Splash Lab TSL.R.030 Series, TSL.R.030.C.E120, TSL.R.030.CP.E120, TSL.R.030.BK.E120, TSL.R.030.BR.E120 Installation And Maintenance Manual

...

TSL.R.030

ribbon hand dryer

installation + maintenance

contents

3 Safety and Warnings

4 Box Contents

5 Technical Data

6 Before You Install

8 How to Install

14 Commissioning

16 Operation

16 Maintenance

17 Cleaning

18 Troubleshooting

21 Diagram

22 Spare Parts / Accessories

23 Warranty

Back Cover Contact Details

2 TSL. R.030 RIB BON HA ND DRYER MANUAL

TSL.R.030 ribbon hand dryer

Read and save these instructions

WARNING

To reduce the risk of fire, electric shock or injury to persons, observe the following:

+ Use this unit only in the manner intended by the manufacturer. If you have any

questions, contact the manufacturer (see back page for details)

+ This equipment should be installed in a way that ensures all electrical parts are

kept dry.

+ A means of electrical isolation must be incorporated in the fixed wiring, in

accordance with the current local regulations in force.

+ Disconnect the power supply before performing any maintenance on the product

+ Children should not play with this equipment. Cleaning and maintenance shall not

be performed by children without supervision.

+ This equipment is designed to be used in commercial and public areas; it is not

intended for domestic or residential use.

+ Replace fuse only with the same type and rating of fuse.

+ Ensure wiring and cover is installed correctly before connecting to live power

supply.

+ If in doubt, consult an electrician.

+ This product is not intended for use in a domestic or residential application.

+ The dryer must be installed in accordance with the electrical installation

regulations in force at the time of installation.

+ The hand dryer must be earthed.

!

General information

+1 310 410 5008

5450 W 83rd St, Los Angeles CA90045

500 7th Ave, New York NY10018

Technical support

technical@thesplashlab.com

For further contact information visit:

www.thesplashlab.com

Original instructions

TSL. R.030 RIB BON HA ND DRYER MANUAL 3

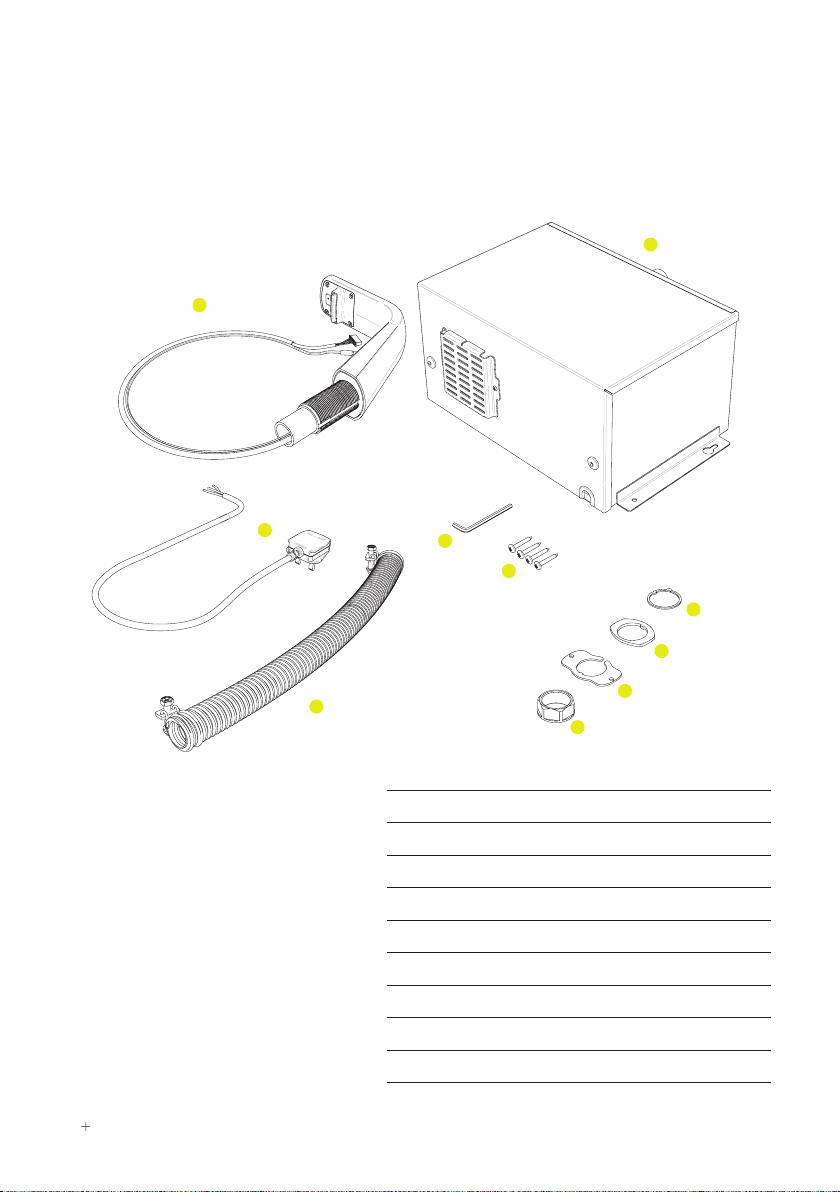

box contents

A

B

C

K

J

H

D

E

F

G

A Dryer head assembly

B Hand dryer motor unit

C Power cable

D Anti-rotation collar (already installed)

E Gasket

F Anti-rotation washer

G Fixing nut

H Motor mounting screws

I Hex wrench

J Air hose

4 TSL. R.030 RIB BON HA ND DRYER MANUAL

technical data

Finishes TSL.R.030.C.E120 Bright Polished Stainless steel

TSL.R.030.CS.E120 Brushed Stainless steel

TSL.R.030.CP.E120 Brushed Copper

TSL.R.030.BK.E120 Brushed Black

TSL.R.030.BR.E120 Brushed Brass

TSL.R.030.BZ.E120 Brushed Bronze

Voltage 110 - 120V ac; 60Hz

Current 7.6 - 8.4A

Power consumption 0.84 - 1.0kW

Standby power 0.3 - 0.4kW

Drying time <15 seconds

Weight 17lb 13oz

Material AISI 304 stainless steel

Noise levels 70.6dB

Heating element 500W

Motor type Brush type; dual ball bearings

Motor power 500 - 350W

Air speed 36 7 ft/s

Air flow 25.3 cu ft/min

Sensor range 5” +/-1 ”

Security cut-off time 30 seconds

Motor thermal protection Auto resetting thermostat set at 275°F

Heater thermal protection Auto resetting thermostat set at 185°F

Thermal cutout fuse set to 288°F

Insulation Class 1

IP rating IP35

Approvals CE, UL, RoHS

Warranty 1 year parts and labour; additional 4 years parts

only (Motor brushes excluded as these are a

wearing part, and dependant on usage)

TSL. R.030 RIB BON HA ND DRYER MANUAL 5

before you install

Location

Ribbon hand dryers are supplied with 18”

of flexible hose, so the dryer motor unit

must be fitted within 18” of the head unit,

to ensure that the motor air-outlet head

can be connected

Basins

Use of a The Splash Lab Monolith basin

is recommended for use with the Ribbon

range of products.

If an alternative basin is used, then

appropriate mounting points must

be created in basin or countertop to

accommodate the Ribbon products.

Ø

1 3/8"

Power supply

A 15A fused supply must be provided for

connection to the mains power supply.

Disclaimer: Circuits should only use

80% of their given amperage to prevent

overloads. The standard US 120V 15 Amp

circuit should only use up to 12 of its 15

amps.

