Data di emissione: Novembre, 2015 Revisione: 1 Pag. : 1/24

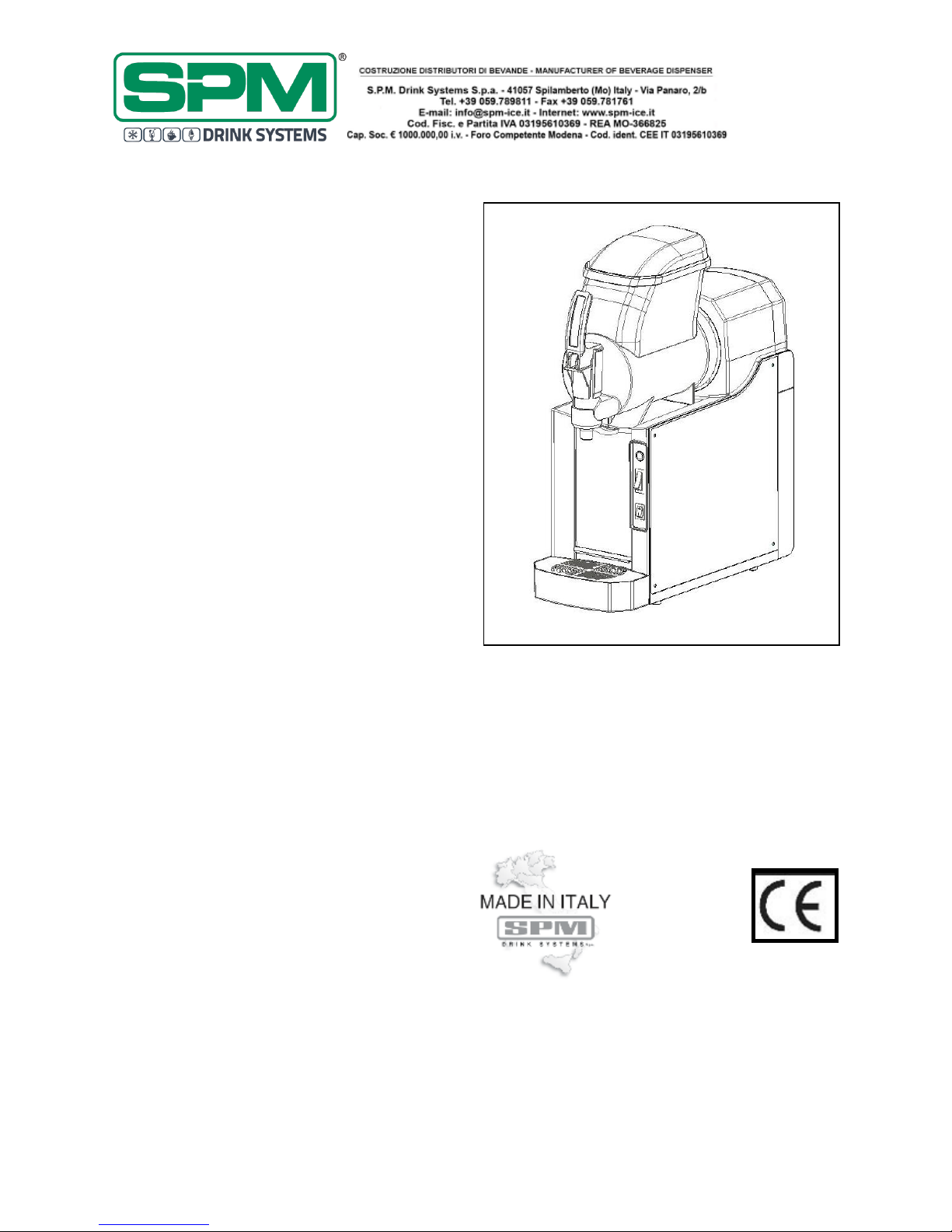

NINA HOT

Operator’s manual

Page 2

Data di emissione: Novembre, 2015 Revisione: 1 Pag. : 2/24

Published by:

SPM DRINK SYSTEMS S.p.a.

Via Panaro n° 2

41057 Spilamberto (MO)

Edition: 01/2016

Revision: 02

© 2016 – SPM Drink Systems

All copying rights are reserved to SPM DRINK SYSTEMS; copying, even partial, is illegal.

The descriptions and illustrations refer to the specific machine at issue. SPM Drink Systems reserves the right to

modify at any time the equipment for mass production.

This manual:

- is integral part of the supply and must be carefully read, in order to be properly used, in compliance with

the essential safety requirements;

- has been drafted by following the dispositions 2006/42/CE and reports the technical information that are

necessary to correctly run all the procedures, under safety conditions;

- must be carefully kept (protected by a transparent, watertight wrapping, in order to avoid any damage)

and must go with the machine during its life, including potential changes of ownership. In case of loss or

damage, it’s possible to ask for a copy to SPM DRINK SYSTEMS, pointing out the information stated on

the identification label;

SPM DRINK SYSTEMS declines all responsibility for a wrong usage of the machine and/or damages caused by

operations not provided for in this manual..

