Page 1

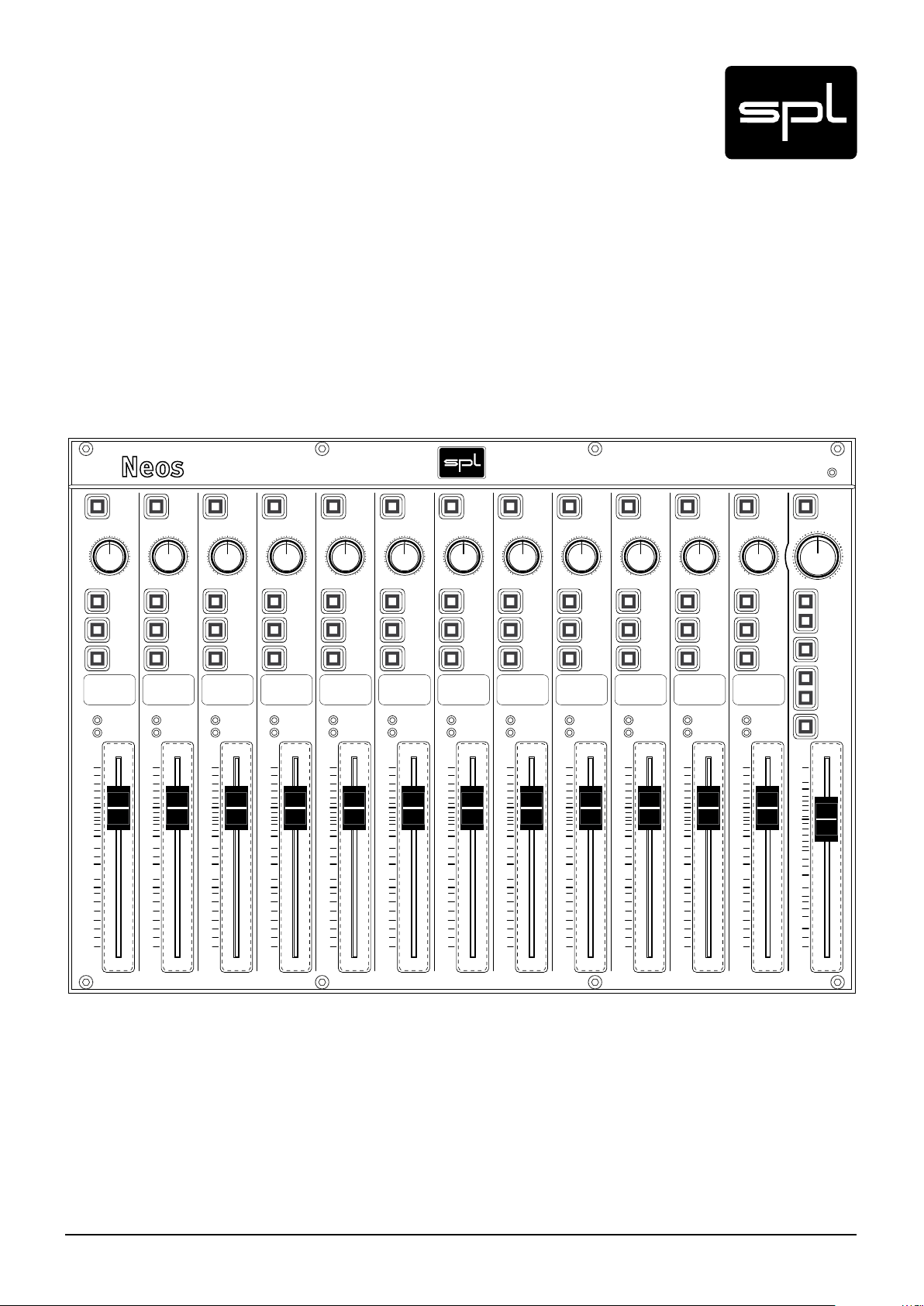

24|2 Mixing Cons ole

Manual

W

E

120 Volts Analog

Pure Audio Performan ce

R

O

P

MONO

N

A

P

C

R

L

CUT

To Monitor

Only

SOLO

SIG SIG SIG SIG SIG SIG SIG SIG SIG SIG SIG SIG

1

2

dB

+6

5

4

3

2

0

-2

-4

-5

-6

-8

-10

-12

-15

-18

-20

-24

-28

-36

-40

-50

-

∞

MONO

N

A

P

C

R

L

CUT

To Monitor

Only

SOLO

3

4

dB

+6

5

4

3

2

0

-2

-4

-5

-6

-8

-10

-12

-15

-18

-20

-24

-28

-36

-40

-50

-

∞

MONO

N

A

P

C

R

L

CUT

To Monitor

Only

SOLO

5

6

dB

+6

5

4

3

2

0

-2

-4

-5

-6

-8

-10

-12

-15

-18

-20

-24

-28

-36

-40

-50

-

∞

MONO

N

A

P

C

R

L

CUT

To Monitor

Only

SOLO

7

8

dB

+6

5

4

3

2

0

-2

-4

-5

-6

-8

-10

-12

-15

-18

-20

-24

-28

-36

-40

-50

-

∞

MONO

N

A

P

C

R

L

CUT

To Monitor

Only

SOLO

9

10

dB

+6

5

4

3

2

0

-2

-4

-5

-6

-8

-10

-12

-15

-18

-20

-24

-28

-36

-40

-50

-

∞

MONO

N

A

P

C

R

L

CUT

To Monitor

Only

SOLO

11

12

dB

+6

5

4

3

2

0

-2

-4

-5

-6

-8

-10

-12

-15

-18

-20

-24

-28

-36

-40

-50

-

∞

MONO

N

A

P

C

R

L

CUT

To Monitor

Only

SOLO

13

14

dB

+6

5

4

3

2

0

-2

-4

-5

-6

-8

-10

-12

-15

-18

-20

-24

-28

-36

-40

-50

-

∞

MONO

N

A

P

C

R

L

CUT

To Monitor

Only

SOLO

15

16

dB

+6

5

4

3

2

0

-2

-4

-5

-6

-8

-10

-12

-15

-18

-20

-24

-28

-36

-40

-50

-

∞

MONO

N

A

P

C

R

L

CUT

To Monitor

Only

SOLO

17

18

dB

+6

5

4

3

2

0

-2

-4

-5

-6

-8

-10

-12

-15

-18

-20

-24

-28

-36

-40

-50

-

∞

MONO

N

A

P

C

R

L

CUT

To Monitor

Only

SOLO

19

20

dB

+6

5

4

3

2

0

-2

-4

-5

-6

-8

-10

-12

-15

-18

-20

-24

-28

-36

-40

-50

-

∞

MONO

N

A

P

C

R

L

CUT

To Monitor

Only

SOLO

21

22

dB

+6

5

4

3

2

0

-2

-4

-5

-6

-8

-10

-12

-15

-18

-20

-24

-28

-36

-40

-50

-

∞

A

P

C

L

dB dB

+6

5

4

3

2

0

-2

-4

-5

-6

-8

-10

-12

-15

-18

-20

-24

-28

-36

-40

-50

-

∞

MONO

N

R

CUT

To Monitor

Only

SOLO

23

24

MON B

I

T

N

O

O

R

M

0

1

-

-

8

2

1

-

-

6

6

1

-

-

4

8

1

-

-

1

2

2

-

6

2

-

0

3

-

8

3

-

6

0

1

3

4

5

4

-

6

0

6

-

+

0

7

8

-

MUTE

DIM

MONO

TAPE

RETURN

MASTER

INSERT

BEND

+8

7

6

5

3

2

0

-2

-4

-5

-6

-8

-10

-12

-15

-18

-20

-24

-28

-36

-46

-

∞

Model 1010

Made in Germany

Neos

Model 1010

120-Volt Summing and Monitoring Console

Page 2

Content

Manual Neos 4

Declaration of CE Conformity 4

Notes on Environmental Protection 4

Contact 4

Scope of Delivery and Packaging 5

Symbols and Notes 5

Introduction 6

The High Voltage Console 6

Concept 7

Features 7

Special Features 7

Special Technical Features 7

Important Security Advices 8

Placement 9

Rack Mounting 9

Placement Of The External Power Supply 9

Voltage Selector (External Power Supply) 9

Power connection and fuse 9

Hook Up 9

Power Connection 10

Signal Connections 10

On/Of f Switch 10

GND Lift 11

XLR Sockets 11

DB 25 Sockets 11

Balanced Connections 11

Unbalanced connections (TS and RCA connectors) 11

Rear Panel – Switches & Connections, Basics 11

Rear Panel – Power Wiring Diagram 12

Rear Panel – Signal Wiring Diagram 13

Rear Panel 14

Inputs 1-8, 9-16, 17-24 14

Slave (additional input for additional Neos consoles) 14

Ins. Return (Insert Return) 14

Tape Rt. (Tape Return) 15

Rec Out

(Recording Output) 15

Monitor A and Monitor B 15

Alt. Out

(Alternative Output) 15

Ins. Send (Insert Send) 15

Metering 15

2

Neos

Page 3

Operation 16

Overview 16

Control Elements Input Path 16

Mono 16

Pan 17

Cut 17

To Monitor Only 17

Solo 17

Label Field 17

SIG LEDs 17

Fader 17

Control Elements Master Path 18

Mon B 18

Monitor 18

Monitoring with the Neos 18

Calibration 18

Mute 18

Dim 19

Mono 19

Tape Return 19

Master Insert 19

Bend 19

Fader 19

Content

DAW-Integration 20

Integration Examples and Channel Assignment 20

Specifications 21

Inputs & Outputs 21

Measurements 21

Power Supply 21

Dimensions and Weight 21

Dimensions and Weight External Power Supply 21

Copy Master Recall Settings 22

Block Diagram 23

Mounting Dimensions 24

Dimensions and Weight 24

Mounting Angles 25

Neos

3

Page 4

Manual Neos

Model 1010

Version 1.0 – 6/2011

Developer: Wolfgang Neumann

This manual contains a description of the product. It in no way represents a guarantee of

particular characteristics or results of use. The information in this document has been carefully compiled and verified and, unless otherwise stated or agreed upon, correctly describes

the product at the time of packaging with this document.

