Spirax Sarco TN203 E Series, TN203 RH Series, TN215 E Series, TN215 SRH Series, TN2000 Series Installation And Maintenance Instructions Manual

...

PREVIOUS REFERENCE NO. IM-P327-07

3270150 /5

IM-P361-02-EN-ISS1

CTLS

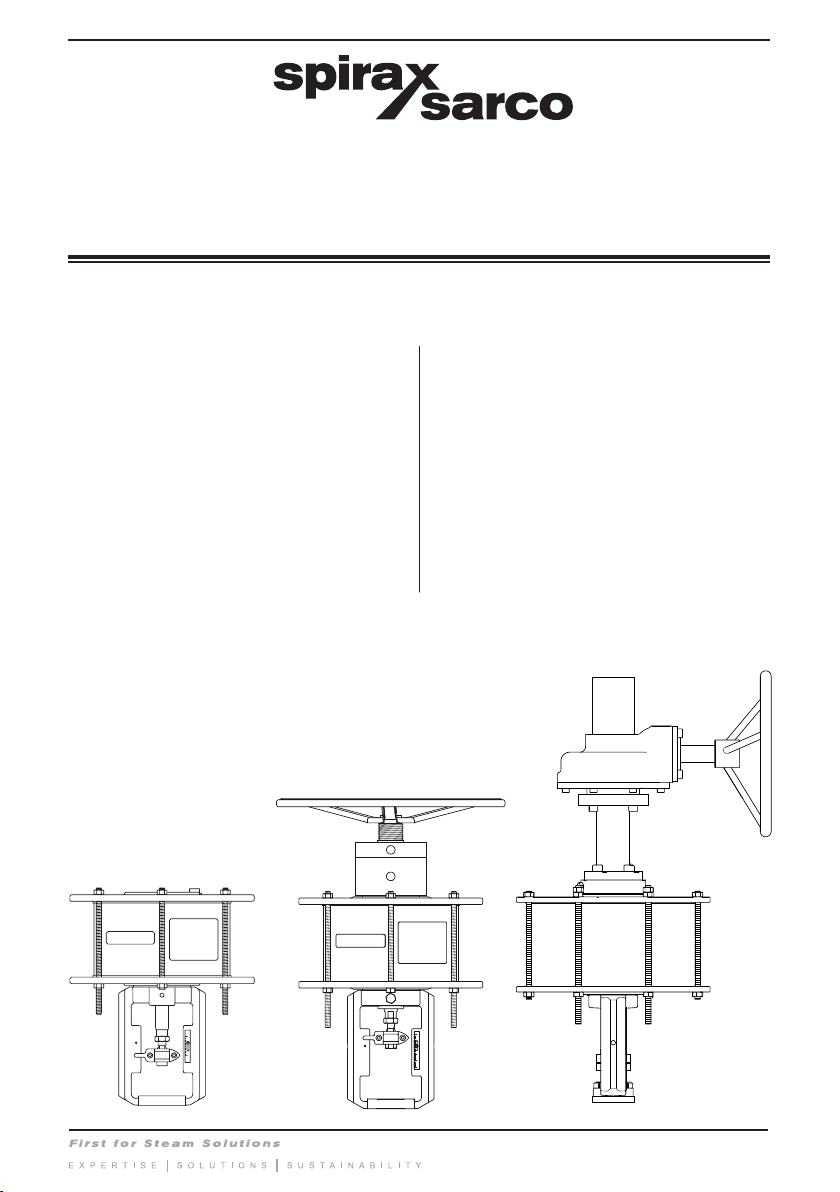

TN2000 Series

Pneumatic Piston Actuators

for DN15 to DN100 Spira-trolTM Series Control Valves

Installation and Maintenance Instructions

1. Safety information

2. General product information

3. Installation

4. Commissioning

5. Spare parts

TN203 _ E

or

TN215 _ E

IM-P361-02-EN-ISS1 CTLS

TN203 _ R H

TN215

_

SRH

© Copyright 2018

Printed in France

1

2

IM-P361-02-EN-ISS1 CTLS

1. Safety information

Safe operation of this product can only be guaranteed if i t is properly installed, commissioned,

used and maintained by qualified personnel (see Section 1.11) in compliance with the operating

instructions. General installation and safety instructions for pipeline and plant construction, as

well as the proper use of tools and safety equipment must also be complied wi th.

