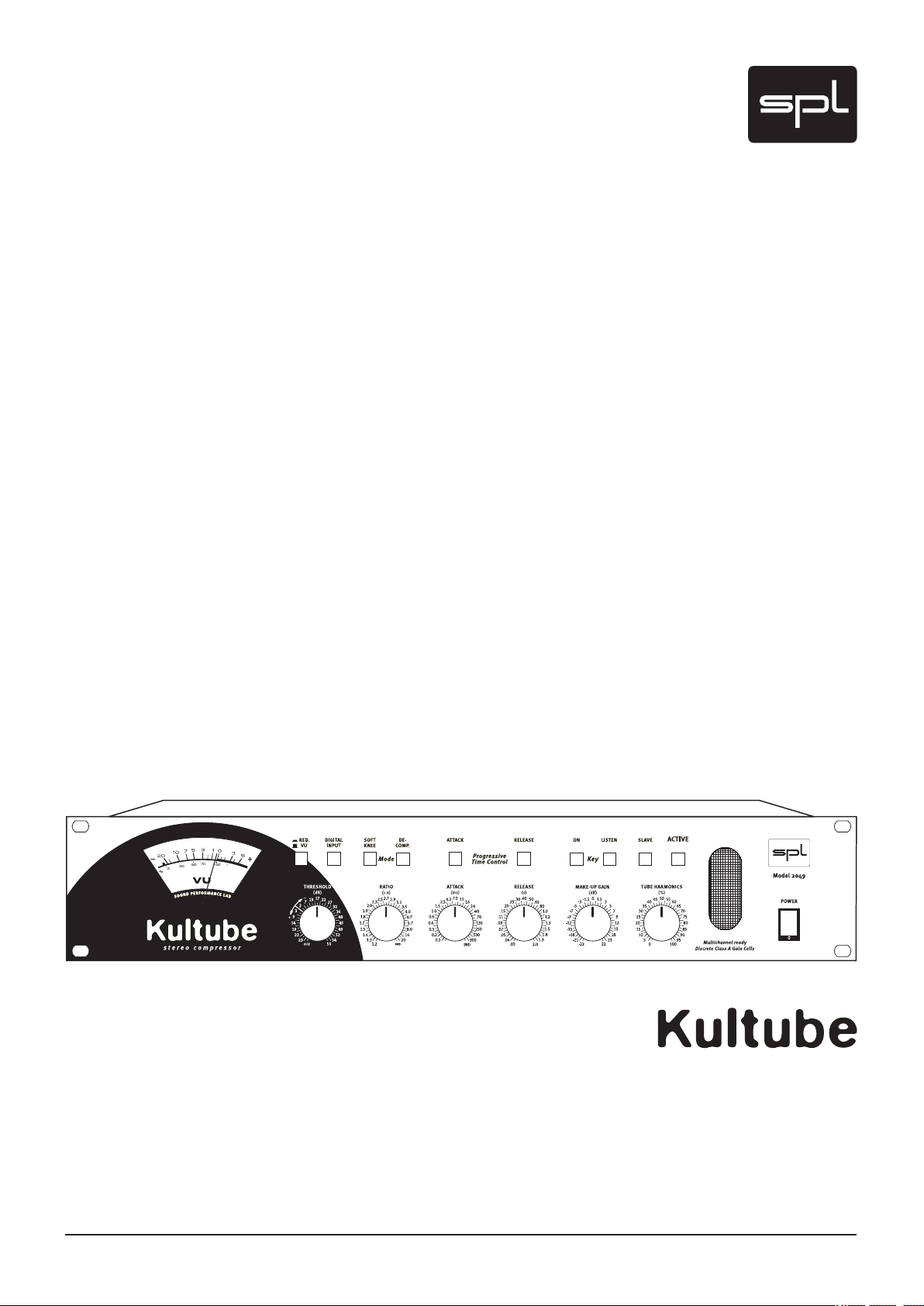

SPL Kultube, 2049 User manual

Manual

Model 2049

Stereo Compressor

2

Kultube (Model 2049)

Manual

Version 1.2 – 11/2008

R & D: Ruben Tilgner

The information in this document has been carefully verified and is assumed

to be correct. However Sound Performance Lab (SPL) reserves the right to

modify the product described in this manual at any time. Changes without

notice. This document is the property of SPL and may not be copied or reproduced in any manner, in part or full without the authorization of SPL.

