Page 1

Technical data are subject to change without notice.

© Copyright SPM 2003-10. 71679 Z

Instruction Manual

Vibrameter VIB-11B

SPM Instrument AB • Box 504 • SE-645 25 Strängnäs • Sweden

Tel +46 152 22500 • Fax +46 152 15075 • info@spminstrument.se • www.spminstrument.com

Page 2

1

Technical data are subject to change without notice.

ISO 9001 certified. © Copyright SPM 2003-10. 71679.Z

SPM Instrument AB • Box 4 • SE-645 21 Strängnäs • Sweden

Tel +46 152 22500 • Fax +46 152 15075 • info@spminstrument.se • www.spminstrument.com

Vibration Monitoring

Instruction Manual for

Vibrameter VIB-11B

Contents

Introduction ........................................................................................ 2

Vibration ............................................................................................. 3

Measurement...................................................................................... 4

Measure Acceleration - Display Velocity ............................................ 5

Machine Classes ................................................................................. 6

Measuring Points ................................................................................ 7

Recording of Readings ....................................................................... 8

Follow-up Form .................................................................................. 9

Measuring Equipment ...................................................................... 10

Transducer Mounting ....................................................................... 10

Hand-held Probe .............................................................................. 11

Taking Readings ............................................................................... 11

Changing Batteries ........................................................................... 11

Maintenance Based on Vibration Records ....................................... 12

Fault Analysis Chart .......................................................................... 13

Technical Specifications, Part Numbers .......................................... 14

Definition of Machine Classes According to ISO 2372 .................... 15

Page 3

2

Technical data are subject to change without notice.

ISO 9001 certified. © Copyright SPM 2003-10. 71679.Z

SPM Instrument AB • Box 4 • SE-645 21 Strängnäs • Sweden

Tel +46 152 22500 • Fax +46 152 15075 • info@spminstrument.se • www.spminstrument.com

Condition Based Maintenance

Condition Based Maintenance is by now a widely accepted concept in industry. The idea is simple and not

exactly new: keep plant machinery in good working condition by locating and repairing minor faults

before they grow large enough to cause expensive breakdowns and production stops.

The problem is to assess machine condition and detect a slow deterioration long before a piece of plant

grinds to a shuddering halt. In the past, a skilled operator could do this largely without the help of

instruments, by listening, touching, smelling. Modern machinery is often unattended, soundproofed, out

of easy reach. It rotates faster and is less massively constructed, which means that even a minor

deterioration of its working condition can have very serious consequences. Therefore personal skill and

subjective judgement have to be supported by monitoring systems and instrument readings.

Vibration Monitoring

Vibration monitoring is a very useful method for an overall assessment of machine condition. Changes in

the vibration level always imply changes in the operating condition. Excessive vibration has basically three

causes: something is loose, misaligned or out of balance. These three causes cover virtually all possible

mechanical faults.

Moreover, the assessment of machine vibration has been much simplified by international standards which

define the acceptable vibration level for a given type of machine and recommend monitoring methods

suitable for industrial purposes.

A Maintenance Tool

Effective Condition Based Maintenance requires economical and simple monitoring methods which can be

applied by maintenance personnel without special training. Their primary task is to locate trouble spots

early and direct the efforts of the maintenance crews to the right place at the right time. Fault analysis and

repairs are a secondary step which may require expert knowledge and a different type of instrumentation.

SPM vibration monitoring equipment is designed as a maintenance aid. In accordance with the international standards, it measures vibration severity over a large frequency range. It allows a practical

classification of machine condition in relative terms: good, acceptable, just tolerable or bad. Regular

measurements will also show the development trend of the vibration level and thus the urgency of the

maintenance problem: stable condition, slow deterioration or fast deterioration.

Measurements can be carried out in various ways; either periodical readings with portable equipment

(Vibrameter VIB-11B), or continuous monitoring of preset limit values (Machine Guard MG4 or CMM

System). This manual gives an introduction to vibration monitoring and describes condition assessment

and basic fault analysis with SPM Vibrameter VIB-11B.

Measuring Units

ISO Recommendations use metric units (mm/s RMS) for measuring vibration severity. In this manual, all

metric units have been converted to inches /1 in = 2.54 mm / 1 mm = 0.03937 in). A metric version (VIB-10)

is available, together with an instruction manual (71678 B) and follow-up forms (VIC-11) with metric tables.

Page 4

3

Technical data are subject to change without notice.

ISO 9001 certified. © Copyright SPM 2003-10. 71679.Z

SPM Instrument AB • Box 4 • SE-645 21 Strängnäs • Sweden

Tel +46 152 22500 • Fax +46 152 15075 • info@spminstrument.se • www.spminstrument.com

Vibration

In every moving machine, part of the force that makes

it work acts on the machine itself. Since no structure

or machine is perfectly rigid, any force acting on it will

cause slight movements.

The forces causing movement are usually cyclic, that

is they operate regularly first in one direction and

then in another. They can act in two main directions,

like the up and down forces associated with piston

engines, or they can rotate with the shaft, like out of

balance forces on a fan. They move the machine back

and forth from its rest position: the machine vibrates.

Up to a degree, vibration is tolerated because it simply cannot be avoided. Machines are designed to

withstand a “normal“ amount of vibration for a long

period of time. To assess the condition of any particular piece of plant, one has to determine its “normal“

vibration level, then measure the actual amount and

type of vibration and compare the two values.

To decide what is normal one has to consider

· the function of the machine and the forces

involved

· the rigidity of the machine structure

A large diesel engine vibrates more than a small electric motor - the forces involved are very different.

