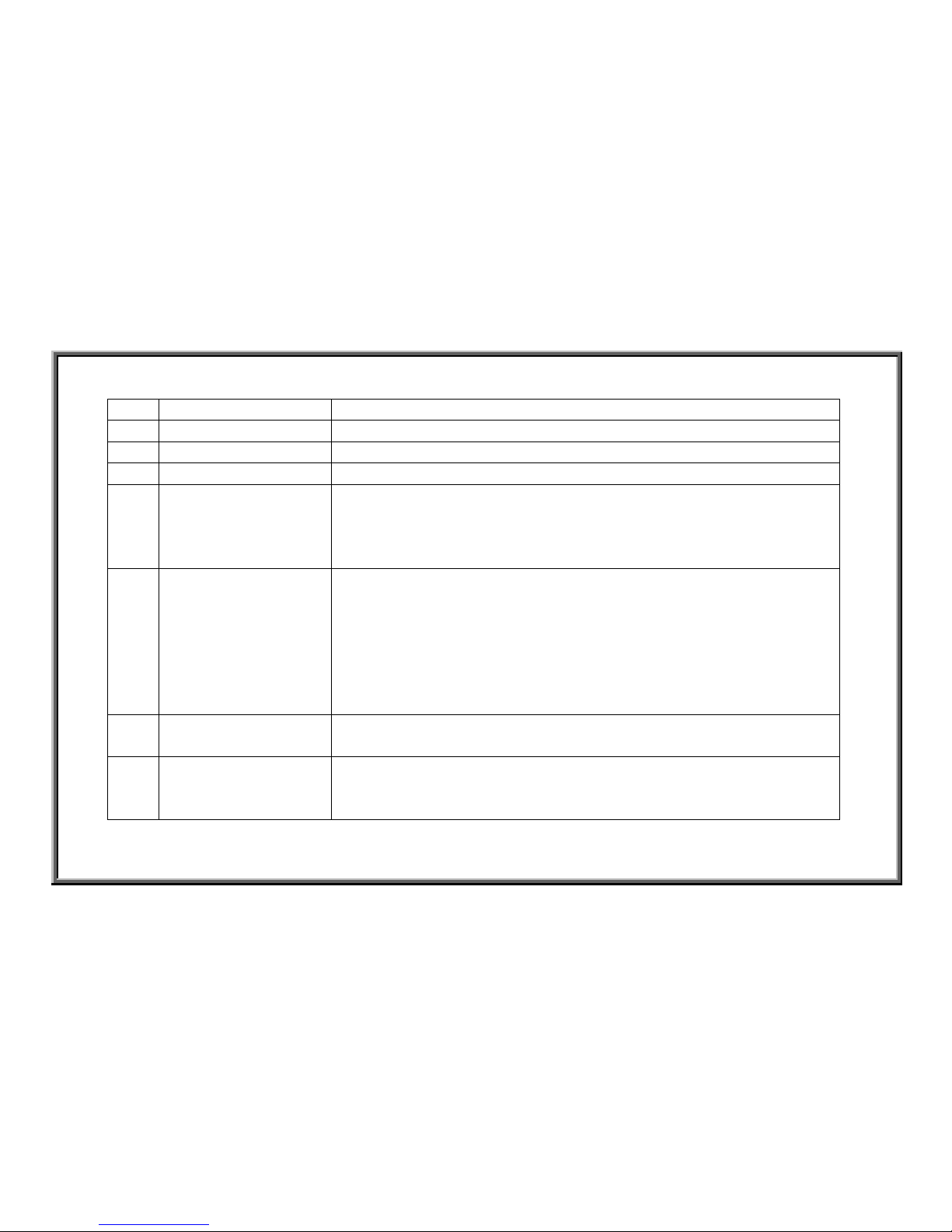

2. Operational Steps

Order Component Operation

1 Soft Keys 1.User inputs the desired speed.

2. Display board SPEED window shows SPEED key setting value.

2 Display Board 1. Display board CPU sends the motor speed signal to the drive board to

control motor speed.

2. The signal travels from the display board to the drive board through the

16-PIN cable.

3 Drive Board 1. Drive board translates the display board motor speed signal into the PWM

speed signal for the display board.

2. The PWM signal emits the drive board motor voltage to control motor

speed.