Dear Customer,

We would like to congratulate you for

choosing this high-quality product, that will

certainly meet all your expectations.

We thank you for the preference reserved to

our company and we invite you to carefully

read the following instruction manual before

machine’s start up.

Data di emissione: Novembre, 2015 Revisione: 1 Pag. : 3/24

INDEX

1. IMPORTANT WARNINGS AND ADVICES

………………………………………………E

rrore. Il segnalibro non è definito.

2. EQUIPMENT KIT Errore. Il segnalibro non

è definito.

3. TRANSPORT TIPSErrore. Il segnalibro non

è definito.

4. LIFTING TIPS ... Errore. Il segnalibro non è

definito.

5. TECNICAL SPECIFICATIONS .... Errore. Il

segnalibro non è definito.

6. POSITIONING .. Errore. Il segnalibro non è

definito.

7. CONNECTION TO THE POWER SUPPLY

MAINSErrore. Il segnalibro non è definito.

8. START-UP PROCEDURES AND

OPERATING INSTRUCTIONS .. Errore. Il

segnalibro non è definito.

Thermostat setting .. Errore. Il segnalibro non è

definito.

9. CLEANING AND DAILY SANITIZING

PROCEDURES Errore. Il segnalibro non è

definito.

10. SPECIAL MAINTENANCE .......... Errore. Il

segnalibro non è definito.

Control and replacement of gaskets .... Errore. Il

segnalibro non è definito.

Winter storage ................................................. 17

Product storage....... Errore. Il segnalibro non è

definito.

11. DISCLAIMER ... Errore. Il segnalibro non è

definito.

12. TROUBLESHOOTING GUIDE .................19

13. WIRING DIAGRAM... Errore. Il segnalibro

non è definito.

Data di emissione: Novembre, 2015 Revisione: 1 Pag. : 4/24

1. IMPORTANT WARNINGS AND

ADVICES

This installation and operation manual is

an integral part of the equipment and must

be kept for future consultation.

Unless otherwise stated, this manual is

addressed to operators (staff members

who uses the equipment on a daily basis)

and to servicemen (staff members qualified

to carry out the installation and/or

maintenance). The parts of the manual

addressed only to servicemen are pointed

out accordingly. Please read carefully the

warnings listed here below before

installation and start-up of the equipment.

This equipment has been designed to

produce soft serve creamy product,

sorbets, and similar products.

Upon receipt of the equipment, make sure

that its part number matches the one

specified in the order, which can be found

on all the delivery documents.

This equipment is exclusively destined to

the purpose for which it was designed. The

manufacturer cannot be held responsible

for any damage due to improper use.

This appliance can be used by children

aged from 8 years and above and persons

with reduced physical, sensory or mental

capabilities or lack of experience and

knowledge if they have been given

supervision or instruction concerning use

of the appliance in a safe way and

understand the hazards involved. Children

shall not play with the appliance. Cleaning

and user maintenance shall not be made

by children without supervision.

This equipment is not suitable for outdoor

use. This machine is not suitable for

installation in locations where water jets

are used.

The appliance is only to be installed in

locations where its use and maintenance is

restricted to trained personnel.

Do not store explosive substances such as

aerosol cans with a flammable propellant

in this

appliance.

This appliance is intended to be used in

household and similar applications such as

– staff kitchen areas in shops, offices and

other working environments;

– farm houses and by clients in hotels,

motels and other residential type

environments;

– bed and breakfast type environments;

– catering and similar non-retail

applications.

2. EQUIPMENT KIT

In the packaging of this equipment you will find

also:

- operator’s manual,

- 1 tube of Vaseline grease lubricant to be used

for machine maintenance;

- EC declaration of conformity;

- 1 drip tray.

3. TRANPORT TIPS

To prevent the oil held in the hermetic

compressor running into the cooling circuit, the

device must be carried, stored and handled in

the upright position, following the direction

instructions on the packing. If the device is

accidentally or intentionally (for transportation

reasons) kept in any other position, it must be

set again in the correct position at least twenty

minutes before start-up procedures, in order to

let the oil flow back into the compressor.

4. LIFTING TIPS

Each machine is equipped with a special wooden

pallet that allows the handling with standard

forklift trucks.

Caution

Never lift the machine alone, but always seek

the assistance of another operator.

To prevent and avoid any damage to the

machine, all loading and unloading operations

should be carried out with special care. The

equipment can be lifted, with either a manual or

engine-powered lifting truck, by positioning

theforks in the base section of the unit.Per non

provocare danni all'apparecchio, le manovre di

carico e scarico sono da effettuarsi con

particolare cura. E' possibile sollevare

l'apparecchio, con carrello elevatore, a motore o

manuale, posizionando le pale nella parte

sottostante dello stesso.