More force is needed to vibrate a machine on a stiff

concrete foundation than it takes to shake the same

machine on a flexible metal frame. The machine structures are different and so are their normal vibration

levels.

Due to changes in the operating conditions and the

mechanical state of machines, vibration levels are subject to gradual or sudden changes. Loose fixing bolts

or excessive bearing play will make the structure less

rigid - vibration will increase. A growing soot layer on

the impeller blades of an exhaust fan adds to the out

of balance forces. Vibration will increase above the

normal level and show that the machine is getting

worse. Usually the deterioration accelerates: heavier

vibration will further weaken the structure which in

turn will raise the vibration level.

Page 5

4

Technical data are subject to change without notice.

ISO 9001 certified. © Copyright SPM 2003-10. 71679.Z

SPM Instrument AB • Box 4 • SE-645 21 Strängnäs • Sweden

Tel +46 152 22500 • Fax +46 152 15075 • info@spminstrument.se • www.spminstrument.com

Measurement

If a fan is out of balance, it will shake at its speed of

rotation, i.e. move backwards and forwards once per

revolution. The number of vibrations per time unit is

the vibration frequency, measured in Hz (Hertz =

cycles per second).

The rotational speed of any piece of plant is known as

its fundamental frequency. For a fan with a speed of

1 500 r.p.m. the fundamental frequency is 25 Hz (1

500 r.p.m. ÷ 60).

In practice, machine vibration usually consists of many

different frequency components. For a general assessment of machine condition one uses wide fre-

quency band measurements, that is all vibrations

within a large frequency range are measured simultaneously.

Cyclic movement can be measured and described in

three different ways, as

· displacement

· acceleration

· velocity

Displacement means the actual distance the object

moves, measured either from its rest position in one

direction (peak) or as the total movement in both

directions (peak to peak). Displacement is usually measured in mils.

A part that is moving from rest, speeding up, slowing

down and stopping twice per cycle is obviously accelerating and decelerating continuously. Acceleration is

measured in g (1 g = 32.17 ft/sec2).

The third measuring parameter is the speed at which

the object moves, the vibration velocity. Velocity is

expressed in in/sec.

Both acceleration and speed are constantly changing.

One can measure a peak value of either, but a mean

value often gives a better indication of the forces

involved in the movement. Most instruments measure

the RMS value (root mean square value) of the movement and use a scaling factor to indicate the peak

levels if they are given at all.

Frequency

Hz

Displacement

mil

Acceleration

g

Velocity

in/s

Page 6

5

Technical data are subject to change without notice.

ISO 9001 certified. © Copyright SPM 2003-10. 71679.Z

SPM Instrument AB • Box 4 • SE-645 21 Strängnäs • Sweden

Tel +46 152 22500 • Fax +46 152 15075 • info@spminstrument.se • www.spminstrument.com

Measure Acceleration - Display Velocity

All three vibration parameters - displacement, acceleration, velocity - are mathematically related. One

can, for example, place an accelerometer on a vibrating surface and convert its signal, via integrating circuitry in the measuring instrument, into a reading of

vibration velocity or displacement.

The choice of displayed parameter (the instrument

reading) and measured parameter (the transducer type

used) depends on the problem to be solved and on

the cost, the complexity and the reliability of the

measuring equipment.

Experience has shown, that the RMS level of vibration

velocity, measured over a frequency range of 10 to

1000 Hz, is most useful for general assessment of

machine condition. The technical term used is vibra-

tion severity, defined as above and displayed in in/s

RMS on the instrument. Vibration severity is directly

related to the energy level of machine vibration, and

thus a good indicator of the destructive forces acting

on the machine.

There are transducers which measure velocity directly,

i.e. seismic probes with either moving coils or moving

magnets. These transducers are normally bulky, easily

damaged and expensive to manufacture. They are

therefore gradually being replaced by accelerometers.

An accelerometer is basically a piezo electric crystal (a

crystal that develops an electric charge when it is

compressed or stretched) with a small reference mass

attached. As the transducer is moved back and forth,

the reference mass compresses and stretches the crystal and the transducer gives an output directly related

to acceleration.

Piezo electric accelerometers are small, very robust

and relatively cheap to produce. They can work over a

very large frequency range. They can be mounted on

machines, held by hand against a vibrating surface or

be temporarily attached by wax or magnets. That is

why most practical measuring systems now use an

accelerometer as the transducer and an integrator

within the instrument to give a display in terms of

velocity.

in/s

RMS

Piezo electric

crystal

Housing

Mass

Base

Output

Integrator

Accelerometer

Piezo electric accelerometer

Page 7

6

Technical data are subject to change without notice.

ISO 9001 certified. © Copyright SPM 2003-10. 71679.Z

SPM Instrument AB • Box 4 • SE-645 21 Strängnäs • Sweden

Tel +46 152 22500 • Fax +46 152 15075 • info@spminstrument.se • www.spminstrument.com

Machine Classes

To assess machine condition, the vibration severity

measured on a specific piece of plant has to be compared with a representative norm value.

The international standards group industrial machinery into six different vibration classes , depending on

·machine size and function

· stiffness of foundation

For each class, the standards give vibration severity

levels in four bands, ranging from very good condition through average and poor to bad. Provided that

the correct class is chosen, the instrument reading

can be directly related to machine condition.

Most industrial plants belong to vibration classes II, III

and IV.

Class I refers to independent parts of machines, for

example electric motors up to 15 kW.