1.1 Intended use

Referring to the Installation and Maintenance Instructions, name-plate and Technical Information

Sheet , check that the product i s suitable for the intend ed use/application. Please note that these

products are out of the scope of the Pressure Equipment Direc tive (PED).

i) This product has been specifically d esigned for use on compressed air, which is in Group 2 of

the above mentioned Pressure Equipment Direc tive. The products’ use on other fluids may be

possi ble but, i f this is cont emplate d, Spirax S arco should b e contact ed to confi rm the suit ability

of the product for the application being considered.

ii) Check material suitability, pressure and temperature and their maximum and minimum values.

If the maximum operating limits of the product are lower than those of the system in which it

is being fit ted, or if malfunction of the pro duct could result in a dangerous overpressure or

overtemperature occurrence,ensure a safety device is included in the syst em to prevent such

over-limit situations.

iii) Spira x Sarco products are not intended to withstand external stresses t hat may b e induced by

any system to which they are fit ted. It is the responsibilit y of the installer to consider these

stresses and take adequate precautions to minimise them.

1.2 Access

Ensure safe access and if necessary a safe working platform (suitably guarded)before attempting

to work on the product. Arrange suitable lifting gear if required.

1.3 Lighting

Ensure adequate lighting, particularly where detailed or intricate work is required.

1.4 Hazardous liquids or gases in the pipeline

Consider what is in the pipeline or what may have been in the pipeline at some previous time.

Consider: flammable materials, substances hazardous to health, extremes of temperature.

1.5 Hazardous environment around the product

Consider: explosion risk areas, lack of oxygen (e.g. tanks, pits), dangerous gases, extremes of

temperature, hot surfaces, fire hazard and solvents.

1.6 The system

Consider the effect on the complete system of the wor k proposed. Will any proposed act ion (e.g.

closi ng isolati on valves, el ectric al isolati on) put any othe r part of t he system or any p ersonne l at risk?

Dangers might include isolation of vents or protective devices or the rendering ineffective of

controls or alarms. Ensure isolation valves are turned on and off in

a gradual way to avoid system shocks.

IM-P361-02-EN-ISS1 CTLS

3

1.7 Pressure systems

Ensure that any pressure is isolated and safely vented to atmospheric pressure. Consider double

isolation (double block and bleed) and the locking or labelling of closed valves. Do not assume

that the system has depressurised even when the pressure gauge indicates zero.

1.8 Temperature

Allow time for temperature to normalise after isolation to avoid danger of burns.

1.9 Tools and consumables

Before star ting work ensure that you have suita ble tools and/or consumables available. Use only

genuine Spirax Sarco replacement parts.

1.10 Protective clothing

Consi der whethe r you and/or oth ers in the vic inity req uire any prote ctive clot hing to prote ct against

the hazards of, for example, chemicals, high/low temperature, radiation, noise, falling objects, and

dangers to eyes and face.

1.11 Permits to work

All work must be carried out or be supervised by a suitably competent person.

Installation and operating personnel should be trained in the correct use of the product according

to the Installation and Maintenance Instructions.

Where a formal 'per mit to work' system is in force it must be complied with. Where there is no such

system , it is recomm ended tha t a responsib le person sho uld know what wo rk is going on a nd, where

necessar y, arrange to have an assi stant whose primary responsibility is safety.

Post 'warning notices' if necessary.

1.12 Handling

Manual handling of large and/or heavy products may present a risk of injur y. Lifting, pushing,

pulling, car rying or suppor ting a load by bodily force can cause injur y particular ly to the back.