Data di emissione: Novembre, 2015 Revisione: 1 Pag. : 5/24

The following operations should always be

avoided:

- to turn upside down the machine;

- to drag the machine with ropes or others;

- to lift the machine with slings or ropes

- to shake or rattle the machine and its

packaging.

The machine must be stored in a dry place with

temperatures from 0°C to 40 °C. No more than

2 machines should be stacked on top of each

other, taking care to maintain the vertical

position, as shown by the arrows on the carton.

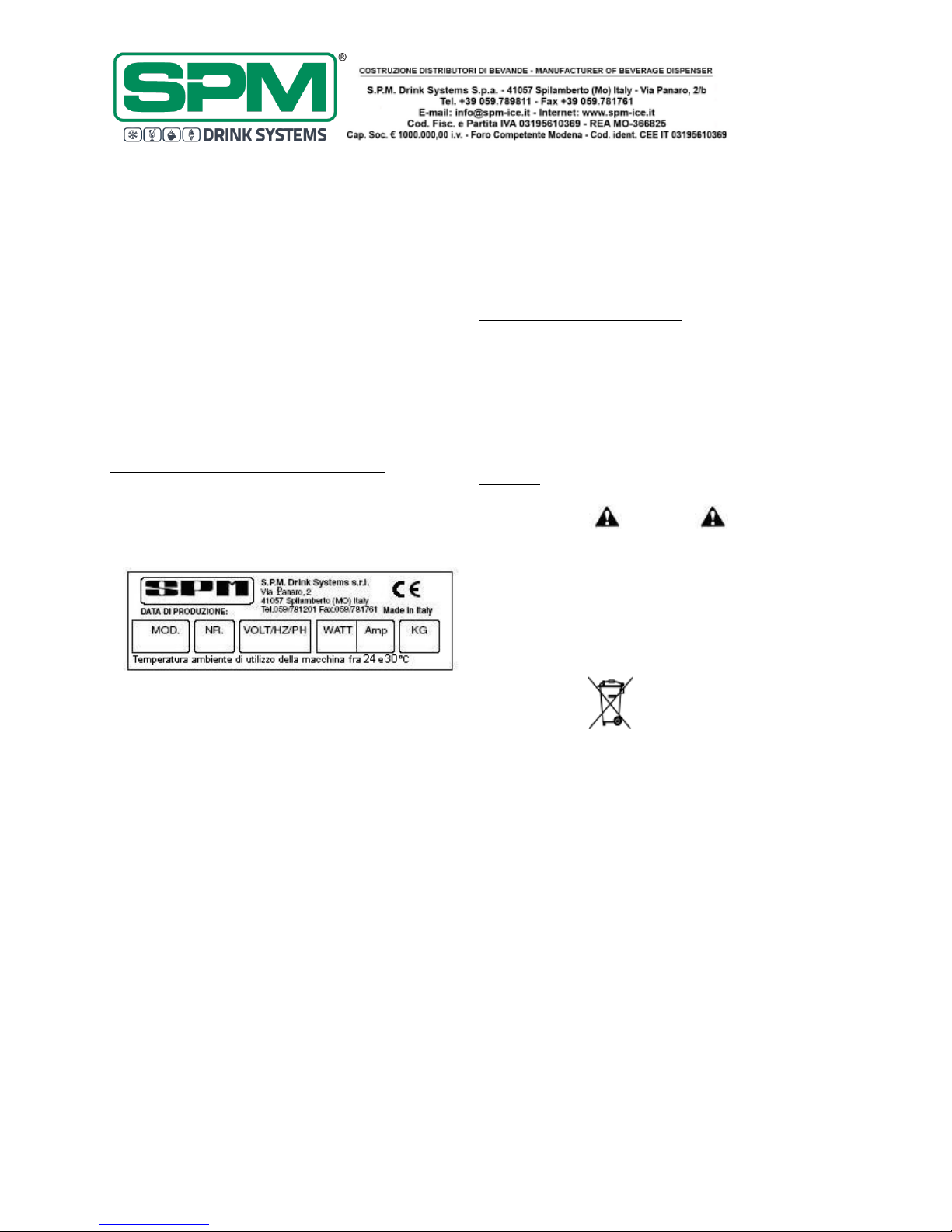

5. TECHNICAL SPECIFICATIONS

Technical and electrical specifications

All the machine’s technical and electrical

specifications are stated on the identification

plate, positioned in the internal part of the

equipment; a sample is shown here below.

The plate specifies:

Model: XX

n°: XX

Electrical specifications: Volt/ Hz

Max. absorption (Watt)

Max. current (Amp)

Machine ambient working temperatures

between 24°C and 30°C.

Dimensions and weight:

NINA1

Height: 487.5 mm

Width: 160 mm

Depth: 380 mm

Weight 15kg

NINA2

Height: 487.5 mm.