Classes V and VI are used for heavy reciprocating

prime movers and machines which are intended to

vibrate - for example vibrating screens (see Appendix

page 15 for precise definitions).

Motor power and types (electric, turbine, diesel), machine size and foundation stiffness (concrete base,

metal frame, etc.) will give a first indication of machine class. For example, most smaller process pumps

on a chemical plant would be Class II. A 100 kW

ventilation fan on a concrete base would be Class III.

However, the same fan fastened to the less rigid

metal deck of a ship could be considered as Class IV.

Classification of machinery is largely a matter of experience because the definitions provided by the standards are deliberately loose. Manufacturers should be

able to specify acceptable vibration levels for their

equipment, and their information can be used as a

reference.

Similarly, if it is reasonably sure that a machine is in

good condition, the actual vibration reading can be

used as a starting point for the assessment of future

changes.

in/s RMS

Limits Class Class Class Class

II Medium size machines

without special foundations

III Large machines on rigid

foundations

IV Large machines on soft

foundations

Page 8

7

Technical data are subject to change without notice.

ISO 9001 certified. © Copyright SPM 2003-10. 71679.Z

SPM Instrument AB • Box 4 • SE-645 21 Strängnäs • Sweden

Tel +46 152 22500 • Fax +46 152 15075 • info@spminstrument.se • www.spminstrument.com

Measuring Points

Vibration at the measuring point should be representative of the overall vibration pattern of the machine. The forces involved are usually transmitted

through the bearings and their housings to the machine foundation. Consequently measuring points

should be located on or near the bearing housings.

Machine guards, cover panels and other parts which

are considerably less stiff than the main structure are

not suitable as measuring points.

Generally speaking, the more measuring points chosen, the easier it is to locate a specific mechanical

problem. Consider a fan, belt driven from an electric

motor. Measurements taken on the fan bearing (3)

will primarily give information on fan balance. If out of

balance is the only problem to guard against, measuring on that bearing will be sufficient. To be able to

make an adequate assessment of the mechanical state

of the whole machine, one should also measure on

the drive end bearing (2) and the motor (1).

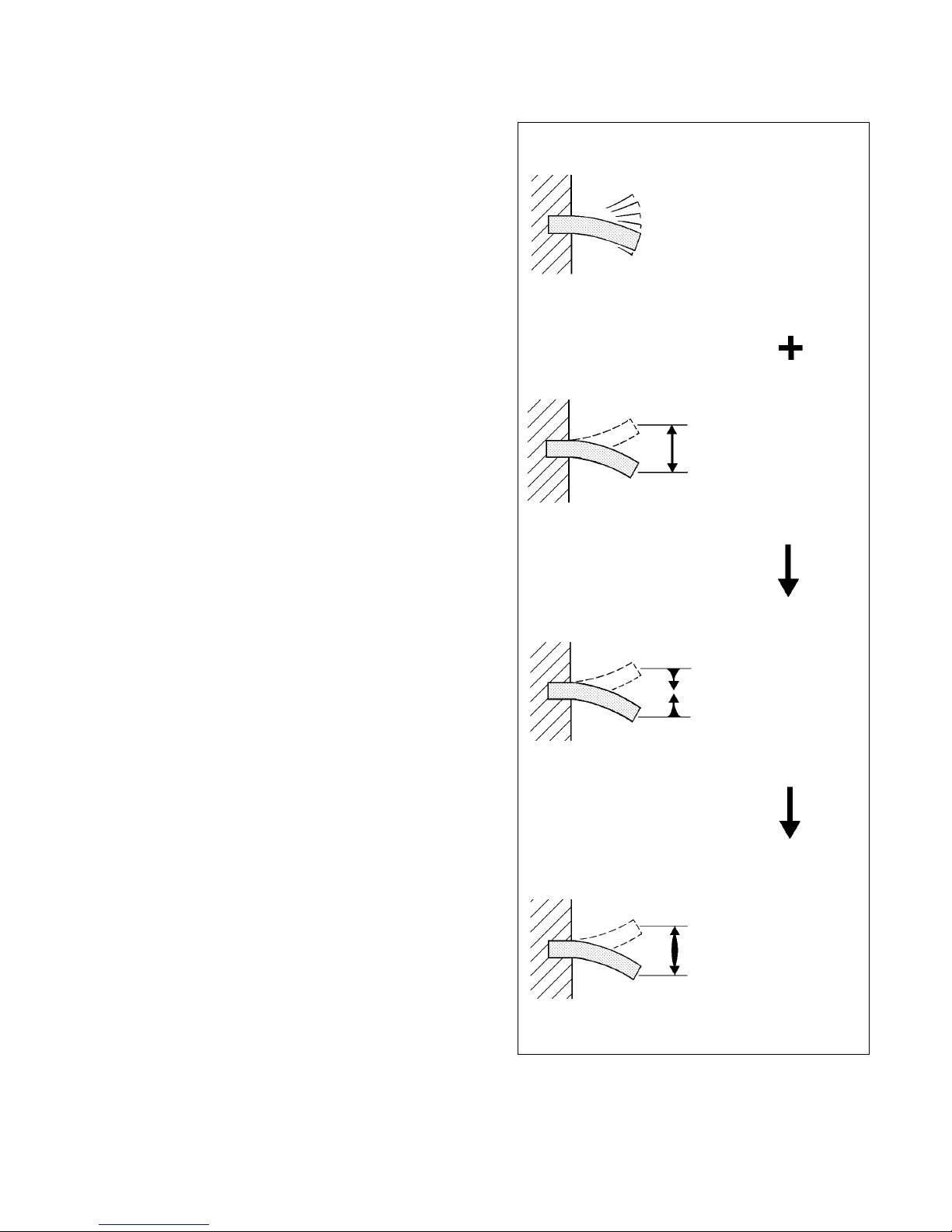

The direction of measurement is very important. Out

of balance forces rotate with the shaft and cause

radial vibration acting in all directions within the plane

of rotation.

