Patents Pending

Kinetic Log Splitter

Owners Manual

Model #45-0503

IMPORTANT: The engine is shipped without

oil. Add oil before starting the engine.

Place Model Number Label in Center of this Box.

Before operating your Split Second

Log Splitter, read and understand

WARNING

http://www.splitsecondlogsplitter.com Form No. 41595

all instructions inside this manual.

French and Spanish language manuals

are available to download at

www.splitsecondlogsplitter.com

Table of Contents

Safety and Operational Labels ................................................................3

Safety Rules ..................................................................................4

General Safety ...................................................................................... 4

Engine Safety ....................................................................................... 4

Towing Safety....................................................................................... 4

Hardware Package Contents ..................................................................5

Assembly Instructions ........................................................................5

Assemble the Tow Bar ............................................................................... 5

Assemble the Tray................................................................................... 5

Position the Tow Bar ................................................................................ 5

Install the Bail Pin ................................................................................... 5

Assembly Instructions ........................................................................5

Assemble the Tow Bar ............................................................................... 5

Assemble the Tray................................................................................... 5

Position the Tow Bar and ............................................................................ 5

Operating Instructions........................................................................ 6

Before Using First Time ..............................................................................6

Before Each Use .....................................................................................6

Adjusting the Log Splitter Height ....................................................................6

Towing the Log Splitter .............................................................................. 6

Starting the Engine.................................................................................. 6

Using the Log Splitter ...............................................................................7

Maintenance Instructions .....................................................................9

Check For Loose Fasteners ...........................................................................9

Check Tire Pressure..................................................................................9

Grease the Rack .....................................................................................9

Grease the Flywheel Bearings ........................................................................ 9

Grease the Wheel Bearings .........................................................................10

Engine Maintenance ...............................................................................10

Cleaning...........................................................................................10

Storing ............................................................................................10

Service and Adjustments ....................................................................11

Adjusting the Belt Tension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Replacing the Belts .................................................................................11

Replacing the Centrifugal Clutch ...................................................................11

Replacing the Wheel Bearings.......................................................................12

Troubleshooting.............................................................................13

Specications ...............................................................................14

Accessories for the Log Splitter...............................................................15

Repair Parts ..............................................................................16-19

Parts Ordering ...................................................................... Back Page

Page 2

Safety and Operational Labels

This page contains copies of all the Safety and Informational labels that are found on your log splitter. Replace

any damaged or missing labels immediately. Order by the part number shown with each label. Refer to the back

cover for ordering information.

SAFETY

ONOFF

41597

LOADING AND OPERATING THE

MACHINE SHOULD ONLY BE DONE

BY THE SAME PERSON.

• Read owner's manual for safety and operating instructions.

• Read engine owner's manual for safety and operating instructions.

• Never grab log by cut ends when placing on beam against wedge.

• Always split wood in the direction of the grain.

• Always operate log splitter on level ground.

• Always operate log splitter in a well-ventilated area.

• Always secure wheels before operating log splitter.

• Keep hands, body parts, and clothing away from splitting wedge, ram, all

moving parts, and partially split wood.

• Before removing pieces of wood stuck on wedge or in ram area, shut off engine

and wait until all parts have stopped moving.

• Do not operate log splitter without housing and belt guards in place.

• Do not refuel engine while hot or running.

• Keep all bystanders at least 25 feet away during operation.

LOCK

Read owner's manual for safety and operating

instructions.

1. Start engine using instructions from engine manual.

2. Advance engine speed to max.

3. The splitting cycle:

4. Ram automatically retracts at end of stroke. To retract

OPERATION

1. Pick up log by sides and place on beam.

2.

3. .drawrof eldnah kcol ytefas hsuP

4. Pull up on control handle and hold until log is split.

5. Release handle at any time and the ram will retract.

the ram before the end of the stroke, release control

handle.

• Read owner's manual for safety and operating instructions.

• Read engine owner's manual for safety and operating instructions.

• Never grab log by cut ends when placing on beam against wedge.

• Always split wood in the direction of the grain.

• Always operate log splitter on level ground.

• Always operate log splitter in a well-ventilated area.

• Always secure wheels before operating log splitter.

• Keep hands, body parts, and clothing away from splitting wedge, ram, all

moving parts, and partially split wood.

• Before removing pieces of wood stuck on wedge or in ram area, shut off engine

and wait until all parts have stopped moving.

• Do not operate log splitter without housing and belt guards in place.

• Do not refuel engine while hot or running.

• Keep all bystanders at least 25 feet away during operation.

41597

OPERATION

Read owner's manual for safety and operating

instructions.

1. Start engine using instructions from engine manual.

2. Advance engine speed to max.

3. The splitting cycle:

1. Pick up log by sides and place on beam.

2.

3. .drawrof eldnah kcol ytefas hsuP

4. Pull up on control handle and hold until log is split.

5. Release handle at any time and the ram will retract.

4. Ram automatically retracts at end of stroke. To retract

the ram before the end of the stroke, release control

handle.

41598

41599

SAFETY

LOCK

LOADING AND OPERATING THE

MACHINE SHOULD ONLY BE DONE

BY THE SAME PERSON.

ON OFF

41598

• Do not exceed weight capacity of ball or load limits stamped on coupler.

• Always use safety chains when towing.

• Always check that coupler handle is locked before towing.

• Always use correct ball size that is stamped on coupler.

• Always adjust coupler locking pressure on ball before use.

• Check coupler tightness before and after towing 50 miles.

• Always check coupler and ball for damage before towing. Replace if damaged.