Width: 280 mm.

Depth: 387.5 mm.

NINA3

Height: 520 mm.

Width: 420 mm.

Depth: 390 mm.

Noise emissions

The continuous, equivalent, weighted level of

acoustic pressure is below 70 dB.

In the event of breakdown:

In most cases, any technical problem can be

settled with slight interventions (please see the

troubleshooting guide at the end of this

manual); we therefore recommend you to

carefully read this handbook before contacting

the manufacturer or service centre.

Disposal

Caution

All the parts of the packaging must be kept

beyond the range of children, as they might

represent a potential safety/health risk.

Important

In respect of the environment, please dispose

the packaging as illustrated.

This symbol: means that the machine

cannot be disposed as common waste. It must

be handled in compliance with the provisions of

European directive 2003/108/EC (Waste

Electrical and Electronic Devices - WEEE) and

the resulting national legislation, in order to

prevent any potential damage to the

environment and to create health risks.

In order to correctly dispose of the device,

please contact the distributor from which you

purchased it or our after-sales service.

Data di emissione: Novembre, 2015 Revisione: 1 Pag. : 6/24

Fig. 1

6. POSITIONING

FOR MAINTENANCE WORKER ONLY

The installation and subsequent servicing

operations must be carried out by skilled

members who have been trained to use the

device and in compliance with the

regulations in force.

a) Remove the packing and preserve it in order

to reuse for winter storage.

Caution

All the parts of the packaging must be kept

beyond the range of children, as they might

represent a potential safety/health risk.

b) Make sure the machine is in perfect

condition.

b) Rest the machine on a sturdy, horizontal

surface making sure it is well ventilated by

leaving a gap of 20 cm around it and do not

install it near heat sources (fig.1); we

recommend you to maintain a room

temperature between 24 and 30°C.

c) Check that the power mains voltage meets

the specifications on the equipment

identification plate and that the output available

meets the device’s power requirements.

Fit the plug into an earthed socket, removing all

multiple adaptors.

FOR FURTHER PRECAUTIONS, READ THE

SECTION “CONNECTION TO THE ELECTRICITY

MAINS” CAREFULLY.

d) The installation must be carried out in

accordance with the manufacturer’s instructions.

Failure to comply with the positioning and

installation instructions may impair the

machine’s operation.

Important

You are legally required to provide a suitable

grounding system for the equipment.

Before carrying out any cleaning and/or special

maintenance on the device, make sure it is

disconnected from the mains by unplugging it.

In the event of a breakdown or malfunctioning,

switch off the device and remove the plug.

