Page 1

DGP00673AAA

GSS4100

USER MANUAL

THE INFORMATION CONTAINED IN THIS DOCUMENT IS THE PROPERTY OF SPIRENT

COMMUNICATIONS (SW) LIMITED. EXCEPT AS SPECIFICALLY AUTHORISED IN WRITING BY

SPIRENT COMMUNICATIONS (SW) LIMITED, THE HOLDER OF THIS DOCUMENT SHALL KEEP ALL

INFORMATION CONTAINED HEREIN CONFIDENTIAL AND SHALL PROTECT SAME IN WHOLE OR IN

PART FROM DISCLOSURE AND DISSEMINATION TO ALL THIRD PARTIES TO THE SAME DEGREE IT

PROTECTS ITS OWN CONFIDENTIAL INFORMATION.

© COPYRIGHT SPIRENT COMMUNICATIONS (SW) LIMITED 2001

PROPRIETARY INFORMATION

Issue 1.02, December 2001

Page 2

DGP00673AAA 1.02

RECORD OF ISSUE

Issue Date Reason for Change

Draft 1.00 June 2001 First issue for initial customer evaluation.

1.00 August 2001 DCR0075

1.01 September 2001 DCR0078

1.02 December 2001 DCR0082, DCR0086

2 GSS4100 User Manual

© Spirent Communications 2001

Page 3

1.02 DGP00673AAA

CONTENTS

1 INTRODUCTION

1.1 GUI OR REMOTE IEEE OPERATION 6

1.2 Referenced Documents 7

1.3 DELIVERABLES 7

2 SOFTWARE INSTALLATION 8

2.1 Software Installation Procedure 8

3 HARDWARE OVERVIEW AND INSTALLATION 13

3.2 Installation and connection to host PC 14

3.3 Safety Notice 16

4 PRINCIPLES OF OPERATION 17

4.1 Overview 17

4.2 GUI Interface 18

4.3 Navigation Data Templates 35

4.4 Hardware Settings Display 37

4.5 Synchronisation 40

4.6 Updating Software 43

5 GPIB INTERFACE & COMMANDS 46

5.2 Command Availability by Mode 62

5.3 Serial Poll – Status Bits 64

5.4 Example command sequences 64

6 HARDWARE CALIBRATION / CONFIGURATION 69

6.1 Introduction 69

6.2 Removing the GSS4100 case 69

6.3 Frequency calibration 70

6.4 Power Level Calibration 71

6.5 BITE Reporting 72

6.6 Upgrading the firmware using the flash memory loader 72

7CONTACTING SPIRENT 74

qqqqqqqqqqqqqqqqqqqqqq

6

GSS4100 User Manual

© Spirent Communications 2001

3

Page 4

DGP00673AAA 1.02

TABLE OF APPENDICES

A GLOSSARY 75

B CONNECTING A GPS RECEIVER 76

C SIGNAL GENERATOR CONNECTIVITY 78

D SIGNAL CAPABILITY 80

E ENVIRONMENTAL 81

F GSS4100 BITE RESPONSE MESSAGE 82

G STANDARD GPS NAVIGATION MESSAGE 85

G.1 Introduction85

G.1.1 Telemetry (TLM) Word – All Subrames 86

G.1.2 Handover Word (HOW) – All Subframes 86

G.1.3 Subframe’s 1 through 3 87

G.1.4 Subframes 4 and 5 94

G.1.5 Page ID’s 1 through 32 95

G.1.6 Page ID 51 98

G.1.7 Page ID’s 52 Through 54 101

G.1.8 Page ID 55 103

G.1.9 Page ID 56 105

G.1.10 Page ID 57 108

G.1.11 Page ID’s 58 Through 62 110

G.1.12 Page ID 63 112

H USER DEFINABLE NAVIGATION DATA 116

H.1 Introduction116

H.2 Format of File 116

H.2.1 General 116

H.2.2 Data Fields 117

I SBAS CORRECTION DATA FILES 120

I.1 Creating and Editing a SBAS Correction Data File 120

I.1.1 Example 121

I.1.2 Default *.WAS File, WAAS_DEF.WAS 121

I.1.3 Possible *.WAS Data Errors 142

4 GSS4100 User Manual

© Spirent Communications 2001

Page 5

1.02 DGP00673AAA

LIST OF FIGURES

Figure 1 Installation Welcome 8

Figure 2 Installation Folder 9

Figure 3 Start Menu Folder 10

Figure 4 Confirmation Installation Complete 11

Figure 5 Confirm Uninstall 12

Figure 6 Uninstall Complete 12

Figure 7 SimCHAN Display 18

Figure 8 Control Bar 20

Figure 9 Setting Pseudo Range Velocity 22

Figure 10 Setting Carrier Doppler Offset 24

Figure 11 Setting RF Power Level 24

Figure 12 Setting Simulation Time 26

Figure 13 Setting the PRN 27

Figure 14 Navigation Message Controls 29

Figure 15 Setting SBAS Data Rate 30

Figure 16 Setting the Initial Pseudo Range 31

Figure 17 Warning & Prompts Log Window 32

Figure 18 Velocity Profile Elements 33

Figure 19 Loading a Navigation Message Template 36

Figure 20 Hardware Settings Display 37

Figure 21 Timing requirements for 1PPS IN and resulting start timing 41

Figure 23 Timing requirements for TRIG IN (Immediate Mode) and resulting start timing 42

Figure 25 Open the Update File 43

Figure 26 Firmware Ready to Load 44

Figure 27 Firmware Update Complete 44

Figure 28 Raw SBAS Correction Data Diagram 120

Figure 29 SBAS Message Structure 120

Figure 30 Bit Sequence Message Type 1 124

IBM PC/AT are registered trademarks of International Business Machines Corporation.

MSDOS, Windows 95 and Windows 98 are registered trademarks of Microsoft Corporation.

InstallShield is a registered trademark of InstallShield Software Corporation.

GSS4100 User Manual

© Spirent Communications 2001

5

Page 6

DGP00673AAA 1.02

qqqqqqqqqqqqqqqqqqqqqq

1 INTRODUCTION

qqqqqqqqqqqqqqqqqqqqqq

qqqqqqqqqqqqqqqqqqqqqqqqqqqqqqqqqqqqqqqqqqqq

Thank you for purchasing a GSS4100 GPS/SBAS Simulator from

SPIRENT, world leaders in the field of Satellite Navigation Systems

Simulation.

The Global Positioning System (GPS) is based upon a constellation of

earth-orbiting satellites supporting world-wide precise positioning,

navigation and timing for both terrestrial and earth orbiting vehicles.

Satellite Based Augmentation Systems (SBAS) provide enhanced

accuracy, availability and integrity for GPS users in the civil community via

one or more geosynchronous satellites. The Wide Area Augmentation

System (WAAS) is a system planned for the continental United States.

Similar compatible systems are also planned for Europe (EGNOS) and the

Far East (MSAS). The GSS4100 fully supports both standard GPS and

SBAS.

The GSS4100 is a standalone single-channel L1 C/A code GPS Simulator.

It has been designed as precision test equipment for evaluating GPS/SBAS

receivers, in the areas of design verification, production test, comparative

evaluation, statistical data-generation through extended and repeated tests,

and incoming product test.

1.1 GUI OR REMOTE IEEE OPERATION

The GSS4100 can be controlled in one of two ways

1

:

• GUI

A user-friendly PC interface broadly based upon Spirent’s STR4775 and

STR4500 products. This software package is called SimCHAN and it

communicates with the GS4100 via USB.

• IEEE instruction set.

In this mode simulation control is via Spirent’s proprietary IEEE command

set. This command set was developed around the GSS4700 product

(STR4775 with IEEE control) and as such will mean existing GSS4700

code can be easily ported to the GSS4100.

1

It should be noted that both modes of operation offer identical control capability.

6 GSS4100 User Manual

© Spirent Communications 2001

Page 7

1.02 DGP00673AAA

1.2 REFERENCED DOCUMENTS

a) ICD-GPS-200 The document defining the GPS system space and user

segments.

b) STANAG 4294 The NATO equivalent of the above document.

c) NMEA 0183 – Document defining a standard set of navigational

messages supported by many GPS receivers.

d) RTCM-SC104 – Document defining a set of differential correction

messages accepted by many GPS receivers.

e) RTCA-DO229Minimum operational performance standards for Global

Positioning System/Wide Area Augmentation System Airborne

Equipment

1.3 DELIVERABLES

1. GSS4100 GPS/SBAS Simulator

2. User Manual (This book)

4. GSS4100 SimChan software on CD-ROM

5. USB cable

6. Power cables (Country specific)

7. SPIRENT mouse mat

GSS4100 User Manual

© Spirent Communications 2001

7

Page 8

DGP00673AAA 1.02

2 SOFTWARE INSTALLATION

The SimCHAN software controls the GSS4100 via the USB. The SimCHAN

USB interface uses the Microsoft Plug and Play Manager to install a

GSS4100 USB driver. In consequence the SimCHAN software must be

installed BEFORE the GSS4100 is connected to the PC. The Plug and Play

system will then automatically install the driver the first time that the

GSS4100 USB cable is plugged in.

