Page 1

Manual

7

5

3

1

0

3

5

30

50

70

100

VU

5

3

1

VU

20

1 0

0

%

M

I

C

G

A

I

N

S

-

R

E

D

U

C

T

I

O

N

I

N

S

T

R

U

M

E

N

T

S

-

D

E

T

E

C

T

A

D

-

O

V

L

1

3

1

4

1

5

1

6

1

8

2

0

2

2

2

4

2

6

2

8

3

0

3

3

3

6

3

9

4

2

4

5

5

2

6

1

6

8

I

N

S

T

R

.

G

A

I

N

L

I

N

E

G

A

I

N

R

A

T

I

O

A

T

T

A

C

K

L

M

F

M

H

F

L

M

F

–

/

+

M

H

F

–

/

+

A

I

R

B

A

N

D

T

U

B

E

S

A

T

U

R

A

T

I

O

N

IN S T R.

LIN E I N

TUB E

+1 5 dB

ON ON

MUTE

EQ PRE

C OM P .

EQ / T UB EC OM P .

EXTERNAL INPUTS

DE-ES.

AUTO

48 V PAD

Recording Channel

Ø

M

A

K

E

-

U

P

R

E

L

E

A

S

E

O

U

T

P

U

T

Sound Performance Lab Made in Germany

ON

0

-

1

-

2

-

3

-

4

-

6

-

9

-

1

1

-

1

2

2

1

1

6

1

1

6

0

-

5

-

9

-

1

6

-

2

2

-

3

0

-

3

8

-

4

6

-

5

4

-

5

8

1

.

2

1

.

4

1

.

7

2

.

0

2

.

3

2

.

7

3

.

0

3

.

6

5

.

0

1

6

∞

0

1

0

2

0

3

0

4

0

5

0

6

0

7

0

8

0

9

0

1

0

0

-

2

0

-

1

3

-

7

.

5

-

4

.

5

-

2

0

1

.

5

3

4

5

5

.

5

0

.

1

0

.

2

0

.

4

1

.

0

2

.

5

7

.

0

1

6

4

0

1

3

0

5

3

0

1

0

0

0

0

.

0

3

0

.

0

5

0

.

0

9

0

.

1

5

0

.

2

5

0

.

4

0

.

6

5

1

.

0

1

.

3

1

.

8

2

.

0

0

0

.

5

1

2

3

4

5

6

7

8

9

1

0

1

2

1

4

1

6

1

9

2

0

-

1

2

-

1

0

-

5

-

2

.

5

0

2

.

5

5

7

.

5

1

0

1

2

-

1

2

-

1

0

-

5

-

2

.

5

0

2

.

5

5

7

.

5

1

0

1

2

-

1

0

-

8

-

6

-

4

-

2

0

2

4

6

8

1

0

6

8

0

8

2

0

1

k

0

1

k

5

2

k

7

3

k

4

4

k

5

6

k

5

1

0

k

1

3

k

1

5

k

3

0

4

0

5

0

8

0

1

2

5

1

6

0

2

0

0

3

0

0

5

0

0

6

4

0

7

0

0

Model 2800

GRVU VU PPM 0 dB - 1 0 dB

T

H

R

E

S

H

O

L

D

Frontliner

6

8

1

1

1

4

1

7

1

9

2

1

2

3

2

5

2

6

2

7

2

9

3

2

3

5

3

7

3

9

4

1

4

2

4

3

-

2

0

-

1

8

-

1

2

-

9

0

3

9

1

0

dB 1 :x dB dB

dB dBHz

Hz %

ms s

dB dB

dB

Frontliner

Model 2800

Recording channel with separate module inputs and outputs

Page 2

2

Frontliner

Manual Frontliner, Model 2800

Version 1.0– 6/2009

Designer: Jens Gronwald

This manual contains a description of the product. It in no way represents a guarantee of

particular characteristics or results of use. The information in this document has been carefully compiled and veried and, unless otherwise stated or agreed upon, correctly describes

the product at the time of packaging with this document.

Sound Performance Lab (SPL) continuously strives to improve its products and reserves the

right to modify the product described in this manual at any time without prior notice. This

document is the property of SPL and may not be copied or reproduced in any manner, in part

or fully, without prior authorization by SPL.

SPL electronics GmbH

Sohlweg 80, 41372 Niederkruechten, Germany

Phone +49 (0)2163 983 40

Fax +49 (0)2163 983 420

E-Mail: info@spl.info

Internet: www.spl.info

The construction of the Frontliner, Model 2800, is in compliance with the standards and regulations of the European Community.

Notes on Environmental Protection

At the end of its operating life, this product must not be disposed of with regular

household waste but must be returned to a collection point for the recycling of

electrical and electronic equipment. The wheelie bin symbol on the product,

user‘s manual and packaging indicates that. The materials can be re-used in

accordance with their markings. Through re-use, recycling of raw materials, or

other forms of recycling of old products, you are making an important contribution to the

protection of our environment. Your local administrative ofce can advise you of the responsible waste disposal point.

WEEE Registration: 973 349 88

© 2009 SPL electronics GmbH. All rights reserved. Names of other companies and their

products are trademarks of their respective owners.

Page 3

3

Frontliner

Symbols & Notes ............................................................................... 4

Scope of Delivery & Packaging ................................................................ 4

Important Security Information ............................................................... 4

Hook Up .......................................................................................... 5

Introduction ..................................................................................... 6

The Frontliner concept, Analog plug-ins ................................................... 6

Special technical features, Options ........................................................ 7

REAR PANEL ..................................................................................... 8

Standard wiring channel strip .............................................................. 8

Wiring examples: live and studio ............................................................ 9

Wiring examples: group of modules, Inserts ............................................. 1 0

Rear panel/sockets ........................................................................ 1 0

Signal connections, TRS socket, XLR sockets,

Balanced connections, Unbalanced connections ......................................... 11

Separate inputs and outputs, Preamplier: MIC IN,

Preamplier: LINE IN, Preamplier: OUT, De-Esser: IN and OUT ......................... 1 2

Compressor: IN and OUT, Equalizer/Tube Sat.: IN and OUT,

Main Outs OUT1 and OUT 2, AD Input 2, Power connection and fuses ................... 13

Rear Panel/Switches ....................................................................... 1 4

Voltage selector, Power switch, 48 V phantom power/rear switches, GND Lift .......... 14

CONTROL ELEMENTS ........................................................................... 1 5

Preamplier ................................................................................. 1 5

MIC GAIN, MIC GAIN adjustments, 48 V, Activating phantom power ..................... 15

Phase reverse, High-pass lter, PAD, Instrument input ................................... 16

LINE GAIN/INSTR. GAIN, LINE GAIN and INSTR. GAIN adjustments,

INSTR. LINE IN, TUBE +15 dB ................................................................ 17

De-Esser .................................................................................... 1 8

ON, S-REDUCTION, SPL De-Esser technology ............................................. 18

Compressor/Limiter ........................................................................ 19

ON, THRESHOLD, RATIO, ATTACK .......................................................... 19

ATTACK with cruise control: Auto Mode, RELEASE,

RELEASE with cruise control: AUTO-Mode, MAKE UP ..................................... 20

Equalizer/Tube Saturation ................................................................. 21

ON, EQ PRE COMP., MHF (mid-/hi lter), MHF -/+ (cut/boost MHF)

LMF (low/Mid lter), LMF -/+ (cut/boost LMF),

AIR BAND, TUBE SATURATION .............................................................. 22

VU-Meter .................................................................................... 23

VU-Meter, VU/GR switch, 0 dB/-10 dB switch, VU/PPM switch ............................ 23

Output ....................................................................................... 24

OUTPUT, AD OVL-LED, MUTE switch ...................................................... 24

External Inputs ............................................................................. 25

Excluding a single module, Excluding a group of two or three modules, Ungroup ...... 25

Determining inserts, Key lock, Keys and switches ......................................... 26

2 1

Content

Options .......................................................................................... 27

24/96 A/D converter model 2376, Information on I/O transformers ... . . .. .. .. .. . .. .. .. . 27

Specications ................................................................................... 28

Copy master: recall settings ................................................................... 30

Block diagrams .................................................................................. 31

Table Switch Logic .............................................................................. 33

Page 4

4

Frontliner

Symbole and Notes

IN THIS MANUAL A LIGHTNING SYMBOL WITHIN A TRIANGLE WARNS YOU ABOUT THE

POTENTIAL FOR DANGEROUS ELECTRICAL SHOCKS – WHICH CAN ALSO OCCUR EVEN AFTER

THE MACHINE HAS BEEN DISCONNECTED FROM A POWER SOURCE.

AN EXCLAMATION MARK (!) WITHIN A TRIANGLE IS INTENDED TO MAKE YOU AWARE OF

IMPORTANT OPERATIONAL ADVICE AND/OR WARNINGS THAT MUST BE FOLLOWED. BE

ESPECIALLY ATTENTIVE TO THESE AND ALWAYS FOLLOW THE ADVICE THEY GIVE.

The symbol of a lamp directs your attention to explanations of important functions or applications.

Attention: Do not attempt any alterations to this machine without the approval or supervision

of SPL electronics GmbH. Doing so could nullif y completely any and all of your warranty/guarantee rights and claims to user support.

Scope of Delivery & Packaging

The scope of delivery comprises the Cabulator, the external power supply, the guarantee card

and this manual.

Please keep the original packaging. In case of a service procedure the original packaging

ensures a safe transport. It also serves as a safe packaging for your own transports if you do

not use special transportation cases.

Important Security Information

Please note and retain this manual. Carefully read and follow all of the safety and operating

instructions before you use the machine. Be doubly careful to follow all warnings and special

safety instructions noted in this manual and on the unit.