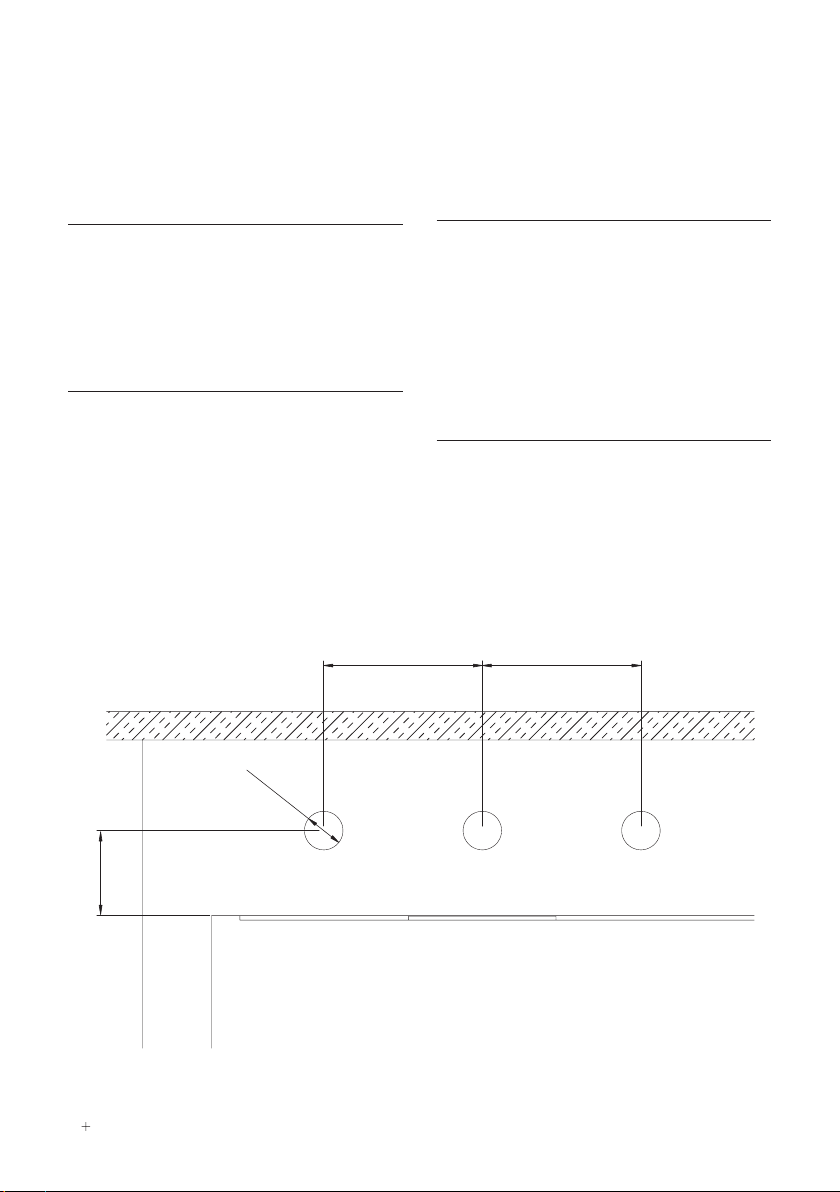

Spacing

If the Ribbon hand dryer is installed with

other units from the Ribbon range, these

should be fitted at 5 1/2” centres.

5 1/2" 5 1/2"

3"