You are advised to assess the risks taking into account the task, the individual, the load and the

working environment and use the appropriate handling method depending on the circumstances

of the work being done.

1.13 Residual hazards

In some c ases the p roduct is p rovided wi th pre- compre ssed spri ngs. Any ope ration to o pen the sp ring

housing is to be c arried out strictly following the correct procedure as detailed in this document .

1.14 Freezing

Provision must b e made to protect products which are not self- draining against frost damage in

environments where they may be exposed to temperatures below freezing point.

4

IM-P361-02-EN-ISS1 CTLS

1.15 Disposal

This product should not be dismantled without first releasing the compression on the spring (if

fit ted). This p roduct is re cyclable a nd no ecolog ical haz ard is antic ipated wi th its dis posal provi ding

due care is taken, however the following list of exception will require individual disposal in line

with local health and safety regulations:

PTFE

-

Polythene

-

PVC

-

Composite tube

-

Nitrile NBR 70 shore 'O' ring s and 'X ' ring s.

-

1.16 Returning products

Custom ers and stockists are reminded that under EC Health, Safety and Environment Law, when

retur ning prod ucts to Spi rax Sarco t hey must prov ide infor mation on a ny hazard s and the pre cautio ns

to be taken due to conta mination residues or mechanical da mage which may present a health,

safety or environmental risk. This information must be provided in writing including Health and

Safet y data sheets relating to any substanc es identif ied as hazardous or potentially hazardous.

IM-P361-02-EN-ISS1 CTLS

5

2. General product information

2.1 Description

The TN2000 series of pneumatic piston actuators are suitable for use with DN15 to DN100 Spira-trolTM control

valves of which three versions are available: Single-acting (with spring), Double-acting (with spring) and

Double -acting (no spring). The availability of these three versions meets the requirements of valves at various

differential pressures and in a var iety of applications.

2.2 Technical data

Temperature range -15 °C to +110 °C (5 °F to 230 °F)

TN203_ 10 bar g (145 psi g)

TN2153 DE/DR

Maximum operating inlet pressure

Air supply connection ¼" or " screwed NPT

Actuator travel

TN215N DA

TN2153 SR/SE 8 bar g (116 psi g)

TN2150 SE/SE 7 bar g (101 psi g)

