Page 1

SPM Instrument AB • Box 504 • SE-645 25 Strängnäs • Sweden

Technical data are subject to change without notice.

Tel +46 152 225 00 • Fax +46 152 15075 • info@spminstrument.se • www.spminstrument.com

ISO 9001 certified. © Copyright SPM 2008-06. 71796 B

User Guide

Page 2

Page 3

Contents

Instrument Overview ........................................................................2

Instrument parts ................................................................................ 2

General description ...........................................................................2

Displays and icons ............................................................................. 3

Start up ..............................................................................................4

Batteries ............................................................................................5

Settings .............................................................................................. 6

Battery type ....................................................................................6

Unit for temperature measurement ..................................................6

Unit for bearing diameter setting .....................................................6

Accessories ................................................................................... 7

Shock Pulse Measurement ...................................................... 8

The Shock Pulse Method ................................................................... 8

Carpet value dBc .............................................................................8

Maximum value dBm .......................................................................8

dBm/dBc.........................................................................................8

Normalized shock pulse values with dBi ............................................9

Unnormalized readings............................................................................9

The dBm/dBc technique................................................................... 10

Rules for measuring points................................................................ 11

Measuring points, examples ............................................................. 12

Measuring range .............................................................................14

Creating acceptable measuring conditions ....................................... 15

Measuring intervals .........................................................................16

Shock pulse transducers.................................................................... 17

Bearing Measurement ............................................................... 19

Input data .......................................................................................... 19

Entering shaft diameter and rpm for dBi calculation ..........................19

Entering dBi manually ...................................................................... 19

Shock pulse measurement ................................................................20

Transducer Line Test ..........................................................................21

Storing measurement results ............................................................ 21

Listening to the shock pulse pattern ................................................22

Evaluating the Bearing Condition ........................................... 23

Identifying the shock pulse source ...................................................24

Shock pulse patterns – condition codes ........................................... 25

Typical shock pulse patterns from rolling bearings ..........................26

Confirming bearing damage ............................................................. 30

Evaluation flow chart .........................................................................32

Temperature Measurement ...................................................... 34

Using the Stethoscope Function ............................................. 35

Technical Specifications ............................................................. 36

Maintenance and calibration .............................................................37

Page 4

Page 5

1

Document Outline

This User Guide contains useful information about the Bearing Checker, beginning with general information about instrument parts, user interface, batteries and settings.

A chapter explaining the theories of shock pulse measurement follows. It is advisable that you read this

as it is valuable in order to understand measurement results and to evaluate them correctly.

The shock pulse theories chapter is followed by chapters describing the hands-on use of the instrument

and how to confirm and evaluate measurement results.

References to icons, displays and modes in the instrument are in bold text. References to instrument

keys are in capital letters.

Page 6

2

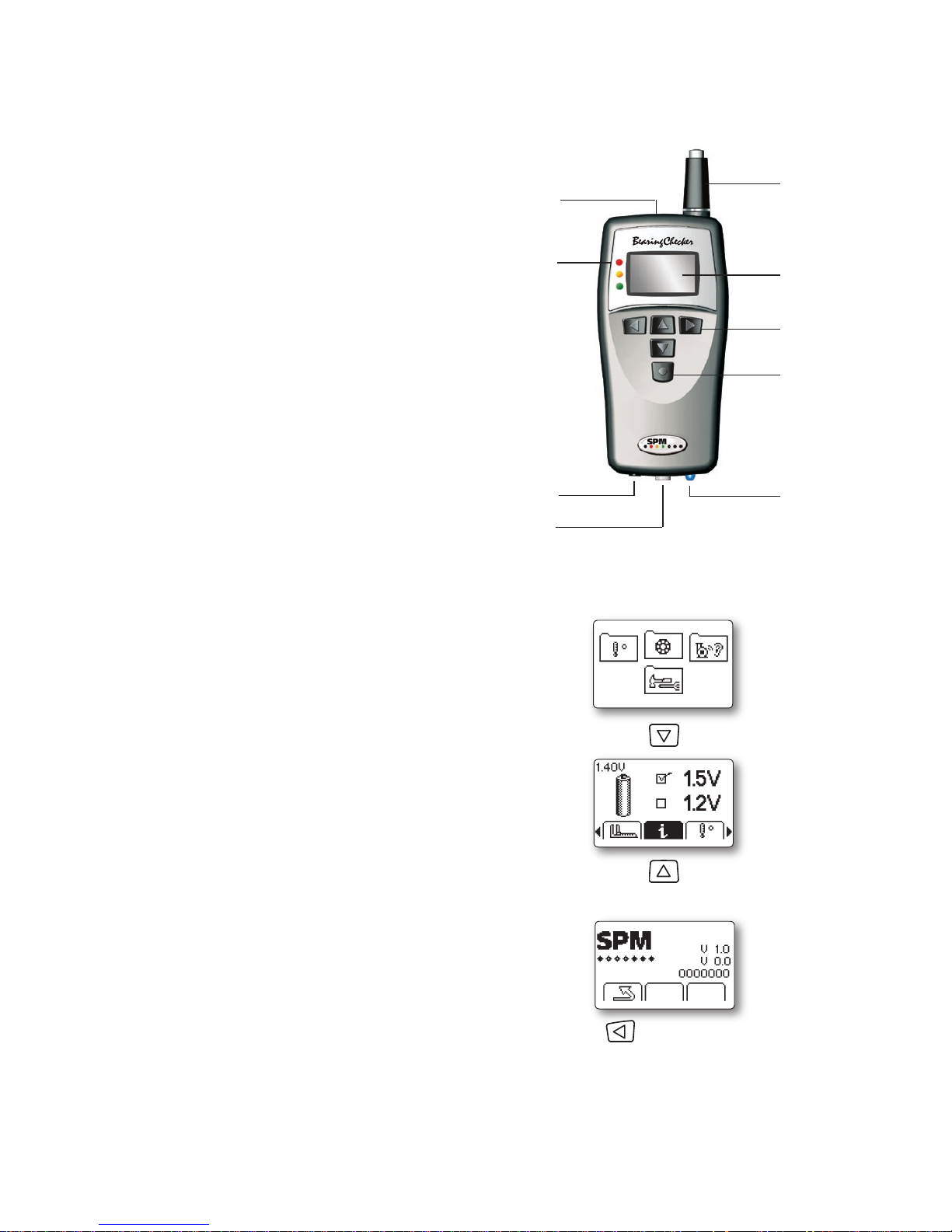

Instrument parts

1 Measuring probe

2 Temperature IR sensor

3 Condition indicators

4 Graphical display

5 Navigation keys

6 Measuring key and power on

7 Output for headphones

8 Transducer input

9 Measuring LED

10 Battery compartment

11 Serial number label

Instrument Overview

1

3

4

7 9

2

5

6

8

General description

The Bearing Checker is a shock pulse meter based on the well proven SPM method for quick and easy

identification of bearing faults. The instrument has a built-in microprocessor programmed to analyze

shock pulse patterns from all types of ball and roller bearings and display evaluated information on the

operating condition of the bearing.

Bearing Checker is battery powered and designed for use in harsh industrial environments. The graphic

display (4) gives the condition readings and the LED indicators (3) give an immediate evaluated bearing

condition in green-yellow-red.

The shock pulse transducer (1) of probe type is built-in. All types of SPM shock pulse transducers for adapters and permanent installation can also be used, connected to the transducer input (8). The dBi value is

programmed into the instrument and the measurement is started with key (6). The actual condition reading

is displayed on the graphical display (4) as a carpet value “dBc” and a maximum value “dBm”. The condition indicators (3) indicate the evaluated bearing condition in green-yellow-red. Headphones for listening

to the shock pulse pattern can be connected to the output (7).

The Bearing Checker can also be used for measuring surface temperature via the IR sensor (2), and for

detecting machine sound irregularities via headphones using the stethoscope function.

Internal or external probes can be used for listening.

11

10

Page 7

3

Displays and icons

Bearing measurement

Temperature

measurement

Stethoscope

function

General settings

Bearing measurement

Input data Measurement

Input dBi

MemoryTLT test Listening

Back/Return

Main display

Temperature measurement Stethoscope function

Measure (or press the probe tip)

Back/Return

Back/Return

Volume (1– 8)

Back

to main menu

Battery Unit

About

Temperature

General settings

Page 8

4

Pressing the measuring key (6) switches on the instrument.

Set up and measuring modes are selected with the arrow keys (5).

Measuring is started automatically whenever the internal

probe is pressed in. When using external probes, measuring is started manually by pressing the measuring key

(6) while in the Bearing mode.

The blue measuring LED (9) stops blinking when an SPM

measuring cycle is completed.

The green, yellow and red LEDs (4) beside the display

indicate the bearing condition after an SPM measurement.

If not used, the instrument will automatically shut off

after 2 minutes. It can also be shut off by simultaneously

pressing the LEFT and RIGHT arrow keys.

When switched back on, the instrument will resume its

last mode.