Connections: Only use the connections as described. Other connections can lead to health

risks and equipment damage.

Water and humidity: Do not use this machine anywhere near water (for example near a wash

basin or bath, in a damp cellar, near swimming pools, or the like). In such cases there is an

extremely high risk of fatal electrical shocks!

Insertion of foreign objects or uids: Never allow a foreign object through any of the

machine‘s chassis openings. You can easily come into contact with dangerous voltage or

cause a damaging short circuit. Never allow any uids to be spilled or sprayed on the machine.

Such actions can lead to dangerous electrical shocks or re!

Opening the unit: Do not open the machine housing, as there is great risk you will damage the

machine, or – even after being disconnected – you may receive a dangerous electrical shock!

Electrical power: Run this machine only from power sources which can provide proper power

in the range from 100 to 250 volts. When in doubt about a source, contact your dealer or a

professional electrician. To be sure you have isolated the machine, do so by disconnecting all

power and signal connections. Be sure that the power supply plug is always accessible. When

not using the machine for a longer period, make sure to unplug it from your wall power socket

and from the guitar amp.

Cord protection: Make sure that your power and guitar amplier signal cords are arranged

to avoid being stepped on or any kind of crimping and damage related to such event. Do not

allow any equipment or furniture to crimp the cords.

Power connection overloads: Avoid any kind of overload in connections to wall sockets,

extension or splitter power cords, or to signal inputs. Always keep manufacturer warnings

and instructions in mind. Overloads create re hazards and risk of dangerous shocks! >

Page 5

5

Frontliner

Lightning: Before thunderstorms or other severe weather, disconnect the machine from wall

power (but to avoid life threatening lightning strikes, not during a storm). Similarly, before

any severe weather, disconnect all the power connections of other machines and antenna and

phone/network cables which may be interconnected so that no lightning damage or overload

results from such secondary connections.

Air circulation: Chassis openings offer ventilation and serve to protect the machine from overheating. Never cover or otherwise close off these openings. Never place the machine on a soft

surface (carpet, sofa, etc.). Make sure to provide for a mounting space of 4-5 cm/2 inches to

the sides and top of the unit when mounting the unit in racks or on cabinets.

Controls and switches: Operate the controls and switches only as described in the manual.

Incorrect adjustments outside safe parameters can lead to damage and unnecessary repair

costs. Never use the switches or level controls to effect excessive or extreme changes.

Repairs: Unplug the unit from all power and signal connections and immediately contact a qualied technician when you think repairs are needed – or when moisture or foreign objects may accidentally have gotten in to the housing, or in cases when the machine may have fallen and shows

any sign of having been damaged. This also applies to any situation in which the unit has not

been subjected to any of these unusual circumstances but still is not functioning normally or its

performance is substantially altered.

In cases of damage to the power supply and cord, rst consider turning off the main circuit

breaker before unplugging the power cord.

Replacement/substitute parts: Be sure that any ser vice technician uses original replacement

parts or those with identical specications as the originals. Incorrectly substituted parts can

lead to re, electrical shock, or other dangers, including further equipment damage.

Important Security Information

Safety inspection: Be sure always to ask a service technician to conduct a thorough safety

check and ensure that the state of the repaired machine is in all respects up to factor y standards.

Cleaning: In cleaning, do not use any solvents, as these can damage the chassis nish. Use

a clean, dry cloth (if necessary, with an acid-free cleaning oil). Disconnect the machine from

your power source before cleaning.

Be very careful to check that the rear chassis power selection switch is set to the correct

local line voltage position before using the unit (230 V position: 220-240 V/50 Hz, 115 V position: 110-120 V/60 Hz)! When in doubt about a source, contact your dealer or a professional

electrician.

Before connecting any equipment make sure that any machine to be connected is turned off.

Follow all safety instructions on pages 4 and 5 and read further information on connections

on pages 8, 9 an 10.

Place the unit on a level and stable surface. The unit’s enclosure is EMC-safe and effectively

shielded against HF interference. Nonetheless, you should carefully consider where you place

the unit to avoid electrical disturbances. It should be positioned so that you can easily reach

it, but there are other considerations. Try not to place it near heat sources or in direct sunlight,

and avoid exposure to vibrations, dust, heat, cold or moisture. It should also be kept away

from transformers, motors, power ampliers and digital processors. Always ensure sufcient

air circulation by keeping a distance of 4-5 cm/2 inches to the sides and top of the unit.

Hook Up

Page 6

6

Frontliner

Introduction

Our preceding recording channels Track One and Channel One have already been

successful units by combining fast and easy operation with high processing quality. These

channel strips particularly benefit from previous developments for single processors: the

DynaMaxx compressor/limiter delivered the essentials for the respective channel strip

stage, the unique SPL De-Esser is also available as a single, dual-channel unit – and the

preamplifier modules were also derived from existing products.

The development of new units in the last years inevitably evoked the wish to conceive a

new channel strip which would benefit from our latest achievements.

Now the Frontliner comprises the same discrete, hybrid semiconductor/tube preamplifier design like the GoldMike MK2. The compressor module is based upon the Kultube

providing a full set of classic controls. We also integrated the Kultube's highlight, a signaldependent automation of attack and release parameters which can still be influenced

manually – with this option, manual and automatic control can be merged to always f ind

the best settings.

The EQ section provides two semi-parametric filters for low and mid band as well as a bell

filter delivering a silky and smooth top end. This filter set offers a perfect frequency first

aid kit and is rounded off with a Tube Saturation control.

In contrast to semiconductors, a tube does not clip from a certain level, but approaches its

limits by increasingly producing harmonic distortions. The sound effects from saturating

a tube can often be used to improve the audio signal. The sound results resemble tape

saturation effects and increase the density and perceived energy in a very pleasant way.

The Frontliner concept

The Frontliner comprises a hybrid semiconductor/tube preamplifier with microphone,

line and instrument input, a de-esser, a compressor/limiter and an EQ section with tube

saturation stage. In addition to its primary function as a recording channel with all tools

onboard to process a signal prior to storing, its modules can also serve for high-end

analog processing during mixing.

The enumeration of the Frontliner’s modules also makes clear that the task of a channel

strip is relatively complex. There is not one specialized device for one job, but a unit that

combines a lot of technology for the preamplification and processing of audio signals. That

is why especially the Frontliner benefits very much from SPL’s innovations for targeted,

efficient work. The SPL De-Esser, for example, performs a highly complex processing, but

can simply be adjusted with one single knob.

The straight and clear front panel design also suppor ts fast and safe operation.

Analog plug-ins

In the last years we have been busy with modular concepts. One result is the RackPack

series: a RackPack frame hosts up to eight 3U high modules for free placement and (inter-)

connection.

But we have also transferred the modular idea to the Frontliner. Each Frontliner module

disposes of its own inputs and outputs. Sophisticated switching options allow to integrate Frontliner’s modules into a studio environment as if they were stand-alone devices.

You can also group modules in any combination and you can determine inserts at each

module’s input.

If you imagine the Frontliner modules as analog plug-ins, the additional value suddenly

becomes apparent: this channel strip also is a versatile analog processing station. With

one single unit, especially DAW based studios benefit from a first-class recording frontend and have access to high end analog processors for the main signal processing tasks.

Page 7

7

Frontliner

Special technical features

• Three separate, individually optimized inputs for microphones, line signals and instruments.

• Discrete semiconductor/tube hybrid preamplif ier to combine the advantages – high

dynamic range and low noise operation of semiconductors with the musical qualities of

tube sounds (appealing top end, beautiful spacial impression). Discrete construction is

based upon single transistors instead of integrated circuits (ICs) from industrial production

and ensures a higher level of optimization.

• 250 volts tube circuits in the preamplifier and for tube saturation stages.

• High-grade operational amplifiers from Burr-Brown at critical positions.

• The SPL De-Esser applies the method of phase cancellation for reducing sibilants. This

innovative approach works much more neutral than traditional compression methods – a

unique method for unobtrusive results and extremely fast operation.

• The compressor is operated by SPL’s double VCA drive circuitry. A differential stage elimi-

nates side effects and the half load per VCA dramatically reduces THD.

• The operational amplifiers for the compressor circuitry meet military specifications.

Therefore the regulating voltages are extremely precise – a precondition for high signal

processing quality.

• Selected condensers for the EQ filters with pleasant sound characteristics. Especially with

vocals, amplified frequencies are not sounding too bright, and on the other hand reductions can tame harsh sounds without sounding dull.

Introduction

• Central star ground wiring scheme minimizes influences that could affect the ground paths.

The audio ground is separated from the ground of the remaining equipment. This leads, in

the truest sense of the word ”clean”, to considerably improved tonal quality.

• The power supply is built around two toroidal transformers, one for the audio voltages and

one for the other supply voltages (tube heating, LEDs, micro controller etc.) Mutual interferences are excluded and lavishly over-dimensioned capacities ensure absolutely stable

supplies for all audio circuitries.

Options

• Lundahl input transformer for the microphone input. The input transformers add ca. 14 dB

gain (depending on the microphone). This must be added to the scaled values. The additional passive gain relieves the preamplifier electronics at any gain level. Microphone input

transformers are highly recommended for ribbon microphones, as they are demanding a lot

of amplification.

• OUT 1 from the MAIN OUTPUTS can optionally be equipped with an output transformer from

Lundahl.

• The Frontliner can optionally be equipped with a digital output 24bit/96 kHz AD converter

card, model 2376). The Frontliner is a mono channel strip. An additional socket at the rear

panel (AD Input 2) allows to feed the dual-channel converter with feed a second signal

source.

• Refer to page 27 for further information on the optional equipment.