Sound Performance Lab (SPL) continuously strives to improve its products and reserves the

right to modify the product described in this manual at any time without prior notice.

© 2011 SPL electronics GmbH. All rights reserved. This document is the property of SPL and

may not be copied or reproduced in any manner, in part or fully, without prior authorization by

SPL. Names of other companies and their produc ts are trademarks of their re spe ctive owners.

Declaration of CE Conformity

The construction of the Neos, Model 1010, is in compliance with the standards

and regulations of the European Community.

Notes on Environmental Protection

At the end of its operating life, this product must not be disposed of with regular

household waste but must be returned to a collection point for the recycling of

electrical and electronic equipment. The wheelie bin symbol on the product,

user‘s manual and packaging indicates that. The materials can be re-used in

accordance with their markings. Through re-use, recycling of raw materials, or other forms

of recycling of old products, you are making an important contribution to the protection of

our environment. Your local administrative office can advise you of the responsible waste

disposal point. WEEE Registration: 973 349 88.

Contact

SPL electronics GmbH

Sohlweg 80, 41372 Niederkruechten, Germany

Phone +49 (0) 21 63 98 34 0, Fax +49 (0) 21 63 98 34 20

E-Mail: info@spl.info, Website: spl.info

4

Neos

Page 5

IN THIS MANUAL A LIGHTNING SYMBOL WITHIN A TRIANGLE WARNS YOU ABOUT THE

POTENTIAL FOR DANGEROUS ELECTRICAL SHOCKS – WHICH CAN ALSO OCCUR EVEN AFTER

THE MACHINE HAS BEEN DISCONNECTED FROM A POWER SOURCE.

AN EXCLAMATION MARK (!) WITHIN A TRIANGLE IS INTENDED TO MAKE YOU AWARE OF

IMPORTANT OPERATIONAL ADVICE AND/OR WARNINGS THAT MUST BE FOLLOWED. BE

ESPECIALLY ATTENTIVE TO THESE AND ALWAYS FOLLOW THE ADVICE THE Y GIVE.

The symbol of a lamp directs your attention to explanations of important functions or applications.

Attention: Do not attempt any alterations to this machine without the approval or supervision

of SPL electronics GmbH. Doing so could nullif y completely any and all of your warrant y/guarantee rights and claims to user support.

Scope of Delivery and Packaging

The scope of delivery comprises the Neos console, 19" rack-mounting side brackets, the

external power supply with fixed cable for connection to the Neos, the external power

supply’s power cord, the guarantee card and this manual.

Please keep the original packaging. In case of a service procedure the original packaging

ensures a safe transport. It also serves as a safe packaging for your own transports if you do

not use special transportation cases.

Symbols and Notes

Neos

5

Page 6

Introduction

The High Voltage Console

Shortly after the turn of the millennium, SPL laid down new foundations for the improvement

of analog audio signal processing. Thanks to new components, circuitries and manufacturing

methods, we were able to increase the operating voltage enormously. Up to then, average

operating voltage ranged form 30 to 36 volts (+/- 15 or 18 volts, considering that voltage

supply is symmetrical). Maximum operating voltages reached 60 volts (+/- 30 volts). At the

core of our new technology are the handmade OP-amps that operate at 120 volts (+/- 60 volts),

which means that we have in fact doubled the highest levels ever reached until then.

The first products to integrate the 120-volt technology were exclusive, handmade custom solutions for major mastering studios. At the time, music production had already been uprooted

by digital technology and the changes it brought with itself in terms of outfitting and workflow in music studios. Coincidentally, a new „mastering“ sector had already been established

— both in terms of the actual process and the gear in studios. If traditional recording and

mixing studios were on their way to digitalization, the most sophisticated mastering studios

were and have always been keen on analog technology, including high-quality signal processors that can still make a difference compared to the widely available software solutions. But

also technically demanding requirements such as superior sounding and designed switching

and monitoring consoles were among the products we were able to offer. While analog technology was being heralded as dead, SPL was decisively going in the opposite direction: we

were able to deliver analog products of the highest quality whose performance surpassed all

previous specifications — regardless of whether it was in the analog or digital realm.

In the last decade we have been able to keep up with the rapidly evolving developments in

digital technology while pushing further our analog products. It was imperative to work on the

foundations of the products‘ performance. Thus, if we consider that the basis of every circuit

is directly related to a voltage/performance ratio, the operating voltage is crucial for the

performance of any circuit. Given that audio technology is conceived to translate sound into

voltage, doubling the formerly highest operating voltage available results in a great improvement, specially with regard to signal dynamics and the way they are processed. Technically

speaking, a wider dynamic range also means that the gap between the actual signal and other

undesired signals, such as noise and distortion, is larger — in the case of the Neos console,

for example, this results in not hearing any noises at all, regardless of the situation.

Our measurements reveal the improvements the 120-volt technology offers in comparison to

standard solutions (see „Technical Specifications“ on page 21). All these advantages are due

to the oversized signal traces, the rigorous selection of every single element and, of course,

the handmade components that contain no unnecessary audio processing parts (which are

very common in mass-produced operation amplifiers). But the technical specifications and

design say very little about the actual sound of an audio equipment. At the end of the day, an

audio device has to prove itself in use in the hands of sound engineers and musicians. We can

state with great satisfaction that our solution not only prevailed — ever since their introduction, our 120-volt products have passed all tests and proven wor thy of the best.

The Neos is the first summing console based on the 120-volt technology. The basic concept

behind it was to combine essential summing capabilities, including faders and panorama

controls, with a complete and practical monitoring section — all in a compact design.

Accordingly, it fulf ills the highest expectations regarding sound quality in mixing and monitoring situations. Thus, the Neos was conceived with sound engineers that set great importance on artistic and musical production in mind and whose workflow does not rely primarily

on undo and preset options. Nevertheless, the compact Neos can integrate seamlessly in

computer-based environments providing the characteristic high-quality sound and handling

of analog devices.

6

Neos

Page 7

Concept

• 24 channel summing console with faders and panorama controls

• Ideal for DAW-based studios with emphasis on audio quality. .

Features

• Input path with 100-mm ALPS faders, Pan controls, Mono, Cut, Solo, and “To Monitor

Only” push buttons, signal LEDs

• Master path with 100-mm ALPS faders, Insert s, Bend func tion (Limiting)

• Comprehensive monitoring section with Volume control, Tape Mix (DAW return), as well

as Mute, Dim and Mono push buttons

• Input: three eight-channel DB25 connectors (balanced, TASCAM standard); balanced

XLR connectors: Slave, Insert Return, Tape Return

• Output connectors (balanced XLR): Recording Out, Monitor A and Monitor B,

• Output connectors (unbalanced XLR): Alternative Out, Insert Send, Metering

Special Features

• Ultimate Mix and Monitoring Quality

Introduction

• Compact design: 19"/7U

• Cascadable

• Hand made in Germany

Special Technical Features

• Unique 120-volt operating voltage. In comparison with common production mixers, the

Neos mixing and monitoring console uses four times as much operating voltage. A higher

voltage results in better performance: over 30 dB of headroom at the input, more than

122 dB of dynamic range, 92 dB signal-to-noise ratio over all channels.

• At the core of the 120-volt technology are our handmade, discrete op-amps with 116

dB signal-to-noise ratio and 34 dB of headroom. The 150 dB dynamic range covers a

frequency range of up to 200 kHz. These key figures are way beyond the demands of

current PCM digital formats with 24 bit/192 kHz sample rates and DSD digital formats

with 1 bit and 256 fs. It is not expected for digital technology to evolve so much in the

foreseeable future as to make the Neos a bottleneck in the signal processing path.

• All selected components for each unit are matched at the pre-production stage

• Important switching functions are performed via sealed relays

• Oversized signal traces, generous PCB layout for greater trace separation, star ground

scheme, linear power supply

Neos

7

Page 8

Important Security Advices

Please note and retain this manual. Carefully read and follow all of the safety and operating

instructions before you use the machine. Be doubly careful to follow all warnings and special

safety instructions noted in this manual and on the unit.

