Page 1

Manual

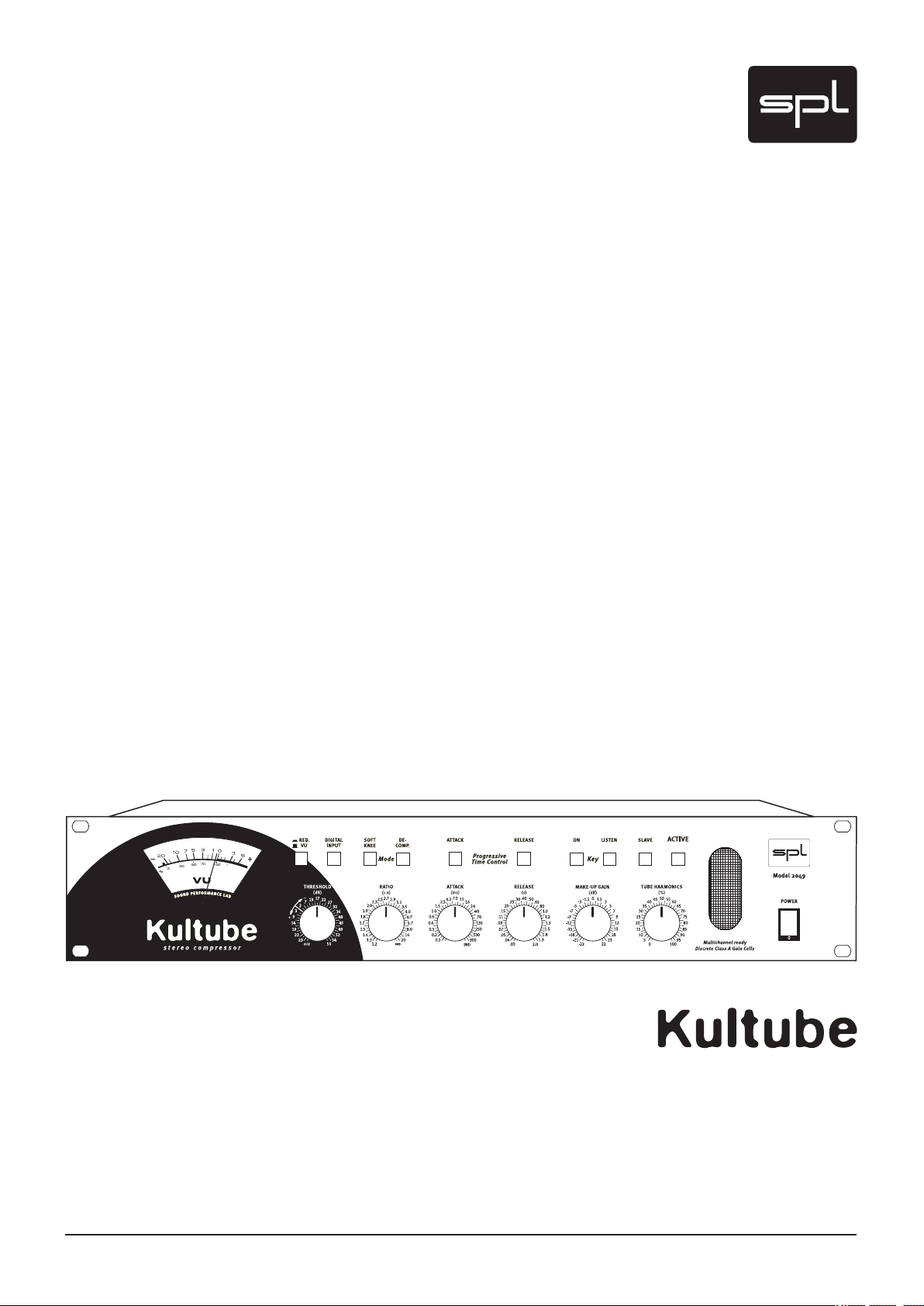

Model 2049

Stereo Compressor

Page 2

2

Kultube (Model 2049)

Manual

Version 1.2 – 11/2008

R & D: Ruben Tilgner

The information in this document has been carefully verified and is assumed

to be correct. However Sound Performance Lab (SPL) reserves the right to

modify the product described in this manual at any time. Changes without

notice. This document is the property of SPL and may not be copied or reproduced in any manner, in part or full without the authorization of SPL.

Limitations of Liability:

In no event will SPL be liable for any damages, including loss of data, lost

profits, cost of cover or other special, incidental, consequential or indirect

damages arising from the use of the unit, however caused and on any theory

of liability. This limitation will apply even if SPL or an authorized dealer has

been advised of the possibility of such damage.

CE Declaration of Conformity

Manufacturer: SPL electronics GmbH

Type of Equipment: Audio Signal Processor

Product: Kultube, Model 2049

Compliance Engineer: Wolfgang Neumann

Test Basis: EN50081-1:1992, EN50082-1:1992, EN60065:1993, EN61000-33:1995, EN60065:2002, EN55013:2001, EN55020:2002, EN61000-3-2:2000,

73/23 EWG; 93/68 EWG.

We herewith declare, that the construction of the Kultube, Model 2049, is in

compliance with the standards and regulations mentioned above.