Page 8

8

Frontliner

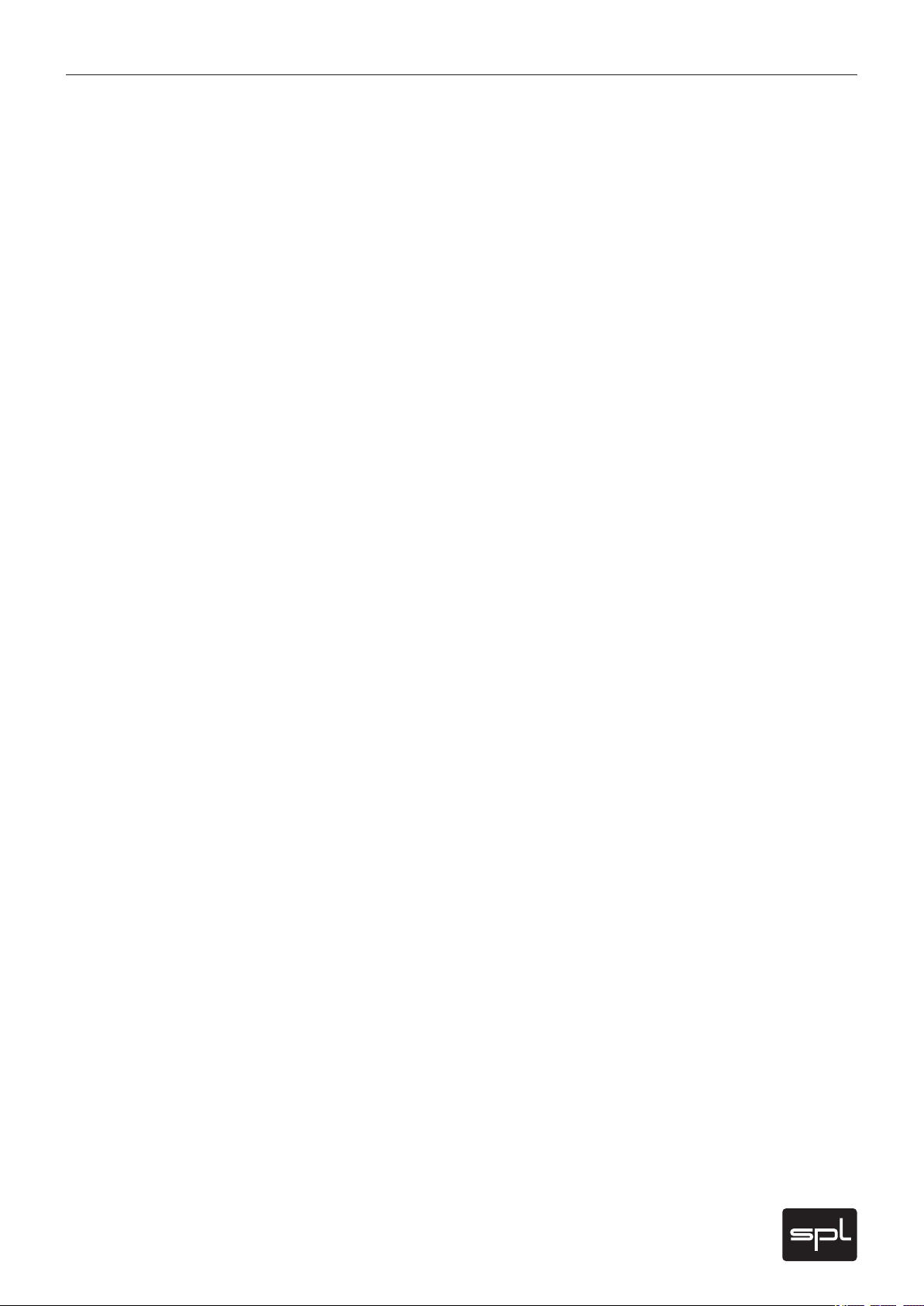

Standard wiring channel strip

Rear Panel

MIC IN

DISABLE

48V ON

FRONT

48V

ON

LINE IN

LINE IN

OUT

OUT

IN

IN

OUT

OUT

230V ~50Hz

Fuse: 315m A slow

115V ~60Hz

Fuse: 630 mA slow

A D IN PU T 2

TO REDUCE RISK OF FIRE OR EL ECTRIC SHOCK

DO NOT EXPOSE T HIS UNIT

TO RAIN OR MOIS TURE.

THIS EQUIPMENT MUST BE E ARTHED.

WARNING

M AI N S IN P UT

MAINS INPUT

AVIS: RISQUE DE CHOC ÉLEC TRIQUE - NE PAS OUVRIR

RISK OF ELECTRIC SHO CK

DO NOT OPEN

CAUTION

DISCRETE T UBE PREAMPLIFI ER

CONNECTOR WI RING

D IS CR E TE TU BE PR E AM P LI F IE R

DE-ESSER

D E- E S SE R

IN

IN

OUT

OUT

COMPRESSOR / L IM.

CO M PR E SS O R / L IM .

IN

IN

OUT

OUT

EQUALIZER / TUB E SAT.

EQ U AL I ZE R / T UB E S AT .

OUT 2

OUT 2

OUT 1

OUT 1

MAIN OUTPUT S

M A IN OU T P U TS

S P L CO N VE R TE R S L OT – OP T IO N AL

SPL CONVER TER SLOT – OPTI ONAL

CONVERTER SER IAL #

SoundPerformanceLab.com

MADE IN GERMAN Y

FRONTLINER SERI AL # OPTIONS

GND LIFT

GND LIFT

GND

GN D L IF T

POWER

P OW E R

VO L TA GE | F U SE

VOLTAGE | FUSE

XLR WIRING: PIN 1 = GN D / PIN 2 = HOT (+) / PIN 3 = COLD (–)

TRS WIRING: TI P = LEFT / RING = RIGHT / SLEEVE = G ND

AD INPUT 2

0

Make sure that

the voltage switch setting

reflects the correct

local power line voltage.

Each of the two MAIN OUTPUTS is fed by its own

driver stage to provide an independent connection for parallel use.

Make sure that the

48V ON switch is only

activated if the microphone

needs phantom power supply.

Monitoring Recording

Monitor FOH console

Line signals

Synthesizer, sampler etc.

Microphone

Instruments

1/4" TRS jack front panel

Interface/DAW

P. A.

Pin wiring 1/4" TRS socket (stereo jack):

tip=left, ring=right, sleeve=ground

Pin wiring XLR input sockets:

1=ground, 2=hot (+), 3=cold (-)

Pin wiring XLR output sockets:

1=ground, 2=hot (+), 3=cold (-)

PUSH

2

1

3

21

3

Page 9

9

Frontliner

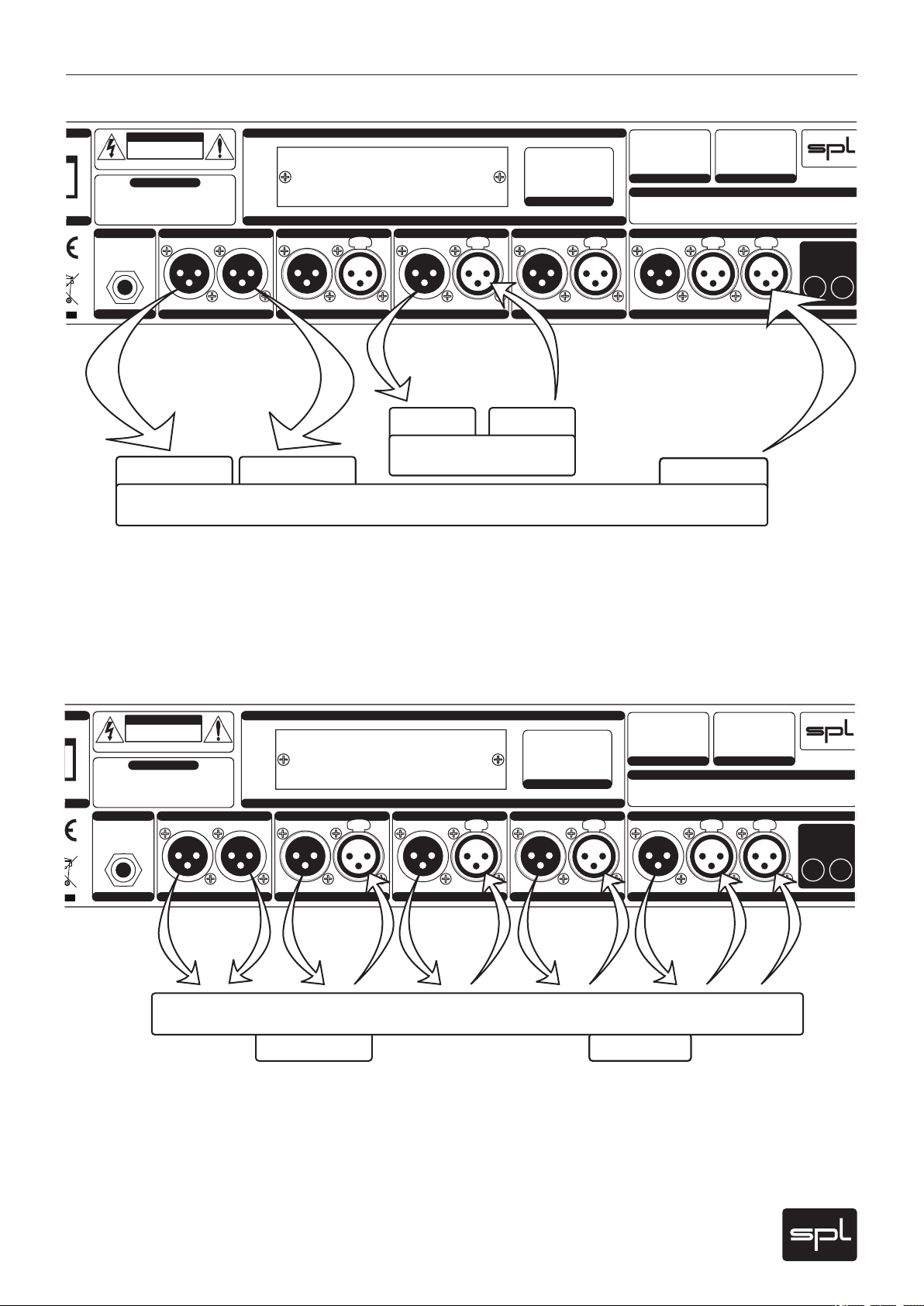

Wiring examples: live and studio

MIC IN

DISABLE

48V ON

FRONT

48V

ON

LINE IN

LINE IN

OUT

OUT

IN

IN

OUT

OUT

A D IN PU T 2

TO REDUCE RISK OF FIRE OR ELECTRIC SHOCK

DO NOT EXPOSE T HIS UNIT

TO RAIN OR MOIS TURE.