Connections: Only use the connections as described. Other connections can lead to health

risks and equipment damage.

Water and humidity: Do not use this machine anywhere near water (for example near a wash

basin or bath, in a damp cellar, near swimming pools, or the like). In such cases there is an

extremely high risk of fatal elec trical shocks!

Insertion of foreign objects or fluids: Never allow a foreign object through any of the

machine‘s chassis openings. You can easily come into contact with dangerous voltage or

cause a damaging short circuit. Never allow any fluids to be spilled or sprayed on the machine.

Such actions can lead to dangerous electrical shocks or fire!

Opening the unit: Do not open the machine housing, as there is great risk you will damage the

machine, or – even af ter being disconnected – you may receive a dangerous electrical shock!

Electrical power: Run this machine only from power sources which can provide proper power

in the range from 100 to 250 volts. When in doubt about a source, contact your dealer or a

professional electrician. To be sure you have isolated the machine, do so by disconnecting all

power and signal connections. Be sure that the power supply plug is always accessible. When

not using the machine for a longer period, make sure to unplug it from your wall power socket

and from the guitar amp.

Cord protection: Make sure that your power and guitar amplifier signal cords are arranged

to avoid being stepped on or any kind of crimping and damage related to such event. Do not

allow any equipment or furniture to crimp the cords.

Power connection overloads: Avoid any kind of overload in connections to wall sockets,

extension or splitter power cords, or to signal inputs. Always keep manufacturer warnings

and instructions in mind. Overloads create fire hazards and risk of dangerous shocks!

Lightning: Before thunderstorms or other severe weather, disconnect the machine from wall

power (but to avoid life threatening lightning strikes, not during a storm). Similarly, before

any severe weather, disconnect all the power connections of other machines and antenna and

phone/network cables which may be interconnected so that no lightning damage or overload

results from such secondary connections.

Air circulation: Chassis openings offer ventilation and serve to protect the machine from overheating. Never cover or otherwise close off these openings. Never place the machine on a soft

surface (carpet, sofa, etc.). Make sure to provide for a mounting space of 4-5 cm/2 inches to

the sides and top of the unit when mounting the unit in racks or on cabinets.

Controls and switches: Operate the controls and switches only as described in the manual.

Incorrect adjustments outside safe parameters can lead to damage and unnecessary repair

costs. Never use the switches or level controls to effect excessive or extreme changes.

Repairs: Unplug the unit from all power and signal connections and immediately contact a

qualified technician when you think repairs are needed – or when moisture or foreign objects

may accidentally have gotten in to the housing, or in cases when the machine may have fallen

and shows any sign of having been damaged. This also applies to any situation in which the

unit has not been subjected to any of these unusual circumstances but still is not functioning

normally or its performance is substantially altered. In cases of damage to the power supply

and cord, first consider turning off the main circuit breaker before unplugging the power cord.

Replacement/substitute parts: Be sure that any service technician uses original replacement

parts or those with identical specifications as the originals. Incorrectly substituted parts can

lead to fire, electrical shock, or other dangers, including further equipment damage.

Safety inspection: Be sure always to ask a service technician to conduct a thorough safety

check and ensure that the state of the repaired machine is in all respects up to factory standards.

Cleaning: In cleaning, do not use any solvents, as these can damage the chassis finish. Use

a clean, dry cloth (if necessary, with an acid-free cleaning oil). Disconnect the machine from

your power source before cleaning.

8

Neos

Page 9

Placement

Place the unit on a level and stable surface or mount it into dedicated rack frames. The unit’s

enclosure is EMC-safe and effectively shielded against HF interference. Nonetheless, you

should carefully consider where you place the unit to avoid electrical disturbances. It should

be positioned so that you can easily reach it, but there are other considerations. Try not to

place it near heat sources or in direct sunlight, and avoid exposure to vibrations, dust, heat,

cold or moisture. It should also be kept away from transformers, motors, power amplifiers

and digital processors.

Rack Mounting

Be sure that both above and below the machine you maintain a distance of 4-5 cm/2 inches

in order to eliminate electromagnetic or high frequency interference from other equipment.

Moreover, this will ensure adequate air circulation to prevent overheating. Do NOT locate

other machines that produce excessive heat below the unit. The rear side of the machine

should be properly supported – especially when transport is involved.

Placement Of The External Power Supply

Do not place the external power supply on top of the Neos and vice versa. Place the external

power supply on a level and stable surface only. We recommend a distance of at least 50

cm/20 inches to avoid any interferences between the external power supply and the Neos

frame or other devices.

Hook Up

Choose a place that is easily accessible so that you can switch off the external power supply

quickly in case of an emergency.

Please mind the notes under “Power Connection” and “On And Off” on the next page.

Voltage Selector (External Power Supply)

Be very careful to check that the voltage selection switch is set to the correct local line

voltage position before using the unit (230 V position: 220-240 V/50 Hz, 115 V position:

110-120 V/60 Hz)! When in doubt about a source, contact your dealer or a professional electrician.

BEFORE you connect electrical power make sure that the VOLTAGE selector setting reflects

the correct local power line voltage.

Power connection and fuse

Connect the power cord to the MAINS INPUT socket of the external power supply. Transformer,

power cord and case connection conform to VDE, UL and CSA requirements.

The fuse is accessible from outside and placed right behind the flap right from the socket.

Fuse ratings are 2 A slow blow (

230

volts) or 4 A slow blow (

115

volts).

230V~50Hz | 2A slow

115V~60Hz | 4A slow

Use slow blow fuse.

VOLTAGE | FUSE

Neos

9

Page 10

Hook Up

CONNECT TO EXTERNAL PSU

CONNECT TO EXTERNAL PSU

Power Connection

The Neos is fed through the external power supply. Before connecting the power supply

always make sure that the position of the voltage selector on the back of the RackPack corresponds to the voltage of your local power supply (115V position: 110-120V, 230 V position:

220-240V). In case of doubt please ask your dealer, a professional electrician or your local

power supplier.

Before you connect the external power supply to the wall socket please switch its POWER

button to OFF. Also turn off all devices that you may have already connected to the RackPack.

If signal or power connections are changed in the future, always switch off power before.

Before you connect the external power supply to the wall socket you should connect it to the

Neos (see illustration on page 12). The cable fixed to the external power supply with the multipin connector on the other end is made to connect to the Neos. It is not possible to connect it

incorrectly; place the groove at the end of the plug on the spring at the socket on the Neos and

tighten the screw.

After connecting the external power supply to the Neos and selecting the correct voltage on

the external power supply, connect the power supply to the wall socket and then turn on the

Neos with the POWER switch.

IMPORTANT: Never disconnect the external power supply from the Neos while the power is

switched on. Always turn the external power supply off first and then wait approximately

one minute to allow for any residual current to discharge. Now you may disconnect the multipin connector. Mind that residual current can damage the unit if you do not follow this procedure!

120 Volts Analog

Pure Audio Performance

POWER

W

O

P

Please read and follow all security advices on pages 4 and 5.

Signal Connections

IMPORTANT: Before first connecting any other equipment – and in all other cases where you

are connecting cables with or from other sources – you should be sure to shut the unit and

all machines to be connected off (external power supply). Otherwise you risk to damage the

unit, connected gear or your ears.

On/Off Switch

With the external power supply’s Power switch you activate and deactivate the Neos, operational status is confirmed by the blue Power LED on the Neos front panel (top right corner).

On And Off

E

R

In switching on and off, you do not need to follow any particular sequence with connected

devices in the periphery of the Neos. There is, however, the general rule for a chain of devices

in the audio processing to always turn on power amplifiers last and to turn them off first.

If specified sufficiently you can also switch the external power supply on and off through a

multiway connector or other main switches.

10

Neos

Page 11

Rear Panel – Switches & Connections, Basics

GND Lift

The rear panel GND LIFT switch eliminates hum by separating the internal ground from the

unit’s housing ground. Hum can, for example, result when this unit’s housing has a common

ground connection with other devices that might have a different ground potential. The

switch is usually deactivated to retain the shielding of the housing.

