Spirax Sarco PN 4000, PN 3400, PN 3500, PN 3600, PN 4200 Installation And Maintenance Instructions Manual

...

3.561.5275.201

IM-P357-12

Issue 3.1 - 2013

© Copyright 2006

EXPERTISE SOLUTIONS SUSTAINABILITY

1. Safety Information

2. General

3. Installation

4. Commissioning

5. Maintenance

6. Spare Parts

Types PN 3000 and PN 4000 Series

Pneumatic Actuators

Installation and Maintenance Instructions

ATTENZIONE

Lavorare in sicurezza con apparecchiature

in ghisa e vapore

Working safely with cast iron products on steam

Informazioni di sicurezza supplementari - Additional Informations for safety

Lavorare in sicurezza con prodotti

in ghisa per linee vapore

I prodotti di ghisa sono comunemente presenti

in molti sistemi a vapore.

Se installati correttamente, in accordo alle

migliori pratiche ingegneristiche, sono dispositivi

totalmente sicuri.

Tuttavia la ghisa, a causa delle sue proprietà

meccaniche, è meno malleabile di altri materiali

come la ghisa sferoidale o l’acciaio al carbonio.

Di seguito sono indicate le migliori pratiche

ingegneristiche necessarie per evitare i colpi

d'ariete e garantire condizioni di lavoro sicure

sui sistemi a vapore.

Movimentazione in sicurezza

La ghisa è un materiale fragile: in caso di

caduta accidentale il prodotto in ghisa non è

più utilizzabile. Per informazioni più dettagliate

consultare il manuale d'istruzioni del prodotto.

Rimuovere la targhetta prima di effettuare la

messa in servizio.

Working safely with cast iron

products on steam

Cast iron products are commonly found on steam

and condensate systems.

If installed correctly using good steam

engineering practices, it is perfectly safe.

However, because of its mechanical properties,

it is less forgiving compared to other materials

such as SG iron or carbon steel.

The following are the good engineering practices required to prevent waterhammer and

ensure safe working conditions on a steam

system.

Safe Handling

Cast Iron is a brittle material. If the product is dropped

during installation and there is any risk of damage

the product should not be used unless it is fully

inspected and pressure tested by the manufacturer.

Please remove label before commissioning

Vapore

Steam

Flusso

Flow

Esempi di esecuzioni corrette ( ) ed errate ( ) sulle linee vapore:

Steam Mains - Do's and Dont's:

Flusso

Flow

Prevenzione dai colpi d’ariete - Prevention of water hammer

Scarico condensa nelle linee vapore - Steam trapping on steam mains:

Intervalli di 30÷50 m. intervals

Pendenza -

Gradient

1:100

Vapore

Steam

Gruppo di scarico

Trap set

Condensa - Condasate

Pendenza -

Gradient

1:100

Gruppo di scarico

Trap set

Gruppo di scarico

Trap set

Condensa - Condasate

Condensa - Condasate

Vapore

Steam

Prevenzione delle sollecitazioni di trazione

Prevention of tensile stressing

Evitare il disallineamento delle tubazioni - Pipe misalignment:

Installazione dei prodotti o loro rimontaggio post-manutenzione:

Installing products or re-assembling after maintenance:

Evitare l’eccessivo serraggio.

Utilizzare le coppie di serraggio

raccomandate.

Do not over tighten.

Use correct torque gures.

Per garantire l’uniformità del carico e dell'allineamento,

i bulloni delle ange devono essere serrati in modo

graduale e in sequenza, come indicato in gura.

Flange bolts should be gradually tightened across

diameters to ensure even load and alignment.

Dilatazioni termiche - Thermal expansion:

Gli esempi mostrano l’uso corretto dei compensatori di dilatzione. Si consiglia di richiedere una

consulenza specialistica ai tecnici dell’azienda che produce i compensatori di dilatazione.

Examples showing the use of expansion bellows. It is highly recommended that expert advise is

sought from the bellows manufacturer.

Guide

Guides

Distanza breve

Short distance

Punto di ssaggio

Fixing point

Movimento assiale

Axial movement

Distanza

media

Medium

distance

Tiranti limitatori

Limit rods

Piccolo

movimento

laterale

Small

lateral

movement

Piccolo

movimento

laterale

Small

lateral

movement

Ampio

movimento

laterale

Large

lateral

movement

Ampio

movimento

laterale

Large

lateral

movement

Guide

Guides

Guide

Guides

Guide

Guides

Punto di ssaggio

Fixing point

Tiranti limitatori

Limit rods

Movimento assiale

Axial movement

3.561.5275.201

2

1.1 Intended use

Referring to the Installation and Maintenance Instructions, name-plate and Technical

Information Sheet, check that the product is suitable for the intended use/application. The

products listed below comply with the requirements of the European Pressure Equipment

Directive 97/23/EC. The products fall within the following Pressure Equipment Directive

categories:

1. Safety Information

* SEP= not subjected to CE marking as per paragraph 3.3 of Directive 97/23/EC.