Start up

1

3

4

7 9

2

5

6

8

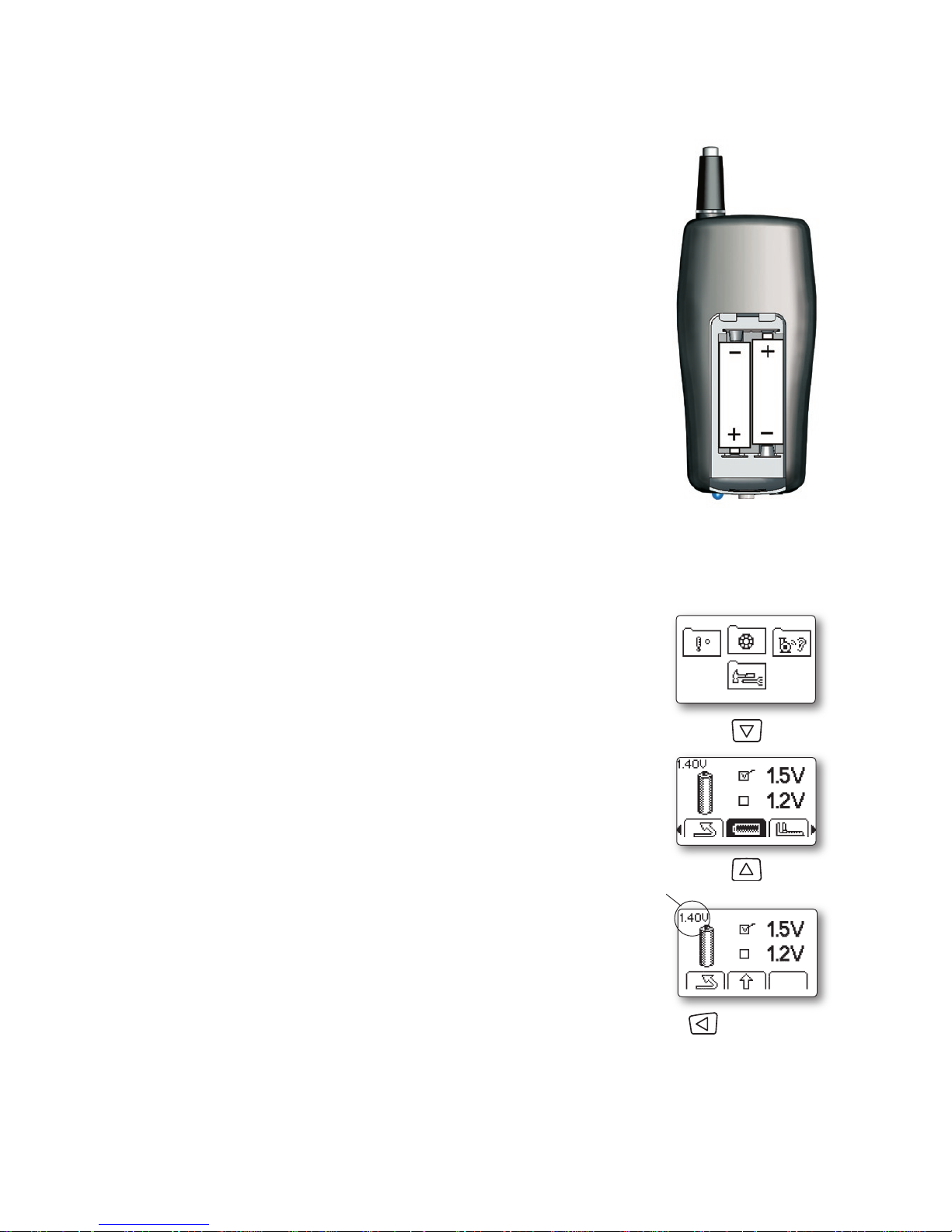

Serial number and software version

To check which software version is in your instrument

and find out the instrument serial number, go to the

Main display. Press the DOWN arrow key to enter the

General Settings mode. Use LEFT/RIGHT arrow keys

to highlight the Information icon (i), then press the UP

arrow key to see the software version and serial number.

To return to the General Settings mode, press the LEFT

arrow key.

To return to the Main display, use LEFT/RIGHT arrow

keys to highlight the Return icon, then press the UP

arrow key.

General

settings

Software version

and serial number

Back/Return

Main display

Page 9

5

The instrument is powered by two batteries type MN 1500 LR6. Alkaline

or rechargeable batteries can be used. Please note that rechargeable

batteries must be removed from the instrument before recharging. The

battery compartment is located at the back. Press and push the lid to

open the compartment.

The battery test on the setup menu shows the present battery voltage.

The battery status icon will show when the batteries are low and have

to be replaced or recharged.

The battery life depends on how the instrument is used. Full power is

only consumed while a reading is in progress: from pressing the measuring key until a measured value is displayed.

Before long-time storage of the instrument, keep in mind to remove

the batteries.

Batteries

Battery check

For exact battery voltage, go to the battery setup menu:

From the Main display, press the DOWN arrow key to enter the General

Settings folder. Use LEFT/RIGHT arrow keys to highlight the battery icon,

then press the UP arrow key to enter battery type setup. The present battery voltage is shown in the upper left corner.

To return to the General Settings menu press the LEFT arrow key.

General

settings

Battery type

Battery

voltage

Back/Return

Main display

Page 10

6

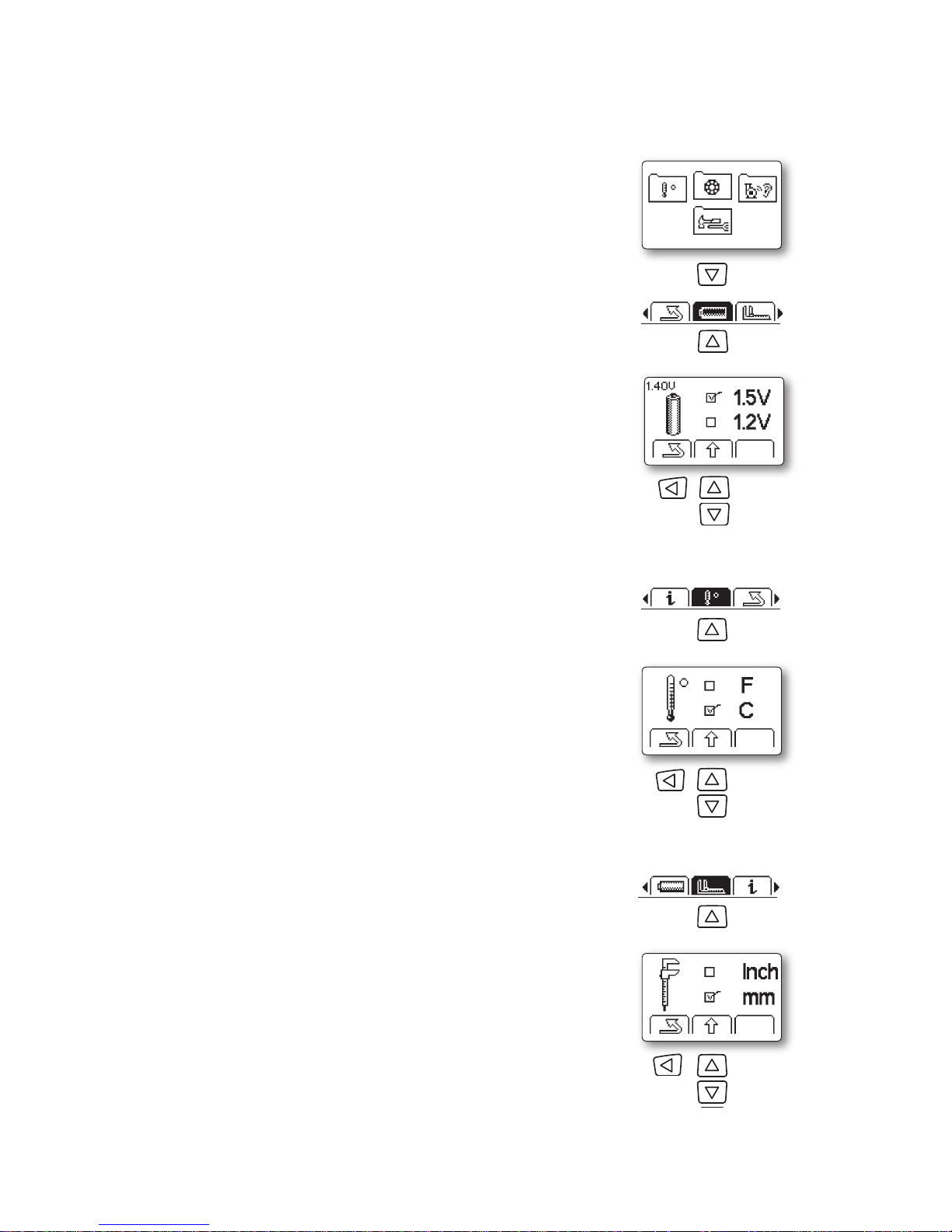

Battery type

Alcaline or rechargeable batteries can be used in Bearing Checker. The

battery type has no influence on instrument functionality or operation, but

should be set for the battery status icon to correctly show battery level.

From the Main display, press DOWN arrow key to enter the General Set-

tings folder. Use LEFT/RIGHT arrow keys to highlight the Battery icon,

then press the UP arrow key to enter battery type setup. Use UP/DOWN

arrow keys to set the battery type of your choice (1.2 V for rechargeable,

1.5 V for alcaline batteries). To save and return to the General Settings

menu press the LEFT arrow key.

To return to the Main display, use LEFT/RIGHT arrow keys to higlight the

Return icon, then press the UP arrow key.

Unit for temperature measurement

Temperature can be displayed in either Celsius or Fahrenheit. To choose

your unit of measurement, use the DOWN arrow key in the Main display

to enter the General Settings mode. Use the LEFT/RIGHT arrow keys

to highlight the Temperature icon, then press the UP arrow key. Use the

UP/DOWN arrow keys to set the measurement unit of your choice. To save

and return to the General Settings menu press the LEFT arrow key.

To return to the Main display, use the LEFT arrow key to highlight the

Return icon, then press the UP arrow key.

Unit for bearing diameter setting

Bearing diameter can be displayed in either mm or inch. To choose your

unit of measurement, use the DOWN arrow key in the Main display to

enter the General Settings mode. Use the LEFT/RIGHT arrow keys to

highlight the Measurement icon, then press the UP arrow key. Use the

UP/DOWN arrow keys to set the measurement unit of your choice. To save

and return to the General Settings menu press the LEFT arrow key.

To return to the Main display, use the LEFT arrow key to highlight the

Return icon, then press the UP arrow key.