2.1 SOFTWARE INSTALLATION PROCEDURE

Leave the GSS4100 switched off.

To install the operating software on your system hard disk, place the

supplied CD into the CD-ROM drive. The SETUP program will normally

auto-run, if it does not then simply run the application SETUP.EXE in the

root directory on the CD.

This will start an InstallShield script that will guide you through the

Installation process.

Figure 1 Installation Welcome

8 GSS4100 User Manual

© Spirent Communications 2001

Page 9

1.02 DGP00673AAA

The Welcome screen confirms that you are about to install the SimCHAN

software. You progress through the installation stages by clicking on the

Next button. You may backtrack the stages to change items you have

entered or selected by clicking the Back button. Cancel aborts the

installation.

Figure 2 Installation Folder

The Installation program will offer to install the SimCHAN software in a subfolder of C:\Program Files. You may select another location or folder name

by clicking the Browse button.

GSS4100 User Manual

© Spirent Communications 2001

9

Page 10

DGP00673AAA 1.02

Figure 3 Start Menu Folder

The Installation program creates shortcuts that may be used to start

SimCHAN. The start menu shortcut will be called SimCHAN and will be

placed in a new Spirent Communications folder. You elect to have the

shortcut placed in another existing folder by selecting it from the list.

10 GSS4100 User Manual

© Spirent Communications 2001

Page 11

1.02 DGP00673AAA

Figure 4 Confirmation Installation Complete

Once the folder selections are accepted the Installation proceeds to copy

the files. In addition to the SimCHAN program files, two driver files are also

copied to system folders. A file GSS4100.INF is added to the Windows\INF

or WINNT\INF folder and a file GSS4100.SYS is added to

Windows\System32\Drivers or WINNT\System32\Drivers. These two driver

files will be recognised by the Plug and Play process and become active

when the GSS4100 is connected to the USB port.

It will not be necessary to reboot the PC.

If it becomes necessary to remove the SimCHAN software, re-activate the

Installation program by either inserting the Installation CD or via the

Add/Remove Programs facility in the PC’s Control Panel folder. The initial

installation creates an Uninstall file that enables the installed files to be

identified and removed.

GSS4100 User Manual

© Spirent Communications 2001

11

Page 12

DGP00673AAA 1.02

Figure 5 Confirm Uninstall

The Uninstall program will prompt you to confirm that you wish to perform

this action. The Uninstall program removes the files created by the

Installation process and any folders that are thus left empty. If further files

have been added to these folders since installation then they will be left in

place and the folders will not be deleted.

Figure 6 Uninstall Complete

The Uninstall process will confirm successful completion.

12 GSS4100 User Manual

© Spirent Communications 2001

Page 13

1.02 DGP00673AAA

p

3 HARDWARE OVERVIEW AND INSTALLATION

This section gives a brief overview of the indicators and connectors on the

GSS4100 and how to connect it to the host PC. Signals are fully

characterised in the Technical Specifications, Appendices C, D, and E.

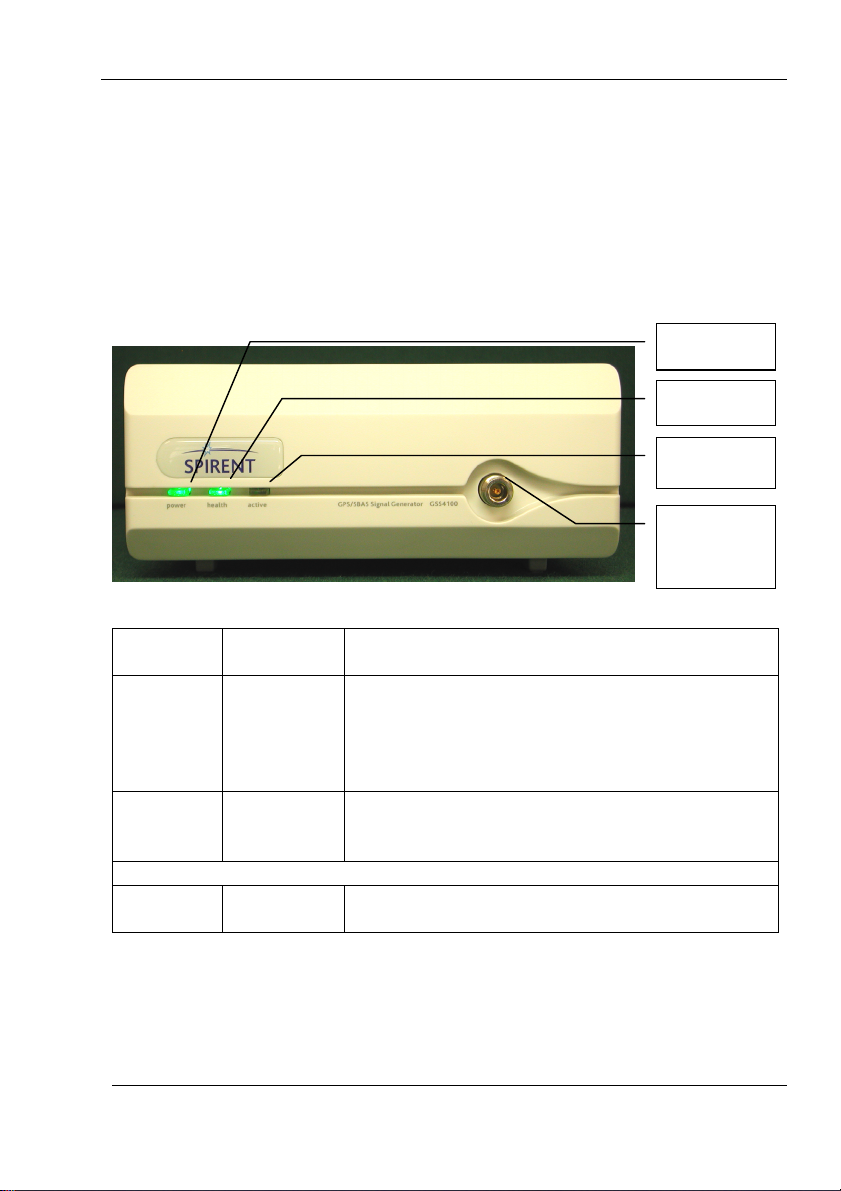

3.1.1 FRONT PANEL

POWER

HEALTH

ACTIVE

Primary

RF

Out

ut

POWER LED ON when power is connected and internal

power supply is operational.

HEALTH LED ON unless the internal monitoring detects:

a) An error, in which case it flashes at a 1Hz

rate.

b) Whilst acquiring external reference lock,

when it flashes at a 4Hz rate.

ACTIVE LED ON when a simulation is in progress. Flashes

when awaiting an external trigger signal on

rear panel TRIG IN

Primary

RF Output

GSS4100 User Manual

© Spirent Communications 2001

‘N’ Type

connector

Provides a composite GPS/SBAS signal

13

Page 14

DGP00673AAA 1.02

3.1.2 REAR PANEL

HOST (USB)

MON

CAL

AUX

OUTPUTS

TRIG IN 10MHz OUTEXT REF IN

HOST (IEEE-488)

Made in U.K.

Connector Type Description

MON/CAL Output SMA female

connector

AUX OUTPUT 25 way Dtype See Appendix C.

TRIG IN BNC Allows an external trigger signal to

EXT REF IN BNC Allows unit to be locked to an

10 MHz OUT BNC Internal OCXO reference output.

HOST (USB) USB

downstream

connector

Provides a high level version of the

front panel RF output.

start a simulation.

external frequency reference.

Control and data connection to the

host PC.

HOST (IEEE488) IEEE488 Control and data connection to the

host PC.

Power

IEC Power in, refer to Appendix C

in/switch/fuse

Further details of these connectors are given in Appendix C.

3.2 INSTALLATION AND CONNECTION TO HOST PC

When the software Installation is complete you may proceed to power on

the GSS4100 and connect, via, your chosen interface to the controlling host

14 GSS4100 User Manual

© Spirent Communications 2001

Page 15

1.02 DGP00673AAA

PC, either USB for SimChan Software operation or an IEEE.488 cable for

remote control

2

.

The power input to the GSS4100 is auto sensing for 100-120V or 220-240V

operation. Connect the power cord to the GSS4100.

Turn on the GSS4100.

After a brief power-up sequence the POWER and HEALTH LEDs on the

GSS4100 front panel illuminate continuously to show that everything is

operating correctly.

If you have opted for IEEE.488 control, the unit is now ready for operation.

If you have opted for SimChan software control the Plug and Play process

will recognise that a new device is connected to the USB bus and search

for the device’s driver. A message box with the legend ‘Found New Device’

is displayed, this will change to indicate device ‘GSS4100 L1 Simulator’

found and the message box will then close. If you are running Windows

2000 an icon will appear in the system tray on the Taskbar. If you position

the cursor over this icon a list of the connected USB devices will appear.