Limitations of Liability:

In no event will SPL be liable for any damages, including loss of data, lost

profits, cost of cover or other special, incidental, consequential or indirect

damages arising from the use of the unit, however caused and on any theory

of liability. This limitation will apply even if SPL or an authorized dealer has

been advised of the possibility of such damage.

CE Declaration of Conformity

Manufacturer: SPL electronics GmbH

Type of Equipment: Audio Signal Processor

Product: Kultube, Model 2049

Compliance Engineer: Wolfgang Neumann

Test Basis: EN50081-1:1992, EN50082-1:1992, EN60065:1993, EN61000-33:1995, EN60065:2002, EN55013:2001, EN55020:2002, EN61000-3-2:2000,

73/23 EWG; 93/68 EWG.

We herewith declare, that the construction of the Kultube, Model 2049, is in

compliance with the standards and regulations mentioned above.

Notes on environmental protection

At the end of its operating life, this product must not be disposed of

with regular household waste but must be returned to a collection

point for the recycling of electrical and electronic equipment. The

“wheelie bin“ symbol on the product, user‘s manual and packaging

indicates that. The materials can be re-used in accordance with

their markings. Through re-use, recycling of raw materials, or other forms of

recycling of old products, you are making an important contribution to the

protection of our environment. Your local administrative office can advise you

of the responsible waste disposal point.

WEEE Registration: 973 349 88

Sound Performance Lab

SPL electronics GmbH

P.O. Box 12 27

D- 41 368 Niederkruechten, Germany

Phone +49 21 63 98 34 0

Fax +49 21 63 98 34 20

E-Mail: info@soundperformancelab.com

www.soundperformancelab.com

© 2008 SPL electronics GmbH. All rights reserved.

3

Important Security Information ................................................................. 4

Installation, Power Supply ........................................................................ 6

Introduction .............................................................................................. 7

Connections

Rear Panel/Wiring ..................................................................................... 8

General Advices, Sockets & Switches ........................................................ 9

Control Elements

Red. /VU, Digital Input, Softknee, De Comp. ............................................. 11

PTC-Attack, PTC-Release, Key On, Key Listen, Slave, Active ....................... 12

Threshold, Ratio, Release, Make Up Gain .................................................. 13

Tube Harmonics ......................................................................................... 14

Operation – Understanding and enjoying the Kultube

The Threshold Control ............................................................................... 14

The Ratio Control ....................................................................................... 15

The Attack Control ..................................................................................... 16

Progressive Time Control – Attack ............................................................. 17

The Release Control ................................................................................... 18

Progressive Time Control – Release ........................................................... 19

Content

Applications – Using and enjoying the Kultube

Summed Signal Processing ....................................................................... 21

Single Track & Subgroup Processing .......................................................... 21

Side-chain ................................................................................................. 22

Multi Channel and 5.1 Surround Processing ............................................... 23

Specifications ............................................................................................ 24

Guarantee ................................................................................................. 24

4

Important Security Information

Please note and retain this manual. Carefully read and follow all of the safety

and operating instructions before you use the machine.

Be doubly careful to follow all warnings and special safety instructions

noted in this manual and on the unit.

Connections: Only use the connections as described. Other connections can

lead to health risks and equipment damage.

Water And Humidity: Do NOT use this machine anywhere near water (for

example near a wash basin or bath, in a damp cellar, near swimming pools,

or the like). In such cases there is an extremely high risk of fatal electrical

shocks!