THIS EQUIPMENT MUST BE E ARTHED.

WARNING

AVIS: RISQUE DE CHOC ÉLEC TRIQUE - NE PAS OUVRIR

RISK OF ELECTRIC SHO CK

DO NOT OPEN

CAUTION

DISCRETE T UBE PREAMPLIFI ER

CONNECTOR WI RING

D IS CR E TE TU BE PR E AM P LI F IE R

DE-ESSER

D E- E S SE R

IN

IN

OUT

OUT

COMPRESSOR / L IM.

CO M PR E SS O R / L IM .

IN

IN

OUT

OUT

EQUALIZER / TUB E SAT.

EQ U AL I ZE R / T UB E S AT .

OUT 2

OUT 2

OUT 1

OUT 1

MAIN OUTPUT S

M A IN OU T P U TS

S P L CO N VE R TE R S L OT – OP T IO N AL

SPL CONVER TER SLOT – OPTI ONAL

CONVERTER SER IAL #

SoundPerformanceLab.com

MADE IN GERMAN Y

FRONTLINER SERI AL # OPTIONS

P OW E R

XLR WIRING: PIN 1 = GN D / PIN 2 = HOT (+) / PIN 3 = COLD (–)

TRS WIRING: TI P = LEFT / RING = RIGHT / SLEEVE = G ND

AD INPUT 2

Console

DAW

Patchbay

MIC IN

DISABLE

48V ON

FRONT

48V

ON

LINE IN

LINE IN

OUT

OUT

IN

IN

OUT

OUT

A D IN PU T 2

TO REDUCE RISK OF FIRE OR ELECTRIC SHOCK

DO NOT EXPOSE T HIS UNIT

TO RAIN OR MOIS TURE.

THIS EQUIPMENT MUST BE E ARTHED.

WARNING

AVIS: RISQUE DE CHOC ÉLEC TRIQUE - NE PAS OUVRIR

RISK OF ELECTRIC SHO CK

DO NOT OPEN

CAUTION

DISCRETE T UBE PREAMPLIFI ER

CONNECTOR WI RING

D IS CR E TE TU BE PR E AM P LI F IE R

DE-ESSER

D E- E S SE R

IN

IN

OUT

OUT

COMPRESSOR / L IM.

CO M PR E SS O R / L IM .

IN

IN

OUT

OUT

EQUALIZER / TUB E SAT.

EQ U AL I ZE R / T UB E S AT .

OUT 2

OUT 2

OUT 1

OUT 1

MAIN OUTPUT S

M A IN OU T P U TS

S P L CO N VE R TE R S L OT – OP T IO N AL

SPL CONVER TER SLOT – OPTI ONAL

CONVERTER SER IAL #

SoundPerformanceLab.com

MADE IN GERMAN Y

FRONTLINER SERI AL # OPTIONS

P OW E R

XLR WIRING: PIN 1 = GN D / PIN 2 = HOT (+) / PIN 3 = COLD (–)

TRS WIRING: TI P = LEFT / RING = RIGHT / SLEEVE = G ND

AD INPUT 2

2: Monitor 1: Console

Microphone

BassConsole

Channel strip for vocals

Compressor for bass

Live application: channel strip for vocals, one module used separately

Rear Panel

An example for a live setup: The compressor module is separated from the channel strip.

The vocal signal can be processed with all remaining modules, while the compressor is used

for processing bass. In the same way, each module can be taken out of the channel strip,

e. g. using the De-Esser separately while processing an acoustic guitar with the (remaining)

channel strip and so on. Detailed information on page 25.

Studio application: all inputs and outputs are routed to a patchbay

Our recommendation for studio wiring: all inputs and outputs are connected to a patchbay so

that each Frontliner module can be routed with maximum flexibility within a studio environment. Connections to a console or to DAW interfaces for example can always be configured

to meet the respective requirements. Aside from the switching options that the Frontliner

provides the sequence of modules can be determined in any way with the patchbay.

Page 10

10

Frontliner

Rear Panel

MIC IN

DISABLE

48V ON

FRONT

48V

ON

LINE IN

LINE IN

OUT

OUT

IN

IN

OUT

OUT

A D IN PU T 2

TO REDUCE RISK OF FIRE OR ELECTRIC SHOCK

DO NOT EXPOSE T HIS UNIT

TO RAIN OR MOIS TURE.

THIS EQUIPMENT MUST BE E ARTHED.

WARNING

AVIS: RISQUE DE CHOC ÉLEC TRIQUE - NE PAS OUVRIR

RISK OF ELECTRIC SHO CK

DO NOT OPEN

CAUTION

DISCRETE T UBE PREAMPLIFI ER

CONNECTOR WI RING

D IS CR E TE TU BE PR E AM P LI F IE R

DE-ESSER

D E- E S SE R

IN

IN

OUT

OUT

COMPRESSOR / L IM.

CO M PR E SS O R / L IM .

IN

IN

OUT

OUT

EQUALIZER / TUB E SAT.

EQ U AL I ZE R / T UB E S AT .

OUT 2

OUT 2

OUT 1

OUT 1

MAIN OUTPUT S

M A IN OU T P U TS

S P L CO N VE R TE R S L OT – OP T IO N AL

SPL CONVER TER SLOT – OPTI ONAL

CONVERTER SER IAL #

SoundPerformanceLab.com

MADE IN GERMAN Y

FRONTLINER SERI AL # OPTIONS

P OW E R

XLR WIRING: PIN 1 = GN D / PIN 2 = HOT (+) / PIN 3 = COLD (–)

TRS WIRING: TI P = LEFT / RING = RIGHT / SLEEVE = G ND

AD INPUT 2

Signal input (line)

Option: use single outputs

2: Monitoring, 1: Recording

MIC IN

DISABLE

48V ON

FRONT

48V

ON

LINE IN

LINE IN

OUT

OUT

IN

IN

OUT

OUT

A D IN PU T 2

TO REDUCE RISK OF FIRE OR ELECTRIC SHOCK

DO NOT EXPOSE T HIS UNIT

TO RAIN OR MOIS TURE.

THIS EQUIPMENT MUST BE E ARTHED.

WARNING

AVIS: RISQUE DE CHOC ÉLEC TRIQUE - NE PAS OUVRIR

RISK OF ELECTRIC SHO CK

DO NOT OPEN

CAUTION

DISCRETE T UBE PREAMPLIFI ER

CONNECTOR WI RING

D IS CR E TE TU BE PR E AM P LI F IE R

DE-ESSER

D E- E S SE R

IN

IN

OUT

OUT

COMPRESSOR / L IM.

CO M PR E SS O R / L IM .

IN

IN

OUT

OUT

EQUALIZER / TUB E SAT.

EQ U AL I ZE R / T UB E S AT .

OUT 2

OUT 2

OUT 1

OUT 1

MAIN OUTPUT S

M A IN OU T P U TS

S P L CO N VE R TE R S L OT – OP T IO N AL

SPL CONVER TER SLOT – OPTI ONAL

CONVERTER SER IAL #

SoundPerformanceLab.com

MADE IN GERMAN Y

FRONTLINER SERI AL # OPTIONS

P OW E R

XLR WIRING: PIN 1 = GN D / PIN 2 = HOT (+) / PIN 3 = COLD (–)