6 TSL. R.030 RIB BON HA ND DRYER MANUAL

before you install

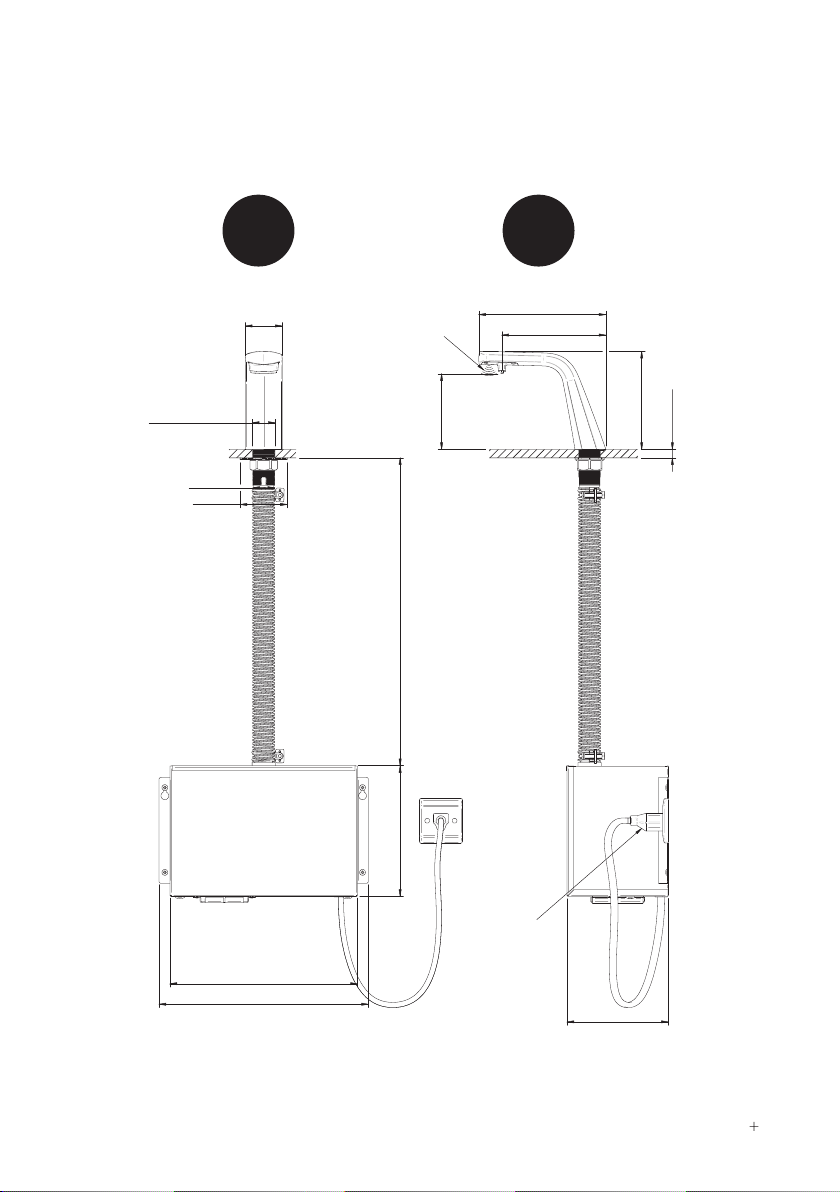

FRONT SIDE

Default

Sensor

2-1/8"

Range

3/4"-5-1/8"

7-5/16"

6"

1-5/16"

Ø

THROUGH HOLE

Ø

1-1/4"

2-11/16"

10-3/4"

12-1/16"

5-7/8"

5-5/8"

3/8" MIN

1-3/8" MAX

4-3/8"

11-3/4" - 12-9/16"7-9/16"