Settings

Unit for temperature

General

settings

Select

type

Battery type

Back/Return

Main display

Select

inch or

mm

Unit for diameter

Select

°F or °C

Back/Return

Back/Return

Page 11

7

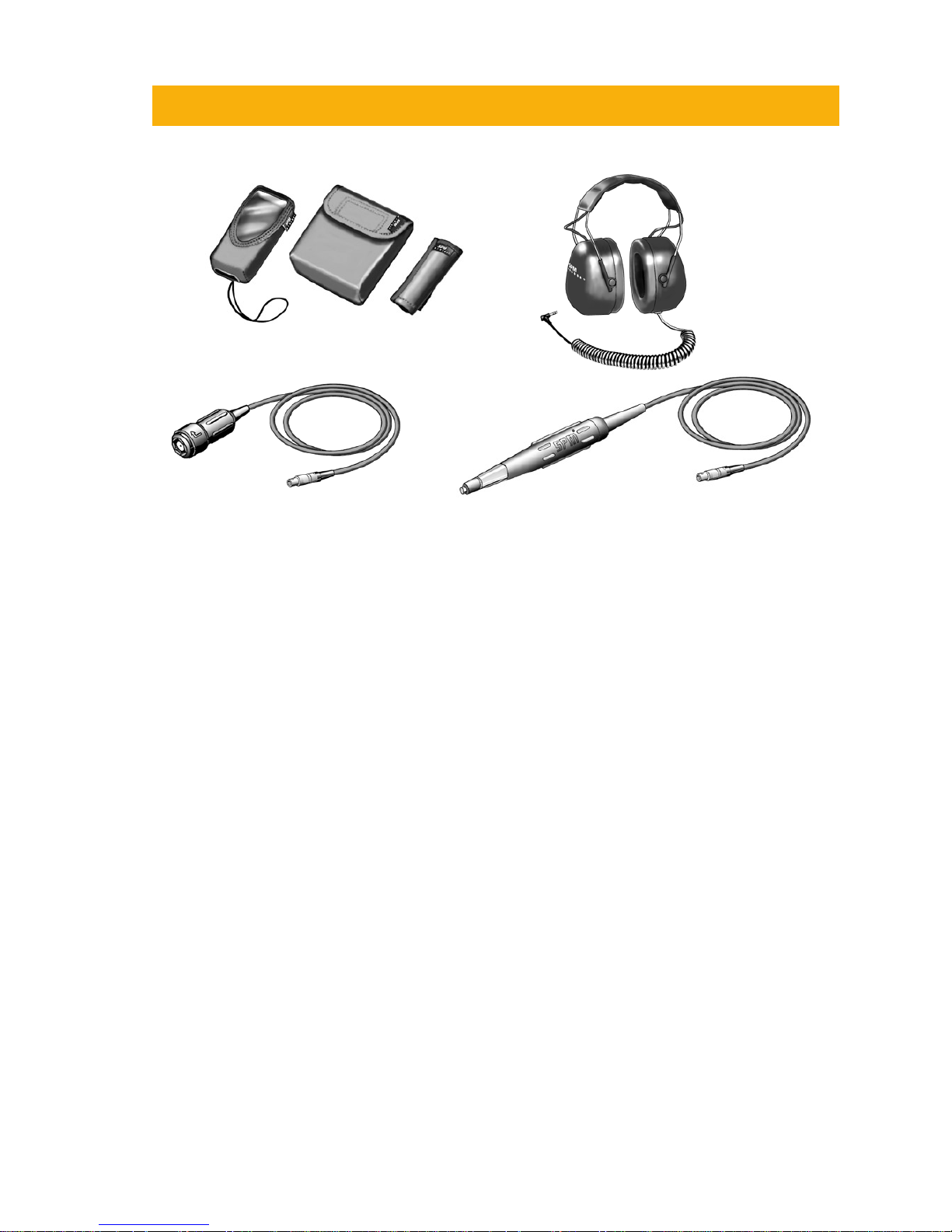

Accessories

Accessories

EAR12 Headphones with ear defenders

TRA73 External transducer with probe

TRA74 Transducer with quick connector for adapters

CAB52 Measuring cable with slip-on connector for permanently installed transducers, 1,5 m

15286 Belt holder for external probe transducer

15287 Belt case for accessories

15288 Protective cover with wrist strap

15455 Protective cover with belt clip and wrist strap

93363 Cable adapter, LEMO-BNC

93062 Cable adapter, BNC-TNC, plug-jack

Spare parts

13108 Rubber sleeve for probe tip, chloroprene, maximum 110 °C (230 °F)

15288

15455

15287 15286

EAR12

TRA74

TRA73

Page 12

8

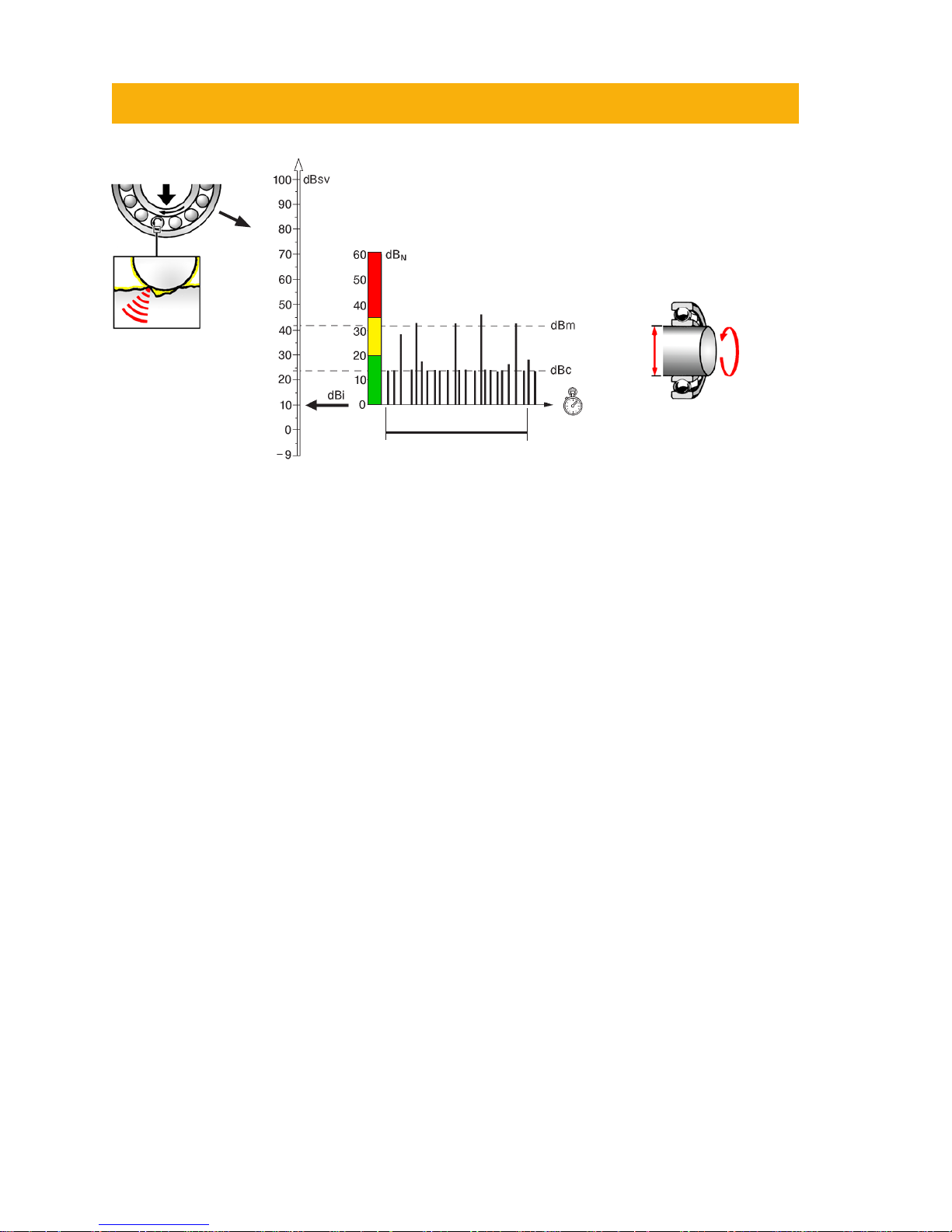

The Shock Pulse Method

The Bearing Checker is based on the Shock Pulse Method. Measurements with the SPM method give an

indirect measure of impact velocity, i.e. the difference in velocity between two bodies at the moment of

impact. At the point of impact, a mechanical compression wave (a shock pulse) arises instantly in each

body. The peak value of the shock pulse is determined by the impact velocity and is not influenced by

the mass or the shape of the colliding bodies. Shock pulses in rotating ball and roller bearings are caused

by impacts between raceways and rolling elements. From the points of impact the shock pulses travel

through the bearing and the bearing housing. Extensive experience proves that there is a simple relationship between the bearing’s operating condition and the value of the shock pulses.

A transducer detects the shock pulses in the bearing. The transducer signals are processed in the bearing

detector’s microprocessor and the measured shock pulse values are shown on the display. An headphone

can be connected to the instrument for listening to the shock pulse pattern. Please note that this instrument cannot be used for plain bearings.

Shock pulses are short duration pressure pulses which are generated by mechanical impacts. Mechanical

impacts occur in all rotating rolling bearings because of irregularities in the surfaces of the raceways and

the rolling elements. The magnitude of the shock pulses depends on the impact velocity.

Carpet value dBc

Surface roughness (small irregularities) will cause a rapid sequence of minor shock pulses which together

constitute the shock carpet of the bearing. The magnitude of the shock carpet is expressed by the carpet

value dBc (decibel carpet value). The carpet value is affected by the oil film between rolling elements and

raceways. When the film thickness is normal, the bearing’s carpet value is low. Poor alignment and installation as well as insufficient lubrication will reduce the thickness of the oil film in the whole or parts of the

bearing. This causes the carpet value dBc to rise above normal.

Maximum value dBm

Bearing damage, i.e. relatively large irregularities in the surfaces, will cause single shock pulses with higher

magnitudes at random intervals. The highest shock pulse value measured on a bearing is called its maximum value dBm (decibel maximum value). The maximum value dBm is used to determine the operating

condition of the bearing. The carpet value dBc helps to analyze the cause of reduced or bad operating

condition.

Shock Pulse Measurement

dBi = Initial value of a bearing

dBc = Carpet value (weak pulses)

dBm = Maximum value (strong pulses)

dBn = Unit for normalized shock level

dBsv = Unit for absolute shock level

rpm

d

The initial value dBi

depends on rpm and

shaft diameter d.