TRS WIRING: TI P = LEFT / RING = RIGHT / SLEEVE = G ND

AD INPUT 2

2: Monitor 1: DAW

Microphone

SendReturn

Channel strip

External processor

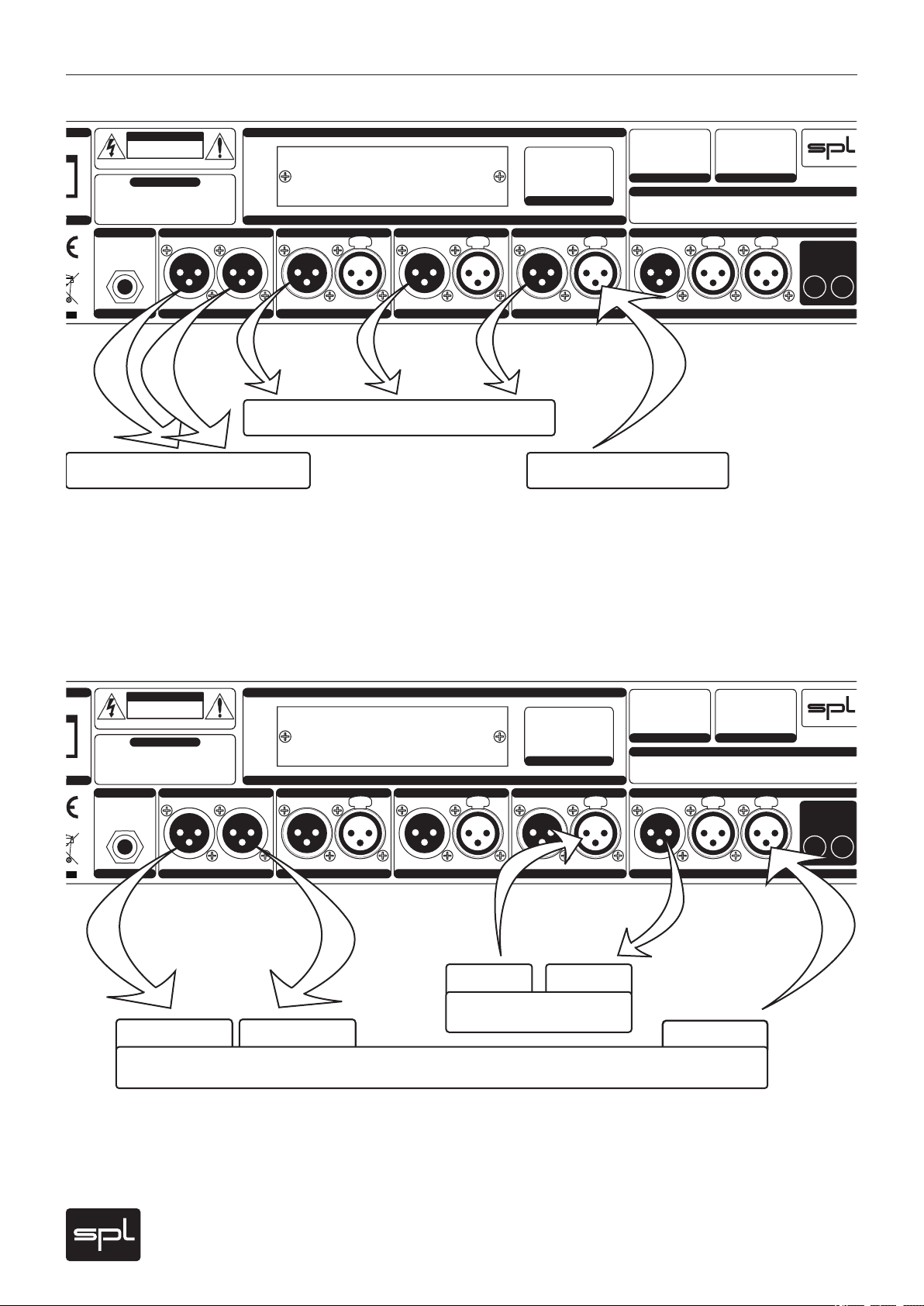

Wiring examples: group of modules, inserts

Excluding a group of modules from the channel strip

This example shows the exclusion of de-esser, compressor and EQ/tube saturation as a

group. The input signal is connected to the input of the first module. If all three processors are

excluded as a group, the output signal of the group is present at the MAIN OUTPUTS. If a dual

processor group is excluded, the output of the last module is always the group output. In the

example above the preamplifier can be used separately via its own I/Os. Further information

on page 25.

Determining inserts for external processors

You can determine inserts between every processing module. In the example above, an insert

is determined between preamplifier and de-esser. The insert is routed via preamplifier output

and de-esser input as send and return. Refer to page 26 for further information.

Page 11

11

Frontliner

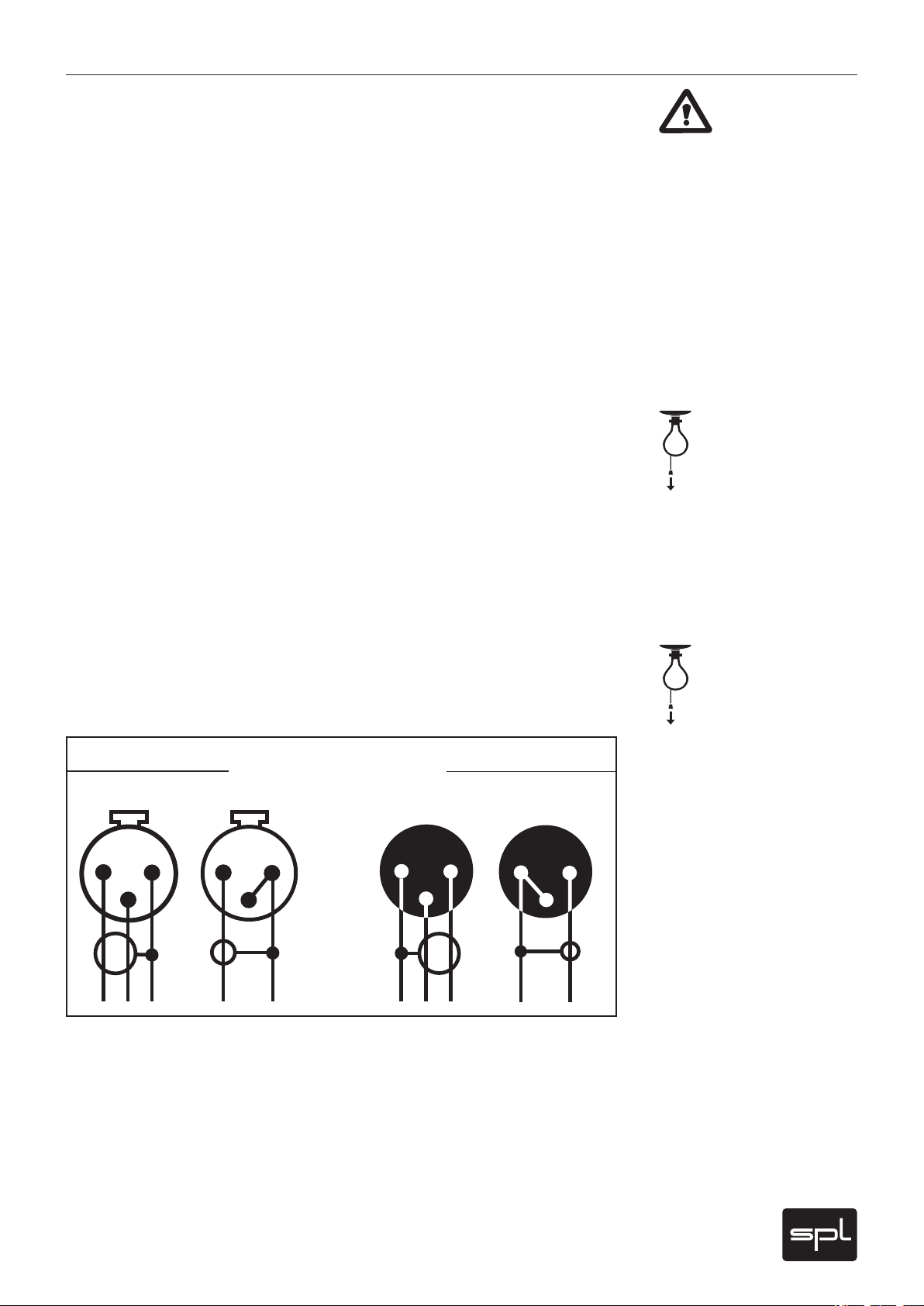

Connections

Input

Output

balanced

unbalanced

balanced

unbalanced

1=GND

2=hot (+)

3=cold (-)

1

2

3

1

2

3

1

2

3

1

2

3

Signal connection

Switch off the unit before you begin the process of making the rst or any subsequent connections. Neglecting this can damage either or both your ears and your equipment.

1/4" TRS socket

The TRS socket AD INPUT 2 supports both balanced (1/4" TRS/stereo jack connector) and

unbalanced connections (1/4" TS/mono jack connector). Refer to page 13 for further information on that input.

XLR sockets

All XLR sockets are balanced inputs or outputs. Input sockets are always female for plugging

in male connectors, output sockets are always male for female connectors. All in all a comprehensible principle.

Balanced connections

It is impossible to exclude all interferences when a single audio signal is transmitted. Shielding

is effective against electric, but not against electromagnetic inuences. Motors, transformers,

and alternating current can always induce interferences. But even if the transmission would

succeed, differences in ground potentials between driver and receiver would produce disturbances.

Rear Panel

In balanced connections a reference signal with reversed polarity is transmitted additionally

to the audio signal through a second wire. The ground signal is routed separately through

a third wire. Input and output stages are drivers and receivers, and the receiving stage can

suppress interferences by subtracting the difference between audio and reference signal.

Unbalanced connections

Unbalanced connections from and to RCA or 1/4" TS sockets can be made without adaptors to

the balanced XLR sockets. The correct wiring is important. The diagram shows the pin conguration of the XLR sockets and how to correctly connect them for unbalanced connections:

Connections to RCA sockets are always unbalanced, a wiring to jack connectors can be both

balanced (1/4" TRS/stereo jack) or unbalanced (1/4" TS/mono jack). We recommend to use

individually congured cables from XLR to RCA or jack sockets instead of adaptors. You can

get cables in any needed conguration from audio dealers. With the diagram above, the dealer

can ensure to provide the appropriate cable for your application.

Page 12

12

Frontliner

Sockets

Rear Panel

Separate inputs and outputs

Each Frontliner module is equipped with its own input and output stage. An obvious purpose

is to route the signal from any output, e. g. right after the preamp to store the pure recording

signal. Further applications such as using single or grouped modules separately or inserting

external processors are depicted on pages 9 and 10. Inserts can be determined before each

processing module input.