Insertion Of Foreign Objects Or Fluids: NEVER allow a foreign object through

any of the machine‘s chassis openings. You can easily come into contact with

dangerous voltage or cause a damaging short circuit. NEVER allow any fluids

to be spilled or sprayed on the machine. Such actions can lead to dangerous

electrical shocks or fire!

Opening the Machine: Do NOT open the machine housing, as there is great

risk you will damage the machine, or – even after being disconnected – you

may receive a dangerous electrical shock!

Electrical Power: Run this machine ONLY from sources which can provide

proper power at the prescribed rating. When in doubt about a source, contact

your dealer or a professional electrician. To be sure you have isolated the

machine, do so by disconnecting the power cord from your wall connection.

Be sure that the power cord plug is always accessible. When not using the

machine for a longer period, make sure to unplug it from your wall power

socket.

Power Cord Protection: Make sure that your power cord is arranged to avoid

being stepped on or any kind of crimping and damage related to such event.

Do not allow any equipment or furniture to crimp this power cord.

Power Connection Overloads: Avoid any kind of overload in connections to

wall sockets, extension or splitter power cords. Always keep manufacturer

warnings and instructions in mind. Overloads create fire hazards and risk of

dangerous shocks!

Lightning: Before thunderstorms or other severe weather, disconnect the

machine from wall power (but to avoid life threatening lightning strikes, not

during a storm). Similarly, before any severe weather, disconnect ALL the

power connections of other machines and antenna and phone/network cables

which may be interconnected so that no lightning damage or overload results

from such secondary connections.

5

Important Security Information

Air Circulation: Chassis openings offer ventilation and serve to protect the

machine from overheating. NEVER cover or otherwise close off these openings. NEVER place the machine on a soft surface (carpet, sofa, etc.). Make

sure to provide for a mounting space of 4-5 cm/2 inches when mounting the

machine in racks or cabinets.

Controls And Switches: Operate the controls and switches only as

described in the manual. Incorrect adjustments outside safe parameters can lead to damage and unnecessary repair costs. Never use the

switches or level controls to effect excessive or extreme changes.

Repairs: Unplug the machine and immediately contact a qualified techni-

cian when you think repairs are needed – or when moisture or foreign objects

may accidentally have gotten in to the housing, or in cases when the machine

may have fallen and shows any sign of having been damaged. This also

applies to any situation in which the machine has not been subjected to any of

these unusual circumstances but still is not functioning normally or its performance is substantially altered.

In cases of damage to the power cord or its plug, first consider turning off the

main circuit breaker before unplugging the power cord.

Replacement/Substitute Parts: Be sure that any service technician uses

original replacement parts or those with identical specifications as the originals. Incorrectly substituted parts can lead to fire, electrical shock, or other

dangers, including further equipment damage.

Safety Inspection: Be sure always to ask a service technician to conduct a

thorough safety check and ensure that the state of the repaired machine is in

all respects up to factory standards.

Cleaning: In cleaning, do NOT use any solvents, as these can damage the

chassis finish. Use a clean, dry cloth (if necessary, with an acid-free cleaning

oil). Disconnect the machine from your power source before cleaning.