4 Motor 1.The motor rotates according to the drive board voltage.

2. After the motor operates, the rollers turn, moving the walking belt.

5 Tach Wheel; Optic Sensor 1. Motor operation moves the tachometer wheel.

2. The optic sensor detect the tachometer signal.

3. The signal travels the 4-PIN cable to the drive board.

6 Drive Board 1. The drive board translates the optic sensor signal from wave to rectified

form.

2. The drive board CLK indicator flashes or remains lit.

3. The optic sensor signal travels the 16-PIN cable to the display board.

7 Display Board 1. If the display board senses the optic sensor signal, it keeps emitting the

motor signal, allowing the motor to operate.

2-2-2

SPORTS ART INDUSTRIAL CO., LTD.

3. Operational Procedure

Step Operation

1

Press SPEED<▲> or SPEED<▼> key

2 Display board SPEED window setting speed value appears.

3 Motor starts operating; the tachometer wheel moves, and the treadmill belt rotates.

4 Drive board CLK indicator lights.

5 The display doesn’t show any error message; the motor continues to operate.

2-2-3

SPORTS ART INDUSTRIAL CO., LTD.

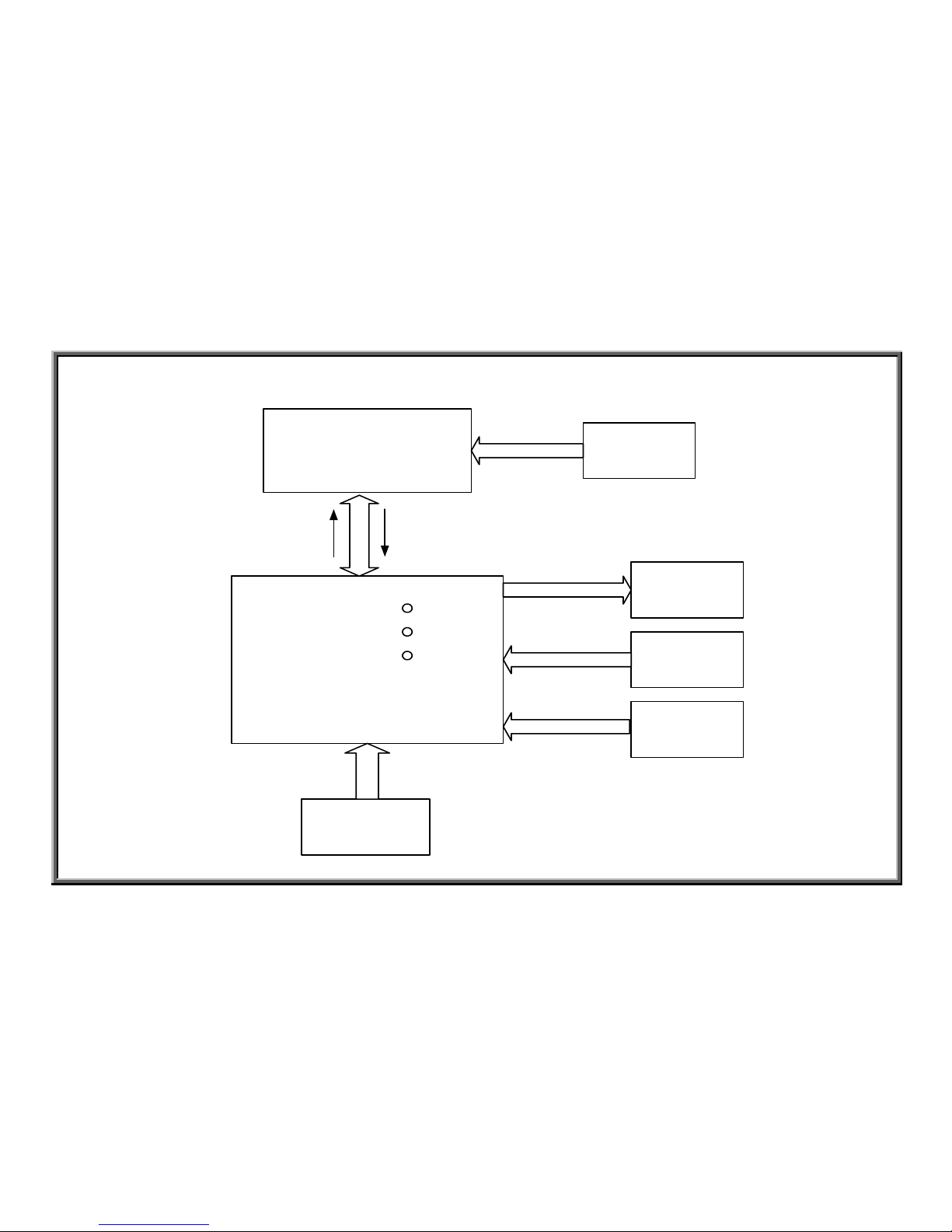

6150/E/6100/E Incline Operation Flow Chart

1. Configuration

Display Board

Drive Board

Transformer

UP

Incline Up/Down

Signal

Incline VR

Voltage; LIMIT

Signal

Transformer

Voltage

Incline

Motor

Incline VR

Set

Incline

LIMIT Switch

16 PIN

Incline

Motor

Voltage

Incline LIMIT

Signal

Incline VR

Voltage

DOWN

ERR

Soft Key

INC UP,DN

2-3-1

SPORTS ART INDUSTRIAL CO., LTD.

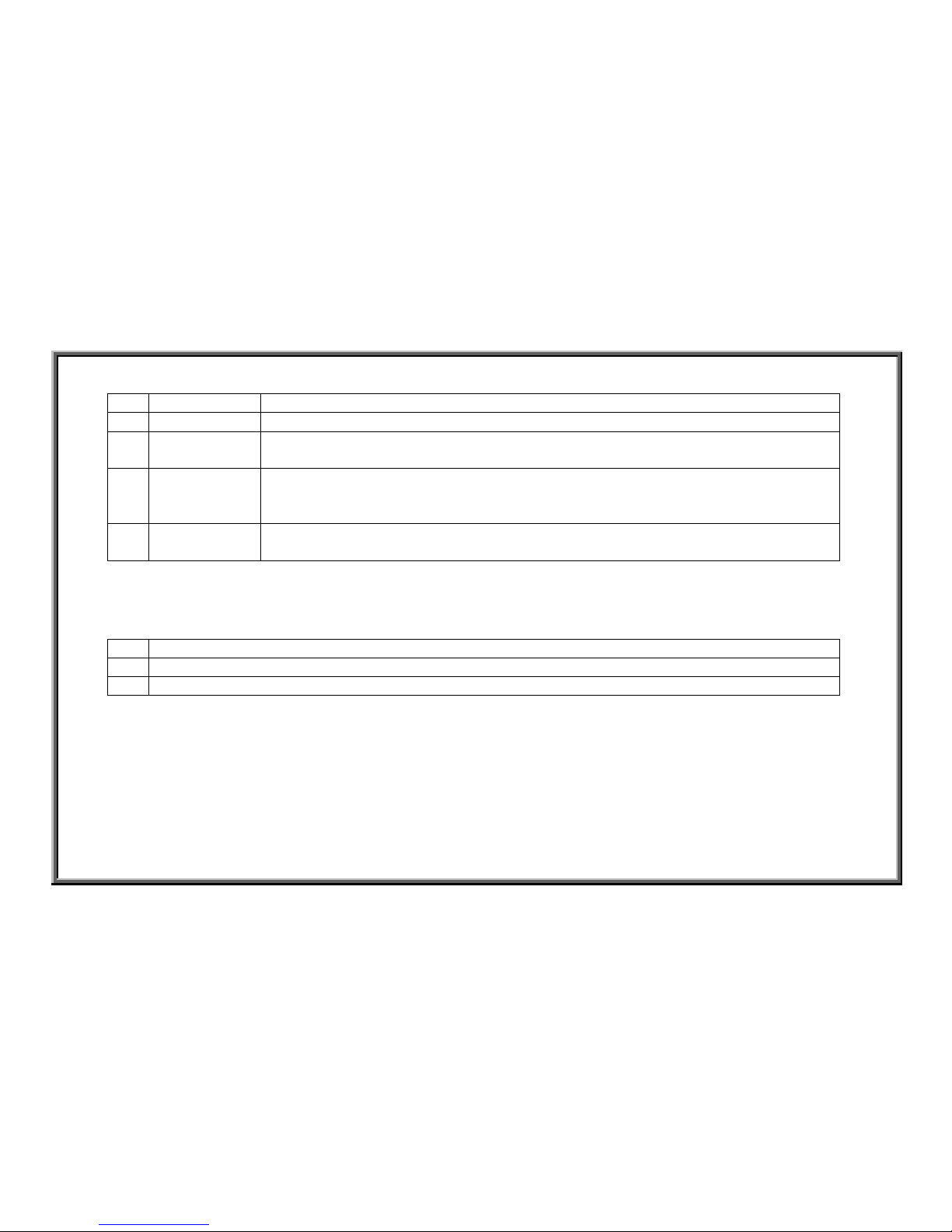

1. Operation

Order Part Operation

1 Soft Keys 1.User inputs incline height through the keys.

2 Display Board 1.The display board CPU sends the incline height setting signal to the drive board to

command incline action.