Start the SimCHAN software by double clicking the SimCHAN Icon on the

desktop or via the shortcut in the Start Menu.

2

It should be noted that new users to the GSS4100 may benefit from using SimChan before

moving onto IEEE operation as they may find simulation set-up, control and adjustment via the

GUI initially more instructive.

GSS4100 User Manual

15

© Spirent Communications 2001

Page 16

DGP00673AAA 1.02

3.3 SAFETY NOTICE

PRODUCT TITLE : GPS/SBAS SIMULATOR

PRODUCT CODE : GSS4100

DATA SHEET No : N/A

PRODUCT SAFETY INFORMATION SHEET

This safety Information Sheet should be read in conjunction with the Product Data Sheet

(where applicable).

Failure to observe the ratings and the information on this sheet may result in a

safety hazard.

This PSIS applies to the signal generator unit of the

simulator only. For information on the computer

workstation (where applicable) see safety section of the

manufacturer’s handbook.

1.MATERIAL CONTENT

This unit contains Printed Circuit Board semi-conductor

assemblies. Materials contained within the unit include

PTFE, ABS and epoxy/glass laminate.

2.PHYSICAL FORM

The equipment is housed in a vented aluminium

enclosure.

Enclosure dimensions are 99mm(h) x 345mm(d) x

254mm(w) (approx). Total weight of the Simulator Unit

is 5kg (approx).

3.INTRINSIC PROPERTIES

(a) Non-operating

Safe, when isolated from primary power source.

(b) Operating

Removing fixed panels during operation presents an

electric shock hazard. Fixed panels may only be

removed by suitably qualified personnel. High voltage

hazard warning labels are affixed to the outside of the

Unit.

WARNING: This equipment must be earthed.

4.FIRE CHARACTERISTICS

Primary

Overload conditions could present a fire hazard.

The limiting oxygen index value of the glass/epoxy

laminate is 25-32.

Protection circuits incorporated minimise the overload

and/or component failure hazards.

The case is vented to minimise heat and gas

concentration.

(b) Secondary

Under overload conditions the external finishing

paint will burn. Excessive overload/heating of

materials will cause emission of toxic gases.

5.HANDLING

The unit is sensibly robust but dropping or excessive

vibration may lead to immediate damage or later

component failure with consequent damage.

The portable unit weighs 5kg (approx).

The unit is supplied in an approved design package

to minimise damage in transit.

6.STORAGE

Care should be observed when storing to ensure

units cannot be subjected to environmental

conditions in excess of those given in the relevant

data.

Units should not be stored in conditions exceeding

the temperature range of -20°C to +60°C.

7.DISPOSAL

Disposal of the unit should be accordance with the

toxic waste disposal procedure, current at the time of

disposal.

Units must not be incinerated due to the presence of

PTFE which would emit toxic fumes.

8.UNSAFE USE

Electric shock hazard is present if panels are

removed during operation. Fire hazard could occur

during overload conditions.

Replacement fuses should be of the correct rating

and type to minimise overload conditions.

Toxic fume hazard possible if unit is overheated from

internal or external source.

Mechanical hazard can occur if the unit is

mishandled or incorrectly secured.

Under damage conditions do not use.

16 GSS4100 User Manual

© Spirent Communications 2001

Page 17

1.02 DGP00673AAA

4 PRINCIPLES OF OPERATION

4.1 OVERVIEW

The GSS4100 Simulator requires instructions to configure and commence a

simulation, from either the SimCHAN software via the USB or by command

sequences transmitted to the IEEE.488 (GPIB) port.

Regardless of which method of control is selected the simulator has three

software states, Halt, Arm and Run.

Essentially, whilst in the Halted State the user configures the next

simulation run, i.e. selects the satellite PRN number, navigation message

parameters (TOW, Week Number), initial power/velocity and any hardware

conditions such as external reference lock or external trigger control. Once

all those attributes have been set, the simulator is ARMed. The ARM mode

is an interim step prior to RUNing to configure the hardware and to allow

the user an opportunity to make any final adjustments to certain parameter

types. Finally, once in the RUN state the Simulator is actually operational,

i.e. the all requested simulation characteristics will be present on the RF

output port. Whilst in the RUN mode many parameters can be re-adjusted

and controlled to suit whatever simulation profile is required. At the end of

the run the simulator is again Halted and the process repeated as required.

Now that the basic fundamentals have been considered the following subsections work through each of the available simulation and hardware

control parameters. For clarity these descriptions revolve around the GUI

software, but for ease of use a cross-reference to all applicable IEEE

control commands is also included.

A full alphabetical listing of all the IEEE control commands can be found in

section 5.

GSS4100 User Manual

© Spirent Communications 2001

17

Page 18

DGP00673AAA 1.02

4.2 GUI INTERFACE

Figure 7 SimCHAN Display

The SimCHAN software allows the operating parameters of the GSS4100

to be set and adjusted in real time and any responses to be displayed.

The display has three main elements:

• The Outer Frame with Drop Down Menus and Toolbar,

• The main Control Display,

• Status Bar

4.2.1 ENTERING PARAMETERS

The interface uses a combination of the standard Windows Edit fields,

toggled button controls, and drop-down list selection controls.

Data values may be entered directly to the Edit fields by selecting the field,

typing the value and then pressing the Enter key. Alternatively most fields

are equipped with Spin button controls (Up/Down arrow buttons) that can

18 GSS4100 User Manual

© Spirent Communications 2001

Page 19

1.02 DGP00673AAA

be selected to scan through the range of allowed values. The Spin buttons

may be operated by the mouse or by the keyboard cursor keys. The

Velocity and RF Power fields each have an associated Increment field that

adjust the step size of changes to the main Velocity and RF Power ranges.

This allows the Velocity & RF power fields to be varied by both fine and

coarse increments. The RF Power may also be set by the horizontal slider

control.

Some parameters have just two states and these are operated by selecting

the Check marks on or off to enable or disable the function.

Other multiple choice selections are made from drop-down lists. Here the

user opens the list and then picks one of the options to become the active

selection.

4.2.2 CONTROLLING SIMULATIONS

The Arm, Run and Halt control actions may be invoked in each of three

ways to suit user preference:

By selecting with the mouse or keyboard from the Run Menu.

By clicking the buttons of the application Toolbar.

By the Hot keys: Ctrl+A, Ctrl+R and Ctrl+H.

In common with most Windows applications you may find that the mouse is

the most useful method of control.

N.B. Due to a limitation of the Windows interface the Hot keys and

keyboard menu actions are only effective when the application frame is

active, i.e. the Title bar is highlighted. The standard Windows Hot key

Alt+F6 toggles the frame to the active state.

4.2.3 CONTEXT SENSITIVE HELP

The standard Windows Help key F1 will activate the Windows Help facility

and locate the topic appropriate to the Application element in use.

In addition the Status bar will show a prompt appropriate to the screen

element under the mouse cursor.

GSS4100 User Manual

© Spirent Communications 2001

19

Page 20

DGP00673AAA 1.02

4.2.4 STATUS BAR

In addition to the Quick Help prompts the Status Bar has fields that show:

• The Application/ Simulation state,

• Internal/External Frequency Reference signal,

• Presence of a working USB connection.

4.2.5 MAKING AND USING STANDARD SIMULATIONS

The Control application follows the document paradigm. As the user applies

parameter settings these are recorded in an internal document. This

document may be saved to disk using the File menu options, and is given

the extension .GSS by default. Documents saved in this manner may be

loaded while the application is not running a simulation thereby setting the

simulation parameters to a known state with the minimum of effort.

Following this document analogy the New document options reset the

application parameters to the basic default states.

4.2.6 SELECTING GPS OR SBAS SIMULATION MODE

[IEEE Command: SIGT, see section 5.1.28]

Under the Nav Data Message settings for Message Type, select either GPS

or SBAS from the drop-down list.

On the GPS setting the RF signal from a GPS type satellite will be

simulated and the control options appropriate to GPS are activated.

On the SBAS setting the RF signal from an SBAS type satellite will be

simulated and the control options appropriate to SBAS are activated.

4.2.7 SIMULATION CONTROL

The primary method of control is via the application Toolbar.

Figure 8 Control Bar

The toolbar offers a quick method to execute the basic control functions of

ARM, RUN and HALT.

20 GSS4100 User Manual

© Spirent Communications 2001

Page 21

1.02 DGP00673AAA

It also gives access to the document functions of:

New Close any open parameters document and Reset Simulation

Parameters.

Open Offers the standard Windows document location Window to

select a file.

Save Records the current parameters to an open file or prompts for a

new name.

4.2.7.1 ARM the Simulation

[IEEE Command: ARMS see section 5.1.5]

Select the ARM button to load the selected simulation parameters to the

GSS4100 and to prepare for a simulation run. Completion of the Arming

sequence is indicated by the Status ‘Ready to Run’.

