Page 1

SR5500

Wireless Channel Emulator

Operations Manual

Page 2

Safety Summary

If the equipment is used in a manner not specified by the manufacturer the protection provided by the

equipment may be impaired.

Safety Symbols

The following safety symbols are used throughout this manual and may be found on the instrument. Familiarize

yourself with each symbol and its meaning before operating this instrument.

Instruction manual symbol. The

product is marked with this symbol

when it is necessary for you to refer to

the instruction manual to protect

against damage to the instrument.

Protective ground (earth) terminal.

Used to identify any terminal which is

intended for connection to an external

protective conductor for protection

against electrical shock in case of a

fault, or to the terminal of a protective

ground (earth) electrode.

Indicates dangerous voltage (terminals

fed from the interior by voltage

exceeding 1000 volts must be so

marked).

Frame terminal. A connection to

the frame (chassis) of the

equipment which normally includes

all exposed metal structures.

The caution sign denotes a hazard.

It calls attention to an operating

procedure, practice, condition or

the like, which, if not correctly

performed or adhered to, could

result in damage to or destruction

of part or all of the product or you’s

data.

Alternating current (power line).

Page 3

Résumé des règles de sécurité

Si le matériel est utilisé d’une façon non conforme aux spécifications du constructeur, la protection assurée

par le matériel peut être mise en défaut.

Symboles de sécurité

Les symboles suivants sont utilisés dans tout le manuel et peuvent être trouvés sur le matériel. Il est

recommandé de se familiariser avec chaque symbole et sa signification avant de manipuler le matériel.

Symbole « manuel d’instruction ». Ce

symbole apparaît sur le produit

lorsqu’il est nécessaire de se référer

au manuel d’instruction pour éviter

une détérioration du matériel.

Terre : ce symbole identifie la

connexion de terre chargée de

protéger le matériel contre les chocs

électriques. Cette connexion doit être

raccordée vers un conducteur externe

de protection ou vers une électrode de

type terre.

Ce symbole indique un voltage

dangereux (connexion alimentée en

interne par un voltage excédant 1000

volts).

Spirent Communications, Inc.

541 Industrial Way West

Eatontown, NJ 07724

Phone: (732) 544-8700

Fax: (732) 544-8347

This manual applies to the SR5500, Version 2.

Page Part Number: 2700-8351 Version A

7

30 and higher

Masse. Ce symbole identifie une

connexion au châssis du matériel

(ce châssis inclut normalement

toutes les structures métalliques

exposées).

Ce symbole désigne une opération

ou une condition dite « sensible »,

qui, si elle n’est pas correctement

réalisée, pourrait entraîner de

sérieuses détériorations au

matériel ou aux données

utilisateur.

Courant alternatif (ligne de

puissance).

Copyright

© 2007, Spirent Communications, Inc.

Printed in the USA.

Technical Support is available 8:30 AM – 5:30 PM EST, Monday - Friday

Phone support is available through Spirent Customer Care at +1 732-544-8700

Email support is available at wireless@spirent.com.

Information furnished by Spirent Communications is believed to be accurate and reliable. However, no responsibility is assumed by Spirent

Communications for its use. Specifications are subject to change without notice.

Page 4

Page 5

Table of Contents

1. Introduction ..................................................................................... 1

1.1. Overview ...........................................................................................1

1.2. SR5500 Applications..........................................................................2

1.2.1. Applicable to All Design Phases ............................................................... 3

1.2.2. Evaluating Radio Access Technologies .....................................................4

1.2.3. Evaluating Air Interface Performance ....................................................... 5

1.3. Key Product Features ......................................................................... 5

1.3.1. Wireless Channel Emulation Features....................................................... 5

1.3.2. Ease of Use Features ................................................................................ 6

1.4. SR5500 Guided Tour .......................................................................... 6

1.4.1. Front Panel Description............................................................................6

1.4.2. Rear Panel Description............................................................................. 8

1.5. Quick Start Procedure ........................................................................9

1.6. Verification Procedure...................................................................... 11

1.7. Quick Start Using Test Assistant ....................................................... 12

1.8. Version History ................................................................................15

2. Operation Reference....................................................................... 19

2.1. Overview .........................................................................................19

2.2. Operational Overview....................................................................... 19

2.2.1. Connecting to the SR5500......................................................................20

2.2.2. Basic Operation..................................................................................... 21

2.3. Using the Test Assistant................................................................... 25

2.3.1. Accessing the Test Assistant .................................................................. 25

2.3.2. Changing the Carrier Frequency............................................................. 26

2.3.3. Automatically Selecting a Channel Profile .............................................. 26

2.3.4. Completing the Configuration ................................................................ 27

2.4. Channel Player................................................................................. 27

2.5. File Operations ................................................................................ 28

2.5.1. Settings Saved in the Settings File .........................................................29

Page 6

ii | SR5500 Operations Manual

2.5.2. Recent File List....................................................................................... 29

2.6. Operational Detail............................................................................ 29

2.6.1. Channel I/O Parameters......................................................................... 29

2.6.2. Path Parameters.................................................................................... 38

2.6.3. Interference........................................................................................... 43

2.6.4. Instrument Setup View........................................................................... 45

2.7. Dynamic Environment Emulation ...................................................... 46

2.7.1. Method.................................................................................................. 47

2.7.2. Emulation File Creation (DEE Template).................................................. 48

2.7.3. Dynamic Environment Emulation (DEE) View .......................................... 52

2.7.4. Using DEE with Multiple SR5500s........................................................... 54

2.8. Power Meter Parameters ..................................................................54

2.9. Using the SR5500 with 6 GHz/6GHz-EX Option ................................. 55

2.9.1. Configuring TestKit for the 6 GHz(-EX) Option ......................................... 56

2.9.2. Selecting Lower/Middle/Upper Band ..................................................... 56

2.9.3. Parameter Dependencies....................................................................... 56

2.10. Downloading Firmware to the SR5500 .............................................. 57

2.10.1. Starting the Download ............................................................................57

2.10.2. During the Download............................................................................. 58

2.10.3. Recovery in Case of Failure..................................................................... 58

2.11. Changing the Remote Connection ..................................................... 58

2.11.1. Changing the SR5500 IP Address Configuration ..................................... 59

2.11.2. Changing the IP Address in SR5500 TestKit ............................................ 60

2.12. Updating the SR5500 Options .......................................................... 60

2.13. Controlling Multiple SR5500s...........................................................61

2.13.1. Connecting Synchronization Cables ....................................................... 61

2.13.2. Configuring TestKit to Control Multiple Units .......................................... 62

2.13.3. Switching Between Units........................................................................63

2.13.4. Player Functionality. .............................................................................. 63

2.13.5. Correlation Coefficient Type. ..................................................................63

2.13.6. System-Based Correlation. .................................................................... 64

2.14. Summary View................................................................................. 65

2.14.1. Path Parameters.................................................................................... 66

2.14.2. System Parameters................................................................................ 66

Page 7

Table of Contents | iii

3. Technical Reference ....................................................................... 67

3.1. Overview .........................................................................................67

3.2. Radio Channel Power Delay Profile ................................................... 68

3.3. Static Relative Path Delay................................................................. 69

3.4. Time-Varying Relative Path Delay...................................................... 69

3.4.1. Sliding Relative Path Delay .................................................................... 70

3.4.2. Birth-Death Time-varying Relative Path Delay..........................................71

3.5. Relative Path Loss............................................................................ 72

3.6. Fast Fading ...................................................................................... 72

3.6.1. Rayleigh Fading Amplitude Distribution ................................................. 73

3.6.2. Rician Fading Amplitude Distribution ..................................................... 76

3.6.3. Fast Fading Power Spectrum Shapes...................................................... 78

3.7. Static Amplitude Channel Effects ...................................................... 78

3.7.1. Frequency Shift (Static Doppler)............................................................. 79

3.7.2. Static Phase Shift................................................................................... 79

3.8. Slow Shadow Fading........................................................................ 79

3.9. Additive White Gaussian Noise (AWGN) interferer.............................. 81

3.10. Power Meter .................................................................................... 86

4. Instrument API ............................................................................... 89

4.1. Overview .........................................................................................89

4.2. Benefits and Features ...................................................................... 90

4.3. Development Environments..............................................................90

4.4. API Usage Example .......................................................................... 90

4.5. API Front Panel.................................................................................91

4.5.1. The API Front Panel Window Components............................................... 92

4.6. Further Information .......................................................................... 96

5. Remote Programming Interface Operation...................................... 97

5.1. Overview .........................................................................................97

5.2. Remote Control Features ..................................................................97

5.3. Configuring SR5500 TestKit for Remote Control................................. 97

5.3.1. Setting up the Remote Programming Interface ....................................... 98

5.3.2. Start/Stop the Listener........................................................................... 99

Page 8

iv | SR5500 Operations Manual

5.3.3. Local/Remote Mode............................................................................... 99

5.3.4. Enable Monitor Messages.................................................................... 100

5.3.5. Enable TCP/IP Echo .............................................................................. 100

5.3.6. Automatically Configuring SR5500 TestKit for Remote Control .............. 100

5.4. SR5500 TestKit Command Protocol................................................. 100

5.4.1. Command Types .................................................................................. 100

5.4.2. Command Sequence.............................................................................101

5.4.3. Program Messages...............................................................................101

5.4.4. Response Format ................................................................................. 102

5.4.5. Long Form and Short Form of Mnemonics............................................. 102

5.4.6. Hierarchical Default Format.................................................................. 103

5.4.7. Error Message Format.......................................................................... 103

5.5. Transmission Layer Protocols ......................................................... 104

5.5.1. LAN CR/LF Protocol .............................................................................. 104

5.5.2. GPIB Protocol .......................................................................................105

6. RPI Command Reference...............................................................111

6.1. Conventions to Specify Commands................................................. 111

6.2. Command Summary.......................................................................112

6.3. Command Descriptions .................................................................. 115

6.4. Command Dependencies................................................................ 132

6.5. Autosets........................................................................................ 133

6.6. Overload Status.............................................................................133

6.7. Dynamic Environment Emulation (DEE)............................................ 134

7. Technical Specifications............................................................... 136

7.1. Overview .......................................................................................136

7.2. RF Channel Specifications (without the SR5500 6 GHz Option).........136

7.3. RF Channel Specifications (with the SR5500 6 GHz Option)..............137

7.4. RF Channel Specifications (with the SR5500 6 GHz-EX Option)......... 139

7.5. Channel Emulation Characteristics .................................................140

7.6. Interference Generation Characteristics .......................................... 143

7.7. Power Measurement Characteristics............................................... 145

7.8. Interface and Environmental Characteristics ................................... 145

Page 9

1. Introduction

1.1. Overview

The Spirent SR5500 Wireless Channel Emulator accurately emulates complex wideband

wireless channel characteristics such as time-varying multi-path delay spread, fading,

and channel loss. By providing a programmable and repeatable set of emulated radio

channel conditions, the SR5500 enables a thorough, structured approach to receiver

performance characterization. The SR5500, shown in Figure 1-1, replicates real-world

deployment conditions using powerful digital signal processing techniques, making it

possible to isolate performance issues early in the development and design verification

cycle. Optional AWGN enhances the real-world conditions emulated by the SR5500. Early

optimization of performance accelerates time to market and minimizes post-deployment

issues.

Figure 1-1: SR5500 Wireless Channel Emulator

Complete analysis of the performance of today’s complex radio transmission schemes

requires a channel simulator that offers rich emulation of radio channel characteristics.

This is required to ensure that lab and field performance measurements align. At the

same time, the instrument implementation must contribute minimal unwanted parasitic

simulation effects that can distort test results. The SR5500 high performance, all-digital

signal processing engine presents a realistic set of radio channel conditions to the most

complex radio transmission technologies. The use of the SR5500 DEE (Dynamic

Environment Emulation) further replicates real-world fading scenarios by allowing

dynamic control over fading parameters. With a high fidelity channel and long simulation

repetition rates, the SR5500 ensures reliable and accurate performance evaluation.

Page 10

2 | SR5500 Operations Manual

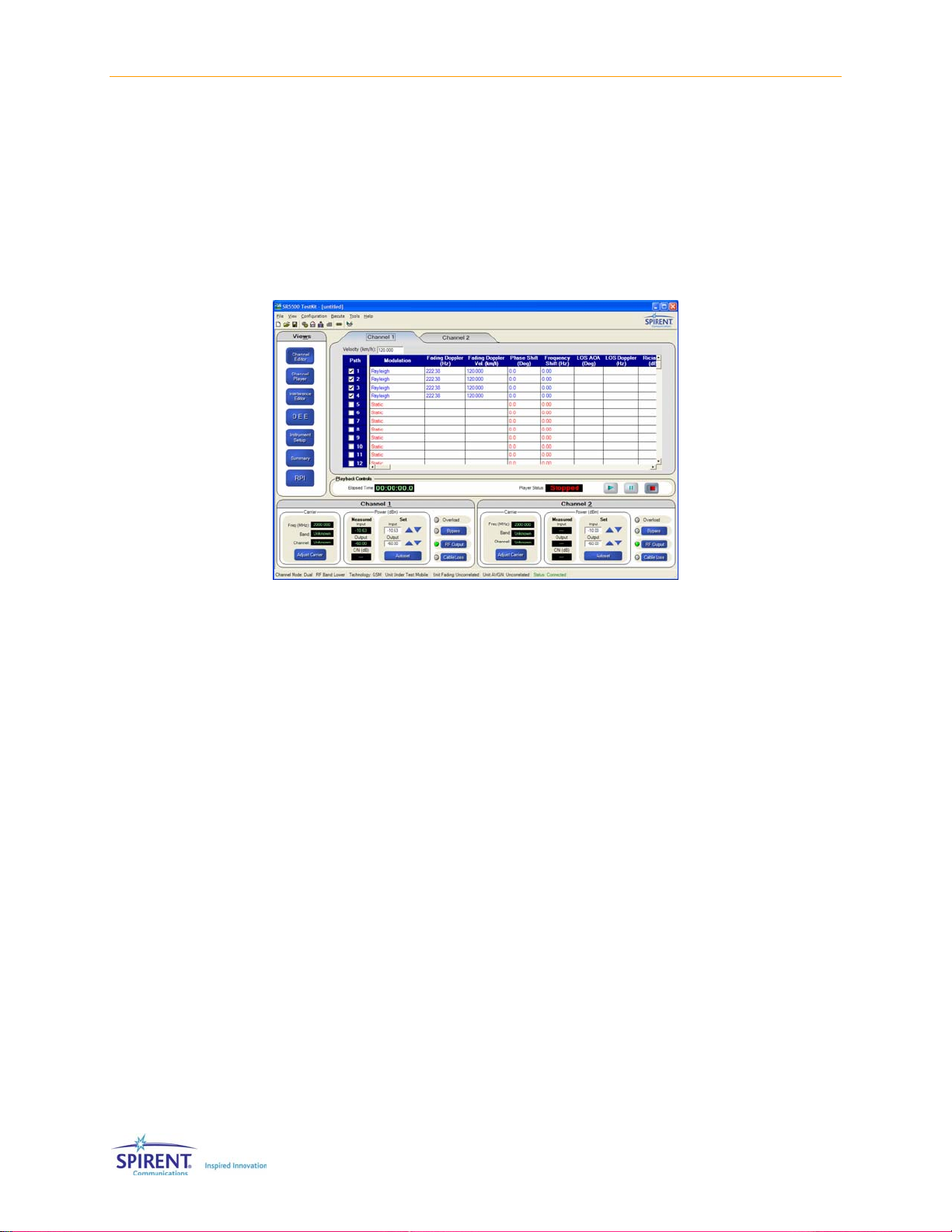

The SR5500 Graphical User Interface (GUI) shown in Figure 1-2, enables you to select

channel models from a vast library of pre-defined industry standard channel models or

custom configurations that provide extreme precision using the Channel Model Editor.