• Avoid sharp turns and steep vertical angles when towing to prevent damage to coupler and its components.

41717

DANGER

KEEP BODY

PARTS AND

CLOTHING AWAY

FROM OPENING

41647

41647

41648

LIFT TO ENGAGE

DO NOT

EXCEED

41599

45 MPH

4159941717

41648

41649

Page 3

Safety Rules

Remember, any power equipment can cause injury if operated

improperly of if the user does not understand how to operate the

WARNING

General Safety

y Read and understand the instructions in the owner's manual before operating the log splitter.

y Never allow anyone who has not read and understood these instructions to operate the log splitter.

y Never allow more than one person at a time to use the log splitter. The same person should both load and

operate the log splitter.

y Never allow children to operate the log splitter.

y Never allow children in the area while the log splitter is running. Stop the engine if a child approaches.

y Never allow bystanders in the area of operation when the log splitter is running.

y Never operate the log splitter without all guards and covers in place.

y Do not modify the safety controls. Make sure they are operating properly before each use.

y Do not make any modications to the log splitter.

y Do not use this log splitter for any purpose other than splitting logs.

y Do not exceed the manufacturer's recommended capacity of the log splitter.

y Always check for loose nuts and bolts before each use and tighten any that are found to be loose.

y Always wear safety glasses or goggles while using the log splitter.

y Never wear loose tting clothing or jewelry while operating the log splitter.

y Wear snug tting gloves while operating the log splitter.

y Never operate the log splitter while barefoot or while wearing sandals. Always wear protective shoes with

non-skid soles while operating the log splitter. Safety toe shoes are recommended.

y Always wear hearing protection when using the log splitter for prolonged periods of time.

y Only operate the log splitter on a at, level surface with secure footing.

y Always shut o the engine and make sure all moving parts have come to a stop before making adjustments.

equipment. Exercise caution at all times when using power equipment.

Engine Safety

y Always keep hands away from the engine, belts and pulleys when the engine is running.

y Never run engine in an enclosed area. Adequate ventilation is required to prevent carbon monoxide

poisoning.

y Do not ll the fuel tank indoors, or while the engine is running or while the engine is hot. Reinstall the fuel

tank cap and wipe o any spilled fuel before starting the engine.

y Do not store the log splitter near an open ame or a heat source when fuel is left in the tank.

y Do not operate engine with air cleaner or cover removed. Removal of these parts could create a re hazard.

y Never change the engine governor settings.

y Always allow the engine to cool completely before making adjustments or repairs or cleaning.

y Always disconnect the spark plug wire before making adjustments or repairs. Keep the wire away from the

plug to prevent accidental starting.

y Always allow the engine to cool completely before covering or storing in an enclosed area.

Towing Safety

y Do not exceed the 45 mph while towing the log splitter.

y Always use safety chains when towing.

y Always check that coupler handle is locked before towing.

y Always use correct ball size that is stamped on coupler.

y Check coupler tightness before towing and after towing 50 miles. Adjust locking pressure as required.

y Always check coupler and ball for damage before towing. Replace if damaged.