4.2.7.2 Start the Simulation Running

[IEEE Command: RUNS see section 5.1.25]

This button releases the GSS4100 to begin the prepared simulation.

GSS4100 User Manual

© Spirent Communications 2001

21

Page 22

DGP00673AAA 1.02

Independent of mode (see section 4.4.1.2) the user must use this button to

start the simulation. It should also be noted that the front panel ‘Active’

LED will become illuminated

3

. To return to the idle state without running the

simulation, select the Halt button.

4.2.7.3 Halt the Simulation

[IEEE Command: HALT see section 5.1.11]

The Halt button aborts the simulation in progress or terminates the Ready

to Run state and returns the Application to the Idle state, allowing

parameters to be altered if desired.

4.2.8 PSEUDO RANGE (DOPPLER) VELOCITY

[IEEE Command: VCTY see section 5.1.355.1.33]

This value is the rate of change of the Satellite’s simulated Pseudo Range

in metres per second. The allowed values range from -15000.00 to

+15000.00 at a resolution of 0.01 meters per second.

Figure 9 Setting Pseudo Range Velocity

The velocity may be set by typing the desired value and pressing the Enter

key or by clicking the Up or Down arrow buttons next to the value. On

clicking these buttons the value shown in the Pseudo Range Increment field

will be added or subtracted to the Pseudo Range Velocity.

3

The time at which the RUN command is actioned in the hardware is dependent upon the

selected Ext Trigger mode. The simulation start time will coincide with the next rising edge of

1PPS OUT, if Ext Trigger is ‘disabled’ or in ‘delayed’ mode, or immediately if Trigger mode

‘immediate’ has been selected.

22 GSS4100 User Manual

© Spirent Communications 2001

Page 23

1.02 DGP00673AAA

4.2.8.1 Stepping Rate for the Pseudo Range Velocity

This value is added or subtracted from the Pseudo Range Velocity when an

Up or Down arrow next to the Pseudo Range value is clicked.

The value may be set to any value in range by typing a new value and

pressing Enter or by clicking on the Up or Down arrow buttons next to the

value.

The allowed values range from 0.01 to 5000.00 metres per second.

4.2.8.2 Stepping through the Range of Pseudo Range Velocity

The Up and Down arrow controls next to the Velocity display may be used

to step the velocity from –15000.00 through to +15000.00 m/s. The step

size may be adjusted by setting the Increment value in the control below.

When the Pseudo Range Velocity edit box is the active control (i.e. its value

is highlighted) the Up and Down arrow controls will respond to the keyboard

up and down cursor keys in addition to mouse clicks when the screen

cursor is placed over the up or down control.

4.2.9 ENABLE OR DISABLE A VELOCITY PROFILE

[IEEE Command: PROF see section 5.1.21]

This option only becomes available when the simulation is running.

On selecting this option the Profile with the identifier shown is activated and

used to superimpose a cyclic sequence of changes to the Pseudo Range

Velocity in force.

The sequence will continue to be applied until the user cancels this option.

4.2.9.1 Selecting the Required Velocity Profile

[IEEE Command: PFIL see section 5.1.20]

Click on the arrow button to show a drop down list of the Profile Identifiers

available.

Eight standard profiles (PROF1 through PROF8) are incorporated in the

GSS4100 firmware.

These correspond to the Standard Receiver Performance Test profiles

defined in ICD-GPS-204.

GSS4100 User Manual

© Spirent Communications 2001

23

Page 24

DGP00673AAA 1.02

4.2.10 CARRIER DOPPLER OFFSET

[IEEE Command: VCTY see section 5.1.35]

Figure 10 Setting Carrier Doppler Offset

The Carrier Doppler Velocity Offset can be used to simulate Ionospheric

delay type effects by applying a fixed doppler velocity offset to the current

carrier doppler velocity. The code Doppler velocity remains unchanged.

The value has a range from –1000.00 through +1000.00 to a resolution of

0.01 m/s.

It may be set by entering a value and pressing the Enter key or by selecting

the Up and Down arrow buttons next to the control. The buttons also

respond to the keyboard up/down cursor keys.

4.2.11 RF POWER LEVEL

[IEEE Command: LEVL see section 5.1.14]

Figure 11 Setting RF Power Level

The RF Output power level may be varied to + or – 20.0 dB of the base

level to a resolution of 0.1 dB.

The level may be set by entering a value and pressing the Enter key on the

keyboard, by clicking and holding the Up/Down arrow buttons next to the

control or by dragging the associated slider control. The buttons also

24 GSS4100 User Manual

© Spirent Communications 2001

Page 25

1.02 DGP00673AAA

respond to the keyboard up/down cursor keys when this is the active

control. If a value is entered that is outside the allowed range, it will be

truncated to the limit value.

The Up and Down buttons increment and decrement the level by a value

defined by the step size control below the level control. The Up or Down

buttons just add or subtract the increment value, the slider also forces the

level to a multiple of the selected increment value.

4.2.11.1 Stepping Rate for the RF Power Level controls

A stepping rate or increment value may be set by entering a value and

pressing the keyboard Enter key. Any value may be set including values

greater than the RF Power Level range of 40.0 dB.

Alternatively a value may be selected from the range of pre-defined values

by selecting the Up/Down arrow buttons next to the control.

4.2.11.2 RF Power Control

The RF Power Slider Control allows the level to be set quickly and easily by

either dragging the slider with the mouse cursor or by pressing the left/right

keyboard cursor keys. The slider control adjusts the level to values that are

multiples of the Stepping Rate defined for the RF Power Level.

If a user defined Stepping Rate is in force, to avoid discontinuities at the

range limits the value used is the nearest pre-defined Stepping Rate value

rather than the user’s value.

To adjust the power level by fine amounts ensure that a small stepping rate

is selected.

GSS4100 User Manual

© Spirent Communications 2001

25

Page 26

DGP00673AAA 1.02

4.2.12 GPS WEEK NUMBER

[IEEE Command: WEEK see section 5.1.36]

Figure 12 Setting Simulation Time

This parameter is closely linked with the start of week since it defines the

GPS week for the simulation. GPS week zero is defined as starting at 00:00

hours, Sunday 6

th

January 1980.

For example, the default value of 800 corresponds to the week starting

Sunday, 7

th

May 1995. GPS week numbers greater than 1023 will be

truncated internally modulo 1024, i.e. Week 1025 is treated as week 1.

The week number may be entered as a value between 0 through 9999, by

typing the number and pressing the Keyboard Enter key or by clicking the

Up and Down arrow buttons next to the control. The arrow buttons also

respond to the Up and Down cursor keys on the Keyboard.

The Up/Down buttons apply acceleration i.e. the rate at which the week

value increments or decrements increases if a button is held for a period,

being initially in units, then tens, then hundreds and later in thousands.

4.2.13 TIME OF WEEK

[IEEE Command: ZCNT see section 5.1.38]

This value is the time into the week expressed in GPS Epochs that will be

applied at the start of the simulation. When the simulation is running, this

value increments to show the current Time of Week.

The time may be entered by typing the desired value and pressing the

Enter key or by clicking the Up or Down arrow buttons next to the value.

The allowed values range from 0 through 403196 in steps of 4 GPS

Epochs.

1 GPS Epoch = 1.5 Seconds

26 GSS4100 User Manual

© Spirent Communications 2001

Page 27

1.02 DGP00673AAA

4.2.14 PRN NUMBER

[IEEE Command: SVID see section 5.1.31 & SG2D see section 5.1.27]

Figure 13 Setting the PRN

The Pseudo Random Noise (PRN) Number defines the C/A code for the

satellite being simulated and equates to the SV ID (Satellite Vehicle

Identity).

The PRN value is constrained to the range 1 to 37 for GPS type satellites

and 120 to 140 for SBAS satellites.

The application offers a default value of 1 for the GPS constellation and 120

for an SBAS constellation.

The value may be selected by typing a value and pressing the Enter key on

the keyboard or by clicking the Up and Down arrow buttons next to the

control. The Up/Down buttons will also respond to the keyboard up/down

cursor keys.

4.2.14.1 PRN Code Selection

The GSS4100 is capable of generating any one of the 1023 possible

random sequences associated with the GPS C/A encoder. Each sequence

or code is determined by the start conditions of the G1 and G2 encoders.

The G1 encoder is hardwired to start in the all one state, the G2 encoder,

can start in any state except all zeros. The G2 start conditions can be

described by a ‘G2 delay’. This G2 delay can take on values between 0

and 1022. By convention several of the 1023 codes (mainly codes with

good orthogonal properties i.e. Low cross correlation) have had assigned to

them PRN numbers. The table overpage details the PRN assignments to

date.

GSS4100 User Manual

© Spirent Communications 2001

27

Page 28

DGP00673AAA 1.02

PRN No. Assignment

1-37 GPS

38-61 GLONASS

62-119 Future GLONASS

120-140 GEO/SBAS

141-210 Future GNSS/GEO/SBAS/Pseudolites

The SimCHAN software constrains the PRN assignment to the values

allocated for GPS or SBAS satellites.