2 seconds

Page 13

9

Normalized and unnormalized readings

The Bearing Checker measures impact velocity over a large dynamic range. In order to simplify readout

and evaluation, a logarithmic measuring unit is used: decibel shock value (dBsv).

dBsv is the general measuring unit for shock pulses. By measuring the shock pulses from a bearing in dBsv

a value for their magnitude is obtained, for instance 42 dBsv. However, this value is only part of the information needed to judge the operating condition of the bearing. We also need a standard of comparison,

i.e. a norm value for identical or similar bearings.

Such norm values have been obtained empirically, by measuring the shock pulses from a large number of

new, perfect ball and roller bearings. They are called “initial values” dBi (decibel initial). The dBi value can

be set manually or calculated by the instrument after input of rpm and shaft diameter (see chapter “Input

data”). The highest dBi value that can be entered is +60, the lowest -9. Any attempt to enter values below

this will result in dBi “- -” and an unnormalized shock pulse reading (see below).

By subtracting the dBi from the dBsv value we obtain the “normalized” shock pulse value or dBn (decibel

normalized) of the bearing, for example: 42 dBsv–10 dBi = 32 dBn”. The normalized shock pulse value dBn

is the measuring unit for the operating condition of bearings. A maximum value of 32 dBn means “32 dB

above normal”, which implies “reduced operating condition” for the measured bearing. By programming

the Bearing Checker with the dBi before taking a reading, the bearing condition will be indicated directly

on the condition display in green-yellow-red for “good”, “reduced” or “bad” operating condition for the

measured bearing. “Bad operating condition” can be synonymous with “bearing damage”, but the term

also includes a number of other “bearing faults” which can be detected by shock pulse measurement. The

initial value dBi of a bearing is directly related to its rotational speed and shaft diameter.

The absolute shock pulse level of a bearing, measured in dBsv (decibel shock value), is both a function of

rolling velocity and of bearing condition. The dBi value of the bearing must be entered in order to neutralize the effect of rolling velocity on the measured value.

The Bearing Checker takes a sample count of the shock pulses occurring over a period of time and displays:

• the maximum value dBm for the small number of strong shock pulses.

• the carpet value dBc for the large number of weaker shock pulses.

• a lit-up LED on the condition scale (for normalized readings only): green for dBn up to 20 dBn =

good condition, yellow for 21-34 dBn = caution, red for 35 dBn and more = bad condition.

The maximum value dBm defines the bearing’s position on the condition scale. The difference between

dBm and dBc is used for a finer analysis of the causes for reduced or bad condition.

Unnormalized readings

For unnormalized readings, set the dBi value to “- -” (see chapter “Input data”). You will then measure in

dBsv (absolute shock values) and get no condition indication, as the condition scale is graded in normalized shock values, dBn. This method is used for comparative readings on different bearings and/or other

shock pulse sources.

Page 14

10

The dBm/dBc technique

The dBm/dBc technique has been successfully applied for more than 35 years and continues to be widely

used. It is well suited for industrial condition monitoring, because it works with few, easy to understand

in- and output data.

Even on a logarithmic scale, there is normally a large, distinct difference between the maximum values

from good and bad bearings. Thus, minor inaccuracies in the input data (rpm and shaft diameter) have

little effect on the evaluated measuring result.

Lubrication condition is indicated by the delta value, i.e. the difference between dBm and dBc. High readings and a small delta value indicate poor lubrication or dry running. This is sufficient for maintenance

purposes.

dBm and dBc are measured in a fixed time window and automatically displayed.

The headphone is used to listen to the shock pulse pattern in case of suspect or high readings. This,

and the possibility to search for shock pulse sources with the probe transducer, are means to verify the

measuring result and its cause.

Life time

Page 15

11

The rules for the selection of SPM measuring points have a

very practical purpose. We are trying to capture low energy

signals which are getting weaker the farther they travel and

the more they are bounced about inside a piece of metal. We

know that they lose strength when they cross over from one

piece of metal to another. We cannot know, for all bearing

applications, how much of the strength of the signal emitted

by the bearing will reach the measuring point. However, by

necessity we try to apply general evaluation rules, i. e. treat

all measured signals as if they were of the same quality.

The rules for SPM measuring points try to assure that most

of them are ”within tolerance” and that the green-yellow-red

condition zones are valid:

1 The signal path between bearing and measuring

point shall be as short and straight as possible.

2 The signal path must contain only one mechanical

interface: that between bearing and bearing housing.

3 The measuring point shall be located in the load zone

of the bearing.

“Short” means up to 75 mm (3 in.), but that depends also

on how straight the path is: bends cause re- and deflections

whose effects are hard to judge. The load zone is the load

carrying half of the bearing housing, normally the lower one.

Allow for the pull of belts or other forces which can shift the

load to one side. Use the probe to find the spot yielding the

strongest signal. When a measuring point cannot conform to

the rules (because an ideal spot cannot be reached), make

allowance for a weaker signal.

Measuring

point

Load

1. Straight and short path

2. No interface!

3. In the load zone of the

bearing

Rules for measuring points

Page 16

12

The following two pages show measuring points and possible adapter or transducer installations. How to install

measuring equipment is described in the SPM installation

manual.

Through hole for long adapter

Figure A shows how a measuring point beneath a fan cover

can be reached with a long adapter, through a hole in the

cover.

Adapter with lock nut

In figure B, the fan cover is fastened directly to the motor shield, which is also the bearing housing. One of the

cover’s holding screws can be replaced by an adapter with

lock nut.

Bearing housings beneath brackets

Consult machine drawings and identify the bearing housing

before selecting a measuring point.

In figure C, showing a pump, the bearings are placed in two

separate housings inside the bearing bracket.

The bearing pair at measuring point 1 can be reached with

a long adapter through a clearance hole in the bracket. The

hole must be large enough to allow bearing adjustment

and still prevent metallic contact between bracket and

adapter.

Measuring point 2, placed below and opposite to the pump

outlet (load direction!) can be reached with a long adapter

through an opening in the pump shield.

Multiple bearings in one housing

If there are several bearings in the same housing, they are

normally treated as a single bearing. Figure D shows the

bearing arrangement for a vertical pump. It is not possible

to distinguish between the shock pulses from the paired

bearings in point 1.

There is also a risk for cross talk between point 1 and point

2, which means that the shock pulses from the bearing in

worst condition are picked up at both points. Check signal

strength with the probe. Use one measuring point only if

readings are identical in both points. This point (x) can be

placed halfway between points 1 and 2.

A

Measuring points, examples

1

2

C

B

D

Page 17

13

On large electric motors, the bearings are often mounted in

housings which are welded or bolted to the motor shields.

Because of the damping in the interface between the bushing and the shield, the measuring point should be on the

bushing.

The bearing housing at the drive end (A) is usually within

reach. A long adapter is installed at an angle to the shield, so

that there is enough space for connecting the transducer.

Installed transducer

The bearing at the fan end (B) requires a permanent transducer installation. The transducer is installed in the bushing.

The coaxial cable is run through a slit in the fan cover to a

measuring terminal on the stator frame.

Check installed equipment

Incorrectly installed adapters or transducers can cause a

significant damping of the shock pulse signal.

Check all installations. Make sure that mounting holes are correctly countersunk and that the seat surfaces of adapters have

good contact with the material of the bearing housings.

Any metallic machine part knocking or rubbing against the

adapter will produce a disturbance. This must be avoided by

making large clearance holes and using soft, elastic sealing

material.

Use high temperature cables and moisture proof equipment

where required, and protect installations against damage.

Adapters should be fitted with protective caps.

Mark the measuring points

Measuring points for the probe transducer should be clearly

marked. To get comparable readings, one must always use

the same measuring point.

A

drive end

A

B

B

fan end

Page 18

14

The measuring range of the Bearing Checker is large and

covers most bearing applications, but there are a few cases

where shock pulse monitoring should only be attempted with

installed measuring equipment, or not at all.

High speed bearings: The Bearing Checker accepts max.

19 999 rpm, 1 999 mm shaft diameter, and a dBi of 40. The

upper part of the table contains examples of possible combinations of shaft diameter and rpm giving a maximum dBi

of 40. The lower part of the table examplifies combinations

that give dBi = 0. The instrument calculates the dBi up to 40.

However, it is possible to manually set the dBi to max. 60. A

reason for setting dbi > 40 is when measuring on e.g. turbo

chargers, high speed gear boxes etc.

Low speed bearings: The lowest acceptable dBi is -9 dB.

However, it is nearly impossible to get a meaningful reading from bearings in the extremely low speed ranges. The

practical limit are bearings with a dBi around 0 dB (see lower

half of the table).

A heavy load with a well defined direction and a low interference level make it easier to get readings from low speed

bearings. Successful SPM monitoring has been carried out

on bearings with dBi = –3 (54 rpm, shaft diameter 260 mm).

Note that the dynamic measuring range decreases when dBi

values get below 0. For example, a bearing with dBi = –3

showed very heavy damages at dBn = 40.

Installed adapters required: The installation of adapters is

strongly recommended for all systematic shock pulse monitoring. In some cases it is a requirement:

• on bearings with dBi below 5

• on heavily vibrating bearing housings

• on covered bearing housings.

Low speed: Do not use a handheld probe on low speed

bearings. As a rule, the measurement should cover at least

10 full revolutions of the shaft. A single damaged part in the

raceway will cause a strong pulse only when hit by a rolling

element while passing through the load zone. It can take

several revolutions before that event occurs or is repeated.

Adapters required!

Covered

housing

dBi < 5

Heavy vibration

Shaft, mm rpm dBi

50 19 999 40

100 13 000 40

180 10 000 40

300 6 000 40

500 5 000 40

1 000 3 400 40

1 999 2 200 40

1 999 24 0

1 000 35 0

650 45 0

500 52 0

300 72 0

180 100 0

100 140 0

50 210 0

Measuring range

Page 19

15

The clicking of valves, high pressure steam flow, mechanical rubbing, damaged or badly adjusted gears,

and load shocks from machine operation can cause a general high shock level on the machine frame. This

interference can mask the bearing signal in cases where he shock level measured outside of the bearing

housings is as high or higher than the shock level on the bearing housings.