Notes on environmental protection

At the end of its operating life, this product must not be disposed of

with regular household waste but must be returned to a collection

point for the recycling of electrical and electronic equipment. The

“wheelie bin“ symbol on the product, user‘s manual and packaging

indicates that. The materials can be re-used in accordance with

their markings. Through re-use, recycling of raw materials, or other forms of

recycling of old products, you are making an important contribution to the

protection of our environment. Your local administrative office can advise you

of the responsible waste disposal point.

WEEE Registration: 973 349 88

Sound Performance Lab

SPL electronics GmbH

P.O. Box 12 27

D- 41 368 Niederkruechten, Germany

Phone +49 21 63 98 34 0

Fax +49 21 63 98 34 20

E-Mail: info@soundperformancelab.com

www.soundperformancelab.com

© 2008 SPL electronics GmbH. All rights reserved.

Page 3

3

Important Security Information ................................................................. 4

Installation, Power Supply ........................................................................ 6

Introduction .............................................................................................. 7

Connections

Rear Panel/Wiring ..................................................................................... 8

General Advices, Sockets & Switches ........................................................ 9

Control Elements

Red. /VU, Digital Input, Softknee, De Comp. ............................................. 11

PTC-Attack, PTC-Release, Key On, Key Listen, Slave, Active ....................... 12

Threshold, Ratio, Release, Make Up Gain .................................................. 13

Tube Harmonics ......................................................................................... 14

Operation – Understanding and enjoying the Kultube

The Threshold Control ............................................................................... 14

The Ratio Control ....................................................................................... 15

The Attack Control ..................................................................................... 16

Progressive Time Control – Attack ............................................................. 17

The Release Control ................................................................................... 18

Progressive Time Control – Release ........................................................... 19

Content

Applications – Using and enjoying the Kultube

Summed Signal Processing ....................................................................... 21

Single Track & Subgroup Processing .......................................................... 21

Side-chain ................................................................................................. 22

Multi Channel and 5.1 Surround Processing ............................................... 23

Specifications ............................................................................................ 24

Guarantee ................................................................................................. 24

Page 4

4

Important Security Information

Please note and retain this manual. Carefully read and follow all of the safety

and operating instructions before you use the machine.

Be doubly careful to follow all warnings and special safety instructions

noted in this manual and on the unit.

Connections: Only use the connections as described. Other connections can

lead to health risks and equipment damage.

Water And Humidity: Do NOT use this machine anywhere near water (for

example near a wash basin or bath, in a damp cellar, near swimming pools,

or the like). In such cases there is an extremely high risk of fatal electrical

shocks!

Insertion Of Foreign Objects Or Fluids: NEVER allow a foreign object through

any of the machine‘s chassis openings. You can easily come into contact with

dangerous voltage or cause a damaging short circuit. NEVER allow any fluids

to be spilled or sprayed on the machine. Such actions can lead to dangerous

electrical shocks or fire!

Opening the Machine: Do NOT open the machine housing, as there is great

risk you will damage the machine, or – even after being disconnected – you

may receive a dangerous electrical shock!

Electrical Power: Run this machine ONLY from sources which can provide

proper power at the prescribed rating. When in doubt about a source, contact

your dealer or a professional electrician. To be sure you have isolated the

machine, do so by disconnecting the power cord from your wall connection.

Be sure that the power cord plug is always accessible. When not using the

machine for a longer period, make sure to unplug it from your wall power

socket.

Power Cord Protection: Make sure that your power cord is arranged to avoid

being stepped on or any kind of crimping and damage related to such event.

Do not allow any equipment or furniture to crimp this power cord.

Power Connection Overloads: Avoid any kind of overload in connections to

wall sockets, extension or splitter power cords. Always keep manufacturer

warnings and instructions in mind. Overloads create fire hazards and risk of

dangerous shocks!

Lightning: Before thunderstorms or other severe weather, disconnect the

machine from wall power (but to avoid life threatening lightning strikes, not

during a storm). Similarly, before any severe weather, disconnect ALL the

power connections of other machines and antenna and phone/network cables

which may be interconnected so that no lightning damage or overload results

from such secondary connections.

Page 5

5

Important Security Information

Air Circulation: Chassis openings offer ventilation and serve to protect the

machine from overheating. NEVER cover or otherwise close off these openings. NEVER place the machine on a soft surface (carpet, sofa, etc.). Make

sure to provide for a mounting space of 4-5 cm/2 inches when mounting the

machine in racks or cabinets.

Controls And Switches: Operate the controls and switches only as

described in the manual. Incorrect adjustments outside safe parameters can lead to damage and unnecessary repair costs. Never use the

switches or level controls to effect excessive or extreme changes.

Repairs: Unplug the machine and immediately contact a qualified techni-

cian when you think repairs are needed – or when moisture or foreign objects

may accidentally have gotten in to the housing, or in cases when the machine

may have fallen and shows any sign of having been damaged. This also

applies to any situation in which the machine has not been subjected to any of

these unusual circumstances but still is not functioning normally or its performance is substantially altered.

In cases of damage to the power cord or its plug, first consider turning off the

main circuit breaker before unplugging the power cord.

Replacement/Substitute Parts: Be sure that any service technician uses

original replacement parts or those with identical specifications as the originals. Incorrectly substituted parts can lead to fire, electrical shock, or other

dangers, including further equipment damage.

Safety Inspection: Be sure always to ask a service technician to conduct a

thorough safety check and ensure that the state of the repaired machine is in

all respects up to factory standards.