Mains

Power Supply

TSL. R.030 RIB BON HA ND DRYER MANUAL 7

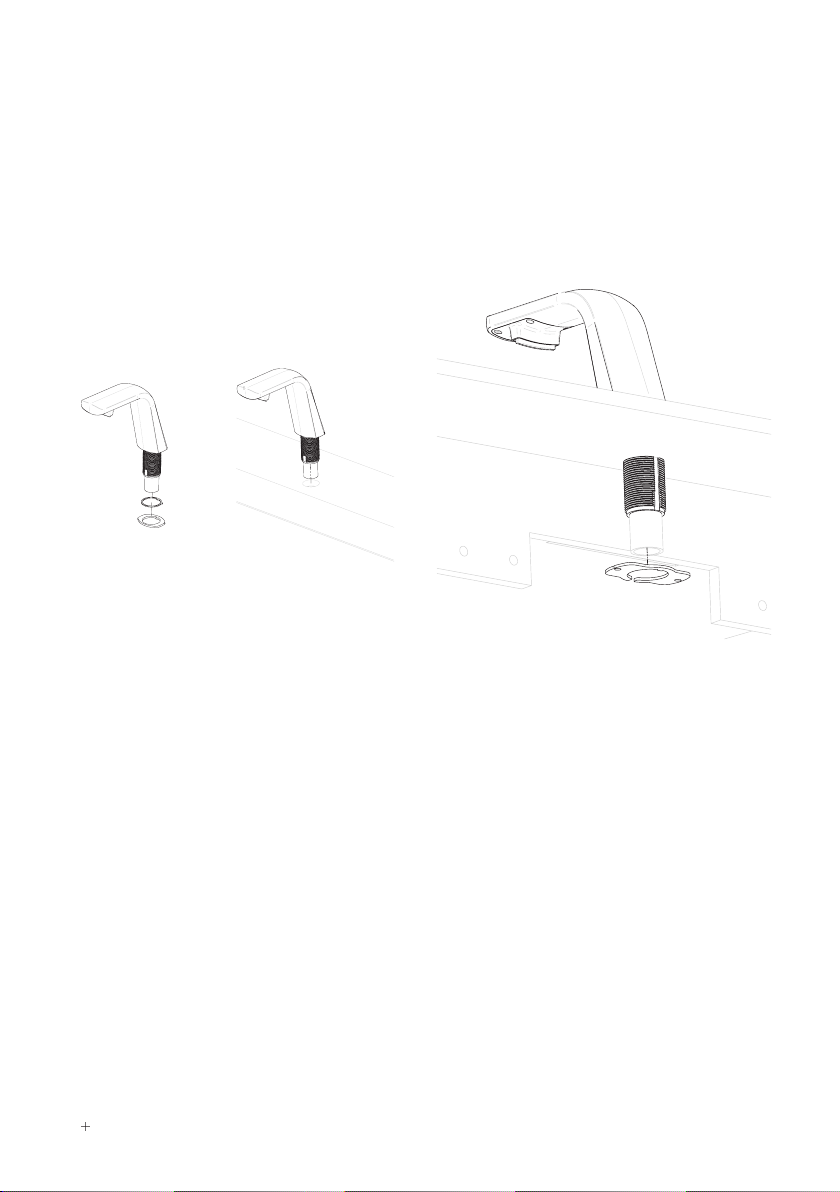

how to install

1

Drill hole 1 3/8” diameter in counter-top, if

not already cut.

8 TSL. R.030 RIB BON HA ND DRYER MANUAL

2

Fit anti-rotation washer from below basin

3

Fit fixing nut, and secure using spanner.

4

Remove cover-fixing screws from

underside of dryer motor using the

security hex key provided, and then

remove the cover.

TSL. R.030 RIB BON HA ND DRYER MANUAL 9

how to install

5

Fit the dryer motor unit to wall or cabinet,

within 18” of the dryer nozzle already

installed on the basin / countertop.

10 TSL. R.03 0 RIBB ON HAN D DRYER MANUAL

6

Thread the power cable through the

knockout in the back or base of the dryer

and feed to connector block. Connect

the cables as marked on the dryer unit.

7

Thread the sensor and earth cables

through the air-hose.

8

Feed cables into air outlet nozzle and

then through cable exit grommet.

TSL. R.030 RIB BON HA ND DRYER MANUAL 11

how to install

9

Connect the sensor cable to the 6-pin

fitting on the PCB control, and the

ground cable to the corresponding earth

connector in the dryer motor unit.

12 TSL. R.03 0 RIBB ON HAN D DRYER MANUAL

10

Connect air hose onto outlet nozzle on

dryer motor and tighten hose clamp.

11

Re-fit the dryer cover and tighten the

fixing screws.

TSL. R.030 RIB BON HA ND DRYER MANUAL 13

commissioning

Turn on the power supply to the dryer, and then test that the dryer will operate when

the user’s hands are placed within the detection range.

The motor speed and sensor range can be adjusted to suit user preference and the

environment, if required. The heater element can also be switched off if desired.

Warm air speed adjustment

1. Switch off the power, loosen the cover

screws and remove the cover.

2. Use small Phillips head screwdriver

to turn variable resistor shaft. Turn

clockwise to increase the motor

speed; turn anticlockwise to reduce

the motor speed

14 TSL. R.030 RIBBON HAND DRYER MANUAL

Sensor range adjustment

1. Switch off the power, loosen the cover

screws and remove the cover.

2. Use small Phillips head screwdriver

to adjust the variable resistor. Turn

clockwise to increase the sensitivity;

turn anti-clockwise to reduce the

range.