Remove sources of interference

In most cases, interference is the result of bad machine condition. For example – cavitation in a pump is

due to flow conditions for which the pump was not designed. Cavitation does more than interfere with

bearing monitoring – it slowly erodes the material of the pump.

Monitoring the bearings is pointless if the machine breaks down or requires frequent repairs because of

other poorly maintained parts or badly adjusted operating parameters. Therefore, do not accept interference – try to remove the cause.

Coping with interference

If the source of interference cannot be removed, there are several possibilities:

• If it is intermittent, measure while there is no interference.

If interference is persistent, measure its shock pulse level with the same dBi setting as the bearing and

compare it with the condition zones:

• If interference masks the green zone, you can get true bearing condition readings in the yellow and

red zone.

• If interference masks the yellow zone, you can get true bearing condition readings in the red zone,

i.e. find a damaged bearing.

If the interference level is persistently higher than the shock level that would be caused by bad bearing

condition (35 to 40 dB above the dBi), do not try to monitor the bearing.

Alignment

Scraping,

alignment

Cavitation

Gear tooth

damage

No interference Low level interference High level interference

Creating acceptable measuring conditions

Page 20

16

Unpredicted, very rapid damage development is rare. Normally, surface damage develops slowly, over

a period of many months. These are the general guidelines for selecting the interval between periodic

readings:

• The bearings should be checked at least once every three months.

• The bearings in critical machinery and heavily preloaded bearings (e.g. spindle bearings) should be

measured more often than other bearings.

• The bearings should be measured more frequently when their condition is unstable (rising or irregular readings).

• Damaged bearings should be closely watched until they can be replaced.

This implies that one has to allow time for extra checks on bearings in dubious or bad condition.

Check stand-by equipment

Vibration and corrosion can damage the bearings in stand-by machines. Check bearing condition each

time such machines are being tested or used.

Synchronize with lubrication

It may be necessary to synchronize regreasing and measuring intervals. Grease lubricated bearings should

not be measured until they have run for approximately one hour after regreasing (except when doing a

lubrication test).

Keep in mind that bad bearing condition is often connected with lubrication problems. For grease lubricated bearings, a lubrication test usually provides the final proof of bearing damage. Make sure that the

right type and quantity of grease is used.

Measuring personnel

should know about:

• lubricant type

• maximum quantity

• lubricating intervals

1-3 months

several days,

one week

measure

often

Measuring intervals

Page 21

17

Shock pulse transducers

Rubber sleeve in contact with

the surface

Point at the bearing

Hold steady

Built-in transducer with probe

Measuring points for the built-in probe should be clearly

marked. Always measure in the same spot. In addition, the

probe is used to measure elsewhere on the machine, in case

it is necessary to search for other shock pulse sources such as

pump cavitation or rubbing parts.

The probe tip is spring loaded and moves within a sleeve of

hard rubber. To maintain a steady pressure on the tip, press the

probe tip against the measuring point until the rubber sleeve

is in contact with the surface.

Hold the probe steady to avoid rubbing between probe tip

and surface.

The probe is directionally sensitive. It has to be pointed straight

at the bearing.

The centre of the probe tip should touch the surface. Avoid

pressing the probe tip against cavities and fillets which are

smaller than the probe tip.

Shock pulse transducer with handheld

probe

The handheld probe can be used to reach measuring points in

narrow spaces and has the same construction and method of

operation as the built-in transducer (see above).

The only part likely to wear out is the rubber sleeve for the

probe tip. It is made of chloroprene rubber (neoprene) and

tolerates 110° C (230° F). Spare sleeves have part number

13108.

Avoid small cavities and fillets

Transducer with probe

TRA73

Page 22

18

Transducer with quick connector

All types of shock pulse transducers are connected to the transducer

input (8). The choice of transducer type depends on how the measuring point is prepared. For systematic shock pulse monitoring, SPM

recommends the use of permanently installed adapters and quickconnect transducer wherever possible.

Adapters are solid metal bolts of different length and thread sizes,

tuned for correct signal transmission. They are installed in threaded,

countersunk mounting holes on the bearing housings. Glue-on adapters are available.

To attach the transducer with quick connector, press it against the

adapter and twist clockwise. Twist counter-clockwise to remove it.

Adapter surfaces must be clean and plane. Use an adapter cap to

protect them.

Check that installed transducers and adapters are properly mounted

(see the instruction on SPM installations) and in good condition. You

cannot expect a useful signal by attaching the quick connect transducer to a rusty lump of metal, or from a transducer that is rolling

on the floor on the other side of a partition.

Push and

twist

Installed

transducer

Measuring

terminal

Permanently installed transducers and

measuring terminal

A permanently installed transducer and a measuring terminal (BNC

or TNC connector) are used when the bearing cannot be reached

directly. Use a measuring cable to connect instrument and terminal.

Use SPM dust caps to protect the connector.

Check that installed transducers and adapters are properly mounted

(see the instruction on SPM installations) and in good condition. You

cannot expect a useful signal by attaching the quick connect transducer to a rusty lump of metal, or from a transducer that is rolling

on the floor on the other side of a partition.

TRA74

Standard

adapter

Standard

transducer

Page 23

19

Bearing Measurement

Input data

For a reading of bearing condition with Bearing Checker, you need

the initial value, dBi. If you do not know the bearing´s dBi, Bearing Checker will calculate and display the dBi given the rotational

speed (rpm) and the shaft diameter. Neglecting to enter this

information will produce incorrect measurement results.

Entering shaft diameter and rpm for dBi

calculation

From the Main display, press the UP arrow key to enter Bearing

mode. Use LEFT/RIGHT arrow keys to highlight the Input Data

icon, then press the UP arrow key. Use the LEFT/RIGHT arrow keys

to position the cursor and the UP/DOWN arrow keys to increase or

decrease the rpm value, respectively. To enter the shaft diameter,

first press the measuring key, then use the arrow keys to set the

diameter value the same way rpm was set.

Press the measuring key to return to Bearing mode.

Entering dBi manually

Changing the dBi directly is faster when you know it from your

records:

From the Main display, press the UP arrow key to enter Bearing

mode. Use LEFT/RIGHT arrow keys to highlight the dBi icon,

then press the UP arrow key. First, position the cursor using the

LEFT/RIGHT arrow keys, then use the UP/DOWN arrow keys to

increase or decrease the dBi value, respectively.

The highest dBi value that can be entered is +60, the lowest -9.

Any attempt to enter values below this results in dBi = “- -” and an

unnormalized shock pulse reading (see also chapters “Normalized

shock pulse values with dBi” and “Readings on gearboxes”). To

set the dBi value back from “- -” to “+” or “-”, press the UP arrow

key, then position the cursor as required to set the dBi.

Press the measuring key to return to Bearing mode.

The dBi value, whether calculated by the instrument or manually

input, is shown in the lower right part of the Bearing display.

shaft

diameter ø

rpm

Bearing

measurement

Enter rpm

OK

OK

Enter shaft diameter

Enter dBi value

OK

Page 24

20

For shock pulse measurement, press the UP arrow key in

the Main display to enter the Bearing display. Make sure

the shaft diameter and rotational speed of the bearing,

or its dBi, have been entered (se chapter Input data), or

the reading will be incorrect.

From the Bearing display, press the transducer to the meas-

uring point. Measurement starts automatically, taking a few

seconds, during which the blue measuring LED is lit up.

The two measuring results are the maximum value, dBm,

and the carpet value, dBc. Depending on the dBm value,

the green, yellow or red light LED to the left of the display

will light up.

When an external transducer is used, the instrument will

display a TLT warning sign if the transducer line test result

is unsatisfactory. To see the TLT value for the latest reading, go to the TLT menu. For further information about TLT,

please see chapter “Transducer Line Test”.

When measurement is finished, the LED indicators show

the bearing condition, and an evaluation code is displayed.

The code refers to the Evaluation Flow Chart on page 3233, which must be used to further evaluate the bearing

condition.

When you get high readings (yellow and red zone), you

should immediately verify their nature and probable cause.

Do not give the verdict ”bearing damage” before making

a further investigation. As a first measure:

• use the headphones to identify the shock pulse pattern.

• measure on and outside of the bearing housing to

identify the shock pulse source.

Surface temperature is measured automatically when an

SPM measurement is made. To see the temperature reading, use LEFT/RIGHT arrow keys to activate the Return

icon in the Bearing display, then press the UP arrow key to

enter the Main display. Press the LEFT arrow key to enter

Temperature mode and see the reading. To return to the

Main display, press the LEFT arrow key.

Shock pulse measurement

Condition indicators:

red - bad (≥35)

yellow - caution (21–34)

green - good (≤ 20)

Check:

- Shaft diameter and rpm, dBi setting

- Measuring point in the load zone

- Probe pointed straight at the

bearing

- Adapter (transducer) properly

mounted

- Adapter surface clean, undamaged

- Quick connect transducer firmly

attached

Bearing measurement

Evaluation

code

Measure

(or press the

probe tip)

TLT warning

Page 25

21

Transducer Line Test

When measuring shock pulses with external transducers, a

transducer line test (TLT) will automatically be made to check

the quality of the signal transmission between transducer and

instrument (the TLT value for the latest reading is always saved

and is shown in the TLT window). Part of your signal will be

lost in a poor transducer line, so your measuring results will

be lower than they should be. If an SPM measurement is made

with a poor transducer line, the instrument will display a TLT

warning sign.

To perform a transducer line test (TLT) manually, connect the

external transducer to the instrument. From the Main display,

press the UP arrow key to enter the Bearing folder, then use

LEFT/RIGHT arrow keys to highlight the TLT icon. Press the

UP arrow key to enter the TLT menu. Press the measuring key

briefly. The blue measuring LED lights up and the reading is

shown in the display.

The TLT test window also displays transducer type: IPR (internal

probe), EPR (external probe), TRA (40000 type) or TMU (42000

type). TRA is also displayed in case of a cable breakdown. The

TLT value then depends on the distance to the breakage point

(1-2 dB/meter). In case of a shortcircuit, TMU and the value 0

(normally) is displayed.

At TLT values from 15 upward, there is normally no signal loss

due to poor transmission between transducer and instrument.