Axial vibration, along the line of the shaft, is normally

caused by faulty alignment, i.e. badly assembled couplings or bent shafts.

Normal practice is to take vibration readings in three

directions at each measuring point: vertical (V), horizontal (H) and axial (A). Of the two radial measurements, a reading in the vertical direction tends to give

information about structural weakness, whereas the

horizontal reading is most representative of balance

conditions.

The measuring point, meaning the exact spot on the

machine where the transducer is placed, should be

clearly marked and used each time a reading is taken.

Relatively small changes in the measuring point can

cause misleading changes in the measured value and

trend analysis difficult.

Axial vibration

Radial vibration

Page 9

8

Technical data are subject to change without notice.

ISO 9001 certified. © Copyright SPM 2003-10. 71679.Z

SPM Instrument AB • Box 4 • SE-645 21 Strängnäs • Sweden

Tel +46 152 22500 • Fax +46 152 15075 • info@spminstrument.se • www.spminstrument.com

Recording of Readings

The SPM follow-up form provides space for readings

in all three directions at up to four different points,

which should adequately cover most industrial machines. Experience will soon show which of the points

and directions provide the most useful information

for diagnosing a specific problem on any particular

piece of plant.

In the case of a furnace extract fan (example opposite), three measuring points should be sufficient. With

this type of machine, the usual problem is out of

balance caused by soot on the impeller blades. That

makes the vibrations measured in the horizontal direction at point 3 most significant. General directives

for maintenance (6) should be based on the readings

at that point.

A graph (11) is the best way to show clearly all significant changes of the vibration level. To keep the form

simple, draw only the graph for the most significant

direction (7), normally that giving the highest readings.

In the example, the extra space (17) was used for a

second graph for the important point 3, in order to

show the axial vibration trend as well.

There are no general rules about how often vibration

should be measured. The intervals between readings

- a day, a week, perhaps a whole month - depend

wholly on the individual machine, its work, its importance for the plant and on the rate of change in its

vibration level. Obviously an exhaust fan with a soot

problem will need more frequent surveillance than a

fresh air fan, but only practical experience can help to

determine the optimal number of checks per month.

If the form is to be used for machines class I, V or VI,

fill in the relevant vibration levels under (16). Note

that the condition bands (12-15) only apply if the

machine is classed correctly.

Preparation

1 Record chart number

2Machine designation, number and

location

3Machine class

4Machine sketch with numbered

measuring points

5 Vibration class and levels (cross out

figures which do not apply)

6 Directives for maintenance

7 Number of measuring point and

direction plotted on chart

8H = horizontal, V = vertical, A = axial

Measurements

9 Date of measurement

10 Measured value in three directions

11 Plotted value of main direction

Machine Condition

12 dark red – bad condition

13 pale red – just tolerable

14 pale green – acceptable

15 dark green – good condition

Chart Modification

16 Other machine classes and their

respective vibration levels:

bad

tolerable

acceptable

good

IVVI

0.43 2,80 4.33

0.28 1.77 2.80

0.18 1.10 1.77

0.11 0.71 1.10

0.07 0.43 0.71

0.04 0.28 0.43

0.03 0.18 0.28

0.02 0.11 0.18

0.01 0.07 0.11

Page 10

9

Technical data are subject to change without notice.

ISO 9001 certified. © Copyright SPM 2003-10. 71679.Z

SPM Instrument AB • Box 4 • SE-645 21 Strängnäs • Sweden

Tel +46 152 22500 • Fax +46 152 15075 • info@spminstrument.se • www.spminstrument.com

VIC-12

Page 11

10

Technical data are subject to change without notice.

ISO 9001 certified. © Copyright SPM 2003-10. 71679.Z

SPM Instrument AB • Box 4 • SE-645 21 Strängnäs • Sweden

Tel +46 152 22500 • Fax +46 152 15075 • info@spminstrument.se • www.spminstrument.com