Data di emissione: Novembre, 2015 Revisione: 1 Pag. : 7/24

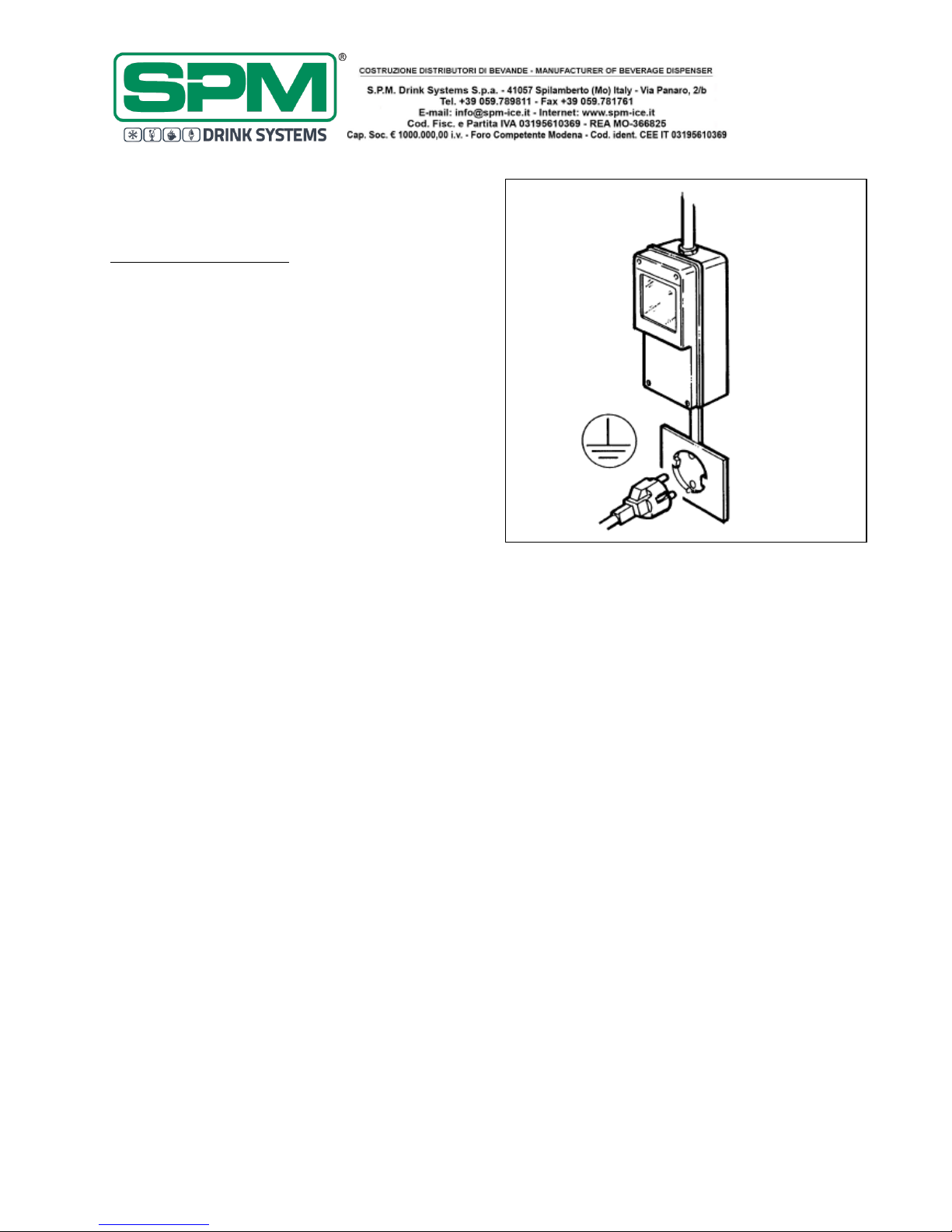

7. CONNECTION TO THE POWER

SUPPLY MAINS

FOR SERVICEMAN ONLY

Before fitting the plug in the power supply

socket, for your own safety, as already

mentioned in the previous paragraph, please

read the following precautions.

- The machine’s electrical safety is only

guaranteed when it is connected to a suitable

earth system, structured as provided by the

national safety current regulations (fig.2).

Therefore, the manufacturer cannot be held

responsible for any damage due to failure of the

grounding system of the machine.

- Always verify electrical specifications on the

data plate of each machine. Data plate

specifications always replace the information of

this manual.

- For a safe and correct installation, it is

essential to provide a suitable socket controlled

by a thermal cut-out switch whose contacts are

at least 3 mm apart, in accordance with the

current national safety regulations (see fig.3).

- Never use extensions or multiple adaptors.

- Check the power lead along its entire length to

make sure it is not crushed in any way.

- To unplug the device, first disconnect the

power supply with the switch, then grip the plug

and gently pull it out.

Important

IF THE POWER CABLE IS DAMAGED, IT MUST

BE REPLACED BY THE MANUFACTURER, ITS

AFTER SALE SERVICE OR BY QUALIFIED

PERSONNEL, TO PREVENT ANY POSSIBLE RISK.

Fig. 2

Data di emissione: Novembre, 2015 Revisione: 1 Pag. : 8/24

8. START-UP PROCEDURES

!IMPORTANT!

BEFORE STARTING THE MACHINE, CARRY OUT

THE CLEANING AND SANITISING PROCEDURES

DESCRIBED IN CHAPTER 10.

- Dilute and mix the product in a separate

container according to the manufacturer’s

instructions (see fig.3).

NOTE: “mix” is the result of the blending

between water or milk with the powder to

make soft serve creamy product, sorbets,

and similar products.

Don’t introduce more than 1.5 litres of mix

inside the bowl. This kind of product has a not

negligible overrun during its freezing, so it is

very important to control it in order to avoid to

go over the bowl maximum level (please see the

chapter about the overrun calculation).

- Pour the mix obtained into the bowl (see

fig.4).

- Restore the transparent cover.

Note -----------------------------------------------

Each bowl is equipped with a very efficient

safety mechanism designed to protect the

operator; it is activated when cover is lifted.

This device automatically and immediately stops

all moving parts.

If the cover is not correctly positioned, the

correspondent mixing system will not

work.

------------------------------------------------------

- Insert the female plug into the electrical power

inlet (fig.5) and then the male one into the

power supply socket.

- Switch on the unit main switch A (fig.9 and

10).

1.

Fig. 3

Fig. 4

Fig. 5

Data di emissione: Novembre, 2015 Revisione: 1 Pag. : 9/24

- In order to activate the mixing auger it is

necessary to start up the switch A (fig.6).

- In order to activate the warming elementi it is

necessary to start up the switch B, considering

that if the mixing auger is not working (switch A

not in I position) the warming element does not

work (fig.6).

NOTE: when the heating component the red

light C is on (fig.6); the machine warms up and

keeps the product at the right temperature,

trough ON/OFF cycles, therefore during the

normal functioning the light C will turn ON and

OFF to show when the warming element is

ON/OFF.