Page 4

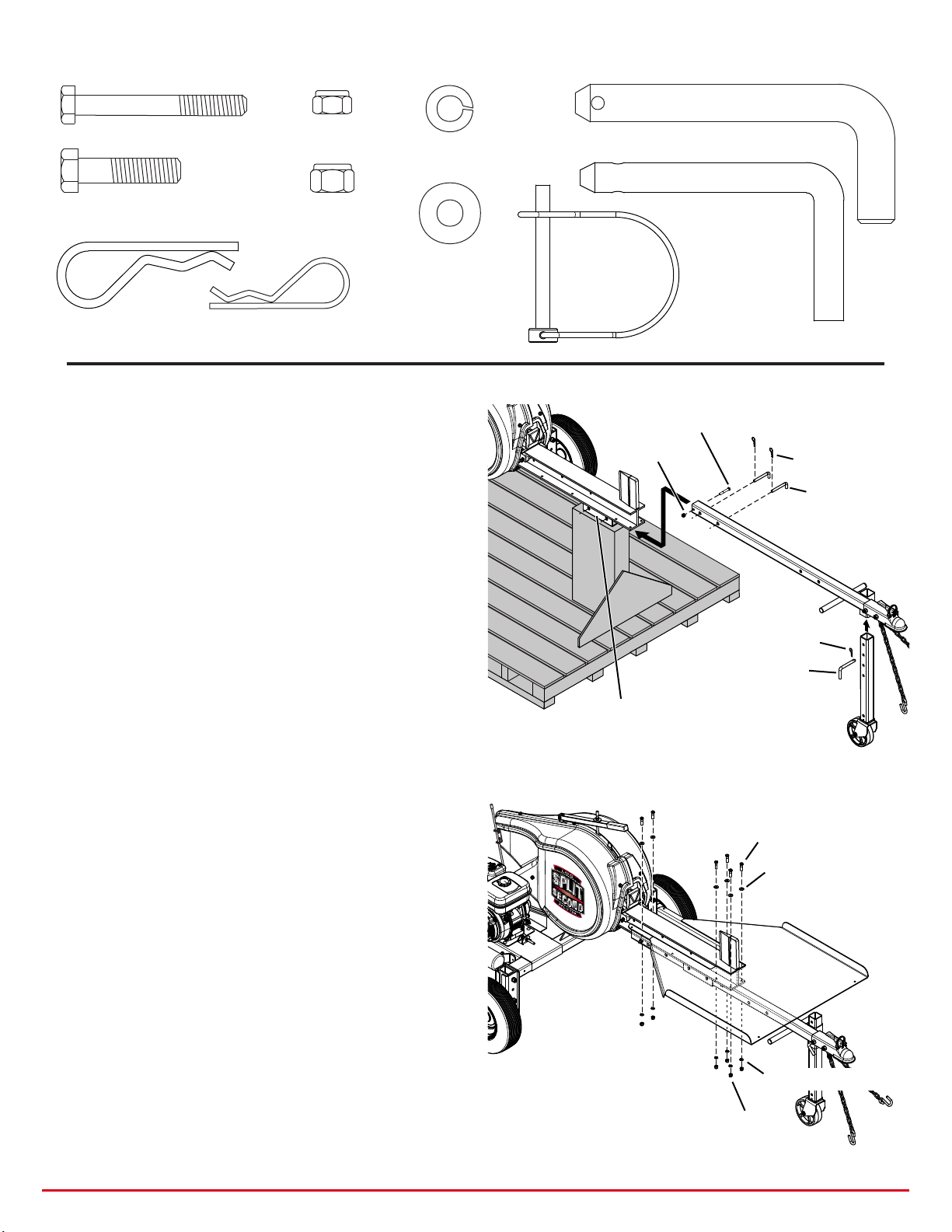

Hardware Package Contents

HAIR COTTER PIN

5/16” x 2-1/2” Hex Bolt

44292 (1 pc.)

3/8” x 1-1/2” Hex Bolt

43062 (6 pcs.)

Hairpin Cotter

714-0117 (2 pcs.)

Hairpin Cotter

43343 (1 pc.)

5/16” Hex Nut

47810 (1 pc.)

3/8” Hex Nut

HA21362 (6 pcs.)

3/8” Lock Washer

43003 (6 pcs.)

3/8” Washer

43081 (6 pcs.)

Assembly Instructions

Assemble the Tow Bar – (See Figure 1.)

1. Remove the front strapping from the log splitter,

but leave the log splitter on the pallet.

2. Insert the front stand into the tow bar and install

the pin through the second hole in the front stand.

3. Slide the tow bar into the receiver tube. Install the

pins through the rst set of holes in the tow bar.

4. Install a 5/16" x 2-1/2" hex bolt and 5/16" nut in the

end hole of the tow bar as a safety catch.

5. Remove the log splitter from the pallet.

Locking Pin

48978 (2 pcs.)

Locating Pin

HA5236 (1 pc.)

48515

Bail Pin

5/16” x 2-1/2” HEX BOLT

5/16” NUT

LOCKING PIN

HAIR COTTER PIN

LOCATING PIN

Assemble the Tray – (See Figure 2.)

1. Slide the tongue in about half way for clearance.

2. From the front of the log splitter, slide the tray onto

the bottom ange of the I-beam. Align the holes in

the tray and the I-beam and install six 3/8" x 1-1/2"

hex bolts and at washers down into the holes.

Assemble 3/8" lock washers and 3/8" nuts onto the

bolts and secure the tray to the I-beam.

Position the Tow Bar

1. Pull the tow bar out to the towing position, or push

it in to the working position. Align the holes in the

tow bar and the receiver tube and install the two

locking pins and hair cotter pins.

Install the Bail Pin

1. Install the bail pin in the trailer hitch coupler.

RECEIVER TUBE

FIGURE 1

3/8” x 1-1/2” HEX BOLT

3/8” FLAT WASHER

3/8” LOCK WASHER

3/8” NUT

FIGURE 2

Page 5

Operating Instructions

FUEL SHUT-OFF VALVE

SPEED CONTROL LEVER

STOP SWITCH

TABLE HEIGHT SETTINGS

Never allow more than one person at a time to use the log splitter. This log splitter is designed for

use by only one person. The same person should both load and operate the log splitter. Use by