Once the channel model is configured, the Channel Model Player enables low-level

control over playback including the ability to play, pause, and stop the simulation. If

changes to the channel model are required, the SR5500 real-time fading sequence

generation enables modifications to take effect instantly. This eliminates the need to

tolerate the testing delays associated with fading simulators that must pre-calculate

fading sequences.

Figure 1-2: SR5500 Wireless Channel Emulator Graphical User Interface

With the standard instrument configuration equipped with 24 independent multi-paths,

the SR5500 delivers performance evaluation beyond the minimum performance

requirements associated with 3G technologies, such as CDMA2000 and WCDMA, and

with evolving Wireless LAN standards. The SR5500 enables you to program time-varying

channel conditions, which is a critical capability required to properly assess the overall

performance of high-speed transmission technologies such as 1xEV-DO, 1xEV-DV, and

WCDMA HSDPA that employ adaptive modulation and coding schemes.

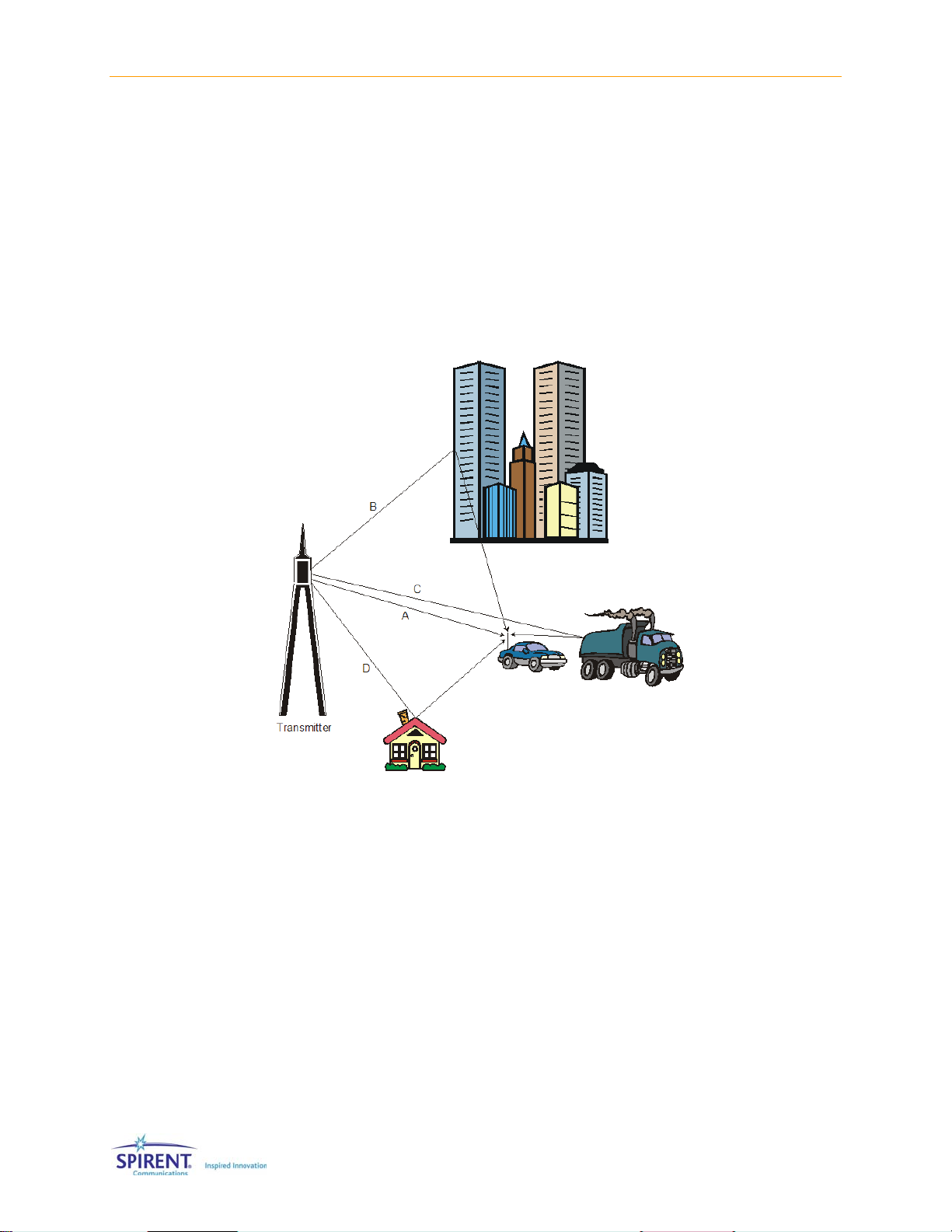

1.2. SR5500 Applications

The SR5500 emulates a wide array of radio channel conditions ranging from indoor

micro cellular environments with low mobility to macro-cellular environments with highspeed mobility. With a channel modeling engine capable of an assortment of

configurations, the SR5500 can analyze the performance of current and emerging air

interface technologies such as EDGE/GSM/GPRS, CDMA2000, WCDMA, 802.16, and

802.11a/b/g in representative deployment conditions without leaving the test lab. To

facilitate testing that requires co-channel interference, the SR5500 optionally includes

the ability to generate AWGN. The SR5500 can be utilized in both Handset and Base

Station test applications as shown in Figure 1-3 and Figure 1-4. These capabilities make

it possible for the SR5500 to play a valuable role in all phases of the product realization

cycle.

Page 11

Figure 1-3: SR5500 Handset Test Setup

Chapter One: Introduction | 3

Figure 1-4: SR5500 Base Station Test Setup

1.2.1. Applicable to All Design Phases

Comprehensive performance evaluation throughout the product development cycle

improves the probability of identifying potential design issues at a stage where they can

be easily addressed. The SR5500 plays a valuable role throughout the product

realization process.

1.2.1.1 Research and Development

Early in the design and standardization of new air interface technologies, physical layer

modulation schemes, channel coding, and mobility algorithms must be evaluated and

compared. The SR5500 can analyze the performance of competing technologies by

providing repeatable test conditions across test campaigns. It is capable of sophisticated

channel models and low signal distortion, and can accommodate the evaluation of nextgeneration, wide-bandwidth signal formats.

Page 12

4 | SR5500 Operations Manual

1.2.1.2 Design Verification Test

Comprehensive evaluation of reference designs and commercial products against

original design objectives is a critical phase in the product realization process. You can

configure the SR5500 to emulate a wide range of radio propagation environments with

precise control over channel conditions for performance breakpoint analysis. With an

easy to use software application programming interface (API), the SR5500 also easily

integrates into automatic test systems capable of performing a large number of test

cases in minimal time.

1.2.1.3 Acceptance/Conformance Test

Before deployment, commercial products must typically undergo a series of acceptance

and conformance tests based on minimum industry performance standards. The

SR5500 User Interface features a Test Assistant that makes it easy to emulate

propagation conditions defined in various industry test specifications. These propagation

conditions are defined by ETSI, 3GPP, 3GPP2, and ITU.

1.2.1.4 System Performance Test

Once deployed to the field, the performance of wireless equipment is analyzed and

optimized. To accelerate the optimization process, it is necessary to recreate challenging

field scenarios on a controlled, repeatable test bed. By utilizing both RF channels in the

instrument, you can configure the SR5500 for bi-directional full duplex performance

evaluation. You can also program the SR5500 to play back field conditions repeatedly,

enabling the adjustment of algorithms until optimal performance is realized.

1.2.2. Evaluating Radio Access Technologies

The SR5500 possesses the capabilities necessary to evaluate a broad range of local and

wide area wireless network technologies. With frequency coverage up to 6 GHz, the

SR5500 covers all of the world’s deployment frequency bands. Supported technologies

include:

• GSM/GPRS/EDGE

• WCDMA

• WCDMA HSDPA

• CDMA2000 1x

• CDMA2000 1xEV-DO

• CDMA2000 1xEV-DV

• Location Based Services

• 802.11.a/b/g

• 802.16(WiMAX)

• HiperLAN

Page 13

Chapter One: Introduction | 5

1.2.3. Evaluating Air Interface Performance

Radio access technologies possess layers of algorithms designed to mitigate the harsh

effects of radio propagation and to deliver seamless mobility. The SR5500 possesses the

critical features required to stress test air interface performance and to identify

opportunities to improve product design. The SR5500 can be used to evaluate and

improve the performance of:

• Baseband Demodulation

• Rake Finger Tracking

• Diversity Reception

• Channel Equalization

• Power Control Schemes

• Handover Efficiency

• Radio Link Protocols (RLPs)

• Geolocation

1.3. Key Product Features

1.3.1. Wireless Channel Emulation Features

With a powerful all-digital signal processing engine, the SR5500 emulates wideband

channel conditions with unprecedented accuracy and programmability. RF Channel

Emulation features include:

• Comprehensive channel models with up to 24 independent paths enables evaluation

of 3G and Wireless LAN equipment well beyond minimum performance standards.

• Real-time fading sequence generation enables channel model modifications without

the lengthy delays required to pre-calculate fading coefficients.

• Superior channel fidelity required to properly evaluate higher-order modulation

schemes, minimizing unwanted distortion that leads to false test results.

• Digital AWGN gives accurate and repeatable C/N, C/No, and Eb/No ratios.

• Creation of real-world fading scenarios with DEE (Dynamic Environment Emulation)

enables time-vary fading parameters.

• Long fading sequence repetition rate ensures realistic test conditions results.

• Time-varying channel models include dynamic Power Delay Profiles that evaluate

adaptive modulation and coding schemes.

• Real-time display of channel conditions and low-level control over channel model

playback.

• Frequency range extends to 6 GHz to cover 802.11a applications.

• Power meter capable of both continuous and triggered mode, ideal for bursty signals

like GSM/GPRS/EDGE and WLAN.

Page 14

6 | SR5500 Operations Manual

1.3.2. Ease of Use Features

The SR5500 simplifies test setup and control with easy-to-use local and remote

interfaces. Some of these features include the ability to:

• Quickly recall industry standard fading profiles from 3GPP, 3GPP2, ITU and JTC.

• Create realistic user-defined scenarios using the SR5500 Channel Model Editor

providing easy access to emulation parameters.

• Set the absolute channel output level, without the need for external attenuators and

calibration, ensuring accurate signal levels are always present at the receiver under

test.

• Make real time changes to AWGN with the Interference Editor, eliminating the need

to re-configure the fading profile, significantly reducing test time.

• Monitor the Power Delay Profile and input/output power levels of the SR5500 in real-

time to provide valuable user feedback on current test conditions.

• Integrate the SR5500 into automatic test systems using a Windows .NET-based

software API.

1.4. SR5500 Guided Tour

All SR5500 functionality is controlled through the instrument control software SR5500

TestKit or the Application Programming Interface (API). Refer to the Setup Guide included

with the instrument for details on how to connect the SR5500 system.

1.4.1. Front Panel Description

Figure 1-5: SR5500 Front Panel

Page 15

Chapter One: Introduction | 7

Front Panel Control/Indicators

c

d

e

f

POWER Switch

The Power switch is located in the bottom right hand corner of the front panel.

STATUS LED

The Status LED is located next to the power switch and indicates the current status of the

unit. SR5500 is operating normally if the LED is green. An error condition exists when the

STATUS LED is red. The LED takes a few seconds to illuminate during power up.

CHANNEL 1 OVERLOAD LED and CHANNEL 2 OVERLOAD LED

The LED indicates the RF input signal has peak levels above the permitted range and will be

clipped by the instruments input circuitry. The overload LEDs should be monitored to ensure

the signal applied at the RF Channel input is within the specified range.

CHANNEL 1 BYPASS LED and CHANNEL 2 BYPASS LED

This indicator tells you the channel is in bypass mode. The channel is bypassed when the

LED is green.

Front Panel Signal Input/Output Connectors

g

h

i

j

k

l

CHANNEL 1 and CHANNEL 2 RF IN

N Connector (50 Ω) - This connector functions as the channel RF input.

CHANNEL 1 RF OUT [DUPLEX]

N Connector (50 Ω) - This connector functions as the channel 1 RF output.

CHANNEL 1 RF OUT [OUT2]

N Connector (50 Ω) - Reserved for future use.

CHANNEL 2 RF OUT

N Connector (50 Ω) - This connector functions as the channel 2 RF output.

CHANNEL 1 and CHANNEL 2 LO IN

N Connector (50 Ω) - This connector functions as the channel local oscillator input. LO IN

must be connected to LO OUT via the Loop-back cable supplied with the SR5500.