2.The signal travels from the display board through the16-PIN cable to the drive board.

3 Transformer 1.The transformer provides the incline motor with power to operate.

4 Drive Board 1.The drive board incline circuit operates according to the incline signal from the display

board.

2.By changing the polarity of the voltage, the drive board makes the DC incline motor turn

up or down.

3.The drive board UP indicator lights to indicate up incline action.

4

.The drive board DN indicator lights to indicate down incline action.

5 Incline VR Set 1. The incline gears turn, turning the VR, which increases or decreases the incline value.

2. Incline height is determined according to the incline VR value voltage.

6 LIMIT 1. When the incline motor leaves the incline VR value range, the incline VR gear hits the

LIMIT switch.

2. A broken LIMIT switch circuit means that the incline set has exceeded its range.

7 Drive Board 1.The incline LIMIT signal enters the drive board for processing. If the LIMIT switch

circuit is short (normal), then ERR indicator doesn’t light. If the LIMIT switch circuit is

broken (not normal), the ERR indicator lights.

2.If the ERR indicator lights, incline action immediately stops.

3.The incline VR wire VR value enters the drive board.

4.The incline LIMIT signal and VR value travels the 16-PIN cable to the display board.

8 Display Board 1.The display board senses the VR value and constantly emits the incline signal.

2. The signal is emitted until the incline VR value and the setting value are the same. Once

these are the same, the signal stops, and the incline action stops.

2-3-2

SPORTS ART INDUSTRIAL CO., LTD.

3. Operational Steps

Step Operation

1

Press the INCL<▲> or INCL<▼> key.

2 Display board INCL window shows incline value setting.

3 Drive board UP or DOWN indicator lights; ERR indicator doesn’t light.

4 Incline action begins.

5 Once the incline position is reached, action stops.

2-3-3

SPORTS ART INDUSTRIAL CO., LTD.

