Data di emissione: February, 2016 Revisione: 1 Pag. : 1/48

NINA HOT &

COLD

Operator’s manual Page 2

Betriebs- und Wartungsanleitung Seite 23

Data di emissione: February, 2016 Revisione: 1 Pag. : 2/48

Published by:

SPM DRINK SYSTEMS S.p.a.

Via Panaro n° 2

41057 Spilamberto (MO)

Edition: 02/2016

Revision: 01

© 2016 – SPM Drink Systems

All copying rights are reserved to SPM DRINK SYSTEMS; copying, even partial, is illegal.

The descriptions and illustrations refer to the specific machine at issue. SPM Drink Systems reserves the right to

modify at any time the equipment for mass production.

This manual:

- is integral part of the supply and must be carefully read, in order to be properly used, in compliance with

the essential safety requirements;

- has been drafted by following the dispositions 2006/42/CE and reports the technical information that

are necessary to correctly run all the procedures, under safety conditions;

- must be carefully kept (protected by a transparent, watertight wrapping, in order to avoid any damage)

and must go with the machine during its life, including potential changes of ownership. In case of loss or

damage, it’s possible to ask for a copy to SPM DRINK SYSTEMS, pointing out the information stated on

the identification label;

SPM DRINK SYSTEMS declines all responsibility for a wrong usage of the machine and/or damages caused by

operations not provided for in this manual..

Data di emissione: February, 2016 Revisione: 1 Pag. : 3/48

INDEX

1. IMPORTANT WARNINGS AND ADVICES4

2. EQUIPMENT KIT .........................................4

3. TRANPORT TIPS .........................................4

4. LIFTING TIPS ...............................................4

5. TECHNICAL SPECIFICATIONS ................5

6. POSITIONING ..............................................6

7. CONNECTION TO THE POWER SUPPLY

MAINS .........................................................7

8. START-UP PROCEDURES AND

OPERATING INSTRUCTIONS .................8

9. CLEANING AND DAILY SANITIZING

PROCEDURES..........................................11

10. SPECIAL MAINTENTANCE.....................18

Condenser cleaning ......................................... 18

Control and replacement of seals .................... 19

Winter storage ................................................. 19

Product storage................................................ 19

11. SOFT SERVE ICE CREAM INFORMATION

....................................................................20

12. DISCLAIMER .............................................20

13. TROUBLESHOOTING GUIDE .................21

14. WIRING DIAGRAM...................................23

Data di emissione: February, 2016 Revisione: 1 Pag. : 4/48

1. IMPORTANT WARNINGS AND

ADVICES

This installation and operation manual is an

integral part of the equipment and must be

kept for future consultation.

Unless otherwise stated, this manual is

addressed to operators (staff members who

uses the equipment on a daily basis) and to

servicemen (staff members qualified to

carry out the installation and/or

maintenance). The parts of the manual

addressed only to servicemen are pointed

out accordingly. Please read carefully the

warnings listed here below before

installation and start-up of the equipment.

This equipment has been designed to

produce both frozen and hot products such

soft serve creamy product, sorbets, hot

chocolate custards and similar products.

Upon receipt of the equipment, make sure

that its part number matches the one

specified in the order, which can be found

on all the delivery documents.

This equipment is exclusively destined to

the purpose for which it was designed. The

manufacturer cannot be held responsible

for any damage due to improper use.

This appliance can be used by children

aged from 8 years and above and persons

with reduced physical, sensory or mental

capabilities or lack of experience and

knowledge if they have been given

supervision or instruction concerning use

of the appliance in a safe way and

understand the hazards involved. Children

shall not play with the appliance. Cleaning

and user maintenance shall not be made

by children without supervision.

This equipment is not suitable for outdoor

use. This machine is not suitable for

installation in locations where water jets

are used.

The appliance is only to be installed in

locations where its use and maintenance is

restricted to trained personnel.

Do not store explosive substances such as

aerosol cans with a flammable propellant

in this

appliance.

This appliance is intended to be used in

household and similar applications such as

– staff kitchen areas in shops, offices and

other working environments;

– farm houses and by clients in hotels,

motels and other residential type

environments;

– bed and breakfast type environments;

– catering and similar non-retail

applications.

2. EQUIPMENT KIT

In the packaging of this equipment you will find

also:

- operator’s manual,

- 1 tube of Vaseline grease lubricant to be used

for machine maintenance;

- EC declaration of conformity;

- drip trays.

3. TRANPORT TIPS

To prevent the oil held in the hermetic

compressor running into the cooling circuit, the

device must be carried, stored and handled in the

upright position, following the direction

instructions on the packing. If the device is

accidentally or intentionally (for transportation

reasons) kept in any other position, it must be

set again in the correct position at least twenty

minutes before start-up procedures, in order to

let the oil flow back into the compressor.

4. LIFTING TIPS

Each machine is equipped with a special wooden

pallet that allows the handling with standard

forklift trucks.

Caution

Never lift the machine alone, but always seek

the assistance of another operator.

To prevent and avoid any damage to the

machine, all loading and unloading operations

should be carried out with special care. The

equipment can be lifted, with either a manual or

engine-powered lifting truck, by positioning the

forks in the base section of the unit.

Data di emissione: February, 2016 Revisione: 1 Pag. : 5/48

The following operations should always be

avoided:

- to turn upside down the machine;

- to drag the machine with ropes or others;

- to lift the machine with slings or ropes

- to shake or rattle the machine and its

packaging.

The machine must be stored in a dry place with

temperatures from 0°C to 40 °C. No more than 2

machines should be stacked on top of each other,

taking care to maintain the vertical position, as

shown by the arrows on the carton.

5. TECHNICAL SPECIFICATIONS

Technical and electrical specifications

All the machine’s technical and electrical

specifications are stated on the identification

plate, positioned in the internal part of the

equipment; a sample is shown here below.

The plate specifies:

Model: XX

n°: XX

Electrical specifications: Volt/ Hz

Max. absorption (Watt)

Max. current (Amp)

Machine ambient working temperatures

between 24°C and 30°C.

Dimensions and weight:

NINA2 HOT&COLD

Height: 487.5 mm.

Width: 280 mm.

Depth: 387.5 mm.

NINA3 HOT&COLD

Height: 520 mm.

Width: 420 mm.

Depth: 390 mm.

Noise emissions

The continuous, equivalent, weighted level of

acoustic pressure is below 70 dB.

In the event of breakdown:

In most cases, any technical problem can be

settled with slight interventions (please see the

troubleshooting guide at the end of this manual);

we therefore recommend you to carefully read

this handbook before contacting the

manufacturer or service centre.

Disposal

Caution

All the parts of the packaging must be kept

beyond the range of children, as they might

represent a potential safety/health risk.

Important

In respect of the environment, please dispose the

packaging as illustrated.

This symbol: means that the machine

cannot be disposed as common waste. It must be

handled in compliance with the provisions of

European directive 2003/108/EC (Waste

Electrical and Electronic Devices - WEEE) and the

resulting national legislation, in order to prevent

any potential damage to the environment and to

create health risks.

In order to correctly dispose of the device, please

contact the distributor from which you purchased

it or our after-sales service.

Data di emissione: February, 2016 Revisione: 1 Pag. : 6/48

6. POSITIONING

FOR MAINTENANCE WORKER ONLY

The installation and subsequent servicing

operations must be carried out by skilled

members who have been trained to use the

device and in compliance with the

regulations in force.

a) Remove the packing and preserve it in order

to reuse for winter storage.

Caution

All the parts of the packaging must be kept

beyond the range of children, as they might

represent a potential safety/health risk.

b) Make sure the machine is in perfect condition.

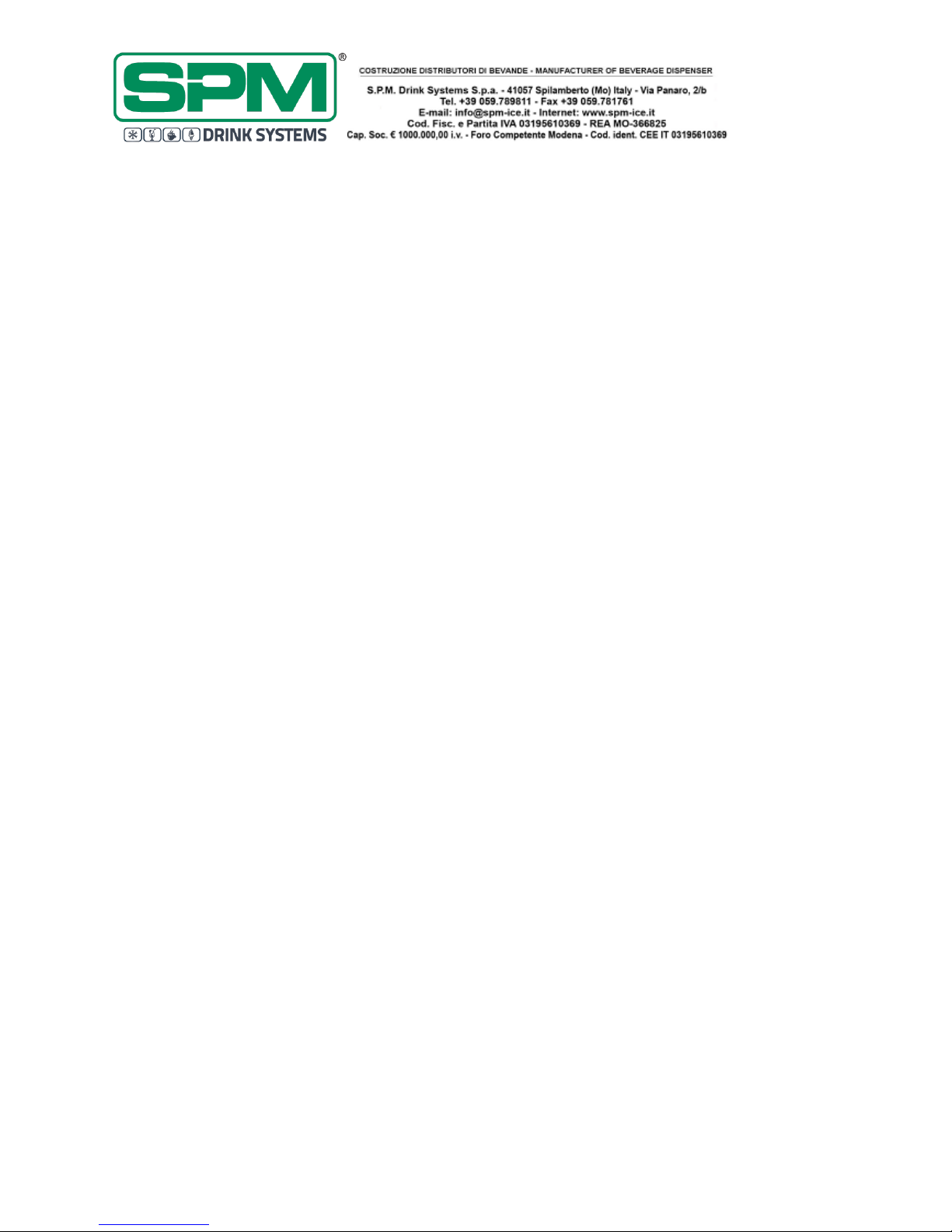

b) Rest the machine on a sturdy, horizontal

surface making sure it is well ventilated by

leaving a gap of 20 cm around it and do not install

it near heat sources (fig.1); we recommend

you to maintain a room temperature

between 24 and 30°C.

c) Check that the power mains voltage meets the

specifications on the equipment identification

plate and that the output available meets the

device’s power requirements.

Fit the plug into an earthed socket, removing all

multiple adaptors.

FOR FURTHER PRECAUTIONS, READ THE

SECTION “CONNECTION TO THE ELECTRICITY

MAINS” CAREFULLY.

d) The installation must be carried out in

accordance with the manufacturer’s instructions.

Failure to comply with the positioning and

installation instructions may impair the

machine’s operation.

Important

You are legally required to provide a suitable

grounding system for the equipment.

Before carrying out any cleaning and/or special

maintenance on the device, make sure it is

disconnected from the mains by unplugging it.

In the event of a breakdown or malfunctioning,

switch off the device and remove the plug.

Fig. 1

Data di emissione: February, 2016 Revisione: 1 Pag. : 7/48

7. CONNECTION TO THE POWER

SUPPLY MAINS

FOR SERVICEMAN ONLY

Before fitting the plug in the power supply socket,

for your own safety, as already mentioned in the

previous paragraph, please read the following

precautions.