CHANNEL 1 and CHANNEL 2 LO OUT

N Connector (50 Ω) - This connector functions as the channel local oscillator output. LO IN

must be connected to LO OUT via the Loop-back cable supplied with the SR5500.

CAUTION: The RF IN and OUT Ports can accept a limited power range; refer to

the technical specifications to ensure absolute maximum levels are not

exceeded.

Page 16

8 | SR5500 Operations Manual

1.4.2. Rear Panel Description

Rear Panel Controls

c

d

e

f

g

h

i

j

k

l

n

10 MHz IN

BNC Type Connector (50 Ω) - Accepts an externally supplied 10 MHz sine wave reference

signal which can be used to drive the internal signal processing circuitry of the SR5500.

10 MHz OUT

BNC Type Connector (50 Ω) - Provides a 10 MHz sine wave reference signal as an output.

CH 1 and CH 2 I/IF IN

BNC Type Connector (50 Ω) - Reserved for future use.

CH 1 and CH 2 Q IN

BNC Type Connector (50 Ω) - Reserved for future use.

CH 1 and CH 2 I/IF OUT

BNC Type Connector (50 Ω) - Reserved for future use.

CH 1 and CH2 Q OUT

BNC Type Connector (50 Ω) - Reserved for future use.

DBB IN1, IN2, and IN3

26 Pin MDR Type Connector - Reserved for future use.

DBB OUT

26 Pin MDR Type Connector - Reserved for future use.

SYNC IN

15 Pin MDR Type Connector - Used to synchronize fading data between multiple SR5500

systems.

SYNC OUT

15 Pin MDR Type Connector - Used to synchronize fading data between multiple SR5500

systems.

CH 1 and CH 2 TRIG IN

BNC Type Connector (50 Ω) - Reserved for future use.

Figure 1-6: SR5500 Rear Panel

Page 17

Rear Panel Controls

o

p

q

r

s

t

u

CH 1 and CH 2 SYNC OUT

BNC Type Connector (50 Ω) - Reserved for future use.

GPIB

Reserved for future use.

ETHERNET

RJ-45 Type Connector - The Ethernet port supports TCP/IP. It is recommended that a

Category 5 Ethernet cable be used.

SERIAL

RJ-45 Type Connector - Control port used exclusively for configuring Ethernet

communication parameters.

AUX 1

RJ-45 Type Connector - This port is used to control the SR5500 6 GHz(-EX) RF Converter.

AUX 2

RJ-45 Type Connector - Reserved for future use.

AC Power Receptacle

The AC universal power receptacle is located on the lower left corner of the rear panel. This

receptacle also contains the fuses for the unit.

Chapter One: Introduction | 9

1.5. Quick Start Procedure

To prepare the SR5500 for initial operation, perform the following steps. Refer to the

table below to determine the number of cartons in the SR5500 shipment.

1. Unpack the SR5500 shipping cartons. There should be two shipping cartons, one

containing the SR5500 and accessories and the other containing the PC. An optional

third carton contains the SR5500 6 GHz(-EX) RF Converter and accessories.

a. The cartons should contain a packing list detailing all the items in the cartons.

b. Make sure that all parts listed on the packing list are contained in your SR5500

shipping cartons.

c. Save the shipping cartons and packing materials until you have completed the

system installation and initial check. If you must return equipment, please use

the original box and packing material.

d. Check each item for physical damage. If any part appears to be damaged, contact

the Spirent Communications Customer Service department.

2. Plug one end of the supplied AC power cord into the rear panel, and then plug the

other end into your AC source. Repeat as necessary.

3. Connect supplied loop-back cables from LO IN CH1 to LO OUT CH1. Repeat for LO

CH2.

4. OPTIONAL: Connect the following cables between the SR5500 and the SR5500 6

GHz(-EX) RF Converter.

(From) SR5500 (To) 6 GHz(-EX) RF Converter Cable Used

CHANNEL 1 RF IN IF - CH1 OUT Supplied N-N cable

CHANNEL 1 RF OUT IF - CH1 IN Supplied N-N cable

Page 18

10 | SR5500 Operations Manual

(From) SR5500 (To) 6 GHz(-EX) RF Converter Cable Used

CHANNEL 2 RF IN IF - CH2 OUT Supplied N-N cable

CHANNEL 2 RF OUT IF - CH2 IN Supplied N-N cable

AUX 1 (Unlabeled RJ-45 connector on

5. Connect the supplied cross over cable from the PC built-in Ethernet port (not the PC

Card Ethernet Port), to the SR5500 Ethernet port on the rear panel. Optionally, you

can connect the PC Card Ethernet Port to the LAN.

NOTE: When connecting the 6 GHz(EX) RF connector to the SR5500 the supplied

N, N cables must be used in order to maintain level accuracy.

6. Turn the power on.

e. Set the AC power switch on the lower right corner of the front panel to the "|"

position. The SR5500 now executes its power-up self test and calibration

sequence, this takes a few seconds. You will hear two beeps and the status light

will illuminate green. Note: The STATUS Light will take a few seconds before

turning on.

f. OPTIONAL: If the SR5500 6 GHz(-EX) RF Converter is present, turn the power on

by setting the AC power switch to the “|” position on the rear of the unit.

g. Power on the PC. Refer to the PC documentation for details.

7. Launch the instrument control software SR5500 TestKit on the PC by clicking the

TestKit icon

complete the connection to the SR5500 by clicking the Connect icon

Figure 1-7.

RJ-45 Cable

rear panel)

on the desktop. After launching the SR5500 TestKit application,

shown in

Figure 1-7: SR5500 TestKit Software Menus

8. TestKit indicates the connected status by displaying Status: Connected in the status

bar at the bottom of the window as shown in Figure 1-8.

Page 19

Figure 1-8: Status Connected Indicator

1.6. Verification Procedure

This procedure verifies the basic operation of the SR5500. It is not necessary to

complete these steps to use the SR5500. A signal generator and spectrum analyzer

capable of operating at 900 MHz is needed for this verification. The SR5500 default

settings are used for this procedure. Use the table and block diagram below to connect

the required equipment.

Connect From Connect To Cable

Signal Generator Output SR5500 CHANNEL 1 RF IN N to N

SR5500 CHANNEL 1 RF OUT Spectrum Analyzer Input N to N

Chapter One: Introduction | 11

Signal

Generator

SR5500

CH1

RF In

Figure 1-9: SR5500 Verification Setup Diagram

CH1

RF Out

Spec tr um

Analyzer

OPTIONAL: Use the table and block diagram shown in Figure 1-10 to

connect the equipment to a SR5500 equipped with the 6 GHz(EX) RF

Converter.

Connector 1 (From) Connector 2 (To) Cable

Signal Generator Output SR5500 6 GHz(-EX) RF Converter

CH 1 RF IN

SR5500 6 GHz(-EX) RF Converter CH

1 RF OUT

CH1 In

Spectrum Analyzer Input N-Type

CH1 Out

N-Type

6GH z Option

Signa l

Gener ator

SR5500

Spec tr um

Analy zer

Figure 1-10: SR5500 with 6GHz (-EX) Option Verification Setup

Page 20

12 | SR5500 Operations Manual

To run the Verification Procedure:

1. Set the signal generator to 900 MHz with an output power of -10 dBm.

2. Set the spectrum analyzer to 900 MHz with a span of 30 MHz.

3. The output signal should be about -40 dBm, as in the spectrum analyzer display

shown in Figure 1-11.

Figure 1-11: Spectrum Analyzer Output Signal of SR55 00 at 90 0 MHz

1.7. Quick Start Using Test Assistant

This procedure uses the Test Assistant to step through an example of a GSM standard

Specification Test. Test Assistant automatically configures the SR5500 for the specific

test application.

A Base Station Emulator, circulator, and a DUT (GSM Mobile) are used for this procedure.

Figure 1-12 shows the setup for the Mobile Test.

Figure 1-12: Mobile Test Setup

1. Connect the Base Station Emulator RF Output Port to the Channel 1 RF IN of the

SR5500 with the appropriate cable.

2. From Channel 1 RF OUT on the SR5500 connect to Port 1 of a Circulator, using the

appropriate cable.

Page 21

Chapter One: Introduction | 13

3. Connect Port 2 of the circulator to the Antenna Port of the GSM DUT (mobile phone

for this example). This completes the required connections for the downlink path

(Base Station to Mobile Station).

4. Connect Port 3 of the Circulator to the RF Input Port of the Base Station Emulator.

This connection establishes the unimpaired uplink path (Mobile Station to Base

Station).

5. After completing the interconnections outlined in Figure 1-12, power-on all

instruments in the test setup.

Before proceeding with the Test Assistant configuration, ensure the SR5500 TestKit is

running and connected to the SR5500.

6. Click the Test Assistant icon

The Test Assistant Window displays as shown in Figure 1-13.

located on the toolbar of SR5500 TestKit.

Figure 1-13: Test Assistant Window

7. Set the following parameters:

h. Set Technology to GSM.

i. Set Unit Under Test to Mobile.

j. Set Band to E-GSM900.

k. Set Channel Number to 50.

8. Select Use the following standard fading profile shown in Figure 1-14.

Figure 1-14: Test Assistant Window – Profile Selection Option

9. Select the HT2 (100 km/h, 12 path) model from the profile list.

Page 22

14 | SR5500 Operations Manual

10. Click the OK button.

The Channel Editor is now set to the test case Hilly Terrain 12 path model used for

3GPP test standards.

Figure 1-15: Sample Channel Editor with Correct Values Entered

11. Set the Base Station Emulator output power to -10 dBm.

12. Program the Output Level to -65 dBm shown in Figure 1-16.

Figure 1-16: Output Level Meter

13. Click the Autoset button in the Channel Editor as shown in Figure 1-17.

Figure 1-17: The Autoset Button

14. Click the Channel Player icon to get a channel representation of the fading profile

generated by the SR5500.

Figure 1-18: The Channel Player Button

Page 23

Figure 1-19: Sample TestKit Window

15. Click the Play button to start the Fading Emulation.

You are now ready to perform a Mobile Performance Test.

Chapter One: Introduction | 15

1.8. Version History

The following information provides a summary of feature releases for the SR55500 since

the initial Version 1.00 release. To upgrade to a particular version, the SR5500

instrument Annual Service Agreement (ASA) expiration date must be later than or equal

to the release ASA date. To verify the ASA expiration date, refer to Section 2.12 on page

60.

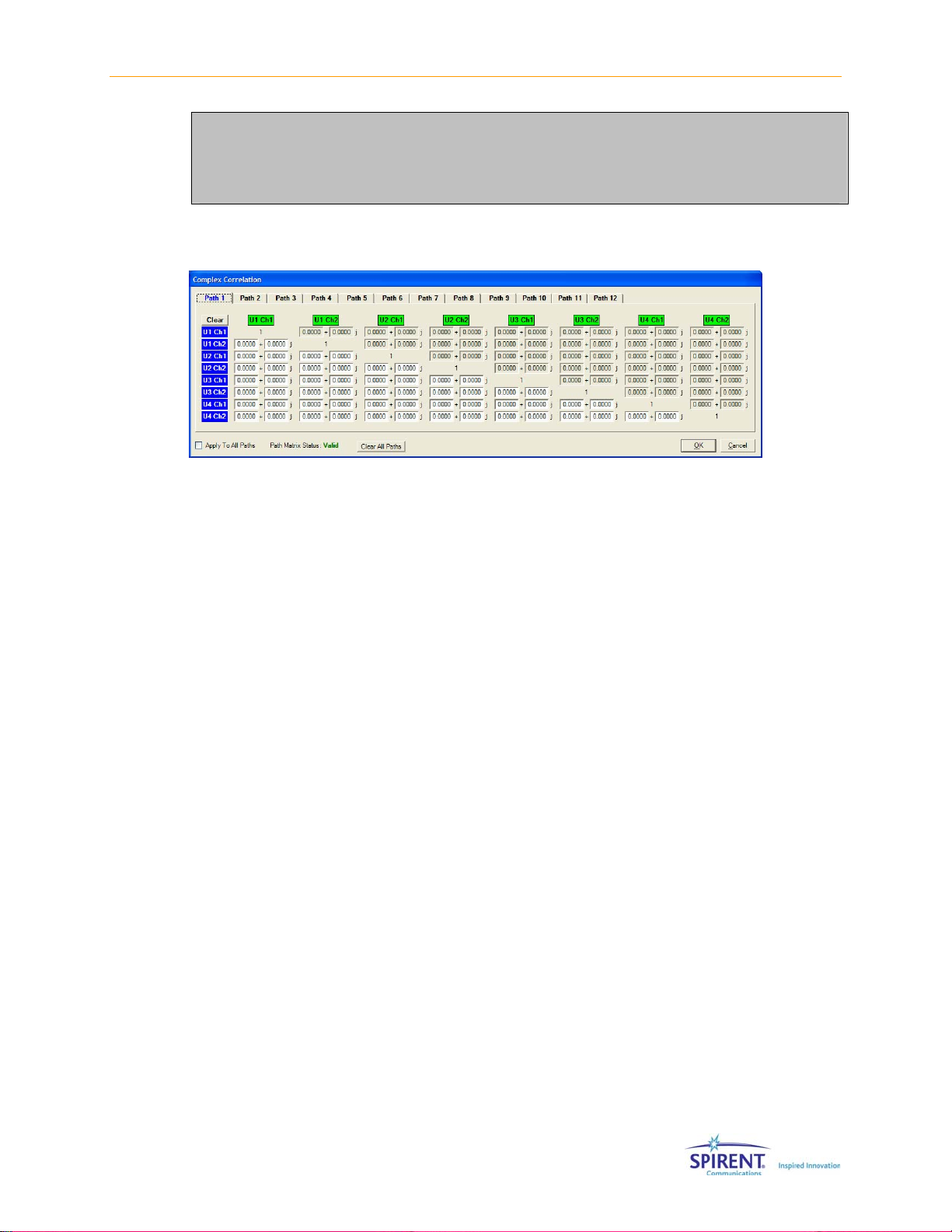

Version 2.30 (Release ASA DATE: MAY 2007)

• Added the ability to set Complex Correlation between any two channels located in

different SR5500 systems. In addition, a unique Complex Correlation value can be

specified between each corresponding path between the two channels.