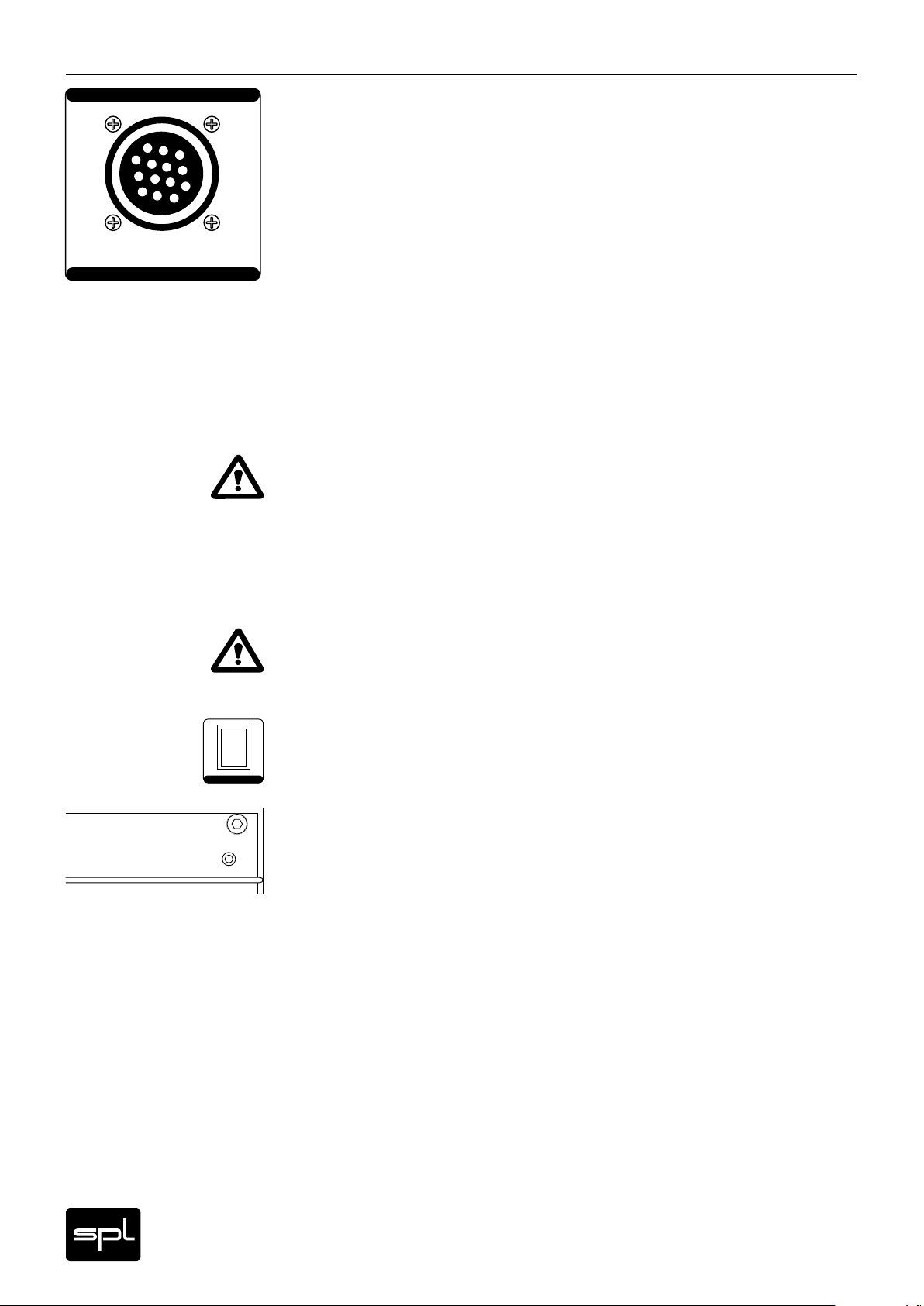

XLR Sockets

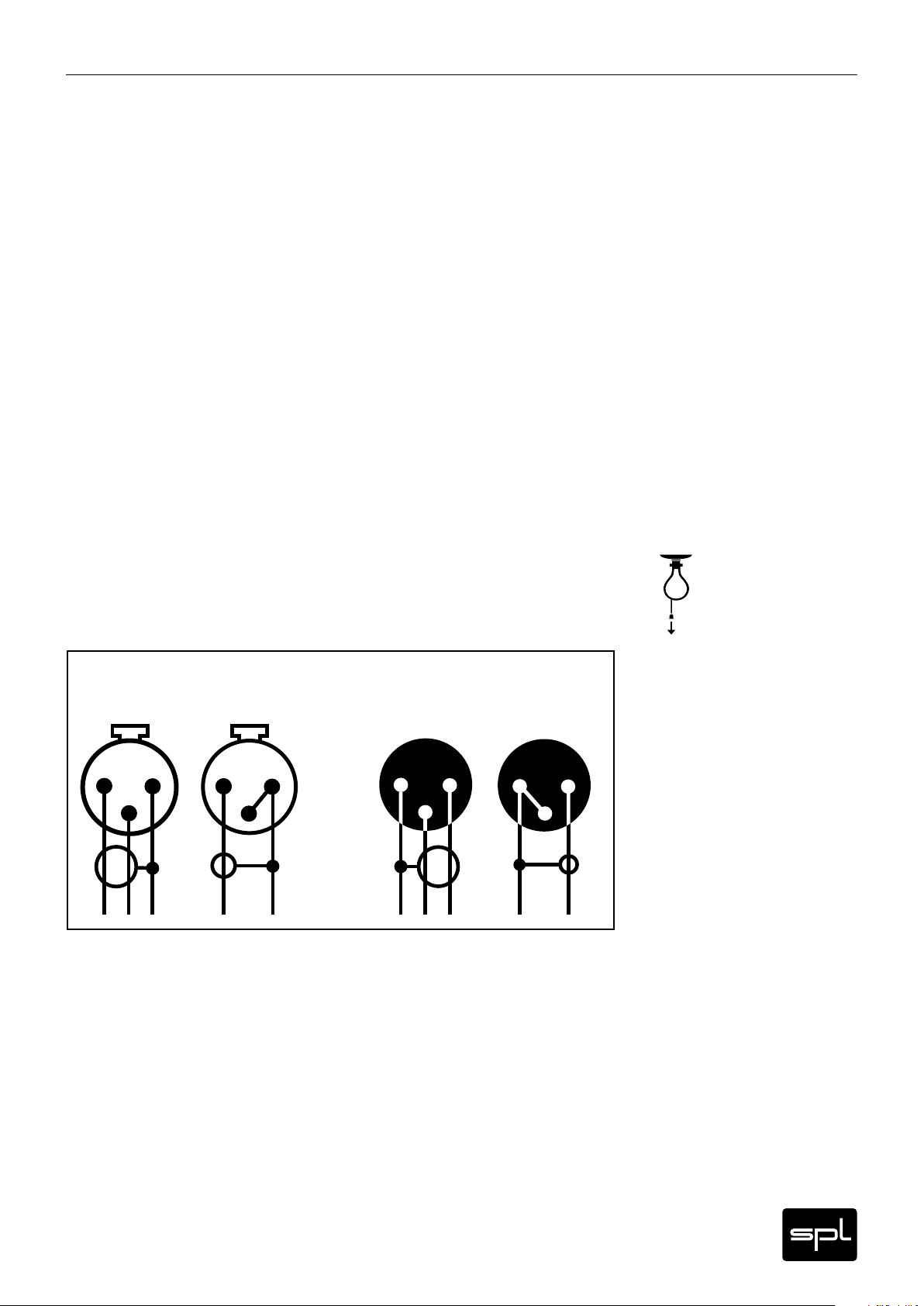

All signal connections are made via balanced or unbalanced XLR sockets. Pin wiring is shown

in the diagram below. Inputs are always female and accept male connectors; outputs are

always male. All in all, a comprehensible principle.

DB 25 Sockets

All 24 inputs are distributed on three eight-channel, female DB25 sockets. The connectors are

balanced and adhere to the Tascam standard (details on page 12).

Balanced Connections

In balanced connections a reference signal with reversed polarity is transmitted additionally

to the audio signal through a second wire. The ground signal is routed separately through

a third wire. Input and output stages are drivers and receivers, and the receiving stage can

suppress possible interferences by subtracting the difference between audio and reference

signal. The Neos employs electronic balancing stages (no transformers).

Unbalanced connections (TS and RCA connectors)

Unbalanced connections from and to RCA or 1/4" TS sockets can be made without adaptors to

the balanced XLR sockets. The correct wiring is important. The diagram shows the pin conf iguration of the XLR sockets and how to correctly connect them for unbalanced connections:

Input

balanced

2

Connections to RCA sockets are always unbalanced, a wiring to jack connectors can be both

balanced (1/4" TRS/stereo jack) or unbalanced (1/4" TS/mono jack). We recommend to use

individually configured cables from XLR to RCA or jack sockets instead of adaptors. You can

get cables in any needed configuration from audio dealers. With the diagram above, the

dealer can ensure to provide the appropriate cable for your application.

1

3

unbalanced

2

1

3

1=GND

2= hot (+)

3= cold (-)

balanced

1

2

3

Output

unbalanced

1

2

3

Neos

11

Page 12

Rear Panel – Power Wiring Diagram

L RREC OUT

INPUTS 1 – 8

DB 25 CONNEC TOR WIRING

DB25 COMPLY WITH TASCA M STANDARD.

PLEASE REFE R TO MANUAL FOR DETAILS.

1 = GND

SLAVE CONN ECTOR WIRING

INPUTS 9 – 16

MONITOR BUS: 4 = HOT (+) | 5 = COLD (–)

RECORDING BUS: 2 = HOT (+) | 3 = COLD (–)

INPUTS 17 – 24

LR INS. RETURNLR INS. SENDLR METERINGLR SLAVE

XLR CONNEC TOR WIRING

Neos – Model 1010

ALT. OUT XLR (UNBAL.):

1 = GND | 2 = HOT (+) | 3 = GND

XLR (BAL.): 1 = GND | 2 = HOT (+) | 3 = COLD (–)

Serial Number

www.spl.info

Made in Ger many

L RTAPE Rt.

