Page 1

Manual

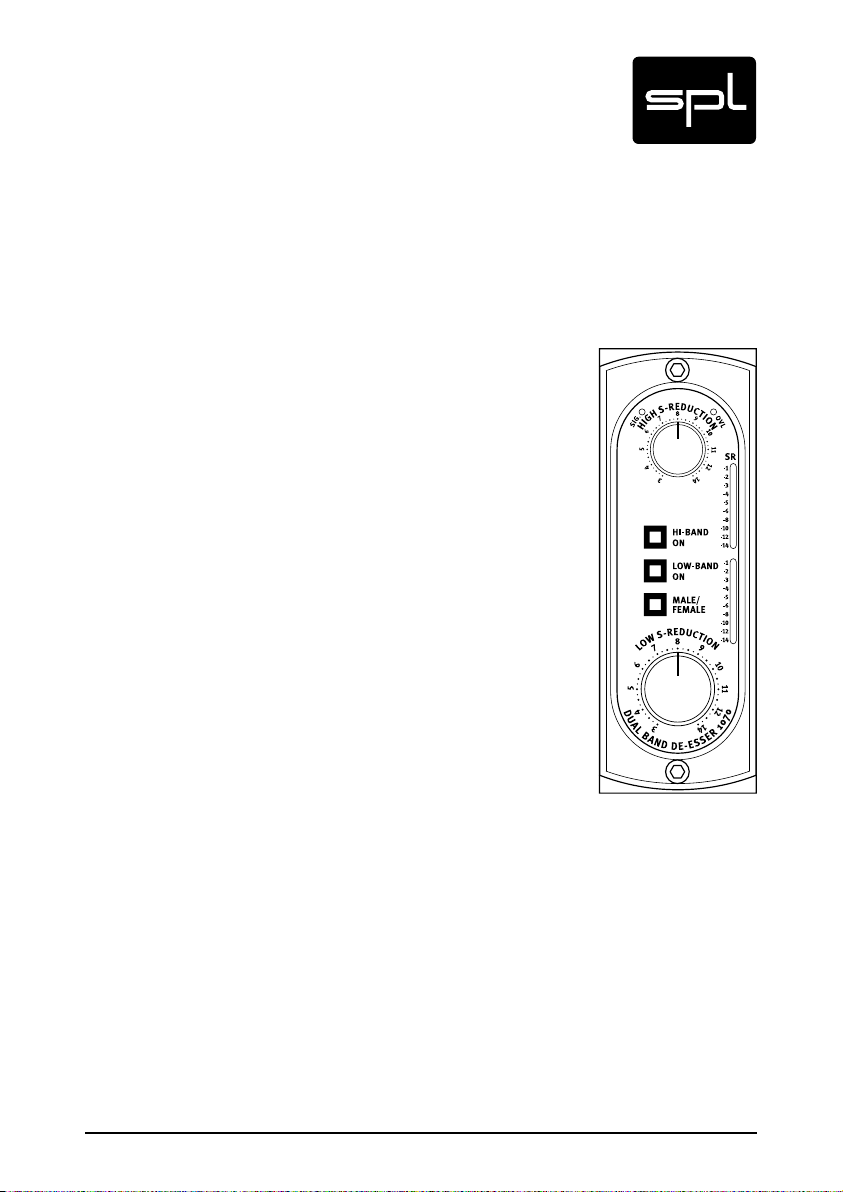

Dual-Band De-Esser

RackPack Module, Model 1070

Processor to remove sibilance

Page 2

Manual Dual-Band De-Esser

Version 1.0 – 8/2010

Developer: Vincenzo Triolo

This user‘s guide contains a description of the product. It in no way

represents a guarantee of particular characteristics or results of use.

The information in this document has been carefully compiled and verified and, unless otherwise stated or agreed upon, correctly describes

the product at the time of packaging with this document. Sound

Performance Lab (SPL) continuously strives to improve its products

and reserves the right to modify the product described in this manual

at any time without prior notice. This document is the property of SPL

and may not be copied or reproduced in any manner, in part or fully,

without prior authorization by SPL.

SPL electronics GmbH

Sohlweg 80, 41372 Niederkruechten, Germany

Phone +49 (0)2163 983 40

Fax +49 (0)2163 983 420

E-Mail: info@spl.info

Internet: www.spl.info

CE Declaration of Conformity

The construction of this audio signal processor is in compliance with the standards and regulations of the European

Community.