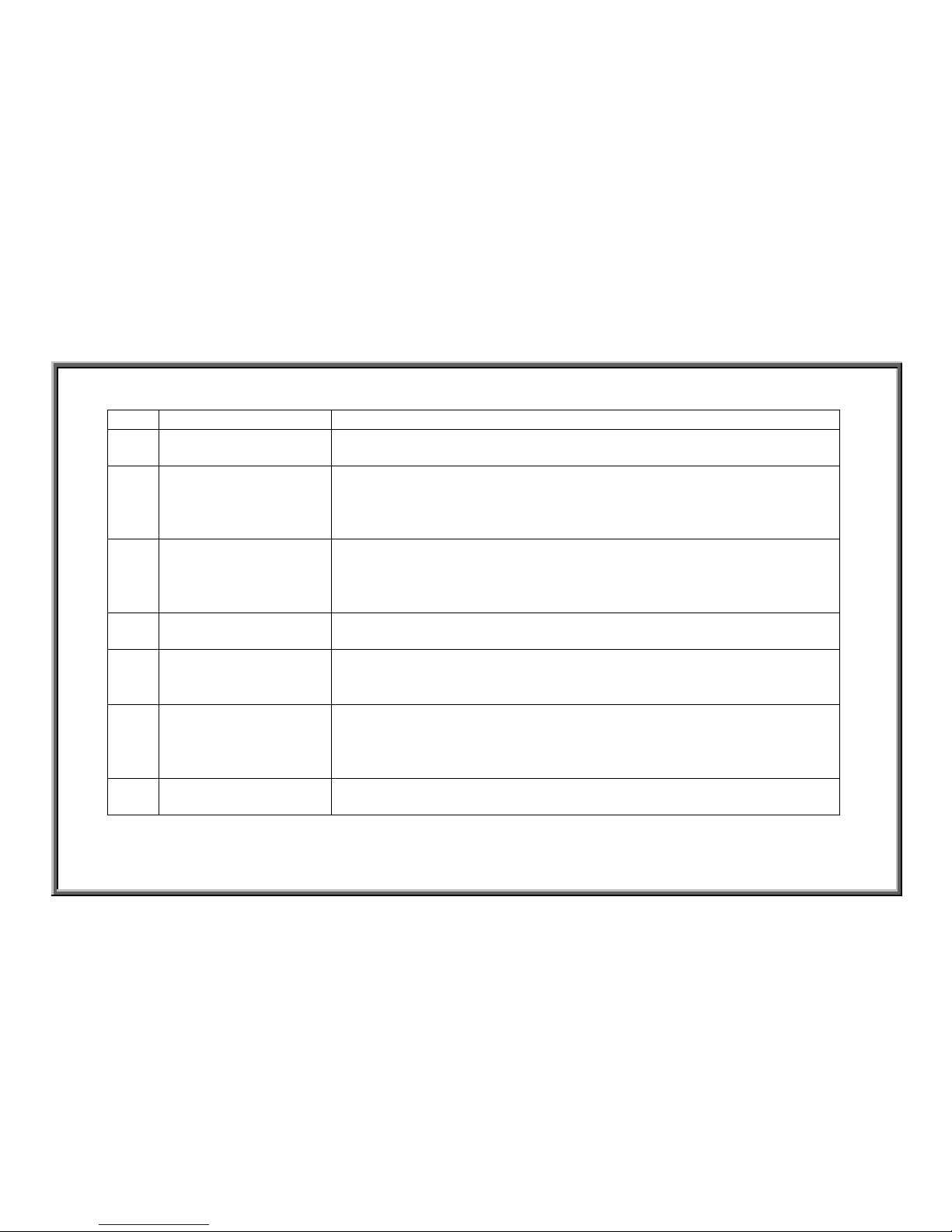

6150/E/6100/E Motor/Resistor Operation Flow Chart

1. Configuration

Drive Board

Motor

Big Resistor

FUSE

Optic Sensor

CLK

Motor Voltage

2-4-1

SPORTS ART INDUSTRIAL CO., LTD.