4.2.14.2 Enable or Disable PRN code

[IEEE Command: COSW see section 5.1.7]

PRN code generation may be suppressed by clearing the check mark

against the ‘PRN Code On’ button.

This may be achieved by clicking with the mouse or by pressing the Tab

key until the ‘PRN Code On’ legend is surrounded by a dashed rectangle,

indicating that it is the active control, and then pressing the space bar or by

pressing the ‘Hot Key’ Alt+N.

4.2.15 NAVIGATION AND CORRECTION DATA MESSAGES

[IEEE Command: LEVL ?

Query the front panel RF signal power level.

Commands the unit to return an ASCII string detailing the current RF signal

power.

The message format is:

LEVL ?

Example Response:

LEVL –5.6

NDSW see section 5.1.15]

28 GSS4100 User Manual

© Spirent Communications 2001

Page 29

1.02 DGP00673AAA

Figure 14 Navigation Message Controls

Generation of the Navigation Message may be suppressed by clearing the

check mark against the ‘Message On’ button.

This may be achieved by clicking with the mouse or by pressing the Tab

key until the ‘Message On’ legend is surrounded by a dashed rectangle,

indicating that it is the active control, and then pressing the space bar or by

pressing the ‘Hot Key’ Alt+O.

4.2.15.1 Selecting Parity Normal/inverted for the Navigation Message

[IEEE Command: PRTY see section 5.1.23]

Parity errors may be simulated on the Navigation Message by clearing the

check mark against the ‘Message Parity’ button. This inverts each parity

bit, thus invalidating it.

This may be achieved by clicking with the mouse or by pressing the Tab

key until the ‘Message Parity’ legend is surrounded by a dashed rectangle,

indicating that it is the active control, and then pressing the space bar or by

pressing the ‘Hot Key’ Alt+P.

Note: The data message is buffered in hardware. When the parity status is

changed whilst the simulation is running a delay will elapse before the

change is reflected in the RF output. It is recommended that this feature be

only set up while the application is idle without a simulation in progress.

4.2.15.2 Selecting a Message Definition file

[IEEE Command: NSEL see section 5.1.19]

The GSS4100 has provision to store up to 8 Message Definition Templates

in its Flash memory storage. These memory slots may be filled with four

GPS Navigation Message Templates and four SBAS Correction Data

GSS4100 User Manual

© Spirent Communications 2001

29

Page 30

DGP00673AAA 1.02

message Templates. When the GPS constellation is selected then

Templates for GPS Navigation Messages are selected; otherwise SBAS

Correction Message Templates are selected.

An ID number in the range 0 to 3 identifies the Templates. The Template ID

shown will be the active selection during a simulation and used to generate

the Navigation/Correction message component of the RF signal.

To select a file using a mouse: click the down arrow button to open the list

of file then click on an ID number to make it the active selection.

To select a file using the keyboard: tab through the various controls until the

Message Definition file control is highlighted. Then use the up/down cursor

keys on the keyboard to move the highlight to the desired ID Number, and

then press the Enter key on the keyboard or the tab to mark that ID as the

active selection.

4.2.16 SBAS MESSAGE TRANSMISSION RATE

[IEEE Command: WRTE see section 5.1.37]

Figure 15 Setting SBAS Data Rate

The rate may be varied for SBAS type simulations only. The value shown

as the active value will control the rate at which the Correction message is

transmitted during an SBAS type simulation.

There are four rates available: 50, 100, 125 and 250 data bits per second

with 250 bps being set by default, equivalent to 500 symbols per second

when forward error corrected.

To select a rate using a mouse: click the down arrow button to open the list

of rates then click on a value to make it the active selection.

30 GSS4100 User Manual

© Spirent Communications 2001

Page 31

1.02 DGP00673AAA

To select a rate using the keyboard: tab through the various controls until

the Message Transmission Rate control is highlighted. Then use the

up/down cursor keys on the keyboard to move the highlight to the desired

value, and then press the Enter key on the keyboard or the tab to mark that

value as the active selection.

N.B. The Message Transmission rate for GPS satellites is fixed at 50 bps.

4.2.17 TIME INTO RUN IN SECONDS

This shows the elapsed time into the simulation in seconds.

4.2.18 INITIAL PSEUDO RANGE

[IEEE Command: IPRG see section 5.1.13]

Figure 16 Setting the Initial Pseudo Range

This value may be set while the simulation is idle only. It simulates the

distance between the receiver and the satellite at the start of the run. This

ranging effect is produced by delaying the start of the PRN and data

message signals to simulate the desired pseudo range. The time delay is

relative to rising edge of the 1PPS OUT signal (Ext Trigger mode ‘disabled’

or ‘delayed’ or relative to the External Trigger pulse itself if Trigger mode

‘immediate’ has been selected, (see section 4.4.1.2).

The pseudo range can take any value between 0 and 99999999 metres

(equivalent to 333 ms time delay) and has a resolution of 1 metre.

To set the value: select the control with the mouse or by tabbing through

the various controls until it is highlighted. Type the required value and press

the Enter key on the Keyboard.

GSS4100 User Manual

© Spirent Communications 2001

31

Page 32

DGP00673AAA 1.02

4.2.19 LOG OF PROMPTS, WARNINGS AND ERRORS

[IEEE Command: BITE see section 5.1.6]

Figure 17 Warning & Prompts Log Window

The application will display single line texts describing events that occur

during execution of the program. The texts are stored in time sequence with

the latest on display. The record of events may be viewed by selecting the

down arrow button to open the list and then operating the scrollbar to scan

the recorded events.

The record of events may be cleared by clicking the Clear button.

4.2.19.1 Removing the stored Warning and Error Message Texts

Clicking the Clear button will remove all the event texts recorded in the Log

Window.

It is not normally necessary to do this as the application will automatically

remove the oldest records but may be useful to confirm that no new events

are occurring.

4.2.20 VELOCITY PROFILES

[IEEE Command: PROS see section 5.1.22]

The velocity profiles are described in terms of maximum jerk (A), maximum

acceleration (E), constant acceleration period (C) and constant velocity

period (D). The profile takes the form of a series of step jerk periods of

equal amplitude and period. These jerk periods then translate into

acceleration, velocity and finally range profiles.

Maximum Jerk, A, units: m/s

3

Jerk Period, B, units: s

Constant acceleration period, C, units: s

Constant velocity period, D, units: s

Maximum acceleration, E, units: m/s

2

32 GSS4100 User Manual

© Spirent Communications 2001

Page 33

1.02 DGP00673AAA

Figure 18 Velocity Profile Elements

Note: The velocity profile has been drawn showing either constant or

linearly changing velocity. It should be noted however, that during

the jerk period (period of linearly increasing/decreasing acceleration)

the velocity will actually be changing non-linearly. These effects are

fully modelled by the GSS4100.

The profile is documented in The Standard Receiver Performance Tests,

ICD-GPS-204, and comprises the following sequence:

Constant Initial Velocity Period (D)

Positive Jerk Period (B = Max Acceleration/ Maximum Jerk (A))

Constant Acceleration Period (C)

Negative Jerk Period (as ii)

Constant Positive Velocity Period (D)

Negative Jerk Period (as ii)

Constant Deceleration period (C)

Positive Jerk Period (as ii)

The profile then repeats but with the Jerk sign reversed, producing negative

velocities. Finally, the entire profile repeats from the start.

GSS4100 User Manual

© Spirent Communications 2001

33

Page 34

DGP00673AAA 1.02

The four input parameters are:

Jerk amplitude (range –100 to +100m/s

Maximum acceleration (range –100 to +100m/s

3

), Zero Jerk is not allowed.

2

)

Period of constant acceleration (0 to 540 seconds)

Period of constant velocity (0 to 540 seconds)

The velocities generated by the profile are in addition to any fixed velocity

specified. The maximum achievable velocity is +/-15000m/s. All values

exceeding these limits will be clipped to the appropriate maximum velocity.

The eight receiver velocity profile tests documented in The Standard

Receiver Performance Tests, ICD-GPS-204 are included on the distribution

diskette as read only files PROF1.DAT through to PROF8.DAT.

Note: Jerk period = (max acceleration / 10msecs)

The jerk application period must be divisible by the interrupt step size, i.e.

10ms. To ensure this case is always true the entered jerk is modified

accordingly. For example a jerk value of 20 m/s

2

m/s

produces a jerk period of 0.775 seconds. This value is not divisible by

10ms and so the jerk period will be rounded down to 0.770 seconds and the

jerk will be modified to 19.4805m/s

3

.

2

and acceleration of 15.5

34 GSS4100 User Manual

© Spirent Communications 2001

Page 35

1.02 DGP00673AAA

4.3 NAVIGATION DATA TEMPLATES

The GPS Navigation message and the Correction Data message in SBAS

mode are generated from templates stored in the GSS4100 flash memory.