Model 1070

Notes on environmental protection

At the end of its operating life, this product must not be

disposed of with regular household waste but must be

returned to a collection point for the recycling of electrical

and electronic equipment. The “wheelie bin“ symbol on the product,

user‘s manual and packaging indicates that. The materials can be

re-used in accordance with their markings. Through re-use, recycling

of raw materials, or other forms of recycling of old products, you are

making an impor tant contribution to the protection of our environment. Your local administrative office can advise you of the responsible waste disposal point.

WEEE Registration: 973 349 88

© 2010 SPL electronics GmbH. All rights reserved. Names of other

companies and their products are trademarks of their respective

owners.

2

RackPack: Dual-Band De-Esser

Page 3

Important Security Information 4

Hook Up 6

Fitting A Module 6

Scope of Delivery 6

Introduction 7

The Dual-Band De-Esser 7

Rear Panel/Connections 8

Lundahl I/O Transformers 9

Channel Split 9

Control Elements 10

HI-BAND ON, LOW-BAND ON; LOW S-REDUCTION 10

HIGH S-REDUCTION, MALE/FEMALE 11

Signal-LED (SIG.), Overload-LED (OVL) 12

Content

Option: I/O Transformers 12

Specifications 13

Block Diagrams 14

Copy Master Recall Settings 15

RackPack: Dual-Band De-Esser

3

Page 4

Important Security Information

Please note and retain this information. Carefully read and follow all

of the safety and operating instructions before you use the machine.

Be doubly careful to follow all warnings and special safety instructions

noted in this manual and on the unit. The following information refers

to modules built into the RackPack frame.

Connections: Only use the connections as described. Other connections can lead to health risks and equipment damage.

Water And Humidity: Do not use this mac hine anywhere near water (for

example near a wash basin or bath, in a damp cellar, near swimming

pools, or the like). In such cases there is an extremely high risk of fatal

electrical shocks!

Insertion Of Foreign Objects Or Fluids: Never allow a foreign object

through any of the machine‘s chassis openings. You can easily come

into contact with dangerous voltage or cause a damaging short circuit.

NEVER allow any fluids to be spilled or sprayed on the machine. Such

actions can lead to dangerous electrical shocks or fire!

OPENING THE DEVICE: Open the device only to fit or exchange modules.

The fit ting and/or exchange of modules should only be carried out by

qualified persons. In the light of possible physical damage or injuries

any manipulation is at your own risk. In order to avoid any residual

voltage, the device should be disconnected from any power source at

least 5 minutes prior to opening it. If you handle the device improperly

or ignore the manual (par t of the delivery of the RackPack frame) you

risk to damage the device or expose yourself to an electric shock. In

these cases SPL electronics GmbH denies any responsibility.

Electrical Power: Run this machine ONLY from sources which can

provide proper power at the prescribed rating. When in doubt about

a source, contact your dealer or a professional electrician. To be sure

you have isolated the machine, do so by disconnecting the power cord

from your wall connection. Be sure that the power cord plug is always

accessible. When not using the machine for a longer period, make sure

to unplug it from your wall power socket.

Power Cord Protection: Make sure that your power cord is arranged

to avoid being stepped on or any kind of crimping and damage related

to such event. Do not allow any equipment or furniture to crimp this

power cord.

Power Connection Overloads: Avoid any kind of overload in connections to wall sockets, extension or splitter power cords. Always keep

manufacturer warnings and instructions in mind. Overloads create fire

hazards and risk of dangerou s shocks!

4

RackPack: Dual-Band De-Esser

Page 5

Important Security Information

Lightning: Before thunderstorms or other severe weather, discon-

nect the machine from wall power ( but to avoid life threatening lightning strikes, not during a storm). Similarly, before any severe weather,

disconnect ALL the power connections of other machines and antenna

and phone/internet cables which may be interconnected so that no

lightning damage or overload results from such secondary connections.

Air Circulation: Chassis openings of fer ventilation and serve to protect

the machine from overheating. NEVER cover or otherwise close off

these openings. NEVER place the machine on a soft surface (carpet,

sofa, etc.). Make sure to provide for a mounting space of 4-5 cm/2

inches when mounting the machine in racks or cabinet s.