L RMONITOR A

L RMONITOR B

R LREC OUT

R LTAPE Rt.

R LMONITOR A

R LMONITOR B

NEVER disconnect the external power supply

BEFORE switching on the external power supply,

connect the external power supply and the Neos

with the multi-pin power cord fixed to the external power supply.

from the Neos while the power supply

is still switched on.

First switch off the external power supply

and wait at least one minute before disconnecting.

3

Otherwise residual currents can cause serious damages!

CONNECT TO EXTERNAL PSU

L RALT. OUT

2

WARNING

THIS EQUIPMENT MUST BE E ARTHED.

TO REDUCE RISK OF FIRE OR EL ECTRIC SHOCK.

DO NOT EXPOS E THIS UNIT RAIN OR MOIS TURE.

DISCONNECT MA INS BEFORE REMOVING COVER.

GND LIFT

GND

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

GND LIFT

GND LIFT

AVIS: RISQUE DE CHOC ÉLEC TRIQUE – NE PAS OUVRIR

R LALT. OUT

GND LIFT

The rear panel GND lift switches

eliminate hum by separating

the internal ground from the

unit’s housing ground.

If hum occurs, press the

switches to activate GND lift.

CONNECT POWER CORD

IMPORTANT:

TO NEOS BEFORE SWITCHING ON POWER!

TO REDUCE RISK OF FIRE OR ELECTRIC SHOCK DO

BEFORE REMOVING COVER. THIS EQUIPMENT MUST BE EARTHED.

NOT EXPOSE THIS UNIT TO RAIN OR MOISTURE. DISCONNECT MAINS

WARNING:

spl.info

NEOS

Power Supply Unit

POWER OUTPUT TO AUDIO UNIT

Model 1010-P

MADE IN GERMANY

POWER

230V~50Hz | 2A slow

SERIAL NUMBER

Before you use the Neos, make sure that this voltage selector switch setting reflects

the correct local power line voltage (115V position: 110-120V, 230 V position: 220-240V).

In the drawing above the 230 V position is selected.

VOLTAGE | FUSE GND LIFT

Use slow blow fuse.

115V~60Hz | 4A slow

1

CAUTION

DO NOT OPEN

MAINS INPUT

RISK OF ELECTRIC SHOCK

AVIS: RISQUE DE CHOC ÉLECTRIQUE - NE PAS OUVRIR

12

CONNECT TO EXTERNAL PSU

Neos

Page 13

Pin Wiring XLR Outputs:

1=GND, 2=hot (+), 3=cold (-)

3

21

Pin Wiring XLR Inputs:

1=GND, 2=hot (+), 3=cold (-)

3

2

1

CONNECT TO EXTERNAL PSU

GND LIFT

Rear Panel – Signal Wiring Diagram

Second Neos: connect

with SPL cable only!

CONNECT TO EXTERNAL PSU

AVIS: RISQUE DE CHOC ÉLEC TRIQUE – NE PAS OUVRIR

DO NOT OPEN

RISK OF ELECTRIC SHOCK

GND LIFT

GND

GND LIFT

CAUTION

GND LIFT

Display

Level

(e. g. Headphone Amplifier)

Alternative Output

unbalanced balanced balanced

(e. g. Compressor, EQ)

Sum Processing

balancedunbalanced balanced

R LALT. OUT

DISCONNECT MA INS BEFORE REMOVING COVER.

DO NOT EXPOS E THIS UNIT RAIN OR MOIS TURE.

TO REDUCE RISK OF FIRE OR EL ECTRIC SHOCK.

THIS EQUIPMENT MUST BE E ARTHED.

(DAW/DA converter, Tape)

Listen to recorded signals

balancedbalanced

(DAW/AD converter, Tape)

Record summed signal

(e. g. Near Field)

Speakers

(e. g. Full Range)

Speakers

R LMONITOR B

R LMONITOR A

R LTAPE Rt.

R LREC OUT

L RALT. OUT

L RMONITOR B

Made in Germ any

L RMONITOR A

L RTAPE Rt.

1 = GND | 2 = HOT (+) | 3 = GND

Neos – Model 1010

www.spl.info

Serial Number

XLR (BAL.): 1 = GND | 2 = HOT (+) | 3 = COLD (–)

ALT. OUT XLR (UNBAL.):

WARNING

LR INS. RETURNLR INS. SENDLR METERINGLR SLAVE

INPUTS 17 – 24

(3 x eight-channel DB25)

Input Channels 1-24

RECORDING BUS: 2 = HOT (+) | 3 = COLD (–)

MONITOR BUS: 4 = HOT (+) | 5 = COLD (–)

SLAVE CONN ECTOR WIRING

INPUTS 9 – 16

XLR CONNEC TOR WIRING

INPUTS 1 – 8

1 = GND

PLEASE REFE R TO MANUAL FOR DETAILS.

DB25 COMPLY WITH TASCA M STANDARD.

DB 25 CONNEC TOR WIRING

Neos

L RREC OUT

13

Page 14

Rear Panel

Inputs

INPUTS 1 – 8

INPUTS 9 – 16

INPUTS 17 – 24

Inputs 1-8, 9-16, 17-24

The balanced DB25 input connectors are meant to connect the different signal sources. The

Neos’ 24 inputs are divided into three DB25 connectors. You can get ready-made XLR or jack

snakes in your local specialized store.

The maximum input level of the DB25 inputs is ›30dBu. The connectors are balanced and

adhere to the Tascam standard according to the following pin assignment:

1 2 3 4 5 6 7 8

GCHGCHGCHGCHGCHGCHGCHGCH

13

25

G=GROUND (GND), C=COLD (-), H=HOT (+)

LR SLAVE

Slave (additional input for additional Neos consoles)

The Slave input allows the connection of additional Neos consoles. When two consoles are

interconnected you have 48 channels at your disposal. You can connect an unlimited number

of Neos with each other. The connector is based on a special 5-pin XLR format.

1

14

IMPORTANT: the interconnection of Neos consoles can only be established via a custommade cable manufactured by SPL under request.

When two or more Neos are interconnected, the stereo output signal is summed, so instead

of summing 24-in-2 channels you have 48 (or more) channels summed into one stereo signal.

The connection has no set direction, which means the sum signal of all channels is always

present in the outputs (Rec Out, Monitor A and B, and Alt Out) of all interconnected Neos.

Therefore, all recording media should be normally connected to only one Neos — but there

are many connection possibilities open with all other units involved.

The slave function applies only to the sum of the stereo output signals pre-Master path.

Generally speaking, the Neos considered the “Master” will be the one to which the monitor

speakers are connected. All switching functions of the Master path can be applied to the

totality of channels which have been summed. All switching functions of a single input path

apply only to the corresponding Neos unit. In this respect, each Neos is to be considered and

operated independently. For example, the Solo function of any input path: to listen to an

isolated channel you have to depress the corresponding Solo switch; however, the channels

of the other interconnected Neos consoles are not muted. A practical solution for this would

be to activate a solo function in your DAW that would affect all channels.

Other interesting possibilities arise when two or more Neos units are connected to the monitoring system along with other gear. There are many individual solutions available, which we

will be more than happy to discuss with you.

LR INS. RETURN

Ins. Return (Insert Return)

14

Use the Master Insert loop to add external signal processors to the Neos’ internal processing.

Connect the Master Insert’s returning signal, i.e. the output signal of the external processor, to

the Ins. Return input.

The maximum level these unbalanced inputs can handle is › 24 dBu. To activate the Insert

function use the Master Insert push button in the Master path (for more information see

Control Elements, Master Inser t, on page 19).

Neos

Page 15

Outputs

Tape Rt. (Tape Return)

The Tape Return function allows you to bring back the recorded signal to the Neos in order to

listen to it. Connect to the Tape Rt. input the output signal of the DA converter or tape machine.

The maximum level these balanced inputs can handle is › 30 dBu. To activate the input use the

Tape Return push button in the Master path (for more information see Control Elements, Tape

Return, on page 19).

Rear Panel

L RTAPE Rt.

R LTAPE Rt.

Rec Out (Recording Output)

The output signal of the Neos is available at the Rec Out so you can record the final mixdown.

This where the AD and tape machines ought to be connected.

The maximum level delivered by the Rec Outputs is › 24 dBu.

Monitor A and Monitor B

The balanced Monitor A and Monitor B outputs are meant to feed power amps or active

monitor speakers. The two separate outputs allow the use of two different monitor speakers.

Generally speaking, Monitor A is always active. To switch to Monitor B use the Mon B push

button on the Maser path.

The maximum level delivered by the Monitor B output is › 24 dBu.

Alt. Out (Alternative Output)

At these outputs you have a copy of the Rec Out signal. The Alternative Outputs can be used

to connect a headphones preamplifier.

L RREC OUT

R LREC OUT

L RMONITOR A

R LMONITOR A

L RALT. OUT

The maximum level delivered by the unbalanced Alt Outputs is › 24 dBu.

Ins. Send (Insert Send)

Use the Master Insert loop to add external signal processors to the Neos’ internal processing.