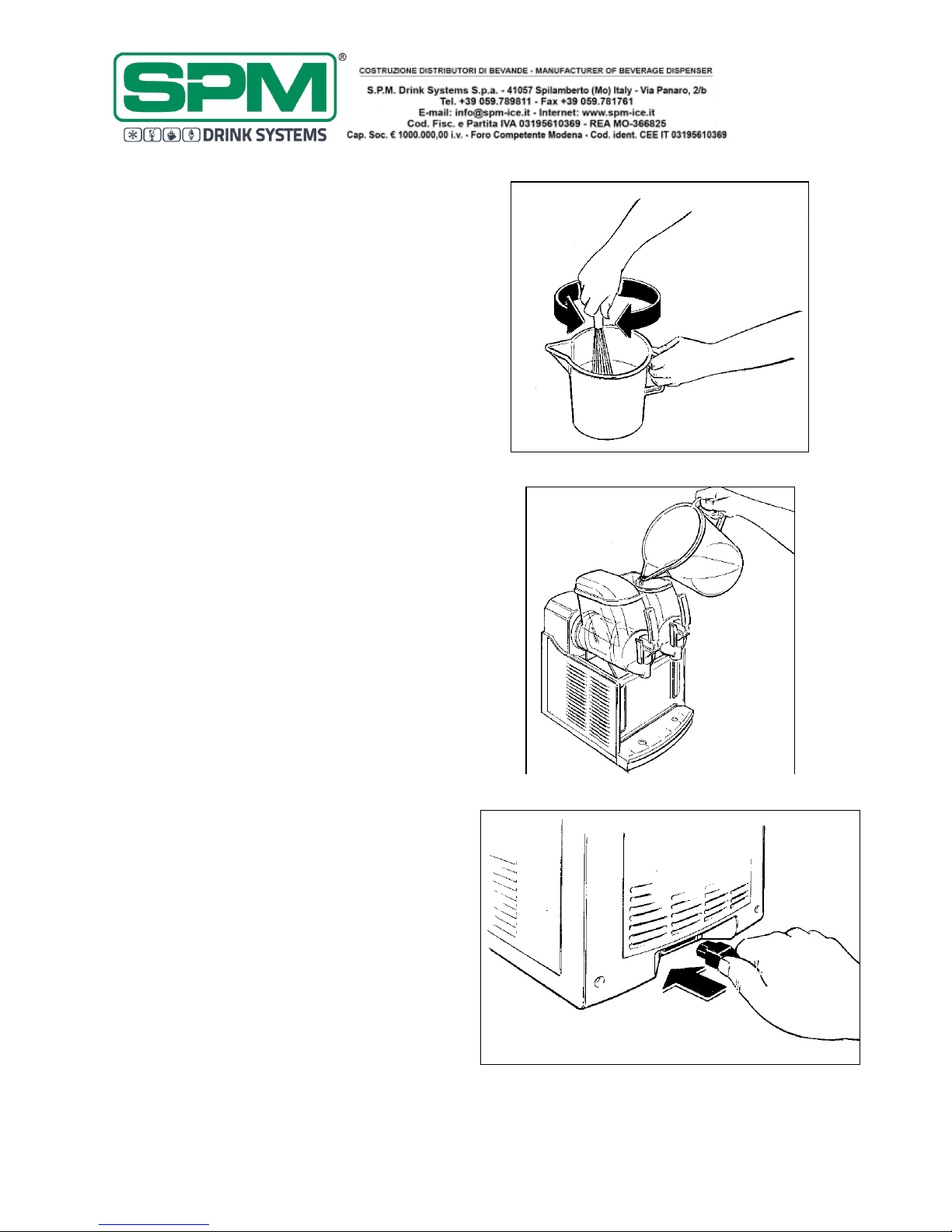

- The machine’s electrical safety is only

guaranteed when it is connected to a suitable

earth system, structured as provided by the

national safety current regulations (fig.2).

Therefore, the manufacturer cannot be held

responsible for any damage due to failure of the

grounding system of the machine.

- Always verify electrical specifications on the

data plate of each machine. Data plate

specifications always replace the information of

this manual.

- For a safe and correct installation, it is essential

to provide a suitable socket controlled by a

thermal cut-out switch whose contacts are at

least 3 mm apart, in accordance with the current

national safety regulations (see fig.3).

- Never use extensions or multiple adaptors.

- Check the power lead along its entire length to

make sure it is not crushed in any way.

- To unplug the device, first disconnect the power

supply with the switch, then grip the plug and

gently pull it out.

Important

IF THE POWER CABLE IS DAMAGED, IT MUST

BE REPLACED BY THE MANUFACTURER, ITS

AFTER SALE SERVICE OR BY QUALIFIED

PERSONNEL, TO PREVENT ANY POSSIBLE RISK.

Fig. 2

Data di emissione: February, 2016 Revisione: 1 Pag. : 8/48

8. START-UP PROCEDURES AND

OPERATING INSTRUCTIONS

!IMPORTANT!

BEFORE STARTING THE MACHINE, CARRY OUT

THE CLEANING AND SANITISING PROCEDURES

DESCRIBED IN CHAPTER 9.

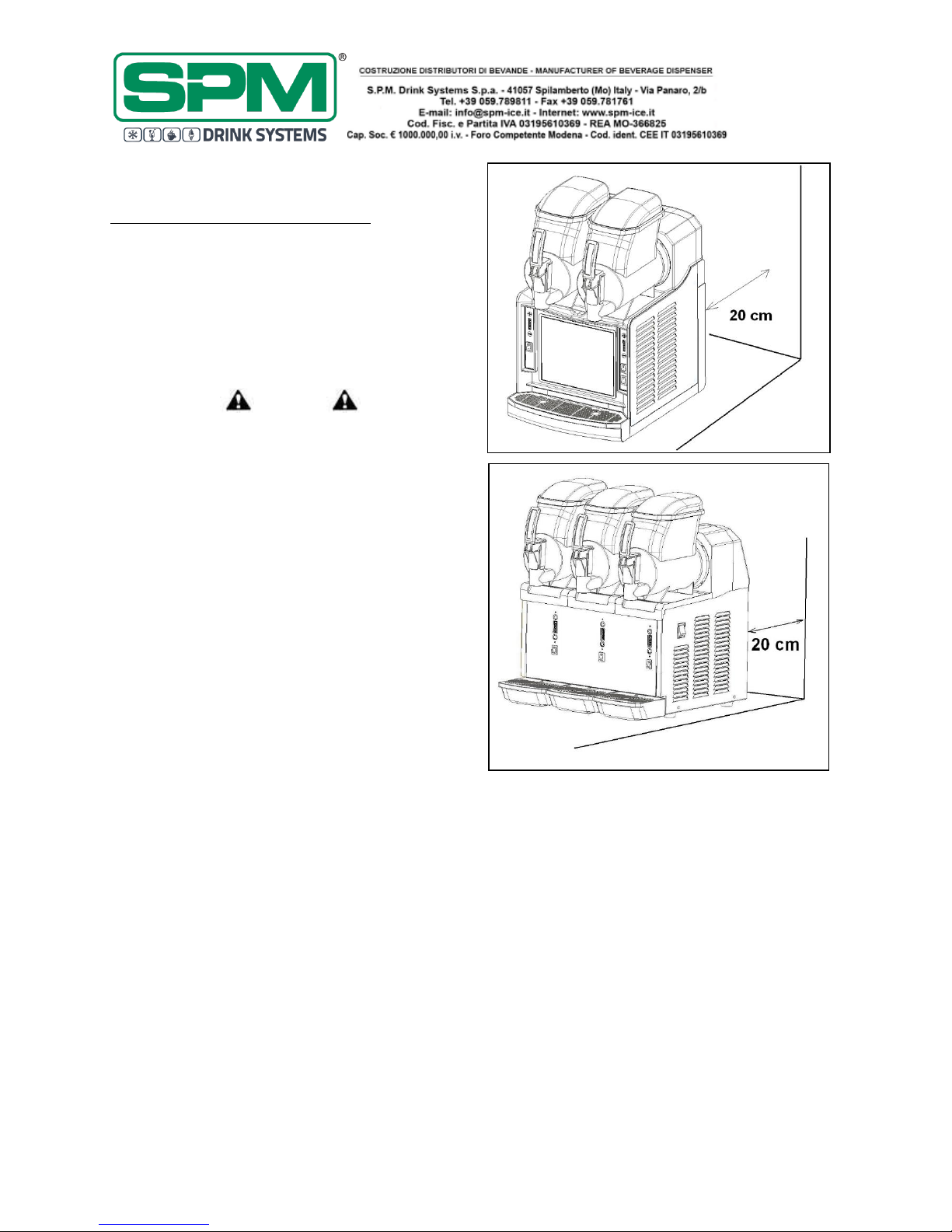

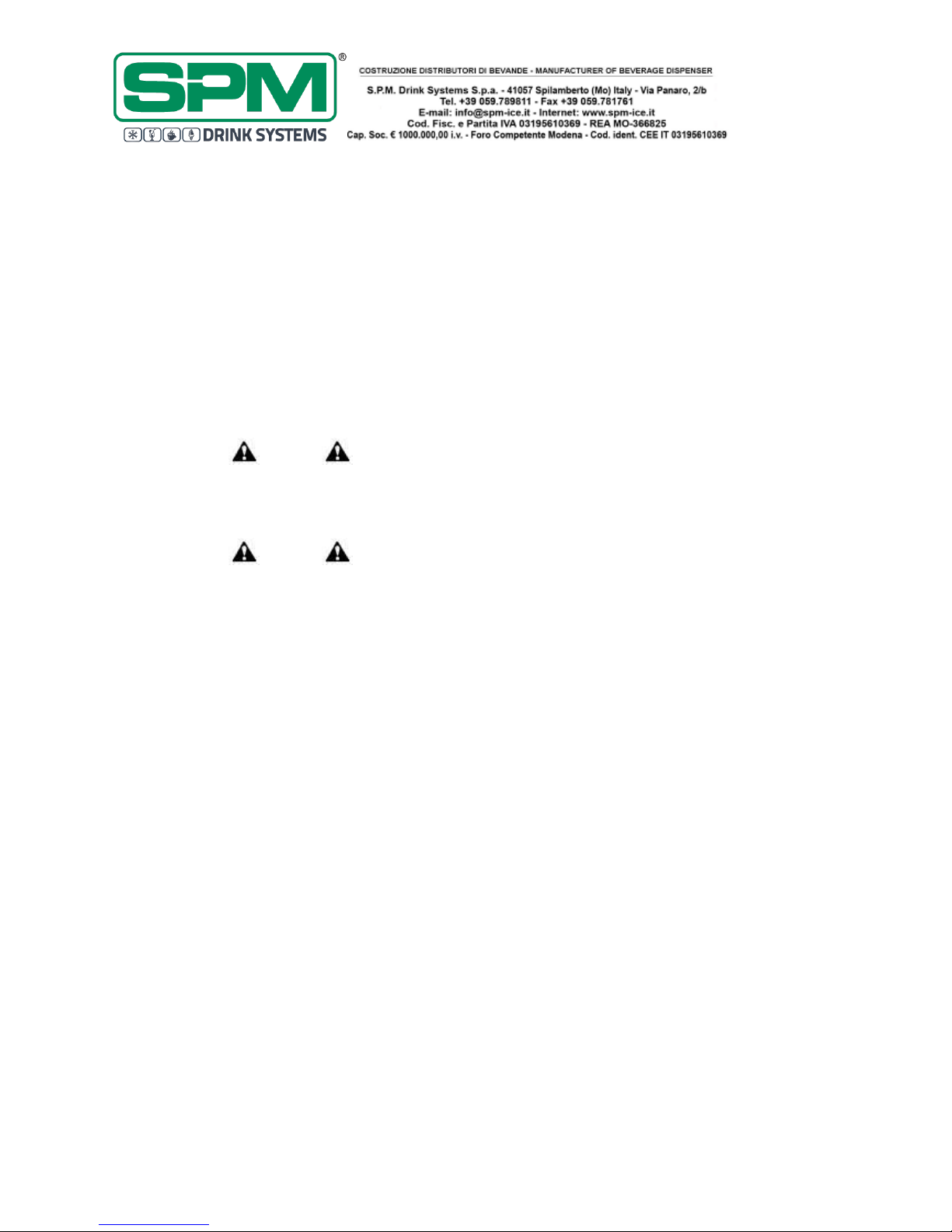

- Dilute and mix the product in a separate

container according to the manufacturer’s

instructions (see fig.3).