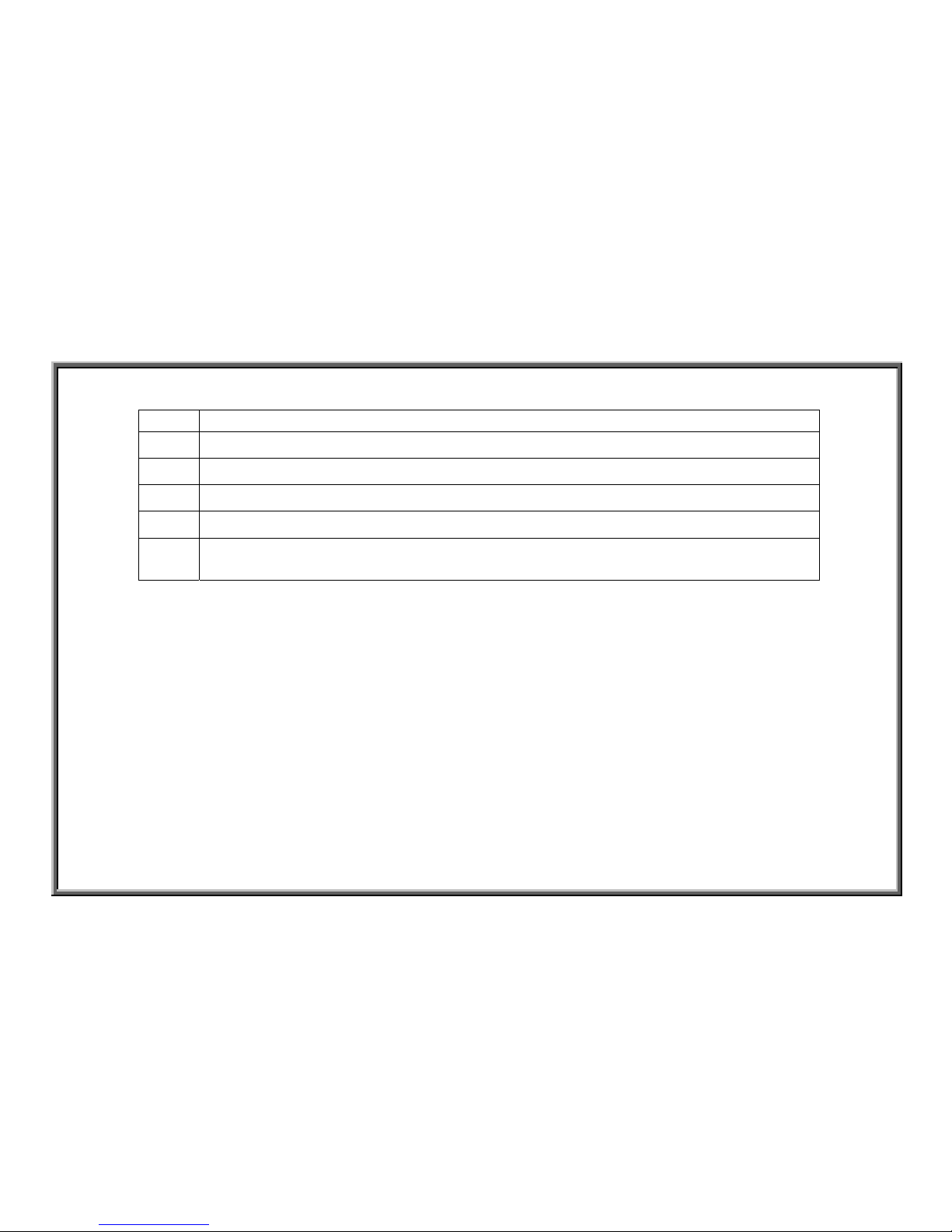

2. Operation

Order Name Operation

1 Motor 1. When the treadmill motor is operating, if the belt is pulled, the motor will speed up.

2 Optic Sensor 1. When the motor speeds up, the optic sensor signal speeds up.

2. The optic sensor signal travels the 4-PIN cable to the drive board.

3 Drive Board 1. When the drive board receives the optic sensor signal, if the signal and the setting differ,

the drive board creates a resistance signal and the drive resistance (large resistor)

operates.

4 Motor 1. When the resistor operates, the motor amp draw creates resistance.

2. If the user pulls the belt, the treadmill belt speed doesn’t increase; resistance is felt.

3. Operational Procedure

Steps Operation

1 Pulling the belt increases belt speed.

2 Resistance is created, and the treadmill belt speed is held steady.

2-4-2

SPORTS ART INDUSTRIAL CO., LTD.