Controls And Switches: Operate the controls and switches only as

described in the manual. Incorrect adjustments outside safe parameters can lead to damage and unnecessary repair costs. Never use

the switches or level controls to effect excessive or extreme changes.

Repairs: Unplug the machine and immediately contact a qualified

technician when you think repairs are needed – or when moisture or

foreign objects may accidentally have gotten in to the housing, or in

cases when the machine may have fallen and shows any sign of having

been damaged. This also applies to any situation in which the machine

has not been subjected to any of these unusual circumstances but

still is not functioning normally or its performance is substantially

altered.

In cases of damage to the power cord or its plug, first consider turning

off the main circuit breaker before unplugging the power cord.

Replacement/Substitute Parts: Be sure that any service technician

uses original replacement parts or those with identical specifications

as the originals. Incorrectly substituted parts can lead to fire, electrical

shock, or other dangers, including further equipment damage.

Safety Inspection: Be sure always to ask a service technician to

conduct a thorough safet y check and ensure that the state of the

repaired machine is in all respec ts up to fac tory standards.

Cleaning: In cleaning, do NOT use any solvents, as these can damage

the chassis finish. Use a clean, dry cloth (if necessary, with an acid-free

cleaning oil). Disconnect the machine from your power source before

cleaning.

RackPack: Dual-Band De-Esser

5

Page 6

Hook Up

Fitting A Module

The fitting and/or exchange of modules should only be carried

out by qualified persons. Please read the manual of the RackPack

frame. It contains all information needed to fit a module as well as all

saf et y and notes and warnings.

If you don‘t have the manual at hand, you can download it like all SPL

product manuals from our website http://www.spl.info.

Symbols And Notes

IN THIS MANUAL A LIGHTNING SYMBOL WITHIN A TRIANGLE WARNS

YOU ABOUT THE POTENTIAL FOR DANGEROUS ELECTRICAL SHOCKS

– WHICH CAN ALSO OCCUR EVEN AFTER THE MACHINE HAS BEEN

DISCONNEC TED FROM A POWER SOURCE.

AN EXCL AMATION MARK (!) WITHIN A TRIANGLE IS INTENDED TO MAKE

YOU AWARE OF IMPORTANT OPERATIONAL ADVICE AND/OR WARNINGS

THAT MUST BE FOLLOWED. BE ESPECIALLY ATTENTIVE TO THESE AND

ALWAYS FOLLOW THE ADVICE THEY GIVE.

The symbol of a lamp directs your attention to explanations of important functions or applications.

Attention

Do not attempt any alterations to this machine without the approval or

supervision of SPL electronics GmbH. Doing so could nullify completely

any and all of your warranty/guarantee rights and claims to user

support.

Scope of Delivery

• The module

• This manual

• Two Philips screws to mount the module to the back panel (if module

6

is delivered separately from the f rame). Fur ther screws needed for

mounting the module remain when you remove front and rear covers

from the RackPack frame.

RackPack: Dual-Band De-Esser

Page 7

Back in the 1990‘s, we developed an alternative way to process signals

in order to reduce sibilance based on phase cancellation. Unlike traditional compression methods, this procedure is much more unobtrusive

and simplifies control to one single parameter. SPL‘s De-Esser quickly

became a standard reference among recording studios, broadcast

stations and live sound engineers.

The most commonly used technology to remove sibilance is based

on compression. In addition to determining the threshold, the center

frequency for processing must also be set. The processing range can

be up to two octaves in order to ef fectively address all possible problems across the frequency spectrum. This results in one of the most

critical disadvantages: the wide range of frequencies being processed

leads to undesired ef fects such as nasalization and lisper.

The SPL De-Esser works on the principle of phase cancellation to

remove unwanted sounds. And it also adds automatic sibilance detection, which allows processing to be limited only to the range where

sibilant sounds are present. The result is a neutral-sounding, unnoticeable but highly effective processing that never requires f ine tuning

level and frequency settings. This way de-essing has the least possible

influence on the voice‘s timbre, avoiding side effects like nasalization

and lisper. Operation is limited to adjusting the processing intensity

with one single control. The SPL De-Esser is a safe and precise tool to

solve sibilance problems, without having to compromise sound quality

nor the hassle of permanently readjusting settings.

Introduction

The Dual-Band De-Esser

The Dual-Band De-Esser module expands on this concept by making

use of two frequency bands that can be used independently or jointly.