WARNING

Before Using First Time

1. Place the log splitter on level ground and add oil as instructed in the engine owner's manual.

Before Each Use

1. Check the oil level with the log splitter on at, level ground. Add oil as instructed in the engine manual.

2. Check the tire pressure. Fill to the recommended pressure that is stamped on the side of the tires.

3. Check for loose fasteners. Tighten any fasteners that are loose.

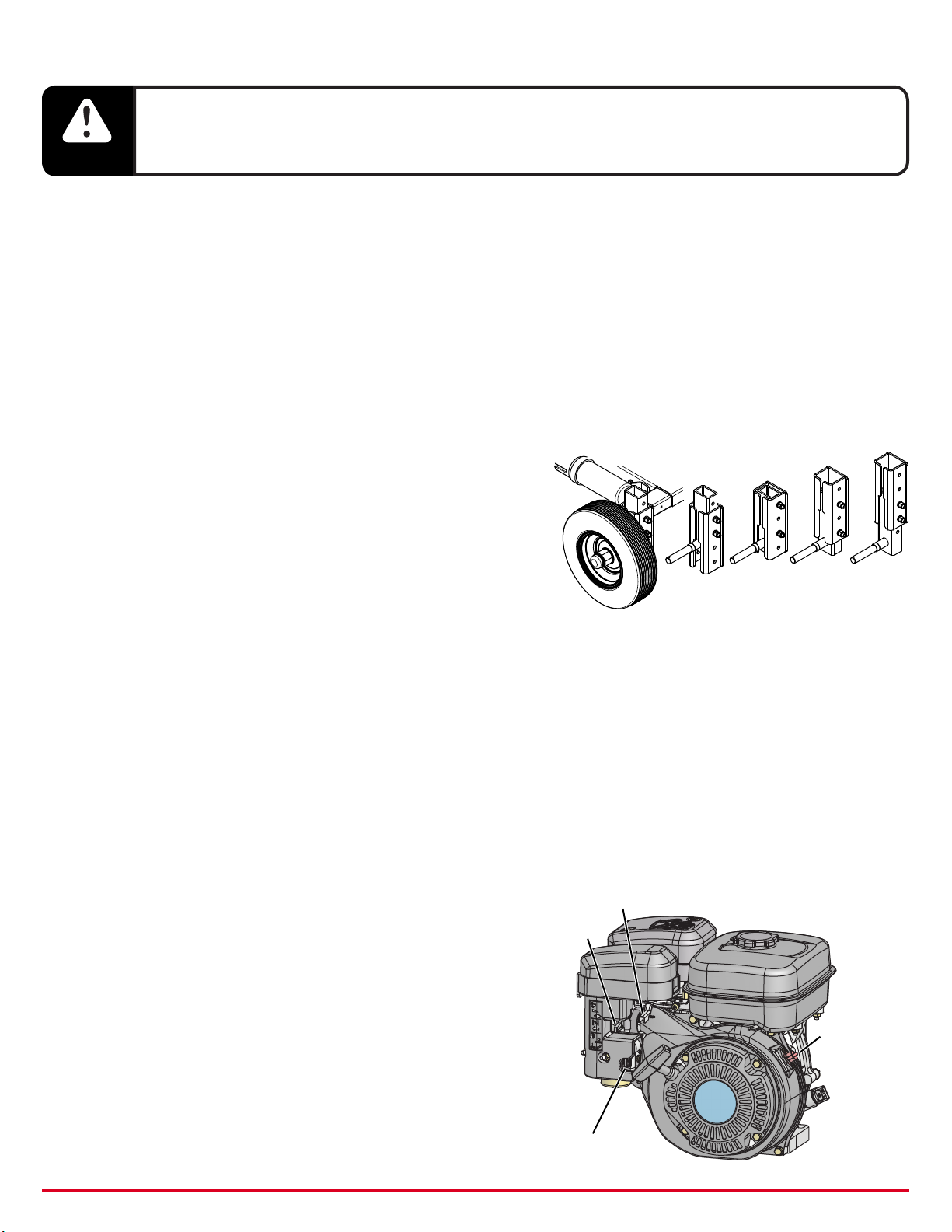

Adjusting the Log Splitter Height – (See Figure 3.)

1. Use a jack to lift the rear of the log splitter. Place supports

under the frame for stability.

2. Remove the bolts from the leg assemblies and move the

wheels to one of four height settings.

3. Reinstall the bolts and nuts and tighten securely.

4. Repeat for the other wheel.

5. Remove the supports from under the rear of the splitter

frame and lower it using the jack.

6. Adjust the front leg stand so that the front of the splitter is

the same height as the rear of the splitter. For the lowest

setting, extend the tow bar out to the towing position.

more than one person at a time creates a risk of injury.

26.5"

29.0"

31.5"

FIGURE 3

34.0"

Towing the Log Splitter

1. Be sure that you are in compliance with all applicable towing laws and regulations.

2. Adjust the height of the log splitter to approximately match the height of the towing vehicle's hitch.

3. Attach the log splitter to a 2" ball hitch on the towing vehicle.

4. Remove the front leg stand if there is not enough ground clearance in the raised position.

5. Adjust the coupler locking pressure and lock the coupler handle.

6. Attach the log splitter's safety chains to the towing vehicle.

7. Raise the plastic rod at the rear of the splitter, leaving 4" or 5" extended below the rod holder.

8. Do not exceed 45 mph while towing the log splitter.

9. Avoid sharp turns and steep vertical angles when towing the log splitter.

Starting the Engine – (See Figure 4.)

1. Set the Fuel Valve Lever to the "I" (OPEN) position.

2. Turn the Stop Switch to the "I" (ON) position.

3. Set the Speed Control Lever to 1/3 of full speed.

4. Close the Choke Lever by moving it to the left if the

engine is cold or the air temperature is low. If the

engine is warm or the air temperature is high, close

the Choke Lever only halfway or leave it fully open.

5. Pull the starter rope slowly until resistance is felt, then

return the rope to its starting position. Pull swiftly on

the handle to start the engine.

6. After the engine is running, gradually move the

Choke Lever to the right until it is fully opened.

Page 6

CHOKE LEVER

FIGURE 4

WARNING

Never allow more than one person at a time to use the log splitter. This log splitter is designed for

use by only one person. The same person should both load and operate the log splitter. Use by

more than one person at a time creates a risk of injury.

Using the Log Splitter

Always stand in the operator zone when

operating the log splitter. Keep your body and

WARNING

1. Select logs for splitting that are cut square on the ends and

are no more than 24" long.

2. Place the log splitter on at, level ground that provides

secure footing.

3. Secure the wheels to prevent unexpected movement.

4. Start the engine and set the throttle to "Fast".

5. Grasp a log on the sides and place it on the log splitter,

centering it on the I-beam. Push the log rmly against the

wedge to help hold it in place. (See Figure 6.)

WARNING

hands away from the ram and the wedge while

the ram is in motion. (See gure 5.)

Do not grasp the log by the ends when loading it

onto the log splitter. (See gure 7.) Doing so may

lead to a potentially severe injury. Always grasp

logs on the sides when loading.

OPERATOR

ZONE

OPERATOR

ZONE

FIGURE 5

FIGURE 6

6. If one end of a log is not cut square, position the log so that

the slanted end faces toward the wedge and butts against the

bottom of the wedge. (See gure 8.)