i) The products have been specifically designed for use on compressed air or condensate

which are in Group 2 of the above mentioned Pressure Equipment Directive. The products’

use on other gas within Group 2 may be possible but, if this is contemplated, Spirax Sarco

should be contacted to confirm the suitability of the product for the application being

considered.

ii) Check material suitability, pressure and temperature and their maximum and minimum

values. If the maximum operating limits of the product are lower than those of the system in

which it is being fitted, or if malfunction of the product could result in a dangerous overpressure

or overtemperature occurrence, ensure a safety device is included in the system to prevent

such over-limit situations.

iii) Determine the correct installation situation and direction of fluid flow.

iv) Spirax Sarco products are not intended to withstand external stresses that may be induced

by any system to which they are fitted. It is the responsibility of the installer to consider these

stresses and take adequate precautions to minimise them.

v) Remove protection covers from all connections before installation.

1.2 Access

Ensure safe access and if necessary a safe working platform (suitably guarded) before attempting

to work on the product. Arrange suitable lifting gear if required.

1.3 Lighting

Ensure adequate lighting, particularly where detailed or intricate work is required.

1.4 Hazardous liquids or gases in the pipeline

Consider what is in the pipeline or what may have been in the pipeline at some

previous time. Consider: flammable materials, substances hazardous to health, extremes of

temperature.

1.5 Hazardous environment around the product

Consider: explosion risk areas, lack of oxygen (e.g. tanks, pits), dangerous gases, extremes

of temperature, hot surfaces, fire hazard (e.g. during welding), excessive noise, moving

machinery.

1.6 The system

Consider the effect on the complete system of the work proposed. Will any proposed action

(e.g. closing isolation valves, electrical isolation) put any other part of the system or any

personnel at risk?

Product: Series PN3000 & PN4000 Group 2 Group 2

Actuators

PS (bar) V (litres)

Gas Liquid

Model PN3200 - PN4200 6.0 0.6 *SEP Model PN3300 - PN4300 (H) 6.0 1.0 *SEP Model PN3400 - PN4400 (H) 4.0 2.1 *SEP Model PN3500 - PN4500 (H) 2.5 3.6 *SEP Model PN3600 - PN4600 (H) 2.5 5.7 *SEP -

3.561.5275.201 3

Dangers might include isolation of vents or protective devices or the rendering ineffective

of controls or alarms. Ensure isolation valves are turned on and off in a gradual way to

avoid system shocks.

1.7 Pressure systems

Ensure that any pressure is isolated and safely vented to atmospheric pressure. Consider

double isolation (double block and bleed) and the locking or labelling of closed valves. Do not

assume that the system has depressurised even when the pressure gauge indicates zero.

1.8 Temperature

Allow time for temperature to normalise after isolation to avoid danger of burns.

1.9 Tools and consumables

Before starting work ensure that you have suitable tools and/or consumables

available. Use only genuine Spirax Sarco replacement parts.

1.10 Protective clothing

Consider whether you and/or others in the vicinity require any protective clothing to protect

against the hazards of, for example, chemicals, high/low temperature, radiation, noise, falling

objects, and dangers to eyes and face.

1.11 Permits to work

All work must be carried out or be supervised by a suitably competent person.

Installation and operating personnel should be trained in the correct use of the

product according to the Installation and Maintenance Instructions.

Where a formal "permit to work" system is in force it must be complied with. Where

there is no such system, it is recommended that a responsible person should know what work

is going on and, where necessary, arrange to have an assistant whose primary responsibility is

safety.

Post "warning notices" if necessary.

1.12 Handling

Manual handling of large and/or heavy products may present a risk of injury. Lifting, pushing,

pulling, carrying or supporting a load by bodily force can cause injury particularly to the back. You

are advised to assess the risks taking into account the task, the individual, the load and the

working environment and use the appropriate handling method depending on the circumstances

of the work being done.

1.13 Residual hazards

In some cases the product is provided with pre-compressed springs.

Any operation to open the spring housing is to be carried on strictly following the correct

procedure given in the Instalaltion and Maintenance Instructions.

1.14 Freezing

Provision must be made to protect products which are not self-draining against frost damage in

environments where they may be exposed to temperatures below freezing point.

1.15 Disposal

Unless otherwise stated in the Installation and Maintenance Instructions, this product is recyclable

and no ecological hazard is anticipated with its disposal providing due care is taken.

1.16 Returning products

Customers and stockists are reminded that under EC Health, Safety and Environment Law,

when returning products to Spirax Sarco they must provide information on any hazards and the

precautions to be taken due to contamination residues or mechanical damage which may

present a health, safety or environmental risk. This information must be provided in writing

including Health and Safety data sheets relating to any substances identified as hazardous or

potentially hazardous.