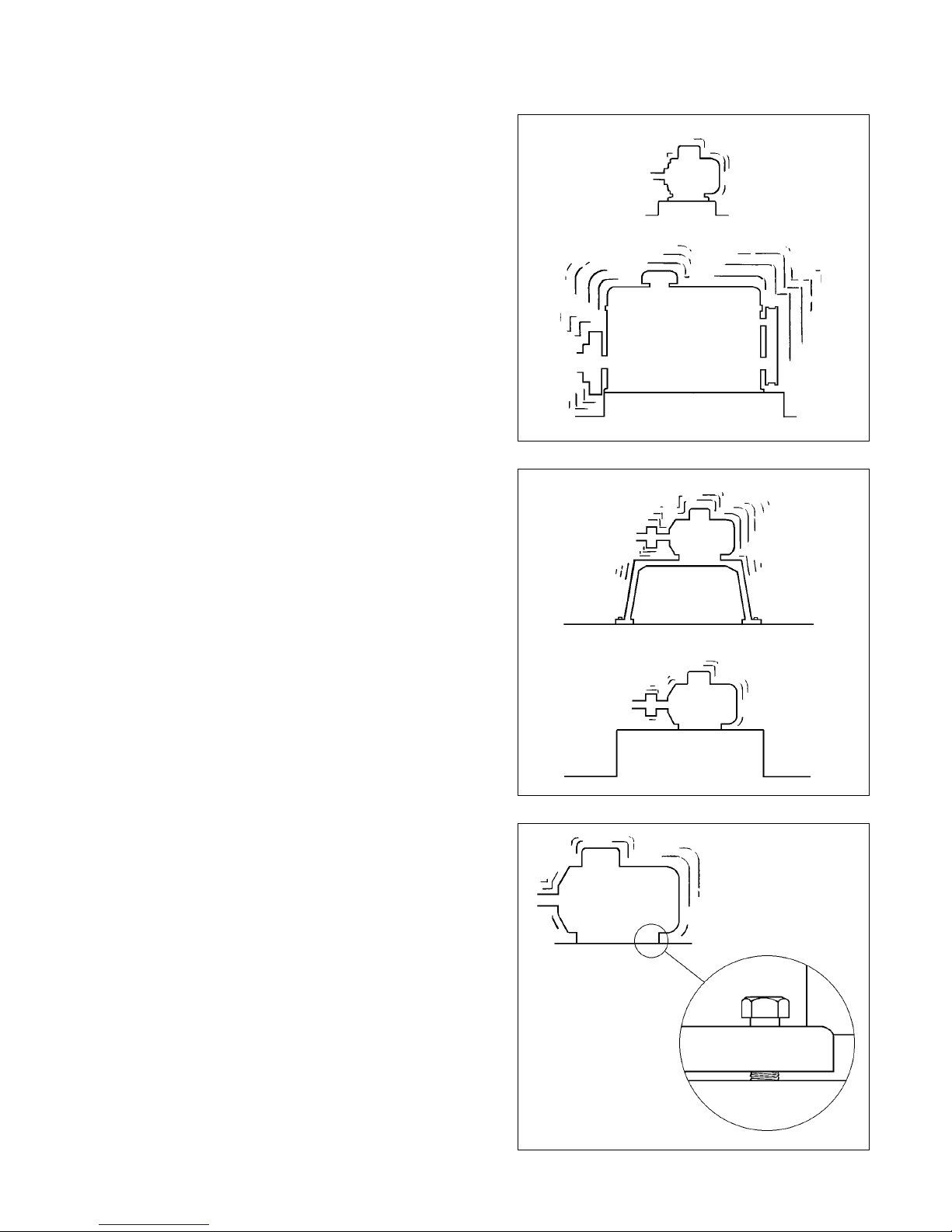

Measuring Equipment

The SPM equipment for manual vibration monitoring

consists of:

• Vibrameter VIB-11B

•Measuring cable 46044 (46045)

• Vibration transducer TRV-23 (TRV-22)

• TRX-16, Magnetic base for TRV-22

• TRX-17, Probe for TRV-22.

Follow-up forms can be supplied in pads of 25 each

(ordering number VIC-12).

Transducer Mounting

The accuracy of vibration readings depends largely

on the connection between transducer and measuring point. Only stiff connections, by magnet, screw or

cement, will allow the transducer to accurately follow

the movements of the vibrating surface.

Magnetic Mounting

The vibration transducer is normally mounted on the

machine with the magnetic base.

Attach the transducer to a smooth, flat surface, with

the main sensitivity axis pointing in the desired measuring direction. Spot-face the contact surface if necessary. The magnetic base has a diameter of 27.5 mm.

Screw Mounting

Screw mounting is the best alternative where the

magnetic base cannot be used. Prepare threaded

mounting holes as shown in the figure.

TRV-23 has thread size UNF 1/4"-28 and TRV-22 has

M8. The transducers are delivered with three washers

for adjusting the connector angle. Each washer turns

the transducer 90°.

If the vibration transducer is to be permanently

mounted on the machine, secure the low noise coaxial

cable with a clamp close to the connector (see figure).

For installations in moist environments, use sealing

TNC cable plugs SPM 13008 to prevent cable corrosion.

TRX-17

TRX-16

TRV-22/23

VIB-11B

Cable

clamp

min. 16ø 6.9

(ø 5.5)

M8

(UNF

1/4" -28)

min. 12

max. 0.7

min. 10

Main sensitivity axis

46044

46045

ø 27

17

ø 27.5

41.5

9

ø 15

t

TRV-22: t = M8

TRV-23: t = UNF 1/4" -28

Page 12

11

Technical data are subject to change without notice.

ISO 9001 certified. © Copyright SPM 2003-10. 71679.Z

SPM Instrument AB • Box 4 • SE-645 21 Strängnäs • Sweden

Tel +46 152 22500 • Fax +46 152 15075 • info@spminstrument.se • www.spminstrument.com