Preampli er: MIC IN

You can connect any kind of microphone to the MIC IN socket (dynamic, condenser, tube and

ribbon microphones). 48 volts phantom power, which is required for some microphones, can

be activated with the 48V switches on the front or rear panel. Please read the important notes

in chapter “48V” on page 15. The microphone input can also be equipped with an optional

transformer (refer to page 27, “Information on I/O transformers”).

Preampli er: LINE IN

Use the balanced LINE IN socket for high-level signals with impedances lower than 1 kOhm,

e. g. D/A converters, synthesizers or samplers. We recommend connection to a patchbay for

easier access.

The maximum input level of the LINE IN is +22 dBu.

High impedance sources (above 1 kOhm), such as e-guitars and basses, acoustic guitars with

pick ups and so on, must be connected to the instrument input (see pages 16 and 17).

IM PO RTANT: The line input is deactivated if the instrument input is in use.

Preampli er: OUT

The electronically balanced, analog preampli er output provides the preampli ed signal prior

to any processing. If you determine an insert between preampli er and de-esser, the preampli er output serves as insert send.

De-Esser: IN and OUT

The analog de-esser input and output sockets are electronically balanced.

Normally the de-esser input signal is the internal preampli er signal. If you are using the

de-esser module separately as single module, you connect the source and receiving units to

the de-esser inputs and outputs. If you are using the de-esser module as part of a group of

modules, you connect the source and receiving units to the group inputs and outputs. If you

determine an insert between preampli er and de-esser, the de-esser input serves as insert

return.

MIC IN

DISABLE

48V ON

FRONT

48V

ON

LINE IN

LINE IN

OUT

OUT

IN

IN

OUT

OUT

230V ~50Hz

Fuse : 3 15mA slow

115V ~60Hz

Fuse : 630mA slow

A D I N P U T 2

TO RE DUCE RI SK O F FI RE O R E LEC TRIC SHO CK

DO NO T EX POS E T HIS UNIT

TO RA IN O R M OIS TURE .

THIS E QUIP MENT MUS T B E E ART HED.

WARNING

M A I N S I N P U T

MAINS INPUT

AVIS: RISQUE DE CHOC ÉLECTRIQUE - NE PAS OUVRIR

RISK OF ELECT RIC SHOC K

DO NOT OPEN

CAUTION

DISCRETE TUBE PREAMPLIFIER

CONNECTOR WIRING

D I S C R E T E T U B E P R E A M P L I F I E R

DE-ESSER

DE - E S S E R

IN

IN

OUT

OUT

COMPRESSOR / LIM.

C O M P R E S S O R / L I M .

IN

IN

OUT

OUT

EQUALIZER / TUBE SAT.

E Q U A L I Z E R / T U B E S A T .

OUT 2

OUT 2

OUT 1

OUT 1

MAIN OUTPUTS

M A I N O U T P U T S

S P L C O N V E R T E R S L O T – O P T I O N A L

SPL CONVERTER SLOT – OPTIONAL

CONVE RTER SERI AL #

SoundPerformanceLab.com

MADE IN GERMANY

FRONT LINER SER IAL # OP T I O N S

GND LIFT

GND LIFT

GND

G N D L I F T

POWER

P O W E R

V O L T A G E | F U S E

VOLTAGE | FUSE

XLR WIRING: PIN 1 = GND / PIN 2 = HOT (+) / PIN 3 = COLD (–)

TRS WIRING: TIP = LEFT / RING = RIGHT / SLEEVE = GND

AD INPUT 2

0

MIC INLINE IN

LINE IN

OUT

OUT

DISCRETE TUBE PREAMPLIFIER

D I SC R E T E T U B E P R E A M P L I FI E R

IN

IN

OUT

OUT

DE-ESSER

D E- E S S ER

Page 13

13

Frontliner

Sockets

IN

IN

OUT

OUT

COMPRESSOR / LIM.

C OM P R E S S O R / L I M .

IN

IN

OUT

OUT

EQUALIZER / TUBE SAT.

E Q UA L I Z E R / TU B E S AT .

OUT 2

OUT 2

OUT 1

OUT 1

MAIN OUTPUTS

M A I N O U T P U T S

A D IN P U T 2

AD INPUT 2

M A I NS I N P U T

MAINS INPUT

Compressor: IN and OUT

The analog compressor input and output sockets are electronically balanced.

Normally the compressor input signal is the internal de-esser signal (or the EQ signal if EQ

PRE COMP. is activated). If you are using the compressor module separately as single module,

you connect the source and receiving units to the compressor inputs and outputs. If you are

using the compres sor module separ ately as part of a mo dule group, yo u connec t the source and

receiving units to the group inputs and outputs. If you determine an insert between de-esser

and compressor, the de-esser output is the insert send and the compressor input is the insert

return.

Equalizer: IN and OUT

The analog equalizer/tube saturation input and output sockets are electronically balanced.

Normally the EQ input signal is the internal compressor signal (or the de-esser signal if EQ

PRE COMP. is activated). If you are using the equalizer module separately as single module, you

connect the source and receiving units to the equalizer inputs and outputs. If you are using the

equalizer module separately as part of a module group, you connect the source and receiving

units to the group inputs and outputs. If you determine an insert between compressor and

equalizer, the compressor output is the insert send and the equalizer input is the insert return.

Rear Panel

MAIN OUTPUTS: OUT 1 and OUT 2

The output signal of the channel strip is supplied by the electronically balanced, analog

outputs OUT 1 and OUT 2. The splitted outputs allow to feed recording and monitoring devices

simultaneously, or, in a live application, monitoring and P. A. paths. Each output is driven by its

own stage to exclude mutual inuences. OUT 1 can optionally be equipped with a transformer

(refer to page 27, “Information on I/O transformers”).

If you have excluded all three processing modules from the channel strip as a group, the

group’s output signal is supplied by the MAIN OUTPUTS. In this case, the preamplier output

signal is only present at the preamp’s output. In all other cases the nal output signal of the

channel strip is always present at the MAIN OUTPUTS.

AD Input 2

The Frontliner is a mono channel strip, but the optional A/D converter card 2376 is a dualchannel device. Therefore a second (external) signal can be converted with the converter

card, if it is connected to the AD INPUT 2. If no signal is connected to the A/D INPUT 2, the

output signal of the Frontliner is routed to both converter channels. The maximum input level

for the converter is +12dBu (=0 dBFS).

Power connection and fuses

Connect the power cord to the rear MAINS INPUT socket. Transformer, power cord and case

connection conform to VDE, UL and CSA requirements.

The Frontliner’s power supply houses two fuses, one for the neutral wire and one for the phase

conductor. The fuses are accessible from outside and placed right behind the ap below the

socket.

Fuse ratings are 315 mA slow blow (

230

volts) or 630 m A slow blow (

115

volts).

Page 14

14

Frontliner

Voltage Selector

The rear panel VOLTAGE SELECTOR sets the local line voltage (115 V position: 110-120

volts/6o Hz, 230 V position: 220-240 volts/50 Hz). The diagram shows the correct switch position for 230 V power supply.

BEFORE you connect electrical power make sure that the VOLTAGE SELECTOR

setting re ects the correct local power line voltage!

Power switch

The rear panel POWER switch activates the unit, con rmed by the illuminated VU meter.

Switch on the unit only after you have checked the correct setting of the rear

VOLTAGE SELECTOR and 48V phantom power supply front and rear switches.

When you activate the Frontliner, the unit commences the warm-up mode to heat

the tubes. The warm-up cycle takes between 45 seconds (if the unit was active shortly before)

and approximately one minute at cold start. During warm-up the MUTE switch ashes. The

MAIN OUTPUTS and the output to the optional converter card are muted, all EXTERNAL INPUTS

keys are deactivated. The MUTE switch stops ashing when warm-up is nished. The MUTE

switch does not illuminate if it was not depressed before. It illuminates permanently after

war m-up when it was activated before.

Phantom power supply/rear panel switches

48 Volt phantom power is only needed for microphones requiring external current

(generally condenser microphones). Other microphones can be damaged if they

are used with activated phantom power, which may damage the Frontliner, too.

Please read the notes on using phantom power and how to activate it under “48 V” on page

15 and “Activating Phantom Power” on page 16.

Since phantom power is critical to operational safety, the Frontliner offers additional switches

on the rear panel to exclude accidental use of the 48 V switch on the front.

If both rear panel switches are not engaged, you can activate and deactivate phantom power

with the 48 V switch on the front.

The switch to the right labelled 48 V ON activates phantom power independently from the

front panel switch setting – now phantom power can no longer be switched off with the front

panel switch.

The left rear panel switch labelled DISABLE 48 V ON FRONT deactivates the 48 V switch on the

front, now phantom power can no longer be activated accidentally with the front panel switch.

The 48 V switch on the front is always illuminated if phantom power is active.

GND Lift

The rear panel GND LIFT switch eliminates hum by separating the internal ground from the

unit’s housing ground. Hum can, for example, result when this unit’s housing has a common

ground connection with other devices that might have a different ground potential. The switch

is usually deactivated to retain the shielding of the housing.

Switches

Rear Panel

POWER

P O WE R

0

230V ~50Hz

Fuse : 315 mA slow

115V ~60Hz

Fuse : 630mA slow

V OL T AG E | F U S E

VOLTAGE | FUSE

GND LIFT

GND LIFT

GND

G N D L I F T

DISABLE

48V ON

FRONT

48V

ON

Page 15

15

Frontliner

Preamplier

7

5

3

1

0

3

5

30

50

70

100

VU

5

3

1

VU

20

10

0

%

M

I

C

G

A

I

N

S

-

R

E

D

U

C

T

I

O

N

I

N

S

T

R

U

M

E

N

T

S

-

D

E

T

E

C

T

A

D

-

O

V

L

1

3

1

4

1

5

1

6

1

8

2

0

2

2

2

4

2

6

2

8

3

0

3

3

3

6

3

9

4

2

4

5

5

2

6

1

6

8

I

N

S

T

R

.