3.561.5275.201

4

2. General

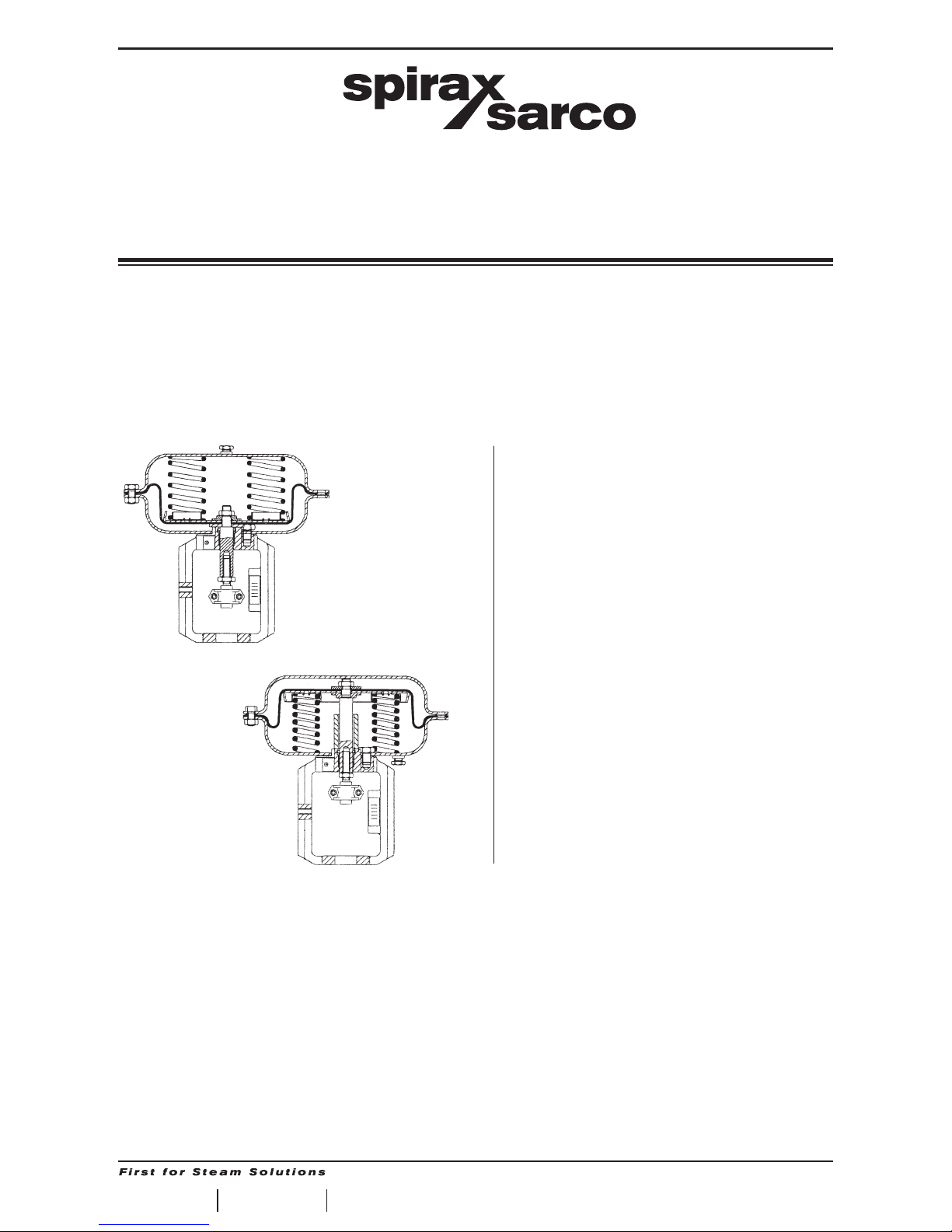

PN 3000 Series, Spring Extend Pneumatic Actuators

Spring ranges

Actuator Types Spring Range Travel

3220 0.2 (0.4) to 1 (1.2) bar 20mm

3225 0.4 to 2 bar 20mm

3229 1 to 2 bar 20mm (15mm on-off)

3320 0.2 (0.4) to 1 (1.2) bar 20mm

3325 0.4 to 2 bar 20mm

3326 1 to 3 bar 20mm

3339 1 to 2 bar 30mm (20mm on-off)

3420 0.2 (0.4) to 1 (1.2) bar 20mm

3425 0.4 to 2 bar 20mm

3426 1 to 3 bar 20mm

3430 0.2 (0.4) to 1 (1.2) bar 30mm

3435 0.4 to 2 bar 30mm

3436 1 to 3 bar 30mm

3520 0.2 (0.4) to 1 (1.2) bar 20mm

3525 0.4 to 2 bar 20mm

3524 0.8 to 1.5 bar 20mm

3530 0.2 (0.4) to 1 (1.2) bar 30mm

3535 0.4 to 2 bar 30mm

3534 0.8 to 1.5 bar 30mm

3620 0.2 (0.4) to 1 (1.2) bar 20mm

3625 0.4 to 2 bar 20mm

3624 0.8 to 1.5 bar 20mm

3630 0.2 (0.4) to 1 (1.2) bar 30mm

3635 0.4 to 2 bar 30mm

3634 0.8 to 1.5 bar 30mm

Actuator Type Valve Type

20 mm travel LE Series (DN 15 - 50)