TN203 _ 30 mm

TN215 _ 50 mm

2.3 Materials Par ts 1 to 14 (See page 8 for parts 15 to 41)

No. Part Material

1 Lower cylinder end cap SG iron EN 1563 EN-GJS-400 -15 : 5.3106

2 Piston SG iron

3 Spring Chrome vanadium steel

4 Upper cylinder end cap SG iron EN 1563 EN-GJS-400 -15 : 5.3106

5 Cylinder Composite tube

6 'O' ring Nitrile NBR 70 SH

7 Threaded bar M8 Carbon steel (plated)

8 Nut M8 Carbon steel (plated)

9 Screw slotted pan head M2.5 x 12 Carbon steel (plated)

10 Yo ke SG iron

11 Front clamp Stainless steel

12 Rear clamp Stainless steel

13 Nut M5 Carbon steel (plated)

14 Formed hex. screw M5 x 16 Carbon steel (plated)

5 bar g (72 psi g)TN2150 DR/DE

6

IM-P361-02-EN-ISS1 CTLS

6

3

6

2

11, 12

13, 14

4

10

8

7

5

1

9

IM-P361-02-EN-ISS1 CTLS

Fig. 1

7

2.3 Materials (continued) Par ts 15 to 41 (See page 6 for par ts 1 to 14)

No. Part Material

15 N ut M12 Carbon steel (plated)

16 Bearing and seal insert Carbon steel (plated)

17 Rod seal wiper Ø20 Polyurethane

18 DU plain bearing Ø20 PTFE/steel composite

19 Spindle Stainless steel

20 Connector Stainless steel

21 Scale Stainless steel

22 Collar Carbon steel (plated)

23 Threaded bar M8 Long Carbon steel (plated)

24 'O' ring 11.6 x 2.4 Nitrile N BR 70 SH

25 Vent plug " NPT Polyamid 6.6

26 'X' ring Nitrile NBR 70 SH

27 Gasket Graphite seal

28 Label blank (Compressed spring warning) Adhesive paper

29 Adaptor Stainless steel

30 Label blank Adhesive paper

31 Sleeve Carbon steel (plated)

32 Formed hex. screw M12 Carbon steel (plated)

33 Formed hex. screw M12 x 25 Carbon steel (plated)

34 Nut M2.5 Carbon steel (plated)

35 Yoke adapter Stainless steel

36 Yoke sleeve Stainless steel

37 Spindle sleeve ( TN21 only) Carbon steel (plated)

38 Connector DA Stainless steel

39 Upper clamp DA Stainless steel

40 Adaptor DA Stainless steel

41 Thin valve nut Carbon steel (plated)

42 Grower washer M10 Stainless steel

8

IM-P361-02-EN-ISS1 CTLS

25

32

TN21 only

37

28

31

33

26

27

16

37 TN21 only

19

15

41

17

18

21

20

22

34

24

30

23

35

Only used

with the

TN2_ _ _ _ _

42

Only used with the TN215_ _ _ C

IM-P361-02-EN-ISS1 CTLS

29

Fig. 2

41

36

Only used with

the TN2 _ _ _ _C

38

39

40

9

Actuator data:

Actuator

range

TN2030 and

variants

TN2033 and

variants

TN2150 and

variants

TN2153 and

variants

Caution:

Those pressure ranges are estimated and directly related to the springs precision ( ±10%).

Furthermore, the working pressure with the valve coupled can be a lit tle bit upper because of the friction

inside of it.

Tra ve l Thrust

30 mm

30 mm

50 mm

50 mm

2.5 kN

562 lbf

1 349 lbf

3.6 k N

809 lbf

14 kN

3 147 lbf

6 kN

Acting

pressure

0 mm

0.79 bar

11. 5 0 ps i

1.89 bar

27. 40 p s i

0.46 bar

6.70 psi

1.95 bar

28.30 psi

X1

Acting

pressure

20 mm

1.47 bar

21.31 psi

4.19 bar

60.80 psi

1.12 bar

16.27 psi

2.73 bar

39.58 psi

Acting

pressure

30 mm

1.81 bar

26.24 psi

5.34 bar

77.49 psi

1.45 bar

21.0 6 psi

3.12 bar

45.23 psi

Acting

pressure

50 mm

2.11 bar

30.64 psi

3.90 bar

56.54 psi

X4

X2

Note: When lifting the

actuator only use a

lifting sling through X1

to X4.

Fig. 3

10

X3

IM-P361-02-EN-ISS1 CTLS

3. Installation

Caution: Sling eyes (X, see Figure 3) are not to be used for lifting an actuated valve assembly.

Sling eyes can only be used to stabilise the assembly. Suitable suppor t of the valve and actuator will

be required.

See separate Installation and Maintenance Instructions for the control valve. For details of differential

pressures associated with the Spira-trolTM KE and KE A control valves refer to the relevant actuator Technical

Information (TI) sheet.

The actuators should be installed in such a position as to allow full access to both the actuator and the valve

for maintenance purposes. The preferred mounting position is with the actuator and valve spindle in the

vertical position or horizontal to the pipewor k (it is essential that support is provided when the installation is

in the horizontal position), see Figure 4).

Note : Due to the thrust that the actuator uses, it can deteriorate the valve or the coupling parts,

if the working pressures are exceeded.

Vertically

above pipework

Optimum

IM-P361-02-EN-ISS1 CTLS

(it is essential that support is provided when the

Horizontal

installation is in the horizontal position)

Vertically

below pipework

Fig. 4

11

3.1 Fitting the actuator (extend) to the valve

Remove the screw and nut (13 and 14) then the rear and front clamp (11 and 12).