• Two de-esser stages increase processing effectiveness without

introducing any audible artifacts

• Focused processing with high and low bands

• Input signals are automatically adjusted so that processing is

uniform, regardless of the distance between source and microphone

• Male/Female modes that adapt processing in the lower band to

male or female voices

RackPack: Dual-Band De-Esser

7

Page 8

Rear Panel

Mixer

Insert Send

or

Converter

Output

I

N

P

U

T

O

U

T

P

U

T

1

O

U

T

P

U

T

2

RackPack

Wiring

T

U

P

N

I

Mixer

Ins. Return

1

T

U

P

T

U

O

or

Converter

Input

Channel

2

T

U

P

T

U

O

Split

8

RackPack: Dual-Band De-Esser

Page 9

Rear Panel/Connections

The Dual-Band De-Esser is fitted with one XLR input and two XLR

outputs for balanced operation.

Pin-wiring of all XLR sockets:

Pin 1 = GND, Pin 2 = hot (+), Pin 3 = cold (-)

Discrete balancing stages for both in- and output provide high common

mode rejection and are capable of driving long cables (depending on

the capacity of the cables and the following input balancing stages).

The illustration shows the correct pin-wiring of the balanced XLR

sockets if an unbalanced wir ing is re quired.

balanced

2

1

3

Input

unbalanced

2

1

3

1=GND

2=hot (+)

3=cold (-)

Output

balanced

1

3

2

unbalanced

2

1

3

Lundahl I/O Transformers

The Input and Output 1 stages may be transformer-balanced if ordered.

The transformer option can not be upgraded after sales anymore.

Please refer to page 12 for detailed information on transformers.

Other wise, all inputs and outputs are balanced electronically. Output 2

cannot be fitted with a transformer. It is actively decoupled and allows

for the input signal to be split into two output signals.

Channel Split

The channel split option through Output 2 always provides alternatives

in processing or routing of the input channel. While one output may be

used directly for mixing, the second output can be routed in any other

way—for example to further RackPack modules, to other effect units

etc.

RackPack: Dual-Band De-Esser

9

Page 10

Control Elements

HI-BAND ON, LOW-BAND ON

Use the HI-BAND ON button to turn the HIGH-S-REDUCTION on or off.

Use the LOW-BAND ON button to turn the LOW-S-REDUCTION on or off.

The but tons light up when eng aged.

You can use the two processing stages separately or jointly. They are

connected in series as independent de-esser modules. The low-band

de-esser is set first in the chain.

If both de-essers are engaged, there is interaction bet ween them: a

signal already processed with the low-band de-esser is different f rom

the raw material that the high-band de-esser would other wise process.

That is the reason why the readings of the high band‘s SR LEDs change

when the low-band de-esser is engaged while the high-band processor

is active.

Hard-Bypass: the Dual-Band De-Esser module features power outage

protection based on relay-controlled hard-bypass circuits to always

guarantee signal flow from input to output. In order to keep signal flow

constant, the bypass is automatically activated whenever a voltage

drop or failure is detec ted.

LOW S-REDUCTION

Use the LOW S-REDUCTION control to adjust the intensity of the sibilance reduction in the lower frequency range. The center frequency

for sibilance recognition is set at 7.6 kHz in FEMALE mode and 6.4 kHz

in MALE mode. For more information, please refer to section „MALE/

FEMALE“ on page 11. The bandwidth of the low-band de-esser is

1 . 44 kH z.

Scale values for the filter are displayed in dB. The actual reduction

values, i.e. after phase cancellation, are displayed in the lower SR

LEDs. Thus, when the control is set to 3 dB, actual reduction might only

be of around 1 dB.

The SR LEDs display sibilance reduction between -1 dB and -14 dB, first

in 1 dB increments and from 6 dB on in 2 dB increments.

In practice, for most applications, the best results are usually achieved

when LOW S-REDUC TION is set between 3 and 7.

10

RackPack: Dual-Band De-Esser

Page 11

Control Elements

HIGH S-REDUCTION

Use the HIGH S-REDUCTION control to adjust the intensity of the sibilance reduction in the upper frequency range.

The center frequency for sibilance recognition is set at 11.2 kHz with a

3 kHz bandwidth.

Scale values for the filter are displayed in dB. The actual reduction

values, i.e. after phase cancellation, are displayed in the upper SR

LEDs. Thus, when the control is set to 3 dB, actual reduction might only

be of around 1 dB.