FIGURE 7

FIGURE 8

Page 7

Never attempt to split logs across the grain;

damage to the splitter or injury to you could

WARNING

occur. (See Figure 9.) Always split logs end to end,

with the grain.

7. If a log is forked, split one leg at a time. Do not try to split down

the middle of the fork. (See Figure 10.)

8. To activate the ram, place one hand on the lock out lever and

the other hand on the engagement handle. Pull forward on

the lock out lever and then lift up rmly on the engagement

handle. Continue lifting up on the handle until the log is fully

split or until the ram reaches the end of its stroke, then release

the handle to retract the ram. (See Figure 11.)

NOTE: To retract the ram at any time during the forward stroke,

simply release the engagement handle.

Keep hands away

from the log while

WARNING

the ram is in motion.

FIGURE 9

FIGURE 10

9. If the ram stops before the log is completely split, release the

handle immediately and allow the ram to fully retract. Repeat

the splitting cycle until the log is split.

NOTE: Do not allow the gear teeth to grind if the ram stops before

the log is split. Release the engagement handle immediately

to avoid excessive wear or damage to the gear teeth.

10. If the ram becomes stuck in the log and will not retract,

immediately strike downward on the engagement handle to

disengage the gear teeth and retract the ram.

11. If a log becomes stuck on the wedge, shut o the engine and

wait 30 seconds, or until the ywheels stop rotating, before

removing the log. Dislodge the log by pulling it straight back,

working it straight up and down as necessary, to remove it from

the wedge. Do not push the log side to side to remove it.

Never try to dislodge a stuck log while the

engine is running. First shut o the engine and

WARNING

wait 30 seconds, or until the ywheels have

stopped rotating.

ENGAGEMENT

HANDLE

LOCK-OUT

LEVER

FIGURE 11

12. Remove logs from the work table as they are split.

13. Keep the beam dry and scraped clean of build-up during use, to allow the ram to slide freely.

Page 8

Maintenance Instructions

PROCEDURE BEFORE EACH

USE

Check for loose fasteners

Check tire pressure

Check engine oil level

Change engine oil

Check and clean air cleaner

Grease Rack

Grease ywheel bearings

Clean spark arrester

Clean spark plug

Grease wheel bearings

Replace air cleaner

1 - After 20 hours of operation for the rst oil change only.

ü

ü

ü

AFTER 20

HOURS

1

ü

EVERY 50

HOURS

ü

ü

Check For Loose Fasteners

1. Do a visual check and tighten any fasteners which may have worked loose during use.

EVERY 100

HOURS

ü

ü

ü

ü

(once a year)

(every 200 hours)

Check Tire Pressure

1. Check tire pressure before each use, and before towing the splitter on the highway. Fill to the

recommended pressure that is stamped on the tire sidewall.

Grease the Rack

1. Wipe a light coat of all purpose grease onto the teeth on the bottom of the rack after every 50 hours of

operation or every 5 cords split.

Grease the Flywheel Bearings

1. Lubricate the ywheel bearings every 100 hours. Pump a small amount of No. 2 or 3 lithium base grease

into the grease ttings. Wipe o excess grease from bearings. Clean o any grease that falls onto the top

surface of the I-beam between the bearings.

Page 9

Grease the Wheel Bearings – (See Figure 10.)

HUB CAP

COTTER PIN

1. Use a jack to lift the rear of the log splitter. Place supports

under the frame for stability.

2. Remove the hub cap and pull the cotter pin from one axle.

3. Unscrew the slotted nut and remove the washer, the loose

ROLLER BEARING

SEAL

WASHER

roller bearing and the wheel from the axle.

4. Remove the seal and the bearing from the other end of

the wheel hub by carefully tapping on the back side of the

bearing in a circular pattern.

5. Wipe o old grease from the bearings and the inside of

the wheel hub. Clean the bearings and wheel hub with

kerosene or solvent, then spray with brake cleaner. Allow

parts to dry before proceeding.

6. Inspect the bearings and seal for damage. Replace worn or

damaged parts.

ROLLER BEARING

WASHER

SLOTTED NUT

7. Apply a generous amount of high quality wheel bearing

grease to the roller bearings, working it around the rollers

FIGURE 12

and into the bearing until the rollers are coated and the

bearing cage is lled.

8. Apply high quality bearing grease to the bearing races that are pressed into the wheel hub.

9. Assemble a bearing into the inward facing end of the wheel hub, and then carefully tap a seal into the end

of the hub.

10. Slide the wheel onto the axle and then install another bearing and a washer into the wheel hub.

11. Thread the slotted nut onto the axle and tighten rmly while spinning the wheel to seat the bearings. Back

the nut o until a slot aligns with the hole in the spindle. Make sure that the wheel spins freely but does

not have end play or wobble. Readjust the nut as necessary.

12. Install the cotter pin and spread the ends.

13. Install the hub cap.

14. Repeat the same procedure for the other wheel.

15. Remove the supports from under the rear of the splitter frame and lower it using the jack.

Engine Maintenance

NOTE: Refer to the instructions in the engine manual for performing the following procedures.

1. Check oil level before each use. Be sure the log splitter is resting on at, level ground.

2. Change the oil after the rst 20 hours of operation and then after every 100 hours of operation.

3. Service air cleaner every 50 hours under normal conditions. Clean every few hours under extremely dusty

conditions. Poor engine performance and ooding usually indicate a dirty air cleaner.

4. The spark plug should be cleaned and the gap checked every 100 hours.

5. Clean the spark arrester every 100 hours.

Cleaning

1. Clean the engine regularly with a cloth or brush. Keep the cooling ns on the engine housing clean to

allow proper cooling. Remove all dirt and debris from muer area.