G

A

I

N

L

I

N

E

G

A

I

N

R

A

T

I

O

A

T

T

A

C

K

L

M

F

M

H

F

L

M

F

–

/

+

M

H

F

–

/

+

A

I

R

B

A

N

D

T

U

B

E

S

A

T

U

R

A

T

I

O

N

INSTR.

LINE IN

TUBE

+15dB

ON ON

MUTE

EQ PRE

CO MP .

EQ/TU BECOM P.

EXTERNAL INPUT S

DE-ES.

AUTO

48 V PAD

Recording Channel

Ø

M

A

K

E

-

U

P

R

E

L

E

A

S

E

O

U

T

P

U

T

Sound Performan ce Lab Made in Germany

ON

0

-

1

-

2

-

3

-

4

-

6

-

9

-

1

1

-

1

2

2

1

1

6

1

1

6

0

-

5

-

9

-

1

6

-

2

2

-

3

0

-

3

8

-

4

6

-

5

4

-

5

8

1

.

2

1

.

4

1

.

7

2

.

0

2

.

3

2

.

7

3

.

0

3

.

6

5

.

0

1

6

∞

0

1

0

2

0

3

0

4

0

5

0

6

0

7

0

8

0

9

0

1

0

0

-

2

0

-

1

3

-

7

.

5

-

4

.

5

-

2

0

1

.

5

3

4

5

5

.

5

0

.

1

0

.

2

0

.

4

1

.

0

2

.

5

7

.

0

1

6

4

0

1

3

0

5

3

0

1

0

0

0

0

.

0

3

0

.

0

5

0

.

0

9

0

.

1

5

0

.

2

5

0

.

4

0

.

6

5

1

.

0

1

.

3

1

.

8

2

.

0

0

0

.

5

1

2

3

4

5

6

7

8

9

1

0

1

2

1

4

1

6

1

9

2

0

-

1

2

-

1

0

-

5

-

2

.

5

0

2

.

5

5

7

.

5

1

0

1

2

-

1

2

-

1

0

-

5

-

2

.

5

0

2

.

5

5

7

.

5

1

0

1

2

-

1

0

-

8

-

6

-

4

-

2

0

2

4

6

8

1

0

6

8

0

8

2

0

1

k

0

1

k

5

2

k

7

3

k

4

4

k

5

6

k

5

1

0

k

1

3

k

1

5

k

3

0

4

0

5

0

8

0

1

2

5

1

6

0

2

0

0

3

0

0

5

0

0

6

4

0

7

0

0

Model 2800

GRVU VU PPM 0 dB -10 dB

T

H

R

E

S

H

O

L

D

Frontliner

6

8

1

1

1

4

1

7

1

9

2

1

2

3

2

5

2

6

2

7

2

9

3

2

3

5

3

7

3

9

4

1

4

2

4

3

-

2

0

-

1

8

-

1

2

-

9

0

3

9

1

0

dB 1: x dB dB

dB dBHz

Hz %

ms s

dB dB

dB

48 V PADØ

M

I

C

G

A

I

N

1

3

1

4

1

5

1

6

1

8

2

0

2

2

2

4

2

6

2

8

3

0

3

3

3

6

3

9

4

2

4

5

5

2

6

1

6

8

dB

MIC GAIN

The MIC GAIN control determines the level of preamplication. The preamplication values

cover a range from +13 dB up to + 68 dB. If an optional microphone input transformer is tted

the scaled values are to be increased by ca. +14 dB (depends upon microphone. Further information on page 27, “Information on I/O transformers”). The potentiometer is a RK 27 from

ALPS, a high-grade model with antilogarithmic characteristic and an especially high resolution between 20 dB and 40 dB to allow for sensitive control within this most important range.

MIC GAIN adjustments

Amplifying a mic signal to line level should principally be done solely with the MIC GAIN

control. Deactivate all processing modules in the rst place. The OUTPUT level control is used

to adjust the proper drive level for subsequent equipment, so initially it should be set to 0 dB

(12 o’clock position). The 0 dB/-10 dB switch should be set to 0dB as well to see the overall

output level (also see “0 dB/-10 dB” on page 23).

Control Elements

Now turn up the MIC GAIN control until the VU shows maximum values between 0 dB and

+3 dB. There is still enough headroom to prevent clipping at varying input levels. Note that

the VU meter shows average levels instead of peak levels (which can be up to 10 dB higher). If

necessary, switch the VU to PPM mode to see peak levels (see “VU/PPM switch” on page 23).

In recording high-level signals such as snare and kick, etc. it may be necessary to engage the

PAD switch (see “PAD” on page 16). You can drive the MIC GAIN harder if you know that unexpected input level changes are unlikely to occur. Choose the -10dB setting with the 0 dB/-10 dB

switch to extend the VU meter range accordingly.

48 V

The 48 V switch activates phantom power for condenser microphones with built-in ampliers.

Phantom power should only be activated when using microphones that require it.

VERY IMPORTANT: All microphones with balanced, ground-free outputs, can be used with

the phantom power activated. Please be sure to deactivate phantom power with all other

microphones. Unbalanced microphones may only be used with phantom power deactivated.

Since phantom power is critical to operational safety, the Frontliner offers additional switches

on the rear panel to exclude accidental use of the 48 V switch on the front. The function of

these rear panel switches is described on the previous page.

Activating phantom power

PLEASE ALWAYS FOLLOW THESE INSTRUCTIONS TO ACTIVATE AND DEACTIVATE PHANTOM

POWER (ALSO WHEN CHANGING MICROPHONES). THE FRONTLINER’S INPUT STAGE CAN BE

DAMAGED IF YOU IGNORE THESE PROCEDURES!

1. Connect the microphone to the Frontliner.

2. Now activate phantom power to use the microphone.

3. When nished, rst deactivate phantom power.

4. Wait at least one minute after deactivation of phantom power before disconnecting the

microphone! This ensures residual current will be discharged.

Page 16

16

Frontliner

Control Elements

48 V PADØ

48 V PADØ

48 V PADØ

I

N

S

T

R

U

M

E

N

T

Preamplier

Phase reverse

The phase reverse function reverses the polarity of the microphone signal, inverting the

phase (by 180°) to correct phase-inverted signals caused by multiple signal sources. A voiceover artist, for example, hears himself during recording through the headphones and simultaneously through the bones in his head. Phase inversion will cause an unnatural sound, and

even minimal variations in distance to the microphone will cause drastic variations in the

sound. Phase inversion is also commonly encountered when using multiple microphones on

a single sound source. We recommend checking for correct polarity before each recording.

Phase reverse can be applied to the preamplier microphone and line inputs.

High-pass filter

This switch activates the high-pass lter, which operates from 85 Hz downwards with 6 dB/

octave (often also called a “rumble lter“). The lter prevents the amplication of unwanted

low-frequencies. Compared to 12 dB/octave lters, the 6 dB lter works relatively moderate,

but very musical.

The high-pass filter can be applied to all three preamplier inputs (microphone, line, and

instrument).

PAD

The PAD switch attenuates the microphone input by 20dB. High-level input signals can be

attenuated in order to prevent over-driving the preamplier. The Frontliner has a minimum

pre-amplication of +13 dB. But with signals from drums or brass this may already be too

much. Engaging PAD attenuates the minimum pre-amplication (MIC GAIN control fully

counter clockwise) to -7 dB, thus providing a useful gain control range for loud input signals.

INSTRUMENT input

The INSTRUMENT input jack is placed on the front for easy access. It should be used to connect

instruments like e-bass and guitars, acoustic guitars with pick-ups, etc. The Instrument input

features a 1 MOhm (one mega Ohm) input impedance. Line signals with lower impedances,

such as from D/A converters, samplers, synths, etc. should be connected to the rear LINE IN

socket.

IMPORTANT: As long as an instrument is plugged into front INSTRUMENT input, the rear

panel LINE IN input is deactivated.

Page 17

17

Frontliner

Preamplier

INSTR.

LINE IN

TUBE

+15 dB

I

N

S

T

R

.

G

A

I

N

L

I

N

E

G

A

I

N

6

8

1

1

1

4

1

7

1

9

2

1

2

3

2

5

2

6

2

7

2

9

3

2

3

5

3

7

3

9

4

1

4

2

4

3

-

2

0

-

1

8

-

1

2

-

9

0

3

9

1

0

dB

INSTR.

LINE IN

TUBE

+15 dB

LINE GAIN/INSTR. GAIN

This control determines the level of preamplication for signals connected either to the rear

LINE IN or to the INSTRUMENT input on the front. You activate the respective input with the

INSTR./LINE IN switch which is described below.

Gain range for line signals reaches from -20 dB to +10 dB. The attenuation allows to also

process very high levels.

Instrument signals can be amplied between +6 dB and +43 dB.

LINE GAIN and INSTR. GAIN adjustments

For optimal leveling of line or instrument signals, deactivate all processing modules and set the

OUTPUT level control to 0 dB (12 o’clock position). The VU meter’s 0 dB/-10 dB switch should be

set to 0dB to see the correct output level (also see “0 dB/-10 dB” on page 23).

Now turn up the LINE GAIN/INSTR. GAIN control until the VU shows maximum values between

0 dB and +3 dB. There is still enough headroom to prevent clipping at varying input levels.