30 mm travel LE Series (DN 65 - 100)

Technical Data

Temperature Range -20° to 100°C

Max operating pressure

PN3200/3300 6 bar

PN3400 4 bar

PN3500/3600 2.5 bar

Air Supply Connection

Actuator Type Connection

PN 3200 to 3600 Series ¼" NPT

Compressed Air Consumption

Actuator Type Travel Volume (NLitres)

3200 Series 20 mm 0.6

3300 Series 20 mm 1.0

3400 Series

20 mm 1.4

30 mm 2.1

3500 Series

20 mm 2.4

30 mm 3.6

3600 Series

20 mm 3.8

30 mm 5.7

Description

A range of compact linear actuators having 5 diaphragm sizes for matching the requirements of

different valves at various differential pressures. Each actuator is fitted with a stroke indicator

and incorporates a semi-rolling diaphragm which gives good linearity over the operating

stroke.These actuators are designed to operate with two port LE valves as detailed below.

Available types

Spring extend spindle, multi spring, yoke mounted actuators 3200, 3300, 3400, 3500, and 3600 Series.

3.561.5275.201 5

Materials

No Part Material

1 Diaphragm Housing Pressed Steel

2 Diaphragm Reinforced Nitrile Rubber

3 Diaphragm Plate Pressed Steel

4 Springs Spring Steel

5 Spindle Stainless Steel

6 Lock Nut Stainless Steel

7 Spacer Zinc Plated Steel

8 "O" Ring Rubber

9 Spring Guide Zinc Plated Steel

10 Diaphragm Clamp Zinc Plated Steel

11 Bearing Bronze

12 "V" Ring Rubber

13 Yoke Cast Iron

14 Gasket Non Asbestos Fibre

15 Fixing Screws Steel

16 Housing Bolts & Nuts Steel

17 Top Adaptor Steel

18 Lock Nut Steel

19 Bottom Adaptor Steel

20 Connectors Stainless Steel

21 Connectors Bolts & Nuts Stainless Steel

22 Travel Indicator Aluminum

23 Cap (with vent hole) Plastic

Fig. 1

3.561.5275.201

6

PN 4000 Series, Spring Retract Pneumatic Actuators

Available types

Spring retract spindle, multi spring, yoke mounted actuators 4200, 4300, 4400, 4500, and 4600

Series.

Description

A range of compact linear actuators having 5 diaphragm sizes for matching the requirements of

different valves at various differential pressures. Each actuator is fitted with a stroke indicator

and incorporates a semi-rolling diaphragm which gives good linearity over the operating

stroke.These actuators are designed to operate with two port LE valves as detailed below.

Spring ranges

Actuator Types Spring Range Travel

4220 0.2 to 1 bar 20mm

4320 0.2 to 1 bar 20mm

4420 0.2 to 1 bar 20mm

4430 0.2 to 1 bar 30mm

4520 0.2 to 1 bar 20mm

4530 0.2 to 1 bar 30mm

4620 0.2 to 1 bar 20mm

4630 0.2 to 1 bar 30mm

Actuator Type Valve Type

20 mm travel LE Series (DN 15 - 50)

30 mm travel LE Series (DN 65 - 100)

Technical Data

Temperature Range -20° to 100°C

Max operating pressure

PN4200/4300 6 bar

PN4400 4 bar

PN4500/4600 2.5 bar

Air Supply Connection

Actuator Type Connection

PN 3200 to 3600 Series ¼" NPT

Compressed Air Consumption

Actuator Type Travel Volume (NLitres)

4200 Series 20 mm 0.6

4300 Series 20 mm 1.0

4400 Series

20 mm 1.4

30 mm 2.1

4500 Series

20 mm 2.4

30 mm 3.6

4600 Series

20 mm 3.8

30 mm 5.7

3.561.5275.201 7

Fig. 2

Materials

No Part Material

1 Diaphragm Housing Pressed Steel

2 Diaphragm Reinforced Nitrile Rubber

3 Diaphragm Plate Pressed Steel

4 Springs Spring Steel

5 Spindle Stainless Steel

6 Lock Nut Stainless Steel

7 Spacer Zinc Plated Steel

8 "O" Ring Rubber

9 Spring Guide Zinc Plated Steel

10 Diaphragm Clamp Zinc Plated Steel

11 Bearing Bronze

13 Yoke Cast Iron

14 Gasket Non Asbestos Fibre

15 Fixing Screws Steel

16 Housing Bolts & Nuts Steel

17 Top Adaptor Steel

18 Lock Nut Steel

19 Bottom Adaptor Steel

20 Connectors Stainless Steel

21 Connectors Bolts & Nuts Stainless Steel

22 Travel Indicator Aluminum

23 Cap (with vent hole) Plastic

24 Spacer Plastic

3.561.5275.201

8

See also separate Installation and Maintenance Instructions for the control valves. For details of

differential pressures associated with KE and LE valves refer to Technical Information Sheet TIS

1.312 for PN3000 series actuators and TIS 1.313 for PN4000 series actuators.