Heater Element Switch ON/OFF

1. Switch off the power, loosen the

cover screws and remove the cover.

2. Adjust the heater switch on the

PCB with a small plastic or wood

flat blade probe.

2-1 Slide the switch to ‘ON’ :

Enables heater

2-2 Slide the switch to ‘1’ :

Disables heater

TSL. R.030 RIB BON HA ND DRYER MANUAL 15

operation

+ The user is to shake excess water off their hands.

+ The user then places their hands within the detection range of the sensor to

activate the hand dryer.

+ The motor will start and air is blown onto the user’s hands.

+ The motor will stop when the user’s hands are removed from the detection range.

maintenance

+ The hand dryer should be serviced on a regular basis to ensue long service life of

the unit.

+ Isolate the unit from the power supply before any servicing or maintenance work is

carried out.

+ Remove the cover by unscrewing the fixing screws on the underside of the cover.

+ Remove any dust or foreign body from the air intake and (both inside and outside

the dryer). Where necessary, use a brush or vacuum cleaner.

16 TSL. R.03 0 RIBBON HAN D DRYER MANUAL

cleaning

All grades of stainless steel will stain or discolour if due care and attention is not taken.

The surface must be regularly cleaned to ensure a long service life of the hand dryer.

Use a soft cloth or sponge with a mild solution of soapy water as part of the regular

washroom janitorial routine. Do not use abrasive or cream cleaners as these will

damage the surface finish.

If the hand dryer is subjected to a highly chlorinated environment eg swimming pools

or marine coastal locations, a further treatment, in addition to the regular cleaning as

described above, is recommended by the application of a household cleaning product

containing silicone.

If further information is required, contact The Splash Lab technical team for more

detailed stainless-steel care guidelines.

TSL. R.030 RIB BON HA ND DRYER MANUAL 17

troubleshooting

Corrective Actions for Initial Installation Failures

If the dryer will not run:

+ First ensure that the breaker supplying the dryer is operational. If it is, disconnect

the power and remove the dryer cover. Taking suitable precautions to avoid shock

hazard, reconnect the power and check for voltage at the terminal block. Verify

that connections are made correctly.

The dryer cycles by itself or runs constantly:

+ Ensure that there is no obstruction on or in front of the IR sensor. Clean any dirt or

debris off the sensor lens. If problem persists, replace sensor.

The dryer makes a loud noise and does not run for a complete cycle:

+ Ensure that the supply voltage is correct. Dryer will make a loud humming noise

if the input voltage is too high. Verify voltage requirement on unit rating label and

correct supply as required. (If circuit board module has been damaged, replace it

and the infra-red sensor module.)

The dryer runs but air stream is low pressure and/or low velocity:

+ Ensure that the supply voltage is correct. Dryer will run weakly if the input voltage

is too low. Verify voltage requirement on unit rating label and correct supply as

required.

We are always looking to improve. If these did

not solve your problem please contact us and

we will endeavour to help.

Tel: +1 310 410 5008

Email: technical@thesplashlab.com

18 TSL. R.03 0 RIBB ON HAN D DRYER MANUAL

Corrective Actions for Initial Installation Failures

If the dryer will not run:

+ First ensure that the breaker supplying the dryer is operational. If it is, disconnect

the power and remove the dryer cover. Replace the CBM and IR sensor module.

Taking suitable precautions to avoid shock hazard, reconnect the power and

check for Voltage at the terminal block.

The IR sensor only sees close range objects:

+ Ensure that there is no obstruction on or in front of the IR sensor. Clean any dirt

or debris off the sensor lens. Check variable resistor for sensor range setting, If

problem persists, disconnect the power and remove the dryer cover and replace

CBM, IR sensor module.

The heater gets hot but no air stream is produced:

+ Disconnect the power. Remove the dryer cover. Check variable resistor for speed

setting Disassemble the blower- motor/ fan housing. Replace the fan motor.

Reassemble.