• Added the ability to change C/N, and Doppler Velocity Parameters within DEE.

• Added the latest frequency bands, channels, and fading profiles specified in 3GPP TS

25.101 Release 6 and 7.

Version 2.21 (Release ASA DATE: DECEMBER 2006)

• Resolved an issue in RPI mode that caused DEE to fail unless DEE had been run

manually at least once since power-up of the SR5500.

Version 2.21 (Release ASA DATE: DECEMBER 2006)

• Resolved an issue in RPI mode that caused DEE to fail unless DEE had been run

manually at least once since power-up of the SR5500.

Version 2.20 (Release ASA DATE: DECEMBER 2006)

• Added the Remote Programming Interface view. This allows for remote control of the

TestKit application via either the TCP/IP protocol or GPIB.

Page 24

16 | SR5500 Operations Manual

• Added the ability to change Angle of Arrival, K-Factor, and Frequency Shift

Parameters within DEE.

• Added the ability to control multiple SR5500’s with the SR5500-6GHZ-EX option

simultaneously.

• Added the ability to turn the RF Output on or off with a single command.

• Resolved an issue that caused AWGN not to function properly with some hardware.

Version 2.10 (Release ASA DATE: APRIL 2006)

• Added ability to set Rayleigh fading correlation between channels located in different

SR5500 systems.

• Added support for the SR5500-6GHZ-EX option which adds the 3300-3850 MHz

Band.

• Added a “summary screen” to TestKit which allows you to view all configured paths in

up to four systems simultaneously.

• Added the ability to connect to up to four SR5500 units simultaneously in an

unsynchronized manner.

• Extended the C/N ratio available when the channel Crest Factor is set to a non-

default value or when Log-Normal is enabled.

• Significantly increased the speed of DEE compilation by changing the format of the

source file from an XML based file (SSX) to a raw text file (STB).

• Resolved an issue that prevented the SR5500 from being controlled across a

network router.

Version 2.01 (Release ASA DATE: AUGUST 2005)

• Resolved an issue where, in some cases, noise could be produced at the SR5500

output port when no input signal was presented at the input port. This could also

have occurred during the OFF time of a non-continuous signal.

Version 2.00 (Release ASA DATE: AUGUST 2005)

• Added support for control of up to four SR5500 units from a single TestKit GUI.

• Increased accuracy of output Power Meter when noise is enabled.

• Added real time C/N measurement to main window.

• Added settable duty cycle to Power Meter parameters.

• Increased allowable number of averages on Power Meter.

• Resolved issue with Test Assistant CDMA2K Fading Profile 5, where paths were being

set to Rayleigh instead of static.

• Added 802.16(WiMAX) Models to the Test Assistant.

• Added “Round 12dB” Doppler shape for 802.16(WIMAX) testing.

• Increased resolution of Rayleigh Doppler velocity and frequency to accommodate

802.16(WIMAX) testing.

Version 1.31 (Release ASA DATE: SEPTEMBER 2004)

• Added real time C/I measurement to TestKit.

• Resolved issue which caused a long power-up sequence to occur on some units.

Page 25

Chapter One: Introduction | 17

• Added Settable Crest Factor.

• Resolved issue which caused graphical display of C/I ratio to be incorrect. (C/I ratio

set in SR5500 was correct).

• Various stability improvements were made to TestKit.

• Code Examples added to the installation.

• In BYPASS mode, internal Local Oscillator source is turned off to reduce interference.

Version 1.30 (Release ASA DATE: SEPTEMBER 2004)

• Added programmable correlation support.

• Added Diversity Modes.

• Added API Front Panel Tool.

• Modified STOP state to be a clean channel.

• Added output cable loss corrections factors.

Version 1.25

• Added support and calibration for new internal RF hardware modules.

• Resolved an issue with Birth Death Propagation introduced in 1.20.

• Resolved an intermittent power-up issue.

Version 1.21

• Resolved issue where the crest factor of the signal was miscalculated, resulting in

occasional failed auto-sets.

Version 1.20

• Added Dynamic Environment Emulation (DEE) feature.

• Added Log-Normal Fading feature.

• Improved firmware upgrade process.

Version 1.11

• Maintenance release to resolve an issue with interoperability with TASKIT/C2K.

Version 1.10

• Added AWGN (Additive White Gaussian Noise) feature.

• Added Triggered Power Measurement feature.

Version 1.01

• Maintenance release to resolve a number of TestKit issues.

Version 1.00

• Initial Product Release.

Page 26

18 | SR5500 Operations Manual

Page 27

2. Operation Reference

2.1. Overview

SR5500 TestKit is a PC-based Graphical User Interface (GUI) for the configuration and

control of the SR5500. TestKit runs under the Microsoft Windows operating system,

delivering the same ease of use and GUI features that Windows provides. These features

make it easy to use the SR5500 test system to perform sophisticated tests in a wide

range of communication environments.

NOTE: SR5500 TestKit has already been installed on the PC that accompanies

the SR5500.

• Although SR5500 TestKit is already installed on the accompanying PC, an SR5500

TestKit Install CD is included in the Manual binder. Use this CD to reinstall the

application on the provided PC, if needed.

This section describes the basic operations of SR5500 TestKit. For more detailed

information about the features, refer to Chapter Three on page 67.

NOTE: TestKit first starts in Local mode and does not control the SR5500. Refer

to Section 2.2.1. on page 20 for more information.

NOTE: The SR5500 features a powerful Player function that allows greater

control over the fading emulation. The Player defaults to the Stopped position.

To enable the channel emulation, click the Play button in the Player controls.

2.2. Operational Overview

To start SR5500 TestKit from the Windows Start Menu, click the SR5500 TestKit icon.

You can also start SR5500 TestKit by clicking the program icon on the Windows desktop

.

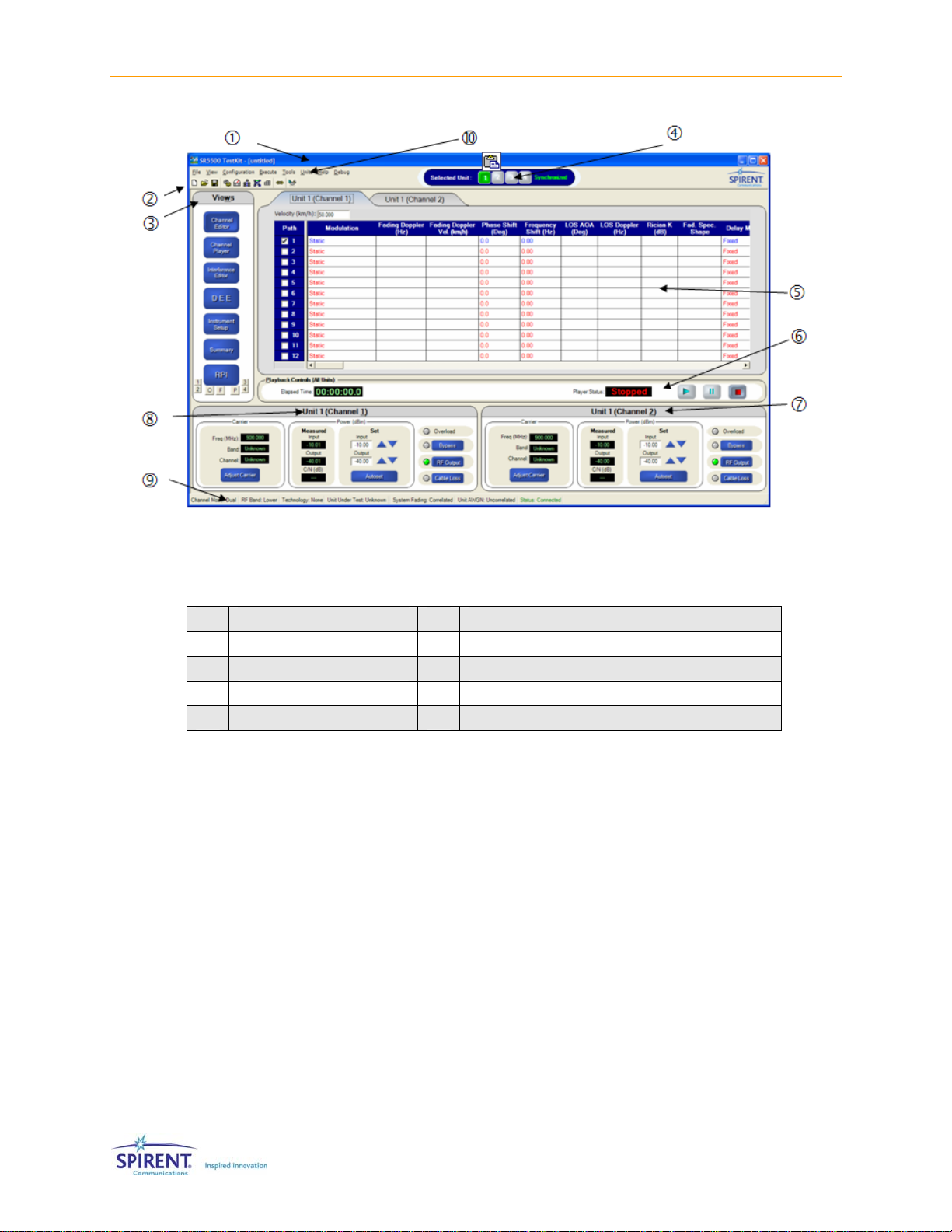

SR5500 TestKit Main Window displays, as shown Figure 2-1. This section will help you

familiarize yourself with the SR5500 TestKit basics.

Page 28

20 | SR5500 Operations Manual

Figure 2-1: TestKit Main Window

The table below indicates the different parts of the SR5500 TestKit Graphical User

Interface (GUI).

c

d

e

f

g

Title Bar

Tool Bar

View Controls

Unit Selection

View Area

Player Controls and Indicators

h

Channel 2 I/O Controls and Indicators

i

Channel 1 I/O Controls and Indicators

j

Menu Bar

k

Unit Selection

l

2.2.1. Connecting to the SR5500

SR5500 TestKit can operate in Local Mode or Remote Mode. In Local Mode, TestKit does

not communicate with the SR5500. It emulates the control of the SR5500 but does not

send any commands and the actual configuration of the SR5500 is not known.

In Remote Mode, SR5500 TestKit sends commands to the SR5500 and receives status

information back. The presentation in Remote Mode is an accurate representation of the

configuration of the SR5500. TestKit starts in Local Mode, and must be manually set-up

to act in Remote Mode. There are two indicators of the Mode TestKit is in. The status bar

on the bottom of the window indicates Not Connected or Connected, respectively. The

Status Indicators are shown in Figure 2-2.

Page 29

Chapter Three: Technical Reference | 21

Figure 2-2: Connection Status Indicators

The icon on the tool bar changes appropriately to indicate the current status. In the

Execute menu, the first item in the menu displays, "Disconnect from SR5500" while in

Remote Mode.

Figure 2-3: Execute Menu – Connect to SR5500

To enter Remote Mode, click the Connect to SR5500 icon , or select

Execute>Connect to SR5500 as shown in Figure 2-3.

While establishing connection to the SR5500, TestKit attempts to communicate with the

SR5500. If successful, it communicates with the SR5500 to synchronize the PC software

and the SR5500 unit. If it is unsuccessful, you receive an error message indicating the

problem.

2.2.2. Basic Operation

2.2.2.1 Title Bar

At the top of the window is the Title Bar, as shown in Figure 2-4, which contains the

program name and the name of the current settings file. After starting SR5500 TestKit,

the current settings file is “[Untitled]”. The buttons at the right side of the Title Bar allow

you to minimize, resize or close the TestKit Application. The title bar also indicates the

current view.

Figure 2-4: TestKit – Sample Title Bar

Page 30

22 | SR5500 Operations Manual

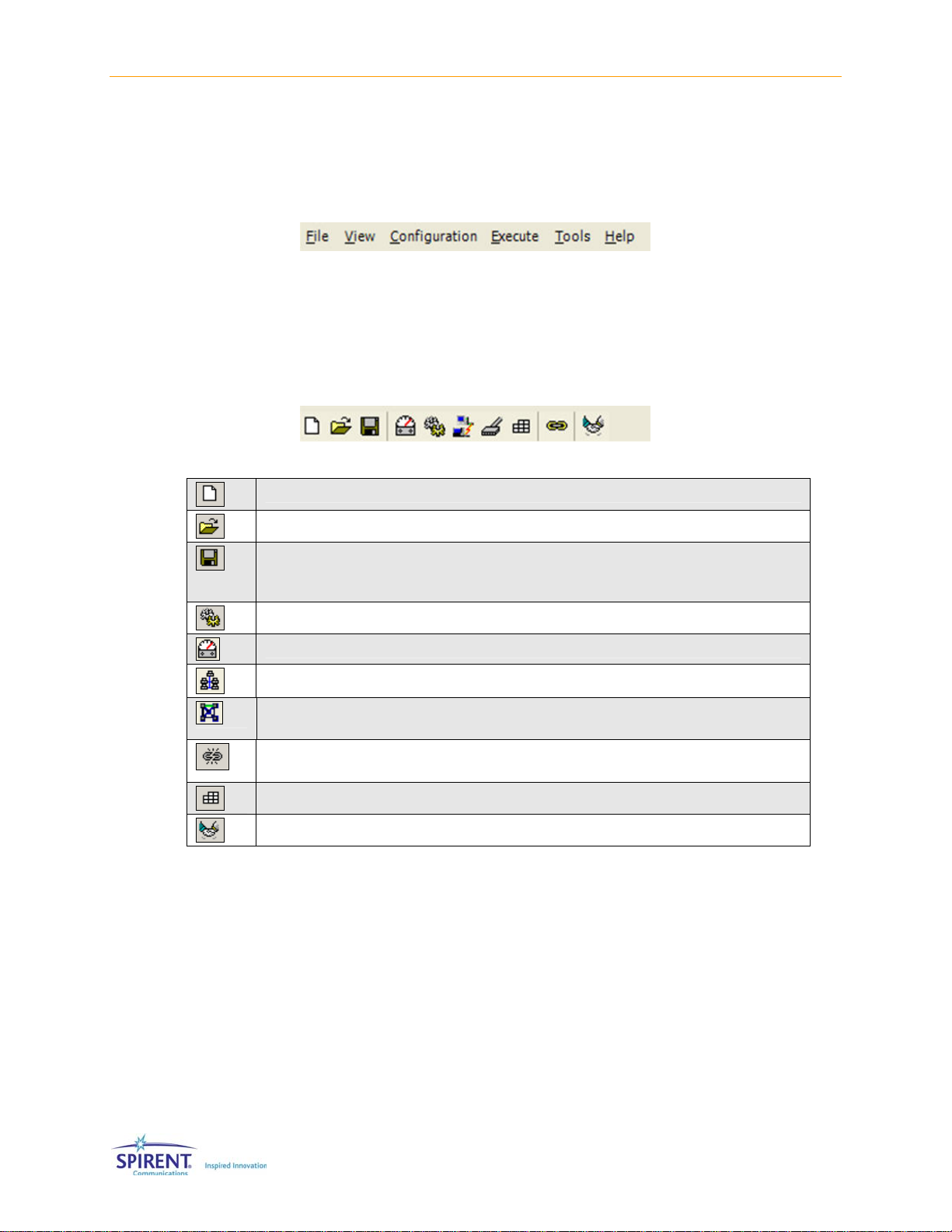

2.2.2.2 Menu Bar

The Menu Bar, shown in Figure 2-5, is located immediately below the Title Bar. To display

the items in that menu, click the menu name or hold down the Alt and the underlined

letter of the menu title. Each menu provides access to a certain type of functionality.