Connect the inputs of external signal processors to the unbalanced Ins. Send outputs. To activate the Inser t function use the Master Insert push button in the Master path (for more information see Control Elements, Master Insert, on page 19).

The Send outputs deliver › 24 dBu.

Metering

Use the unbalanced Metering output to connect VU or PPM meters in order to monitor the

signal of the Rec. Outputs. The nominal level is calibrated to 0 dB. The maximum level delivered by the Metering Outputs is › 24 dBu.

R LALT. OUT

LR INS. SEND

LR METERING

Neos

15

Page 16

Operation

24|2 Mixing Cons ole

Overview

120 Volts Analog

Pure Audio Performan ce

W

E

R

O

P

MONO

N

A

P

C

R

L

CUT

To Monitor

Only

SOLO

SIG SIG SIG SIG SIG SIG SIG SIG SIG SIG SIG SIG

1

2

dB

+6

5

4

3

2

0

-2

-4

-5

-6

-8

-10

-12

-15

-18

-20

-24

-28

-36

-40

-50

-

∞

MONO

N

A

P

C

R

L

CUT

To Monitor

Only

SOLO

3

4

dB

+6

5

4

3

2

0

-2

-4

-5

-6

-8

-10

-12

-15

-18

-20

-24

-28

-36

-40

-50

-

∞

MONO

N

A

P

C

R

L

CUT

To Monitor

Only

SOLO

5

6

dB

+6

5

4

3

2

0

-2

-4

-5

-6

-8

-10

-12

-15

-18

-20

-24

-28

-36

-40

-50

-

∞

MONO

N

A

P

C

R

L

CUT

To Monitor

Only

SOLO

7

8

dB

+6

5

4

3

2

0

-2

-4

-5

-6

-8

-10

-12

-15

-18

-20

-24

-28

-36

-40

-50

-

∞

MONO

N

A

P

C

R

L

CUT

To Monitor

Only

SOLO

9

10

dB

+6

5

4

3

2

0

-2

-4

-5

-6

-8

-10

-12

-15

-18

-20

-24

-28

-36

-40

-50

-

∞

MONO

N

A

P

C

R

L

CUT

To Monitor

Only

SOLO

11

12

dB

+6

5

4

3

2

0

-2

-4

-5

-6

-8

-10

-12

-15

-18

-20

-24

-28

-36

-40

-50

-

∞

MONO

N

A

P

C

R

L

CUT

To Monitor

Only

SOLO

13

14

dB

+6

5

4

3

2

0

-2

-4

-5

-6

-8

-10

-12

-15

-18

-20

-24

-28

-36

-40

-50

-

∞

MONO

N

A

P

C

R

L

CUT

To Monitor

Only

SOLO

15

16

dB

+6

5

4

3

2

0

-2

-4

-5

-6

-8

-10

-12

-15

-18

-20

-24

-28

-36

-40

-50

-

∞

MONO

N

A

P

C

R

L

CUT

To Monitor

Only

SOLO

17

18

dB

+6

5

4

3

2

0

-2

-4

-5

-6

-8

-10

-12

-15

-18

-20

-24

-28

-36

-40

-50

-

∞

MONO

N

A

P

C

R

L

CUT

To Monitor

Only

SOLO

19

20

dB

+6

5

4

3

2

0

-2

-4

-5

-6

-8

-10

-12

-15

-18

-20

-24

-28

-36

-40

-50

-

∞

MONO

N

A

P

C

R

L

CUT

To Monitor

Only

SOLO

21

22

dB

+6

5

4

3

2

0

-2

-4

-5

-6

-8

-10

-12

-15

-18

-20

-24

-28

-36

-40

-50

-

∞

A

P

C

L

dB dB

+6

5

4

3

2

0

-2

-4

-5

-6

-8

-10

-12

-15

-18

-20

-24

-28

-36

-40

-50

-

∞

MONO

N

R

CUT

To Monitor

Only

SOLO

23

24

MON B

I

T

N

O

O

R

M

0

1

-

-

8

2

1

-

-

6

6

1

-

-

4

8

1

-

6

2

-

0

3

-

8

3

-

1

2

2

-

-

0

1

3

4

5

6

4

-

6

0

6

-

+

0

7

8

-

MUTE

DIM

MONO

TAPE

RETURN

MASTER

INSERT

BEND

+8

7

6

5

3

2

0

-2

-4

-5

-6

-8

-10

-12

-15

-18

-20

-24

-28

-36

-46

-

∞

Model 1010

Overview

The control elements of the Neos console are distributed horizontally across the input paths

and Master path.

The Master path is on the far right. This section houses the processing functions and control

elements of the output signal, as well as all monitoring functions.

To the left are the twelve stereo input paths. In the input paths is where the level and

panorama settings, as well as some other functions, of the signals to be mixed is adjusted.

In principle there are only two different types of paths. Thus, it is almost absurd to even think

of a learning curve to actually start working with the Neos — instead, we could say there is

one single learning step, which is almost self-explanatory just by reading the names of the

functions involved.

Control Elements Input Path

MONO

Mono

The Neos offers 24 input channels in total. Two channels make up what we call an input path.

Input paths work generally in stereo. When working with mono signals (vocals, instruments

recorded on one single channel, etc.) you use only one of the channels of the input path.

Depress the Mono push button on the corresponding path to place the signal in the center of

the stereo panorama, instead of hard left. That way you can use the Pan control to place the

signal wherever you want in the stereo field.

Made in Germany

16

Neos

Page 17

Control Elements Input Path

Pan

Use the Pan control to place the signal in the stereo field of the sum signal. Both mono and

stereo signals can be placed continuously in the stereo field anywhere from hard left (L) to

center (C) and hard right (R).

N

A

P

C

R

L

Cut

Use the Cut push button to mute the input signal of the corresponding channel. The input

signal is withdrawn from the mix and therefore is not available anymore in the sum or monitor

signals.

To Monitor Only

Use this push button to assign the corresponding input path exclusively to the monitoring

bus. This function is based upon standard voltage circuitry with a max. I/O level of ‹20 dBu*.

To Monitor Only overrides the Cut function on the monitoring bus. If both push buttons are

engaged, the signal will be heard but not mixed. This can be very convenient, for example,

when you need to only play back a stereo signal.

Solo

The Solo push button mutes all other channels, i.e. the only channel that is heard is the one

with Solo engaged. The Solo function relates only to the monitor bus, it does not affect the

mix signal.

This function is based upon standard voltage circuitry with a max. I/O level of ‹20 dBu*.If you

activate several Solo buttons, you hear alle channels with active Solo button. Compared to

the usual play back, there are two main differences: The signal is always switched to mono,

and the Solo function is carried out in PFL mode (Pre Fader Listening). This means the signal

is routed to Solo before the fader with a fixed level. Faint signals are well audible, too – your

fader settings, eventually found after longer work, do not have to be altered.

CUT

To Monitor

Only

SOLO

Label Field

Use this space to label the channels any way you want. The easiest and most practical way

to label the channels is to use a pencil given that they are easily readable, do not hurt the

sur face and can be easily erased. If you prefer stickers, use removable ones or adhesive tape.

SIG LEDs

The Signal LEDs turn on when the input level surpasses -10 dBu. This allows checking whether

the feed signal is actually being sensed when using complex connections. On the other side, it

also allows you to monitor the signal level.

Fader

The faders are meant to control the signal level. Each fader controls both channels of a single

input path; when in mono mode this applies to the channel in use. The level ranges from +6dB

to -∞.

The ALPS fader with dust cover has a generous 100 mm travel. The fader control cur ve is

optimal for mixing applications and has been matched to the human hearing response, which

means it is not linear. The range with the smoothest and finest response ranges from 0 to

+6dB. But the range from 0 dB to around -15 dB also has a very high resolution.

* All other stages are capable of processing higher input levels (› 30 dB). If the stages of these

monitoring functions are overloaded, the recording and master monitoring signals are not

affected. Reduce the fader setting of the respective channel if necessary.

-

-10

-12

-15

-18

-20

-24

-28

-36

-40

-50

SIG

1

2

dB

+6

5

4

3

2

0

-2

-4

-5

-6

-8

∞

Neos

17

Page 18

Control Elements Master Path

MON B

Mon B

Use the Master path’s top-most push button to activate the Monitor B output. Monitor output

A will be muted. Usually you would have two different sets of monitor speakers connected.

With the Monitor B push button you can choose the set you want to listen to. However, you

can always connect a headphones preamp to one of the Monitor outputs. Take into account

that you should always calibrate both Monitor outputs to always have the same level — even

if you use headphones. In this last case, adjust the level so that when you set 0 dB in the

headphones preamp volume control and the Neos Monitor control you get the same sound

pressure level as you would with monitor speakers in the listening position. Apart from being

able to compare sound pressure levels between different monitor speakers, this also avoids

any unpleasant volume differences when switching from one monitoring set to the other.

Once you are done calibrating the headphones preamp, always adjust the volume level on the

Neos without modifying the preamp’s level control. Please refer to “Calibrate“ on this page.