NOTE: the machine is provided by an internal

thermostat to set the product’s temperature,

you can calibrate this thermostat to a maximum

80°C.

- Once that the product reaches the set

temperature, to deliver, put the glass under the

tap and pull the leve ras shown in figure 7.

Fig. 6

Fig. 7

A

B

C

Data di emissione: Novembre, 2015 Revisione: 1 Pag. : 10/24

Thermostat setting

Caution

Before proceeding to any maintenance

operation, it is compulsory to turn OFF the

machine and to unplug the power cable

from the power socket.

In order to regulate the product’s warming

temperature it is necessary to reach and set the

thermostat wich is inside the machine.

How to reach the thermostat:

- Remove the voltage to the machine

disconnecting the general switch unplugging the

power the power cable.

- Remove the rear panel re leasing the plastics

knobs and polling them thowards you as shown

in figure 8;

- Set the thermostat on the desired temperature

(fig.9), turning the metal ring clockwise you

increase the warming temperature (the

maximum temperature you can reach is 80°C)

turning it counter clockwise you decrease the

temperature.

- Close the rear panel before making the

machine working.

Fig. 8

Fig. 9

Data di emissione: Novembre, 2015 Revisione: 1 Pag. : 11/24

9. CLEANING AND DAILY SANITIZING

PROCEDURES

In order to maintain the unit in like-new

operating condition and to respect current

regulations, it’s absolutely necessary to

frequently and carefully perform the cleaning

and sanitizing operations as described below.

In case of prolonged shutdown (winter storage),

the machine must be disassembled, washed and

sanitized according to the instructions in this

manual before start-up to ensure the best

possible cleanliness.

Caution

Electric shock hazard. Do not splash water

on switches or allow water to flow onto

electrical components inside the machine.

Caution

To prevent bacteria growth, use only

sanitizers approved for plastic and rubber

objects, failure to do so could create a

health hazard.

NOTE: it is responsibility of the operator to be

aware of and conform to the requirements of

current local, state and federal laws concerning

the frequency of cleaning and conservation of

products used.

The cleaning instructions explained in this

section are essential procedures to remove

bacteria and maintain a sanitarily clean

machine.

We recommend to perform the cleaning

and sanitizing procedures every day and

anyway according to the local laws.

The machine and the mix manufacturers decline

all responsibility to damage that directly or

indirectly derives from people, animals, as

consequence of failure to comply with all

cleaning and sanitation instructions indicated in

this manual.

The machine and the mix manufacturers decline

all responsibility to damage that directly or

indirectly derives from people, animals, as

consequence of failure to comply with all

cleaning and sanitation instructions indicated in

this manual.

Data di emissione: Novembre, 2015 Revisione: 1 Pag. : 12/24

- Stop the warming element turning off and let

the machine run with only auger activated for

ten minutes .

- Provide yourself with a sanitizer suitable for

plastic, rubber and stainless steel objects

(AMUCHINA®).

IMPORTANT

Carefully follow the mix producer

prescriptions in terms of time and modes

of conservation.

- Remove the cover (fig.10).

- Pour lukewarm water into the bowl (fig.11)

and, after re-positioning the cover, make the

scraper auger rotating for some minutes (all

LED switched off).

NOTE

Each bowl is equipped with a very efficient

safety mechanism, activated when the cover is

lifted, designed to protect the operator. If the

cover is not correctly positioned, the

machine will not work.

- Empty the bowl and repeat the same

operations until the coming out water is clear

(fig.12).

Fig. 10

Fig. 11

Fig. 12

Data di emissione: Novembre, 2015 Revisione: 1 Pag. : 13/24

Caution

To avoid electrical shock or contact with

moving parts, before proceeding with the

disassembling operations, make sure all

switches are in “OFF” position and that the

main power supply is disconnected.

- Switch off the machine and disconnect the

power cable.

- Remove the cover.

- Wash and sanitize your hands and forearms.

- Remove the flood reducer as indicated in

figure 13

- Simultaneously press the two securing tabs

and lift the tap to extract it from its seat (see

fig.14).

- Disassemble the tap by keeping the body

pressed down and slipping the lever from its

seat (fig.15).

Caution

To prevent bacteria growth, remove all

O-rings when cleaning.

Failure to do so could create a health

hazard.

- Pull the tank upward and outward, as shown,

to completely remove it from its seat (fig.16).

Fig. 13

Fig. 14

Fig. 15

Fig. 16

Data di emissione: Novembre, 2015 Revisione: 1 Pag. : 14/24

- Pull out the mixing unit, the bell shaped seal

and the bowl gasket on the back (fig.17 and

18).

- Remove the drip tray by moving it upward and

pulling it outward (fig.19).

- Thoroughly wash all the removed components

with hot water and dish washing, but do not use

abrasive detergents or powders that can

damage the bowl.

IMPORTANT

Do not use too aggressive sanitizers or

detergents, these kind of products could

damage the bowl and the other

components.