-

Ensure the indicator scale is facing the same way as the valve name-plate.

-

Apply the control signal pressure to the bottom of the actuator to bring the spindle (19) to the mid-travel

-

position.

Manually push the valve spindle down to ensure that the plug is on the valve seat.

-

Screw the yoke adapter (35) onto the valve and tighten it to 50 Nm (36.9 lbf ft) - (TN2 _ _ _ E_ only).

-

Put the yoke sleeve (36) onto the valve bonnet (TN2 _ _ _ EC only).

-

Locate the actuator yoke onto the valve bonnet and fit the lock-nut (A).

-

Screw the lock-nut of the valve’s spindle down to the lowest part of the valve spindle.

-

Screw the bottom connector (29) onto the valve spindle, caution there must be no valve spindle threads

-

above the bottom connector.

Loosen the lock-nut and screw the connector (20) upwards 3 turns, then remove the air supply.

-

Apply the minimum signal pressure + 0.1 bar (1.45 psi) maximum to the bottom of the actuator, and then

-

adjust the connector (20) so that it touches the bottom connector (29), then tighten the lock-nut (15).

Release the control air signal. Fit the front and rear clamps (11 and 12).

-

Fit the locking screws and nuts (13 and 14) loosely.

-

Operate the actuator and valve over its full travel four times to ensure alignment.

-

Tighten the mounting nut to 50 N m (36.9 lbf ft).

-

12

IM-P361-02-EN-ISS1 CTLS

19

15

20

11, 12

13, 14

29

A

Only used

with the

TN2_ _ _ _ _

Fig. 5

35

36

Only used

with the

TN2_ _ _ _ C

IM-P361-02-EN-ISS1 CTLS

13

3.2 Fitting the actuator (retract) to the valve

Remove the screw and nut (13 and 14) then the rear and front clamp (11 and 12).

-

Ensure the indicator scale is facing the same way as the valve name-plate.

-

Apply the control signal pressure to the top of the actuator to bring the spindle (19) to the mid-travel

-

position.

Manually push the valve spindle down to ensure that the plug is on the valve seat.

-

Screw the yoke adapter (35) onto the valve and tighten it to 50 Nm (36.9 lbf ft) - (TN2 _ _ _ E_ only).

-

Put the yoke sleeve (36) onto the valve bonnet (TN2 _ _ _ EC only).

-

Locate the actuator yoke onto the valve bonnet and fit the lock-nut (A).

-

Screw the lock-nut of the valve’s spindle down to the lowest part of the valve spindle.

-

Screw the bottom connector (29) onto the valve spindle, caution there must be no valve spindle threads

-

above the bottom connector.

Loosen the lock-nut and screw the connector (20) upwards 3 turns, then remove the air supply.

-

Adjust the connector (20) so that it touches the bottom connector (29). Apply the minimum signal pressure

-

+ 0.1 bar (1.45 psi) maximum to the top of the actuator then unscrew the c onnector (20) downwards 3

turns, and finally tighten the lock-nut (15).

Release the control air signal. Fit the front and rear clamps (11 and 12).

-

Fit the locking screws and nuts (13 and 14) loosely.

-

Operate the actuator and valve over its full travel four times to ensure alignment.

-

Tighten the mounting nut to 50 N m (36.9 lbf ft).

-

The air supply to the actuator must be 'dr y and free from oil'. Contact Spirax Sarco for more details with

relation to composite tube/media compatibilit y. For high temperature conditions, insulate the control valve

and pipework only to protect the actuator.

Note: The actuator cannot be fitted onto an older style control valve.

Caution: If the complete assembly is installed horizontally then the air supply must be connected at the

lowest point of the actuator.