The actuators should be installed in such a position as to allow full access to both actuator and

valve for maintenance purposes. The preferred mounting position is with the actuator and valve

spindle in the vertical position above or below the horizontal pipework.

The actuator ambient limits are -20°C to +110°C. For low temperature conditions the air supply

must be dry. For high temperature conditions, insulate the control valve and pipework to protect

the actuator.

Warning

The actuator housing must only be pressurized on the opposite side of the diaphragm to the

springs. The housing vent cap must left be unrestricted.

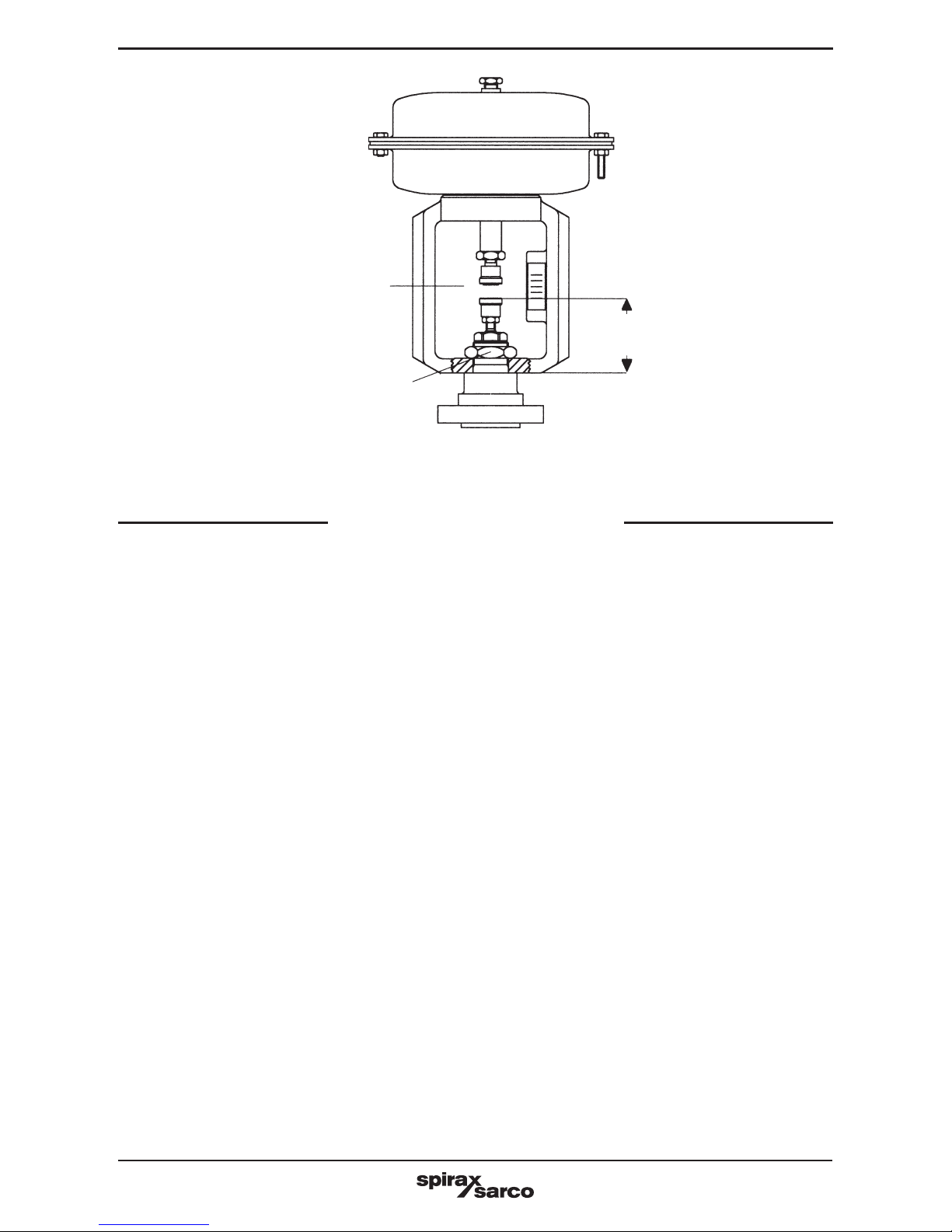

3.1 Fitting Actuator to Valve (Ref. to fig. 1, 2, 3 & 4)

1. Locate valve in support fixture and secure in position. Remove the actuator mounting nut

from the valve.

2. Remove the connector clamp brackets (20) from the actuator spindle by removing the 2

nuts and bolts (21). Remove the valve spindle adaptor (19).