CAUTION

Never perform these washing operation

with a dish washing machine; failure to do

so could seriously damage the unit’s parts.

- Rinse well and then place all the components

in the sanitizer solution; for proper sanitizing

the parts must remain fully plunged for 15

minutes or as recommended by the sanitizer

manufacturer.

- After respecting the correct sanitizing period,

rinse well all the components with clean water

and dry them up with a clean cloth.

- Thoroughly wash the evaporator and the drip

tray surfaces with a sponge soaked with the

sanitizer (see fig.20).

- Repeat all these operations with a clean

sponge soaked with water and carefully dry up

all the surfaces with a clean cloth.

Fig. 17

Fig. 18

Fig. 19

Fig. 20

Data di emissione: Novembre, 2015 Revisione: 1 Pag. : 15/24

Once performed all these cleaning and sanitizing

procedures, it’s possible to reassemble all the

components.

The correct assembly of the device is essential

to prevent leakage of product and damage of

the machine. To assemble the machine you will

need an approved lubricant (such as Vaseline).

Make sure all parts have been washed and

sanitized before assembling. Persons assembling

the machine must first wash and sanitize their

hands and forearms with an approved sanitizer.

- Reassemble the rear gasket respecting the

correct assembling direction as indicated in

figure 21.

- Spread Vaseline on the bell shaped seal

internal surface before reassembling it (fig.22).

- Insert the suction gasket into the auger by

carefully inserting it into its seat (fig. 23).

- Reassemble the mixing unit making sure that

the frontal cylinder perfectly fit inside its

rotating shaft seat (fig.24).

Fig. 21

Fig. 22

Fig. 23

Fig. 24

Data di emissione: Novembre, 2015 Revisione: 1 Pag. : 16/24

- Moisten with water the rear of the tank where

it meets with the seal to facilitate the

reassembling procedures (see fig.25);

- Reassemble the bowl by positioning it back

into its seat until it gets blocked into it (see

fig.26).

- Re-insert the tap (fig.27) spreading Vaseline

on the O-rings to facilitate sliding the tap in its

seat until completely inserted.

!Warning!

If the tap does not perfectly slide into position,

the sealing hold will be endangered.

- Reassemble the drip tray.

Fig. 25

Fig. 26

Fig. 27

Data di emissione: Novembre, 2015 Revisione: 1 Pag. : 17/24

SANITIZING

Whenever the machine has remained unused for

some days after been cleaned and sanitized as

described in the chapter 10, the sanitizing

procedures described below must be performed

just prior to start-up the machine.

- Remove the main cover and the secondary

one.

- Pour sanitizing solution (AMUCHINA®) into the

bowl carefully following the manufacturer

prescriptions.

- After restoring the main cover, switch on the

machine and let the auger rotating (all control

board LED switched off) leaving the sanitizing

solution for the time specified by its producer.

IMPORTANT

Never let the sanitizer inside the bowl for

more than 15 minutes.

- Drain the solution by opening the plunger to

allow the bowl to empty. Open and close the

plunger at least 10 times during draining to

sanitize the product way out area also.

- Thoroughly rinse repeating these operations

with clean water instead of sanitizer solution.

- Now the machine is ready to be used.

10. SPECIAL MAINTENTANCE

Caution

Before proceeding with any maintenance

operation, it is compulsory to switch off the

machine and unplug it from the mains.

Control and replacement of seals

BOWL GASKET (LOCATED AT THE REAR OF

BOWL)

Replace it every 12 months according to the

conditions of use and level of maintenance.

DISPENSE VALVE O-RING

The dispense valve O-rings should be replaced

as necessary when wear is evident. Lubricate

them each time they are replaced or the

dispense valve is removed for cleaning.

SUCTION GASKET

Replace every 3 months according to the

conditions of use and level of maintenance. This

part should be lubricated during the reassembly after every cleaning with Vaseline

Winter storage

To protect the unit during seasonal shutdown,

it’s important to properly store the machine

using the following procedures:

- Disconnect all power to the freezer.

- Disassemble, wash and sanitize all parts that

come into contact with the mix as described in

chapter 10.

- Clean also all the exterior panels.

- Reassemble all these parts.

- Cover the machine with the original package

to protect it from dust or other contaminating

elements.

- Place the machine in dry location.

Data di emissione: Novembre, 2015 Revisione: 1 Pag. : 18/24

Product storage

Since the safety of the product used with this

unit depends upon the temperature and the

duration of storage, it is necessary to refer

directly to the food product producer instruction

and specifications in order to correctly manage

it and in order to avoid any possible safety

issue.

protetta dalla polvere e da altri agenti

contaminanti.

- Posizionare la macchina in un luogo asciutto.

11. DISCLAIMER

The manufacturer declines all responsibility for

any damage that directly or indirectly might be

brought on to people, things, animals, as a

consequence of failure to comply with all

instructions given in this manual with the

warnings concerning installation procedures, use

and maintenance of the machine.