NOTE: “mix” is the result of the blending

between water or milk with the powder to

make soft serve creamy product, sorbets,

and similar products or hot creams or

chocolates.

While in the left hot barrel it is possible to

introduce maximum 2 litres of product, filling

the centre and right frozen ones it is better to

avoid introducing more than 1.5 litres of

mix inside the bowl. This kind of products

have a not negligible overrun during their

freezing process and for this reason it is

important to control it in order to avoid to go

over the bowl maximum level (please see the

chapter about the overrun calculation).

- Pour the mix obtained into the bowl (see

fig.4).

- Restore the transparent cover.

Note -----------------------------------------------

Each bowl is equipped with a very efficient

safety mechanism designed to protect the

operator; it is activated when cover is lifted.

This device automatically and immediately stops

all moving parts.

If the cover is not correctly positioned, the

correspondent mixing system will not

work.

------------------------------------------------------

- Insert, just in the NINA2 HOT&COLD case, the

female plug into the electrical power inlet (fig.5)

and then the male one into the power supply

socket.

Fig. 3

Fig. 4

Fig. 5

Data di emissione: February, 2016 Revisione: 1 Pag. : 9/48

- NINA2 HOT&COLD (fig.6):

C switch (fig.6) activates the right side

auger rotation designed to freeze the

product and enables its functioning.

D switch (fig.6) activates the left side

auger rotation designed to warm up the

product and enables its functioning.

- NINA3 HOT&COLD (fig.7):

Activate the main switch A on the right

side of the unit (fig.7) in order to enable

the heating of the product into the left

barrel.

Activate the main switch B on the right

side of the unit (fig.7) in order to enable

the freezing of the product into the

central and right barrel.

C switch activates the right side auger

rotation designed to freeze the product.

G switch activates the central side auger

rotation designed to freeze the product.

D switch activates the left side auger

rotation designed to warm up the

product.

!WARNING!

In case the corresponding auger will not start

rotating once one of the C, G or D switches are

activated, check for the corresponding lid

correct positioning, each bowl is equipped with a

very efficient safety mechanism, if the lid is not

correctly positioned, the machine will not work.

!WARNING!

Both the refrigerating and the heating system of

each bowl could be activated only if the

correspondent auger is rotating.

FREEZING SIDE FUNCTIONING

- In order to activate the refrigerating system

and to regulate the product consistency, it is

necessary to use the buttons + and - on the

control board (fig.9); operating on the + button,

the number of lighted LED will increase with the

product consistency; operating on the - button,

the number of lighted LED will decrease with the

product consistency (fig.9).

Fig. 6

Fig. 7

Fig. 8

Data di emissione: February, 2016 Revisione: 1 Pag. : 10/48

- In order to activate the refrigerating system in

defrost mode it is necessary to press the –

button an keep it pressed until the first and the

last LED of the scale will turn on.

In order to exit from the defrost mode it is

necessary to press the + button an keep it

pressed until the all the Led will be switched off.

NOTE: when all the LED are switched off the

refrigerating system is not working and the

product is not cooled.

NOTE: when the unit is switched off the

electronic board will keep in memory the last

setting, for this reason the unit will restart in

the same operating mode when switched on

again.

!WARNING!

The refrigerating system is activated when at

least one LED is switched on; in order to avoid

any damage, before activating it, is necessary

to fill up the bowl; failure to do so could damage

the unit.

Important

Do not use the unit with the refrigerating

system activated (this means in both freeze or

defrost mode) with water or sanitizer in the

bowl, the machine will be damaged.

HEATING SIDE FUNCTIONING

- In order to activate the heating system it is

necessary to activate the E switch (fig.10)

considering that if the correspondent auger is

not rotating the heating element will not work.

NOTE: when the heating element is working the

red light F is turned on (fig.10); the heating

system warms up the product until the desired

temperature and keep it at this value with

ON/OFF cycles; for this reason, during the

functioning the light will alternately turn on and

off.

NOTE: the machine is equipped with an internal

thermostat in order to regulate the product final

temperature, the maximum value that is

possible to be set is 80°C.

- Once the desired product consistency is

reached, to dispense product position a cup

under the tap and lower the lever as shown in

figure 11.

Fig. 9

Fig. 10

Fig. 11

Data di emissione: February, 2016 Revisione: 1 Pag. : 11/48

9. CLEANING AND DAILY SANITIZING

PROCEDURES

In order to maintain the unit in like-new

operating condition and to respect current

regulations, it’s absolutely necessary to

frequently and carefully perform the cleaning

and sanitizing operations as described below.

In case of prolonged shutdown (winter storage),

the machine must be disassembled, washed and

sanitized according to the instructions in this

manual before start-up to ensure the best

possible cleanliness.

Caution

Electric shock hazard. Do not splash water

on switches or allow water to flow onto

electrical components inside the machine.

Caution

To prevent bacteria growth, use only

sanitizers approved for plastic and rubber

objects, failure to do so could create a

health hazard.

NOTE: it is responsibility of the operator to be

aware of and conform to the requirements of

current local, state and federal laws concerning

the frequency of cleaning and conservation of

products used.

The cleaning instructions explained in this

section are essential procedures to remove

bacteria and maintain a sanitarily clean

machine.

We recommend to perform the cleaning

and sanitizing procedures every day and

anyway according to the local laws.

The machine and the mix manufacturers decline

all responsibility to damage that directly or

indirectly derives from people, animals, as

consequence of failure to comply with all

cleaning and sanitation instructions indicated in

this manual.

Data di emissione: February, 2016 Revisione: 1 Pag. : 12/48

- Stop the refrigerating (by switching off all the

LED acting on the – button or by pressing the

+button and keep it pressed to switch off the

defrost mode) and the heating system (E switch

in OFF position) and let the machine run with

the only auger activated for ten minutes.

- Remove all the residual product considering

that the hot product could still be at high

temperature.

- Provide yourself with a sanitizer suitable for

plastic, rubber and stainless steel objects

(AMUCHINA®).

IMPORTANT

Carefully follow the mix producer

prescriptions in terms of time and modes

of conservation.

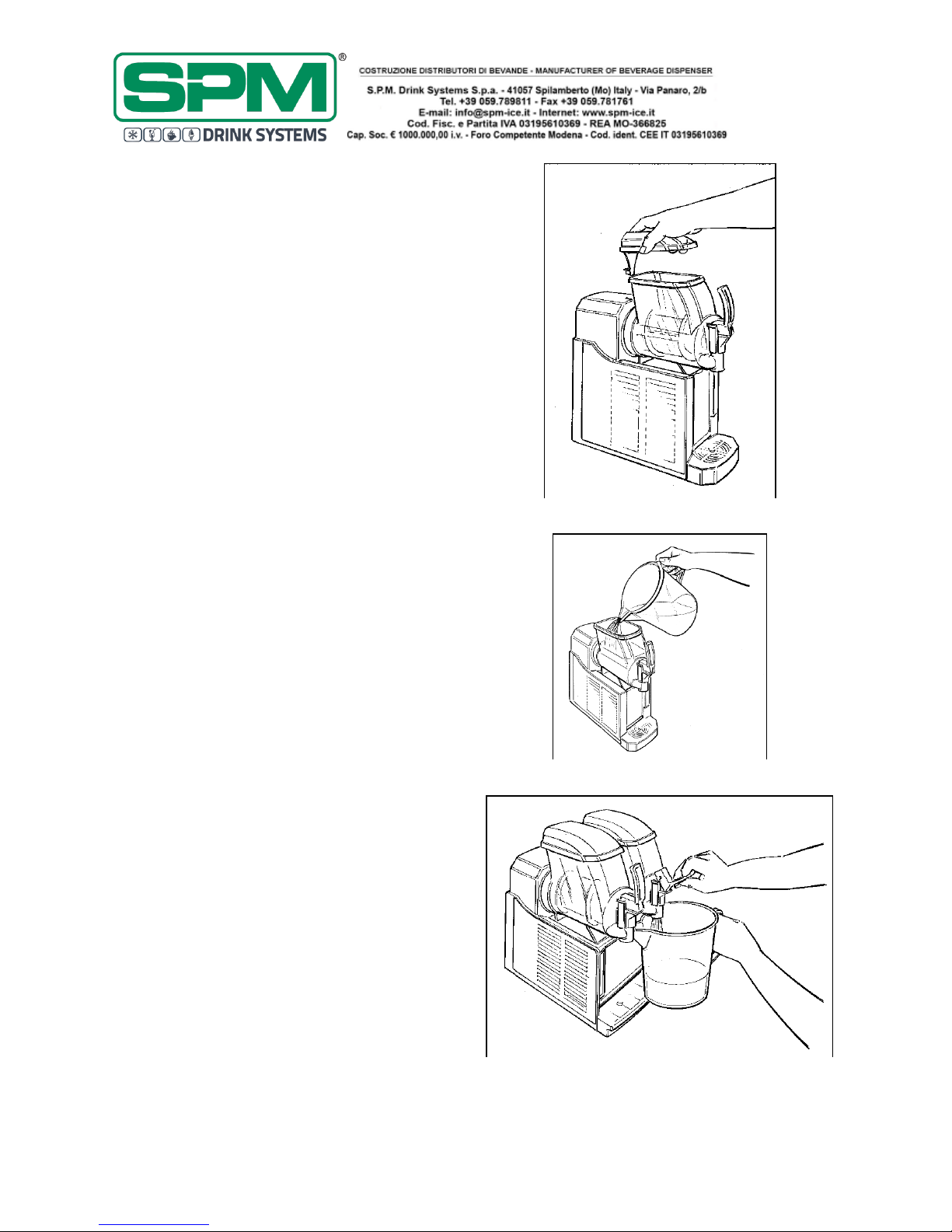

- Remove the cover (fig.12).

- Pour lukewarm water into the bowl (fig.13)

and, after re-positioning the cover, make the

scraper auger rotating for some minutes (all

LED switched off).

NOTE

Each bowl is equipped with a very efficient

safety mechanism, activated when the cover is

lifted, designed to protect the operator. If the

cover is not correctly positioned, the

machine will not work.

- Empty the bowl and repeat the same

operations until the coming out water is clear

(fig.14).

Fig. 12

Fig. 13

Fig. 14

Data di emissione: February, 2016 Revisione: 1 Pag. : 13/48

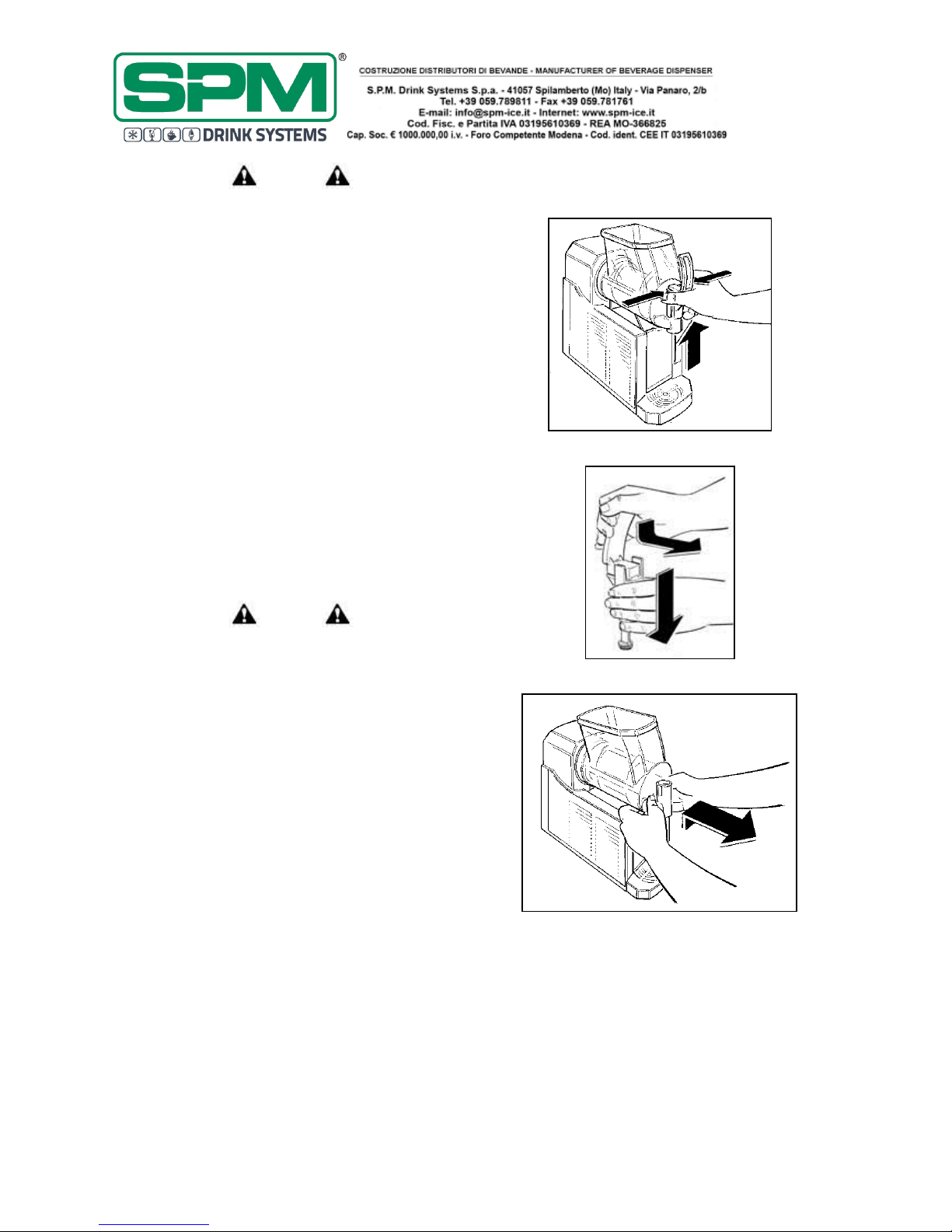

Caution

To avoid electrical shock or contact with

moving parts, before proceeding with the

disassembling operations, make sure all

switches are in “OFF” position and that the

main power supply is disconnected.