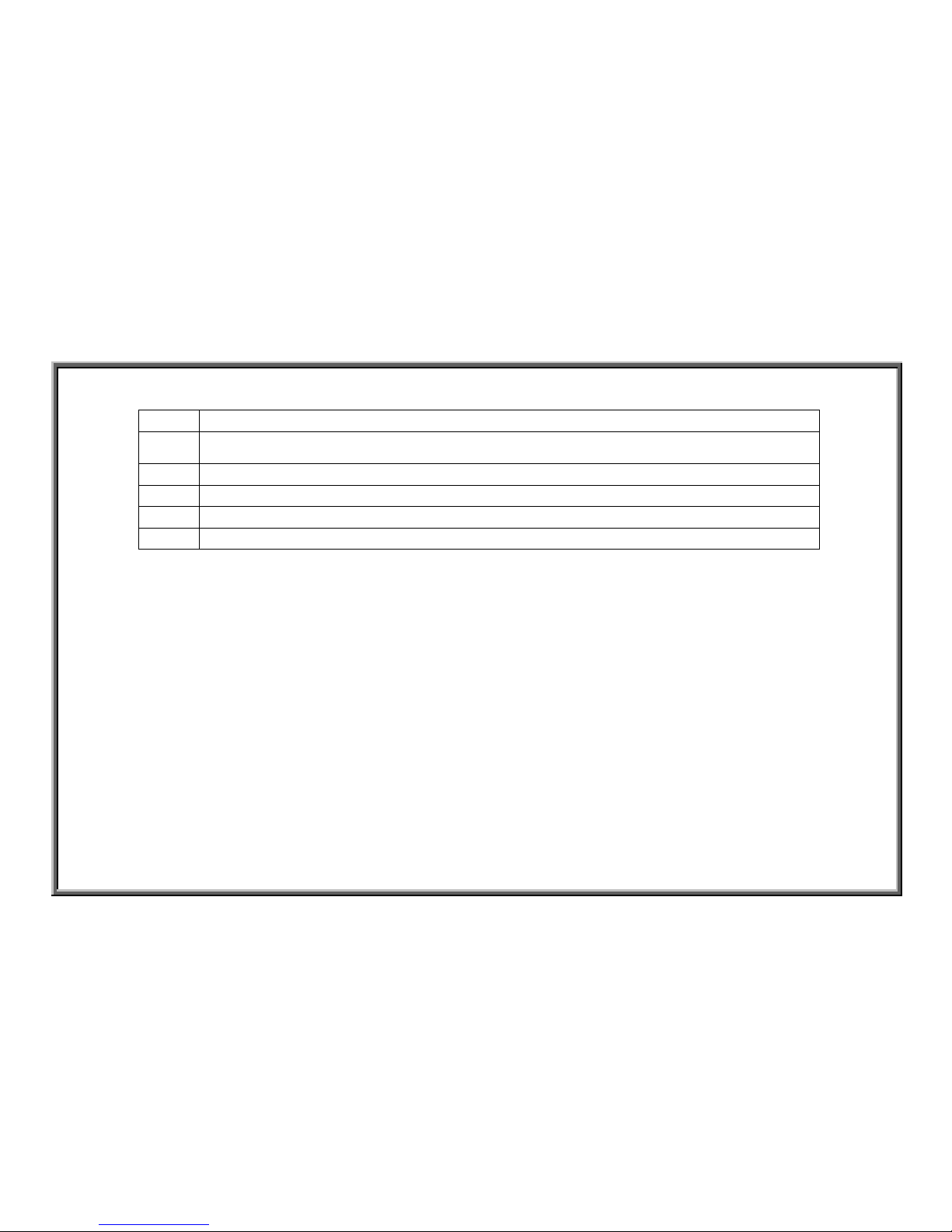

6100/E/6150/E Display Key Function Flow Chart

1. Configuration

Display Board

Soft Keys

Key Signal

2. Operation

Name Operation

Soft Keys 1.Press the display soft keys.

2.The keys send their signal to the display board.

Display Board

1.The key signal is read by the CPU.

2. The CPU implements the key signal action.

2-5-1

SPORTS ART INDUSTRIAL CO., LTD.

3. Operational Steps

Key Operation

INCL<▲> key Continuously press INCL<▲> key; the INCL window value increases to 15.

INCL<▼> key Continuously press INCL<▼> key; the INCL window value decreases to 0.

TIME<▲> key Continuously press TIME<▲> key; the TIME window value increases to 99.00.

TIME<▼> key Continuously press TIME<▼> key; the TIME window value decreases to 0000.

DIST<▲> key Continuously press DIST<▲> key; the LOAD window value increases to 999.0.

DIST<▼> key Continuously press DIST<▼> key; the LOAD window value decreases to 0000.

SPEED<▲> key

Continuously press SPEED<▲> key; the SPEED window value increases to 20.0KPH

(16.0MPH).

SPEED<▼> key

Continuously press SPEED<▼> key; the SPEED window value decreases to 0.2KPH

(0.1MPH).

<RACE> key

Continuously press <RACE> key; the main display window shows “LEVEL

1”-“LEVEL 8”.

<MANUAL/SET> key

Continuously press <MAN’L> key; the main display window:

(1) switches between “MAN’L”/”SET” notices (No HRC function units)

(2) switches between “MAN’L”/”SET”/”HRC” (HRC function units)

<INTERVAL> key Continuously press <INTV> key; the main display window switches between

“INTV1”/”INTV2” notices.

<PROGRAM> key

Continuously press <PROG> key; the main display window shows “PRO 1”

-”PRO12” in order.

<RESET> key

Continuously press <RESET> key three seconds; the display beeps; the main display

w

indow shows; the small window deletes to 0.

2-5-2

SPORTS ART INDUSTRIAL CO., LTD.