If the value is below 15, or if it is deteriorating from a previously higher value, you need to check cables, connectors and

transducers for poor connections and moisture.

The TLT test can be temporarily turned off to force evaluated

measurement results on transducers with TLT below 15, e.g.

when measuring via coupling transformers. In the TLT menu,

press the RIGHT arrow key to turn the test off. The TLT test is au-The TLT test is automatically turned back on by entering the TLT menu again and

when the instrument is automatically or manually turned off.

Storing measurement results

This function is useful for easy comparison of measurement

results for a particular measuring point. It can also be used to

store measurement results temporarily until they can be recorded on paper for trending and follow-up. On the last page

iof the User Guide is a follow-up form which can be copied and

used for this purpose.

The Bearing Checker can store up to ten SPM measurement

results.

In the Bearing display, use LEFT/RIGHT arrow keys to highlight

the Memory icon, then press the UP arrow key to enter Memory

mode. Select memory place (1-10) by using the UP/DOWN arrow keys. Press the RIGHT arrow key to store the reading. This

action will overwrite any previously stored value in the memory

place selected.

To return to the Bearing display, press the LEFT arrow key.

Latest reading

Stored reading

Current memory place

dBi

Transducer Line Test

Bearing measurement

Measure

TLT

Save

Select place

Memory

Bearing measurement

TLT off

Page 26

22

The stream of shock pulses from a rotating bearing is continuous. They vary in strength, depending on the relative

positions of rolling elements and raceways.

The headphone is a means to verify and trace shock pulse

sources. The headphones allow you to listen to the shock

pulse pattern. In the headphone, the noise carpet is represented by a continuous tone. The dBc level is approximately

where you can start to distinguish between an even sound

and individual pulses. Typical for bearing signals is a random

sequence of strong pulses with no discernable rhythm, best

heard a few dB below the dBm level.

A spot of surface damage causing a strong shock pulse will

only register, if a roller hits it during the measuring interval.

Especially at low rotational speeds, the instrument can miss

the strongest pulse, simply because it does not occur during

the measuring interval.

To listen to the shock pulse pattern after taking an SPM

reading, connect your headphones to the output connector

(7). From the Main display, press the UP arrow key to enter

Bearing mode. Use the LEFT/RIGHT arrow keys to highlight

the Listening icon, then press the UP arrow key to enter

listening mode, where the dBm value of the latest reading

is displayed. Use the UP/DOWN arrow keys to adjust the

amplitude level at which you wish to listen; anything below

this value will be filtered out.

To adjust the headphone volume use the RIGHT arrow key.

NOTE! Setting the volume to the maximum level may harm

your hearing.

To return to the Bearing display, press the LEFT arrow

key.

Headphones

dBn

Listening to the shock pulse pattern

Adjust

amplitude

level

Headphone volume

Adjustment of

amplitude level

Listening

Adjust

volume

Back

Bearing measurement

Page 27

23

NOTE! A reading taken with an incorrect dBi value causes an incorrect evaluation of the bearing condition! Always check that the correct dBi for the bearing in question has been entered!

Evaluation simply means that you make sure that the information you pass on to the maintenance personnel is as correct as possible and as detailed as necessary. Always remember that

• some machines can contain many types of shock pulse sources other than the bearing, and

• there can be a number of different causes for bad bearing condition other than damage.

Evaluation requires only normal care and common sense. Use the probe transducer and the headphone,

and also use your senses: look, touch, listen. By being thorough you can avoid raising false alarms or

missing damaged bearings.

Initial readings and changes

There are only two situations where an evaluation is necessary. The first is when you start with bearing

monitoring:

• Always evaluate the first readings on new measuring points and newly installed bearings.

The purpose is to establish a reliable base for routine measurements. You want to be quite sure that you

are measuring shock pulses from the bearing and that the reading itself is correct. If you find that bearing

condition is good, you do not have to evaluate the following readings on that measuring point as long as

there is no significant change.

The other situation is when you notice a change in the readings (or get high readings from the start):

• Investigate any significant increase or decrease of the shock pulse level.

Again, you want to be quite sure that you are measuring shock pulses from the bearing and that the reading itself is correct.

If you find that bearing condition is not good, you have to distinguish between bad installation, poor

lubrication, overload and damage, in order to decide what kind of maintenance work is needed. If you

are getting an interference signal, it is probably caused by machine faults which have to be reported and

repaired.

Machine Bearing Bearing Bearing

alignment lubrication installation damage

High maximum value

Interference

Cross talk from

other bearings

Interference from

mechanical shocks

Operating condition not good

Evaluating the Bearing Condition

1 Reading correct ? Check!

Measuring point? Installation ? Correct dBi ?

dBm?

Look, feel, check data.

2 Shock pulse source? Search!

Bearing ? Interference? Signal pattern? Loose

parts?

Look, listen. Use probe transducer, headphone

.

3

Bearing fault? Analyse!

Lubrication? Alignment? Installation?

Bearing damage?

Identify shock pulse pattern.

Check trend. Test lubrication.

Page 28

24

Sources of interference

Any kind of metallic clatter, hard impacts or scraping produces shock pulses which may interfere with the

measurement on the bearings. Some of the more common sources of interference are:

• Shocks between poorly fastened machine feet and foundation.

• Rubbing between shafts and other machine parts.

• Loose parts striking the machine frame or the bearing housing.

• Excessive play and misalignment of couplings.

• Vibration in connection with loose parts and excessive bearing play (vibration alone does not affect

the reading).

• Cavitation in pumps.

• Gear tooth damage.

• Load and pressure shocks arising during the normal operation of certain machines.

Identifying the shock pulse source

Excessive

play

Gear tooth

damage

Cavitation

Play,

scraping

Shock pulses are strongest close to the source. They spread through the material of all machine parts, but

are dampened (loss of signal) with distance and when passing through interfaces in the material.

• Measure on and near the bearing housing to find the strongest shock pulse source.

• Listen for unusual noises.

Page 29

25

The headphone is a means to verify and trace shock pulse

sources. The signal from a bearing should be highest on the

bearing housing. If you get a higher signal outside of the

bearing housing (across an interface in the material), you are

most likely measuring shock pulses from another bearing

or some other source. Typical for bearing signals is that the

stronger shock pulses, best heard a few dB below the peak

level, appear at random intervals.

The codes refer to the Evaluation Guide, or the Flow Chart

on page 32-33, which must be used to further evaluate the

bearing condition.

If instrument displays “2/3” or “4/5”, use the headphones

to determine the condition code.

1 For a good bearing, the dBm is within the green zone.

dBm and dBc are close together.

2 The shock pulse pattern from a damaged bearing contains strong pulses in the red zone, a random sequence, and

a large difference between dBm and dBc. When you lubricate the bearing, the values should drop but rise again.

3 A dry running bearing has a high carpet value very close

to the dBm. When you lubricate the bearing, the values

should drop and stay low. A similar pattern is caused by

pump cavitation, in which case readings on the pump housing are stronger than those taken on the bearing housing,

and are not influenced by lubricating the bearing.

4 A regular pattern, containing bursts of strong pulses in

a rhythmic sequence, is caused by e.g. scraping parts.

5 Individual pulses in a regular sequence are cause by clicking valves, knocking parts, regular load shocks.

6 A sudden drop in the shock pulse level is suspicious.

Check your measuring equipment. If the reading is correct,

you may have a slipping bearing ring.

Shock pulse patterns – condition codes

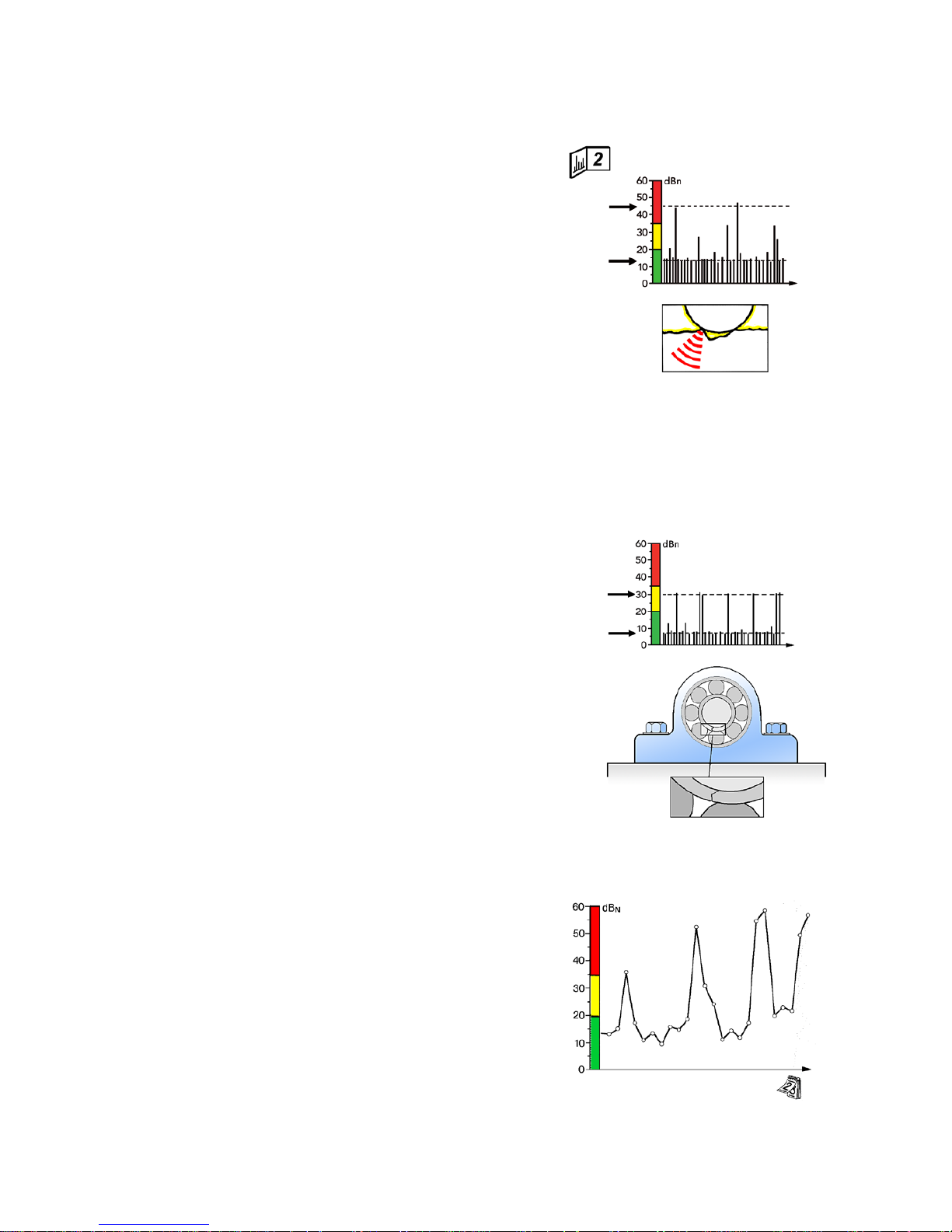

Page 30

26

A) Maximum value dBm

B) Difference between dBm and dBc

C) Rhythm of the strongest pulses

A shock pulse pattern is a sequence of either random

or rhythmical strong pulses (dBm level) above a carpet

of very rapid weaker pulses (dBc level). You have to be

aware of:

• the dBm value

• the difference between dBm and dBc

• the rhythm of the strongest pulses.