- Switch off the machine and disconnect the

power cable.

- Remove the cover.

- Wash and sanitize your hands and forearms.

- Simultaneously press the two securing tabs

and lift the tap to extract it from its seat (see

fig.15).

- Disassemble the tap by keeping the body

pressed down and slipping the lever from its

seat (fig.16).

Caution

To prevent bacteria growth, remove all

O-rings when cleaning.

Failure to do so could create a health

hazard.

- Pull the tank upward and outward, as shown,

to completely remove it from its seat (fig.17).

Fig. 15

Fig. 16

Fig. 17

Data di emissione: February, 2016 Revisione: 1 Pag. : 14/48

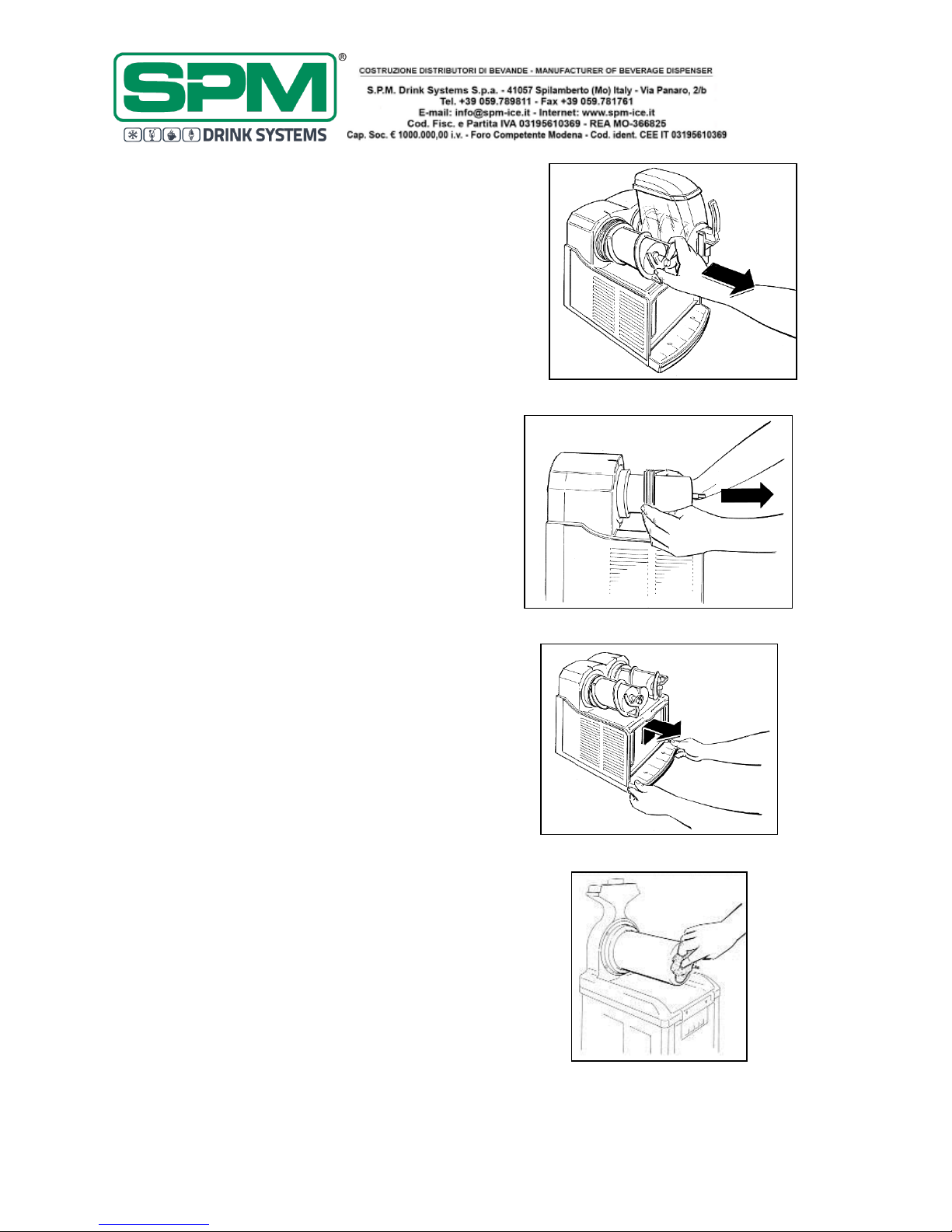

- Pull out the mixing unit, the bell shaped seal

and the bowl gasket on the back (fig.18 and

19).

- Remove the drip tray by moving it upward and

pulling it outward (fig.20).

- Thoroughly wash all the removed components

with hot water and dish washing, but do not use

abrasive detergents or powders that can

damage the bowl.

IMPORTANT

Do not use too aggressive sanitizers or

detergents, these kind of products could

damage the bowl and the other

components.

CAUTION

Never perform these washing operation

with a dish washing machine; failure to do

so could seriously damage the unit’s parts.

- Rinse well and then place all the components

in the sanitizer solution; for proper sanitizing

the parts must remain fully plunged for 15

minutes or as recommended by the sanitizer

manufacturer.

- After respecting the correct sanitizing period,

rinse well all the components with clean water

and dry them up with a clean cloth.

- Thoroughly wash the evaporator and the drip

tray surfaces with a sponge soaked with the

sanitizer (see fig.21).

- Repeat all these operations with a clean

sponge soaked with water and carefully dry up

all the surfaces with a clean cloth.

Fig. 18

Fig. 19

Fig. 20

Fig. 21

Data di emissione: February, 2016 Revisione: 1 Pag. : 15/48

Once performed all these cleaning and sanitizing

procedures, it’s possible to reassemble all the

components.

The correct assembly of the device is essential

to prevent leakage of product and damage of

the machine. To assemble the machine you will

need an approved lubricant (such as Vaseline).

Make sure all parts have been washed and

sanitized before assembling. Persons assembling

the machine must first wash and sanitize their

hands and forearms with an approved sanitizer.

- Reassemble the rear gasket respecting the

correct assembling direction as indicated in

figure 22.

- Spread Vaseline on the bell shaped seal

internal surface before reassembling it (fig.23).

- Insert the suction gasket into the auger by

carefully inserting it into its seat (fig. 24).

- Reassemble the mixing unit making sure that

the frontal cylinder perfectly fit inside its

rotating shaft seat (fig.25).

Fig. 22

Fig. 23

Fig. 24

Fig. 25

Data di emissione: February, 2016 Revisione: 1 Pag. : 16/48

- Moisten with water the rear of the tank where

it meets with the seal to facilitate the

reassembling procedures (see fig.26);

- Reassemble the bowl by positioning it back

into its seat until it gets blocked into it (see

fig.27).

- Re-insert the tap (fig.28) spreading Vaseline

on the O-rings to facilitate sliding the tap in its

seat until completely inserted.

!Warning!

If the tap does not perfectly slide into position,

the sealing hold will be endangered.

- Reassemble the drip tray.

Fig. 26

Fig. 27

Fig. 28

Data di emissione: February, 2016 Revisione: 1 Pag. : 17/48

SANITIZING

Whenever the machine has remained unused for

some days after been cleaned and sanitized as

described in the chapter 9, the sanitizing

procedures described below must be performed

just prior to start-up the machine.

- Remove the main cover and the secondary

one.

- Pour sanitizing solution (AMUCHINA®) into the

bowl carefully following the manufacturer

prescriptions.

- After restoring the main cover, switch on the

machine and let the auger rotating (all control

board LED switched off) leaving the sanitizing

solution for the time specified by its producer.

IMPORTANT

Never let the sanitizer inside the bowl for

more than 15 minutes.

- Drain the solution by opening the plunger to

allow the bowl to empty. Open and close the

plunger at least 10 times during draining to

sanitize the product way out area also.

- Thoroughly rinse repeating these operations

with clean water instead of sanitizer solution.

- Now the machine is ready to be used.

Data di emissione: February, 2016 Revisione: 1 Pag. : 18/48

10. SPECIAL MAINTENTANCE

Caution

Before proceeding with any maintenance

operation, it is compulsory to switch off the

machine and unplug it from the mains.

Condenser cleaning

In order to guarantee good cooling system

performance, the condenser must be well

cleaned every month or whenever

necessary.

How to reach it:

- Switch off the power supply and disconnect the

power cable;

- NINA2 HOT&COLD: remove the rear panel as

indicated in figure 29;

- NINA3 HOT&COLD: take away the left panel

(fig. 30) by removing the two fixing screws;

- Remove, if present, the condenser filter and

wash it carefully, otherwise clean carefully the

condenser fins with a vacuum cleaner;

- Place, if present, the filter back into its seat and

close the plastic panel before re-starting the unit.

IMPORTANT

Never use a screwdriver or sharp object to

clean between fins.

Fig. 29

Fig. 30

Data di emissione: February, 2016 Revisione: 1 Pag. : 19/48

Control and replacement of seals

BOWL GASKET (LOCATED AT THE REAR OF

BOWL)

Replace it every 12 months according to the

conditions of use and level of maintenance.

DISPENSE VALVE O-RING

The dispense valve O-rings should be replaced

as necessary when wear is evident. Lubricate

them each time they are replaced or the

dispense valve is removed for cleaning.

SUCTION GASKET

Replace every 3 months according to the

conditions of use and level of maintenance. This

part should be lubricated during the reassembly after every cleaning with Vaseline.

Winter storage

To protect the unit during seasonal shutdown,

it’s important to properly store the machine

using the following procedures:

- Disconnect all power to the freezer.

- Disassemble, wash and sanitize all parts that

come into contact with the mix as described in

chapter 9.

- Clean also all the exterior panels.

- Reassemble all these parts.

- Cover the machine with the original package

to protect it from dust or other contaminating

elements.

- Place the machine in dry location.

Product storage

Since the safety of the product used with this

unit depends upon the temperature and the

duration of storage, it is necessary to refer

directly to the food product producer instruction

and specifications in order to correctly manage

it and in order to avoid any possible safety

issue.

Data di emissione: February, 2016 Revisione: 1 Pag. : 20/48

11. SOFT SERVE ICE CREAM

INFORMATION

OVERRUN

While the product is frozen in the bowl, its

volume increase; to control overrun is important

as too much of it could go over the bowl

maximum level.