A template is provided for each of these modes that should suffice for most

test purposes. These are pre-loaded to the GSS4100 before delivery and

are also provided as ASCII test files.

The GPS Navigation Message carries date and time information that

increments at the 6 second GPS Epoch rate. This is inserted automatically

by the GSS4100 to match the simulation time. The parity field is also

computed dynamically by the GSS4100 but data other than the Epoch time

remains fixed.

To allow users to adjust data fields to meet specific testing requirements

there is provision for users to load a further 3 templates of each type. This

may be achieved by either the IEEE.488 NSAV command or via the GUI

Interface and USB.

The Templates are plain text files and may be examined and altered by any

basic editor program such as Windows Notepad. Save the modified

Template to the SimCHAN program folder (Typically C:\Program

Files\Spirent Communications\SimCHAN). A GPS Navigation message

Template must be of type *.NAV and an SBAS Correction data message of

type *.WAS.

To load a Template open the Load Navigation Message Template screen

from the Options Menu.

GSS4100 User Manual

© Spirent Communications 2001

35

Page 36

DGP00673AAA 1.02

Figure 19 Loading a Navigation Message Template

Select the type of template to be loaded, either GPS or SBAS. SimCHAN

will display the Templates available in the SimCHAN folder.

Select the ID number of the GSS4100 flash memory location that will hold

the Template. There are four locations numbered 0 to 3. ID number 1 is

offered as the first choice to discourage you from overwriting the GSS

supplied Template pre-loaded in Template number 0.

Select Load to transfer the file.

For a full description of default message parameters and how to define user

*.NAV and *.WAS files see Appendices G, H and I.

36 GSS4100 User Manual

© Spirent Communications 2001

Page 37

1.02 DGP00673AAA

4.4 HARDWARE SETTINGS DISPLAY

Figure 20 Hardware Settings Display

This displays the Serial Number of the connected GSS4100 unit and the

Versions/Release numbers of the various Firmware elements loaded into

the unit. Together with this information, several hardware related

parameters can be controlled and selected.

[IEEE command to check firmware version: *IDN? See 5.1.4]

4.4.1.1 Selecting the Frequency of the External Reference Signal

[IEEE Command: EREF see section 5.1.8 & EREF ? see section 5.1.9]

The GSS4100 can detect the presence of an external frequency reference

signal but cannot automatically determine the frequency. The GSS4100 will

automatically lock to the supplied signal but a fully stable lock is only

achieved when the External Frequency is correctly declared.

GSS4100 User Manual

© Spirent Communications 2001

37

Page 38

DGP00673AAA 1.02

Using the mouse, click on the arrow key to bring down the list of supported

external frequencies: 1, 5 and 10MHz are valid.

Click on the desired frequency to select. The GSS4100 will automatically

seek phase lock with the supplied signal.

The Locked/Unlocked markers with indicate when a stable phase lock has

been achieved and generally phase lock takes between 10 and 20 seconds

to complete.

The External Reference Phase lock is replicated on the Status Bar of the

Main Display. This is grey when no Reference signal is being detected, Red

when out of lock and Green when locked

Note1: You cannot run a simulation while the reference frequency is

Unlocked or attempt to phase lock during a simulation. Further to this an

error will be flagged if the reference frequency becomes unlocked during a

simulation.

Note2: Wait at least 15minutes after switch on before attempting external

reference phase lock to allow GSS4100 10MHz OCXO to stabilise.

4.4.1.2 Enabling or Disabling the External Trigger

[IEEE Command: TRIG see section 5.1.34]

External Trigger: If the system is to be started from an external event set

the required mode.

Regardless of Trigger mode the RUN button must be pressed to invoke a

simulation

4

.

Options are:

1) Disabled No external trigger is required to start the run. The run

will start when the next internal 1PPS event occurs

(‘RUN’ 1PPS event). Simulation start time is coincident

with the rising edge of the 1PPS OUT signal

4

It should be noted that this is different to the STR4775 product where the External Trigger

is applied whilst the Simulator is in the ARMED state. With the GSS4100 the simulator must

be in the RUN state before for the Ext Trigger signal will be actioned.

38 GSS4100 User Manual

© Spirent Communications 2001

Page 39

1.02 DGP00673AAA

2) Immediate In this mode the internal 1PPS signal is stopped and

restarted immediately on the rising edge of a signal

applied to the External Trigger connector. The

simulation will start and 1PPS OUT will transition high

approximately 600-700nsecs after the applied External

Trigger signal.

3) Delayed In this mode the GSS4100 waits for the External

Trigger signal to be applied but will hold off

commencing the simulation until the next internal 1PPS

event occurs (‘RUN’ 1PPS event). Simulation start time

is coincident with the rising edge of the 1PPS OUT

signal

4.4.1.3 1PPS Output Options

[IEEE Command: TIOP see section 5.1.32 & TIOP ? see section 5.1.33]

The 1PPS Out field is used to select the signal on the rear panel connector

of the same name. Options available are:

1PPS Continuously outputs 1Hz pulses with the rising edge of each

pulse coincident with the simulated GPS 1-second epoch

Gated As above but the signal is disabled before a run, so that the first

rising edge coincides with simulation time 0, start of run.

Rising A single rising edge occurs at simulation time 0, start of run

High Sets signal permanently high

Low Sets signal permanently low

4.4.1.4 IEEE Primary Address

[IEEE Command: GPIB see section 5.1.10]

The GSS4100 will use the displayed primary address number (PAD) when

operating under control of the IEEE.488 bus port at the rear of the unit.

The address may be changed by selecting the desired value, in the range 1

through 30, from the drop-down list.

4.4.1.5 Info Mask.

This is a debug facility and users should leave this on the default setting of

zero.

GSS4100 User Manual

© Spirent Communications 2001

39

Page 40

DGP00673AAA 1.02

4.5 SYNCHRONISATION

The GSS4100 simulator incorporates a number of input and

output signal ports which can be used in various ways to

synchronise time between the simulator and the remainder of a

user’s system. This note describes how to use the 1PPS IN

and/or TRIG IN inputs to achieve synchronisation.

The GSS4100 simulator maintains time internally by means of a

time counter clocked by an internal 10MHz clock. Simulations

always start on a one-second rollover of this timer. The timer may

be synchronised to an external system before starting a

simulation by applying a rising edge to the 1PPS IN rear panel

5

input

. Once this has been done, simulations may be started

either by appropriate timing of the software run command (Trigger

Mode: Disabled) or by selecting Delayed Trigger Mode and

applying a rising edge to the TRIG IN input. Both cause the

simulation to start on the next one-second rollover of the timer.

Alternatively, the user can select Immediate Trigger Mode which

forces the timer to a point just before the one second rollover and

freezes it until a rising edge is detected on the TRIG IN input,

whereupon the simulation starts running after a short delay. Note

that the use of TRIG IN (immediate mode) together with 1PPS IN

is inappropriate, as both would be attempting to control the timer,

however TRIG IN (delayed mode) can be used with 1PPS IN.

If coarse synchronisation to the user’s system is sufficient, the

above methods may be used with no additional considerations,

however certain fixed delays, and uncertainties of the order of

100ns will exist. In order to attain precise synchronisation it is

necessary to supply the unit with an external 10MHz frequency

reference, and to observe certain timing requirements between

the 1PPS IN and/or TRIG IN signals and the EXT REF IN signal.

These requirements are detailed below.

4.5.1 1PPS IN

The required timing of the rising edge of 1PPS IN with respect to

EXT REF IN, and the resulting timing of the start of simulation is

shown in Figure 21. Provided these timing requirements are

5

Note this is a 50Ω input and the pulse width of incoming signals should be ≥120nsecs.

40 GSS4100 User Manual

© Spirent Communications 2001

Page 41

1.02 DGP00673AAA

adhered to, the RF signal timing will be fixed and repeatable with

respect to REF IN every time a simulation is run.

The EXT REF IN signal may be a square wave as shown, (for

example a TTL/CMOS signal) or a sinusoid. Whatever the REF

IN input waveform, the timing reference point is the ac zero

crossing of the signal. Note that alignment of 1PPS OUT as

shown in the diagram does not occur immediately, but one

second after 1PPS IN is detected. Note also that the 1PPS IN

input is disabled whilst a simulation is running, i.e.

synchronisation can only take place whilst in the HALTED state.

Timing requirements for 1PPS IN:

EXT_REF_IN_(10MHz

thold (20 ns min)

tsetup (10ns min)

1PPS_IN

(Internal_10MHz_clock)

One second later 1PPS OUT will be aligned as follows:

1PPS_OUT

Start of simulation:

Simulation_state

RF_State

ARMEDARMED RUNNING

Figure 21 Timing requirements for 1PPS IN and resulting start timing

4.5.2 TRIG IN – IMMEDIATE MODE

When using the Immediate Trigger mode, the timing requirements

for the rising edge of TRIG IN with respect to EXT REF IN are the

same as for the 1PPS IN input (i.e. 10ns setup, 20ns hold).