3. Assemble the valve spindle adaptor to the valve spindle ensuring the valve is on its seat.

Adjust the distance between the adaptor top face and the bonnet shoulder to the value

indicated in Fig. 3.

Secure in this position with the spindle locknut.

Do not tighten.

4. Slacken actuator adaptor lock nut (18) & screw adaptor (17) up the actuator spindle as far

as possible.

Do not tighten locknut.

5. Assemble air fitting to actuator housing and locate complete actuator onto the valve assembly.

6. For PN3000 series actuators only.

Apply the maximum air signal pressure (refer to actuator label) to the actuator and assemble

the mounting nut on to valve bonnet.

Tighten to within ~1 full turn of fully tight.

7. For PN3000 series actuators only.

Apply the minimum air signal pressure (refer to actuator label) to the actuator.

8. For PN4000 series actuators only.

Apply the maximum air signal pressure (refer to actuator label), to the actuator.

9. Adjust the top adaptor until it locates with the spindle adaptor.

Do not tighten locknut.

10. Re-assemble the connector clamp brackets with the threaded holes of the bracket at the

same side as the travel indicator plate.

Secure with the 2 nuts and bolts. Torque to 2 nm.

11. Open & close valve 3 times to allow all components to self align (this is why locknuts are left

untightened at this stage).

12. Apply air signal to position valve @ ~ 50% lift position.

13. Tighten both adaptor locknuts. Caution: take care not to turn actuator spindle as this may

cause damage to diaphragm.

14. Tighten mounting nut to secure actuator to valve and torque to 50 nm.

15. This completes the main assembly. However, to check the spindle alignment is perfect,

temporarily remove the connector clamp brackets & inflate the actuator to separate upper

& lower spindle adaptors.

If correctly aligned the connectors will meet each other in perfect alignment. If not, slacken

all tightened nuts & repeat assembly sequence.

Note than some lateral movement between the actuator yoke & the valve bonnet is provided

on more recent PN3000 & PN4000 actuators.

16. Finally, check actuator signal range and stroke at open/closed positions by applying air

signal pressure to the actuator in line with actuator nameplate.

Check for smooth operation and adjust travel indicator on yoke if necessary.

Note: Before mounting the connectors It may be necessary to adjust the position of the actuator

spindle adaptor. Follow the spring adjust procedure as described in Section 4.

3. Installation

3.561.5275.201 9

Fig. 3

A = 71 mm for DN 15 to DN 50 Valves

91 mm for DN 65 to DN 100 Valves

If the actuator/valve has been supplied with a positioner reference should be made to the

separate Installation and Maintenance Instructions for this product.

4.1 Adjusting Spring

The actuator spring range and lift off pressure will be indicated on the nameplate. Should it be

necessary to check or adjust the lift off pressure the procedure is descibed in paragraphs 4.2

and 4.3.

4.2 PN3000 Spring Extend Actuators

Note: Adjustment of the spring will only alter the pressure of the control signal air at which the

valve commences to move off its seat (set point) and will not alter the spring pressure range

require to move the valve through its full travel i.e. 0.2 to 1.0 bar spring (range 0.8 bar) set to

commence to lift at 0.4 bar will require a 1.2 bar air pressure (0.4 + 0.8) to obtain valve full travel.

To adjust set point refer to fig. 2 and proceed as follows:

Ensure the control valve has been isolated and the actuator housing is pressure free.

Loosen and remove connector nuts and screws (21) and remove connectors (20).

Using two spanners whilst holding actuator spindle loosen actuator adaptor lock nut (18).

Apply the control signal pressure required to commence lifting the actuator spindle.

With the valve plug remaining on its seat adjust the actuator spindle adaptor until it presses

tightly against the valve spindle. Finger tighten lock nut (18). See Fig. 4 for correct installation.

Release the control air signal. Fit the connectors across the adaptors (17) and (19). Fit connectors

locking screws and nuts and tighten to 2 Nm.

Recheck that the valve just commences to move off its seat at the right spring range minimum

pressure and is fully open at the spring range maximum pressure. Finally bring the spindle at mid

travel and tighten lock nut (18) to the right torque.

After the test check the position of the travel indicator against the "arrow" of the connector and

adjust its position accordingly.

Important

To prevent damage to the valve seat, please ensure the plug does not turn while pressing on the

seat during assembling or adjustment.

To prevent damage to the diaphragm ensure the actuator spindle is not allowed to

rotate when the diaphragm is assembled within its housing.

4. Commissioning

A

Mid travel

Mounting nut

3.561.5275.201

10

Fig. 4 Assembly of Actuator Adaptor, Valve Adaptor and Connectors

4.3 PN4000 Spring Retract Actuators

Note: Adjustment of the spring will only alter the pressure of the control signal air at which the

valve commences to move off its seat (set point) and will not alter the spring pressure range

require to move the valve through its full travel i.e. 0.2 to 1.0 bar spring (range 0.8 bar) set to

commence to lift at 0.4 bar will require a 1.2 bar air pressure (0.4 + 0.8) to obtain valve full travel.