To correctly measure overrun carry out the

following steps:

- Place an empty container on the scale and

adjust your scale to zero;

- Remove the container from scale and fill it

with liquid product to the top. Weigh container

and record;

- Replace liquid product with frozen one, strike

off the excess of it so it is even with the top of

the container and measure the weight;

- Use the following formula to figure overrun

percentage:

“Weight of liquid mix minus weight of frozen

product divided by the frozen weight. Multiply

by 100””

Example:

Weight of half litre of mix: 530g;

Weight of half litre of frozen product: 380g;

Difference:150g;

150/380=0.4

0.4x100=40% overrun

12. DISCLAIMER

The manufacturer declines all responsibility for

any damage that directly or indirectly might be

brought on to people, things, animals, as a

consequence of failure to comply with all

instructions given in this manual with the

warnings concerning installation procedures, use

and maintenance of the machine.

The manufacturer cannot be held responsible for

possible mistakes due to printing, copying or

translating errors contained in this manual.

In addition, the manufacturer reserves the right

to modify what deemed necessary or useful for

the machine, as well as for the benefit of the

user, yet at the same time maintaining the

essential operative and safety characteristics of

said machine.

Data di emissione: February, 2016 Revisione: 1 Pag. : 21/48

13. TROUBLESHOOTING GUIDE

NOTE: the following procedures must be performed by a qualified service technician.

Problem

Possible cause

Solution

The machine does not cool,

or cools only partially and

the compressor is running

The space around the machine is

inadequate for ventilation

The refrigeration system is working in

DEFROST mode

The condenser filter is clogged with

airborne particles

Fan motor is not running

Refrigerant is leaking

Allow at least 20cm between the

machine and anything next to it;

keep it away from heat sources

Return to FREEZE mode

Clean the condenser filter

Check the fan motor’s electrical

connections and, if

disconnected, reconnect. If still

not operating, replace the motor

Locate the leak, eliminate it and

recharge the system

The machine does not cool,

or cools only partially and

the compressor is not

running

Electrical components of the compressor

are not functioning

Some electrical connections are not

complete

The compressor is malfunctioning

Replace the malfunctioning

components

Check the contacts and and

correct those incomplete

Replace the compressor

The machine is noisy

The fan motor blades are hitting internal

components

Check and correct

The main power switch is

“ON” but the unit is not

running

The main cover is not correctly

assembled

Some electrical connections are not

complete

The main power switch is broken

The control board is faulty

The gear motor is malfunctioning

Assemble the main cover

correctly

Check the contacts and and

correct those incomplete

Replace the switch

Replace the control board

Replace the gear motor

The bowl is leaking

One of the bowl seal is not in place

Replace or reposition the seal

The dispensing valve is

leaking

The dispensing valve has been

incompletely or incorrectly replaced in its

position

The free movement of the valve is

impeded

Dispensing valve O-rings are damaged

Reassemble and replace

Clean and lubricate the valve

and the valve cylinder with the

lubricant provided with the

machine

Replace the O-rings

Product is flowing into drain

tray through drainage plate

The bell shaped seal between the front of

the cylinder and the auger hub has not

been reinstalled properly

The bell shaped shaft seal or the spindle

bushing seal is damaged or worn

Find the seal and put it back in

place

Replace the damaged/worn seal

and check the condition of the

drive shaft

The auger is not turning

The main cover is not correctly

assembled

Some electrical connections are not

complete

The control board is faulty

The gear motor is malfunctioning

Assemble the main cover

correctly

Check the contacts and correct

those incomplete

Replace the control board

Replace the gear motor

The auger is creating noise

as it rotates

The bell shaped shaft seal has been

replaced without lubrication or is

damaged

The auger has been incompletely or

incorrectly reassembled

Replace or clean and lubricate

with the lubricant provided with

the machine

Check and correct

LED errors (from the lower):

- 1st LED blinking

- 2nd LED blinking

- 3rd LED blinking

- 4th LED blinking

- 5th LED blinking

Memory error

Temperature probe short circuit

Temperature probe disconnected

Motor overcurrent

Power overcurrent

Replace the board

Replace the probe

Re-connect the probe

Switch off. Solve the root cause

and switch on again

Switch off. Solve the root cause

and switch on again

Data di emissione: February, 2016 Revisione: 1 Pag. : 22/48

Problema

Possibile causa

Soluzione

The machine does not

heat

The correspondent auger is not

rotating, D switch in OFF position

The heating system is not

activated, E switch in OFF position

Only for NINA3 HOT&COLD, the

heating system is not enabled, A

switch on the right side in OFF

position

L’elemento riscaldante non

funziona

Activate the auger switch D

Activate the heating system by moving

the switch E from OFF to ON position

Enable the heating system with the A

switch

Check the heating element electrical

connections and, if disconnected,

reconnect. If still not operating, replace

the heating cylinder

The machine does not

heat and the red light on

the front side is always

ON

The manual regulation thermostat

is faulty

The safety thermostat is faulty

Replace the manual regulation

thermostat

Replace the safety thermostat

Ausgabedatum: Februar 2016 Revision: 1 Seite: 23/48

Veröffentlichung von:

SPM DRINK SYSTEMS S.p.a.

Via Panaro, 2

41057 Spilamberto (MO)

Ausgabe: 02/2016

Revision: 01

© 2016 – SPM Drink Systems

Alle Rechte auf Vervielfältigung des vorliegenden Handbuchs sind der Fa. SPM DRINK SYSTEMS vorbehalten. Die

auch nur teilweise Vervielfältigung ist untersagt.

Die Beschreibungen und Abbildungen beziehen sich auf die vorstehend genannte Maschine/Anlage. SPM DRINK

SYSTEMS behält sich das Recht vor, an der Serienproduktion jederzeit alle Änderungen vorzunehmen, die sie für

dienlich erachtet.

Die vorliegende Anleitung:

ist wesentlicher Bestandteil der Lieferung und muss zwecks korrektem Betrieb und Einhaltung der

wesentlichen Sicherheitsvorschriften aufmerksam gelesen werden;

wurde aufgrund der Vorschriften der Maschinenrichtlinie 2006/42/EG erstellt und enthält alle

technischen Informationen, die zur Ausführung aller Arbeitsgänge unter Sicherheitsbedingungen notwendig sind;

muss sorgfältig aufbewahrt werden (in einer durchsichtigen, wasserdichten Schutzhülle, um Schäden zu

vermeiden). Sie muss die Maschine während ihrer gesamten Standzeit begleiten, auch im Fall eines

Besitzwechsels. Bei Verlust oder Schädigung kann bei SPM DRINK SYSTEMS unter Angabe der auf dem

Typenschild angegebenen Daten eine Kopie angefordert werden

SPM DRINK SYSTEMS verweigert jegliche Haftung für unsachgemäßen Einsatz der Maschine/Anlage, sowie für

Schäden, die durch in diesem Handbuch nicht vorgesehene Abläufe zustande kommen.

Sehr geehrter Kunde,

wir gratulieren Ihnen zur Wahl eines

Qualitätsprodukts, das mit Sicherheit Ihre

Erwartungen erfüllt.

Wir danken dafür, dass Sie unserem Produkt den

Vorzug gegeben haben und bitten Sie

freundlichst, diese Betriebs- und

Wartungsanleitung aufmerksam zu lesen.

Ausgabedatum: Februar 2016 Revision: 1 Seite: 24/48

INHALT

1. WICHTIGE HINWEISE UND

EMPFEHLUNGEN ...................................25

2. AUSSTATTUNG DES GERÄTS ...............25

3. NÜTZLICHE HINWEISE FÜR DEN

TRANSPORT ............................................25

4. NÜTZLICHE HINWEISE FÜR DAS HEBEN

....................................................................25

5. TECHNISCHE DATEN ..............................26

6. AUFSTELLUNG .........................................27

7. ANSCHLUSS AN DAS STROMNETZ .....28

8. INBETRIEBNAHME UND

BETRIEBSMODALITÄTEN ....................29

9. TÄGLICHE REINIGUNG UND

DESINFIZIERUNG ...................................32

10. AUSSERORDENTLICHE WARTUNG .....39

Reinigung des Kondensators ........................... 39

Kontrolle und Austausch der Dichtungen ....... 40

Einlagerung über Winter ................................. 40

Aufbewahrung Produkt ................................... 40

11. NÜTZLICHE INFORMATIONEN ZUR

HERSTELLUNG VON SPEISEEIS .........41

12. HAFTUNGSAUSSCHLUSS .......................41

13. ANLEITUNG ZUR PROBLEM LÖSUNG 42

14. WIRING DIAGRAM...................................45

Ausgabedatum: Februar 2016 Revision: 1 Seite: 25/48

1. WICHTIGE HINWEISE UND

EMPFEHLUNGEN

Die vorliegende Betriebs- und

Wartungsanleitung ist wesentlicher

Bestandteil des Geräts und muss

aufbewahrt werden, um sie auch in Zukunft

jederzeit nachschlagen zu können. Sofern

nicht anderweitig angegeben, wendet sich

diese Anleitung an die Bediener (d.h. an

das Personal, das täglich mit dem Gerät

umgeht), und an die Wartungstechniker

(d.h. an Personal, das für die Installation

und/oder Wartung qualifiziert ist). Die

Teile dieser Anleitung, die sich an die

Wartungstechniker wenden, sind

entsprechend gekennzeichnet. Die in dieser

Anleitung enthaltenen Hinweise vor der

Installation und dem Betrieb des Geräts

aufmerksam lesen. Dieses Gerät ist für die

parallele Herstellung von warmen und

kalten Produkten wie Cremes, Sorbets und

dgl. ausgelegt. Bei Empfang dieses Geräts

muss sicher gestellt werden, dass die

Kennnummer des Geräts mit dem von

Ihnen bestellten und stets in den

Transportpapieren angegebenen

übereinstimmt, und zwar: - “Bezeichnung

Gerät”, gefolgt von der laufenden

Seriennummer. Dieses Gerät darf

ausschließlich zu dem Zweck verwendet

werden, für den es entwickelt wurde und

der Hersteller kann nicht für Schäden

haftbar gemacht werden, die durch

unsachgemäßen Einsatz zustande kommen.

Dieses Gerät ist nicht für den Gebrauch

durch Kinder im Alter unter 8 Jahren und

Personen mit eingeschränkten

körperlichen, sensorischen oder geistigen

Fähigkeiten, Personen mit mangelnder

Erfahrung oder Kenntnis geeignet, sofern

sie nicht überwacht oder in den Betrieb des

Geräts durch eine Person eingewiesen

werden, die für ihre Sicherheit

verantwortlich ist. Kinder müssen

überwacht werden, damit sie nicht mit dem

Gerät spielen. Reinigung und

Desinfizierung dürfen von Kindern nur

unter strenger Aufsicht vorgenommen

werden. Dieses Gerät ist nicht für den

Einsatz im Freien ausgelegt. Dieses Gerät

ist nicht für die Installation an Orten

geeigneten, in denen Wasserstrahlen zum

Einsatz kommen. Dieses Gerät muss so

installiert werden, dass es von

qualifiziertem Personal überwacht werden

kann. Keine Gasflaschen mit entzündlichen

Gasen in der Nähe des Geräts aufstellen.

Dieses Gerät ist ausgelegt für

Anwendungen wie:

- Teeküchen für die Belegschaft in

Geschäften, Büros und sonstigen

Arbeitsumgebungen;

- Gemeinschaftsräume in Hotels, Motels

oder Gastbetrieben allgemein;

- Bed and Breakfast, Catering und

ähnliche Anwendungsbereiche

2. AUSSTATTUNG DES GERÄTS

In der Verpackung müssen sich beim Öffnen die

folgenden Elemente befinden:

- die vorliegende Betriebs- und

Wartungsanleitung

- die CE- Konformitätserklärung

- 1 Tube Schmiermittel (Vaseline);

- Tropfschalen.

3. NÜTZLICHE HINWEISE FÜR DEN

TRANSPORT

Um zu verhindern, dass das im dichten

Kompressor enthaltene Öl in den Kältekreis

eindringt, muss das Gerät in vertikaler Stellung

transportiert, gelagert und gehandhabt werden,

wobei die Angaben auf der Verpackung zu

beachten sind. Sollte das Gerät versehentlich

oder absichtlich aus Platzgründen beim

Transport in nicht vertikale Stellung gebracht

worden sein, muss es vor der Inbetriebnahme

3-4 Stunden lang aufrecht stehen gelassen

werden, damit das Öl in den Kompressor

zurückfließen kann.

4. NÜTZLICHE HINWEISE FÜR DAS

HEBEN

Jedes Gerät wird auf einer eigenen Holzpalette

ausgeliefert, die das Heben und Befördern mit

normalen Hebe- und Beförderungsmitteln

gestattet.