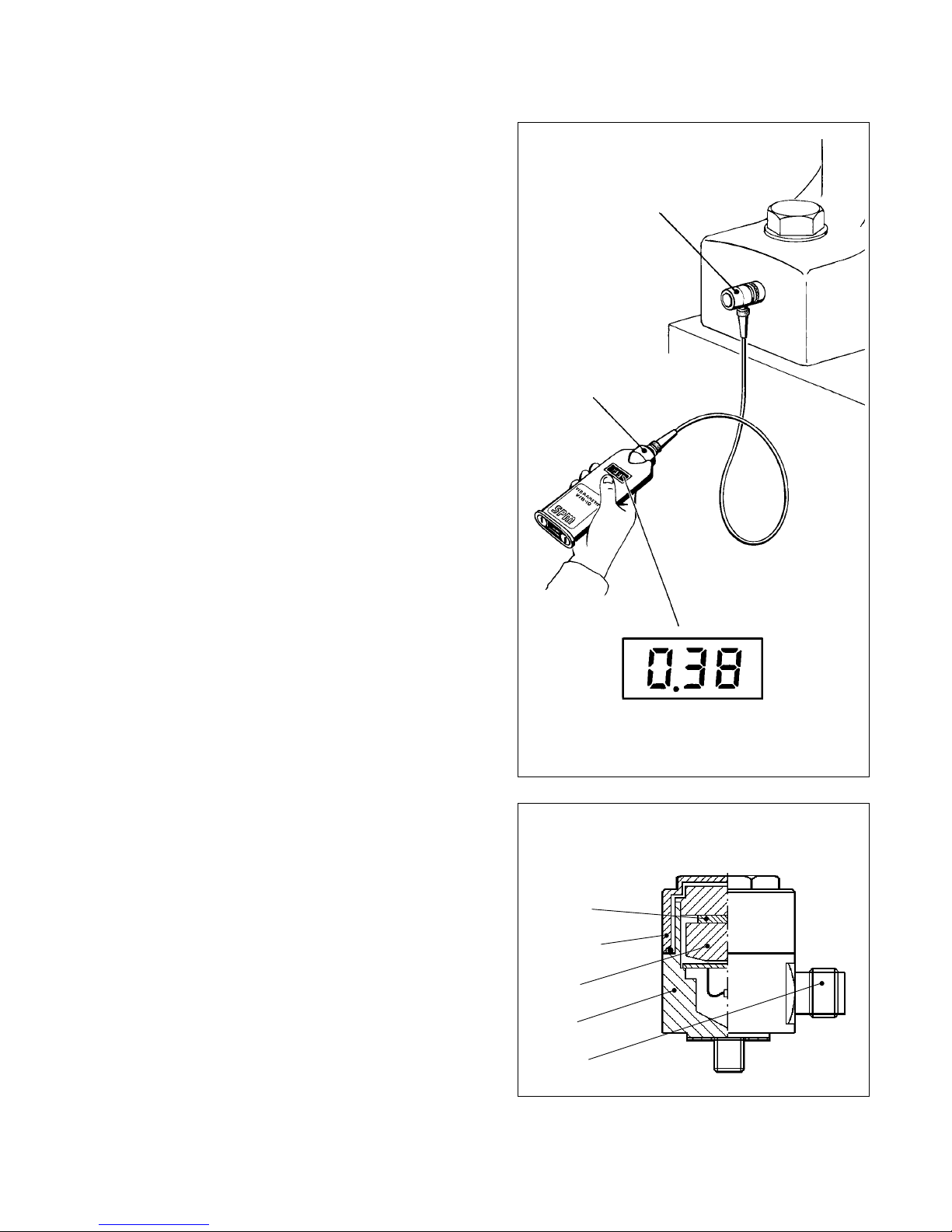

Hand-held Probe

With the probe TRX-17 attached, the vibration transducer can be used as a hand-held probe. The probe

can be fastened directly to the transducer TRV-22.

Hand-held probes are widely used for quick vibration

surveys. The advantages are obvious - there is no

need to prepare measuring points. Note, however,

that the overall stiffness is poor, which can give gross

measuring errors. Using a hand-held probe requires

practice and repeatable results cannot be guaranteed.

Taking Readings

Connect the transducer to Vibrameter VIB-11 with the

measuring cable. Attach the transducer to the measuring point.

Press the button below the display window and hold

it down. Wait for the readout to stabilize. Read and

record the result.

To switch off the instrument, release the button.

If the display shows "OFL", the instrument has an

overflow, caused by signals above the masuring range.

Changing Batteries

The display will show "Lob" when the battery voltage

is getting low.

Use a coin to give both locks of the battery compartments a quarter turn to the right or left. Insert new

batteries as shown on the back of the instrument.

Use only alkaline battery cells, 1.5 V, for example MN

1500 or UCAR E91. Leaking batteries can destroy the

instrument. Remove the batteries before storing the

vibrameter for long periods.

Page 13

12

Technical data are subject to change without notice.

ISO 9001 certified. © Copyright SPM 2003-10. 71679.Z

SPM Instrument AB • Box 4 • SE-645 21 Strängnäs • Sweden

Tel +46 152 22500 • Fax +46 152 15075 • info@spminstrument.se • www.spminstrument.com

Maintenance Based on Vibration Records

The purpose of regular vibration measurements is to

collect data for “condition based maintenance“, i.e.

maintenance carried out whenever condition measurements indicate a need for action.

To be able to plan ahead and work efficiently, a maintenance department needs regular and easily interpreted information on all significant changes in machine condition.

The flow chart opposite provides general rules for the

interpretation of vibration data. The diagram above

shows an example of how maintenance information

can be reduced to a few simple facts, which are passed

easily through one department to another.

Establish Norm Values

Usually, when vibration measurements start, the machine is in good condition. If its vibration class is

correctly chosen, the initial readings taken after a

running-in period should be in the “good“ or “acceptable“ range. Record these values and use them as a

standard of reference for this particular machine.

Provided the vibration level at all measuring points

remains stable, the subsequent readings are a matter

of routine. Small fluctuations of the values on the

follow-up forms are to be expected. They will hardly

show up on the graphs and the actual figures are

unimportant from a maintenance point of view.