2.2.2.3 Toolbar

The Toolbar, shown in Figure 2-6, is located beneath the Menu Bar. The Toolbar provides

quick access to commonly used functions.

New Settings File - Resets all settings to the default values.

Open Settings File - Loads the settings previously saved in a file.

Save Settings File - Saves the current settings to the current file. If the settings

have not yet been saved to a file, you will be prompted to specify a file name and

location.

Displays the System/Communication Setup Window.

Displays the Power Meter Parameters Window.

Displays the Remote Programming Interface (RPI) setup window.

Displays the Correlation Coefficient window (This icon is only available when

controlling multiple SR5500s in a synchronized system-based manner).

Indicates the connection status with the SR5500 unit, and causes the opposite

status to be triggered when clicked.

Displays the Table Format Window.

Displays the Test Assistant Window.

Figure 2-5: TestKit – Sample Menu Bar

Figure 2-6: TestKit – Sample Toolbar

2.2.2.4 View Area

The contents of the View Area can be changed to provide access to different

functionality. Select the contents of the View Area by clicking on the Views buttons, or by

making a selection from the View menu. An example of the View Area is shown in Figure

2-7.

Page 31

Chapter Three: Technical Reference | 23

Figure 2-7: TestKit – Sample View Area

2.2.2.5 View Controls

The View Controls change the contents of the View Area. Different views provide access

to different functionality. The View buttons work the same as selecting the item from the

View menu. A sample View Control area is shown in Figure 2-8.

Figure 2-8: TestKit – Sample View Controls

2.2.2.6 Player Controls and Indicators

The Player Controls and Indicators allow control over the powerful fading playback

engine. For a given set of profile conditions, the engine will always generate the same

fading sequence. A sample Player Control Bar is shown in Figure 2-9.

Figure 2-9: TestKit – Sample Player Control Bar

You can control the fading emulation playback status with the Player Controls similar to

the way you use the controls on a CD player. Observe the current point in the fading

sequence via the Elapsed Time indicator.

Page 32

24 | SR5500 Operations Manual

Use the Play button to cause the fading emulation playback to proceed. Use the

Stop button

zero. Use the Pause button

While paused, use the Play button to resume emulation playback.

While stopped or paused, the SR5500 does not vary the signal passing through it. The

signal is subjected to the exact fading conditions at the moment indicated by the Elapsed

Time indicator.

While stopped, the SR5500 does have modulation enabled. The fading channel behaves

as if a single path were enabled with no modulation. The delay of this path matches what

is set for Path 1 of the channel. In Transmit Diversity Mode, the SR5500 has a clean

channel from RF1 IN to RF1 OUT

to stop the fading emulation playback and reset the Elapsed Time to

to temporarily suspend the fading emulation playback.

NOTE: When changing a parameter during playback, the SR5500 resets the

Time Elapsed indicator to zero and continues playing. When changing a

parameter while paused, the SR5500 resets the Time Elapsed indicator to zero

and stops. Additive impairments are unaffected by the Play, Stop, and Pause

buttons.

NOTE: The player state does not affect the additive interferer state. If AWGN is

enabled, it is present even if the player is stopped.

2.2.2.7 Channel 1 and Channel 2 I/O Controls and Indicators

Below the Player Controls and Indicators are the Channel 1 and Channel 2 I/O Controls

and Indicators. The Carrier Frequency Control and Indicators are on the left. The current

carrier frequency is shown, as is the current Band and Channel for the selected

Technology and Unit Under Test. Refer to Section 2.6. on page 29 for details on

controlling the Carrier Frequency, Band, Channel, Technology and the Unit Under Test.

To the right of the Carrier frequency are the Power Controls and Indicators. Refer to

Section 2.6.1. on page 29 for details on controlling the input and output powers.

Figure 2-10: TestKit – Sample Channel 1 an d 2 Cont rols

2.2.2.8 Status Bar

The status bar indicates the current settings for the following items:

• Channel Mode

• RF Band

Page 33

• Technology

• Unit Under Test

• System Fading

• Unit AWGN

• Remote Status

• Operation Progress

Figure 2-11: TestKit – Sample Status Bar

Refer to appropriate sections for more details on the above settings. The status bar also

has an area to the right to indicate progress for actions that take more than a few

seconds.

2.3. Using the Test Assistant

The Test Assistant is a powerful feature that simplifies setting up the SR5500 for tests

based on industry standards.

Chapter Three: Technical Reference | 25

2.3.1. Accessing the Test Assistant

To access the Test Assistant, select Tools>Test Assistant, or click the Test Assistant icon

on the toolbar. The Test Assistant window displays as shown in Figure 2-12. For a

detailed example on using the Test Assistant, refer to Section 1.5 on page 9.

Figure 2-12: Test Assistant Window

Page 34

26 | SR5500 Operations Manual

2.3.2. Changing the Carrier Frequency

The Test Assistant allows you to enter the exact carrier frequency in MHz, or you can let

the program set the carrier frequency based on your application. To set the carrier

frequency directly, click the Select Carrier Frequency button. Enter the Carrier Frequency

in MHz in the textbox as shown in Figure 2-13.

Figure 2-13: Select Carrier Frequency Button

To set the Carrier Frequency based on the application, select the appropriate Technology,

then the Unit Under Test. Next, click the Select Band and Channel Number button. Select

the appropriate Band from the list box. Finally, enter the appropriate Channel Number.

The Test Assistant uses these settings to calculate the Carrier Frequency. The Carrier

Frequency appears below in the Carrier Frequency textbox.

2.3.3. Automatically Selecting a Channel Profile

The Test Assistant allows you to set the Fading Profile settings in the Channel Editor

according to an industry standard.

Figure 2-14: Test Assistant Channel Editor

If you want to leave the current settings in the Channel Editor, click the Do not overwrite

settings in the channel editor button.

You are permitted to select a fading profile that does not match the Technology and Unit

Under Test settings on the left. This flexibility allows you to apply any industry standard to

the testing application.

Select a fading profile to view a textual summary. A textual summary displays in the

textbox at the bottom of the window.

Page 35

When you have made your final selections, click OK to apply your selections and close

the Test Assistant window. If you want to cancel your selections, click Cancel to close the

window.

2.3.4. Completing the Configuration

Although Test Assistant does most of the work, we recommend you set the output power

and perform an Autoset. The SR5500 may not be properly configured for testing without

completing these additional steps. For details on performing an Autoset and setting the

output power, refer to Sections 2.6.1.4. and 2.6.1.5. on page 33.

NOTE: Selecting a Test Assistant configuration disables any Additive

Impairments. If desired, the Additive Impairment can be enabled in the

window.

2.4. Channel Player

Chapter Three: Technical Reference | 27

View

The Channel Player is a key feature of TestKit. This feature presents a graphical

representation of the fading profile as it changes. To access the Channel Player, click the

Channel Player button from the Views Panel. SR5500 TestKit displays the Channel

Player, similar to the display shown in Figure 2-15.

NOTE: This feature is not accessible when running DEE.

Figure 2-15: Channel Player Window

If the fading emulation playback is paused or stopped, the Channel Player view remains

static. If the playback is running, the Channel Player view constantly changes to show the

latest update in the fading emulation playback. The Channel Player features two unique

presentations. Change the presentation using the list box located above the graph.

Page 36

28 | SR5500 Operations Manual

The first presentation, the Power Delay Profile shows the instantaneous Power Delay

Profile. The delay for each path is represented by the position of each bar on the X axis

(Delay). The power of each path is represented by the height of each bar along on the Y

axis (Power). The Display Relative Path Loss checkbox shows and hides the average

power indicator for each path.

If Additive Impairments are enabled on the selected channel a horizontal line

representing the relative power of the impairment to the channel displays in the Player

view.

NOTE: The average power indicated for each path is relative to the total

composite output power of the channel. This does not map directly to the path

loss settings in the Channel Editor table.

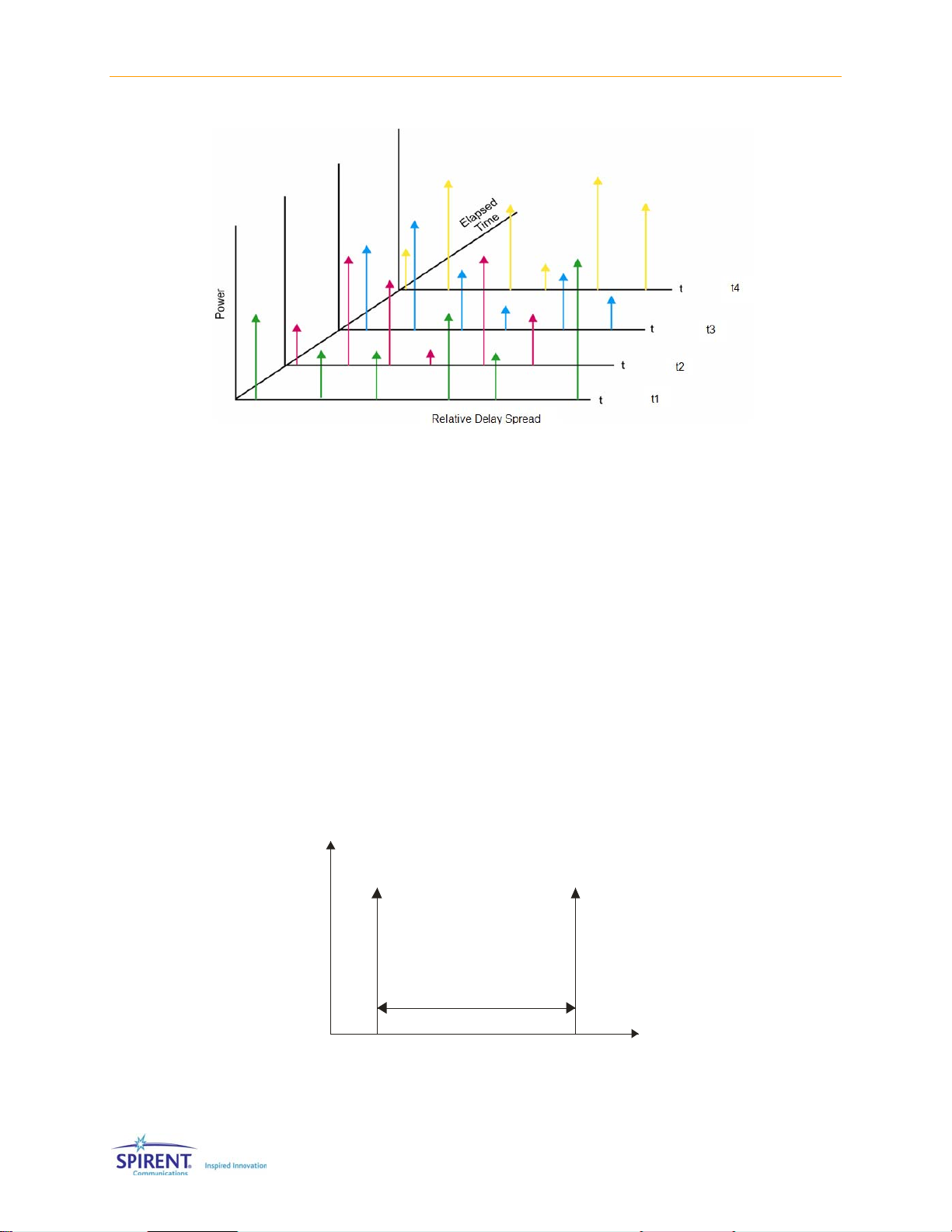

The second presentation, the Power Delay Profile History is similar to the first

presentation, but also displays a brief history. The older instantaneous Power Delay

Profiles move back along the Z axis (time) and the current DPD is added to the front.

2.5. File Operations

SR5500 TestKit supports saving and recalling files to simplify configuration of the

SR5500. As with most Windows applications, certain settings are saved in the file. When

the file is opened at a later time, those settings are restored.

Select File> New Settings File to reset settings back to their default values. Use Open

Settings File, Save Settings File, Save Settings File As, just as you would with any other

Windows application. Use the appropriate toolbar icons instead of selecting from the File

menu.

Figure 2-16: Power Delay – Profile History

Page 37

Chapter Three: Technical Reference | 29

2.5.1. Settings Saved in the Settings File

The following settings are saved in the Settings File and restored after opening a settings

file:

• System configuration (Channel Configuration and RF Frequency Mode).

• Test Assistant settings (Technology, Unit Under Test, Band, Channel, Profile).