The manufacturer cannot be held responsible for

possible mistakes due to printing, copying or

translating errors contained in this manual.

In addition, the manufacturer reserves the right

to modify what deemed necessary or useful for

the machine, as well as for the benefit of the

user, yet at the same time maintaining the

essential operative and safety characteristics of

said machine.

Data di emissione: Novembre, 2015 Revisione: 1 Pag. : 19/24

12. GUIDA ALLA RISOLUZIONE DEI

PROBLEMI

Problema

Possibile causa

Soluzione

The machine doesn’t

warm

The mixing auger is OFF

The machine is working only in

mixing mode

The warming element does not

work

Turn on the mixing auger pressing the

switch A

Turn on the warming element acting on

switch B

Check the electric connections, if

disconnected, connect them. If it doesn’t

work call the assistence

The machine does not

warm and the red light

is always ON

The regulation thermostat is broken

and the security thermostat starts

working

The security thermostat is defective

Replace the regulation thermostat

Replace the security thermostat

The main switch is ON

but the machine doesn

not work

The main lid is not well-positioned

Some electrical connections are

incomplete

The main switch is broken

The gearmotor is defective

Put correctly the main cover

Check the connections and fix the

incompletes

Replace the switch

Replace the gearmotor

The tank is dripping

One of the gaskets is not well

positioned

Reassemble the gasket correctly or

replace it

The tap is dripping

The tap has not been put correctly

The tap is stuck

The O-Rings are damaged or worn

out

Disassemble and assemble the tap

correctly

Wash the tap and its seat and lubrificate

it with vaseline

Replace the o-ring

The product drips from

behind

The gasket is damaged or worn out

Replace the gasket

The mixer does not turn

The main lid is not well-positioned

Some electrical connections are

incomplete

The gearmotor is defective

Put correctly the main cover

Check the connections and fix the

incompletes

Replace the gearmotor

The mixing auger is

noisy during the rotation

The gasket as been replaced

without being correctly lubrificated

The mixing auger has not been

replaced correctly

Disasseble, wash, sanitaze and lubrificate

correctly the gasket

Disassemble and assemble correctly the

mixing auger

NOTA BENE: le seguenti procedure

devono essere eseguite da un tecnico

qualificato

Data di emissione: Novembre, 2015 Revisione: 1 Pag. : 20/24

13. WIRING DIAGRAM

Data di emissione: Novembre, 2015 Revisione: 1 Pag. : 21/24

Data di emissione: Novembre, 2015 Revisione: 1 Pag. : 22/24

Data di emissione: Novembre, 2015 Revisione: 1 Pag. : 23/24

ASSISTENZA TECNICA ITALIA

Mail: info@service-k.it

Tel. 059782884

Conforme alla normativa RoHS

Questo apparecchio è conforme alla direttiva europea 2002/95/CE e successive modifiche per quanto riguarda la restrizione all’uso di

sostanze pericolose nella produzione di apparecchiature elettriche ed elettroniche.

Smaltimento

Ai sensi della direttiva RAEE 2002/96/CE e successiva modifica 2003/108/CE questa apparecchiatura viene contrassegnata con il

seguente simbolo del contenitore di spazzatura con ruote barrato. “ INFORMAZIONE AGLI UTENTI: Ai sensi dell’art. 13 del Decre to

Legislativo 25 Luglio 2005 n. 151 - Attuazione delle Direttive 2002/95/CE e 2002/96/CE, relative alla riduzione dell’uso di sostanze

pericolose nelle apparecchiature elettriche ed elettroniche, nonché allo smaltimento dei rifiuti. Il simbolo del cassonetto barrato indica

che il prodotto, alla fine della sua vita utile, deve essere raccolto separatamente dagli altri rifiuti. L’utente deve conferire

l’apparecchiatura giunta a fine vita ad idonei centri di raccolta differenziata dei rifiuti elettrici ed elettronici, oppure consegnarla al

rivenditore al momento dell’acquisto di nuova apparecchiatura di t ipo equivalente, in ragione di uno ad uno. L’adeguata raccolta

differenziata per l’avvio successivo al trattamento e allo smaltimento ambientalmente compatibile contribuisce ad evitare possibili effetti

negativi sull’ambiente e sulla salute e favorisce il reimpiego e il riciclo dei materiali di cui è composta l’apparecchiatura. Lo smaltimento

abusivo del prodotto da parte dell’utente comporta l’applicazione delle sanzioni amministrative di cui al D.Lgs. n.22/1997 registro AEE

IT13060000008071.”

Data di emissione: Novembre, 2015 Revisione: 1 Pag. : 24/24

INTERNATIONAL CUSTOMER CARE

intcustcare@spm-ice.it

+39 059781761

Company

with certified quality

management system

UN EN ISO 9001

Loading...

Loading...