Cleaning: In cleaning, do NOT use any solvents, as these can damage the

chassis finish. Use a clean, dry cloth (if necessary, with an acid-free cleaning

oil). Disconnect the machine from your power source before cleaning.

Page 6

6

Installation

Power Supply

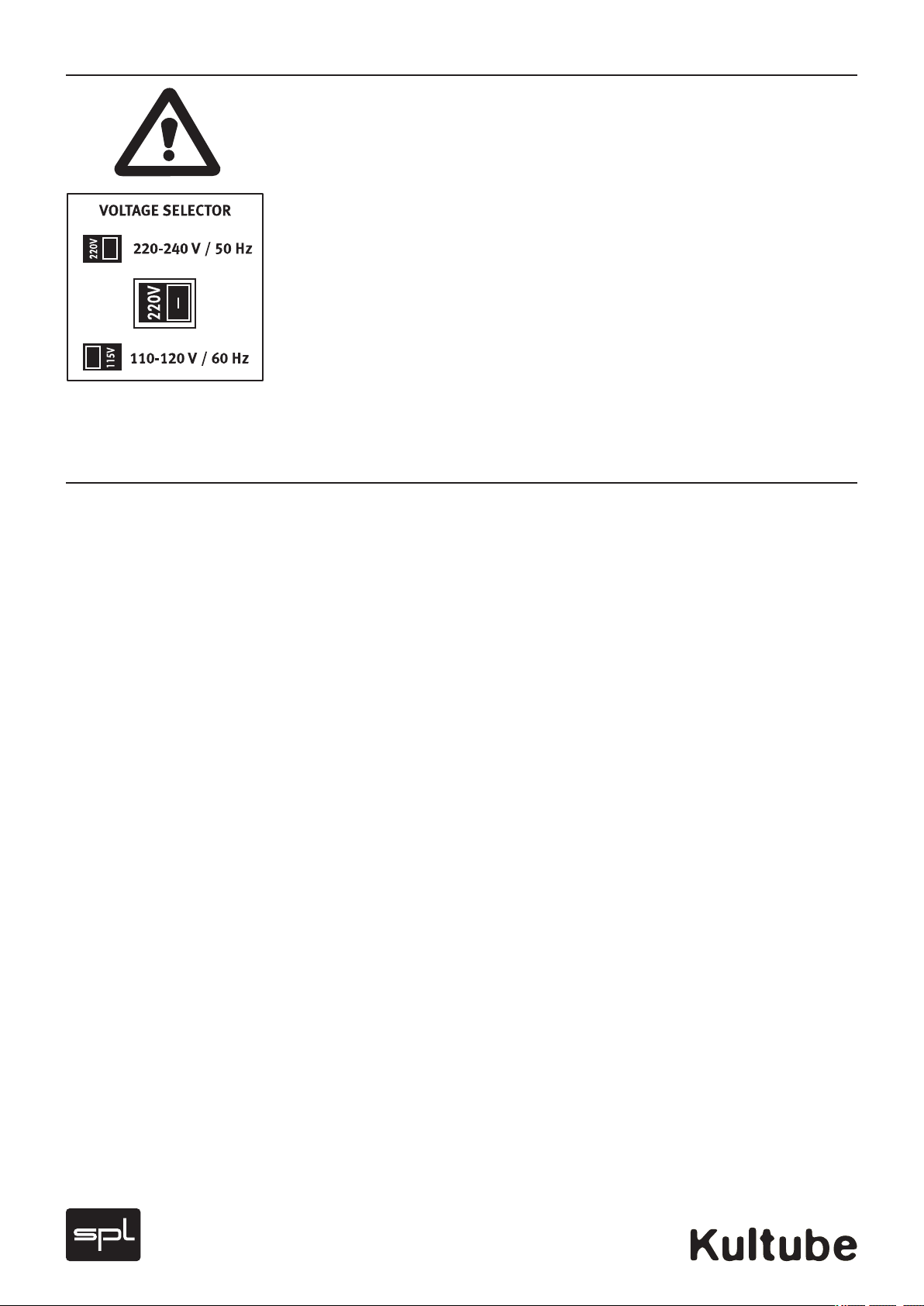

Be very careful to check that the rear chassis power selection switch is set

to the correct local line voltage position before using the unit (230 V position: 220-240 V/50 Hz, 115 V position: 110-120 V/60 Hz)!

When in doubt about a source, contact your dealer or a professional electrician.

Before connecting any equipment make sure that any machine to be

connected is turned off. Follow all safety instructions from page 5.

Place the unit on a level and stable surface. The unit’s enclosure is EMC-safe

and effectively shielded against HF interference. Nonetheless, you should

carefully consider where you place the unit to avoid electrical disturbances.

The unit should be positioned so that you can easily reach it, but there are

other considerations. Try not to place it near heat sources or in direct sunlight,

and avoid exposure to vibrations, dust, heat, cold or moisture. It should also

be kept away from transformers, motors, power amplifiers and digital processors. Always ensure sufficient air circulation by keeping a distance of 4-5 cm/2

inches to other units and to the sides of the unit.

Built around a toroidal transformer, the power supply has a minimal electromagnetic field to avoid hum or mechanical noise.

The power supply‘s output side is filtered by an RC circuit again to extract

noise and hum from the supplied electrical power.

6000 μf capacitors smooth out the positive and negative half waves. An

additional power supply filter is placed before the power switch to eliminate

disturbing interferences.