Monitor

I

T

N

O

O

M

6

1

-

8

1

-

2

2

-

6

2

-

0

3

-

8

3

-

6

4

-

0

6

-

0

R

0

1

-

-

8

2

1

-

-

6

-

4

-

1

0

1

3

4

5

6

+

8

7

-

Use the Monitor control to set the listening volume. This control affects Monitor outputs

A and B. The potentiometer used is a “Big Blue” ALPS (RK27). This type of potentiometers

are well-known for their high overload capacity, even response and a very smooth rotation

with enough resistance but without being stiff. The Monitor control uses a relative dB scale

referenced to the input level. The 0 dB mark is approximately at the 2-o’clock position, which

means that when set to this position the input level is “as is” (the amplification factor is 1 or

“Unity gain”). The control range extends from -80 dB to +7 dB. The control’s sensitivity is

maximal at normal listening levels, due to a higher resolution, from -18 dB to +7 dB, with the

highest resolution above 0 dB.

Monitoring with the Neos

Just like the summing section, the Neos monitoring section also benefits from the 120-volt

technology. This means that the consciously sound-oriented design and highest quality

components result in superb technical specifications providing the ultimate listening quality.

When the best conditions are given for analog signals to be played back, the desire for the

cleanest and most neutral monitoring is also satisfied. Technical evidence suggests that

signal disturbances are far below audible limits and sometimes even near to measuring limits.

What is lef t is sound — unaltered and unlimited, within what is technically feasible. You actually listen to music instead of a “Controller” and its characteristics.

Calibration

Considering that even the slightest level variation of 0.5 dB can produce differences in the

perception of sound quality, it is of utmost importance to be able to make precise comparisons with several loudspeakers or headphones. That is the reason why one of the basics of

monitoring is the calibration of loudspeakers and headphones. Power amplifiers and active

loudspeakers have to be adjusted to the reference level measured at the listening point.

The calibration is made with a sound level meter (or SPL meter; in this case SPL stands for

Sound Pressure Level). The SPL meter can also be used to measure headphones when placed

between the cups. Recommended calibration procedures and other exciting information on

monitoring are incorporated into Bob Katz‘s “K-System,” where monitoring, metering, and

leveling are defined and standardized as an integrated process (Level Practices Part One and

Two, by Bob Katz, Digital Domain, Inc., www.digido.com).

MUTE

DIM

18

Mute

Use the Mute control to momentarily turn off both Monitor outputs without having to modify

the level settings.

Neos

Page 19

Control Elements Master Path

Dim

Dim reduces 20 dB the listening volume of both monitor outputs. This setting can be used,

for example, to compare the same mix at two different listening levels without having to

modify the Volume control. 20 dB is a value which has been accepted in the industry as a

standard.

Mono

The mono switch sums the two channels that make up the stereo signal. The mono signal is

played back on both channels. The mono function allows checking the mono compatibility of

a mix, i.e. which signals are too faint or disappear completely when played back in mono. Even

if this test is not as important today as it used to be, it is still essential for radio mixes and

vinyl productions.

Tape Return

Connect the outputs of the recording device (D/A converter, computer, tape machine, etc.)

to the Tape Return inputs (see also page 13 “Tape Return”). That way you can listen to the

mixdown recorded and compare it to the output signal of the Neos with a simple button. Even

if it is not very common to have signals recorded on tape anymore, we decided to use the

traditional and most common term used for this application.

Master Insert

Use the Master Inser t push button to connect external processors to the Neos via the Send/

Insert Return connectors. The insert affects the sum signal on the master path.

Common signal processors used at this stage are equalizers and compressors.

MUTE

DIM

MONO

TAPE

RETURN

MASTER

INSERT

TAPE

RETURN

MASTER

INSERT

Bend

The Bend function activates a multi-stage, passive diode limiter that can level out curves and

limit signal peaks. The diodes used are made of germanium and silicon. While the former have

smoother curves, silicon diodes are a bit harder. The Bend diode network is designed in a way

that the processing becomes more aggressive the higher the signal level is. The processing

range starts at -6 dB and extends almost 20 dB. When level differences are small processing

is barely noticeable, however dynamic material will produce more distinct results. The interaction between the Bend limiter and the input channels and master signal saturation can be

very interesting. Since limiting is intensified by higher levels, you can achieve clearer targeted

or overall limiting effects. Typical applications are found in rock and pop music whenever the

signal sound needs to be fatter or the coloration of the diodes is desired. With transient-rich

signals it can also have an impact on rhythmic and timing (percussion instruments, piano,

plucked strings, etc.). In a more general sense, the Bend function also works as a protection

device by limiting signal peaks before they reach the conver ter.

Fader

Use the fader to set the level of the sum signal for recording. The level ranges from +8 dB to

-∞. The 0 dB point is shifted slightly compared to the input faders in order to allow for up to

+8 dB of gain. There are roughly two saturation methods: either the input channels are saturated while the sum signal is kept at moderate levels, or the input channel signals are kept

moderate while the sum signal is saturated. Both approaches are valid, the pros and cons

depend on the music genre and other signal processing applied. The Neos certainly offers the

best design and technical conditions for every approach.

-

-10

-12

-15

-18

-20

-24

-28

-36

-46

BEND

dB

+8

7

6

5

3

2

0

-2

-4

-5

-6

-8

∞

Neos

19

Page 20

DAW-Integration

Integration Examples and Channel Assignment

A common way to feed the 24 channels of the Neos would be to use three eight-channel D/A

converters. As a rule, one converter is defined as the main converter and the two others are

connected in chain. As long as the converters have the same DB25 connectors the connection

is straight forward and the channel assignment corresponds to the one in the DAW’s setup.

A high-quality two-channel converter might the best option to record the signal of the Neos’

Rec. Out. The A/D stage could also be integrated through the S/PDIF inputs of the main

converter. The recorded signal can be routed to the two-channel converter through the S/PDIF

outputs of the main converter, whose D/A output would then be connected to the Tape Return

of the Neos.

If the analog outputs of the converter are available as separate XLR and jack connectors, a

clever channel assignment could save converter channels. Typical sessions have usually four

mono channels (vocals, snare, kick, and bass) while the rest of the elements are available as

stereo stems in the DAW (keyboards, guitars, backing vocals, overheads, toms, etc.). In this

scenario you can make the final mixdown with the Neos. Nevertheless, do take into consideration that the more channels available for a production, the better.

Here is an example of such a session: once again we have three eight-channel converters,

however this time they have separate outputs connected via eight XLR/jack-to-D25 snake

cables. In the DAW, route the four mono channels to outputs 5, 6, 7, and 8 of the first converter.

Afterwards, connect the converter outputs with the Neos DB25 inputs 1, 3, 5, and 7. That way,

the mono signals are now controlled by the first faders of the Neos — and considering that

the input paths are stereo, whenever you use mono signals one of the channels is free (in this

example, DB25 outputs 2, 4, 6, and 8). All other stereo stems from the DAW should be routed

to the Neos through the two other converters. On the first converter you still have four output

channels lef t, which you can use for the Tape Return input of the Neos and a headphones mix.

20

Neos

Page 21

Inputs & Outputs

Electronically balanced instrumentation amplifiers

Sockets Inputs: DB25/TASCAM, XLR

Outputs: XLR

Input Impedance 10 k Ohm balanced/20 kOhm unbalanced

Output Impedance 75 Ohm balanced/75 Ohm unbalanced

Nominal Input Level +4 dBu

Maximum Input Level › +30 dBu (30 dBu = limit of measuring equipment)

Maximum Output Level › 24 dBu

Measurements

Frequency Range (-3 dB) 10 Hz to › 200 kHz

Phase 1kHz: 0°/10kHz: -4,5°/ 20kHz: -8.30°

Common Mode Rejection Ratio › 60 dB

(Rec. Out, Insert Send, Monitor A/B)

THD Rec. Out Insert Send Monitor A/B

10Hz 0.0011% 0.0011% 0.0016%

100Hz 0,00060% 0.0009% 0.0016%

1000Hz 0.00090% 0.0013% 0.0020%

5000Hz 0.0032% 0.003% 0.004%

10kHz 0.0028% 0.0018% 0.0027%

22kHz 0.00054% 0.00050% 0.0005%

(Generator output 24dBu, inputs terminated with 40 dBu)

Specifications

Signal to Noise Ratio (A-weighted) Rec. Out Insert Send Monitor A/B

92 dBu 92 dBu 88 dB

(22 Hz - 22 kHz, inputs terminated with 40 dBu)

Dynamic range › 122 dB

Power Supply

Linear power supply with toroidal transformer

Operational Voltage +/- 60 Volt (120 Volt)

Power Consumption (stand by) 230 Volt/50Hz : 0.420 A, 75W, 97,8 VA

Fuses 230 V AC, 50 Hz: 315 mA

115 V AC, 60 Hz: 630 mA

Voltage Selector 115 V/230 V

Dimensions and Weight

Front panel including rack brackets 19"/7 U (483 x 310 mm)

Front panel without rack brackets 440 mm

Housing (W x H x D) 483 x 235 x 330 mm, depth incl. sockets 355 mm

Further Dimensions on page 22

Weight 14.1 kg/ca. 31.08 lbs

Dimensions and Weight External Power Supply

W x H x D 154 x 67 x 236 mm

Gewicht 3 kg/6.61 lbs

Notes:

0 dBu = 0,775 V. All measurements at unity gain.