Warning: The actuator cylinder must only be pressurized on the opposite side of the piston

holding the spring. The housing vent cap must be left unrest ricted. If the assembly is to be mount ed

horizontally then it is essent ial to provide suitable suppor t for the actuator.

14

IM-P361-02-EN-ISS1 CTLS

19

15

35

Only used

with the

TN2_ _ _ _ _

38

39

40

A

36

Only used

with the

TN2_ _ _ _ C

Fig. 6

IM-P361-02-EN-ISS1 CTLS

15

4. Commissioning

Note: Before ac tioning any maintenance programme obser ve the 'Safety information' in Section 1.

Warnings:

1. Actuator support will be required due to weight.

2. The actuator contains a pre-compressed spring.

3. Special assembly tool required.

4. Use POLYLUB GLY 801 (lubricating grease) only.

The TN2000 series of pneumatic actuators are maintenanc e free. To ensure satisfactory operation it is

strongly recommended that the control signal air is filtered and supplied dry and free of oil. Should it be

necessary to replace spare parts the following procedure should be used.

4.1 Removing the actuator from the valve:

Note:

Remove the handwheel first, if fitted, by following the instructions in Sections 4.4 or 4.5.

Remove the screws and nuts (13, 14) then the rear and front clamp (11, 12).

-

Remove the lock-nut (A).

-

Remove the air supply.

-

Remove the actuator from the valve.

-

16

IM-P361-02-EN-ISS1 CTLS

11, 12

13, 14

A

Only used

with the

TN2_ _ _ _ _

Only used

with the

TN2_ _ _ _ C

Fig. 7

IM-P361-02-EN-ISS1 CTLS

17

4.2 Replacing the 'O' and 'X' rings (SE and DE actuators)

Note: Remove the actuator from the valve as described in Section 4.1.

Note: Depending on the actuator size there is either 3 or 4 short threaded bars which must be removed last

to ensure that the spr ing tension is removed before taking the actuator apar t.

Depending on the actuator size loosen and remove the 3 or 4 threaded bars (7).

-

Loosen then remove the remaining long securing nuts (23), see note above.

-

Remove the upper cylinder end cap (4).

-

Remove the spring (3) (not applicable for DA).

-

Remove the cylinder (5 ).

-

If the bearing seals are to be replaced remove the spindle (19) to fit the lower seal (17).

-

Replace the 'O' and 'X' rings (6, 26 and 24).

-

To rebuild the actuator follow the next procedure:

Caution: POLYLUB GLY 801 must be used to ensure smooth operation of the piston.

Replace the spindle (19) if previously removed.

-

Apply grease to the internal of the cylinder (5) and the bearings (18) (approximately 50 mm to be in

-

contact with piston).

Lower the cylinder (5) onto the lower cylinder end cap (1).

-

Replace the springs (3).

-

Replace the upper

-

cylinder end cap (4) over

the springs (3).

Depending on the

-

actuator size refit the 3 or

4 long threaded bar s (23)

and tighten the nuts (8)

evenly to pull the cylinder

(5) onto the lower cylinder

end cap. Then tighten to

30 Nm (22.1 lbf ft).

Refit all remaining

-

securing screws and nuts

(7 and 8) and tighten to

30 Nm (22.1 lbf ft).

Re-at tach the actuator to

-

the valve as described in

Section 3.1.

26

18

17

8

6

6

23

3

5

24

7

19

4

18

Fig. 8 TN2000E

IM-P361-02-EN-ISS1 CTLS

4.3 Replacing the 'O' and 'X' rings (SR and DR actuators)

Note: Remove the actuator from the valve as described in Section 4.1

Note: There are 5 long securing nuts that must be removed last to ensure that the spring tension is removed.

Loosen and remove the connector (20), see Figure 9.

-

Depending on the actuator size loosen and remove the 3 or 4 short threaded bars (7).

-

Evenly loosen and remove the remaining long securing nuts (23), see note above.

-

Remove the upper cylinder cap (4).

-

Remove the piston assembly (A part numbers: 2, 19, 24, 26, 31 and 32).