2. Clean the I-beam, scraping any compacted residue o the top surface.

Storing

1. Clean the log splitter before storing.

2. Store in a dry protected area or cover with a water-resistant cover (optional 45-0509 Cover available).

Page 10

Service and Adjustments

FIGURE 15

Adjusting the Belt Tension – (See Figure 11 and 12.)

NOTE: The belt tension is correct when moderate pressure,

applied to the belts midway between the two pulleys,

results in 1/2" of deection of the belts.

1. Loosen the nuts on the four round head carriage bolts that

secure the motor slide plate to the frame assembly.

2. To increase the belt tension, adjust the two nuts on the end

of the tensioning bolt, loosening the outer nut and then

tightening the inner nut until 1/2" of belt slack is attained.

Tighten the outer nut.

3. To decrease the belt tension, adjust the two nuts on the end

of the tensioning bolt, loosening the inner nut until 1/2" of

belt slack is attained. Tighten the outer nut.

Replacing the Belts – (See Figure 11 and 12.)

1. Remove the plastic housing from the log splitter, starting

with the left side. (The side away from the engine.)

2. Remove the belt guard from the log splitter.

3. Loosen the nuts on the four round head carriage bolts that

secure the motor slide plate to the frame assembly.

4. Loosen the two nuts on the end of the tension adjusting

bolt and screw the inner nut as far as possible onto the bolt.

5. Slide the engine forward and remove the belts.

6. Install new belts and adjust the belt tension using the

instructions in the "Adjusting the Belt Tension" section.

7. Replace the belt guard.

8. Replace the plastic housing. (It is easiest to replace the right

side housing rst.)

TENSIONING BOLT

APPR. 1/2"

INNER

NUT

OUTER

NUT

FIGURE 13

Replacing the Centrifugal Clutch – (See Figure 13.)

1. Remove the belt guard from the log splitter.

2. Remove the bolt and washer from the engine shaft.

3. Remove the clutch and the square key from the engine shaft.

4. Install a new centrifugal clutch and the square key that you

removed onto the engine shaft.

5. Secure the clutch to the engine shaft with the bolt and

washer that were removed.

6. Reattach the belt guard.

FIGURE 14

SQUARE KEY

CLUTCH ASSEMBLY

FLAT WASHER

SELF LOCKING

HEX BOLT

Page 11

Replacing the Wheel Bearings – (See Figure 14.)

HUB CAP

COTTER PIN

1. Use a jack to lift the rear of the log splitter. Place supports

under the frame for stability.

2. Remove the hub cap and pull the cotter pin from one axle.

3. Unscrew the slotted nut and remove the washer, the loose

ROLLER BEARING

SEAL

WASHER

roller bearing and the wheel from the axle.

4. Remove the seal and the bearing from the other end of

the wheel hub by carefully tapping on the back side of the

bearing in a circular pattern.

5. Discard the roller bearings and the seal.

6. Wipe o old grease from the inside of the wheel hub and

then wash out with kerosene or solvent. Finish by spraying

with brake cleaner. Allow to dry thoroughly.

7. Apply high quality wheel bearing grease to the bearing

races that are pressed into the wheel hub.

ROLLER BEARING

WASHER

SLOTTED NUT

8. Apply a generous amount of high quality wheel bearing

grease to the new roller bearings, working it around the

FIGURE 16

rollers and into the bearing until it the rollers are coated

and the bearing cage is lled with grease.

9. Assemble a new bearing into the inward facing end of the wheel hub, and then carefully tap a new seal

into the end of the hub.

10. Slide the wheel onto the axle and then install another new bearing and a washer into the wheel hub.

11. Thread the slotted nut onto the axle and tighten rmly while spinning the wheel to seat the bearings. Back

the nut o until a slot aligns with the hole in the spindle. Make sure that the wheel spins freely but does

not have end play or wobble. Readjust the nut if necessary.

12. Install the cotter pin and spread the ends.

13. Install the hub cap.

14. Repeat the same procedure for the other wheel.

15. Remove the supports from under the rear of the splitter frame and lower it using the jack.

Page 12

Troubleshooting

PROBLEM POSSIBLE CAUSE(S) CORRECTIVE ACTION

Engine fails to

start

Engine overheats 1. Engine oil level low.

Loss of power;

operation erratic

Rack won't

retract

completely

1. Stop switch at OFF position

2. Fuel shut-o valve closed.

3. Fuel tank empty, or stale fuel.

3. Spark plug wire disconnected.

5. Faulty spark plug.

2. Carburetor not adjusted properly.

1. Spark plug wire loose

2. Unit running on CHOKE.

3. Blocked fuel line or stale fuel.

4. Water or dirt in fuel system.

5. Carburetor out of adjustment.

6. Dirty air cleaner.

7. Loose or worn belts.

8. Worn clutch.

1. Dirty beam

2. Machine not level - wedge end too

low.

3. Worn return springs.

4. Broken return springs.

5. Worn or damaged rack support

bearing.

1. Turn switch to ON.

2. Open fuel shut-o valve.

3. Fill tank with clean, fresh fuel.

4. Connect wire to spark plug.

5. Clean, adjust gap or replace.

1. Fill crankcase with proper oil.

2. Adjust carburetor.*

1. Connect and tighten spark plug wire.

2. Move choke lever to OFF position.

3. Clean fuel line; ll tank with clean fresh

gasoline.

4. Disconnect fuel line at carburetor to drain fuel

tank. Reconnect fuel line and rell with fresh fuel.