However there is a delay of six 10MHz clock cycles after the

6

It should be noted that the delay between the 1PPS OUT rising edge and its resulting phase

transition at RF, seen at the RF Output Port, is nominally 0secs ±5 nsecs (1σ) RSS

GSS4100 User Manual

© Spirent Communications 2001

6

41

Page 42

DGP00673AAA 1.02

trigger is recognised before the simulation starts. This is shown in

Figure 22.

XT_REF_IN_(10MHz)

thold (20 ns min)

tsetup (10ns min)

TRIG_IN

nternal_10MHz_clock

1PPS_OUT

Simulation_state

RF_State

ARMEDARMED RUNNING

Figure 22 Timing requirements for TRIG IN (Immediate Mode) and

resulting start timing

4.5.3 TRIG IN – DELAYED MODE

In delayed trigger mode, to start on a defined 1PPS event, the

rising edge of TRIG IN must occur at least 1.1 milliseconds before

the 1PPS OUT rising edge.

42 GSS4100 User Manual

© Spirent Communications 2001

Page 43

1.02 DGP00673AAA

4.6 UPDATING SOFTWARE

GSS4100 Firmware updates are applied via the USB Link. A utility that

performs this task is available from the Spirent Communications Support

Team. It is not anticipated that users will need to change or replace

Firmware elements but if this becomes necessary then the Support Team

will provide full instructions and a copy of the utility as part of the update

package.

To update the Firmware. Connect the unit using USB and Start the update

utility.

Figure 23 Open the Update File

You will be prompted to select the file carrying the updated firmware, in this

example a file of type *.bin.

GSS4100 User Manual

© Spirent Communications 2001

43

Page 44

DGP00673AAA 1.02

Figure 24 Firmware Ready to Load

The utility will only proceed it a recognised GSS unit is connected to the

USB. The utility also checks the selected update file and displays its

embedded identification string and version number.

Check that this is the Firmware you intend to install, then click the Load

button. Loading the GSS4100 firmware takes ~15 seconds. The utility

displays an approximate indication of progress and indicates completion by

a Message.

Figure 25 Firmware Update Complete

44 GSS4100 User Manual

© Spirent Communications 2001

Page 45

1.02 DGP00673AAA

The Firmware will have copied to a holding area in internal memory. This

will be copied to the appropriate memory location the next time that the unit

is switched on.

GSS4100 User Manual

© Spirent Communications 2001

45

Page 46

DGP00673AAA 1.02

5 GPIB INTERFACE & COMMANDS

5.1.1 GPIB COMPLIANCE

The IEEE Std 488.1 Interface Functions subsets implemented are:

SH1, AH1, T6, TE0, L4, LE0, RL0, PP0, DT0, and C0.

Limited Query/response message handshakes are implemented for the

initial release. Status indication is provided by bit settings of the standard

GPIB serial poll register to enable the remote controller to monitor basic

operation only.

5.1.2 DEFAULT GPIB ADDRESS

The GSS4100 is delivered with the IEEE.488 (GPIB) Primary Address set

to 02. This may be inspected and changed if desired with either the

SimCHAN software over the USB or directly by the GPIB command on the

IEEE.488 interface.

To set the address with SimCHAN. Start the SimCHAN software and

connect the GSS4100 via the USB. Select ‘Hardware Settings’ on the

Options menu. The current address is displayed and an alternate address

may be selected from a dropdown list. Select OK or Apply to effect the

change.

5.1.3 IEEE-488 COMMAND SET

5.1.3.1 Semantics

All messages are initiated by an ASCII character identifier such as IDEN, at

least 4 bytes in length. This may be followed by a variable number of ASCII

encoded parameters depending on the message type, each separated by

one or more space characters.

Several messages may be sent in a single transfer but they must be

separated by one or more space characters, and the complete transfer

must end with EOI asserted. The maximum length of a message transfer

must not exceed 256 bytes; if it does the entire transfer will be discarded.

The maximum length of each ASCII encoded parameter is 9 bytes (digits)

for integer parameters and 64 bytes for floating point parameters (up to 9

decimal places).

46 GSS4100 User Manual

© Spirent Communications 2001

Page 47

1.02 DGP00673AAA

Floating point parameters may be supplied in integer or floating point form.

Values will be limited to the ranges and precision stated. Units will be as

stated, qualifying unit codes are not permitted or recognised.

The query response remains valid until one of the following occur; the

response is read, another command query message is received; the RSET

command is received; a DCL or SDC command is received.

Query responses have EOI asserted on the last byte of the response.

5.1.3.1.1 Notes on the Syntax Definition

The following syntax elements are used to define the command set options

and constraints.

The short form of terms is indicated in capitals. Otherwise the names are

not case sensitive.

Parameter values are separated from the sub command string by white

space.

[] Items in brackets are optional.

| Indicates a choice of items, one of which must be supplied

<> These items are to be replaced by numeric values etc.

{} Groups Items to form a single syntax item

… Ellipsis indicates an inclusive range of values

5.1.4 *IDN?

Query IEEE-488 Device ID String

This query is sent by some IEEE-488 Controller applications, e.g. National

Instruments Test and Measurement Explorer, to identify devices on the

IEEE-488 bus. The device responds with a user-friendly name in ASCII.

The message format is:

*IDN?

Response:

<Manufacturer>,<Model>,<serial number>,<firmware>

Where

<Manufacturer> is Spirent Communications

GSS4100 User Manual

© Spirent Communications 2001

47

Page 48

DGP00673AAA 1.02

<Model> is GSS4100

<serial number> is the serial number or zero if not known

<firmware> is the firmware or software revision level, or zero if not

known

Example Response:

Spirent Communications, GSS4100,1234,1-01

5.1.5 ARMS

Prepare to Run

This command informs the simulator that all the initial conditions for the

simulation are complete, and that the simulator should prepare for a run

command (RUNS).

The message format is:

ARMS

5.1.6 BITE

Query the Bite Status

Commands the device to return the state of the various BITE (i.e. error)

flags encoded in an ASCII string. The BITE flags indicate various status

and error conditions.

The response format varies according to the device type.

The message format is:

BITE ?

Response:

Refer to section 6.5.

On the GSS4100 BITE conditions cause the front panel HEALTH LED to

flash and the appropriate flag in the BITE response becomes set. In

general, both the LED flashing condition and the flag in the BITE response

are reset by querying the BITE. Certain fatal conditions are not cleared by

querying BITE. To query and clear Command Syntax errors use the SERR

command, see 5.1.26. An exception to the above is the external reference

out of lock indication, where the LED will stop flashing and the flag in the

48 GSS4100 User Manual

© Spirent Communications 2001

Page 49

1.02 DGP00673AAA

BITE flag is cleared when lock is achieved without the need to query BITE,

provided the unit is in the Halted state. If an out of lock condition occurs in

the Armed or Running state the flashing LED and BITE flag are latched until

queried.

5.1.7 COSW

PRN Code Enable/Disable

Commands the device to transmit or suppress the PRN code modulation.

The code signal sequence progresses whilst modulation is suppressed.

Note that Nav Data modulation is controlled separately (see NDSW)

The message format is:

COSW <code>

Where

<code> 0 PRN code turned off

1 PRN code turned on. This is the default state.

5.1.8 EREF

Set External Reference Frequency

Sets the expected External Reference Frequency to the specified value.

The value is stored in non-volatile memory for use on power-up. The unit

automatically switches to external reference and seeks Phase Lock

whenever a signal is present on the rear panel connector.

The message format is:

EREF 1MHz | 5MHz | 10MHz

Note the parameter is an ASCII string and must be exactly as shown.

5.1.9 EREF ?

Query External Reference Frequency

Commands the unit to return an ASCII string describing the current External

Reference Frequency setting and the lock status.

GSS4100 User Manual

© Spirent Communications 2001

49

Page 50

DGP00673AAA 1.02

The message format is:

EREF ?

Example Response:

EREF 10MHz INT or

EREF 10MHz EXT UNLOCKED or

EREF 10MHz EXT LOCKED

5.1.10 GPIB

Set the GPIB Primary Address

Set the IEEE-488 bus Primary Address of the device. The Primary Address

is saved in non-volatile memory. The unit is supplied with the GPIB address

set to 2. The change takes immediate effect and remains in force

indefinitely.

The message format is:

GPIB <gpib address>

Where

<gpib address> An integer in the range 1 to 30.

5.1.11 HALT

Stop the Simulation

Commands the device to terminate the current run and return to the Idle

State. The Z count and Week Number return to the values used to start the

run and the trigger mode is reset to 0 (disabled). All other settings remain

unchanged.

The message format is:

HALT

5.1.12 IDEN

Query the Unit Configuration Details

Commands the device to return an ASCII string describing the Unit’s

identification, and the firmware release numbers.