Ausgabedatum: Februar 2016 Revision: 1 Seite: 26/48

Achtung

Das Gerät nicht alleine heben, sondern

stets mit Hilfe einer weiteren Person.

Um Schäden des Geräts zu vermeiden muss das

Auf- und Abladen mit besonderer Sorgfalt

vorgenommen werden. Das Gerät kann anhand

eines motor-oder handbetriebenen

Gabelstaplers gehoben werden. Dazu sind die

Gabeln unter dem Gerät einzuführen.

Dagegen muss folgendes vermieden

werden:

- Kippen der Maschine

- Schleppen der Maschine anhand von Seilen

oder Sonstigem

- Heben der Maschine mit Anschlaggurten oder

Seilen

- Rütteln oder Stoßen der verpackten oder

unverpackten Maschine.

Das Gerät muss an einem trockenen Ort mit

Umgebungstemperatur zwischen 0 und 40 °C

gelagert werden. In der Originalverpackung

können maximal 2 Geräte übereinander

gestapelt werden, wobei darauf geachtet

werden muss, dass die durch Pfeile auf der

Verpackung markierte, aufrechte Stellung

beibehalten wird.

5. TECHNISCHE DATEN

Technische und elektrische Merkmale des Geräts

Alle technischen und elektrischen Merkmale des

Geräts sind auf dem Typenschild angegeben,

das im Inneren der Maschine angebracht und

nachstehend abgebildet ist.

Auf dem Typenschild sind angegeben:

Modell

Seriennummer

Stromversorgung in Volt/ Hz

Max. Leistungsaufnahme in Watt

Max. Strom in Amp

Gewicht in kg

Umgebungstemperatur für den Betrieb

der Maschine zwischen 24 und 30°C.

Die Abmessungen des Geräts sind:

NINA2 HOT & COLD

Höhe 487.5 mm

Breite 280 mm

Tiefe 387.5 mm

NINA3 HOT & COLD

Höhe 520 mm

Breite 420 mm

Tiefe 390 mm

Geräuschpegel

Der dauernde äquivalente, gewichtete

Schalldruckpegel liegt unter 70 dB.

Im Störungsfall:

In den meisten Fällen lassen sich eventuelle

technische Störungen durch bescheidene

Maßnahmen beseitigen. Wir empfehlen deshalb,

aufmerksam die vorliegenden Anleitung zu

lesen, bevor Kontakt mit dem Hersteller oder

dessen Kundendienststellen aufgenommen wird.

Entsorgung

Wichtig

Die Bestandteile der Verpackung dürfen nicht in

Reichweite von Kindern liegen gelassen werden,

da sie eine potentielle Gefahrenquelle

darstellen.

Wichtig

Die Verpackungsteile dürfen nicht in der Umwelt

freigesetzt werden. Sie sollten aufbewahrt

werden, um sie bei Bedarf wieder verwenden zu

können (z.B. zur Einlagerung über Winter).

Das Symbol bedeutet, dass das Gerät

nicht als normaler Hausmüll entsorgt werden

darf, sondern aufgrund der Europäischen WEEERichtlinie 2003/108/EG (Waste Electrical and

Electronics Equipments) und den daraus

abgeleiteten nationalen Gesetzesvorschriften

entsorgt werden müssen, um schädliche

Auswirkungen auf die Umwelt und die

Gesundheit des Menschen zu vermeiden.

Ausgabedatum: Februar 2016 Revision: 1 Seite: 27/48

Zur korrekten Entsorgung des Geräts können

Sie Kontakt mit dem Händler aufnehmen, bei

dem Sie es erworben haben, oder mit unserem

After-Sales-Service.

Abb. 1

6. AUFSTELLUNG

NUR FÜR WARTUNGSTECHNIKER

Die Installation und spätere Wartung

müssen aufgrund der einschlägigen

Vorschriften von Fachpersonal

vorgenommen werden, das in den

Gebrauch dieses Geräts eingewiesen

wurde.

a) Alle Verpackungsteile für die WinterEinlagerung aufbewahren und sicherstellen,

dass das Gerät in einwandfreiem Zustand ist.

!WICHTIG!

Die Bestandteile der Verpackung dürfen

nicht in Reichweite von Kindern liegen

gelassen werden, da sie eine potentielle

Gefahrenquelle darstellen.

Das Gerät auf einer horizontalen, soliden und

ausreichend belüfteten Fläche (mindestens 20

cm Freiraum, siehe Abb.1) in einem trockenen

Raum aufstellen. Nicht in der Nähe von

Hitzequellen aufstellen. Die

Umgebungstemperatur für den Betrieb der

Maschine muss zwischen 24 und 30°C

liegen.

c) Kontrollieren, dass die Netzspannung mit den

Angaben auf dem Typenschild übereinstimmt

und dass die verfügbare Leistung für den Bedarf

des Geräts ausreichend ist.

Den Stecker in eine geerdete Steckdose

stecken. Auf Mehrfach-Steckdosen muss

verzichtet werden.

WEITERE VORKEHRUNGEN SIND

SORGFÄLTIG IM ABSCHNITT "ANSCHLUSS

AN DAS STROMNETZ" NACHZULESEN.

d) Die Installation muss aufgrund der

Anweisungen des Herstellers erfolgen. Die

Nichteinhaltung dieser Anweisungen kann die

Funktionstüchtigkeit des Geräts beeinträchtigen.

Wichtig

Die Erdung ist notwendig und gesetzlich

vorgeschrieben. Bevor Reinigungs- oder

Wartungsarbeiten jeglicher Art vorgenommen

werden, durch Abziehen des Steckers

sicherstellen, dass das Gerät von der

Stromversorgung getrennt ist.

Ausgabedatum: Februar 2016 Revision: 1 Seite: 28/48

Bei Defekten oder Funktionsstörungen, das

Gerät abschalten und den Stecker aus der

Steckdose ziehen.

7. ANSCHLUSS AN DAS STROMNETZ

NUR FÜR WARTUNGSTECHNIKER

Bevor der Stecker in die Steckdose

gesteckt wird, sind zu Ihrer eigenen

Sicherheit wie bereits vorstehend erwähnt,

sorgsam die folgenden Vorkehrungen zu

treffen:

- Sicherstellen, dass das Gerät an eine

entsprechend den einschlägigen

Sicherheitsvorschriften wirksam geerdete

Elektroanlage angeschlossen wird (Abb. 3).

Der Hersteller kann nicht für Schäden

haftbar gemacht werden, die durch

mangelnde Erdung der Anlage zustande

kommen.

- Stets die elektrischen Merkmale auf dem

Typenschild des jeweiligen Geräts

kontrollieren. Die Daten auf dem

Typenschild haben jederzeit Vorrang

gegenüber den Angaben dieses Handbuchs.

- Zur korrekten und sicheren Installation

ist es unerlässlich, dass eine

entsprechende Steckdose bereitgestellt

wird, die entsprechend den einschlägigen

nationalen Sicherheitsvorschriften über

einen magnetthermischen Schutzschalter

mit einer Kontaktöffnungsweite gleich oder

größer 3 mm gesteuert wird (Abb. 2).

- Keinesfalls Mehrfach-Steckdosen oder

Verlängerungskabel verwenden.

- Sicher stellen, dass das Versorgungskabel

auf seiner gesamten Länge an keiner Stelle

gequetscht wird.

- Zum Abziehen des Steckers nach

Abschalten des Hauptschalters, direkt den

Stecker greifen und sanft daran ziehen.

Wichtig

SOLLTE DAS VERSORGUNGSKABEL

BESCHÄDIGT SEIN, MUSS ES VOM

HERSTELLER ODER DESSEN KUNDENDIENST

BZW. VON EINER VERGLEICHBAR

QUALIFIZIERTEN PERSON AUSGETAUSCHT

WERDEN, UM JEDES RISIKO ZU VERMEIDEN.

Abb. 2

Ausgabedatum: Februar 2016 Revision: 1 Seite: 29/48

8. INBETRIEBNAHME UND

BETRIEBSMODALITÄTEN

!ACHTUNG!

VOR DER ERSTEN INBETRIEBNAHME DER

MASCHINE MÜSSEN ALLE IN KAPITEL 9

BESCHRIEBENEN REINIGUNGS- UND

DESINFIZIERUNGSMASSNAHMEN GETROFFEN

WERDEN

- In einem Gefäß das Produkt je nach Angaben

des Herstellers (siehe Abb. 3) mit Wasser oder

Milch auflösen und verrühren.

HINWEIS: unter dem Begriff "Produkt"

versteht sich das Ergebnis der

Vermischung von Wasser oder Milch mit

dem Präparat für die Herstellung von

kalten Cremes, Sorbet und dgl. bzw. bei

Verwendung warmer Milch, von warmen

Cremes oder heißer Schokolade.

Während in der warmen linken Wanne bis zu 2

Liter Produkt eingefüllt werden können, muss

bei der Wenn für kalte Produkte unbedingt

darauf geachtet werden, dass nicht mehr als

1.5 Liter Flüssigprodukt eingefüllt wird, da

sich das Volumen durch die Kühlung beachtlich

vergrößert und daher das maximale

Fassungsvermögen der Wanne überschreiten

könnte (siehe Kapitel zur Berechnung der

Volumensteigerung).

- Das Produkt in die Wanne geben (siehe

Abb.4).

- Den durchsichtigen Deckel wieder aufsetzen.

Hinweis -------------------------------------------

Jede Wanne ist mit einer effizienten

Sicherheitsvorrichtung zum Schutz des

Bedieners ausgestattet, die beim Abheben des

Deckels anspricht und automatisch den

sofortigen Stillstand aller bewegten

Maschinenteile bewirkt.

Sollte der Deckel nicht richtig angebracht

sein, kann das Rührwerk nicht in Betrieb

gesetzt werden.

------------------------------------------------------

- Nur bei NINA2 HOT&COLD die Steckbuchse in

die Maschine (Abb. 5) und den Stiftstecker in

die Versorgungssteckdose einstecken.

Abb. 3

Abb. 4

Abb. 5

Ausgabedatum: Februar 2016 Revision: 1 Seite: 30/48

- NINA2 HOT&COLD (Abb.6):

Der Schalter C (Abb.6) aktiviert die

Rotation der Spirale auf der rechten

Seite, die zur Kühlung des Produkts

dient, und gibt deren Betrieb frei.

Der Schalter D (Abb.6) aktiviert die

Rotation der Spirale auf der linken Seite,

die zur Erhitzung des Produkts dient, und

gibt deren Betrieb frei.

- NINA3 HOT&COLD (Abb.7):

Den Hauptschalter A auf der rechten

Seite der Maschine betätigen (Abb. 7),

um das Erhitzen des Produkts in der

linken Wanne freizugeben.

Den Hauptschalter B auf der rechten

Seite der Maschine betätigen (Abb. 7),

um das Kühlen des Produkts in der

mittleren und der rechten Wanne

freizugeben.

Der Schalter C aktiviert die Rotation der

Spirale der rechten Wanne, die zur

Kühlung des Produkts dient.

Der Schalter G aktiviert die Rotation der

Spirale der mittleren Wanne, die zur

Kühlung des Produkts dient.

Der Schalter D aktiviert die Rotation der

Spirale der linken Wanne, die zum

Erhitzen des Produkts dient.

!ACHTUNG!

Sollte sich bei Betätigung der Schalter C, G oder

D die entsprechende Spirale nicht in Bewegung

setzen, kontrollieren, ob der Deckel richtig

aufgesetzt wurde. Jede Wanne ist mit einer

Sicherheitsvorrichtung ausgestattet, die den

Betrieb verhindert, wenn der Deckel nicht

ordnungsgemäß in seine Aufnahme eingesetzt

wurde.

!ACHTUNG!

Sowohl die Kühlungs- als auch die

Erhitzungsanlage der einzelnen Wannen können

nur in Betrieb gesetzt werden, wenn die

zugehörige Spirale in Funktion ist.

FUNKTIONSWEISE DER KÜHLUNGS-SEITE

- Zur Aktivierung der Kälteanlage im Kühlbetrieb

und zur Veränderung der Konsistenz des

Produkts, die Tasten + oder - am Tastenfeld

betätigen (Abb.9). Bei Betätigung der Taste +

leuchten nach und nach mehr Leds auf und die

eingestellte Konsistenz wird erhöht. Bei

Betätigung der Taste - erlöschen nach und nach

die Leds und die Konsistenz wird verringert

(Abb.9).