Report Significant Changes

A one step change in the vibration level is generally

regarded as significant and should be reported. One

step is the space between two lines on the follow-up

form. For all machine classes at any level, it repre-

sents a 1.6 times increase (decrease) from the previous reading or, if the change is gradual, from the

original norm value.

For maintenance, it is a first warning that machine

condition is getting worse. At this stage, tightening a

few bolts or adjusting a belt may be sufficient to get

rid of the excess vibration and prevent further deterioration.

Each condition band consists of two steps. An increase from a starting point in the “good“ range to a

corresponding point in the next range means that

vibration has gone up 2.5 times. A large change like

that should be investigated, even though the vibration level is still “acceptable“.

Reporting changes in step is the simplest way of indicating the extent and urgency of a maintenance problem. If needed, the supporting figures are on record.

Moreover, the method is flexible. As experience increases, individual alarm levels and in-house limits can

be easily marked on the recording forms.

Basic Fault Analysis

It should be clearly understood that Vibrameter VIB11 is not intended to supply data for detailed fault

analysis. However, readings from several measuring

points in three directions can usually give a good

indication of the nature and location of the maintenance problem. Again, the flow chart may serve as a

general guide.

Notice where on the machine and in what direction

the measured value changes most. A simple report

(“motor bearing, up two steps, axial + radial“) gives a

repair crew a starting point and can save them a lot of

trouble.

Vibration

Measurement

(Shutdown)

Effect repairs

Plan major

overhaul

Inspection

minor repairs

Routine

maintenance

(lubrication, etc.)

Report dangerous increase

Report large increase

Report change

+ 4 steps

+ 3 steps

+ 2 steps

+ 1 step

Normal

Vibration severity Breakdown

Maintenance

Activities

Page 14

13

Technical data are subject to change without notice.

ISO 9001 certified. © Copyright SPM 2003-10. 71679.Z

SPM Instrument AB • Box 4 • SE-645 21 Strängnäs • Sweden

Tel +46 152 22500 • Fax +46 152 15075 • info@spminstrument.se • www.spminstrument.com

Fault Analysis Chart

Vibration up 2 steps from original or good level:

Plan to maintain, measure more frequently.

Vibration up 3 steps:

Inspect and maintain as soon as possible,

measure daily.

Vibration up 4 steps or more:

Shut down immediately and investigate.

Where

?

Part of

machine

All over

machine

Axial

+ radial

How

much

?

> 1 step

Record results.

Measure again

according to

schedule.

No

change

Increase

Treat large unexplained decrease like large

increase. Investigate soonest.

Recent maintenance, machine off load or stopped.

Measuring fault.

Something broken, loose, or missing.

Change

?

Measure Vibration Severity

Plan to maintain

when vibration

increases 2 steps

above new or

good level.

Slow build-up of

dirt.

Steady wear,

corrosion.

Stretched or

slipping belts.

Direc-

tion

?

Slack mounting bolts,

loose frame parts,

etc.

Coupling wearing or

stiffening.

Gear tooth wear.

Mainly

radial

< 1 step

Time Schedule Machine Class Measuring Point

Decrease

Radial and axial:

Slack or sheared

mounting bolts.

Damaged machine

feet, bent or

damaged subframes

or supports.

Faulty alignment,

bent or cracked

shaft.

Gear tooth damage.

One step on the chart below (any class at any

level) represents a 1.6 times increase from

previous value.

Each condition band (= 2 steps) represents a

2.5 times increase, i.e. a significant change in

vibration severity.

3 steps up is a fourfold increase, an alarming

change demanding immediate action.

Class Class Class Class Class Class

RMS

mm/s

Limits

1 step

Mainly radial: Failed fan blades,

loss of balance weights,

shedding of dirt. Oil film

hysteresis whirls, excessive

bearing play.

Radial and axial: Changes in

foundation or support structure

causing serious misalignment or

looseness. Bent or fractured

shafts. Critical speed and other

resonances.

Small machines: Possibly

transmitted vibration from

larger machines.

Page 15

14

Technical data are subject to change without notice.

ISO 9001 certified. © Copyright SPM 2003-10. 71679.Z

SPM Instrument AB • Box 4 • SE-645 21 Strängnäs • Sweden

Tel +46 152 22500 • Fax +46 152 15075 • info@spminstrument.se • www.spminstrument.com

Technical Specifications

TRV-22

TRV-23

TRX-16

81030

81031

81057

81027

46044

46045

TRX-17

VIC-11

VIC-12

VIB-11B

Tools

81027 Holder for counterbore

81057 Counterbore, diam. 20 mm

81030 Pilot, UNF 1/4" (TRV-23)

81031 Pilot, M8 (TRV-22)

Literature

70977 B

Balancing with VIB-10/VIB-11

Vibrameter VIB-11B

Measuring range 0.01 to 3.93 in/s RMS,

10 to 1000 Hz

Resolution 0.01 in/s (0.1 mm/s)

Accuracy 2% ± 0.02 in/s (2% ± 0.2 mm/s)

Power supply Four 1.5 V alkaline cells

(e.g. MN 1500 or UCAR E91)

Temperature range 32 to 131 °F (0 to +55 °C)

Display 3 digits, red LED

Switch-off Automatic

Protective cover Polyurethane

Dimensions 8.3" x 2.9" x 1.2"

(210 x 75 x 30 mm)

Weight 14 oz (410 grams) incl. batteries

Connector type TNC

Vibration Transducer TRV-22/23

Nominal sensitivity, main axis 10 pC/m/s

2

(7-12 pC/m/s2 )