-

Remove the cylinder (5 ).

-

Replace the 'O' and 'X' rings (17, 6, 24 and 26).

-

To rebuild the actuator follow the next procedure:

Caution: POLYLUB GLY 801 must be used to ensure smooth operation of the piston.

Apply grease to the internal of the cylinder (5) and the bearings (18) (approximately 50 mm) to be in co ntact

-

with the piston).

Lower the cylinder (5) onto the lower cylinder.

-

Lower the piston assembly into the actuator (2, 19, 24, 26, 31 and 32), taking care not to damage the

-

bearing (18) and seal (17).

Replace the upper

-

cylinder (4).

Depending on the

-

actuator size refit the 3 or

4 long threaded bars (23)

evenly to pull the piston

assembly into the

cylinder (5) and the

cylinder (5) onto the

cylinder end caps (1 and

4). Then tighten to 30 Nm

(22.1 lbf ft).

Refit all remaining

-

securing screws and nuts

(7, 8 and 23) and tighten

to 30 Nm (22.1 lbf ft).

Re-at tach the actuator to

-

the valve as described in

Section 3.2.

8

6

A

6

18

17

23

26

5

24

7

20

4

1

IM-P361-02-EN-ISS1 CTLS

Fig. 9 TN2000R

19

4.4 TN203_SEH or TN203_SRH (handwheel)

Note: Ensure the handwheel has no comprehessive load on the ac tuator springs.

Remove the plastic barrel plug (A), hold the actuator spindle at point (B) with a spanner and

-

simultaneously loosen and remove the screw (C).

Remove the handwheel (D), taking care not to displace the internal bearing (F).

-

To re-attach the handwheel, the above the procedure should be reversed ensuring the correct torques are

used.

Table 1 - Recommended tightening torques

Screw

(C)

N m lbf f t N m lbf ft

20 29.5 40 29.5

Fig. 10 TN20 3 _ SEH

D

A

C

F

E

Spindle connector

(E)

20

B

Fig. 11 TN203 _ SR H

D

A

C

F

E

B

IM-P361-02-EN-ISS1 CTLS

4.5 TN215_SEH or SRH (handwheel)

Note: Ensure the handwheel has no comprehensive load on the actuator springs. Rotating the handwheel

clock wise retracts the spindle, rotating it anti-clock wise extends the spindle. The actuator is shown in the

fully extended position)

Remove the plastic cap (A), hold

-

the actuator spindle at point (B)

A

with a spanner and loosen the

screwed insert (C), or screw (for

retr act).

To re-attach the handwheel, the above

the procedure should be reversed

ensuring the correct torques are used

(see Table 1).

Fig. 12 TN215 _ ECH

C

E

B

A

C

E

IM-P361-02-EN-ISS1 CTLS

Fig. 13 TN215 _ RBH

21

5. Spare parts

The spare parts available are common across the range of actuators det ailed in this document. No other

parts are available as spares.

Available spares

'O' ring kit

Travel indicator kit

Spring kit See the Materials illustration on page 6 for item identication 3

Handwheel

How to order spares

Always order spares by using the description given in the column headed 'Available spares' and state

the actuator model.

Example:

1 - 'O' ring kit for a Spirax Sarco

TN2033SEB pneumatic piston actuator.

See the Materials illustration on pages 6 and 8

for item identication

See the Materials illustration on pages 6 and 8

for item identication

EH kit A

RH kit B

6, 17, 24 and 26

9, 21 and 34

Fig. 14 TN20 3 _ SEH

Fig. 15 TN20 3 _ SRH

24

17

A

26

6

B

3

22

IM-P361-02-EN-ISS1 CTLS

A

B

Fig. 16 TN215 _ ECH

IM-P361-02-EN-ISS1 CTLS

Fig. 17 TN215 _ RBH

23

24

IM-P361-02-EN-ISS1 CTLS

Loading...

Loading...