Abb. 6

Abb. 7

Abb. 8

Ausgabedatum: Februar 2016 Revision: 1 Seite: 31/48

- Zur Aktivierung der Kälteanlage im DefrostBetrieb muss die Taste - einige Sekunden lang

gedrückt gehalten werden, bis der erste und die

letzte Led der Skala aufleuchten.

Zum Verlassen dieser Betriebsart muss die

Taste + gedrückt gehalten werden.

HINWEIS: wenn alle LEDs erloschen sind,

bedeutet dies, dass die Kälteanlage

abgeschaltet ist und somit das Produkt nicht

gekühlt wird.

HINWEIS: wenn die Maschine abgeschaltet wird,

speichert sie den letzten Betriebszustand, der

daher beim Einschalten mit den gleichen

Bedingungen wieder aufgenommen wird.

!ACHTUNG!

Die Kälteanlage ist in Betrieb, wenn mindestens

eine LED- der Konsistenz-Skala leuchtet. Um

Schäden des Geräts zu vermeiden muss vorher

immer sichergestellt werden, dass bereits

Produkt in die Wanne gefüllt wurde. Das Gerät

keinesfalls bei leerer Wanne betreiben.

Wichtig: die Maschine nicht mit Wasser oder

Desinfektionslösung betreiben, wenn die

Kälteanlage aktiviert wurde (also sowohl im

Kühl- als auch im Defrost-Betrieb). Andernfalls

könnte das Rührwerk schaden nehmen.

FUNKTIONSWEISE DER ERHITZUNGS-SEITE

- Zur Aktivierung der Anlage mit Heizbetrieb

muss der Schalter E betätigt werden (Abb.10),

wobei zu berücksichtigen ist, dass das

Heizelement nicht funktioniert, wenn der

zugehörige Mischer nicht in Betrieb ist.

HINWEIS: wenn das Heizelement in Betrieb ist,

leuchtet die rote Lampe F (Abb.10). Die

Maschine erhitzt das Produkt und hält es durch

laufendes Ein- und Ausschalten auf der

richtigen Temperatur. Aus diesem Grund ist es

normal, dass die rote Lampe während des

Betrieb immer wieder ein- und ausgeschaltet

wird.

HINWEIS: die Maschine ist mit einem internen

Thermostaten ausgestattet, um die Temperatur

des Produkts regeln zu können. Dieser

Thermostat kann maximal auf 80°C eingestellt

werden.

- Nachdem das Produkt die gewünschte

Temperatur/Konsistenz erreicht hat, ist zum

Zapfen von Produkt ein Glas unter den

Zapfhahn zu stellen und der Hebel zu ziehen,

wie in der Abb. 11 dargestellt.

Abb. 9

Abb. 10

Abb. 11

Ausgabedatum: Februar 2016 Revision: 1 Seite: 32/48

9. TÄGLICHE REINIGUNG UND

DESINFIZIERUNG

Um eine stets einwandfreie Funktion des Geräts

und die Einhaltung der einschlägigen

Gesundheitsvorschriften zu gewährleisten,

müssen die nachstehend beschriebenen

Reinigungs- und Desinfektionsmaßnahmen

häufig und sorgfältig vorgenommen werden.

Außerdem muss sicher gestellt werden, dass die

Person, die diese Arbeiten ausführt, vorher

Hände und Unterarme gewaschen und

desinfiziert hat.

Sollte das Gerät längere Zeit (saisonbedingt)

nicht benutzt werden, müssen die genannten

Vorgänge immer ausgeführt werden, bevor die

Maschine wieder in Betrieb genommen wird.

Achtung

Um Risiken wie beispielsweise Stromschlag

während der Reinigungsarbeiten zu

vermeiden, kein Wasser auf die Schalter

sprühen und verhindern, dass die

elektrischen Bauteile im Inneren des

Geräts mit Wasser oder den verwendeten

Produkten in Berührung kommen.

Achtung

Um der Entstehung von Bakterien

vorzubeugen, ausschließlich Produkte

verwenden, die für die Desinfizierung von

Kunststoff- und Gummiteilen zugelassen

sind. Die Nichteinhaltung dieser Vorschrift

kann zu Gesundheitsrisiken führen.

HINWEIS: es liegt in der Verantwortung des

Betreibers, sich mit den einschlägigen

Vorschriften vertraut zu machen, um alle

staatlichen, regionalen oder lokalen Gesetze im

Hinblick auf Reinigungshäufigkeit und

Aufbewahrung der verwendeten Produkte

einzuhalten.

Die nachstehend beschriebenen Abläufe sind

von ausschlaggebender Wichtigkeit, um die

Entstehung von Bakterien zu verhindern und die

optimalen Hygienebedingungen der Maschine zu

gewährleisten.

Es empfiehlt sich, die genannten Abläufe

täglich vorzunehmen und in jedem Fall die

einschlägigen Gesetzesvorschriften einzuhalten.

Weder der Hersteller der Maschine noch der

Hersteller des eingefüllten Pulverprodukts

können für Personenschäden verantwortlich

gemacht werden, die direkt oder indirekt durch

mangelnde Einhaltung der in diesem Handbuch

angegebenen Vorschriften, insbesondere im

Hinblick auf Reinigung und Desinfizierung des

Geräts zustande kommen.

Ausgabedatum: Februar 2016 Revision: 1 Seite: 33/48

- Sowohl die Kälteanlage (Taste – drücken, bis

alle LEDs erloschen sind) als auch die

Heizanlage (Taste E in Abschalt-Stellung)

abschalten und die Maschine etwa zehn Minuten

lang nur bei laufendem Mischer betreiben.

- Das gesamte restliche Produkt entfernen,

wobei bei warmen Produkten Vorsicht geboten

ist, das das Produkt noch heiß sein könnte.

- Ein handelsübliches Produkt für die

Desinfizierung von Kunststoff- und

Gummigegenständen bereitstellen (z.B.

AMUCHINA®).

WICHTIG

Die Anweisungen auf dem verwendeten

Produkt in Bezug auf Zeit und

Aufbewahrungsmodalitäten müssen strikt

eingehalten werden.

- Den Deckel entfernen, wie in Abb. 12

dargestellt.

- Die Wanne mit lauwarmem Wasser füllen

(Abb. 13) und das Rührwerk einige Minuten lang

laufen lassen (alle LEDs ausgeschaltet),

nachdem der Deckel wieder aufgesetzt wurde.

!ACHTUNG!

Jede Wanne ist mit einer

Sicherheitsvorrichtung ausgestattet, die

den Betrieb verhindert, wenn der Deckel

nicht ordnungsgemäß in seine Aufnahme

eingesetzt wurde.

- Die Wanne entleeren und den Vorgang

wiederholen, bis das verwendete Wasser klar

bleibt (Abb. 14).

Abb. 12

Abb. 13

Abb. 14

Ausgabedatum: Februar 2016 Revision: 1 Seite: 34/48

Achtung

Um die Gefahr von Stromschlägen oder

Kontakt mit den bewegten Maschinenteilen

zu vermeiden, muss sichergestellt werden,

dass während des Ein- und Ausbaus der

Bauteile alle Schalter auf Off stehen und

das Versorgungskabel aus der Steckdose

gezogen ist.

- Die Hauptschalter A und/oder B auf der

rechten Seite der Frontseite des Geräts

abschalten und den Stecker aus der Steckdose

ziehen.

- Den Deckel abheben

- Bevor die Reinigung vorgenommen wird, die

Hände sorgfältig waschen und desinfizieren.

- Den Hahn von der Wanne abmontieren, indem

gleichzeitig die beiden Verriegelungslaschen

gedrückt und der Hahn nach oben aus seiner

Aufnahme herausgezogen wird (Abb. 15).

- Den Hahn in seine Einzelteile zerlegen. Dazu

den Ventilkörper nach unten gedrückt halten

und den Hebel aus seiner Aufnahme ziehen

(Abb. 16).

Achtung

Um die Entstehung von Bakterien zu

verhindern, stets auch die O-Ringe

herausnehmen und reinigen. Die

mangelnde Einhaltung dieser Anweisung

kann zu Gesundheitsrisiken für die

Verbraucher führen.

- Die Wanne greifen, wie in Abb. 17 dargestellt,

leicht nach oben bewegen, um sie aus ihrer

Aufnahme zu lösen und dann nach außen

ziehen.

Abb. 15

Abb. 16

Abb. 17

Ausgabedatum: Februar 2016 Revision: 1 Seite: 35/48

- Den Spiralrührer und die Napfdichtung

herausnehmen (Abb.18).

- Die Dichtung der Wanne entfernen, wie in Abb.

19 dargestellt.

- Die Tropfschale leicht nach oben bewegen und

dann nach außen abziehen (Abb. 20).

- Alle Einzelteile sorgfältig mit heißem Wasser

und Geschirrspülmittel reinigen.

WICHTIG

Keine scheuernden Reinigungsmittel oder

Pulver verwenden, da diese die Wanne und

die sonstigen Bauteile schädigen können,

mit denen sie in Berührung kommen.

ACHTUNG

Die genannten Elemente keinesfalls in der

Spülmaschine waschen, da sie dort schwer

beschädigt werden können

- Alle Teile gründlich abspülen und in das

Desinfektionsmittel legen. Dabei die vom

Hersteller angegebene Dosierung und

Einwirkungszeit einhalten.

- Nach Ablauf der korrekten Desinfektionszeit,

alle Teile sorgfältig mit reinem Wasser spülen

und mit einem sauberen Tuch trocknen.

- Den Verdampfer und die Kondenswasserschale

sorgfältig reinigen. Alle Produktrückstände mit

einem sauberen, mit Desinfektionsmittel

getränkten Schwamm beseitigen (siehe Abb.

21).

- Den gleichen Vorgang mit einem in reinem

Trinkwasser getränkten Schwamm wiederholen

und dann alle Flächen mit einem sauberen Tuch

trocknen.

Abb. 18

Abb. 19

Abb. 20

Abb. 21

Ausgabedatum: Februar 2016 Revision: 1 Seite: 36/48

Nachdem die obigen Reinigungs- und

Desinfizierungsmaßnahmen sorgfältig

ausgeführt wurden, können die Bauteile wieder

eingebaut werden.

Das richtige Zusammensetzen der Maschine ist

sehr wichtig, da es andernfalls zum Auslaufen

von Produkt und zu Schäden der Maschine

selbst kommen kann.

Beim Zusammenbau ist ein zugelassenes

Schmiermittel erforderlich (Vaseline).

Stets sicherstellen, dass alle Teile

ordnungsgemäß gereinigt und desinfiziert

wurden, und dass alle mit dem Zusammenbau

befassten Personen sorgfältig ihre Hände und

Unterarme gewaschen und desinfiziert haben.

- Die hintere Wannendichtung wieder einbauen,

wobei auf die richtige Lage der Dichtung zu

achten ist. Siehe Abb.22.

- Die Innenseite der Napfdichtung sorgfältig mit

Vaseline-Fett schmieren (Abb.23).

- Die Napfdichtung in ihre Aufnahme am

Spiralrührer einsetzen, bevor die Baugruppe in

das Gerät eingebaut wird (Abb.24).

- Das Rührwerk und die Napfdichtung wieder

einbauen, wobei darauf zu achten ist, dass der

vordere Schaft perfekt in die Rotationswelle

eingreift (Abb.25).

Abb. 22

Abb. 23

Abb. 24

Abb. 25

Ausgabedatum: Februar 2016 Revision: 1 Seite: 37/48

- Um die Montage zu erleichtern, empfiehlt es

sich, den hinteren Teil der Wanne mit sauberem

Wasser an dem Punkt anzufeuchten, an dem sie

an ihrer Dichtung anliegt (siehe Abb. 26);

- Zum Wiedereinbau, die Wanne am Verdampfer

entlang bis zum Anschlag drücken und hinter

dem Sperrprofil in ihrer Aufnahme blockieren.

Sicherstellen, dass sie exakt an ihrer Dichtung

anliegt (siehe Abbildung 27).

- Den Hahn wieder einbauen (Abb.28) und die

Dichtungen mit Vaseline-Fett schmieren, um das

Eingleiten des Hahns in seine Aufnahme zu

erleichtern.

!ACHTUNG!

Ein nicht einwandfreies Gleiten des Hahns

beeinträchtigt dessen Dichtheit.

- Die Tropfschale wieder anbringen.

Abb. 26

Abb. 27

Abb. 28

Ausgabedatum: Februar 2016 Revision: 1 Seite: 38/48

DESINFIZIERUNG

Wenn die Maschine nach sorgfältiger Reinigung

und Desinfizierung gemäß Kapitel 9 mehrere

Tage nicht benutzt wird, muss sie wie

nachstehend beschrieben neu desinfiziert

werden.