Transverse sensitivity max. 10%

Typical base strain sensitivity 0.01 m/s2/µ

Linear frequency range 0 to 5000 Hz

Max. peak acceleration 600 m/s

2

Temperature range -30° C to +150° C

(-22° F to +302° F)

Typical temperature drift 0.25% / °C

Casing Stainless, acid proof,

steel, AISI 316, sealed

Dimensions diam. 27.5 x 45 mm

Weight 171 grams (6 oz)

Connector type TNC

Torque limit 10 Nm (7.4 lbf/ ft)

Part Numbers

VIB-11B Vibrameter in/s, incl.battery cells

TRV-22 Vibration transducer, M8

TRV-23 Vibration transducer, UNF 1/4"-28

TRX-16 Magnetic base for transducer TRV-22

TRX-17 Probe for transducer TRV-22

46044 Measuring cable with connectors, 1.5 m

46045 Measuring cable with sealing TNC plug,

1.5 m

VIC-12 Follow-up forms in/s, pad of 25

VIC-13 Follow-up forms, balancing, pad of 25

Page 16

15

Technical data are subject to change without notice.

ISO 9001 certified. © Copyright SPM 2003-10. 71679.Z

SPM Instrument AB • Box 4 • SE-645 21 Strängnäs • Sweden

Tel +46 152 22500 • Fax +46 152 15075 • info@spminstrument.se • www.spminstrument.com

Definition of Machine Classes According to ISO 2372

The following text is a quotation from ISO 2372 (1974, E, page 6, Annex A). This ISO Recommendation has also

been published as British Standard (BS 4675, part I). A similar vibration classification of industrial machinery can

be found in VDI 2056.

In order to show how the recommended method of

classification may be applied, examples of specific

classes of machines are given below. It should be emphasized, however, that they are simply examples

and it is recognized that other classifications are possible and may be substituted in accordance with the

circum-stances concerned. As and when circumstances

permit, recommendations for acceptable levels of vibration severity for particular types of machines will

be prepared. At present, experience suggests that

the following classes are appropriate for most applications.

Class I

Individual parts of engines and machines, integrally

connected with the complete machine in its normal

operating condition. (Production electrical motors of

up to 15 kW are typical examples of machines in this

category.)

Class II

Medium-sized machines, (typically electrical motors

with 15 to 75 kW output) without special foundations,

rigidly mounted engines or machines (up to 300 kW)

on special foundations.

Class III

Large prime movers and other large machines with

rotating masses on rigid and heavy foundations which

are relatively stiff in the direction of vibration measurement.

Class IV

Large prime movers and other large machines with

rotating masses on foundations which are relatively

soft in the direction of vibration measurement (for

example turbogenerator sets, especially those with

lightweight substructures).

Class V

Machines and mechanical drive systems with unbalanceable inertia effects (due to reciprocating parts),

mounted on foundations which are relatively stiff in

the direction of vibration measurement.

Class VI

Machines and mechanical drive systems with unbalanceable inertia effects (due to reciprocating parts),

mounted on foundations which are relatively soft in

the direction of vibration measurements; machines

with rotating slackcoupled masses such as beater

shafts in grinding mills; machines, like centrifugal machines, with varying unbalances capable of operating

as selfcontained units without connecting components;

vibrating screens, dynamic fatigue-testing machines

and vibration exciters used in processing plants.

Page 17

RETURN TO VALIDATE WARRANTY

CUSTOMER COPY

71409 B

SERIAL NO. ______________________

PRODUCT _____________________________________ VERSION NO. ___________________

PURCHASE DATE ________________________________________________________________

COMPANY ______________________________________________________________________

ADDRESS _______________________________________________________________________

CITY __________________________________________ POSTAL CODE ___________________

COUNTRY _____________________________________ PHONE _________________________

USER NAME(S)_________________________________ FAX _____________________________

AUTHORIZED DISTRIBUTOR ______________________________________________________

CUSTOMER NO. _________________

SERIAL NO. ______________________

PRODUCT _____________________________________ VERSION NO. ___________________

PURCHASE DATE ______________________________ CHECKED BY ____________________

COMPANY ______________________________________________________________________

ADDRESS _______________________________________________________________________

CITY __________________________________________ POSTAL CODE ___________________

COUNTRY _____________________________________ PHONE _________________________

USER NAME(S)_________________________________ FAX _____________________________

AUTHORIZED DISTRIBUTOR ______________________________________________________

CUSTOMER NO. _________________

REGISTERED LIMITED WARRANTY

✂

PLACE

STAMP

HERE

SPM Instrument AB

Box 4

S-645 21 STRÄNGNÄS

Sweden

One (1) year limited warranty from date of purchase against defects in work-

manship or materials. Warranty is void if instrument is altered or repaired by

unauthorized service center. Warranty does not apply on any instrument

subjected to misuse or damaged by leaking batteries. Warranty is for instru-

ment only and does not cover batteries or cables. SPM reserves the right to

determine disposition as to repair or replacement of goods.

Warranty form MUST be completed and returned to SPM Instrument to vali-

date warranty.

Should the instrument require any service whether under warranty or not, you

should contact SPM Instrument or your local distributor for instructions

before returning the goods.

SPM Instrument AB

Box 4

S-645 21 STRÄNGNÄS

Sweden

SPM Instrument AB

Box 504

SE-645 25 STRÄNGNÄS

Sweden

SPM Instrument AB

Box 504

SE-645 25 STRÄNGNÄS

Sweden

Loading...

Loading...