5. Adjust carburetor.*

6. Service air cleaner.*

7. Adjust belt tension or replace belts.

8. Replace clutch.

1. Scrape o top of beam, then wipe o loose dirt.

2. Place on more level ground.

3. Hook ends of springs on next notch.

4. Replace springs.

5. Replace bearing.

Gear teeth won't

stay engaged

* -Refer to the engine manual packed with your unit.

1. Engagement engagement handle

has not been pulled up quickly enough

or with enough force.

2. Rack gear bent from overloading.

1. Pull up on the handle more quickly and with

more force.

2. Replace the rack gear.

Page 13

Specications

Wheels/Tires Highway rated at 45 MPH

Hitch Type 2" Ball Hitch

Towbar Retractable

Max Log Diameter 30 in

Max Log Length 24 in

Cycle Time 3 seconds

Rack Width 2.25 in.

Pinion Shaft Diameter 1.5 in.

Ram Carriage 4 Heavy Duty Sealed Bearings

Flywheel Diameter 18.25 in.

Flywheel Weight 2 at 90 lbs. each

Flywheel Max RPM 365

Splitter Beam Height Adjustable Range 26.5 in. to 34 in.

Splitter Length 112 in.

Splitter Width 55.0 in.

Table Dimensions 33.0 in. x 40.0 in. long

Wedge Height 7.0 in

Wedge Length 5.0 in.

Wedge Thickness 0.75 in.

Weight 570 lbs.

Engine Subaru SP170

Starting Type Recoil

Engine Displacement 169 cc

Horsepower 6 HP

Page 14

Accessories for the Log Splitter

45-02312 FIRE WOOD CART

45-0506 LOG DOLLY

45-0507 LOG LIFT ATTACHMENT

45-0505 TOOL TRAY

45-0509 COVER

Not Shown

Page 15

45-0503 Repair Parts Illustration

the fastest way to purchase parts

www.speedepart.com

63

39

64

63

23

36

2

29

10

31

35

54

4

32

28

6

29 66

30

31

7

34

66

53

30

36

3

24

26

57

36

5

33

38

25

31

52

37

65

45

8

36

9

13

12

13

40

27

33

30

35

55

31

14

13

56

13

15

1

38

52

40

37

41

44

21

60

60

59

52

37

22

61

48

20

58

38

52

19

15

13

Page 16

13

14

42

45

13

12

13

31

11

29

30

43

11

44

47

16

17

51

50

18

49

48

62

44

46

45-0503 Repair Parts List

the fastest way to purchase parts

www.speedepart.com

REF QTY PART

NO

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

1 42920 Housing

1 42916 Housing

2 42901 V-Belt

1 42900 Engine

1 42927 Clutch

1 27623 Plate, Motor Slide

1 68234 Bracket, Rear Housing

1 27648 Cover, Clutch

1 67952 Frame Assembly

1 41628 Manual Container

2 68029 Leg Assembly

2 68284 Wheel and Tire Assembly

2 68285 Bearing Kit (includes one seal,

2 43601 Washer, 1.59 x 1.03 x .06

2 41636 Nut, Slotted 1-14 2A

1 42891 Wheel

1 27722 Bracket, Front Wheel

1 68005 Front Stand

1 42935 Safety Chain W/Hooks

1 42928 Trailer Hitch Coupler

1 68024 Tow Bar

1 67953 Work Table

1 42759 End Marker

4 43085 Hex Bolt, 5/16-18 x 1-1/2"

1 47600 Hex Bolt, 5/16-24 Self Lock

1 736-0231 Washer, .344" x 1.125" x .12"

1 41635 Key

4 44326 Carriage Bolt, 5/16-18 x 1"

10 43088 Washer, 5/16"

14 43086 Lock Washer, 5/16"

14 47810 Hex Nut, 5/16" Nylock

1 44071 Hex Bolt, 3/8-16 x 3-1/2"

3 44072 Hex Nut, 3/8-16 Whizlock

DESCRIPTION

one hub cap, two bearings,

and one item #45 cotter pin)

REF QTY PART

NO

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

1 43661 Hex Bolt, 1/4-20 x 1"

4 47189 Hex Nut, 1/4-20 Nylock

11 43063 Hex Bolt, 5/16-18 x 1"

11 HA21362 Hex Nut, 3/8-16 Nylock

11 43062 Hex Bolt, 3/8-16 x 1-1/2"

1 27828 Bracket, End Marker

10 43003 Lock Washer, 3/8"

1 44292 Hex Bolt, 5/16-18 x 2-1/2"

4 47024 Hex Bolt, 1/2-13 x 4-1/2"

4 43353 Lock Washer, 1/2"

7 41657 Hex Nut, 1/2-13 Nylock

2 43501 Cotter Pin, 9/64" x 1-1/2"

1 27746 Spacer

1 48115 Hex Nut, 1/2-13 Jam Nylock

3 46286 Hex Bolt, 1/2-13 x 3"

1 42980 Washer, Plastic

1 HA5236 Locating Pin, 1/2"

1

12 43081 Washer, 3/8"

4

1 41598 Label, Warning/Operation RH

1 41597 Label, Warning/Operation LH

1 41647 Label, Danger

1 41648 Label, Danger

1 41599 Label, Warning/Towing Safety

1 41717 Label, Warning/Maximum MPH

2 49449 Plug

1 48515 Bail Pin

1 1540-59 Washer, .52" x 1.062" x .09"

2

2

1

6

1 41595 Owners Manual

43343

41633 U-Nut, 5/16-18 Tinnerman

41726

44950

27829

41730

DESCRIPTION

Hairpin Cotter, 3/32"