Specifications are subject to change without notice.

Neos

21

Page 22

Copy Master Recall Settings

E

W

R

O

120 Volts Analog

Artist:

4

-

6

R

-

P

Pure Audio Perfor mance

24|2 Mixing Console

MON B

MONO

MONO

MONO

MONO

MONO

MONO

MONO

MONO

MONO

MONO

MONO

MONO

O

8

-

T

I

0

1

-

N

2

1

O

-

6

M

1

-

8

1

N

C

A

P

N

C

A

P

N

C

A

P

N

C

A

P

N

C

A

P

N

C

A

P

N

C

A

P

N

C

A

P

N

C

A

P

N

C

A

P

N

C

A

P

N

C

A

P

Album/Gig:

3

4

1

0

5

1

-

6

+

7

MUTE

DIM

-

8

0

-

6

0

-

-

4

2

6

2

-

-

3

6

8

2

-

-

3

0

R

CUT

L

R

CUT

L

R

CUT

L

R

CUT

L

R

CUT

L

R

CUT

L

R

CUT

L

R

CUT

L

R

CUT

L

R

CUT

L

R

CUT

L

R

CUT

L

To Monitor

Only

To Monitor

Only

To Monitor

Only

To Monitor

Only

To Monitor

Only

To Monitor

Only

To Monitor

Only

To Monitor

Only

To Monitor

Only

To Monitor

Only

To Monitor

Only

To Monitor

Only

Title:

TAPE

RETURN

MASTER

MONO

SOLO

SOLO

SOLO

SOLO

SOLO

SOLO

SOLO

SOLO

SOLO

SOLO

SOLO

SOLO

INSERT

BEND

23

21

19

17

15

13

11

9

7

5

3

1

SIG SIG SIG SIG SIG SIG SIG SIG SIG SIG SIG SIG

Engineer:

67532

+8

24

5

3

2

4

dB dB

+6

0

-2

22

5

3

2

4

dB

+6

0

-2

20

5

3

2

4

dB

+6

0

-2

18

5

3

2

4

dB

+6

0

-2

16

5

3

2

4

dB

+6

0

-2

14

5

3

2

4

dB

+6

0

-2

12

5

3

2

4

dB

+6

0

-2

10

5

3

2

4

dB

+6

0

-2

8

5

3

2

4

dB

+6

0

-2

6

5

3

2

4

dB

+6

0

-2

4

5

3

2

4

dB

+6

0

-2

2

5

3

2

4

dB

+6

0

-2

Track(s)/Groups:

0

-2

-6

-8

-5

-4

-10

-12

-15

-18

-20

-6

-8

-5

-4

-10

-12

-15

-18

-20

-24

-5

-6

-8

-4

-10

-12

-15

-18

-20

-24

-6

-8

-5

-4

-10

-12

-15

-18

-20

-24

-6

-8

-5

-4

-10

-12

-15

-18

-20

-24

-6

-8

-5

-4

-10

-12

-15

-18

-20

-24

-5

-6

-8

-4

-10

-12

-15

-18

-20

-24

-6

-8

-5

-4

-10

-12

-15

-18

-20

-24

-5

-6

-8

-4

-10

-12

-15

-18

-20

-24

-5

-6

-8

-4

-10

-12

-15

-18

-20

-24

-6

-8

-5

-4

-10

-12

-15

-18

-20

-24

-6

-8

-5

-4

-10

-12

-15

-18

-20

-24

-6

-8

-5

-4

-10

-12

-15

-18

-20

-24

-28

-36

-24

-28

-36

-40

-28

-36

-40

-28

-36

-40

-28

-36

-40

-28

-36

-40

-28

-36

-40

-28

-36

-40

-28

-36

-40

-28

-36

-40

-28

-36

-40

-28

-36

-40

Date:

∞

-46

-

∞

-50

-

∞

-50

-

∞

-50

-

∞

-50

-

∞

-50

-

∞

-50

-

∞

-50

-

∞

-50

-

∞

-50

-

∞

-50

-

∞

-50

-

Made in Germany

Model 1010

-28

∞

-36

-50

-40

-

Page 23

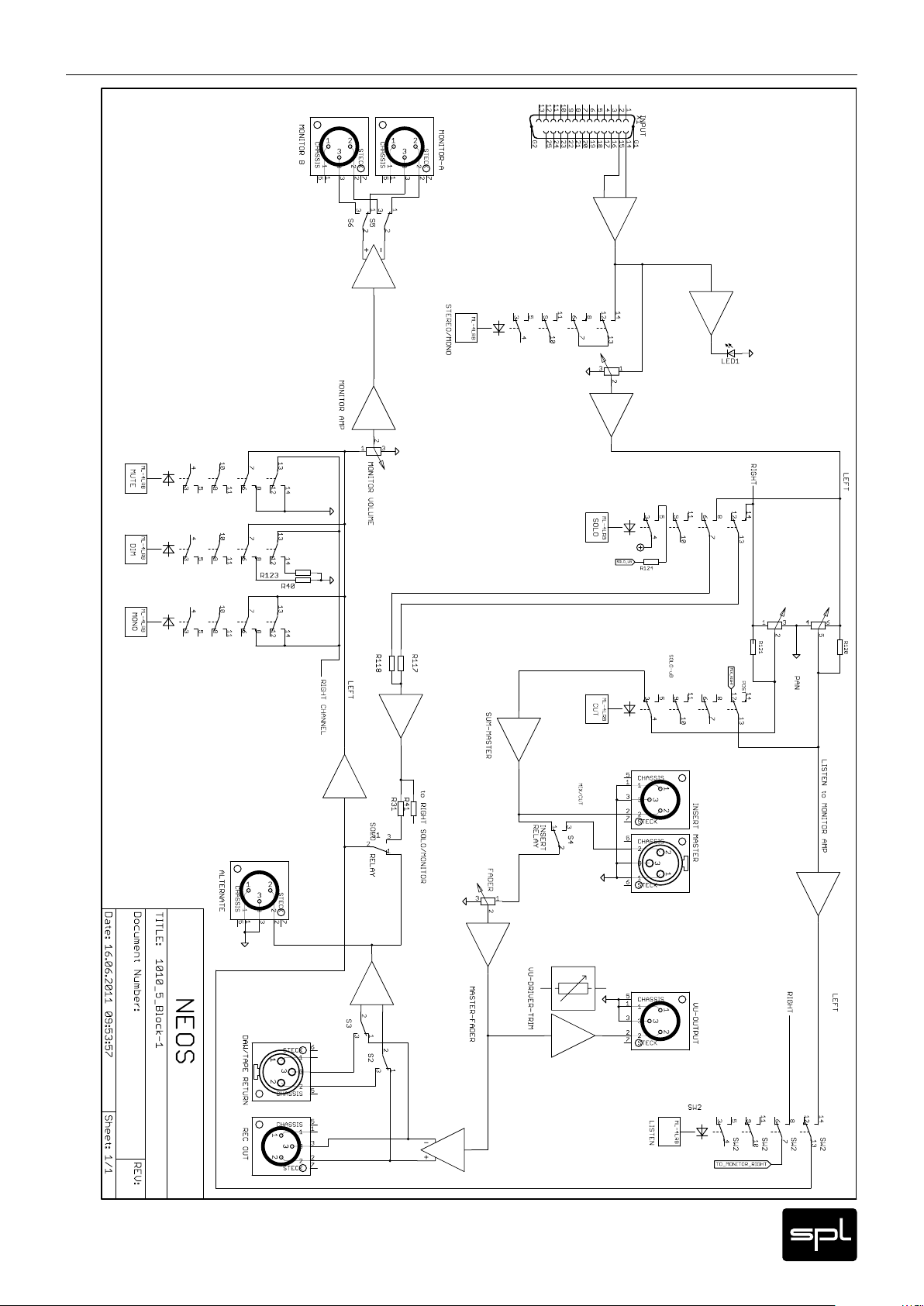

Block Diagram

Neos

23

Page 24

Mounting Dimensions

Dimensions and Weight

Front panel including rack brackets 19 Zoll/7 HE (483 x 310 mm)

Front panel without rack brackets 4 4 0 mm

Housing (W x H x D) 483 x 235 x 330 mm, Depth w, Sockets 355 mm

Fur ther dimensions see diagramm (in millimeters)

Weight 14,1 kg

130

310

62

123

293

24

Neos

Page 25

Zero and ten degree

The Neos comes with 19” rack-mounting side brackets. As you can see here, the holes on the

side of the housing allow for two rack-mounting positions (0 and 10 degrees).

The bracket holes have been designed in order to allow for an easy flush mounting in vertical

or horizontal racks. If it were needed, the brackets can always be adjusted in order to flush

mount the device in the rack. Do consider that all installations, specially without a rack

system, ought to be performed by a specialist and always taking into account the maximum

load capacity.

Mounting Angles

Neos

25

Page 26

Manual Neos

Modell 1010

26

Neos

Loading...

Loading...