• Channel I/O settings (Carrier Frequency, Input Power, Output Power, Bypass).

• All path settings in the Channel Editor view.

NOTE ON MULTI-UNIT USE: The settings for all four units are always saved in the

settings file. This is true even if only one unit is currently active. The number of

active units is stored in the system registry, not in the settings file. For

example, a settings file saved with three units active can be opened and used in

a setup that only has 2 active units.

The following settings are saved in the System Registry and restored after opening

TestKit:

• Number of active units.

• Communications settings for connected units. (IP address, etc.).

2.5.2. Recent File List

SR5500 TestKit maintains a list of the four most recently used files. These display at the

end of the File menu. To recall a file that appears on this list, select it from the File menu.

2.6. Operational Detail

This section details the parameters that control the Channel Input and Output and the

Path Fading parameters.

2.6.1. Channel I/O Parameters

Properly setting the Channel Input and Output parameters ensure the target signal is not

compromised in terms of fidelity and power, and produces the highest level of

performance from the SR5500. This section details the Channel I/O Parameters.

Page 38

30 | SR5500 Operations Manual

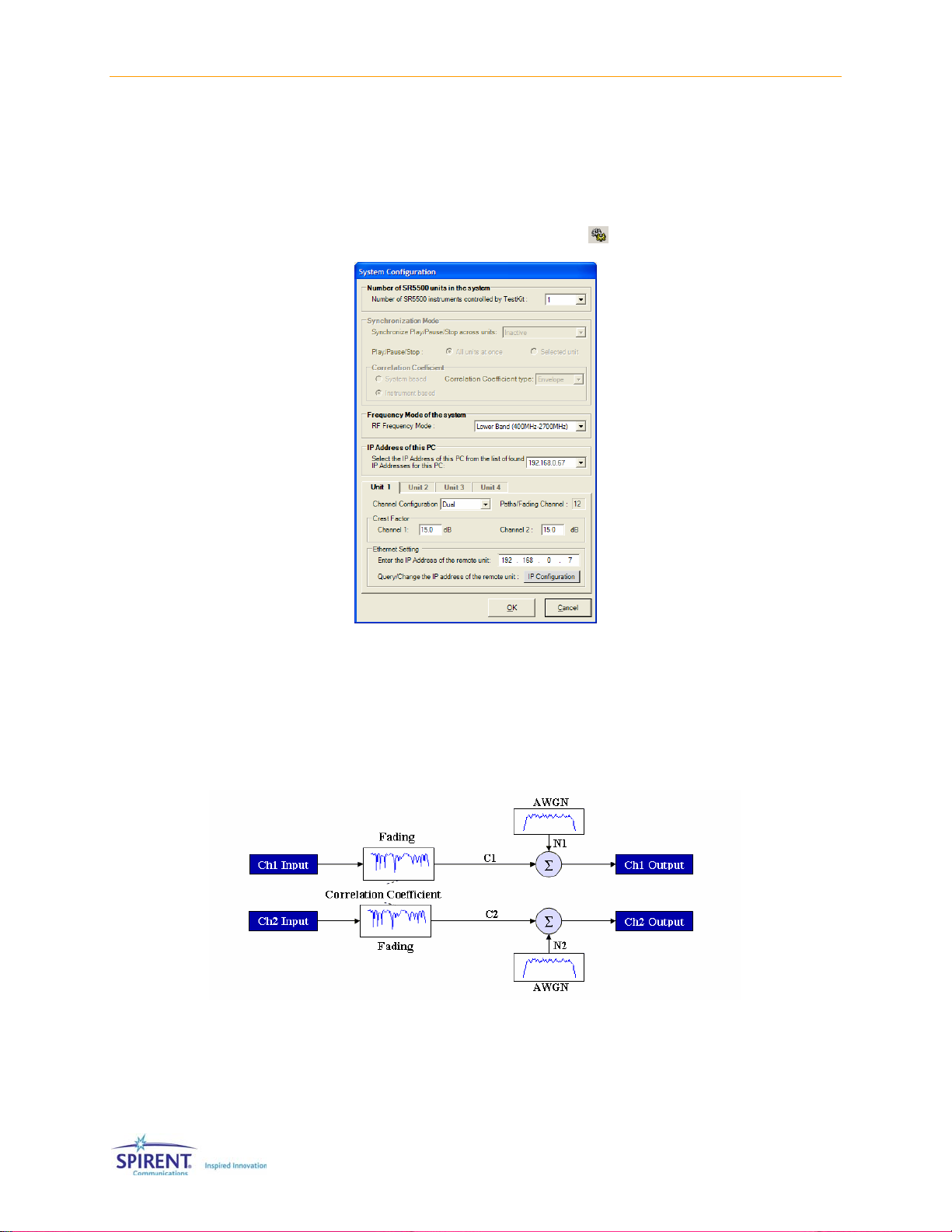

2.6.1.1 Selecting Instrument Configuration

The SR5500 can be configured for a single Channel with 24 Paths, or two Channels with

12 Paths each. Additionally, the SR5500 can be configured in both Receive and Transmit

Diversity modes. The number of Channels and Paths is set in the System/Communication

Setup window. To access this window, select Configuration>System/Communication

Setup, or click the System/Communication Setup icon

from the toolbar.

Figure 2-17: System Configuration Window

Set the Channel Configuration to Single for a single Channel with 24 Paths. Set the

Channel Configuration to Dual for two Channels with 12 Paths each. Set the Channel

Configuration to RX Diversity for two channels with 12 paths each. In this mode, both

channels are sourced by the CH1 RF IN port. Set the Channel Configuration to TX

Diversity for two channels with 12 paths each. These channels are then summed

together and output on the CH1 RF OUT port.

Figure 2-18: Dual Channel Mode Diagra m

Page 39

Chapter Three: Technical Reference | 31

Figure 2-19: Single Channel Mode

Figure 2-20: RX Diversity Mode

Figure 2-21: TX Diversity Mode

2.6.1.2 Setting the Channel Crest Factor

The Channel Crest Factor is a measure of the maximum peak/avg power ratio that the

SR5500 can accept without causing an overload condition. You can configure each

channel of the SR5500 to have a larger than default crest factor setting. To access this

window, select Configuration>System/Communication Setup, or click the

System/Communication Setup icon

from the toolbar.

Page 40

32 | SR5500 Operations Manual

Figure 2-22: System Configuration Window

The SR5500 Crest Factor is set to 15 dB, which is sufficient for most applications. You

can set larger values when required by the application.

NOTE: Increasing this value limits the maximum output power of the SR5500.

Additionally, system noise and spurious performance will be degraded.

2.6.1.3 Adjusting the Carrier Frequency

The Carrier Frequency must be set appropriately for each channel in order for the

SR5500 to function properly. The Carrier Frequency displays in the Channel controls and

indicators as shown in Figure 2-23.

Figure 2-23: Channel Controls and Indicat ors

To change the Carrier Frequency, click the Adjust Carrier button. SR5500 TestKit displays

the Channel Adjust Carrier Frequency window.

Page 41

Chapter Three: Technical Reference | 33

Figure 2-24: Channel Adjust Carrier Frequency Window

Adjust the carrier by setting the Band and Channel, or by selecting the Carrier Frequency

directly in MHz.

To set the Band and Channel:

1. Click the Select Band and Channel Number button.

2. Select the appropriate Band from the list box.

3. Enter the appropriate channel in the Channel Number textbox.

If the values you enter are valid, SR5500 TestKit displays the corresponding Carrier

Frequency in MHz in the read-only Carrier Frequency textbox.

If you want to change the currently selected Technology and/or Unit Under Test, use the

Test Assistant. For details on using the Test Assistant, refer to Section 2.3. on page 25.

To set the Carrier Frequency in MHz directly:

1. Click the Select Carrier Frequency button.

2. Edit the Carrier Frequency in MHz in the textbox.

3. Click OK to save the changes and close the window.

To cancel the changes, click the Cancel button.

2.6.1.4 Input and Output Level Control Overview

Both the SR5500 input ranging circuit and nominal output level can be manually

configured. Set the input ranging circuitry to match the RMS signal power present at the

input port to the SR5500. The output level parameter determines the nominal RMS

output power present at the output port of the SR5500.

NOTE: The output power level specified will only be accurate if the measured

input power matches the set input power settings.

Page 42

34 | SR5500 Operations Manual

To achieve the ideal performance from the SR5500, you must properly configure the

SR5500 input ranging circuit to the RMS input power. The SR5500 can measure the

input signal and automatically set the input ranging circuit, or you can manually set the

input ranging circuit. There are special concerns with directly setting these levels. Refer

to Section 2.6.1.6. on page 35 for details on setting the Input Power manually for details.

Access the automated level control functionality through the Autoset feature. Refer to

page 34 for details on the Autoset feature. SR5500 measures and reports the input

power level in SR5500 TestKit. Refer to the Section on Measured Input and Output

Power Indicators on page 36 for details.

NOTE: If the SR5500 is equipped with the SR5500 6 GHz(-EX) RF Converter, all

input and output power references are mapped to the input and output of the

SR5500 6 GHz(-EX) RF Converter.

2.6.1.5 Using Autoset

The Autoset feature measures the input signal power and configures the channel signal

levels for optimal output performance. The SR5500 performs the Autoset function once

each time you click the Autoset button. The SR5500 does not continually re-range for

changing input signal powers.

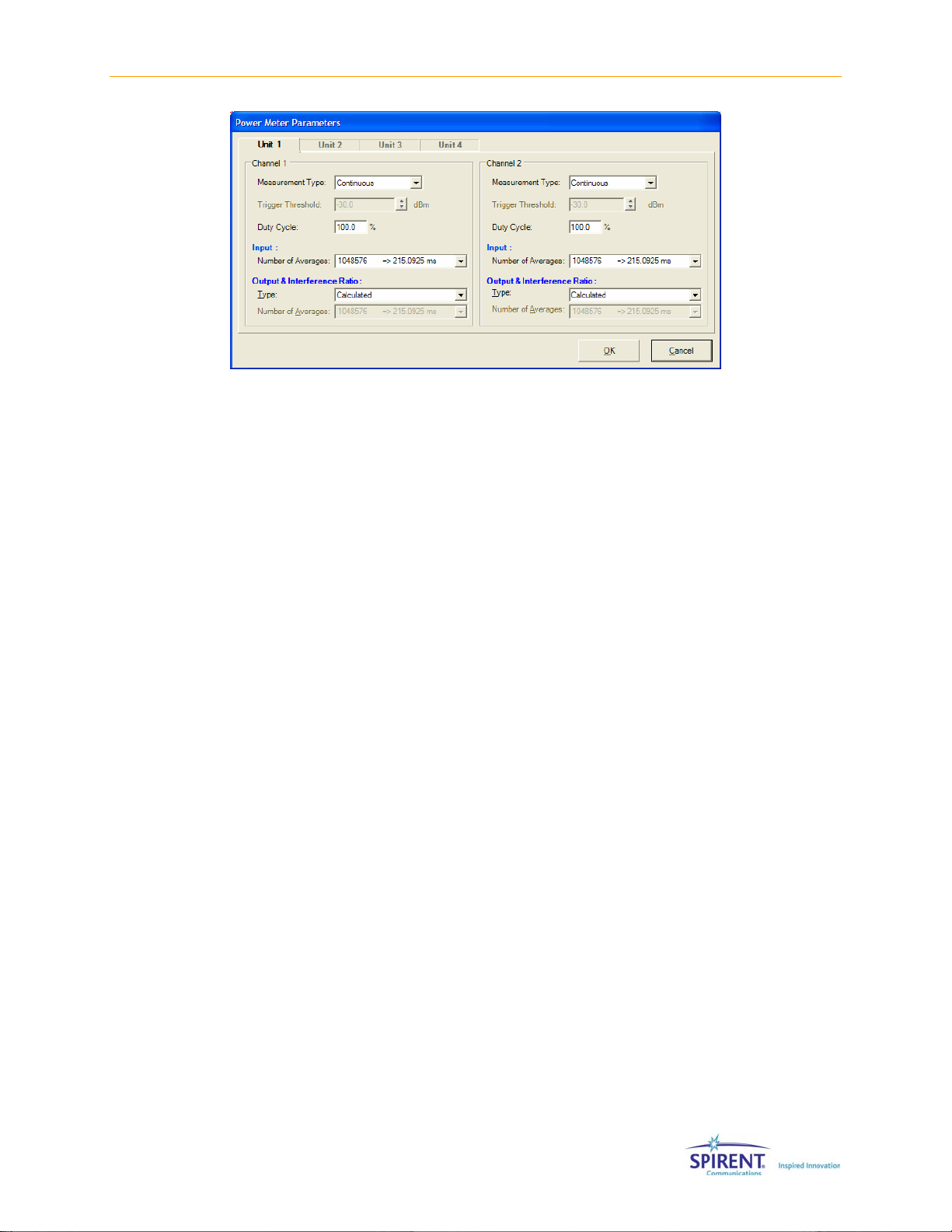

Figure 2-25: Autoset Option

To perform an Autoset:

Apply the appropriate input signal to the SR5500, then click the Autoset button. The

SR5500 measures the RMS input level and sets the correct input level circuitry.

The SR5500 also adjusts the output attenuation to achieve the set nominal RMS output

level. If the Autoset is successful, TestKit automatically updates the Set Input level

textbox.

If the Autoset is unsuccessful, TestKit reports the problem. If the input signal is bursty,

set the Power Meter in Triggered mode to measure the input signal correctly.

NOTE: As the input signal level changes over time, the output level change by

an equal amount. It may be necessary to repeat the Autoset because the

SR5500 does not automatically repeat the function. Make sure your measured

input power equals set input power.