TSL. R.030 RIB BON HA ND DRYER MANUAL 19

troubleshooting

Corrective Actions for Initial Installation Failures

The dryer only blows cold air during a full cycle:

+ Disconnect the power. Remove the dryer cover and check/ ensure heater switch

is ON. Disassemble the blower-motor/fan housing. Test the thermostat for open

circuit. Check the heater element for signs of burning or breakage. Damaged

element must be replaced.

The air stream is low pressure and velocity:

+ Check the output nozzle for obstructions. If none are present, disconnect the

power. Remove the dryer cover. Remove any dust/lint buildup from intake vent

slots. Check VR for speed setting. Disassemble the blower / motor/ fan housing.

Check the motor brushes for worn condition (1 1/4” graphite remains) and replace

them, if necessary. Check motor brushes for wear; if less than 1 1/4” is remaining,

replace brushes.

20 TSL. R.030 RIBBON HAND DRYE R MANUAL

diagram

29

28

27

34

11

1

30

31

32

33

9

2

3

4

5

6

7

8

11

12

13

14

15

16

17

20

18

38

19

TSL. R.030 RIB BON HA ND DRYER MANUAL 21

24

23

22

21

26

25

spare parts & accessories

Spare parts`

1 Flexible air hose

2 Stainless steel hose clamp

3 Stainless steel motor case

4 Connector – top cap

5 Connector packing

6 Connector – bottom cap

7 Cable exit grommet

8 Sensor & cable assembly

9 Circuit board module (PCB)

10 Blower mounting bracket

11 Blower motor housing –

lower section

12 Motor mounting rubber -

Lower

13 Motor

14 Heater element

15 Motor mounting rubber –

Upper

16 Blower motor housing –

upper section

17 Stainless steel front cover plate

18 Motor cover fixing screws

(2 required)

19 Hex wrench

20 Motor case cable entry

grommet

21 Terminal block

22 Mains cable clamp

23 Terminal block insulation plate –

Mylar

24 Earth screw

25 Motor base plate

26 Motor back plate cable entry

grommet

27 Air outlet fixing screws

28 Air outlet faceplate

29 Air outlet body

30 Anti-rotation ring

31 Sealing gasket

32 Air outlet tube / mounting

spigot

33 Anti-rotation fixing washer

34 Mounting nut

If further information is required,

contact The Splash Lab technical team

for more detailed guidelines.

22 TSL. R.03 0 RIBB ON HAN D DRYER MANUAL

warranty

We believe the future is personal. With a global mindset, we challenge conventional

restroom norms via product innovation to create considered washroom solutions for

corporate and educational spaces. We use rich raw materials, cutting-edge automation

and considered washroom design to powerfully and positively influence the lives of

people. We are The Splash Lab.

Demonstrating our commitment to quality and our belief in the strength of our designs,

we can offer the following warranties.

The Splash Lab will warrant that its products will be free of manufacturing and material

defects during normal use and environmental conditions as detailed below:

Ribbon Collection 3 years’ parts & labour

If a defect is found in normal use, The Splash Lab will, at their discretion, repair, provide

a replacement part or product, or make appropriate adjustments. Damage caused by

accident, misuse, or abuse is not covered by this warranty. Improper care and cleaning

will void the warranty.

Non-operation of the product due to environmental conditions beyond our control,

installation error, incorrect maintenance, water quality, fair wear and tear, incorrect or

inappropriate installation, misuse and abuse is not covered by the warranty.

Proof of purchase (original sales receipt) must be provided to The Splash Lab with all

warranty claims.

The above warranty is valid for goods supplied within North America.

For goods supplied outside of North America, The Splash Lab will honour the above

stated warranty periods for the parts only.

THE SPLASH LAB DISCLAIM ANY LIABILITY FOR SPECIAL, INCIDENTAL OR

CONSEQUENTIAL DAMAGES.

TSL. R.030 RIB BON HA ND DRYER MANUAL 23

contact

General information

+1 310 410 5008

5450 W 83rd St, Los Angeles CA90045

500 7th Ave, New York NY10018

Technical support

technical@thesplashlab.com

For further contact information visit:

www.thesplashlab.com

TSL. R.030 US RE V 2-01/04/19

Loading...

Loading...