To adjust set point refer to fig. 2 and proceed as follows:Ensure the control valve has been isolated and the actuator housing is pressure free.

Loosen and remove connectors nuts and screws (21) and remove connectors (20).

Using two spanners whilst holding actuator spindle loosen actuator adaptor lock nut (18).

Apply the control signal pressure required to complete the full travel of the actuator spindle.

With the valve plug remaining on its seat adjust the actuator spindle adaptor until it presses

tightly against the valve spindle. Finger tighten lock nut (18).See Fig. 4 for correct installation.

Fit the connectors across the adaptors (17) and (19). Fit connectors locking screws and nuts

and tighten to 2 Nm.

Release the air control pressure and recheck that the valve just commences to move toward

the seat at the right spring range minimum pressure and is fully closed at the spring range

maximum pressure.

Finally bring the spindle at mid travel and tighten lock nut (18) to the right torque.

After the test check the position of the travel indicator against the "arrow" of the connector and

adjust its position accordingly.

Actuator Spindle

Valve Spindle

Lock Nut (22)

Valve Adaptor (19)

Connectors (20)

Actuator Adaptor (17)

Lock Nut (18)

Connectors Locking

Screws (21)

3.561.5275.201 11

Table 1: PN3000/PN4000 Spring

Actuator Spring Numb. of Ins. Dia. Length Identification

Type Range

Travel

Springs (mm) (mm) (Vert.Stripe)

3220/4220 0.2-1.0 bar 20 mm

1 42 73 Black

1 29 73 Red

3225 0.4-2.0 bar 20 mm

1 42 73 Yellow

1 29 73 Violet

3229 1.0-2.0 bar

20 mm 1 54

84

Black

(15mm on-off) 1 69 Black

3320/4320 0.2-1.0 bar 20 mm 4 42 84 Black

3325 0.4-2.0 bar 20 mm 4 42 84 Yellow

3326 1.0-3.0 bar 20 mm

4 42 84 Yellow

4 29 84 Red

3339 1.0-2.0 bar

30 mm

4 54 84 Black

(20mm on-off)

3420/4420 0.2-1.0 bar 20 mm

2 42 84 Yellow

2 42 84 Black

3425 0.4-2.0 bar 20 mm

5 42 84 Yellow

4 29 84 Red

3426 1.0-3.0 bar 20 mm 5 42 104 White

3430/4430 0.2-1.0 bar 30 mm

2 54,5 107 White

2 36 107 Green

3435 0.4-2.0 bar 30 mm

4 54,5 107 White

4 36 107 Green

3436 1.0-3.0 bar 30 mm

4 54,5 125 White

5 36 125 Green

3520/4520 0.2-1.0 bar 20 mm

6 54,5 107 White

2 36 107 Green

3525 0.4-2.0 bar 20 mm 8 42 104 White

3524 0.8-1.5 bar 20 mm 7 45 125 Brown

3530/4530 0.2-1.0 bar 30 mm

4 54,5 125 White

2 36 125 Green

3535 0.4-2.0 bar 30 mm

6 54,5 125 White

6 36 125 Green

3534 0.8-1.5 bar 30 mm 7 47 135 Blue

3620/4620 0.2-1.0 bar 20 mm

8 54,5 125 White

6 36 125 Green

3625 0.4-2.0 bar 20 mm 12 42 104 White

3624 0.8-1.5 bar 20 mm 8 56 123 Brown

3630/4630 0.2-1.0 bar 30 mm

6 54,5 125 White

2 36 125 Green

3635 0.4-2.0 bar 30 mm

9 54,5 125 White

8 36 125 Green

3634 0.8-1.5 bar 30 mm 8 57 134 Blue

3.561.5275.201

12

The PN3000 and PN4000 series pneumatic actuators are maintenance free. To ensure satisfactory

operation it is strongly recommended that the control signal air is filtered and supplied free of oil and

water. Should it be necessary to replace spare parts the following procedure should be used.

5.1 Removing Actuator from Valve

Drive actuator into approximately mid-travel position with the air supply. Loosen and remove

connectors nuts and screws (21) and remove connectors (20).

Loosen and remove yoke monting nut and lift actuator off the valve.

Reduce air supply pressure until housing is pressure free. Disconnect air supply from the actuator.

5.2 PN3000 Series

5.2.1 Diaphragm Kit - How to Fit

Remove actuator from valve as described in Section 5.1. Loosen and remove housing screws

(16) and remove housing lid (1).

Note 1 - On certain spring ranges 3 off longer hosing bolts are fitted (16). These should be

removed after all other bolts are removed and should be loosened evenly to prevent distortion.

Using two spanners whilst holding actuator spindle (5), loosen plate locknut (6). Remove springs

(4), spacer (7), "O" ring (8), diaphragm plate (3) and diaphragm (2).

Refit new diaphragm and "O" ring reassembling all items in reverse order. Using two spanners,

whilst holding actuator spindle tighten plate lock nut. Refer to Table 1 for torque rating.