6100/E/6150/E POLAR Heart Rate Operation Flow Chart

1. Configuration

Display Board

POLAR

Heart Rate

Receiver

3 PIN CABLE

PULSE

Heart Rate

Transmitter

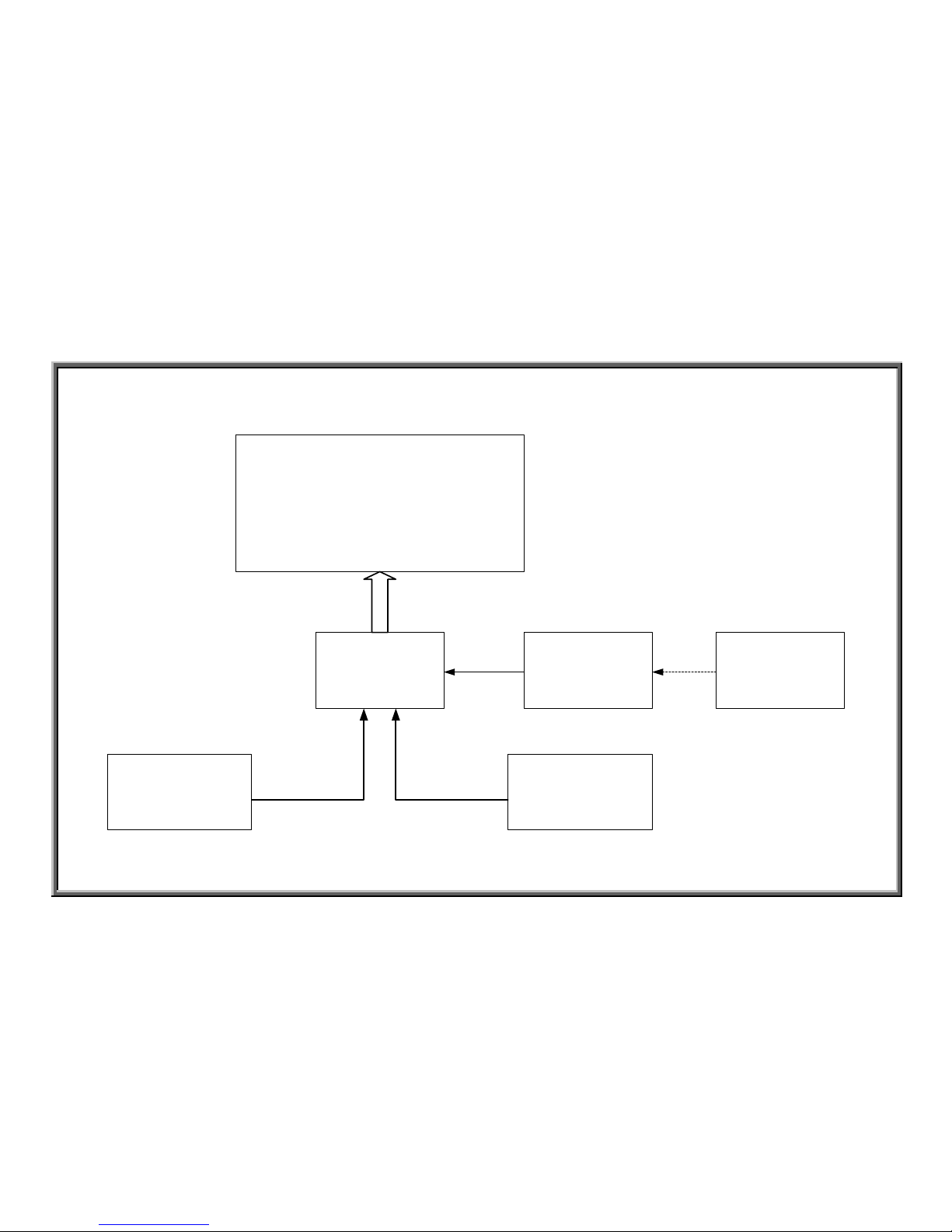

2. Operational Procedure

Part Operation

Heart Rate Transmitter 1. Put on the POLAR transmitter.

2. The POLAR transmitter senses the wearer’s heart beat and transmits

the heart rate to the receiver.

3.POLAR heart rate transmitter transmits within a distance of 90

centimeters.

POLAR Heart Rate

Receiver

1.POLAR receiver receives the signal from the transmitter through a

wireless transmission.

2. After the heart rate signal is processed, it travels the 3-PIN cable to the

display board.

Display Board

1.After receiving and processing the heart rate signal, it is sent to the

program which then determines the heart rate value.

2. The display board PULSE window shows the heart rate value.

2-6-1

SPORTS ART INDUSTRIAL CO., LTD.

3. Operational Procedure

Step Operation

1 Put on the POLAR transmitter; stand on the treadmill.

2 Within 5 seconds, the PULSE window shows the heart rate value.

2-6-2

SPORTS ART INDUSTRIAL CO., LTD.

6100/E/6150/E Display Board HTR Heart Rate Flow Chart

1. Configuration

Display Board

HTR Board

HTR Handlebar

(left)

HTR Handlebar

(Right)

Heart Rate

Signal

HTR Handlebar

Signal

POLAR Receiver

POLAR

Transmitter

HTR Handlebar

Signal

2-7-1

Loading...

Loading...