Grommet, Rubber

Carriage Bolt, 1/4-20 x 3/4"

Cover, Front Clutch

Plastic Washer, Black

Page 17

45-0503 Repair Parts Illustration - Continued

the fastest way to purchase parts

www.speedepart.com

50

68

51

18

33

49

48

48

49

17

47

46

46

67

6

45

48

31

44

38

33

16

15

42

14

5

47

13

46

67

40

39

4

19

6

52

39

53

21

45

57

22

55

56

59

64

28

48

28

62

63

10

46

2

65

29

47

1

69

66

45

27

20

54

58

23

24

60

25

26

61

48

45

12

43

11

41

10

9

70

7

31

38

4

39

40

57

34

35

32

37

3

69

8

36

30

29

47

61

Page 18

45-0503 Repair Parts List - Continued

the fastest way to purchase parts

www.speedepart.com

REF QTY PART NO DESCRIPTION

1 1 67948 I-Beam Assembly

2 1 68232 Upper Housing Bracket

3 1 68233 Lower Housing Bracket

4 2 42922 Bearing

5 1 42864 Spur Shaft

6 2 42800 Flywheel, 90 LB.

7 1 27640 Spindle Shaft

8 1 27703 Lever, Lock Out

9 1 41669 Grip

10 6 42924 Bearing

11 1 67956 Ram Engagement Assembly

12 1 42911 Engagement Rod

13 1 42923 Lock Out Pin

14 1 27702 Bracket, Lock Out

15 1 HA19445 Spring

16 1 27643 Bracket, Pin Support

17 1 42915 Handle Grip

18 1 42914 Engagement Handle

19 1 42863 Rack

20 1 67954 Ram Head Assembly

21 1 42918 Spring, Rack Support

22 1 27645 Plate, Rack Support

23 1 27646 Bracket, Bearing Holder

24 1 42919 Bearing

25 1 67955 Ram Head Slider Assembly

26 1 27639 Plate, Brass Slider

27 2 42917 Spring, Rack Return

28 2 27638 Bracket, Bearing Support

29

30 2 43062 Hex Bolt, 3/8-16 x 1-1/2"

31 2 41646 Bearing, Needle

32 1 43661 Hex Bolt, 1/4-20 x 1"

33 2 47189 Hex Nut, 1/4-20 Nylock

34 2 43069 Carriage Bolt, 3/8-16 x 1-1/2"

35 2 44072 Hex Nut, 3/8-16 Whizlock

4

41730

Plastic Washer, Black

REF QTY PART NO DESCRIPTION

36 2 42925 Bumper Stop

37 2 46978 Hex Nut, 1/4-20 SIMS

38 2 1650-1 Retaining Ring

39 10 43353 Lock Washer, 1/2"

40 8 R74780828 Hex Bolt, 1/2-13 x 1-3/4"

41 1 43082 Hex Lock Nut, 3/8-16 2-Way

42 1 43509 Hex Bolt, 3/8-16 x 2-3/4

43 1 44101 Cotter Pin, 3/32" x 3/4"

44 1 43081 Washer, 3/8"

45 6 47810 Hex Nut, 5/16-18 Nylock

46

47 8 43063 Hex Bolt, 5/16-18 x 1"

48 14 HA21362 Hex Nut, 3/8-16 Nylock

49 2 HA4506 Washer, .406" x 1.5"

50

51 1 1509-69 Hex Bolt, 1/4-20 x 1-3/4"

52 2 41596 Hex Bolt, 1/2-13 x 2"

53 1 42934 Shoulder Bolt, Socket Head

54 1 41657 Hex Nut, 1/2-13 Nylock

55 2 43177 Lock Washer, 1/4"

56 2 43866 Hex Bolt, 1/4-20 x 5/8"

57 2 43088 Washer, 5/16"

58 1 43840 Hex Bolt, 5/16-18 x 1-1/4"

59 1 41634 Skt. Hd. Bolt, 5/16-18 x 1-1/4"

60 6 43574 Hex Bolt, 3/8-16 x 3"

61 8 43003 Lock Washer, 3/8"

62 4 43432 Hex Bolt, 3/8-16 x 2-1/2"

63 4 44137 Washer, .518" x 1" x .02"

64 2 42210 Hex Nut, 3/8-16 Jam Nylock

65 2 714-0117 Hair Cotter Pin, 5/32"

66 2 48978 Pin

67 2 42926 Key, 3/8" Square

68 1 41649 Label, Control Handle

69

70

4 41638 Skt. Hd. Cap Bolt, 3/8-16 x 1"

1 41655 Grip

4 43086 Lock Washer, 5/16"

1

41735

Spacer

Page 19

the fastest way to purchase parts

www.speedepart.com

We truly appreciate your purchase of the Split Second Log Splitter. After you have split a few thousand pieces of

rewood, please take a picture and send us an e-mail. We would enjoy seeing you with your pile of rewood.

Best Regards,

Mike Cohan

President

Agri-Fab, Incorporated

Sullivan, Illinois

REPAIR PARTS

Agri-Fab, Inc.

809 South Hamilton

Sullivan, IL 61951

1-800-448-9282

www.splitsecondlogsplitter.com

Once photos and information are submitted to Agri-Fab, Inc., the submitter is granting Agri-Fab, Inc., permission to use photos,

pictures, or images deemed necessary by Agri-Fab, Inc. Agri-Fab, Inc., cannot and will not be held responsible for any legal

consequences of images submitted by its users.

© 2014 Agri-Fab, Inc.

Loading...

Loading...