6

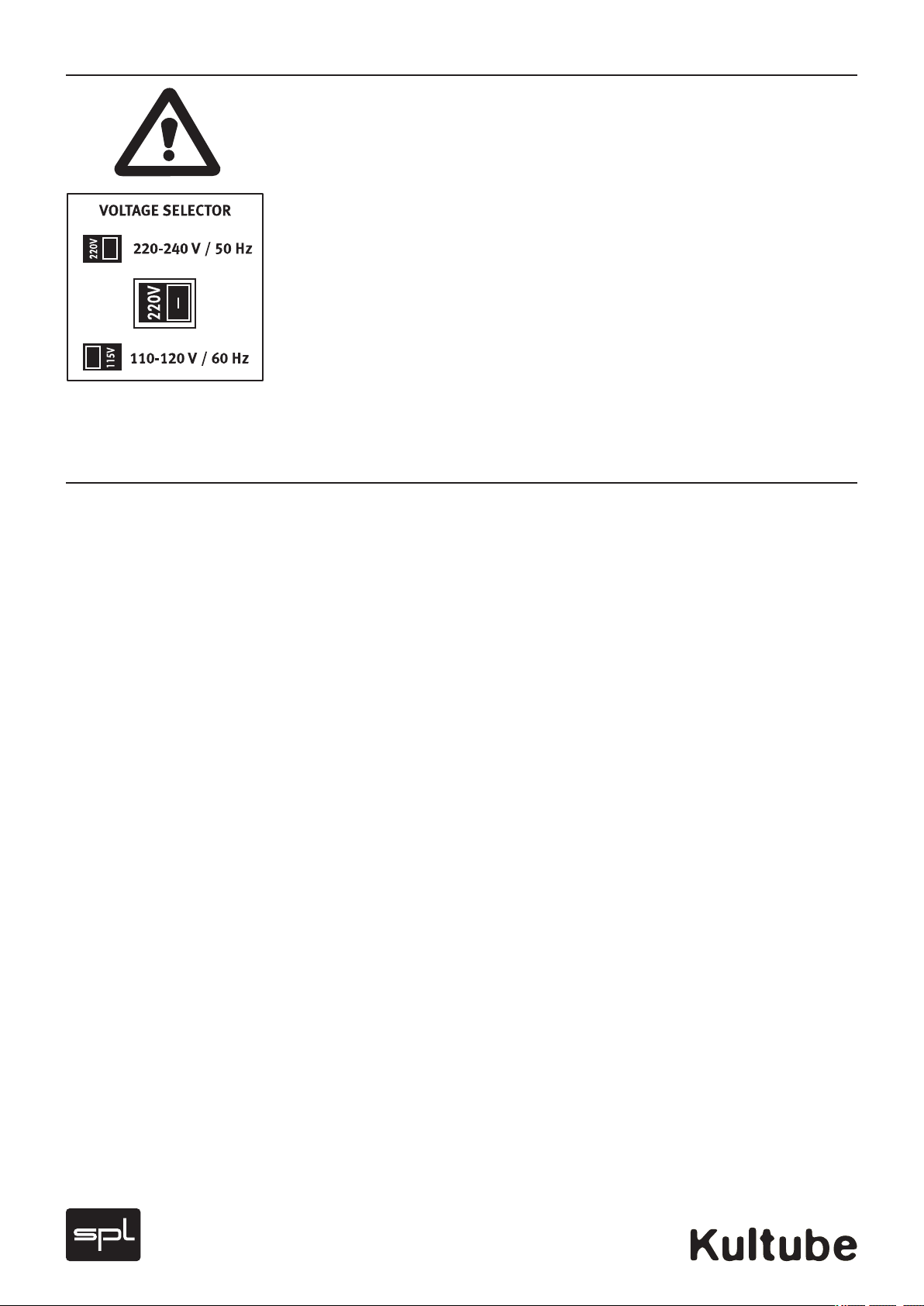

Installation

Power Supply

Be very careful to check that the rear chassis power selection switch is set

to the correct local line voltage position before using the unit (230 V position: 220-240 V/50 Hz, 115 V position: 110-120 V/60 Hz)!

When in doubt about a source, contact your dealer or a professional electrician.

Before connecting any equipment make sure that any machine to be

connected is turned off. Follow all safety instructions from page 5.

Place the unit on a level and stable surface. The unit’s enclosure is EMC-safe

and effectively shielded against HF interference. Nonetheless, you should

carefully consider where you place the unit to avoid electrical disturbances.