The rhythm of the strongest pulses is best discerned by

listening with the headphone at a setting a few dB below

the dBm level. Typical for bearing signals is a random

sequence of strong pulses (no discernable rhythm).

Rhythmical shocks can come from a bearing but are

more often a sign of interference. Typical patterns are

described on the next pages.

The Bearing Checker recognizes the pattern of the

reading taken and determines which of the six patterns

below is a match. The matching number is displayed in

the upper left corner of the Bearing display when the

measurement is completed. This number corresponds

to the pattern numbers below.

There may be times when the instrument displays a

combination of the numbers “2/3” or “4/5”, in which

case the instrument can not distinguish between the two

codes. Use the headphones and listen to the pattern to

determine condition code.

1 Pattern from a good bearing

A bearing in good condition should have a dBm value

below 20 and a dBc value approximately 5 to 10 dB lower.

Once you have verified the reading, there is no need for

any further evaluation.

The maximum value can be lower than 0. However, be

suspicious when the measured value is very low. The

cause is often a bad measuring point or an incorrectly

installed adapter or transducer. If the reading is very

low, check the installation. Measure on other parts of

the bearing housing and try to pick up a stronger signal.

Another possible reason for a very low reading is that

there is no load on the bearing. This can happen with well

balanced fans and similar rotating machines.

Typical shock pulse patterns from rolling bearings

A

B

C

dBm

dBc

Evaluation code

Page 31

27

2 Signal from a damaged bearing

The pattern shown is typical for damaged bearing surfaces:

a dBm above 35 dB, a large gap between dBm and dBc,

and a random pattern of strong pulses. The strength of the

maximum value dBm indicates the degree of damage:

35 – 40 dBN Slight damage

40 – 45 dB

N

Severe damage

> 45 dBN High breakdown risk.

First signs of damage

dBm values between 20 and 35 dB (in the yellow zone)

and a moderate increase of the carpet value are a sign of

stress in the bearing surfaces or minor damage. Note that

the gap between dBm and dBc gets larger.

Bearings with dBm values in the yellow zone should be

measured more frequently, to determine if their condition

is stable or deteriorating.

Note: a similar pattern is caused by contaminations in the

lubricant (metal or dirt). The particles either originate from

parts of the bearing itself, for instance from a damaged

cage, or they are transported by the lubricant into the

(undamaged) bearing. Test bearing and lubricant according to the description “Confirming bearing damage” in

this manual.

Cracked inner ring

A clean crack in the inner ring of a bearing is difficult to

detect, especially at a low rpm. You may get low readings

through most of the bearing’s rotation, then one or two

peaks while the crack is in the load zone. Signal strength

can differ considerably as the crack opens or closes depending on bearing temperature. In time, the surface

tends to spall along the crack, leaving sharp edges and

metal particles which cause high shock values until they

are rolled out.

dBm

dBc

dBm

dBc

Irregular measuring results

Large variations between consecutive readings are a danger sign. Damaged bearings do not improve with time,

although their shock values may temporarily drop.

Make sure the measuring interval is established according

the variations in production load (e.g. air compressors).

Always measure under the same production conditions.

Wide variations in the readings taken at different times

can occur on heavily loaded roller bearings with surface

damage. The high readings are caused by metal particles

breaking off the surfaces and by the sharp edges of new

spallings. When particles and edges are rolled out, the

readings will drop again.

Page 32

28

3 Patterns from poorly lubricated bearings

A high carpet value, very close to the maximum value, is

typical for dry running bearings. The dBm does not always

reach the red zone – typical for poor lubrication is that

the gap between dBm and dBc is very small. If the signal

is strongest on the bearing housing, it can have several

causes:

• insufficient lubricant supply to the bearing (poor oil

flow; old , caked, or cold grease)

• very low or very high bearing speed (preventing the

build-up of an oil film separation between the loaded

rolling elements and the raceway)

• installation fault (excessive preload) or out-of-round

bearing housing

• misalignment or bent shaft.

If possible, lubricate the bearing or increase the oil flow.

Measure immediately afterwards, and again a few hours

later. If the problem was insufficient lubricant supply, the

shock pulse level should drop and stay low.

In the case of very low or very high bearing speed, one

can try lubricants of a different viscosity or use additives

to prevent metal to metal contact between the bearing

surfaces.

In cases of installation faults, unround housings, and misalignment) the shock pulse level may drop after lubrication

but will soon rise again. Misalignment normally affects the

bearings on both sides of the coupling or at both ends of

the shaft.

Cavitation and similar interference

The shock pulse pattern caused by a cavitating pump or by

persistent rubbing is identical with that from a dry running

bearing. You have an interference signal when the shock

pulse level is highest outside of the bearing housing and

is not affected by lubricating the bearing.

If you cannot remove the cause of interference, you have a

“blind spot”: up to a certain level, the interference signal

will mask the signal from one or more bearings. However,

you may still be able to detect bearing damage. When the

dBm rises above the interference level, it must be caused

by something else – probably bad bearing condition. In

that case, lubricating the bearing should cause the value

to drop, at least temporarily.

Cavitation

Poor lubrication

dBm

dBc

Page 33

29

6 Large drop in the readings

If the shock pulse level drops after a sequence of

normal readings, you have either a malfunction of the

instrument, a failure in a transducer installation, or a

serious bearing fault.

Check the instrument by measuring on some other

bearing. In case of an installed transducer, try to get

a reading by tapping on the bearing housing. If your

reading is correct, it is possible that one of the bearing

races is slipping, either on the shaft or in the housing. In

case of a heavily loaded bearing with previous readings

in the red zone, suspect cage failure.

dBm

dBc

dBm

dBc

5 Rhythmical peaks

Single, rhythmical peaks can be caused by load and

pressure shocks which occur during the machine’s

normal operation. Other possible causes are clicking

valves or loose parts knocking regularly against the

machine frame.

If the signal is strongest on the bearing housing, you

can suspect a cracked inner ring.

4 Periodic bursts

Periodic bursts are a typical interference signal, caused

by rubbing between machine parts, e.g. shaft against

bearing housing or seal. The burst occurs at an rpm

related frequency.

Page 34

30

On receiving the typical bearing damage signal – high dBm, large

difference between dBm and dBc, random peaks, strongest signal

on the bearing housing – you must confirm one of the following

causes for the reading:

• tapping of loose parts against the bearing housing

• excessive bearing play in combination with vibration

• particles in the lubricant

• bearing damage.

Interference can usually be detected by a careful inspection.

Lubrication test

A lubrication test is the best means to reach a conclusive verdict:

• Make sure that the lubricant is clean and not contaminated.

• Lubricate the bearing and repeat the measurement. Meas-

ure immediately after lubricating and again a few hours later.

Make sure that the lubricant reaches the bearing. Typically, you

will get the following results:

A The shock pulse level remains constant. The signal is caused

by interference or cross talk from another bearing.

B The shock pulse level drops immediately after lubricating

and remains low. Foreign particles in the bearing were removed by the fresh lubricant.

C The shock pulse level drops immediately after lubricating

but rises again within a few hours.

The bearing is damaged.

Note that metal particles in the lubricant can originate from the

bearing itself. Measure the bearing again over the next few days

and make sure that the values stay low.

Confirming bearing damage

Page 35

31

Shock pulses can sometimes spread through a machine

housing without significant damping. This means that the

shock pulses from the bearing with the highest shock

pulse level can, under unfavourable circumstances, interfere with the readings on all the other bearings.

The problem is aggravated when the bearings are of different sizes and rotating at different speeds, as in a gear

box. A bearing with high rotational speed has a high dBi

value and generates relatively strong pulses even when

its operating condition is good. The same shock pulse

level measured on a bearing with a low dBi may indicate

bad bearing condition.

In such cases, you must proceed as follows:

1 Take a reading with dBi set to “--” on all bearings.

This will reveal the strongest shock pulse source on

the machine. In the example in the figure, you get

a reading of 53 dBsv for bearing A and 47 dBsv for

bearing B.

NOTE! When taking readings with dBi set to “--”

the evaluation in green - yellow- red does not

apply! See also chapters “Normalized shock pulse

values with dBi” and “Input data”.

2 Work out the direction of possible cross talk. You

know that the stronger source can mask the signal

of the weaker source. In this case, cross talk must

go from bearing A to bearing B.

3 Subtract the dBi values from the dBsv values. In the

example, you get 26 dBN for bearing A, 40 dBN for

bearing B.

You can now draw two conclusions: The reading for

bearing A, coming from the stronger source, is probably

accurate. The bearing condition is reduced (26 dB = yellow zone) but not seriously so.

The reading from bearing B is either true or false. If true,

it indicates bad bearing condition (40 dB = red zone), but

you cannot confirm that with the instrument before condition gets worse and bearing B becomes the stronger

shock pulse source. Your solution is to take frequent

readings and compare the results from both bearings.