All signal processing components are supplied with two separate current

regulators to exclude influences from the remaining components.

The 220 v current for the tube stage power is smoothed out with 200 μF and

stabilized precisely by current regulators. The anode current is switched on

after warm up. Both measures ensure a remarkable extension of the tube‘s

lifetime.

The unit‘s supply voltage can be set to 230 V/50 Hz or 115 V/60 Hz. Check

your local power requirements for the appropriate setting. An AC power cord

is included to feed the IEC-spec, 3-prong connector. Transformer, AC cord

and IEC-receptacle are VDE, UL and CSA approved. The main fuse is rated at

315 mA for 230 v and 630 mA for 115 v. Chassis ground and AC ground can be

physically disconnected with the “GND Lift” switch on the rear panel to eliminate hum.

Page 7

7

The Kultube user disposes over a unique range of powerful compression

tools ranging from subtle unobtrusive processing to very obvious ‘effect‘

compressions. Used conventionally or as an effect, in professional recording

or mastering applications, the Kultube combines outstanding audio quality

with the acclaimed musicality and user-friendliness that SPL units stand for.

Applications cover those of a classic compressor for vocals and instruments,

in both mono and stereo, through stereo operation for subgroup processing

to stereo mastering and multi-channel/surround projects.

Progressive Time Control

With the unique Progressive Time Control (PTC) option for attack and release,

time constants can be optimized by unique circuitry that reacts both to the

input signal and to the user settings - for example, fast impulses are intercepted by an attack time as fast as 20 us. PTC can be seen as an interactively

controllable automation which is not based on fix presets but reacts to the

audio material in a musically useful way.

Discrete Gain Cells

Introduction

SPL has developed discrete, very high performance gain cells that are used

instead of the usual VCAs and the Kultube is the first product to use them.

They ensure the highest level of musicality and clarity in signal processing

and demonstrate significantly improved distortion values over VCAs.

Tube Harmonics

The adjustable tube saturation of the output stages combined with automatic

output level adjustment can produce tube sound effects that range from the

delicate to the raucous whilst a useful de-compressor mode can reanimate

over-compressed material (such as samples).

Master/Slave Mode

In master/slave mode, any number of devices can be controlled from one

master unit.

Features

• Discrete, high performance gain cells instead of industrial VCAs

• Progressive Time Control: interactively controllable automation for Attack

and Release parameters

• Adjustable tube saturation with output level adjustment

• Selectable soft or hard knee characteristics

• Unique de-compression mode

• Large VU meter displays gain reduction or (mono summed) output level

• Side-chain inputs on the front panel

• Slave mode for multi-channel operation

Page 8

8

Connections

Further Kultubes

as slaves in multi-

channel link mode

2

1

3

Pin wiring XLR Input:

1=GND 2=Hot (+) 3=Cold (-)

1

2

3

Pin wiring XLR Output:

1 = GND 2 = Hot (+) 3 = Cold (-)

Pin wiring Stereo Jack Connector:

Tip = Hot (+) Ring = Cold (-) Sleeve = GND

Connection to console:

Insert Sends > Analog Inputs

Insert Returns > Analog Outputs

The Kultube can optionally be equipped with a 24 bit/96 kHz converter module

Connector for external

processing units (e. g.

Equalizer)

Rear Panel/Wiring

Page 9

9

General Advices

Input

Output

balanced

unbalanced

balanced

unbalanced

1=GND

2=hot (+)

3=cold (-)

1

2

3

1

2

3

1

2

3

1

2

3

Again, while Kultube‘s housing is EMV safe and protects against HF interferences, proper placement of the unit is very important. Before connecting the

Kultube or any other equipment turn off all power. Adjust the voltage setting

on the back so that it corresponds with your local electrical power conditions.

The following graph shows the correct wiring for connecting unbalanced

signals to the balanced XLR connectors:

Connections

Alternatively unbalanced signals can be connected with mono Jack connec-

tors to the balanced Jack sockets.

Sockets & Rear Switch

Analog XLR and TRS jacks

Symmetrical XLR and TRS jacks are used for analog in- and outputs. An analog

mixing console is generally connected here (Insert Send/Return). Since the

TRS and XLR jacks are wired in parallel, unbalanced operation of the TRS

jack will have the same effect on the XLR jack and vice-versa. The Kultube is

configured for a nominal level of +4dBu and can handle an input level of max.

25 dBu, with max. +23 dBu available on the output. It is recommended to drive

the Kultube with a signal level of between 0 dBu and 12 dBu – this being the

optimum drive range for signal processing in which also the signal-to-noise

ratio is the best.

Connections

Page 10

10

Connections

Sockets & Rear Switch

Side-chain inputs

This jack is used as a side-chain input for connecting an external audio signal

to control the Kultube (e. g. an equalizer for frequency dependent processing).

It is configured as a stereo TRS jack, with the left channel on the tip and the

right channel on the ring.

Ideally you should use a normal insert cable that combines a stereo TRS plug

(connected to the Kultube) and two mono TRS plugs (connected to the control

device). When using an equalizer you can connect its inputs to the unused

jack inputs on the Kultube. In this way both the equalizer and the Kultube get

the same signal, since the XLR and TRS jacks are wired in parallel.

To use the side-chain input, activate the KEY ON switch on the front panel.

To monitor the signal, activate the KEY LISTEN switch. For other notes on using

the side-chain function, see the section on page 20.

Multi Channel Link

The MULTI CHANNEL LINK jacks can be used to connect multiple Kultube units

for multi-channel operation, so that they can be used together with a master

unit. Before connecting the link cable, determine which is the master unit and

connect the link cable to the MASTER jack. All linked devices are connected

only through the SLAVE jack.

IMPORTANT WARNING: Always define only one master device! Never

connect more than one device through the MASTER jack – otherwise components may be destroyed!

After you have made the cable connections, the SLAVE switch on the front

panel of each slave unit must be activated. From now on all functions of all

slave units are controlled by the master.

See page 21 for additional information about multi-channel operation.

Hum? Ground Lift!

Hum can be eliminated with the GROUND LIFT switch on the rear of the

unit (isolates the internal ground from chassis ground). Hum can occur for

example when the Kultube is connected to devices having a different ground

potential.

Hum problems can also be avoided however by consistently installing

balanced wirings. For this reason the GND lift function is by default not activated.

Page 11

11

Switches

Please note also the information on various controls under „Understanding

and enjoying the Kultube“ starting page 12.

RED/V U

This switch changes the VU meter over to Gain Reduction mode. The indicator

needle then jumps to the 0 dB value and moves to the left with increasing

compression. The scaled values now refer to gain reduction.

If the RED/VU switch is not pressed, the VU meter indicates the output

level.

Control Elements

If neither the RED/VU nor the ACTIVE switch is pressed, the VU meter indicates the input level. In Slave mode gain reduction is controlled by the master

device.

DIGITAL INPUT

The DIGITAL INPUT switch served to select the converted digital signals as an

input source for the Kultube and adds digital in- and outputs, allowing it to be

easily integrated into a digital production chain.

PLEASE NOTE: This switch function only applies to the converter module

2053 which was discontinued in 2005. It does not work with the current AD

converter module 2376.

SOFTKNEE

SOFTKNEE alters the slope of the compressor. Normally the unit operates in

hardknee mode, but pressing the SOFTKNEE switch activates the soft-knee

mode.

SOFTKNEE provides unobtrusive compression results; the greatest possible

loudness however can only be achieved in hard-knee mode. The slope of the

curves is shown on page 13.

DE-COMP:

This switch activates Decompression mode. This mode causes the compressor

to work in reverse: All signals above the preset threshold become louder, and

the Ratio controller determines the intensity of the volume increase. Please

note that the Make-Up controller now works exactly in reverse: the signal

becomes softer when the controller is turned to the right and louder when

turned to the left.

Page 12

12

Control Elements

Switches

Progressive Time Control: ATTACK

This function allows to switch in an adjustable automatization of the time

constants which is set up with the ATTACK control.

Put simply you can now influence the compression intensity for rapid signal

increases, or when the function is turned off determine the time until a certain

compression level is reached.

Progressive Time Control: RELEASE

The release times can also be switched to automatic based on the Release

control: the latter then determines an average value to return the release to.

Use of the Progressive Time Control is especially recommended with complex

summed signals.

KEY ON

KEY ON allows you to use an external signal as the control source for the

compressor.

This signal is brought in to the SIDECHAIN INPUT jack on the rear of the unit.

Now the control activity of the compressor is determined only by the external

signal.

KEY LISTEN

Use the KEY LISTEN switch to monitor the external side-chain signal. This

makes it easy for example to monitor and adjust a connected equalizer.

Whereas the VU meter normally indicates the in- and output level, enabling

KEY LISTEN causes the meter to indicate the side-chain signal. This provides a

quick way to check also whether a signal is present.

SLAVE

This allows you to switch the Kultube to Slave mode so that it can be controlled

from the Master device. All the function except for TUBE HARMONICS are now

controlled by the Master. Both the Master and all the Slave units now get the

same control signal. Also the Slave unit signals are evaluated for analysis.

ACTIVE

The ACTIVE switch turns on the Kultube. If the device is not turned on, the

input signal is fed directly to the output jacks via a relay hard bypass. The

ACTIVE switch thus allows for a quick A/B comparison. When the Kultube

is turned on the LED on the ACTIVE switch flashes to indicate the warm-up

process for the tubes. The unit is ready when the LED no longer flashes.

Page 13

13

Controls

THRESHOLD

The Threshold control determines the compressor threshold value. The value

scale for the THRESHOLD control indicates the level in dBu. Turning fully left

provides no control, and fully right provides compression starting at a level of

approximately –40 dBu.

RATIO

The RATIO control is used to set the ratio between the original signal and the

compressed signal. A ratio of 1:4 means that a level increase of 4 dB on the

input results in an output change of 1 dB. The more the control is turned right,

the more ‘dense’ the sound becomes. Turned fully right the unit works as a

limiter.

ATTACK

The ATTACK control determines the time the compressor needs to achieve a

reduction of 63% at a level jump of 20 dB. When turned fully left this time is

approximately 100 ms, and turned fully right the time is approximately 0.9 s.

When Progressive Time Control is enabled the effect is somewhat different:

now you are determining the degree to which the fast signal jumps are

compressed, whereas the attack time is automatically optimized (adapted).

Progressive Time Control mode is often advantageous, since the attack time

is only as fast as is necessary for the respective signal. The result is considerably unobtrusive and thus more musical compression behavior without undesired side-effects.

Control Elements

RELEASE

The RELEASE control is used to set the time the compressor needs to back off

by 63% to the original value. Turned fully left this time is approximately 30 ms,

or approximately 2 s for fully right. If Progressive Time Control is enabled,

the Release control is used to set the average value to which the automatic

release time is set back. The more the control is turned right, the slower the

averaging. This gives much better results than with the conventional method

of rigid release time control especially with complex musical material.

MAKE UP GAIN

The MAKE UP GAIN controller is used to change the output level within a

range of approximately –22 dB to +22 dB. For compression you thus set the

value that is indicated on the VU meter in GAIN REDUCT MODE. Actuating

the ACTIVE switch makes the volume increase perceptible. With the built-in

digital converter option the MAKE UP GAIN control is also used to set the level

for the converter. In DE-COMP mode the MAKE UP GAIN control works exactly

in reverse: Turning fully CW results in a damping of –22 dB, whereas fully left

results in a gain of +22 dB.

Page 14

14

Control Elements

Operation

Controls

TUBE HARMONICS

The TUBE HARMONICS control allows you to drive the tube output stage infinitely variable to desperation: the more the control is turned in, the further

the tube gets into saturation and the more harmonics are produced.

The output level of this stage is automatically adjusted, i.e. it keeps virtually the same level as the input signal. This allows you to to change the entire

sonic behavior of the tubes with just one control.

Understanding and enjoying the Kultube

In this section we will describe the individual parameters of the Kultube in

greater and use diagrams to enhance your understanding of how and why the

Kultube works.

The Threshold control

Fig. 1,

„Threshold Input vs. Output“

This parameter is used to determine at which level (or loudness) the unit

even responds by specifying a corresponding threshold value. Sometimes

you only need to process individual peaks, and at other times you need to

take more drastic action and set the threshold lower.

Fig. 1 shows the curves for various threshold settings. The X-axis represents the input level, from –50 dBu to +22 dBu. The Y-axis shows the output

level. You can see a definite change where the compressor is starting to work.

Before this point the ratio between the in- and output is exactly the same, so

that for example an input level of –30 dBu will also be present on the output.

In the area where the curve turns sharply the ratio is approximately 1:4. This

means that only a fourth of the dynamic gain is present on the output. A level

jump of 8 dB will be reflected by just 2 dB on the output.

Page 15

15

Understanding and enjoying the Kultube

The Ratio control

As indicated above, this determines the ratio between the in- and output

level above the threshold setting. The preset value specifies how the input

dynamics should behave with respect to the output: a ratio of 1 to 2 means

that only half of the dynamic change will be present on the output. At 10 dB

of dynamics there will only be 5 dB on the output, whereas using a ratio of 1:8

means 10dB becomes just 1.25 dB, etc.

In short, this determines how much dynamics is allowed to remain. If the

compressor is used to process vocals with very large variations in loudness,

you would select a high ratio value (1:5 – 1:10) to produce a well-balanced and

intelligible signal. When processing summed signals on the other hand, very

high settings will be used in part to process only the peaks of the signal. This

means careful setting of the threshold control is very important.

Operation

Fig. 2,

„Ratio Hardknee“

The slope of the compressor curve may be straight with a sudden rise (hardknee, Fig. 2), but it may also show a softly curved slope in which compression

begins slowly (soft-knee, Fig. 3).

Fig. 3,

„Ratio Softknee“

Page 16

16

Operation

Understanding and enjoying the Kultube

In the latter case the ratio changes depending on the in0ut signal. As the

preset threshold value is approached the ratio is comparatively small (1:1.5)

and doesn’t reach the preset maximum value until high input levels are

present. The result is much less conspicuous compression, since the process

does not kick in as suddenly as with hard-knee mode. On the other hand,

hard-knee results in greater loudness and density of the program material.

When using the de-compressor the ratio is exactly reversed, i.e. an input

level change of 2dB for example results in an output of 4dB. The printed ratio

values cannot be used here, since they clearly deviate. You should therefore

use the de-compressor with care, since it will always make the signals louder.

Setting of the threshold control should also be done with caution.

The Attack control

Among the most important functions of a compressor is controlling the

time constants. The attack control determines one of these times, namely the

kick-in behavior of the compressor. In general terms this determines the time

starting at which the signal should be reduced. This allows you to specify how

rapid signal jumps are handled.

Fig 4

„Attack Normal“

How this look with a sinus-burst (test signal) is shown in Fig. 4.

Here you can clearly see that the first part of the burst signal is unprocessed

and only responded to when the settings are faster. When attack times are

set very short, the compressor responds to even the most rapid transients,

so that the peaks are captured. With slower settings transients are allowed to

pass untouched – a kind of leveling in which the compressor responds more

to the average level. If you are processing a drum loop for example, changing

the attack time can cause a few transients to be passed through. Changing

the attack control now determines how many transients remain unprocessed.

Using very short values (0.5 ms) allows in part just a half-wave of a signal to

remain unprocessed, whereas medium values (10ms) result in a whole series

of waveforms to be ignored. This type of response is also frequently used to

make transients in a signal more clearly audible.

Page 17

17

Understanding and enjoying the Kultube

Processed in this way, drums get more self assertion and sound ‚faster’.

The best setting is not always easy to find, since you usually need to find a

compromise. Very fast settings run the risk of producing audible distortions

– especially in the case of low frequencies, since the compressor now tries

to control each waveform rise. The corresponding control signal assumes a

“saw-tooth” form which distorts the audio signal.

To suppress this effect, you would have to again increase the attack

time until the distortions no longer occur. In normal operation the Kultube

attack control works exactly as just described. There is a unique feature of

the Kultube however that greatly expands the compression possibilities by

providing special technologies to achieve optimum results in all situations:

the Progressive Time Control (PTC), which is described in the following.

Progressive Time Control (Attack)

Simply put, the Progressive Time Control (PTC) is an adjustable automatic

process that works as follows.

The usual (rigid) attack control of a compressor functions, as described

above, such that a resistance value can be varied within the controller circuit

to determine the control response time. The main drawback to this, particularly when it comes to complex musical material, is that the setting only

applies to a moment, but is not ideal for every moment.

Operation

Automatic setting of the attack time (in response to the input signal) has

the advantage of making the optimum setting for each moment. For this the

changing of the resistance value that determines the attack times needs to be

automated. A special circuit determines the momentary ideal attack time and

sets the VCF appropriately. These times can vary between 20 μs and 980 ms

and are set in fractions of a second.

This automatic process is thus a guarantee for perfect compression results,

but the PTC in the Kultube goes even a step further: The attack control can be

used to determine the intensity with which fast signal jumps are compressed

in automatic mode. When you change the attack time using PTC, as for

example when processing drum sounds, you can specify the handling of rapid

signal jumps while at the same time ensuring that the attack behavior is

not affected. A drum loop thus retains its original sonic character while still

appearing denser.

Page 18

18

Operation

Fig. 5,

„Attack PTC“

Understanding and enjoying the Kultube

Fig. 5 shows the control behavior using a sinus burst as an example. In various

settings it is clearly to see that the burst signal remains almost unchanged in

its form; only the intensity changes.

Fig. 6,

„Release Normal“

The PTC feature can provide outstanding results not only for percussive

signals but also for many other musical signals (vocals, guitar, bass, horns,

synthesizers, etc.), since compression is used with the greatest efficiency,

is unobtrusive and sounds „natural“. You should feel free to jump right in to

experimenting with the PTC and find out what it can do for you.

The Release control

The Release control is used to determine how long the compressor needs

after a reduction to drop back to the original value. How it works is shown in

Fig. 6.

Here you see the same sinus burst as for the attack diagrams, but just the

last burst-on part is shown. You can clearly see how the times within which

the original is reached change with various settings of the release control.

Page 19

19

Understanding and enjoying the Kultube

The release parameter is also for the most part responsible for unobtrusive

compression. This means it is hard to find the perfect setting as with the Attack

control – particularly in the case of complex summed signals a fixed release

time may hardly be usable. As with the attack times you must always find

a compromise: for very fast and short signal peaks (e.g. drums and percussion) you will want to select short release times (100 ms). But this setting is

usually unusable in all other parts of the musical piece, since now every single

dynamic change will be processed – which will quickly sound very rough and

distorted.

By selecting longer release times (1 s), the remaining sections will sound

quieter, but when short, loud peaks occur your music will start pumping. Here

again the PTC will yield better results.

Progressive Time Control (Release)

Here again we are talking about an automatic release that can be influenced by the release control. When PTC release control is activated, the

Kultube calculates an average of the levels that the music signal is providing.

Automatic control of the release time now refers to this average value, so that

while short, loud peaks are handled correspondingly fast, when it comes to

complex material (summed) the system will not respond to each and every

little peak near the average.

Operation

Furthermore the PTC allows you to affect the averaging: the faster the

release time in PTC mode, the more signal components are included in the

processing. This means you will want to select rather slower release values

for summed signals, whereas drum processing for example will yield the best

results using fast settings.

How various settings for a drum loop might look is shown in Figs. 7a-c. Line

A represents the control voltage for the discrete gain cell (instead of VCAs),

Line B the rectified musical signal, and C the averaging.

A B C

Fig. 7a

Page 20

Operation

Fig. 7b

Fig. 7c

Understanding and enjoying the Kultube

A B C

A

For settings with larger averages the change in the release time is easy to

recognize. With very small values the control voltage for the Gain Cell “sticks”

to the rectified signal and works almost like an envelope follower.

Fig. 8 on the next page shows the various effects of different release time

settings on a sinus burst, although the principle is not as easily seen here.

These changes are most clearly heard in a drum loop with lots of dynamics.

Turned fully left (fast averaging) the drums pump and you get lots of volume,

whereas turned fully right the control is unobtrusive, but you gain less loudness. For summed signals a mid-range setting (0.8 s to 1.5 s) is therefore

recommended. As in the case of attack control with PTC, release control

makes sense not just for sum processing, but can also be used to outstanding

advantage with other signal types such as bass, percussion, effects or that at

least as problematic as widespread signal type “untrained speaker”, while at

the same time greatly simplifying your processing.

B C

20

Page 21

Understanding and enjoying the Kultube

Operation

Fig 8 „Release – PTC“

Using and enjoying the Kultube

Summed signal processing

The main application area for the Kultube is in stereo summed signal compression together with an analog mixing console.

Here the Kultube is looped into the insert paths („Insert Send/Return“).

The insert paths are generally in front of the console master fader so that

the compressor is driven independent of the master fader settings. If additional effects devices (such as EQ) are located in the same insert loop, the

Kultube may be connected either in front or behind – there is no certain order

required.

Single track and subgroup processing

Another important application is single track processing (vocals, bass,

guitar, strings etc.). The Kultube is looped in the insert paths of the respective

channels. Processing is then usually done during mixdown. The same applies

of course to subgroup processing for selectively compressing individual

instrumental groups (such as drums).

Applications

Console:

Inserts Send/Return

Single tracks and

subgroups:

Channel inserts

21

Page 22

22

Applications

Using and enjoying the Kultube

Sidechain

External

compression control

Frequency-selective

Compression

De-Essing

Ducking:

Automatically a desired

level relation between two

signals (e.g. music and

microphone)

Ducking &

De-Compression:

Transferring rhythmic

structures to any signal

Use of the SIDECHAIN inputs expands the possibilities for controlling

compression. A typical application is frequency-selective compression,

whereby an external equalizer is used to raise the frequencies at which the

compressor should respond or to filter out the frequency band you wish the

compressor to ignore.

If a summed signal has a lot of bass for example that you want to preserve,

you often run into the problem that the compressor responds strongly to

these frequency ranges, making it difficult to process mid- and high frequencies. By using the equalizer to reduce bass frequencies, the Kultube will no

longer respond to them as intensely and you can address the other ranges

with no difficulty.

Yet another typical application is de-essing: The corresponding frequency

range (around 6-8kHz) is raised so that the compressor engages precisely

there to reduce the sibilance. To monitor the filtered signal (i.e. the signal

supplied by the EQ), press the KEY LISTEN switch on the front panel. Now you

can easily monitor the EQ setting without any additional measures. As soon as

you need to use the signal in the side-chain, simply press the KEY ON switch.

Another interesting and useful feature is ducking, whereby the side-chain is

fed for example with a microphone signal. The music volume is reduced whenever speech is introduced (great for DJs). Other very interesting effects can

be obtained by turning on decompression mode with the ducking application.

To do this, turn the MAKE UP GAIN controller to full clockwise (means lower

in this mode!) and use the Threshold and Ration controllers to determine the

desired processing point. Now the loudness of the music signal is controlled

by the side-chain, i.e. the louder the side-chain, the louder the music signal

becomes. This technique allows you to create totally new sounds! Here is just

one example: feed a synthpad to the audio input of the Kultube and a drum

loop to the side-chain. The synthpad now gets the same rhythm as the drum

loop!

Note on the VU meter: if the meter indicates output level, pressing the KEY

LISTEN switch will show the signal from the side-chain input.

22

Page 23

23

Using and enjoying the Kultube

Multi-channel and 5.1 surround applications

Applications

The Kultube lets you use the MULTI CHANNEL LINK function to link any

number of devices for multi-channel or surround applications. Simply define a

master for controlling all the other units (slaves). Each slave must be defined

as a slave using the SLAVE switch on the front panel. All functions except for

TUBE HARMONICS output control are not controlled by the master: ACTIVE,

THRESHOLD, RATIO, ATTACK, RELEASE, MAKE-UP GAIN, SOFT KNEE, DE-COMP

and PTC. Please note that the PTC lights on the slaves will not come on even

though the master activates the function. The TUBE HARMONICS control must

be set individually on each unit, since this control is not affected by a control

voltage – such “remote control” would be extremely complex and would be

far out of proportion to the benefit, especially since this setting is generally

not changed continuously anyway.

The data from all slave units are also used to create control voltages, so that

all units operate with the same control voltage.

We recommend proceeding as follows when working with 5.1 surround:

The master unit is responsible for the front left and right channels. A second

Kultube processes the rear surround channels (SL & SR) and is operated in

slave mode. The third unit (2nd slave) is used to process the center and subchannel. All the settings are made on the master, with the ACTIVE switch used

to conveniently select all the devices. To process certain channels separately

you need to deactivate the SLAVE switch only on the corresponding device.

Multi Channel Link:

Multi channel or

surround processing in

master/slave-mode

Recommended con-

guration for 5.1 processing

23

Page 24

Specications

Measurements

Frequency range (100 kHz = -3 dB) .......... 10 Hz-150 kHz

Common mode rejection (@ 0 dBu) ......... 1 kHz: › 80 dB / 10 kHz: › 65 dB

THD & N (@ 0 dBu) .................................. › 82 dB

S/N (A-weighted) .................................... 90 dBu

Inputs

Input impedance ..................................... Line: 20 kOhm

Max. input level ...................................... Line: +22 dBu

Outputs

Max. output level (XLR & Jack) ................ +22 dBu

Output impedance ................................... ‹ 50 Ohm

Power Supply

Toroidal transformer ............................... 30 VA

Fuses ...................................................... 230 V/50 Hz: 500 mA

... 115 V/60 Hz: 800 mA

Guarantee

Dimensions

Standard-EIA-Housing (19 inch/2U) ......... 482 x 88 x 210 mm

Weight ..................................................... 4,3 kg

All SPL products come with a two-year manufacturer’s guarantee against

defects in material or assembly from the date of purchase. End users are

supported in the two-year guarantee through their distributor or dealer.

In such cases, please contact your dealer for full guarantee conditions and

service.

Direct SPL product support requires product registration. Please fill out the

guarantee card enclosed in the package legibly in printed letters and send it

directly to SPL. Or use the online registration form that may be reached at

www.soundperformancelab.com (international clients) or www.spl-usa.com

(US clients).

24

Loading...

Loading...