- Den Sicherheitsdeckel abheben.

- Die Wanne mit Wasser und

nahrungsmittelechtem Desinfektionsmittel

(AMUCHINA®) füllen, wobei die

Dosierungsanweisungen des Herstellers

beachtet werden müssen.

- Nachdem der Deckel wieder angebracht

wurde, das Rührwerk in Betrieb setzen (alle

LEDs erloschen) und das Produkt nach Vorschrift

des Herstellers einwirken lassen.

WICHTIG

Das Desinfektionsmittel nicht länger als

vom Hersteller vorgeschrieben in der

Wanne belassen

- Die Wanne entleeren, indem das Ventil

mindestens 10 Mal geöffnet und geschlossen

wird. Auf diese Weise wird auch der gesamte

Durchlaufbereich des Produkts desinfiziert.

- Sorgfältig nachspülen, d.h. die obigen

Vorgänge mit reinem Wasser anstelle von

Desinfektionsmittel wiederholen.

- Nachdem die vorstehend beschriebene

Desinfektion sorgfältig vorgenommen wurde, ist

die Maschine gebrauchsbereit.

Ausgabedatum: Februar 2016 Revision: 1 Seite: 39/48

10. AUSSERORDENTLICHE WARTUNG

Achtung

Bevor Wartungsarbeiten jeglicher Art

ausgeführt werden, muss obligatorisch das

Gerät abgeschaltet und der Stecker aus der

Steckdose gezogen werden.

Reinigung des Kondensators

Um eine einwandfreie Leistung der Kälteanlage

zu gewährleisten, muss für sorgfältige Reinigung

des

Kondensators mindestens einmal monatlich

oder immer dann gesorgt werden, wenn

der Verstopfungsgrad dies notwendig

macht.

Für den Zugang zum Kondensator

- die Spannungsversorgung des Geräts durch

Abschalten des Hauptschalters und Abziehen

des Steckers aus der Steckdose unterbrechen;

- Bei NINA2 HOT&COLD die untere Verkleidung

an der Rückseite entfernen, indem die

Kunststoffklammern gelöst und die Verkleidung

leich nach außen gezogen wird, wie in Abb. 29

dargestellt;

- Bei NINA3 HOT&COLD das linke Seitenteil

entfernen, nachdem die beiden

Befestigungsschrauben abgeschraubt wurden

(Abb. 30);

- Sofern vorhanden, den Filter herausnehmen

und sorgfältig spülen. Andernfalls sorgfältig die

Flügel des Kondensators mit einem Staubsauger

reinigen;

- Den eventuellen Filter wieder einsetzen und

die Verkleidung wieder anbringen, bevor die

Maschine in Betrieb gesetzt wird.

WICHTIG

Zum Entfernen des Schmutzes zwischen

den Lamellen des Kondensators keinesfalls

Schraubenzieher oder sonstige

scharfkantige Gegenstände verwenden.

Abb. 29

Abb. 30

Ausgabedatum: Februar 2016 Revision: 1 Seite: 40/48

Kontrolle und Austausch der Dichtungen

WANNENDICHTUNG

Die Dichtung an der Rückseite der Wanne muss

alle 12 Monate ausgetauscht werden, je nach

Verschleiß und Wartungs- bzw.

Schmierungszustand.

DICHTUNGEN (O-RINGE) DES HAHNS

Die O-Ringdichtungen des Zapfhahns müssen

ersetzt werden, sobald sie verschlissen sind.

Diese Dichtungen müssen bei jedem

Zusammenbau der Maschine nach der Reinigung

geschmiert und sorgfältig kontrolliert werden,

um unerwünschte Leckagen zu vermeiden.

NAPFDICHTUNG

Die Napfdichtung an der Vorderseite des

Verdampfers muss alle 3 Monate ausgetauscht

werden, bzw. immer dann, wenn sie

verschlissen ist. Diese Dichtung muss bei jedem

Zusammenbau der Maschine nach der Reinigung

mit dem mitgelieferten Vaseline-Fett geschmiert

werden.

Einlagerung über Winter

Um die Maschine bei Stillstandszeiten wie

beispielsweise im Winter zu schützen, muss sie

ordnungsgemäß gelagert werden, wie

nachstehend beschrieben:

- Die Maschine von allen Energiequellen

trennen.

- Alle Teile, die mit dem Produkt in Berührung

kommen ausbauen, reinigen und desinfizieren,

wie in Kapitel 9 beschrieben.

- Auch die Außenplatten reinigen

- Alle Bauteile wieder ordnungsgemäß einbauen.

- Die Maschine vollständig montiert mit der

Originalverpackung bedecken, um sie vor Staub

und sonstigen Verschmutzungen zu schützen.

- Die Maschine an einem trockenen Ort

verwahren.

Aufbewahrung Produkt

Da die Haltbarkeit des Produkts von der

Temperatur und von der Dauer der

Aufbewahrung abhängig ist, müssen unbedingt

die Angaben des Herstellers eingehalten

werden, um Gesundheitsrisiken durch ein wegen

falscher Aufbewahrungsbedingungen schlecht

gewordenes Produkt zu vermeiden.

Ausgabedatum: Februar 2016 Revision: 1 Seite: 41/48

11. NÜTZLICHE INFORMATIONEN ZUR

HERSTELLUNG VON SPEISEEIS

VOLUMENSTEIGERUNG

Beim Übergang vom flüssigen Anfangszustand

in den verdickten, cremigen Endzustand nimmt

das Volumen des Produkt beachtlich zu. Die

Quantifizierung des Ausmaßes dieser

Volumensteigerung kann sehr hilfreich sein, um

das Überfüllen der Wanne mit zu viel Produkt zu

vermeiden.

Die folgende, einfache Berechnung gestattet die

Bestimmung des Prozentsatzes, um den sich

das Volumen vergrößern wird.

- Einen leeren Behälter auf eine Waage stellen

und diese somit auf Null Gewicht einstellen;

- Den Behälter abnehmen, vollständig mit

flüssigem Produkt füllen, wiegen und das

Gewicht notieren;

- Den gleichen Vorgang wiederholen, indem der

Behälter mit dem Produkt gefüllt wird, das die

gewünschte Dichte aufweist: wiegen und das

erzielte Gewicht notieren;

- Nun anhand der nachstehenden Formel die

prozentuale Volumensteigerung berechnen:

“Gewicht des flüssigen Produkts minus Gewicht

des cremigen Produkt, geteilt durch das Gewicht

des cremigen Produkts und dann multipliziert

mal 100”

Beispiel:

Gewicht eines halben Liters flüssigen Produkts:

530 g

Gewicht eines halben Liters cremigen Produkts:

380 g

Differenz:150 g

150/380=0.4

0.4x100=40% Volumensteigerung

12. HAFTUNGSAUSSCHLUSS

Der Hersteller verweigert jegliche Haftung für

eventuelle direkte oder indirekte Personen-,

Sach- und Tierschäden infolge der mangelnden

Einhaltung der Vorschriften dieses Handbuchs,

insbesondere der Hinweise in Bezug auf

Installation, Betrieb und Wartung des Geräts.

Der Hersteller haftet nicht für eventuell in

diesem Handbuch enthaltene Ungenauigkeiten

infolge von Druck-, Abschrift- oder

Übersetzungsfehlern und behält sich das Recht

vor, alle Änderungen vorzunehmen, die er für

notwendig oder dienlich erachtet, ohne die

wesentlichen Funktions- und

Sicherheitsmerkmale der Maschine zu

beeinträchtigen.

Ausgabedatum: Februar 2016 Revision: 1 Seite: 42/48

13. ANLEITUNG ZUR PROBLEM

LÖSUNG

Problem

Mögliche Ursache

Abhilfe

Die Maschine kühlt nicht

oder nur teilweise, und

der Kompressor

funktioniert

Der Belüftungs-Freiraum rings um

die Maschine ist nicht ausreichend

Die Maschine arbeitet nur im

Rührbetrieb

Der Kondensator ist verschmutzt

oder verstaubt

Der Lüfter funktioniert nicht

Es liegt eine Kältemittel-Leckage

vor

Mindestens 20 cm Freiraum rings um die

Maschine belassen und die Maschine fern

von Hitzequellen aufstellen

Die Kälteanlage durch Drücken der Taste

+ einschalten

Den Filter des Kondensators reinigen

Die elektrischen Anschlüsse kontrollieren

und eventuell wieder herstellen. Sollte

die Maschine trotzdem nicht

funktionieren, den Lüfter austauschen

Die Leckstelle feststellen, beseitigen und

die Anlage wieder füllen

Die Maschine kühlt nicht

oder nur teilweise, und

der Kompressor

funktioniert nicht

Die elektrischen Teile des

Kompressors funktionieren nicht

Einige Elektroanschlüsse sind

unvollständig

Der Kompressor ist defekt

Die Bauteile austauschen, die nicht

funktionieren

Die Anschlüsse kontrollieren und

unvollständige Anschlüsse in Ordnung

bringen

Den Kompressor austauschen

Die Maschine läuft laut

Die Flügel des Lüfters stoßen an

interne Bauteile

Überprüfen und in Ordnung bringen

Der Hauptschalter steht

auf ON, aber die

Maschine funktioniert

nicht

Der Hauptdeckel wurde nicht

ordnungsgemäß angebracht

Einige Elektroanschlüsse sind

unvollständig

Der Hauptschalter ist defekt

Die elektronische Steuerkarte ist

defekt

Der Getriebemotor ist defekt

Den Hauptdeckel ordnungsgemäß

anbringen

Die Anschlüsse kontrollieren und

unvollständige Anschlüsse in Ordnung

bringen

Den Schalter austauschen

Die Steuerkarte austauschen

Den Getriebemotor austauschen

Die Wanne hat

Leckstellen

Eine der Dichtungen ist nicht richtig

eingelegt

Die Dichtung entfernen und richtig

anbringen. Falls notwendig, die Dichtung

austauschen

Leck am Zapfhahn

Der Zapfhahn wurde nicht

ordnungsgemäß montiert

Die Bewegung des Hahns ist

behindert

Die O-Ringdichtungen sind

beschädigt oder verschlissen

Den Hahn aus- und korrekt wieder

einbauen

Den Hahn und seine Aufnahme reinigen

und mit dem zur Lieferung gehörenden

Vaseline-Fett schmieren

Die O-Ringe austauschen

Das Produkt läuft an der

Rückseite auf die

Tropfschale

Die Napfdichtung und die

Haltebuchse der Welle sind

beschädigt oder verschlissen

Die Dichtungen entfernen und ersetzen

Das Rührwerk dreht sich

nicht

Der Hauptdeckel wurde nicht

ordnungsgemäß angebracht

Einige Elektroanschlüsse sind

unvollständig

Die Steuerkarte des Motors ist

defekt

Der Getriebemotor ist defekt

Den Hauptdeckel ordnungsgemäß

anbringen

Die Anschlüsse kontrollieren und

unvollständige Anschlüsse in Ordnung

bringen

Die Steuerkarte des Motors austauschen

Den Getriebemotor austauschen

Das Rührwerk läuft laut

während der Rotation

Die Napfdichtung wurde

ausgetauscht, ohne sie

ordnungsgemäß zu schmieren

Die Mischerspirale wurde nicht

ordnungsgemäß montiert

Die Dichtung herausnehmen, reinigen,

desinfizieren und ordnungsgemäß

schmieren

Die Spirale und das gesamte Rührwerk

aus- und korrekt wieder einbauen

HINWEIS: die nachstehenden

Arbeitsgänge müssen von technischem

Fachpersonal ausgeführt werden

Ausgabedatum: Februar 2016 Revision: 1 Seite: 43/48

Problem

Mögliche Ursache

Abhilfe

Fehleranzeigen der

LEDs (von unten nach

oben):

- Blinken der 1. LED

- Blinken der 2. LED

- Blinken der 3. LED

- Blinken der 4. LED

- Blinken der 5. LED

Speicherfehler

Sonde der Wanne kurzgeschlossen

Sonde der Wanne nicht

angeschlossen

Überstrom des Motors

Netzspannungsfehler

Karte austauschen

Sonde austauschen

Sonde anschließen

Abschalten, Störung beseitigen und

wieder einschalten

Abschalten, Störung beseitigen und

wieder einschalten

Die Maschine heizt nicht