1 Readings with dBi = “--” reveal

the stronger source

3 The reading from the

stronger source is

normally accurate

The reading from the

weaker source cannot

be confirmed

Cross talk !?

2 Cross talk must go from the

stronger to the weaker source

Readings on gear boxes

Page 36

32

Evaluation flow chart

On the

bearing

housing

Where

do you

get the

highest

reading?

Adjacent to

the bearing

housing

On the

bearing

housing

Locate the signal source.

Probable causes:

• Load or pressure shocks from equipment installed on

the machine frame.

• Other mechanical shocks from the machine’s operation

If possible, isolate the source of disturbance and test

again.

Probable causes:

• Load or pressure shocks in the machine’s operation

causing mechanical shocks in the bearing.

• Individual gear tooth damage

• Bearing damage

Probable causes:

• The shaft rubs against the bearing housing or the end of

the shaft rubs against the bearing cap.

• Gear tooth damage

• Other mechanical rubbing

Newly installed bearing?

Locate the signal source. The reading can be caused by

interference from other defective bearings, cavitation

in pumps or mechanical rubbing. If possible, isolate the

source of disturbance and test again.

Locate the signal source. If possible, isolate the source of

disturbance and test again.

Adjacent to

the bearing

housing

Check the value of adjacent bearings.

Are the signals from these bearings similar to the tested

bearing?

Locate the signal source. The reading can be caused by

cross talk from other defective bearings or disturbances

from other mechanical shocks. If possible, isolate the

source of disturbance and test again.

Adjacent to

the bearing

housing

On the

bearing

housing

Where

do you

get the

highest

reading?

Adjacent to

the bearing

housing

Where

do you

get the

highest

reading?

On the

bearing

housing

No signal or only a very low value can be obtained.

Where

do you

get the

highest

reading?

Good bearing condition, installation and lubrication.

Page 37

33

Probable causes: axial shocks, load shocks, defective shaft coupling, gear tooth damage, cross talk

from other defective bearings.

If possible, lubricate

the bearing and

check the reading at

the same time.

When lubricating,

check that the lubricant penetrates into

the bearing.

No

The reading does not drop.

Probable causes: disturbances from loose bearing cap,

protecting cover or similar items.

Can also be caused by: Large bearing damage.

The reading drops to normal level and does not increase

again. Cause: foreign particles in the bearing which have

been removed by the new lubricant.

Have normal values

been previous observed?

NOTE: Be suspicious

when sudden drastic

changes in readings

occur.

Probable causes:

• Insufficient lubrica

tion, possibly in

com-bination with

minor bearing damage

• Cavitation in pumps

• Mechanical rubbing

• Gear tooth damage

Yes

Probable causes:

• Bearing damage.

Measure in shorter

in-tervals, follow the

pro-gress of the damage .

• Foreign particles in

the lubricant.

Can also be caused by

disturbance from loose

bearing cap, protecting cover or similar

items.

If possible, isolate the

source of disturbance

The reading drops to normal level and does not increase

again. Cause: insufficient lubrication.

The reading does not drop.

Probably causes:

• Cavitation in pumps

• Mechanical rubbing

• Gear tooth damage

The reading drops but the max. value increases again

within a few hours.

Probable causes: insufficient lubrication which probably

has caused minor bearing damage.

The reading does not drop.

Probably causes:

• Incorrect bearing installation

• Cavitation in pumps

• Mechanical rubbing

• Gear tooth damage

The reading drops but the dBm increases again within a

few hours.

Probable causes: insufficient lubrication which probably

has caused minor bearing damage.

The reading drops to normal level and does not increase

again. Cause: insufficient lubrication.

Probably causes:

• The bearing’s inner ring is slipping on the shaft.

• The bearing’s outer ring is slipping in the housing.

• The reading has been taken just after lubricating a

grease lubricated bearing.

If possible, lubricate

the bearing and

check the reading at

the same time.

When lubricating,

check that the lubricant penetrates into

the bearing.

Probable causes:

• Incorrect bearing

installation

• Insufficient lubrica

tion possibly in combination with minor

bearing damage

• Cavitation in pumps

• Mechanical rubbing

• Gear tooth damage

Yes

No

If possible, lubricate

the bearing and

check the reading at

the same time.

When lubricating,

check that the lubricant penetrates into

the bearing.

Yes

• Is the instrument and the

transducer working ok?

• Is the measuring point cor

-

rect?

• Is the adapter or the trans

-

ducer correctly installed?

• Is the machine in operation?

The reading drops but increases again within a few hours.

Cause: bearing damage.

Shorten measuring intervals to follow the progress of the

damage.

Page 38

34

Temperature measurement is carried out with a contact-free infrared

sensor (IR). The sensor is placed on top of the instrument, next to the

probe transducer.

The window of the sensor is covered with a filter for infrared radiation.

If the window is covered or smudged with some other material, e.g.

water, the sensor will not be able to detect the correct amount of radiation and the instrument will therefore give an incorrect reading.

A polished metal surface emits less radiation than a painted surface.

If you want to measure on a polished metal surface, you may have

to attach a paper label or paint the surface to get a correct reading.

Also, bear in mind that a blank surface may reflect heat radiation from

surrounding objects.

Emissivity of some common materials:

Brass, polished 0,03

Brass, oxidized 0,61

Copper, roughly polished 0,07

Copper, black, oxidized 0,78

Paint, varnish, black 0,96

Aluminum foil 0,09

Lead, oxidized 0,43

Iron, corroded 0,78

Iron, oxidized 0,84

The viewing angle of the sensor is 60 degrees, giving a measuring

area of 36 mm diameter at the distance of the probe tip and 115 mm

at a 10 cm distance.

To measure temperature:

From the Main display, press the LEFT arrow key to enter Temperature

mode. Hold the probe tip against the surface you wish to measure

and press the measuring key to get a temperature reading. For most

accurate results, take two consecutive readings a few seconds apart.

Measurement will continue as long as the measurement key, or the

probe tip, is being pressed.

To return to the Main menu, press the LEFT arrow key.

NOTE: If you are using an optional transducer for shock pulse

measurement, measure temperature manually (see instructions in

paragraph above).

Machine surface temperature is also measured automatically when an

SPM measurement is made:

To see the temperature reading after an SPM measurement, use

LEFT/RIGHT arrow keys to activate the Return icon in the Bearing

display, then press the UP arrow key to enter the Main display. Press

the LEFT arrow key to enter Temperature mode and see the reading.

The value presented is always the latest reading, whether automatically or manually (see above) measured. To return to the Main display,

press the LEFT arrow key.

Temperature Measurement

Measurement area

Temperature measurement

Measure

Measurement

indicator

Back/

Return

Page 39

35

The stethoscope function is useful for detecting machine

sound irregularities, such as load shocks and scraping.

Connect your headphones to the output connector (7).

From the Main display, use the RIGHT arrow button to

enter the Stethoscope mode. Hold the probe tip against

the object. Use UP/DOWN arrow keys to adjust the

volume (1-8).

NOTE! Setting the volume to the maximum level may

harm your hearing.

To return to the Main display, press the LEFT arrow

key.

Using the Stethoscope Function

Stethoscope function

Volume (1–8)

(7)

Back/Return

Page 40

36

Technical Specifications

Material, casing: ABS/PC

Size: 158 x 62 x 30 mm

(6.2 x 2.4 x 1.2 in)

Weight: 185 g (6.5 ounces) including battery

Keypad: Sealed membrane (silicone rubber)

Display: Graphic monochrome, 64 x 128 pixels, LED backlight

Bearing condition indication: Green, yellow and red light LEDs

Measurement indication: Blue light LED

Power supply: 2 x 1.5 V AA batteries, alkaline or rechargeable

Battery life: > 20 hrs of normal use

Operating temperature: 0 to +50°C (32 to 122°F)

Input connector: Lemo coaxial, for external shock pulse transducers (probe or

quick connector)

Output connector: 3,5 mm stereo mini plug for headphones

General functions: Battery status display, transducer line test, metric or Imperial

units of measurement, language independent menus with

symbols, storage of up to 10 measurement values

Shock pulse measurement

Measurement technique: dBm/dBc, measuring range -9 to 90 dBsv, +3 dBsv

Transducer type: Built-in probe transducer

Temperature measurement

Temperature range: –10 to +185 °C (14 to 365°F)

Resolution: 1 °C (1°F)

Transducer type: Thermopile Sensor TPS 334/3161, built-in contact free IR-sensor

Stethoscope

Headphone mode: 8 level amplification

Article no.

BC100 Bearing Checker

Accessories

EAR12 Headphones with ear defenders

TRA73 External transducer with probe

TRA74 Transducer with quick connector for adapters

CAB52 Measuring cable with slip-on connector for permanently installed transducers, 1,5 m

15286 Belt holder for external probe transducer

15287 Belt case for accessories

15288 Protective cover with wrist strap

15455 Protective cover with belt clip and wrist strap

93363 Cable adapter, LEMO-BNC

93062 Cable adapter, BNC-TNC, plug-jack

Page 41

37

An instrument calibration, e.g. for the purpose of compliance with ISO quality standard requirements, is

recommended once a year. Please contact your SPM representative for service, upgrading the software

or calibration.

Maintenance and calibration

EU Directive on waste electrical and electronic equipment

WEEE is EU Directive 2002/96/EC of the European Parliament and of the Council on waste electrical

and electronic equipment.

The purpose of this directive is, as a first priority, the prevention of waste electrical and electronic

equipment (WEEE), and in addition, the reuse, recycling and other forms of recovery of such wastes so

as to reduce the disposal of waste.

This product must be disposed of as electronic waste and is marked with a crossed-out wheeled bin

symbol in order to prevent it being discarded with household waste.

Once the life cycle of the product is over you can return it to your local SPM representative

for correct treatment, or dispose of it together with your other electronic waste.

Page 42

40

50

30

20

10

dB

N

40

50

30

20

10

dB

N

40

50

30

20

10

dB

N

M

40

50

30

20

10

dB

N

dB

dB

C

dB

i

d

n

M

dB

dB

C

dB

i

d

n

d

dB

i

n

M

dB

dB

C

dB

i

dB

M

dB

C

d

n

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .