Page 1

Manual

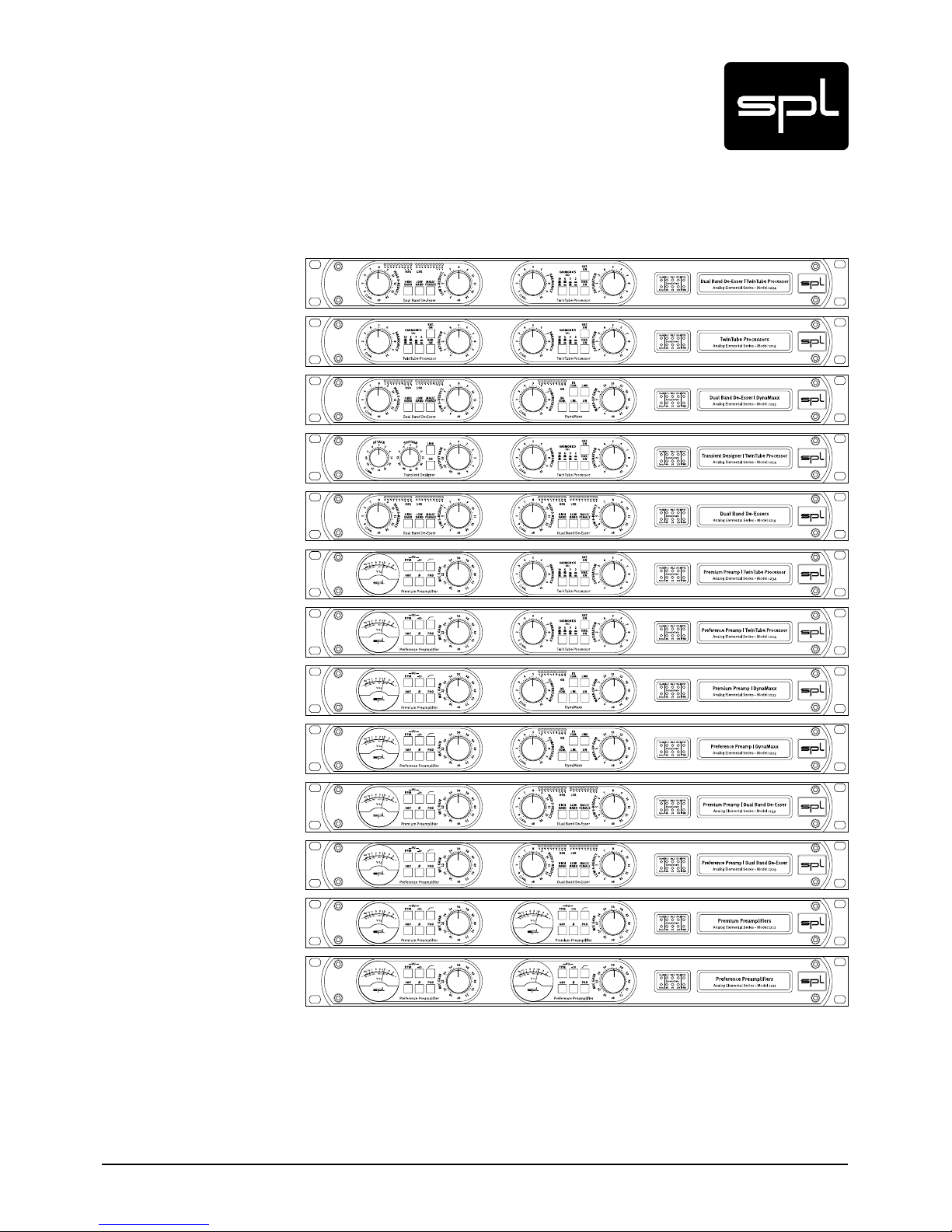

Twin Module Series featuring the modules

Premium Mic Pre, Preference Mic Pre, Dual-Band De-Esser, DynaMaxx, Transient Designer und TwinTube

Analog Elemental Series

Models 1211, 1212, 1214, 1219, 1223, 1224, 1229, 1233, 1234, 1239, 1254, 1293, 1294

Page 2

2

Analog Elemental Series

Content

Manual Analog Elemental Series 6

CE Conformity 6

Notes on Environmental Protection 6

Contact 6

Symbols and Notes 6

Important Security Advices 7

Scope of Delivery and Packaging 8

Hook Up 8

Placement 8

Introduction 8

The Analog Elements 8

Die Signalprozessoren der zweiten Generation 9

Concept and Categories of the Analog Elemental Series 9

Dual-Channel Preamplifiers 9

Channel Strips 9

Processing Units 10

Optional Features 11

Information on Transformers 11

Common Technical Specifications 11

Dimensions and Weight 11

Rear Panel | Wiring Diagram 12

Rear Panel | Versions 13

Rear Panel 1 13

Rear Panel 2 13

Rear Panel 3 13

Optional Converter: Wiring Diagram 13

Rear Panel | Connections and Switches 14

Signal Connections 14

Input and Output Electronics 14

XLR sockets 14

Balanced connections 14

Unbalanced connections 14

Power connection and fuse 15

Voltage Selector 15

Power switch 15

GND Lift 15

Channel Strip Switch (Ch. 1 OUT = Ch.2 IN) 15

Page 3

3

Analog Elemental Series

Content

The Modules 16

Premium Mic Pre | Introduction 16

Features 16

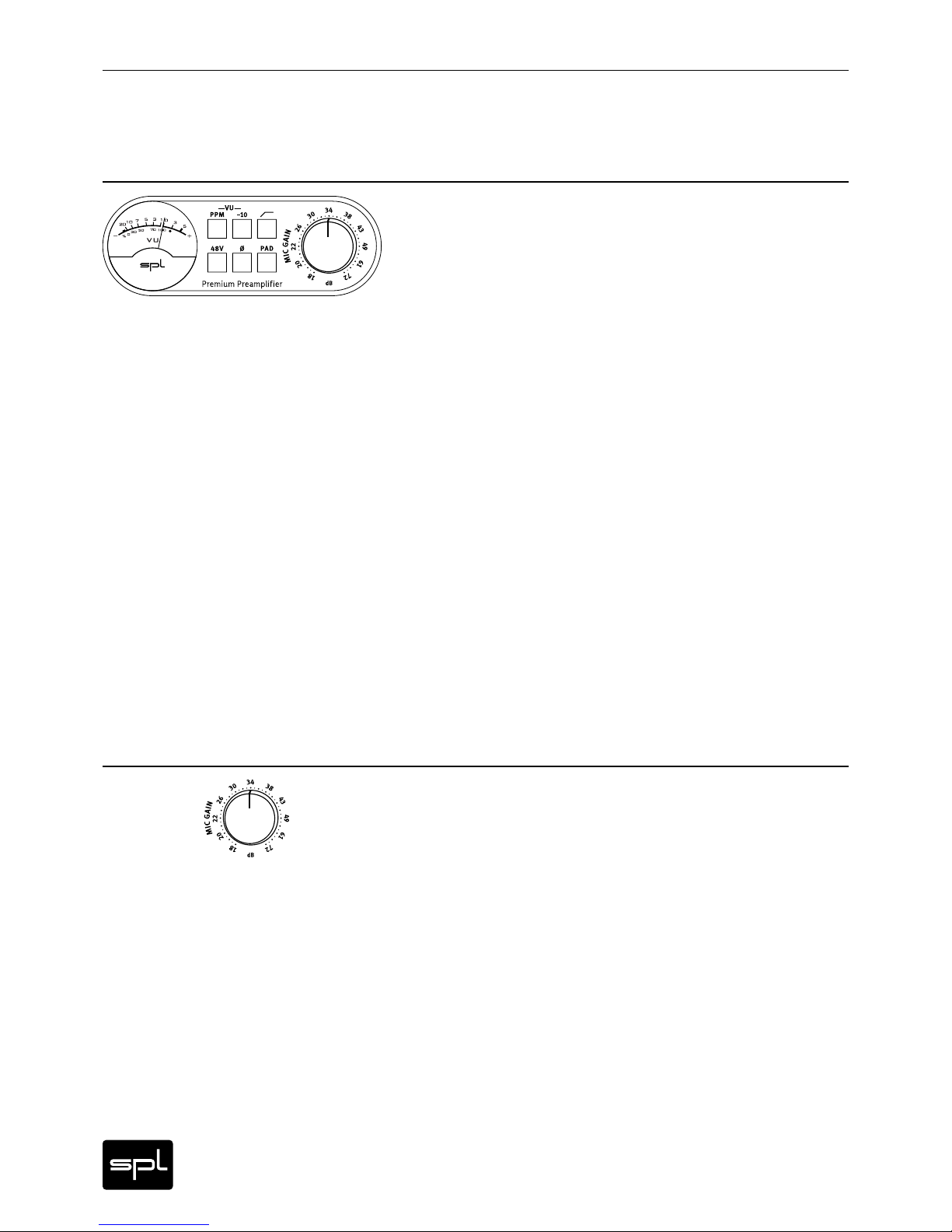

Premium Mic Pre | Control Elements 16

Mic Gain 16

About Leveling 17

VU Meter 17

PPM 17

-10 17

48 V Phantom Power Supply 18

Pad 18

Phase Reverse 18

High-Pass Filter 18

Premium Mic Pre | Technology 19

Triple Stage Preamp 19

Stage 1 – The Input Transformer 19

Stage 2 – The Discrete Differential Amplif ier 19

Stage 3 – The Instrumentation Amplifier 20

Foil and Styroflex Capacitors 20

Output Stages 20

Premium Mic Pre | Technical Specifications 20

Audio 20

Input 20

Output 20

Control Elements 20

Premium Mic Pre | Block Diagram 21

Preference Mic Pre | Introduction 22

Main Features 22

Preference Mic Pre | Control Elements 22

Mic Gain 22

About Leveling 22

VU Meter 23

PPM 23

-10 dB 23

48-V-Phantom Power Supply 23

Phase Reverse 24

High-Pass Filter 24

Preference Mic Pre | Technology 25

SSM 2019 25

Servo Drive Design 25

Foil And Styroflex Capacitors 25

Output 25

Preference Mic Pre | Technical Specifications 26

Audio 26

Input 26

Output 26

Control Elements 26

Preference Mic Pre | Block Diagram 27

Page 4

4

Analog Elemental Series

Content

Dual-Band De-Esser | Introduction 28

The Dual-Band De-Esser 28

Dual-Band De-Esser | Control Elements 28

HI-Band On, Low-Band On 28

Low S-Reduction 29

High S-Reduction 29

Male/Female 29

Signal-LED (SIG.) 29

Dual-Band De-Esser | Technical Specifications 30

Audio 30

Output 30

Control Elements 30

Dual-Band De-Esser | Block Diagram 31

DynaMaxx | Introduction 32

DynaMaxx | Control Elements 32

Compression 32

Make-Up Gain 33

Gain Reduction LEDs 33

DE-COM. (De-Compression) 33

FX Com. (Effect Compression) 34

Lim. (Limiter) 34

On 34

Link 35

Signal-LED (SIG.) 35

DynaMaxx | Technology 35

Why are conventional compressors unsatisfactory? 35

Full-Band versus Multi-Band 36

Attack Time Automation 36

Release Time Automation 37

Threshold And Ratio 37

DynaMaxx | Technical Specifications 38

Audio 38

Input 38

Output 38

DynaMaxx | Block Diagramm 39

Page 5

5

Analog Elemental Series

Content

Transient Designer | Introduction 40

Transient Designer | Control Elements 40

On 40

Attack 40

Sustain 41

Output Gain 41

Link Mode 41

Signal LED 41

Transient Designer | Applications 42

Drums & Percussions 42

Guitars 43

Bass: Staccato vs. Legato 43

Ambience 43

Keyboards & Sampler 43

Post Production 43

Mastering 43

Transient Designer | Technical Specifications 44

Audio 44

Input 44

Outputs 44

Transient Designer | Block Diagram 45

TwinTube | Introduction 46

TwinTube | Control Elements 46

HAR. ON/SAT. ON 46

HARMONICS Control 46

HARMONICS Switch 47

SATUR ATION Control 47

Signal LED 47

TwinTube | Applications 47

Vocals 47

Acoustic Guitars 47

TwinTube | Measurements 48

TwinTube | Technical Specifications 50

AUDIO 50

AUDIO – CUMUL ATIVE (Harmonics and Saturation Stage) 50

TwinTube | Block Diagram 51

Page 6

6

Analog Elemental Series

Symbols and Notes

Version 1.0 – 6/2012

Developers: Wolfgang Neumann, Enzo Triolo, Jens Gronwald

This manual contains a description of the product. It in no way represents a guarantee of

particular characteristics or results of use. The information in this document has been carefully compiled and verified and, unless otherwise stated or agreed upon, correctly describes

the product at the time of packaging with this document.

Sound Performance Lab (SPL) continuously strives to improve its products and reserves the

right to modify the product described in this manual at any time without prior notice.

© 2012 SPL electronics GmbH. All rights reserved. This document is the property of SPL and

may not be copied or reproduced in any manner, in par t or fully, without prior authorization by

SPL. Names of other companies and their products are trademarks of their respective owners.

CE Conformity

The construction of the Analog Elemental Series is in compliance with the

standards and regulations of the European Community.

Notes on Environmental Protection

At the end of its operating life, this product must not be disposed of with regular

household waste but must be returned to a collection point for the recycling of

electrical and electronic equipment. The wheelie bin symbol on the product,

user‘s manual and packaging indicates that. The materials can be re-used in

accordance with their markings. Through re-use, recycling of raw materials, or other forms

of recycling of old products, you are making an important contribution to the protection of

our environment. Your local administrative of fice can advise you of the responsible waste

disposal point. WEEE Registration: 973 349 88.

Contact

SPL electronics GmbH

Sohlweg 80, 41372 Niederkruechten, Germany

Phone +49 (0) 2 1 63 98 34 0, Fax +49 (0) 2 1 63 98 34 20

E-Mail: info@spl.info, Website: spl.info

© 2012 SPL electronics GmbH. All rights, technical changes, mistakes and misprints reserved.

The SPL logo, Analog Code®,

Vitalizer

®

and Atmos® are tr ademark s of SPL elect ronics Gmb H.

All oth er logos and b rand name s are registe red trade marks

of thei r respecti ve owners .

IN THIS MANUAL A LIGHTNING SYMBOL WITHIN A TRIANGLE WARNS YOU ABOUT THE

POTENTIAL FOR DANGEROUS ELECTRICAL SHOCKS – WHICH CAN ALSO OCCUR EVEN AFTER

THE MACHINE HAS BEEN DISCONNECTED FROM A POWER SOURCE.

AN EXCLAMATION MARK (!) WITHIN A TRIANGLE IS INTENDED TO MAKE YOU AWARE OF

IMPORTANT OPERATIONAL ADVICE AND/OR WARNINGS THAT MUST BE FOLLOWED. BE

ESPECIALLY ATTENTIVE TO THESE AND ALWAYS FOLLOW THE ADVICE THEY GIVE.

The symbol of a lamp directs your attention to explanations of important functions or applications.

Attention: Do not attempt any alterations to this machine without the approval or supervision

of SPL electronics GmbH. Doing so could nullif y completely any and all of your warranty/guarantee rights and claims to user support.

Manual Analog Elemental Series

Page 7

7

Analog Elemental Series

Please note and retain this manual. Carefully read and follow all of the safety and operating

instructions before you use the machine. Be doubly careful to follow all warnings and special

safety instructions noted in this manual and on the unit.

Connections: Only use the connections as described. Other connections can lead to health

risks and equipment damage.

Water and humidity: Do not use this machine anywhere near water (for example near a wash

basin or bath, in a damp cellar, near swimming pools, or the like). In such cases there is an

extremely high risk of fatal electrical shocks!

Insertion of foreign objects or fluids: Never allow a foreign object through any of the

machine‘s chassis openings. You can easily come into contact with dangerous voltage or

cause a damaging shor t circuit. Never allow any fluids to be spilled or sprayed on the machine.

Such actions can lead to dangerous electrical shocks or fire!

Opening the unit: Do not open the machine housing, as there is great risk you will damage the

machine, or – even after being disconnected – you may receive a dangerous electrical shock!

Electrical power: Run this machine only from power sources which can provide proper power

in the range from 100 to 250 volts. When in doubt about a source, contact your dealer or a

professional electrician. To be sure you have isolated the machine, do so by disconnecting all

power and signal connections. Be sure that the power supply plug is always accessible. When

not using the machine for a longer period, make sure to unplug it from your wall power socket

and from the guitar amp.

Cord protection: Make sure that your power and guitar amplifier signal cords are arranged

to avoid being stepped on or any kind of crimping and damage related to such event. Do not

allow any equipment or furniture to crimp the cords.

Power connection overloads: Avoid any kind of overload in connections to wall sockets,

extension or splitter power cords, or to signal inputs. Always keep manufacturer warnings

and instructions in mind. Overloads create fire hazards and risk of dangerous shocks!

Lightning: Before thunderstorms or other severe weather, disconnect the machine from wall

power (but to avoid life threatening lightning strikes, not during a storm). Similarly, before

any severe weather, disconnect all the power connections of other machines and antenna and

phone/network cables which may be interconnected so that no lightning damage or overload

results from such secondary connections.

Air circulation: Chassis openings offer ventilation and ser ve to protect the machine from overheating. Never cover or otherwise close of f these openings. Never place the machine on a soft

surface (carpet, sofa, etc.). Make sure to provide for a mounting space of 4-5 cm/2 inches to

the sides and top of the unit when mounting the unit in racks or on cabinets.

Controls and switches: Operate the controls and switches only as described in the manual.

Incorrect adjustments outside safe parameters can lead to damage and unnecessary repair

costs. Never use the switches or level controls to ef fect excessive or extreme changes.

Repairs: Unplug the unit from all power and signal connections and immediately contact a

qualified technician when you think repairs are needed – or when moisture or foreign objects

may accidentally have gotten in to the housing, or in cases when the machine may have fallen

and shows any sign of having been damaged. This also applies to any situation in which the

unit has not been subjected to any of these unusual circumstances but still is not functioning

normally or its performance is substantially altered. In cases of damage to the power supply

and cord, first consider turning off the main circuit breaker before unplugging the power cord.

Replacement/substitute parts: Be sure that any service technician uses original replacement

parts or those with identical specifications as the originals. Incorrectly substituted parts can

lead to fire, electrical shock, or other dangers, including further equipment damage.

Safety inspection: Be sure always to ask a ser vice technician to conduct a thorough safety

check and ensure that the state of the repaired machine is in all respects up to factory standards.

Cleaning: In cleaning, do not use any solvents, as these can damage the chassis finish. Use

a clean, dry cloth (if necessary, with an acid-free cleaning oil). Disconnect the machine from

your power source before cleaning.

Important Security Advices

Page 8

8

Analog Elemental Series

Scope of Delivery and Packaging

Hook Up

Introduction

The scope of delivery comprises the Analog Elemental Series unit, the power cord, the guarantee card and this manual.

Please keep the original packaging. In case of a ser vice procedure the original packaging

ensures a safe transport. It also serves as a safe packaging for your own transports if you do

not use special transportation cases.

Be very careful to check that the rear chassis power selection switch is set to the correct

local line voltage position before using the unit (230 V position: 220-240 V/50 Hz, 115 V position: 110-120 V/60 Hz)! When in doubt about a source, contact your dealer or a professional

electrician.

Before connecting any equipment make sure that any machine to be connected is turned off.

Follow all safety instructions on page 5 and read further information on connections on page

10 onwards.

Placement

Place the unit on a level and stable surface. The unit’s enclosure is EMC-safe and effectively

shielded against HF interference. Nonetheless, you should carefully consider where you place

the unit to avoid electrical disturbances. It should be positioned so that you can easily reach

it, but there are other considerations. Try not to place it near heat sources or in direc t sunlight,

and avoid exposure to vibrations, dust, heat, cold or moisture. It should also be kept away

from transformers, motors, power amplifiers and digital processors. Always ensure sufficient

air circulation by keeping a distance of 4-5 cm/2 inches to the sides and top of the unit.

The Analog Elements

Our research and development efforts are always ruled by two maxims: innovation and ease

of use. In many occasions both approaches get interleaved so that a good product idea is, at

the same time, very easy to use, when implemented as a musically sound solution. Hence, it

is no surprise that our „one knob“ devices, like the SPL De-Esser and DynaMax x compressor,

have been successful for so many years and are considered classics among our products.

Even though originally conceived in 1U 19-inch format, the possibility of applying the modular

concept to our preamps and processors, in order to satisfy the wishes of customers with ver y

specific needs, has always been lingering in our minds. The introduction of the RackPack

Series f inally allowed for a modular system that can accommodate six different modules in

three frame options:

• Premium Mic Pre — High-end microphone preamplifier with transformer

• Preference Mic Pre — Reliable preamplif ier ideal for multi-channel applications

• Dual-Band De-Esser — Second generation of our unique De-Esser with phase cancellation

technolog y

• DynaMaxx — Second generation of the best set & forget compressor with signal-dependent automation

• Transient Designer — Second generation processor by the original inventor of the transient tool

• TwinTube — Tube processor for saturation and presence effects

Key to the selec tion of modules was the idea of offering an elemental collection of combinable

analog components for music production. Some modules were developed from scratch with

this in mind (Premium and Preference preamps, TwinTube), while some others were enhanced

and adapted to the modular concept (which resulted in the second generation of our beloved

DynaMaxx, Dual-Band De-Esser and Transient Designer processors). In order to put to use

all the work invested in developing our analog elements and translate it into single units, we

created the Analog Elemental Series.

Page 9

9

Analog Elemental Series

The Next Generation Signal Processors

The development of the processors brought with itself the following advances:

• On all three processors that were revised the operating voltage was increased from +/-15

to +/-18 volts. This allows us to enhance the performance of a circuit, considering that the

basis of every circuit is the voltage/performance ratio. Thus, dynamic range, signal-tonoise ratio and THD can be improved.

• Dual-Band-De-Esser: two bands for more precise and flexible processing.

• DynaMaxx: modifications to allow for the optional fitting of a transformer.

• Transient Designer: additional output level control — an important enhancement to the

device‘s operation which allows for an immediate control of level dif ferences.

Concept and Categories of the Analog Elemental Series

Every Analog Elemental unit combines two modules. Depending on the application, the 13

resulting units can be sorted into three product categories:

• Preamplifiers consisting of two Premium or Preference modules — the outstanding

RackPack Preamps in 1U 19-inch units.

• Channel Strips consisting of preamp and processing modules — perfect front ends with

optimally matched processing for vocals or instruments.

• Processing Units to complement analog outboard equipment.

The Analog Elemental concept makes it possible to build any imaginable conf iguration with

SPL‘s elemental processing tools. Every module combination results in an exceptional and

unique unit. We have summarized here the most impor tant aspects of the different conf igurations.

Dual-Channel Preamplifiers

Premium Preamplifiers

It is not easy to make high-quality recordings. An exceptional sonic foundation to work upon

is a must. This can be achieved with microphones and preamps whose impulse response and

transduction capabilities are not limited — just like the SPL Premium Preamps. Created by

SPL founder Wolfgang Neumann, these classic solid-state masterpieces featuring an integrated transformer seduce anybody that lends an ear to them. The two-channel unit resulting

from the combination of two Premium Preamp Modules could withstand comparison to any

product, regardless of their price. Model Number: 1212.

Preference Preamplifiers

Our goal when developing the Preference Preamps was to match professional sound quality

to the highest reliability possible. Our decade-long experience designing and manufacturing

microphone and instrument preamps guarantees the best price-performance ratio. The

results can be heard in all sorts of situations — regardless of whether it is live or in the studio,

the SPL Preference Preamps provide a rock-solid foundation for any production. And they are

also perfectly suited to replace the integrated preamps of audio interfaces and mixers. Model

Number: 1211.

Channel Strips

Premium or Preference Preamp & DynaMaxx

Do you play or have to record instruments often? There are lots of ways to do it, but then

again, it all comes down to the end result. Our way to achieving outstanding results is arguably the shortest one, considering that it consists of only two knobs: „Gain“ (preamplification) and „Compression.“ This applies to vocal recordings as well. The high-end alternative to

the Preference/DynaMaxx Combo, Model 1223, is the Premium/DynaMaxx unit, Model 1233.

>

Introduction

Page 10

10

Analog Elemental Series

Premium or Preference Preamp & Dual Band De-Esser

The combination of a Premium or Preference Preamp with the Dual-Band De-Esser preserves

the sound character and timbre of voices, even with extreme settings. An unbeatable combination for live applications. The high-end alternative to the Preference/Dual-Band De-Esser

Combo, Model 1229, is the Premium/Dual-Band De-Esser unit, Model 1239.

Premium or Preference Preamp & TwinTube

The combination of a preamp w ith the TwinTube effec ts processor allow s for fascinating sound

shaping possibilities. Two totally independent tube effects — Saturation and Harmonics —

make vocals sound more sonorous and rootsy, while highlighting their presence and emphasizing the harmonics. Presence, authority, cutting edge, glaze... take full advantage of the

character of the vocals. The high-end alternative to the Preference/TwinTube Combo, Model

1224, is the Premium/TwinTube unit, Model 1234.

Processing Units

Dual-Band De-Essers

Those who need two Dual-Band De-Esser units will find in this combination the perfect 1U 19“

solution. In case more units are needed, a RackPack frame is the best way to go ( 3U 19“ rack

frames that can host four or eight Analog Elemental Series modules).

Dual Band De-Esser & TwinTube

This combination effectively expands any sound engineer‘s processing needs: De-Essing and

TwinTube processors are ideal for vocal tracks and are the perfect complement to any respectable preamp. Model Number: 1294.

Dual-Band De-Esser & DynaMax x

A very nice processing combination for vocals. Being able to have the two most straightforward one-knob SPL processors under the same hood is not only exciting but also comforting

— it is very easy to abandon oneself to their magic and prowess. Model Number: 1293.

TwinTube Processors

Considered one of the world‘s finest tube effects processors, the TwinTube provides the two

single most important artifacts generated by tubes: Saturation and Harmonics. The warmth,

presence and suppleness analog tube and coil filtering provide can enrich any production,

regardless of the music genre. Model Number: 1214.

Transient Designer & TwinTube

The second generation Transient Designer (with output level control) and the exceptional

TwinTube together in one processing unit — a combination that can certainly fill the gaps of

many studios when it comes to analog processing arsenal. This is a perfect example of something that is much more than the sum of its parts: the Transient Designer allows to clearly

emphasize sound parts that can then be processed with the TwinTube. Very effective on all

sorts of percussive signals, the tube sound complements perfectly the Transient Designer

and opens up an unprecedented amount of sound shaping possibilities. Model Number: 1254.

Introduction

Page 11

11

Analog Elemental Series

Optional Features

• Optional for all processing modules: Lundhal transformers at the input and output stages.

Premium preamplifier modules integrate input and output transformers. Preference

preamplifier modules cannot be fitted with transformers. Transformers are not visible

from the outside and are only available as a factor y option during purchase. Retrofitting is

not contemplated. More information on transformers below.

• Optional for every Analog Elemental unit: additional digital output via a converter module.

For more information on the Converter Module refer to page 9.

• Additional functions for Channel Strip modules: channel strip switcher on the rear. When

engaged, this switch internally forwards the output signal of the first module directly into

the input of the second module, making external cabling unnecessary.

Information on Transformers

All processing modules can be equipped with input and output transformers. Exceptions:

Preference Mic Pre is not available with transformers, Premium Mic Pre always comes with

inout and output transformers.

We think a good part of the „warmth“ that is commonly associated with vintage gear comes

from transformers. With transformers the low end and lower mids sound rounder, full-bodied

with more punch. The top end gets a silky touch and benef its from improved presence without

sounding boosted. Reasons are reduced odd harmonics (which produce harsh top end

impressions) and a slower characteristic compared to electronic stages which causes a more

voluminous sound.

We recommend transformers especially for vocals while electronic stages can be better for

highest precision in signal transmission (transients), but in the end it‘s a question of personal

taste, applications or for example which mics are in use.

Transformers transmit the signal by induction. This means there is no static connection (like

a wire) to transmit the signal. This protects the unit from damage caused by power failures in

the input/output connections. In addition, hum problems are effectively avoided if balanced

connections are used throughout. That‘s why transformers can be very interesting for live

units or in units used for facilities that need highest operational safety (broadcast, sound

reinforcement). Another notable advantage for many live and recording applications is that

very long cable leng ths are possible with no loss in signal quality. At the end of the day, it

depends on personal taste, main applications or for example on the microphone and other

equipment if transformers are required or not.

Common Technical Specifications

Power Supply Toroidal transformer

Fuses 230 V AC, 50 Hz: 315 mA

120 V AC, 60 Hz: 630 mA

Voltage Selector 115V/230V

Power Consumption @ 2 30 V: 9,1 W/10,8 VA

@ 115 V: 5 ,6 W/7,1 VA

Dimensions and Weight

Housing (W x H x D) 482 x 88 x 320 mm (depth includes knobs and sockets)

Weight ca. 4,6 kg

Weight with Premium Module(s): ca. 4,9 kg

Weight with TwinTube Module(s): ca. 4,8 kg

Introduction

Page 12

12

Analog Elemental Series

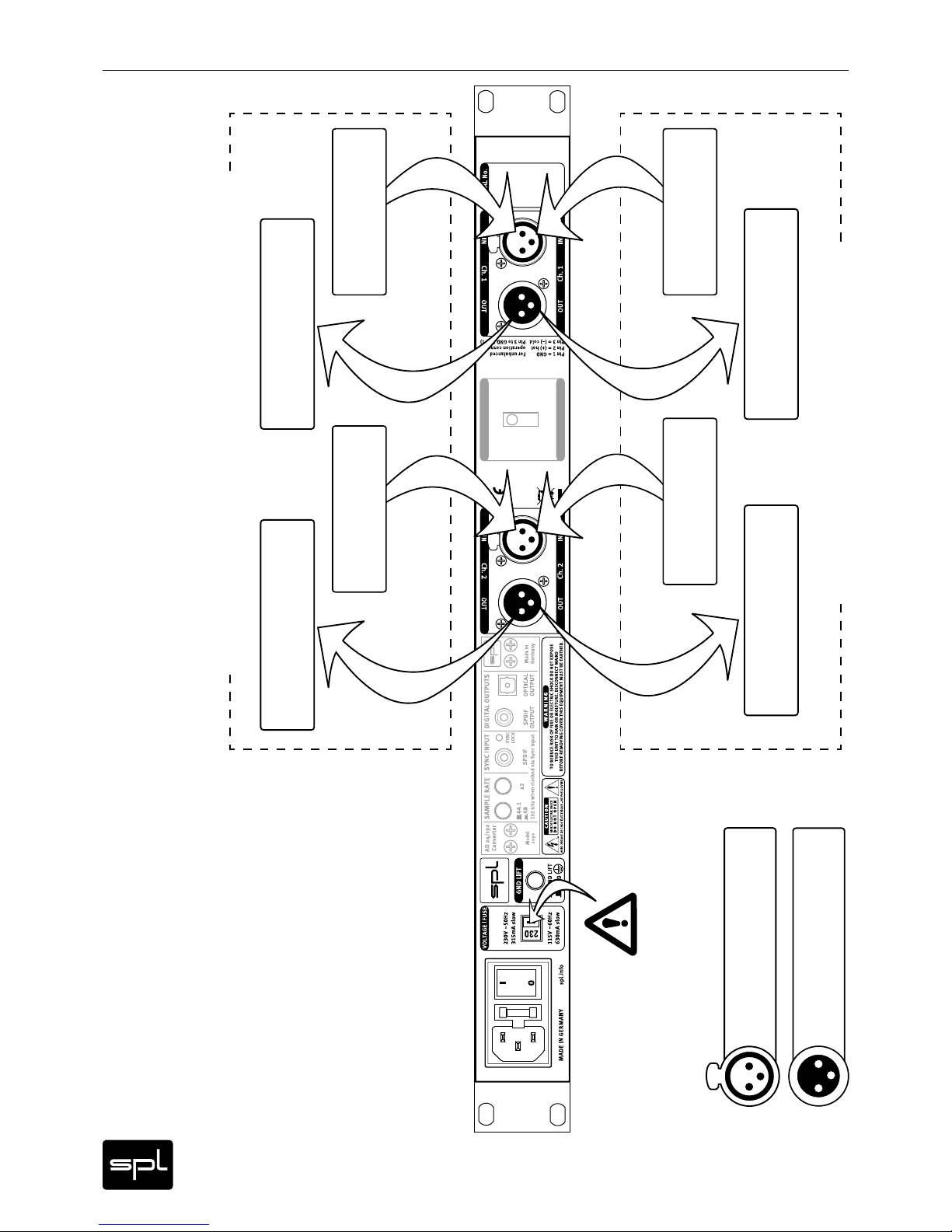

Rear Panel | Wiring Diagram

Ch. 1 OUT = Ch. 2 IN

Ch. 1 OUT = Ch. 2 IN

ON

OFF

Make sure that the voltage switch setting

reflects the correct local power line voltage.

Console, Patchbay,

DAW/Interface

Console, Patchbay,

DAW/Interface

Console, Patchbay,

DAW/Interface

Pin wiring XLR input sockets:

1=GND, 2=hot (+), 3=cold (-)

Pin wiring XLR output sockets:

1=GND, 2=hot (+), 3=cold (-)

PUSH

2

1

3

21

3

Console, Patchbay,

DAW/Interface

Microphone Microphone

Line SignalLine Signal

Wiring Diagram for Microphone Preamplifier Modules

Wiring Diagram for Processing Modules

Page 13

13

Analog Elemental Series

Rear Panel | Versions

OUT INCh. 1

IN OUTCh. 1

OUT INCh. 2

IN OUTCh. 2

MADE IN GERMANY spl.info

AVIS: RISQUE DE CHOC ÉLECTRIQUE – NE PAS OUVRIR

RISK OF ELECTRIC SHOCK

DO NOT OPEN

CAUTION

Pin 1 = GND

Pin 2 = (+) hot

Pin 3 = (–) cold

For unbalanced

operation connect

Pin 3 to GND (Pin 1)

SERIAL No.

VOLTAGE | FUSE

GND LIFT

GND LIFT

GND

TO REDUCE RISK OF FIRE OR ELECTRIC SHOCK DO NOT EXPOSE

THIS UNIT TO RAIN OR MOISTURE. DISCONNECT MAINS

BEFORE REMOVING COVER.THIS EQUIPMENT MUST BE EARTHED.

WARNING

0

I

230V ~50Hz

800mA slow

115V ~60Hz

1.6 A slow

OUT INCh. 1

IN OUTCh. 1

OUT INCh. 2

IN OUTCh. 2

MADE IN GERMANY spl.info

AVIS: RISQUE DE CHOC ÉLECTRIQUE – NE PAS OUVRIR

RISK OF ELECTRIC SHOCK

DO NOT OPEN

CAUTION

Pin 1 = GND

Pin 2 = (+) hot

Pin 3 = (–) cold

For unbalanced

operation connect

Pin 3 to GND (Pin 1)

SERIAL No.

VOLTAGE | FUSE

GND LIFT

GND LIFT

GND

TO REDUCE RISK OF FIRE OR ELECTRIC SHOCK DO NOT EXPOSE

THIS UNIT TO RAIN OR MOISTURE. DISCONNECT MAINS

BEFORE REMOVING COVER.THIS EQUIPMENT MUST BE EARTHED.

WARNING

0

I

Ch. 1 OUT = Ch. 2 IN

Ch. 1 OUT = Ch. 2 IN

ON

OFF

230V ~50Hz

800mA slow

115V ~60Hz

1.6 A slow

OUT INCh. 1

IN OUTCh. 1

OUT INCh. 2

IN OUTCh. 2

MADE IN GERMANY spl.info

AVIS: RISQUE DE CHOC ÉLECTRIQUE – NE PAS OUVRIR

RISK OF ELECTRIC SHOCK

DO NOT OPEN

CAUTION

Pin 1 = GND

Pin 2 = (+) hot

Pin 3 = (–) cold

For unbalanced

operation connect

Pin 3 to GND (Pin 1)

SERIAL No.

VOLTAGE | FUSE

GND LIFT

GND LIFT

GND

TO REDUCE RISK OF FIRE OR ELECTRIC SHOCK DO NOT EXPOSE

THIS UNIT TO RAIN OR MOISTURE. DISCONNECT MAINS

BEFORE REMOVING COVER.THIS EQUIPMENT MUST BE EARTHED.

WARNING

OPTICAL

SPDIF

SPDIF

AD 24/192

Converter

DIGITAL OUTPUTSSYNC INPUT

SAMPLE RATE

OUTPUT OUTPUT

SYNC

LOCK

Model

1090

Made in

Germany

x2

192 kHz when clocked via Syn c Input

48

44.1

0

I

Ch. 1 OUT = Ch. 2 IN

Ch. 1 OUT = Ch. 2 IN

ON

OFF

230V ~50Hz

800mA slow

115V ~60Hz

1.6 A slow

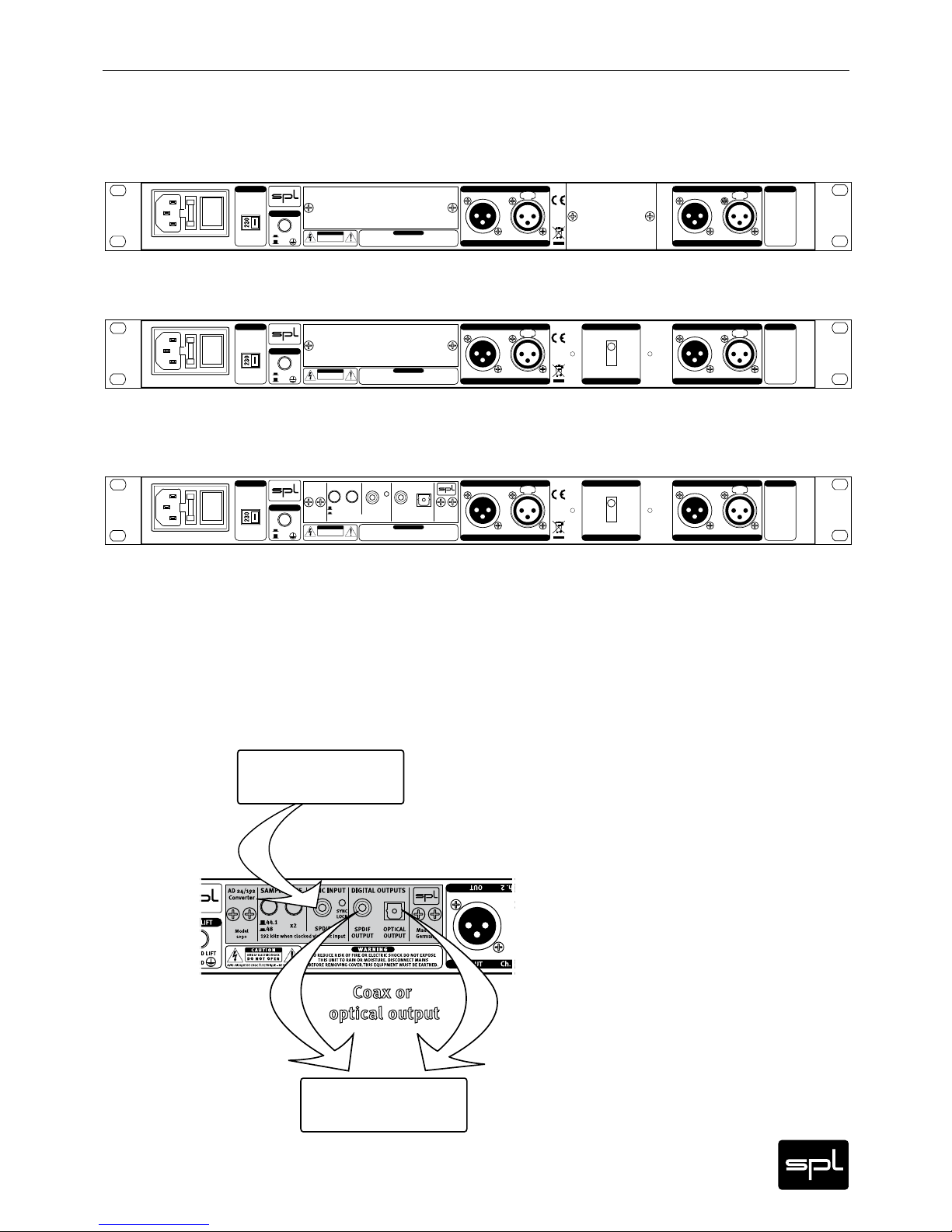

Depending on their configuration and additional features, the Analog Elemental Series

modules can have three different rear panels. The additional elements are the optional AD

converter (digital output) and the channel strip switch, which internally forwards the output

signal of the f irst module to the input of the second module, ruling out the need for external

cabling.

Rear Panel 1

Without converter or channel strip switch (configuration example: two preamp module).

Rear Panel 2

Without converter, with channel strip switch (configuration example: channel strip consisting

of preamp and processing module).

Rear Panel 3

With converter and channel strip switch (configuration example: channel strip consisting of

preamp and processing module, including digital output).

Optional Converter: Wiring Diagram

The optional AD conver ter provides an additional digital output. The diagram shows how to

connect it to an interface. For more detailed information refer to the converter module user‘s

manual.

DAW/Interface

(Output)

DAW/Interface

(Input)

Page 14

14

Analog Elemental Series

Rear Panel | Connections and Switches

Signal Connections

Turn off the unit before connecting or disconnecting any cable or equipment to it. Otherwise

you risk the possibility of damaging your ears or equipment.

Input and Output Electronics

The input and output electronics are based upon bridge circuits that keep the signal flow

constant, regardless of malfunctioning equipment and power outages (power fail safety

by relay hard bypasses). The bridge and insert circuits rely on high-quality relays. Contact

surfaces are gold-plated to provide better conductivity and encapsulated to avoid external

influences due to climate or atmospheric conditions.

XLR sockets

All signal connections are made via balanced XLR connectors. Inputs are always female and

accept male connectors; outputs are always male. All in all, a very comprehensible principle.

Balanced connections

It is impossible to exclude interferences when a single audio signal is transmitted. Shielding is

effective against electric, but not against electromagnetic influences. Motors, transformers,

and alternating current can always induce interferences. But even if the transmission would

succeed, dif ferences in ground potentials between driver and receiver would produce disturbances.

In balanced connections a reference signal with reversed polarity is transmitted additionally

to the audio signal through a second wire. The ground signal is routed separately through

a third wire. Input and output stages are drivers and receivers, and the receiving stage can

suppress interferences by subtracting the difference between audio and reference signal.

Unbalanced connections

Unbalanced connections from and to RCA or 1/4“ TS sockets can be made without adaptors to

the balanced XLR sockets. The correct wiring is important. The diagram shows the pin configuration of the XLR sockets and how to correctly connect them for unbalanced connections:

Connections to RCA sockets are always unbalanced, a wiring to jack connectors can be both

balanced (1/4“ TRS/stereo jack) or unbalanced (1/4“ TS/mono jack). We recommend to use

individually configured cables from XLR to RC A or jack sockets instead of adaptors. You can

get cables in any needed configuration from audio dealers. With the diagram above, the

dealer can ensure to provide the appropriate cable for your application.

Input

Output

balanced

unbalanced

balanced

unbalanced

1=GND

2= hot (+)

3= cold (-)

1

2

3

1

2

3

1

2

3

1

2

3

Page 15

15

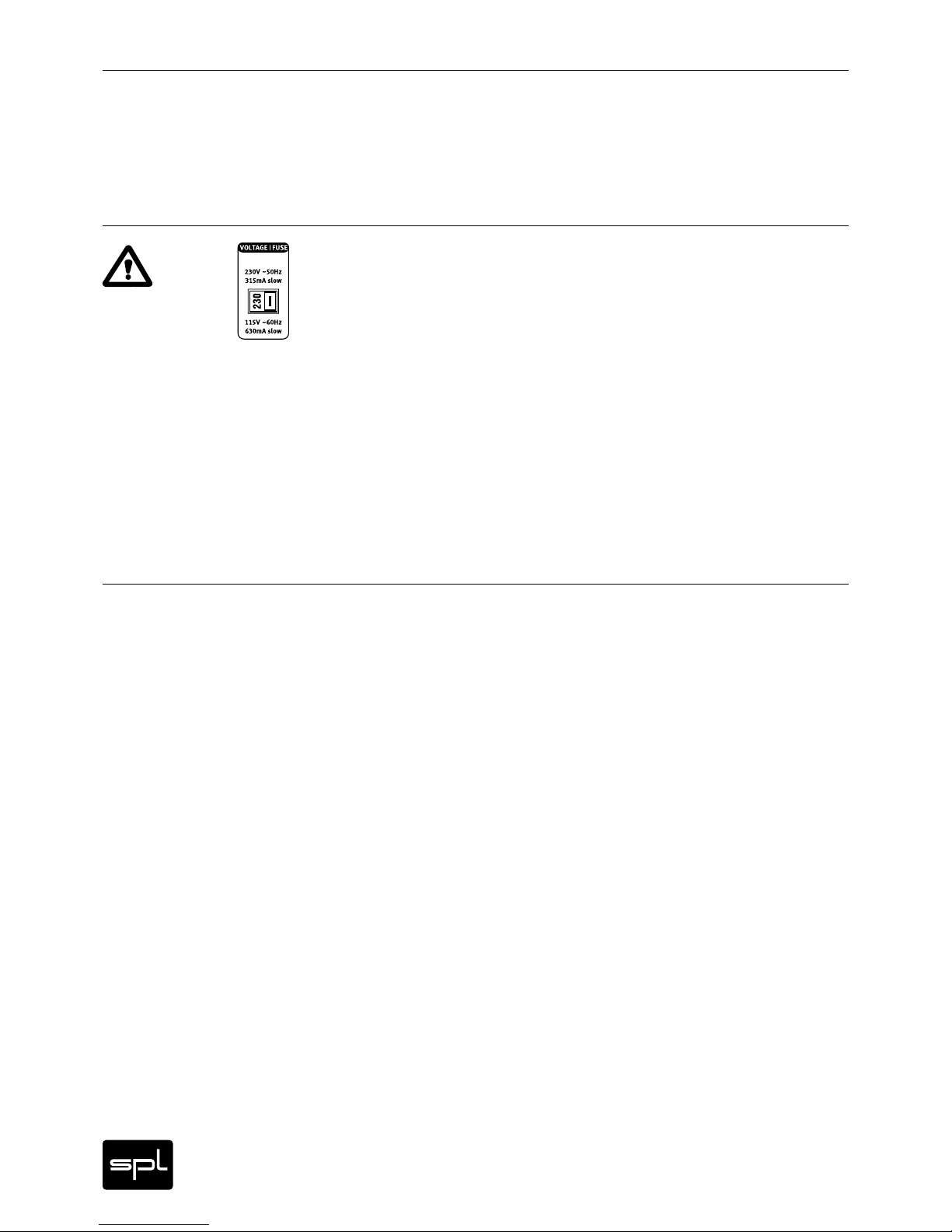

Analog Elemental Series

Rear Panel | Connections and Switches

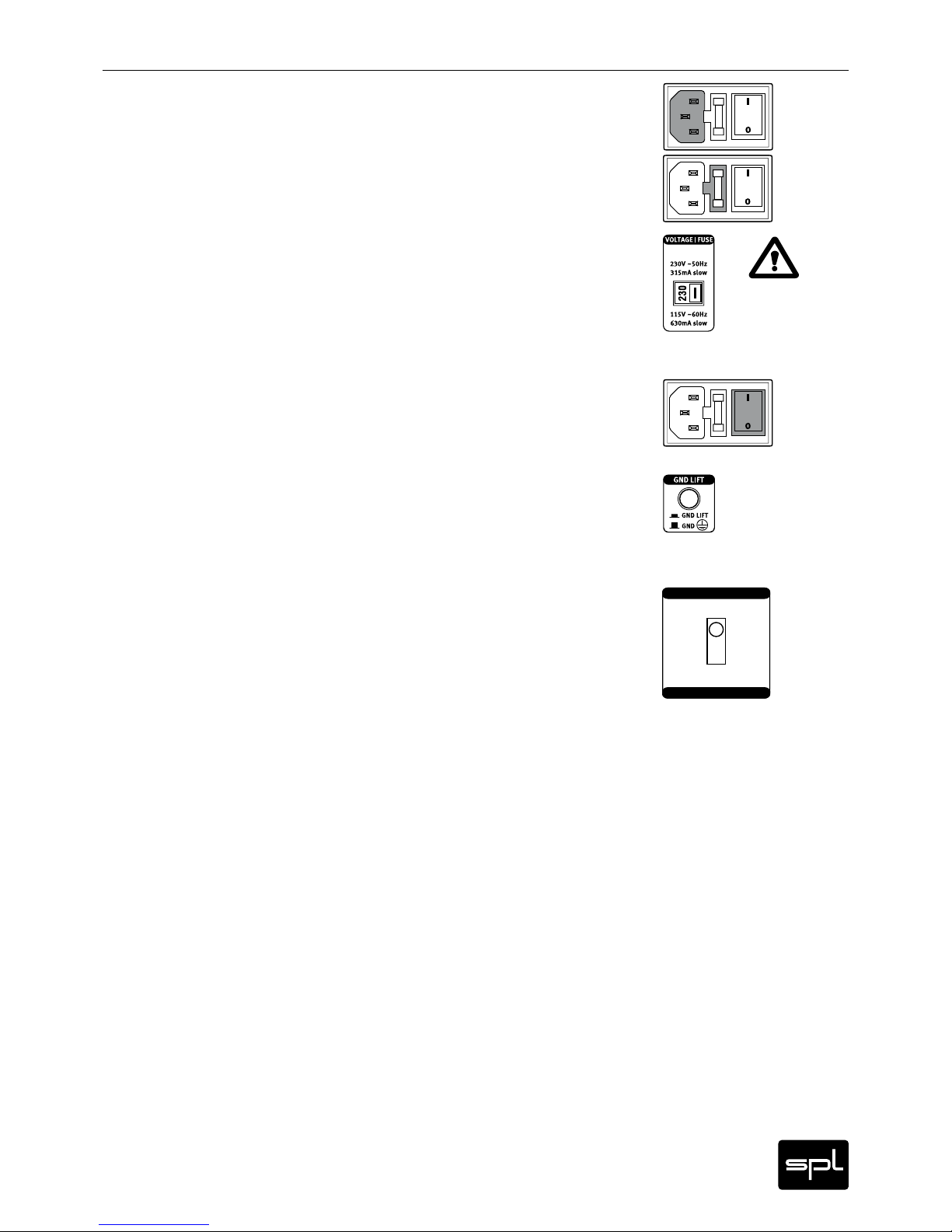

Power connection and fuse

Connect the power cord to the rear MAINS INPUT socket. Transformer, power cord and case

connection conform to VDE, UL and CSA requirements.

The fuse is accessible from outside and placed right behind the flap right from the socket.

Fuse ratings are 315 mA slow blow (

230

volts) or 630 mA slow blow (

115

volts).

Voltage Selector

The rear pan el VOLTAGE selector sets the lo cal line voltage (115 V position: 110 -120 volts/6o Hz,

230 V position: 220-240 volts/50 Hz). The diagram shows the correct switch position for 230 V

power supply.

BEFORE you connect electrical power make sure that the VOLTAGE selector setting reflects

the correct local power line voltage.

Power switch

Use the POWER switch on the rear panel to turn the unit on or off. The VU-meters on the front

panel will light on as soon as you turn the unit on, regardless of the position of the ACTIVE

push button. Thus, they fulfill a second function as power indicators.

GND Lift

The rear panel GND LIFT switch eliminates hum by separating the internal ground from the

unit’s housing ground. Hum can, for example, result when this unit’s housing has a common

ground connection with other devices that might have a diff erent ground potential . The switch

is usually deactivated to retain the shielding of the housing.

Channel Strip Switch (Ch. 1 OUT = Ch.2 IN)

The channel strip switch connects two modules internally with each other, as long as the

signal flow allows for it. For instance, with an Analog Elemental unit consisting of a preamp

and a processing module (Channel Strip configuration). When the switch is set to „ON“, the

output signal of the preamp feeds the input of the processing module directly. This simplifies the signal f low and makes it unnecessary to connect the output and input of the modules

externally via cables.

Ch. 1 OUT = Ch. 2 IN

Ch. 1 OUT = Ch. 2 IN

ON

OFF

Page 16

16

Analog Elemental Series

The Modules

Premium Mic Pre | Introduction

Premium Mic Pre | Control Elements

Each of the Analog Elemental Series units combines two of the following modules. For more

information on the design of the devices, refer to the Introduction on page 8. Here you will

find a detailed description of the single modules.

When recording acoustic instruments or vocals, using a microphone is inevi-

table. The actual output level of a microphone is very low and therefore has to

be boosted to studio or line level (0 dB) with a preamplif ier. Sometimes signals

have to be boosted by a factor of 2000 or more. As a consequence, the resulting

sound quality provided by the preamp is of paramount impor tance, so a good

microphone preamp that does not overdrive is the definitive requirement in order to

record acoustic instruments or vocals with sufficient dynamics and untainted sound.

The section “technology“ from page 19 explains how the Premium Mic Pre complies with

these requirements on the highest level and how it delivers premium results even in difficult

and critical set-ups.

Even the less technically interested users get an impression of the great efforts it takes in

development, circuitry design, selection of parts and assembly to create a product on the

Premium Mic Pre’s quality level. From there we deduce a superior price/performance ratio

– emphasizing on the performance which lends the Premium Mic Pre a world-class sound

quality.

Features

• The Premium Mic Pre offers preamplification values of up to +72 dB with lowest noise

operation and a high common mode rejection.

• Input stage and output are equipped with Lundahl transformers (High Performance

Series).

• A VU meter with two modes for average levels (VU) and peak levels (PPM) displays the

output levels.

• A very stable phantom power supply (48 V) is provided to power condenser microphones.

• The polarity of the microphone can be switched with the phase reverse switch.

• A high-pass filter protects against low frequency interferences.

• The signal LED indicates that an input signal is present

Mic Gain

With the Mic Gain control you can regulate the preamplification of the microphone signal.

It ranges from +18 dB to +72 dB. The input stage can handle input levels of up to 10 dB. The

value set with the Mic Gain control defines the output level.

When you set the Mic Gain you have to consider the type of microphone that you are using

(dynamic or condenser microphone) as well as its sensitivity. The sensitivity of a dynamic

microphone is at around 2 mV/Pa whereas the sensitivity of a condenser microphone can be

up to 20 mV/Pa. The result is a difference in output of 20 dB.

You should also consider the sound pressure level of the sound source, the distance of the

microphone to it and the acoustics of the room when you set the preamplification.

Page 17

17

Analog Elemental Series

Premium Mic Pre | Control Elements

About Leveling

Initially you should always deactivate the -10 dB button to have correc t values displayed by the

VU meter (see “-10 dB” below). Now turn up the Mic Gain control until the VU meter displays

maximum levels between 0 dB and +3 dB. At this level you don’t risk any overdrive when you

experience sudden and unexpected peaks in the level of the source. Always remember that

the VU meter only shows average values and that a peak level can be much higher (up to

+10 dB). If necessary, turn on the PPM mode to see the actual peak levels.

Usually levels of around 0 dB and +3 dB are safe. If, however, you experience very high peaks

already at minimum Mic Gain values (i.e. drums, brass instruments), you can activate the

PAD function (see “PAD” on page 18). The input level is now reduced so that you can regulate

Mic Gain again in a useful range.

If you know in advance that the level will be very consistent you can always turn up Mic Gain.

In this case you can activate the -10dB button to have more headroom in the display.

VU Meter

The VU meter displays the output level of the preamp. The gauge indicates levels from -20 dB

to +5 dB. If necessary you can lower the sensitivity by 10 dB so that the gauge goes up to

+15 dB output level (see “-10dB” below and “About Leveling” above).

The VU meter is custom made to meet SPL specifications and assures a balanced optical

perception thanks to it’s optimized ballistics.

An especially interesting feature is the option to switch between two display modes: VU mode

and PPM mode. The VU mode (VU=Volume Unit) displays average levels, thus provides information on the overall loudness. The PPM mode (PPM=Peak Program Meter) displays the peak

levels.

The integration time of the display complies with the BBC requirements. In VU mode the rise

time up to 0 dB is approx. 300 ms. In PPM mode the rise time up to 0 dB is about 2 ms and the

release time down to -20 dB is at a “slow” 1,5 seconds. This calibration ensures to display even

short peaks up to about +6 dB since the needle does not have to travel the entire distance of

the gauge every time.

PPM

The PPM button allows to switch the VU metering characteristics from VU display mode

(button is deactivated and not illuminated) to PPM display mode (button is active and illuminated). A/D converter display also make use of the PPM mode. Monitoring peak levels is most

important to avoid overloading the converter and to prevent audible distortion. Peak levels

are always above the average levels. It may make sense in most cases to also press the -10 dB

button to prevent the needle from getting stuck on the right side of the gauge.

-10

With this button you can change the sensitivity of the VU display. If you press the -10 dB button

(button is illuminated), the sensitivity of the display is lowered by 10 dB. With the needle for

example at 0dB, a value of +10 dB is displayed. Now you can read values of up to +15 dB.

You always have to add these 10 dB to the displayed values, for example if you compare these

values with those of an A/D converter. Remember that A/D converters show peak levels, not

average levels. For comparison press the PPM button to activate the PPM mode. >

Page 18

18

Analog Elemental Series

Premium Mic Pre | Bedienelemente

48 V Phantom Power Supply

The Premium Mic Pre provides 48 volt phantom power for microphones requiring external

current (generally condenser microphones). Such microphones are dependent upon a clean,

consistent and noise-free power supply for optimal operation and audio quality. The Premium

Mic Pre continuously delivers precisely 48 V and a maximum current of 14 mA, which will

power all microphones.

IMPORTANT: All microphones with balanced, ground-free outputs can be used with the

phantom power activated. Unbalanced microphones may only be used with phantom power

deactivated.

Phantom power should only be activated when using microphones that require it. Please be

sure to deactivate phantom power with all other microphones (including tube microphones

which are supplied from their own power supply, thus need no extra phantom power supply).

ALWAYS FOLLOW THESE RULES WHEN WORKING WITH PHANTOM POWER – THE INPUT

STAGES OF THE PREMIUM MIC PRE CAN BE DAMAGED IF YOU DO NOT ACT ACCORDINGLY:

1. First connect the microphone to the Premium Mic Pre.

2. Then activate phantom power – you can star t working now.

3. When you have finished recording, turn the phantom power off f irst.

4. DO NOT disconnect the microphone from the Premium Mic Pre UNTIL phantom power has

been switched off for a minute and all residual current is discharged.

Pad

The Pad function allows you to attenuate the input signal by 20 dB so that you can process

even very high levels, i.e. from drums or brass instruments.

If the VU meter shows levels above +3 dB even while Mic Gain is set very low (and the -10 dB

button deactivated), the time has come to press the Pad button. It illuminates when it is activated.

Phase Reverse

With the phase reverse button you invert the polarity of the microphone signal. When not

pressed ( button is not illuminated) the polarity is in phase. After pushing the button (button

is illuminated) the polarity is inverted.

The phase reverse feature comes in very handy if you have to switch the polarity of the XLR

input according to the polarity of the microphone or the microphone cable. The pin wiring of

the XLR sockets are as follows: Pin 1 = ground, Pin 2 = hot (+), Pin 3 = cold (-).

Sometimes it is useful to switch the polarity of a microphone, for example in the case of M/S

miking. A second classic application is the miking of a snare drum with two microphones that

are placed above and below the snare: Since both drum heads move in the same direction

when the drum is played, the microphones are out of phase. Switch the polarity of the bottom

mic and you avoid any cancellations when you join both signals in the mix.

High-Pass Filter

The high-pass f ilter, also known as rumble filter, helps to eliminate any interferences

within the lowest frequencies. The f irst order filter operates smoothly with 6 dB per

octave, starting from 75 Hz with -3 dB. This characteristic usually helps in most cases

and has the least sonic disadvantages. If you need to filter on a more extreme scale, even

second order filters (12 dB/octave) are overstrained frequently and sonic disadvantages

become more and more apparent. In those cases a variable filter is the means of choice.

Page 19

19

Analog Elemental Series

Premium Mic Pre | Technology

Triple Stage Preamp

The preamplifier circuitry of the Premium Mic Pre is composed of three stages: a transformer, a discrete differential amplifier stage and an instrument preamplifier all contribute (in

different shares) to the main amplification. The three stage setup firstly ensures a load distribution that minimizes the risk of overloads. Secondly, each stage can be optimally configured

through select components and sophisticated circuits – a decisive advantage over single IC

circuitries where the main amplif ication is achieved by just one stage.

In addition, the potentiometer (as the control element of the differential amplifier stage) only

has to cover a range of approximately 68 dB while the maximum amplification is at around

80 dB. In practice this means that even very high amplification values are still outside of the

extreme control range positions – which are critical for any potentiometer.

Stage 1 – The Input Transformer

Inherent part of the Premium Mic Pre design are the input and output transformers of the High

Performance Series by Lundahl. These transformers are lavishly handcrafted. They replace

common input and output balancing stages. These classic components of fer a very high

sound quality and common mode rejection but they are also very reliable and provide connections and signals of superior quality.

Lundahl transformers have a very high reputation in terms of manufacturing quality and the

resulting longevity as we have seen proven impressively throughout many years of experience.

In any microphone preamplif ier the input transformer is of special relevance as it is an integral par t of the preamp circuitry: it contributes to the main amplification through a passive

and permanent boost of, in this case, 6 dB. The advantage of passive amplification over

active amplification is that it does not add any noise. A second advantage of integrating this

passive amplification is a signal processing that is, as a matter of principle, lower in overdrive

and noise throughout all following stages simply because the rest of the electronic circuit is

charged with 6 dB less at any setting of the amplification.

In addition, transformers ensure a galvanic isolation, preventing any disturbing or damaging

voltages from being carried in any of the two directions. Electromagnetic, high frequency or

digital interference has no more influence. Problems with humming e. g. in a live environment

that have been caused by differences in the potentials between the stage and the FOH do not

occur. Even a voltage that has accidentally or through technical failure been connected to a

ground line cannot be transmitted. So transformers can exclude even mishaps or problems in

an installation reaching the categories “improbable” till “unbelievable” ...

Further, the phantom powering of microphones does not require any condensers in the

preamp socket which has further sonic advantages.

From our personal listening impression we can recommend transformers in any case. The

advantages in operational safety can not be overestimated especially in critical or complex

installations for studio, live or broadcast applications.

Stage 2 – The Discrete Differential Amplifier

From the input transformer, the signal is routed to a discrete differential amplifier based upon

a quad parallel transistor circuitry. This parallel circuit of eight single transistors reduces

noise remarkably through distribution of load.

The discrete differential amplifier is the central amplif ying stage; here the amount of the

amplification is controlled by a current-carrying source. Control systems that are triggered

by current rather than voltage have the main advantage that possible negative effects of the

potentiometer will not affect the audio signal.

The discrete differential amplifier offers a maximum amplification of up to 68 dB. A servo

drive circuit actively eliminates DC offsets of the differential amplifier. Servo drive circuitry

minimizes DC offsets more effectively than conventional solutions that utilize capacitors by

setting the DC offset to almost 0 mV. In addition, the active servo drive solution has sonic

advantages over passive capacitors as it tends to produce less distortions.

Page 20

20

Analog Elemental Series

Premium Mic Pre | Technology

Premium Mic Pre | Technical Specifications

Stage 3 – The Instrumentation Amplifier

An instrumentation amplif ier is following the discrete dif ferential amplif ier to produce the

output signal’s voltage. Functionally a summing amplifier it eliminates possible disturbing

voltages and also contributes to the main amplification with an additional +6 dB.

Foil and Styroflex Capacitors

Only the best MKP and styroflex capacitors are used in the various circuits. They sound more

open and dynamic in contrast to the conventional ceramic capacitors.

Output Stages

The Premium Mic Pre is based upon a transformer output capable of driving very long cables

(up to a few hundred yards, depending on the capacity of the cables and the input stages on

the other end). The maximum output level is +22 dBu.

Audio

Frequency Range 10 Hz- 68 kHz (-3 dB)

CMR -87 dBu

(@ 1kHz with -30 dBu Input level and 30 dB Gain)

THD&N @ 1 kHz

Input Level Gain THD&N

-30 dBu 30 dB 0,007 1%

-60 dB u 60 dB 0,078%

S/N Ratio Gain A/N Ratio A-weighted

80 dB -48,3 dBu

60 dB -64 ,2 dBu

30 dB -89, 0 dBu

E.I.N. (Equivalent Input Noise): -128 ,3 dBu

Dynamic Range 111,0 dB

Input

XLR socket, transformer balanced

Impedance unbalanced ca. 2,0 kOhm

Impedanz balanced ca. 4,0 kOhm

Max. Input Level +10 dBu, +30 dBu with Pad activated

Output

XLR socket, transformer balanced

Impedance unbalanced ca. 60 Ohm

Impedance balanced ca. 120 Ohm

Max. Output Level +22 dBu

Control Elements

Mic Gain Range 18 dB – 72 dB

Pad Switch -20 dB

High-Pass Filter fg = 75 Hz (-3 dB)

Phantom Power Supply 48 V

0 dBu = 0,775 V. Sugbject to change without notice.

Page 21

21

Analog Elemental Series

Premium Mic Pre | Block Diagram

Page 22

22

Analog Elemental Series

Preference Mic Pre | Introduction

Preference Mic Pre | Control Elements

When recording acoustic instruments or vocals, using a microphone is inevitable. The

actual output level of a microphone is very low and therefore has to be boosted

to studio or line level (0 dB) with a preamplifier. Sometimes signals have to be

boosted by a factor of 2000 or more. As a consequence, the resulting sound

quality provided by the preamp is of paramount importance, so a good micro-

phone preamp that does not overdrive is the definitive requirement in order to

record acoustic instruments or vocals with sufficient dynamics and untainted sound.

The section “Technology” on page 24 explains how the Preference Mic Pre meets these

requirements.

Main Features

• The Preference Mic Pre offers preamplification values of up to +72 dB with lowest noise

operation and a high common mode rejection.

• A VU meter with two modes for average levels (VU) and peak levels (PPM) displays the

output levels.

• A very stable phantom power supply (48 V) is provided to power condenser microphones.

• The polarity of the microphone can be switched with the phase reverse switch.

• A high-pass filter protects against low frequency interferences.

Mic Gain

With the Mic Gain control you can regulate the preamplification of the microphone signal. It

ranges from +18 dB to +72 dB. The input stage can handle input levels of up to 18 dB. The value

set with the Mic Gain control defines the output level equally for both Output 1 and Output 2.

When you set the Mic Gain you have to consider the type of microphone that you are using

(dynamic or condenser microphone) as well as its sensitivity. The sensitivity of a dynamic

microphone is at around 2 mV/Pa whereas the sensitivity of a condenser microphone can be

up to 20 mV/Pa. The result is a difference in output of 20 dB.

You should also consider the sound pressure level of the sound source, the distance of the

microphone to it and the acoustics of the room when you set the preamplification.

About Leveling

Initially you should always ensure to have deactivated the -10 dB button so that the VU meter

displays correct values (see “-10 dB” onthe next page). Now turn up the Mic Gain control until

the VU meter displays maximum levels between 0 dB and +3 dB. At this level you don’t risk

any overdrive when you experience sudden and unexpected peaks in the level of the source.

Always remember that the VU meter only shows average values and that a peak level can be

much higher (up to +10 dB). If necessary, turn on the PPM mode to see the actual peak levels.

Usually levels of around 0 dB and +3 dB are safe. If, however, you experience very high peaks

already at minimum Mic Gain values (i.e. drums, brass instruments), you can activate the PAD

function (see “PAD” on page 24). The input level is now reduced so that you can regulate

Mic Gain again in a useful range.

If you know in advance that the level will be very consistent you can always turn up Mic Gain.

In this case you can activate the -10dB button to have more headroom in the display.

Page 23

23

Analog Elemental Series

Preference Mic Pre | Control Elements

VU Meter

The VU meter displays the output level of the preamp. The gauge indicates levels from -20 dB

to +5 dB. If necessary you can lower the sensitivity by 10 dB so that the gauge goes up to

+15 dB output level (see “-10 dB” below and “About Leveling” on the previous page).

The VU meter is custom made to meet SPL specifications and assures a balanced optical

perception thanks to it’s optimized ballistics.

An especially interesting feature is the option to switch between two display modes: VU mode

and PPM mode. The VU mode (VU=Volume Unit) displays average levels, thus provides information on the overall loudness. The PPM mode (PPM=Peak Program Meter) displays the peak

levels.

The integration time of the display complies with the BBC requirements. In VU mode the rise

time up to 0 dB is approx. 300 ms. In PPM mode the rise time up to 0 dB is about 2 ms and the

release time down to -20 dB is at a “slow” 1,5 seconds. This calibration ensures to display even

short peaks up to about +6 dB since the needle does not have to travel the entire distance of

the gauge every time.

PPM

The PPM button allows to switch the VU metering characteristics from VU display mode

(button is deactivated and not illuminated) to PPM display mode (button is active and illuminated). A/D converter display also make use of the PPM mode. Monitoring peak levels is most

important to avoid overloading the converter and to prevent audible distortion. Peak levels

are always above the average levels. It may make sense in most cases to also press the -10 dB

button to prevent the needle from getting stuck on the right side of the gauge.

-10 dB

With this button you can change the sensitivit y of the VU display. If you press the -10 dB button

(button is illuminated), the sensitivity of the display is lowered by 10 dB. With the needle for

example at 0dB, a value of +10 dB is displayed. Now you can read values of up to +15 dB.

You always have to add these 10 dB to the displayed values, for example if you compare these

values with those of an A/D converter. Remember that A/D converters show peak levels, not

average levels. For comparison press the PPM button to activate the PPM mode.

48 V Phantom Power Supply

The Preference Mic Pre provides 48 volt phantom power for microphones requiring external

current (generally condenser microphones). Such microphones are dependent upon a

clean, consistent and noise-free power supply for optimal operation and audio quality. The

Preference Mic Pre continuously delivers precisely 48 V and a maximum current of 14 mA,

which will power all microphones.

IMPORTANT: All microphones with balanced, ground-free outputs can be used with the

phantom power activated. Unbalanced microphones may only be used with phantom power

deactivated.

Phantom power should only be activated when using microphones that require it. Please be

sure to deactivate phantom power with all other microphones (including tube microphones

which are supplied from their own power supply, thus need no extra phantom power supply).

ALWAYS FOLLOW THESE RULES WHEN WORKING WITH PHANTOM POWER – THE INPUT

STAGES OF THE PREMIUM MIC PRE CAN BE DAMAGED IF YOU DO NOT ACT ACCORDINGLY:

1. First connect the microphone to the Preference Mic Pre.

2. Then activate phantom power – you can start working now.

3. When you have f inished recording, turn the phantom power off first.

4. DO NOT disconnect the microphone from the Preference Mic Pre UNTIL phantom power

has been switched off for a minute and all residual current is discharged.

Page 24

24

Analog Elemental Series

Preference Mic Pre | Control Elements

Pad

The Pad function allows you to attenuate the input signal by 20 dB so that you can process

even very high levels, i.e. from drums or brass instruments.

If the VU meter shows levels above +3 dB even while Mic Gain is set very low (and the -10 dB

button deactivated), the time has come to press the Pad button. It illuminates when it is activated.

Phase Reverse

With the phase reverse button you invert the polarity of the microphone signal. When not

pressed ( button is not illuminated) the polarity is in phase. After pushing the button (button

is illuminated) the polarity is inverted.

The phase reverse feature comes in very handy if you have to switch the polarity of the XLR

input according to the polarity of the microphone or the microphone cable. The pin wiring of

the XLR sockets are as follows: Pin 1 = ground, Pin 2 = hot (+), Pin 3 = cold (-).

Sometimes it is useful to switch the polarity of a microphone, for example in the case of M/S

miking. A second classic application is the miking of a snare drum with two microphones that

are placed above and below the snare: Since both drum heads move in the same direction

when the drum is played, the microphones are out of phase. Switch the polarity of the bottom

mic and you avoid any cancellations when you join both signals in the mix.

High-Pass Filter

The high-pass f ilter, also known as rumble filter, helps to eliminate any interferences

within the lowest frequencies. The f irst order filter operates smoothly with 6 dB per

octave, starting from 75 Hz with -3 dB. This characteristic usually helps in most cases

and has the least sonic disadvantages. If you need to filter on a more extreme scale, even

second order filters (12 dB/octave) are overstrained frequently and sonic disadvantages

become more and more apparent. In those cases a variable filter is the means of choice.

Page 25

25

Analog Elemental Series

Preference Mic Pre | Technology

SSM 2019

The Preference Mic Pre is suitable for all common dynamic and condenser microphones. It

works along the principles of an instrumentation amplifier which is a technology that is also

used in measurement and medical equipment due to its high common mode rejection of stray

pick-ups. It is based on the semiconductor SSM 2019 which sounds more balanced than available alternatives. Low noise and distortion values as well as a broad bandwidth and a fast

slew rate are its forte.

Servo Drive Design

The main focus during the development of the Preference Mic Pre was its acoustic transparency and its natural representation of the source signal. Reducing DC offsets in the audio

signal paths is a decisive part of this design job.

DC offsets are produced in relatively large amounts especially when amplifying a microphone

signal because the signal is amplified by extreme factors from the pico volt range to 0dB

nominal level. DC offsets impair the signal quality as they induce noise and distortion that

lead to a diffuse sound.

The Preference Mic Pre‘s servo drive design minimizes these problems much more effectively

than the common solution based on capacitors by setting the DC offset to almost 0 mV. In

addition to that, the active servo drive circuitry tends to produce less distor tions than passive

capacitors.

The servo drive design incorporates three operational amplif iers. The SSM 2019 is the first

op-amp. The second op-amp acts as a sensor to detect voltage differences. These dif ferences

are then compensated for in a third op-amp working as summing stage.

Of course an elaborate active servo drive circuitry is a more expensive solution than simply

using passive capacitors, but especially in a microphone preamplifier this effort pays off with

improved sound quality.

Foil And Styroflex Capacitors

Only the best MKP and styroflex capacitors are used in the various circuits. They sound more

open and dynamic in contrast to the conventional ceramic capacitors.

Output

The output stage is electronically balanced and capable of driving very long cables (up to a

few hundred yards, depending on the capacity of the cables and the input stages on the other

end). The maximum output level is +22 dBu.

Page 26

26

Analog Elemental Series

Audio

Frequency Range 10Hz to › 200 kHz

CMR -84 dBu

(@ 1 kHz with -30 dBu input level and 30 dB gain)

THD&N @ 1 kHz

Input Level Gain THD&N

-30 dBu 30 dB 0,0035%

-60 dB u 60 dB 0 ,047%

S/N Ratio Gain S/N Ratio A-weighted

72 dB -57,0 dBu

60 dB -69 ,0 dBu

30 dB -91 ,7 dBu

E.I.N. (Equivalent Input Noise) -129,0 dBu

Dynamic Range 114, 0 dB

Input

XLR socket, elektronically balanced

Impedance unbalanced ca. 1,6 kOhm

Impedance balanced ca. 3,2 kOhm

Max. Input Level +18 dBu, +38dBu with Pad activated

Output

XLR socket, elektronically balanced

Impedance unbalanced ca. 75 Ohm

Impedance balanced ca. 150 Ohm

Max. Output Level +22 dBu

Control Elements

Mic Gain Range 18 dB - 72 dB

Pad Switch -20 dB

High-Pass Switch fg = 75 Hz (-3 dB)

Phantom Power Supply 48 V

0 dBu = 0,775 V. Technical changes subject to change without notice.

Preference Mic Pre | Technical Specifications

Page 27

27

Analog Elemental Series

Preference Mic Pre | Block Diagram

Page 28

28

Analog Elemental Series

Back in the 1990ies, we developed an alternative way to process signals in order

to reduce sibilance based on phase cancellation. Unlike traditional compression

methods, this procedure is much more unobtrusive and simplifies control to one

single parameter. SPL‘s De-Esser quickly became a standard reference among

recording studios, broadcast stations and live sound engineers.

The most commonly used technology to remove sibilance is based on compression. In

addition to determining the threshold, the center frequency for processing must also be set.

The processing range can be up to two octaves in order to ef fectively address all possible

problems across the frequency spectrum. This results in one of the most critical disadvantages: the wide range of frequencies being processed leads to undesired effects such as

nasalization and lisper.

The SPL De-Esser works on the principle of phase cancellation to remove unwanted sounds.

And it also adds automatic sibilance detection, which allows processing to be limited only to

the range where sibilant sounds are present. The result is a neutral-sounding, unnoticeable

but highly ef fective processing that never requires fine tuning level and frequency settings.

This way de-essing has the least possible influence on the voice‘s timbre, avoiding side

effects like nasalization and lisper. Operation is limited to adjusting the processing intensity

with one single control. The SPL De-Esser is a safe and precise tool to solve sibilance problems, without having to compromise sound quality nor the hassle of permanently readjusting

settings.

The Dual-Band De-Esser

The Dual-Band De-Esser module expands on this concept by making use of two frequency

bands that can be used independently or jointly.

• Two de-esser stages increase processing effectiveness without introducing any audible

artifacts

• Focused processing with high and low bands

• Input signals are automatically adjusted so that processing is uniform, regardless of the

distance between source and microphone

• Male/Female modes that adapt processing in the lower band to male or female voices

HI-Band On, Low-Band On

Use the HI-BAND ON button to turn the HIGH-S-REDUCTION on or off. Use the LOW-BAND ON

button to turn the LOW-S-REDUCTION on or off. The buttons light up when engaged.

You can use the two processing stages separately or jointly. They are connected in series as

independent de-esser modules. The low-band de-esser is set first in the chain.

If both de-essers are engaged, there is interaction between them: a signal already processed

with the low-band de-esser is different from the raw material that the high-band de-esser

would otherwise process. That is the reason why the readings of the high band‘s SR LEDs

change when the low-band de-esser is engaged while the high-band processor is active.

Hard-Bypass: the Dual-Band De-Esser module features power outage protection based on

relay-controlled hard-bypass circuits to always guarantee signal flow from input to output. In

order to keep signal flow constant, the bypass is automatically activated whenever a voltage

drop or failure is detected.

Dual-Band De-Esser | Introduction

Dual-Band De-Esser | Control Elements

Page 29

29

Analog Elemental Series

Dual-Band De-Esser | Control Elements

Low S-Reduction

Use the LOW S-REDUCTION control to adjust the intensity of the sibilance reduction in

the lower frequency range. The center frequency for sibilance recognition is set at 7.6 kHz

in FEMALE mode and 6.4 kHz in MALE mode. For more information, please refer to section

“MALE/FEMALE“ below. The bandwidth of the low-band de-esser is 1.44 kHz.

Scale values for the f ilter are displayed in dB. The actual reduction values, i.e. af ter phase

cancellation, are displayed in the lower SR LEDs. Thus, when the control is set to 3 dB, actual

reduction might only be of around 1 dB.

The SR LEDs display sibilance reduction between -1 dB and -14 dB, first in 1 dB increments and

from 6 dB on in 2 dB increments.

In practice, for most applications, the best results are usually achieved when LOW

S-REDUCTION is set between 3 and 7.

High S-Reduction

Use the HIGH S-REDUCTION control to adjust the intensity of the sibilance reduction in the

upper frequency range.

The center frequency for sibilance recognition is set at 11.2 kHz with a 3 kHz bandwidth.

Scale values for the f ilter are displayed in dB. The actual reduction values, i.e. af ter phase

cancellation, are displayed in the upper SR LEDs. Thus, when the control is set to 3 dB, actual

reduction might only be of around 1 dB.

The SR LEDs display sibilance reduction between -1 dB and -14 dB, first in 1 dB increments and

from 6 dB on in 2 dB increments.

Please note that the MALE/FEMALE button has no effect on the high-band de-esser.

In practice, for most applications, the best results are usually achieved when HIGH

S-REDUCTION is set between 3 and 7.

Male/Female

The MALE/FEMALE button allows you to adjust the low-band de-esser to the type of voice

being processed. When engaged, the mode selected for the low-band de-esser is FEMALE,

otherwise the de-esser works in MALE mode. The mode selected affects the center frequency

for sibilance recognition: in FEMALE mode it is set at 7.6 kHz, while in MALE mode it is set at

6.4 k Hz.

These values have been determined by practical experience, so that the processor adapts

better to gender. Nevertheless, you cannot take for granted that these settings will suit every

single male and female voice. Consider the MALE/FEMALE function as an additional tool to

help you set the low-band de-esser more precisely according to your needs. Always trust your

ears to find the best settings.

Signal-LED (SIG.)

The SIG. LED indicates that an audio signal reaches the input with a level above -20 dB. This

LED helps the operator especially in complex setups to determine immediately whether the

Dual-Band De-Esser actually receives any signal.

Page 30

30

Analog Elemental Series

Audio

Frequenc y Range: 10 Hz-80 k Hz

CMR: ›60 dBu

@ 1 kHz, 0 dBu input level and unity gain

S/N Ratio: -106 dBu

A-weightedt

Dynamic Range: 128 dB

THD&N: 0,01%

@ 1 kHz, 0 dBu input level and unity gain

Input

XLR socket, electronically balanced, optionally transformer balanced

Impedance ca. 20 kOhm

Max. Input Level +22 dBu

Nominal Input Level +4 dBu

Output

XLR socket, electronically balanced, optionally transformer balanced

Output Impedance 75 Ohm/›600 Ohm with transformer

Max. Output Level +22 dBu

Control Elements

Signal- LED -20 dBu

Overload-LED +19 dBu (peak hold 1,5 seconds)

0 dBu = 0,775 V. Technical changes subject to change without notice.

Dual-Band De-Esser | Technical Specifications

Page 31

31

Analog Elemental Series

Dual-Band De-Esser | Block Diagram

Page 32

32

Analog Elemental Series

The DynaMax x probably is the most consequent interpretation of a “set & forget“

compressor concept. In keeping with the SPL design philosophy, it incorporates

many features not found on standard compressors, and a unique control system

makes is surprisingly easy to use.

The DynaMax x also offers a de-compression mode which may be used to counter

the effects of overcompression in previously processed source material.

Why is DynaMax x so different? Though auto attack and release functions are nothing new,

in the DynaMax x design, the time constants are automated in a very musical way. DynaMax x

optimizes all time constants in real time during processing so that the compression characteristics are continually matched to the source material.

The DynaMax x circuitry actually uses two of the excellent THAT 2181 VCAs in SPL’s Double

VCA-Drive mode configuration, which doubles the operating range while increasing transparency and reducing distortion. Another benef it of the DynaMaxx circuitry is that high

compression ratios do not affect high frequency detail – high amplitude, low-end bass can

be controlled without introducing pumping or other negative side-effects. Similarly, complex

stereo sources can be processed easily and very musically.

The DynaMax x has numerous applications in recording and mixing, as well as for live applications, and because of the level of intelligent processing within the unit, there are only two

controls to adjust per channel, making operation very intuitive.

Compression

The COMPRESSION control sets the compression intensity by var ying both Threshold and

Ratio simultaneously. The further the COMPRESSION control is turned clockwise (which

lowers the Threshold and increases the ratio), the more processing is extended to lower level

signals. The fully clockwise position is equivalent to a Ratio of 3:1.

The exact processing values are always depending on the source material. Loud signal

parts will always be processed with higher compression rates than quieter signal parts. The

DynaMaxx employs soft-knee compression characteristics, following the input signal‘s structures dynamically.

For gentle compression results, turn the COMPRESSION control clockwise until the Gain

Reduction LED ladder shows a peak level reduction of between 2 and 3 dB. Turning the

Compress control fur ther clockwise will lower the Threshold to include more low-level signals

into the compression process. At the same time, compression ratio is increased up to a

maximum of 3:1.

The following diagram shows the gain control curve in normal compression mode with three

different COMPRESSION settings. For better readability of the graph, the gain has been kept

at 0dB, so no compensation for the gain reduction is applied.

DynaMaxx | Introduction

DynaMaxx | Control Elements

Page 33

33

Analog Elemental Series

DynaMaxx | Control Elements

Make-Up Gain

The MA KE-UP GAIN con trol compensates fo r any level decrease w hen applying COMPRE SSION.

The higher the processing intensity the lower the overall output level, the more Gain will be

required to restore the same peak level.

Turn the MAKE-UP GAIN control clockwise until the peak level of the input is the same as the

peak level of the output. Use the GAIN REDUCTION LEDs for a precise adjustment. The control

has a range of 20dB.

If the DE-COMPRESSION mode is activated, the MAKE-UP GAIN control compensates for the

increase in peak level. Note that in this mode, turning the Gain control clockwise decreases

the output level.

Gain Reduction LEDs

The 10-digit LED ladder meter is capable of displaying gain changes to a resolution of 1dB over

the range -1 dB to -14 dB.

When applying COMPRESSION to the audio signal, the LED meter displays the amount of gain

reduction taking place. From here you can see how much gain to compensate for with the

MAKE-UP GAIN control.

When the DE-COMPRESSION mode is activated, the LED display shows the gain increase

imparted to high-level signals.

DE-COM. (De-Compression)

The De-Compression function inverts the operation of the compressor to produce new

dynamic headroom, which may be used to increase the dynamic range of a (previously overcompressed) signal.

The process may also be used to expand the dynamic range of other sources, such as drum

or synthesizer samples. Especially when creating loops, overcompressed samples can

result in lifeless sounds. With the DynaMax x you can simply de-compress the signals again.

Interesting effects can also be achieved by applying different settings to the channels of a

stereo source.

IMPORTANT: While MAKE-UP GAIN increases the output level in standard mode, this function

is also inverted in DE-COMPRESSION mode – turning the control clockwise reduces the output

level.

The following diagrams show different characteristic curves in DE-COMPRESSION mode. If

the Limiter is activated in DE-COMPRESSION mode, the intensity of processing is increased

remarkably. Especially peaks are expanded more intensively.

Page 34

34

Analog Elemental Series

DynaMaxx | Control Elements

FX Com. (Effect Compression)

The FX Com. mode allows to switch off the DynaMax x‘s perfectly automated dynamics