Page 43

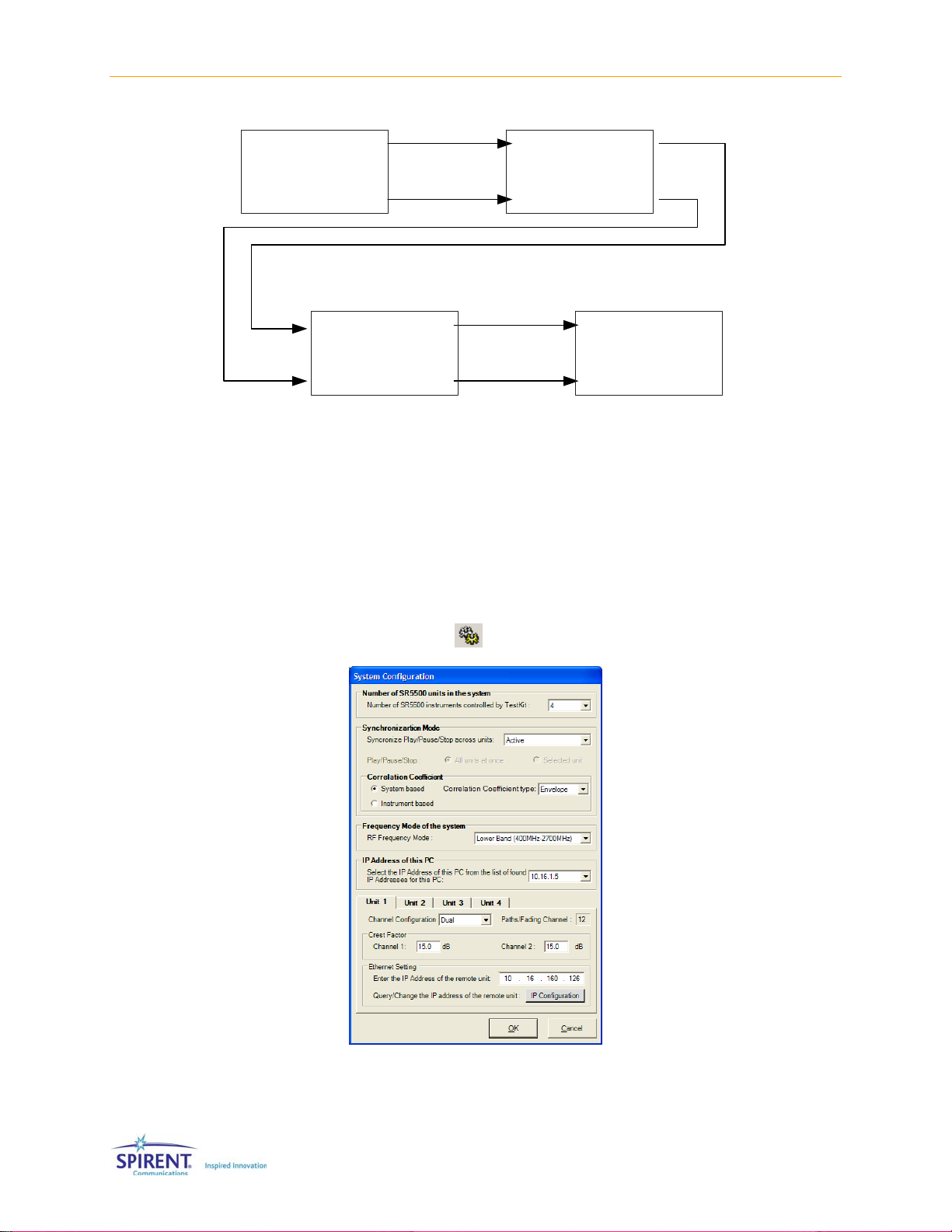

Chapter Three: Technical Reference | 35

2.6.1.6 Manually Setting the Input Power

The Input Ranging Circuit can be configured manually. To perform this operation, enter

the RMS power present at the SR5500 input in the Set Input textbox in TestKit.

Figure 2-26: Input Power Controls

You can also change the Input Level by clicking the Up and Down arrows to adjust the

value in the textbox. The value of the Set Input increases or decreases by 1 dB

increments. Holding down the Up or Down arrows causes the value in the textbox to

change more rapidly.

Examples of input signals that may require manual input level control include:

• A carrier signal with a variable input level.

• A bursty signal with a short on time.

If the carrier signal has a variable input level, configure the Set Input textbox to the

maximum expected RMS input signal power.

2.6.1.7 Input Overload Condition

If at anytime the SR5500 detects that the input signal level is higher than expected by

the input circuitry, an Overload condition exists. During an Overload condition, the

Overload LED on the front panel of the SR5500 displays. Also, TestKit illuminates the

Overload indicator in the Channel Control and Indicators area.

Figure 2-27: Overload Indicator

During an Overload condition, the input signal is too high to be properly sampled by the

unit input circuitry. Therefore, the SR5500 may cause undesired distortion of the input

signal. If the Overload condition exists, or periodically reoccurs, one or more of the

following actions may be necessary:

1. Reduce the signal level input to the SR5500.

2. Repeat the Autoset or manually set the input level with a signal level more

representative of its nominal level.

Page 44

36 | SR5500 Operations Manual

2.6.1.8 Adjust the Power Meter Parameters.

Refer to Section 2.8, Power Meter Parameters on page 54 for details on adjusting Power

Meter parameters.

2.6.1.9 Setting the Output Power

To set the nominal RMS output power level, enter the desired level in the Set Output

textbox in SR5500 TestKit. If the Set Input level accurately shows the actual input signal

level, the nominal RMS output level reflects the value in the Set Output textbox.

Figure 2-28: Output Power Controls

You can also change the nominal RMS output power level by clicking the Up and Down

arrows to adjust the value in the textbox. The value of the the Nominal RMS Output

Power increases or decreases by 1.0 dB increments. Holding down the Up or Down

arrows causes the value in the textbox to change more rapidly.

NOTE: The following are some of the conditions that can cause the Nominal RMS

Output Power to vary from the entered value:

• Input power measured does not match the Set Input textbox.

• Playback Engine in Pause mode.

• Channel Bypass active.

• No paths enabled for this channel.

• Output Cable Loss correction factor is incorrectly set.

2.6.1.10 Measured Input and Output Power Indicators

The SR5500 has built-in Power Meters that enable real-time monitoring of the input and

output. TestKit displays these power measurements in the Power Measurement Input

and Output textboxes. The input power measurement enables you to quickly determine

the accuracy of the Set Input value. The output power measurement represents the

average output power of the SR5500. If an interferer is enabled, TestKit displays the

measured C/N ratio. This measurement is based on the current measured output power

and the set C/N ratio.

You can set the output power measurement to one of two modes; Calculated or

Measured. In Calculated mode, the output power displays based on the measured input

level and the known loss of the channel. In this mode, the output measurement does not

respond to instantaneous changes in output power level caused by fast or slow fading.

This mode is useful when the Doppler is very low.

Page 45

Chapter Three: Technical Reference | 37

When set to Measured mode, the output power is measured and displayed after fading is

performed. The output power in this mode varies instantaneously with fading. The

Measured mode is not available when the Power Meter is set to Triggered mode.

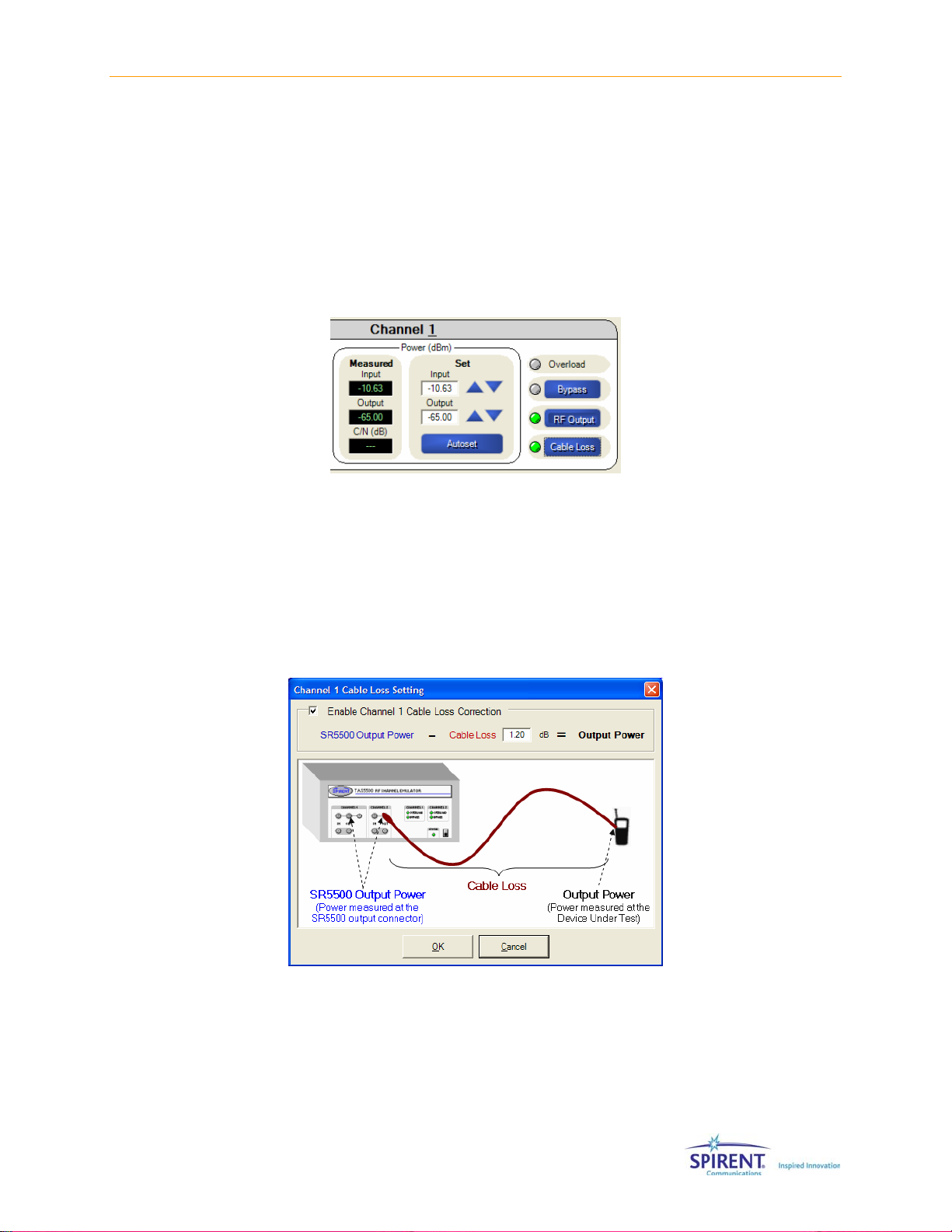

2.6.1.11 Adjusting the Output Power Cable Loss Correction Factors

The SR5500 has the ability to set and offset for measuring cable loss for both the Set

and Measured Power indicators. To perform this operation, click the Cable Loss button in

SR5500 TestKit.

Figure 2-29: Cable Loss Button

This opens the Cable Loss Setting window. This window allows you to enter a value for

the loss associated with a cable connected to the output port of the SR5500. When

enabled, a green LED lights up next to the Cable Loss button on the interface. When

enabled, any output level in the output level textbox is offset by the cable loss value. For

example, if a cable connecting the device has 1.2 db of loss associated with it, enter this

value in the Cable Loss Setting window. If you then set the output level of the SR5500 to

–50 dBm, the actual level at the RF output port of the SR5500 would be set to –48.8

dBm, but the level at the Unit Under Test would be –50dbm.

Figure 2-30: Cable Loss Setting Window

Page 46

38 | SR5500 Operations Manual

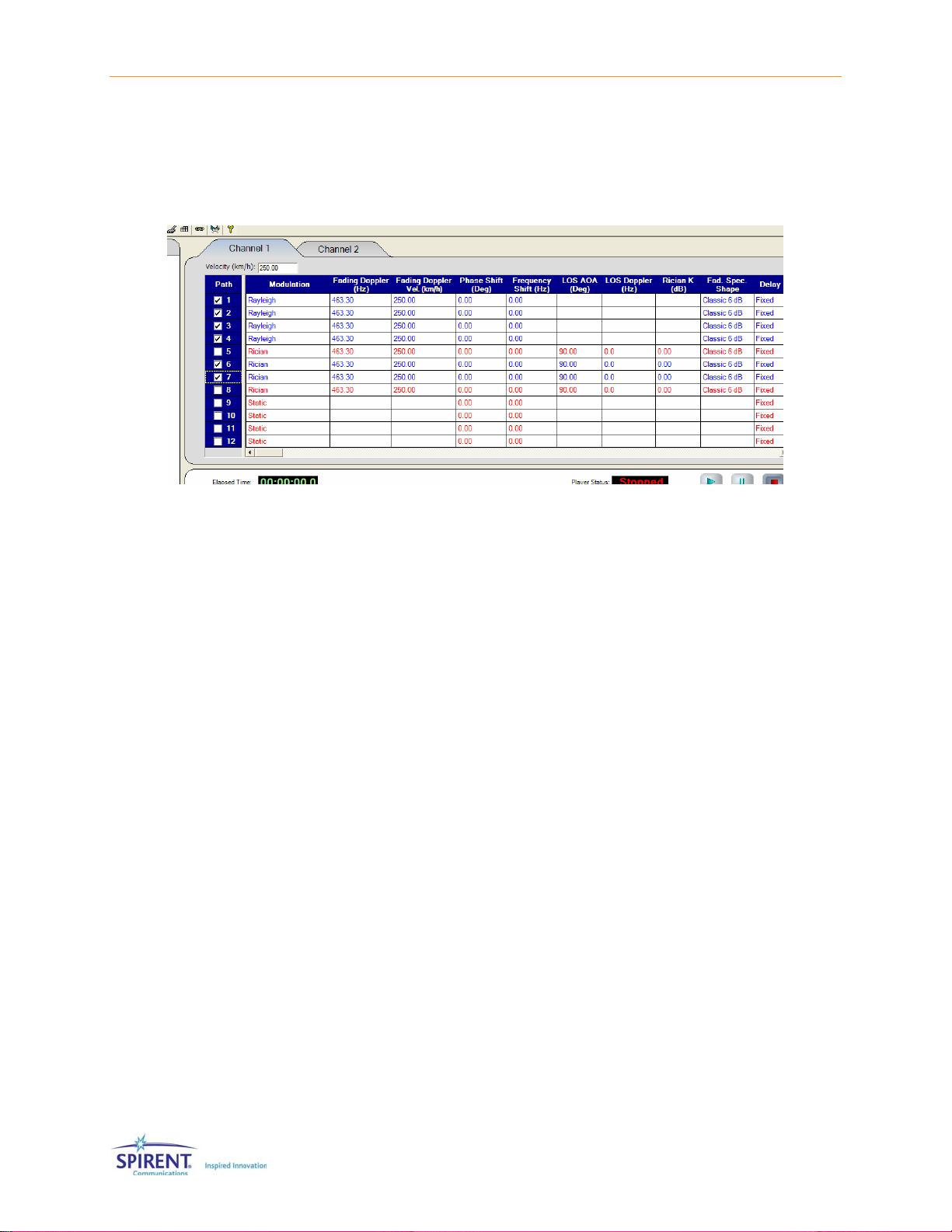

2.6.2. Path Parameters

To use the Channel Editor view to edit the Path Parameters, click the Channel Editor

button on the left to show the Path Parameters. SR5500 TestKit displays the Channel

Editor in the View Area as shown in Figure 2-31.