50 GSS4100 User Manual

© Spirent Communications 2001

Page 51

1.02 DGP00673AAA

The message format is:

IDEN

Example Response:

Type GSS4100

Serial Number 0001

Firmware Issue 1.00

Motherboard Revision 1

5.1.13 IPRG

Set Initial Pseudorange

Sets the initial simulated pseudorange. This is manifest as a time delay

relative to the 1PPS OUT signal.

The message format is:

IPRG <initial pseudo range>

Where

<initial pseudo range> an integer in the range 0 to 99999999 meters

5.1.14 LEVL

Set the RF Output Power Level

Sets the power level for the simulated RF signal at the front panel RF

output. The setting is relative to a base level of –130dBm. The command

accepts any value but clips this to the maximum level, if applicable, and

rounds to the stated resolution.

The message format is:

LEVL <rf power>

Where

<rf power> A floating point number specifying the level in dB.

Range +20.0 to –20.0 to a resolution of 0.1 dB.

GSS4100 User Manual

© Spirent Communications 2001

51

Page 52

DGP00673AAA 1.02

5.1.15 LEVL ?

Query the front panel RF signal power level.

Commands the unit to return an ASCII string detailing the current RF signal

power.

The message format is:

LEVL ?

Example Response:

LEVL –5.6

5.1.16 NDSW

Enable/Disable the Navigation Data Message

Commands the device to transmit or suppress the Navigation Data

Message. The message bit sequence progresses whilst the message is

suppressed during a simulation run.

The message format is:

NDSW <code>

Where

<code> 0 Suppress transmission of the message

1 Transmit the message

5.1.17 NSAV

Save Navigation Template

Commands the device to record and save a Navigation Message template

'file'. A sequence of messages are sent to first select one of the eight

template files, then send text for that file, and finally save the text in the

template file. The template information is multi-line ASCII text and is sent

sequentially line by line using the NSAV #FILE.TEXT# message. The

sequence of messages must be terminated by the NSAV #FILE.SAVE#

message. Each individual message must not exceed 256 characters in

length including the line terminating ‘newline’ character. The complete file

must not exceed 32 Kbytes including comments.

The message formats are:

NSAV {GPS | SBAS} <template>

52 GSS4100 User Manual

© Spirent Communications 2001

Page 53

1.02 DGP00673AAA

NSAV #FILE.TEXT# <text>

NSAV #FILE.SAVE#

Where

<template> Integer value as one of 0 | 1 | 2 | 3.

<text> A line of text to be stored in the currently selected template.

The format rules of each line of text are as follows.

All lines must end with a newline character.

Any line starting with a ! is deemed to be a comment.

All other lines contain data.

Further details are given in Appendices H and I, plus the example files

supplied.

5.1.18 NSAV ?

Query Navigation Template

Commands the unit to return the GPS and SBAS template information.

The message format is:

NSAV ?

The GSS4100 will reply to the query with the size (in bytes) and title string

for each of the GPS and SBAS templates.

GPS 0 6995 !NAV_DATA.NAV

GPS 1 6995 No Record

GPS 2 0 Empty

GPS 3 0 Empty

SBAS 0 25889 !SBAS_CN3.WAS

SBAS 1 0 Empty

SBAS 2 0 Empty

SBAS 3 0 Empty

Templates marked “No Record” were downloaded with earlier firmware

versions and no record was stored.

GSS4100 User Manual

© Spirent Communications 2001

53

Page 54

DGP00673AAA 1.02

5.1.19 NSEL

Select Navigation Template

Commands the device to generate the Navigation Message from the

named template. The unit has the capability to store four templates for each

of GPS and SBAS mode. The unit is supplied with the default navigation

message stored in <template> = 0.

The message format is:

NSEL {GPS|SBAS} <template>

Where

<template> Integer value as one of 0 | 1 | 2 | 3.

5.1.20 PFIL

Select Pre-defined Velocity Profile

Commands the device to use a named set of parameters for generation of

the next velocity profile sequence. In the GSS4100 these sets of

parameters are incorporated in the firmware.

The parameter sets each comprise four floating-point values that together

define the profile. See section 4.2.20 for a detailed description of the profile

shape and its relation to the four parameters.

The selection remains effective until the next RSET, PROS or PFIL

command is processed or the device is powered down.

The message format is:

PFIL <profile name>

Where:

<profile name> PROF1 | PROF2 | … | PROF8

An ASCII string defining the standard profile to be applied.

The PROF1 values will be applied by default.

5.1.21 PROF

Enable/Disable Velocity Profile

54 GSS4100 User Manual

© Spirent Communications 2001

Page 55

1.02 DGP00673AAA

Commands the device to either commence or terminate a velocity profile

sequence. The sequence will be either the most recent sequence

selected/defined by the PROF or PROS commands or the default sequence

defined by PROF1.

The message format is:

PROF <code>

Where:

<code> 1 Initiates the velocity profile sequence.

0 Aborts an active sequence.

5.1.22 PROS

Select Velocity Profile Parameters

Commands the device to generate the next velocity profile sequence from

the supplied parameters. The supplied parameters are not stored

permanently. It is recommended that this command be sent just prior to

each occasion the Velocity Profile is enabled by the PROF command.

The message format is:

PROS <jerk amplitude><max accel><period const accel><period const

vel>

Where:

<jerk amplitude> floating point number in the range: -100 to +100

m/s/s/s

<max accel> floating point number in the range: -100 to +100

m/s/s

<period const accel> floating point number in the range: 0 to 540

seconds

<period const vel> floating point number in the range: 0 to 540

seconds

GSS4100 User Manual

© Spirent Communications 2001

55

Page 56

DGP00673AAA 1.02

5.1.23 PRTY

Enable/Disable Set Parity State

Selects the Navigation Message Data Parity as either Normal (as per ICDGPS-200) or Inverted.

The message format is:

PRTY <code>

Where

<code> 1 Set Message Parity to Normal

0 Set Message Parity to Inverted

5.1.24 RSET

Reset Device

Commands the device to reset its parameters and operating condition to

the power up state. In practice, HALT and RSET perform quite similar

functions, with the exception that RSET defaults all parameters to a known

state.

The message format is:

RSET

5.1.25 RUNS

Begin Simulation

Commands the device to start running in simulation mode.

The message format is:

RUNS

5.1.26 SERR

Query and Clear Syntax Error

Commands the device to return the state of the Command Error flags,

encoded in an ASCII string, together with a string describing the error(s)

and the Command String that caused the error.

The message format is:

SERR ?

Example Response:

56 GSS4100 User Manual

© Spirent Communications 2001

Page 57

1.02 DGP00673AAA

SERR 00000001

0, Command not recognised

WEAK 987

5.1.27 SG2D

Select PRN by G2 Delay

Commands the device to use a specific G2 delay for its C/A code

generator.

The simulator is capable of generating any one of the 1023 possible

random sequences associated with the GPS C/A encoder. Each sequence

or code is determined by the start conditions of the G1 and G2 coders. The

G1 encoder is hardwired to start in the all one state, the G2 encoder, can

start in any state except all zeros. The G2 start conditions can be described

by a ‘G2 delay’. This G2 delay can take on values between 0 and 1022.

Some of the 1023 codes (mainly codes with good orthogonal properties i.e.

Low cross correlation) have had assigned to them PRN numbers. To select

one of these codes it is easier to use the SVID command.

The message format is:

SG2D <g2delay>

Where

<g2delay> Integer in the range 0 to 1023

5.1.28 SIGT

Signal Type

This command defines the required signal type, SBAS or GPS. This setting

determines the form of the Navigation data message transmitted.

The message format is:

SIGT GPS | SBAS

5.1.29 SNUM ?

Query the Device Serial Number

Commands the device to return its serial number.

The message format is:

GSS4100 User Manual

© Spirent Communications 2001

57

Page 58

DGP00673AAA 1.02

SNUM ?

Response

An ASCII string of the form 0999.

5.1.30 STAT

Query Status Flags

Commands the device to return the content of the Serial Poll Status

Register in an ASCII string as two hexadecimal digits together with the

name of the operating state. The status register may also be read by a

Serial Poll, see section 5.3 for the definition of the status bits.

The message format is:

STAT ?

Response:

STAT <hexbyte> <state>

Where:

<hexbyte> is a representation of the 8 bits of the status byte

using hexadecimal digits.

<state> An ASCII string which may one of:

HALTED or ARMED or RUNNING

5.1.31 SVID

Select PRN by SVID

Commands the device to generate the PRN sequence for the specified

Satellite ID number as specified in ICD-GPS-200 (GPS) or RTCA-DO229

(SBAS).

The message format is:

SVID <gps prn> | <sbas prn>

Where

<gps prn> Integer in the range: 1 to 37

<sbas prn> Integer in the range: 120 to 138

58 GSS4100 User Manual

© Spirent Communications 2001

Page 59

1.02 DGP00673AAA

5.1.32 TIOP

Select 1PPS Output Signal

Selects the format of the signal generated on the rear panel “1 PPS out”

connector.

The message format is:

TIOP <code>

Where

<code> HIGH – The output is always high