Note that the VU meter shows average levels instead of peak levels (which can be up to 10 dB

higher). If necessary, switch the VU to PPM mode to see peak levels (see “VU/PPM switch” on

page 23).

Levels between 0 and +3 dB usually are safe. Attenuate very high input levels with the LINE GAIN

control. Switch the VU meter to -10 dB display mode to extend the metering range accordingly.

Control Elements

INSTR./LINE IN

With this switch you select between the microphone (off ) and line or instrument inputs (on).

The rear mic and line inputs can remain connected, regardless of which input is selected. You

can choose the line input as source as long as the instrument input is not being used.

TUBE + 15 dB

The TUBE +15 dB switch increases the degree of tube preamplication. The switch changes

from standard tube preamplication (+6 dB) to +15 dB. In each setting the total output

level of the preamp is automatically accommodated so that output levels do not have to be

re-calibrated when the tube is driven hotter – therefore MIC GAIN settings do not have to be

changed.

Engaging the TUBE +15 dB switch has an impact on the overall sound, as it directly changes

the sonic character of the tube. The higher the input level, the more you will notice the effects

of the tube’s typical even harmonic distortion.

Driving the tube with +15 dB creates subtle to modest presence effects which can put the

signal up front in a mix. For decent effects you should not apply too high MIC GAIN values with

the TUBE +15 dB switch engaged.

Page 18

18

Frontliner

Control Elements

ON

S

-

R

E

D

U

C

T

I

O

N

0

-

1

-

2

-

3

-

4

-

6

-

9

-

1

1

-

1

2

dB

S

-

D

E

T

E

C

T

7

5

3

1

0

3

5

30

50

70

100

VU

5

3

1

VU

20

10

0

%

M

I

C

G

A

I

N

S

-

R

E

D

U

C

T

I

O

N

I

N

S

T

R

U

M

E

N

T

S

-

D

E

T

E

C

T

A

D

-

O

V

L

1

3

1

4

1

5

1

6

1

8

2

0

2

2

2

4

2

6

2

8

3

0

3

3

3

6

3

9

4

2

4

5

5

2

6

1

6

8

I

N

S

T

R

.

G

A

I

N

L

I

N

E

G

A

I

N

R

A

T

I

O

A

T

T

A

C

K

L

M

F

M

H

F

L

M

F

–

/

+

M

H

F

–

/

+

A

I

R

B

A

N

D

T

U

B

E

S

A

T

U

R

A

T

I

O

N

INSTR.

LINE IN

TUBE

+15dB

ON ON

MUTE

EQ PRE

CO MP .

EQ/TU BECOM P.

EXTERNAL INPUT S

DE-ES.

AUTO

48 V PAD

Recording Channel

Ø

M

A

K

E

-

U

P

R

E

L

E

A

S

E

O

U

T

P

U

T

Sound Performan ce Lab Made in Germany

ON

0

-

1

-

2

-

3

-

4

-

6

-

9

-

1

1

-

1

2

2

1

1

6

1

1

6

0

-

5

-

9

-

1

6

-

2

2

-

3

0

-

3

8

-

4

6

-

5

4

-

5

8

1

.

2

1

.

4

1

.

7

2

.

0

2

.

3

2

.

7

3

.

0

3

.

6

5

.

0

1

6

∞

0

1

0

2

0

3

0

4

0

5

0

6

0

7

0

8

0

9

0

1

0

0

-

2

0

-

1

3

-

7

.

5

-

4

.

5

-

2

0

1

.

5

3

4

5

5

.

5

0

.

1

0

.

2

0

.

4

1

.

0

2

.

5

7

.

0

1

6

4

0

1

3

0

5

3

0

1

0

0

0

0

.

0

3

0

.

0

5

0

.

0

9

0

.

1

5

0

.

2

5

0

.

4

0

.

6

5

1

.

0

1

.

3

1

.

8

2

.

0

0

0

.

5

1

2

3

4

5

6

7

8

9

1

0

1

2

1

4

1

6

1

9

2

0

-

1

2

-

1

0

-

5

-

2

.

5

0

2

.

5

5

7

.

5

1

0

1

2

-

1

2

-

1

0

-

5

-

2

.

5

0

2

.

5

5

7

.

5

1

0

1

2

-

1

0

-

8

-

6

-

4

-

2

0

2

4

6

8

1

0

6

8

0

8

2

0

1

k

0

1

k

5

2

k

7

3

k

4

4

k

5

6

k

5

1

0

k

1

3

k

1

5

k

3

0

4

0

5

0

8

0

1

2

5

1

6

0

2

0

0

3

0

0

5

0

0

6

4

0

7

0

0

Model 2800

GRVU VU PPM 0 dB -10 dB

T

H

R

E

S

H

O

L

D

Frontliner

6

8

1

1

1

4

1

7

1

9

2

1

2

3

2

5

2

6

2

7

2

9

3

2

3

5

3

7

3

9

4

1

4

2

4

3

-

2

0

-

1

8

-

1

2

-

9

0

3

9

1

0

dB 1: x dB dB

dB dBHz

Hz %

ms s

dB dB

dB

De-Esser

ON

The first processing module is the de-esser, which removes disturbing sibilants when

required. The de-esser module is activated with the ON button. The S-DETECT LED above the

ON switch shows that S-sounds are being detected.

S-REDUCTION

With the S-REDUCTION control you determine the intensity of S-sound reduction. The

processing is related to the levels of the entire frequency spectrum (see next section), therefore it is more intensive with extreme S-sound levels than with those of lower levels. This

equalizes levels of sibilants in the output signal.

SPL De-Esser technology

In contrast to common de-essers based upon compressor techniques the SPL De-Esser makes

use of the phase cancellation principle. It employs filters that process only the reducible

”S-frequencies” but do not interfere with the remainder of the spectrum. The S-frequencies

are detected automatically, the phase is inverted and mixed with the original signal. This

method of operation has distinct advantages because it is unobtrusive and helps retain the

original tonal quality. Compressor-typical side effects such as lisping or nasal tones do not

occur. Finally its operation is as simple as pulling on the hand brake.

The reduction is accomplished by comparing the average level with the individual S-sounds:

the de-esser functions only when the S-noise level exceeds the average level of the entire

frequency spectrum. This means for example that original S-sounds with a certain S-portion

are not processed whereas those that are too loud, or do not effectively contribute to the

sound, are reduced – but the character of the voice remains unchanged.

A further specialty is the integrated Auto Threshold function which makes processing independent of the input level. Even when the speaker or singer does not maintain a constant distance

to the microphone, processing is retained at the pre-set S-reduction value. Conventional

systems are dependent on the input level and work more intensively as the distance to the

microphone is reduced. As a result, the SPL De-Esser does not need to be monitored and

re-adjusted permanently to keep processing constant – and it can always be applied before

the compressor, as changing its position would not be an advantage. That is why an accordant

switching function is not necessary.

Page 19

19

Frontliner

Compressor/Limiter

7

5

3

1

0

3

5

30

50

70

100

VU

5

3

1

VU

20

10

0

%

M

I

C

G

A

I

N

S

-

R

E

D

U

C

T

I

O

N

I

N

S

T

R

U

M

E

N

T

S

-

D

E

T

E

C

T

A

D

-

O

V

L

1

3

1

4

1

5

1

6

1

8

2

0

2

2

2

4

2

6

2

8

3

0

3

3

3

6

3

9

4

2

4

5

5

2

6

1

6

8

I

N

S

T

R

.

G

A

I

N

L

I

N

E

G

A

I

N

R

A

T

I

O

A

T

T

A

C

K

L

M

F

M

H

F

L

M

F

–

/

+

M

H

F

–

/

+

A

I

R

B

A

N

D

T

U

B

E

S

A

T

U

R

A

T

I

O

N

INSTR.

LINE IN

TUBE

+15dB

ON ON

MUTE

EQ PRE

CO MP .

EQ/TU BECOM P.

EXTERNAL INPUT S

DE-ES.

AUTO

48 V PAD

Recording Channel

Ø

M

A

K

E

-

U

P

R

E

L

E

A

S

E

O

U

T

P

U

T

Sound Performan ce Lab Made in Germany

ON

0

-

1

-

2

-

3

-

4

-

6

-

9

-

1

1

-

1

2

2

1

1

6

1

1

6

0

-

5

-

9

-

1

6

-

2

2

-

3

0

-

3

8

-

4

6

-

5

4

-

5

8

1

.

2

1

.

4

1

.

7

2

.

0

2

.

3

2

.

7

3

.

0

3

.

6

5

.

0

1

6

∞

0

1

0

2

0

3

0

4

0

5

0

6

0

7

0

8

0

9

0

1

0

0

-

2

0

-

1

3

-

7

.

5

-

4

.

5

-

2

0

1

.

5

3

4

5

5

.

5

0

.

1

0

.

2

0

.

4

1

.

0

2

.

5

7

.

0

1

6

4

0

1

3

0

5

3

0

1

0

0

0

0

.

0

3

0

.

0

5

0

.

0

9

0

.

1

5

0

.

2

5

0

.

4

0

.

6

5

1

.

0

1

.

3

1

.

8

2

.

0

0

0

.

5

1

2

3

4

5

6

7

8

9

1

0

1

2

1

4

1

6

1

9

2

0

-

1

2

-

1

0

-

5

-

2

.

5

0

2

.

5

5

7

.

5

1

0

1

2

-

1

2

-

1

0

-

5

-

2

.

5

0

2

.

5

5

7

.

5

1

0

1

2

-

1

0

-

8

-

6

-

4

-

2

0

2

4

6

8

1

0

6

8

0

8

2

0

1

k

0

1

k

5

2

k

7

3

k

4

4

k

5

6

k