The SR LEDs display sibilance reduction between -1 dB and -14 dB, first

in 1 dB increments and from 6 dB on in 2 dB increments.

Please note that the M ALE/FEMALE button has no effect on the highband de-esser.

In practice, for most applications, the best results are usually achieved

when HIGH S-REDUCTION is set bet ween 3 and 7.

MALE/FEMALE

The MALE/FEMALE button allows you to adjust the low-band de-esser

to the type of voice being processed. When engaged, the mode

selected for the low-band de-esser is FEMALE, otherwise the de-esser

works in MALE mode. The mode selected affects the center frequency

for sibilance recognition: in FEMALE mode it is set at 7.6 kHz, while in

MALE mode it is set at 6.4 kHz.

These values have been determined by practical experience, so that

the processor adapts better to gender. Nevertheless, you cannot take

for granted that these settings will suit every single male and female

voice. Consider the MALE/FEMALE function as an additional tool to

help you set the low-band de-esser more precisely according to your

nee ds. Always trust your ears to find the best settings.

RackPack: Dual-Band De-Esser

11

Page 12

Control Elements

Signal-LED (SIG.)

The SIG. LED indicates that an audio signal reaches the input with a

level above -20 dB. This LED helps the operator especially in complex

setups to determine immediately whether the Dual-Band De-Esser

actually receives any signal.

Overload-LED (OVL)

The OVL LED indicates a potential internal overload. It begins indicating approximately 3 dB ahead of any expected overload to leave

headroom for peak levels.

Overloads must be avoided to exclude audible distortions.

The gaining is still perfect in most cases when the OVL LED

3 dB for peak levels.

Permanent illumination of the OVL LED indicates overloads with

possible audible distortions. Reduce the output gain level of source

units if the OVL LED illuminates permanently until the OVL LED goes

out or flashes shortly.

Option: I/O Transformers

Transformers have a pleasant sound characteristic, especially the low

end sounds rounder and more full-bodied. The top end benefits from a

softer and silky atmosphere without being emphasized.

Further advantages are aspects of improved operational safety:

galvanic insulation excludes the transmission of damaging currents.

Electromagnetic, high frequency or digital interferences have no influence on the signal quality, hum potentials are cancelled out.

From our listening experience we can recommend Lundahl I/O transformers in any case, and their impr ov ed oper ational saf ety is an advantage that can not be overestimated in any critical or complex studio,

broadcast or sound reinforcement installation.

is illuminating shortly since there’s still a headroom of

12

RackPack: Dual-Band De-Esser

Page 13

Audio

Frequency range: 10 Hz-80 kHz

Common mode rejection: ›60 dBu

(@ 1 kHz, 0 dBu input level, unity gain)

Signal to noise ratio: -106 dBu

(A-weighted)

Dynamic range: 128 dB

Total harmonic distortion & noise 0,01%

(@ 1 kHz, 0 dBu input level, unity gain)

Input

XLR socket, electronically balanced, optionally transformer-balanced

Impedance ca. 20 kOhm

Maximum input level +22 dBu

Nominal input level +4 dBu

Outputs

Output 1 XLR socket, electr. balanced,

optionally transformer balanced

Output impedance: 75 Ohm/›600 Ohm w. transf.

max. Ausgangspegel +22 dBu

Output 2 XLR socket, electr. balanced

Impedance ca. 75 Ohm

Maximum output level +22 dBu

Specifications

Control Elements

Signal-LED -20 dBu

Overload-LED +19 dBu (peak hold 1,5 seconds)

Measurements & Weight

Heigth x Width x Depth 132 x 46,9 x 315 mm

Weight 0,5 kg

0,7 kg w. I/O transformers

0 dBu = 0,775 V. Specifications subject to change without notice.

RackPack: Dual-Band De-Esser

13

Page 14

Block Diagrams

14

RackPack: Dual-Band De-Esser

Page 15

Copy Master Recall Settings

Artist:

...........................................

Album:

...........................................

Title:

...........................................

Engineer:

...........................................

Track(s)/Group:

...........................................

RackPack: Dual-Band De-Esser

Date:

...........................................

15

Page 16

Manual Dual-Band De-Esser

Model 1070

RackPack: Dual-Band De-Esser

Loading...

Loading...