Figure 2-31: Path Parameters Window

The Technical Reference chapter on page 67 contains details on constructing a fading

profile.

2.6.2.1 Using the Grid

The grid displays the current path parameter settings and allows you to change the

current parameter settings. Each cell displays a unique parameter setting. Some

parameter settings have a list of valid values, while others allow a range of values.

To change a value in the grid:

1. Select the appropriate cell.

If the parameter has a list of values, a list box displays.

2. Click the list box to display the available choices. Click the desired value from the list

to complete the change.

3. If the parameter has a range of values, a textbox displays. Adjust the value in the

textbox to match the desired value. Press Enter when finished to complete the

change.

4. To set the same value in all enabled paths, select the column by clicking the column

name. Enter the desired value in any cell in the selected column.

SR5500 TestKit updates all the enabled paths to match the new setting.

2.6.2.2 Accessing Path Modulation Parameters

The SR5500 supports numerous path parameters to accommodate a wide variety of

testing demands. The grid can display all of these parameters. However, SR5500 TestKit

is initially configured to display only the most commonly used parameters.

Page 47

Chapter Three: Technical Reference | 39

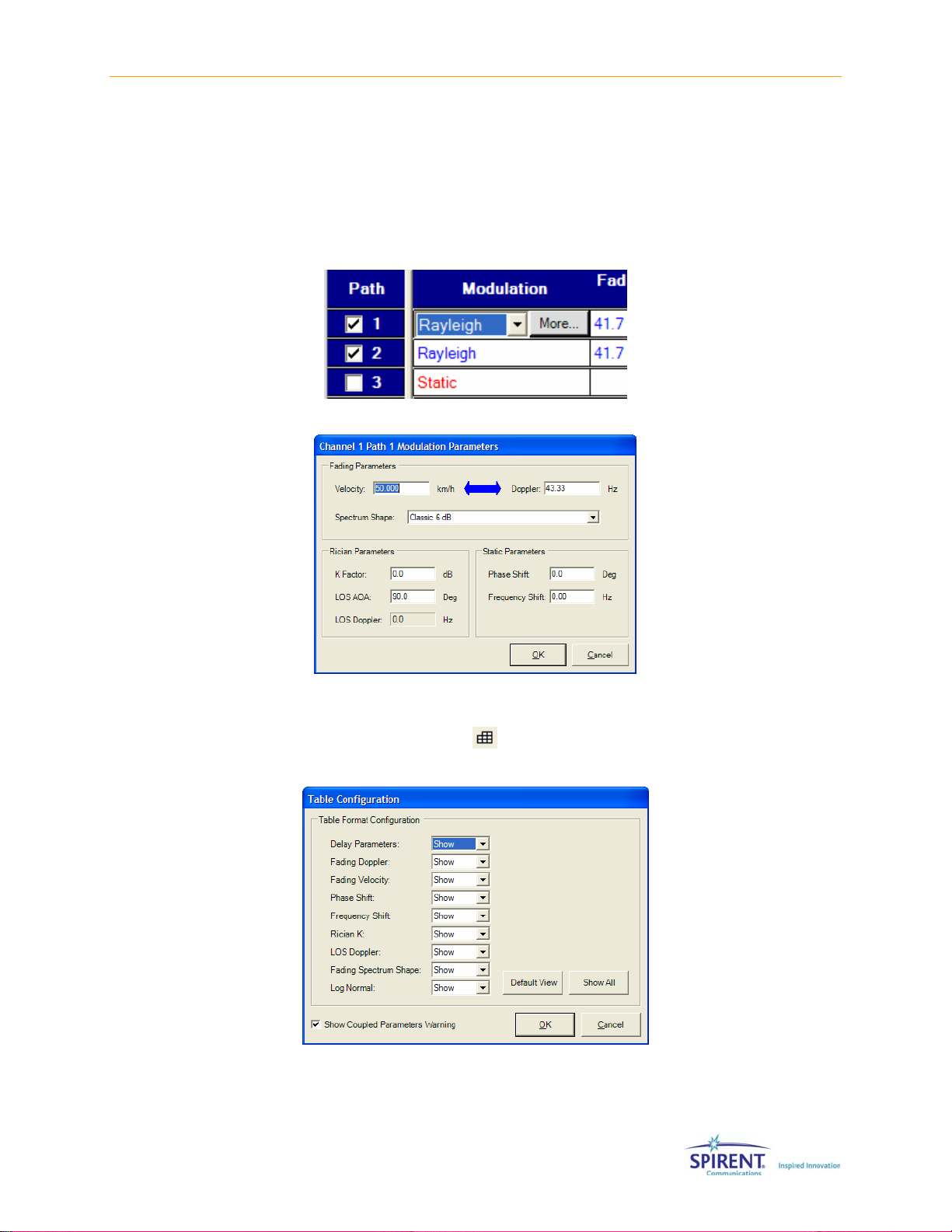

You can access the additional parameters two ways, by opening the Path Modulation

Parameters window, or by adding the parameters to the grid.

To display the Path Modulation Parameters window, place the mouse cursor anywhere in

the appropriate row in the Path Status column and click the More button that displays in

the row.

See Modulation later on page 40 for more details.

Figure 2-32: Modulation List

Figure 2-33: Path Modulation Parameters Window

To add all of the path parameter columns to the grid, select Menu>Configure>Table

Format, or click the Table Format icon

displays.

in the toolbar. The Table Configuration window

Figure 2-34: Table Format Configurat ion Window

Page 48

40 | SR5500 Operations Manual

This window allows you to select which columns display in the grid. Click the Show All

button to display all of the columns. Click the Default View button to show only the most

commonly used path parameters, including Path Status, Delay Mode, Delay Value, and

Relative Path Loss columns.

Select the columns to display in the grid. Click OK to save the changes and close the

window. Click Cancel to abandon the changes and close the window. The grid displays

the updated settings.

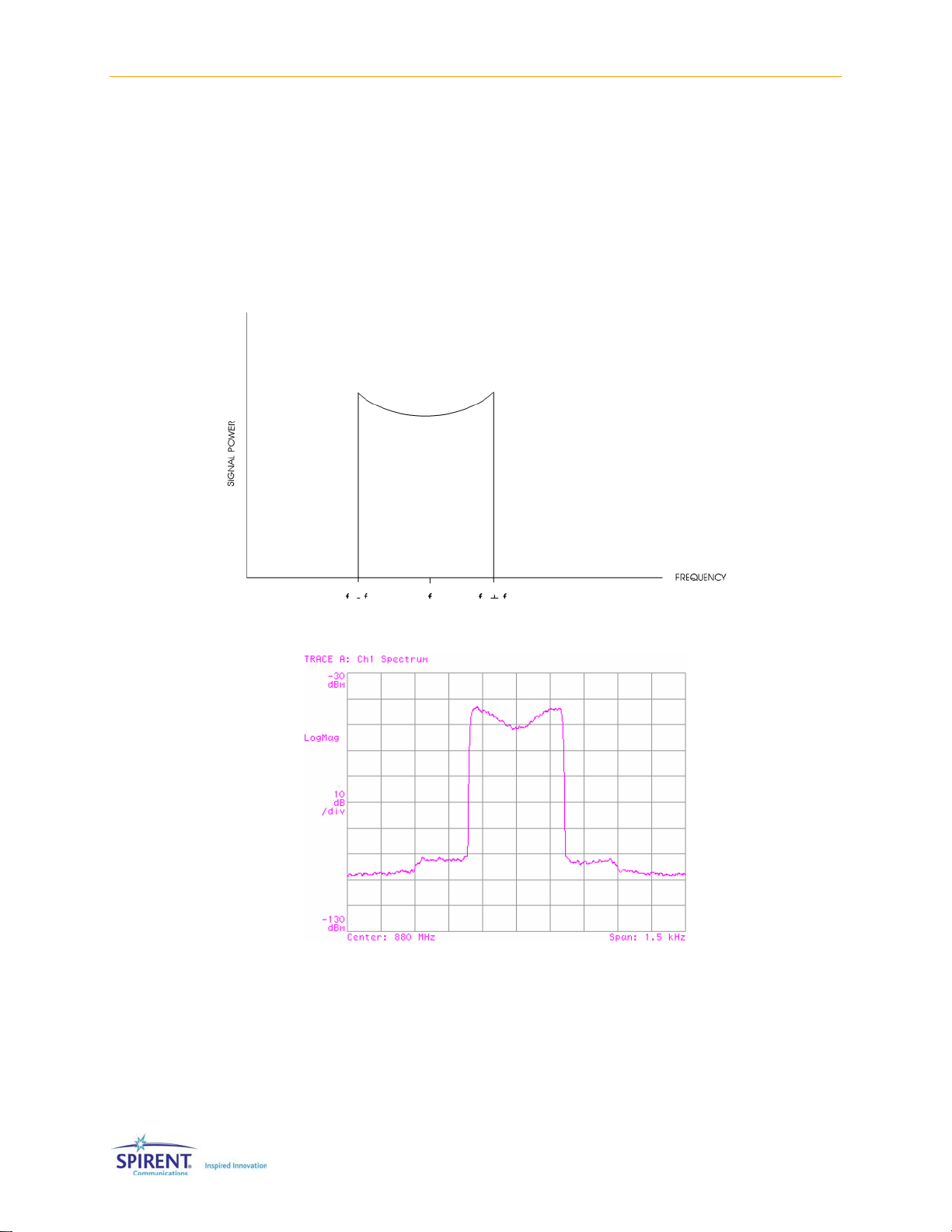

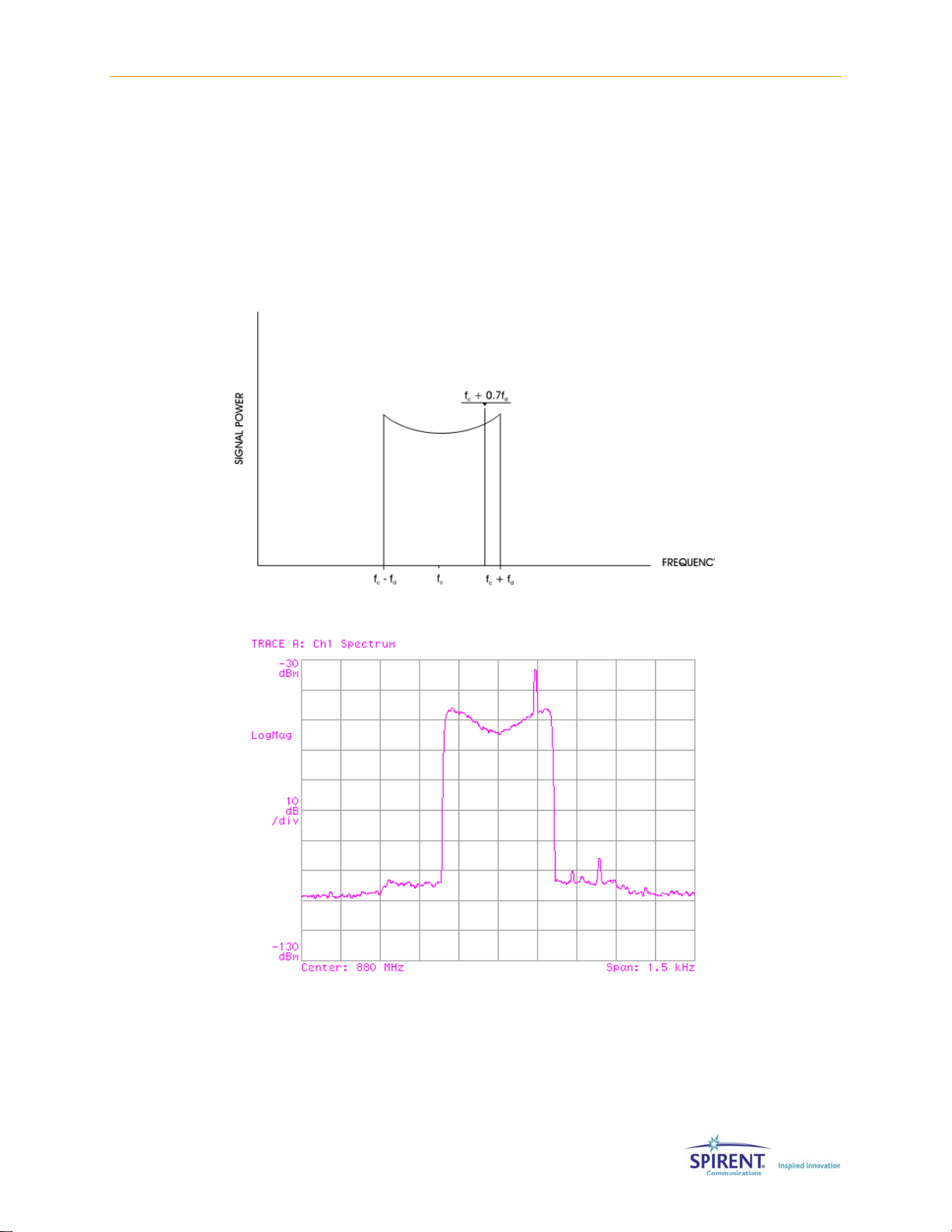

2.6.2.3 Modulation