Refit top housing and securing nuts and bolts.

2 - While supporting the actuator spindle so that the diaphragm sits evenly in the lower housing,

tighten evenly housing securing bolts to avoid distortion. On some spring ranges 3 off longer

housing bolts are provided to cater for the longer spring. If supplied, these should be psitioned

120° apart and tightened evenly prior to fitting the remaining bolts.

3 - To avoid distortion of the diaphragm do not fully tighten housing bolts until all bolts have been

fitted. Final tightening should then be carried out evenly. Refer to Table 2 for torque rating.

5.2.2 Spring Kit - How to Fit

Remove actuator from valve as described in Section 5.1. Loosen and remove housing screws

(16) and remove housing lid (1) as described in Section 5.2.1. Remove springs.

Replace new springs; While supporting the actuator spindle so that the diaphragm sits evenly in

the lower housing, refit top housing and tighten bolts evenly.

Refer to Section 5.2.1. Note 2 and 3.

5. Maintenance

Table 2: Recommended tightening torques

Actuator

Housing Bolts (16) Lock Nut (6)

Series

Size Torque Nm Size Torque Nm

PN3200/4200 M6 5 +/- 0.5 M12 40 +/- 3

PN3300/4300 to PN3600/4600 M10 15 +/- 2 M12 40 +/- 3

Fig. 5

3.561.5275.201 13

5.3 PN4000 Series

5.3.1 Diaphragm Kit - How to Fit

Remove actuator from valve as described in

Section 5.1. Loosen and remove housing screws (16) and remove housing lid (1), as described

in Section 5.2.1.

Using two spanners whilst holding actuator spindle (5), loosen plate locknut (6). Remove

diaphragm clamp (10) and diaphragm (2).

Refit new diaphragm reassembling all items in reverse order. Using two spanners, whilst holding

actuator spindle tighten plate lock nut. Refer to Table 1 for torque rating.

While supporting the actuator spindle so that the diaphragm sits evenly in the lower housing, refit

top housing and securing nuts and bolts, as described in Section 5.2.1.

5.3.2 Spring Kit - How to Fit

Remove actuator from valve as described in

Section 5.1. Loosen and remove housing screws (16) and remove housing lid (1), as described

in Section 5.2.1.

Using two spanners whilst holding actuator spindle (5), loosen plate locknut (6). Remove

diaphragm clamp (10), diaphragm (2), diaphragm plate (3), spacer (7) and "O" ring (8).Remove

springs taking note of their location.. Replace new springs locating in the same position of the

previous set.

Refit all other items in reverse order. Using two spanners, whilst holding actuator spindle tighten

plate lock nut. Refer to Table 1 for torque rating.

While supporting the actuator spindle so that the diaphragm sits evenly in the lower housing, refit

top housing and securing nuts and bolts, as described in Section 5.2.1.

5.4 PN3000 & PN4000 Series

5.4.1 Stem Seal Kit - How to Fit

Remove actuator from valve as described in Section 5.1.

Remove top housing and dismantle as descrIbed in Section 5.2, removing all components

including springs and diaphragm plate clamp.

Withdraw actuator spindle. Remove "V" ring (12) taking care not to damage spindle bearing (11).

Smear new "V" ring with silicon grease and replace. Refit actuator spindle taking care not to

damage "V" ring or bearing. Re-assemble components in reverse order. Refer to Section 5.2.1

or 5.3.1 for longer housing bolts fitted. Refit actuator as described in Section 3 and recommission

as described in Section 4.

Fig. 6

3.561.5275.201

14

The spare parts available are indicated by capital letters. The othe parts are not supplied as

spares.

Available Spares

Stem seal kit

("V" ring and "O" ring)

B, C

Diaphragm kit

(Diaphragm, "V" ring, "O" ring)

A, B, C

Travel indicator kit D

Spring kit

(Set of springs - includes 3 off longer Hex. Head bolts and nuts E, F

on some spring ranges)

Linkage kit

(Lock nut, Top adaptor, bottom adaptor, connectors, bolts and nuts)

G, H, I, L, M

How to order

Always order spares by using the description in the column headed Available Spares and stating

the actuator type.

Example: Stem seal kit for PN3220 pneumatic actuator

6. Spare Parts

Fig. 7

3.561.5275.201 15

REPAIR

Please contact our nearest Branch Office or Agent, or directly Spirax-Sarco S.r.l.

Via per Cinisello 18 - 20834 Nova Milanese (MB) - Tel.: 0362 49 17.1 - Fax: 0362 49 17 315

LOSS OF GUARANTEE

Total or partial disregard of above instructions involves loss of any right to guarantee

3.561.5275.201 Issue 3.1 - 2013.10

Spirax-Sarco S.r.l. - Via per Cinisello, 18 - 20834 Nova Milanese (MB) - Tel.: 0362 49 17.1 - Fax: 0362 49 17 307

Loading...

Loading...