The unit should be positioned so that you can easily reach it, but there are

other considerations. Try not to place it near heat sources or in direct sunlight,

and avoid exposure to vibrations, dust, heat, cold or moisture. It should also

be kept away from transformers, motors, power amplifiers and digital processors. Always ensure sufficient air circulation by keeping a distance of 4-5 cm/2

inches to other units and to the sides of the unit.

Built around a toroidal transformer, the power supply has a minimal electromagnetic field to avoid hum or mechanical noise.

The power supply‘s output side is filtered by an RC circuit again to extract

noise and hum from the supplied electrical power.

6000 μf capacitors smooth out the positive and negative half waves. An

additional power supply filter is placed before the power switch to eliminate

disturbing interferences.

All signal processing components are supplied with two separate current

regulators to exclude influences from the remaining components.

The 220 v current for the tube stage power is smoothed out with 200 μF and

stabilized precisely by current regulators. The anode current is switched on

after warm up. Both measures ensure a remarkable extension of the tube‘s

lifetime.

The unit‘s supply voltage can be set to 230 V/50 Hz or 115 V/60 Hz. Check

your local power requirements for the appropriate setting. An AC power cord

is included to feed the IEC-spec, 3-prong connector. Transformer, AC cord

and IEC-receptacle are VDE, UL and CSA approved. The main fuse is rated at

315 mA for 230 v and 630 mA for 115 v. Chassis ground and AC ground can be

physically disconnected with the “GND Lift” switch on the rear panel to eliminate hum.

7

The Kultube user disposes over a unique range of powerful compression

tools ranging from subtle unobtrusive processing to very obvious ‘effect‘

compressions. Used conventionally or as an effect, in professional recording

or mastering applications, the Kultube combines outstanding audio quality

with the acclaimed musicality and user-friendliness that SPL units stand for.

Applications cover those of a classic compressor for vocals and instruments,

in both mono and stereo, through stereo operation for subgroup processing

to stereo mastering and multi-channel/surround projects.

Progressive Time Control

With the unique Progressive Time Control (PTC) option for attack and release,

time constants can be optimized by unique circuitry that reacts both to the

input signal and to the user settings - for example, fast impulses are intercepted by an attack time as fast as 20 us. PTC can be seen as an interactively

controllable automation which is not based on fix presets but reacts to the

audio material in a musically useful way.

Discrete Gain Cells

Introduction

SPL has developed discrete, very high performance gain cells that are used

instead of the usual VCAs and the Kultube is the first product to use them.

They ensure the highest level of musicality and clarity in signal processing

and demonstrate significantly improved distortion values over VCAs.

Tube Harmonics

The adjustable tube saturation of the output stages combined with automatic

output level adjustment can produce tube sound effects that range from the

delicate to the raucous whilst a useful de-compressor mode can reanimate

over-compressed material (such as samples).

Master/Slave Mode

In master/slave mode, any number of devices can be controlled from one

master unit.

Features

• Discrete, high performance gain cells instead of industrial VCAs

• Progressive Time Control: interactively controllable automation for Attack

and Release parameters

• Adjustable tube saturation with output level adjustment

• Selectable soft or hard knee characteristics

• Unique de-compression mode

• Large VU meter displays gain reduction or (mono summed) output level

• Side-chain inputs on the front panel

• Slave mode for multi-channel operation

8

Connections

Further Kultubes

as slaves in multi-

channel link mode

2

1

3

Pin wiring XLR Input:

1=GND 2=Hot (+) 3=Cold (-)

1

2

3

Pin wiring XLR Output:

1 = GND 2 = Hot (+) 3 = Cold (-)

Pin wiring Stereo Jack Connector:

Tip = Hot (+) Ring = Cold (-) Sleeve = GND

Connection to console:

Insert Sends > Analog Inputs

Insert Returns > Analog Outputs

The Kultube can optionally be equipped with a 24 bit/96 kHz converter module

Connector for external

processing units (e. g.

Equalizer)

Rear Panel/Wiring

Loading...

Loading...