IM-P612-04 ST Issue 12

1

1. Safety information

2. Product information

3. Operation

4. Installation

•

Closed loop steam systems only

5. Commissioning

6. Maintenance

7. Replacement of spares (1):

•

Cover gasket

•

Inlet swing check valve

•

Spring and actuator arm

•

Floats

8. Replacement of spares (2):

•

Trap and outlet check valve

mechanism

•

Steam inlet / exhaust valves and

seats

9. Fault finding guide

IM-P612-04

ST Issue 12

6120250/12

© Copyright 2017

Printed in GB

APT14, APT14HC and APT14SHC

Automatic Pump Traps

Installation and Maintenance Instructions

IM-P612-04 ST Issue 12

2

Safe operation of these products can only be guaranteed if they are properly installed,

commissioned, used and maintained by qualified personnel (see Section 1.11) in

compliance with the operating instructions. General installation and safety

instructions for pipeline and plant construction, as well as the proper use of tools

and safety equipment must also be complied with.

1.1 Intended use

Referring to the Installation and Maintenance Instructions, name-plate and Technical

Information Sheet, check that the product is suitable for the intended use/application.

The products listed below fully comply with the requirements of the European

Pressure Equipment Directive 97/23/EC, ATEX Directive 94/9/EC and carry the

and marks when so required.

The products fall within the following Pressure Equipment Directive categories:

Product

Group 1

Liquids

Group 2

Gases

Group 1

Gases

Group 2

Liquids

APT14 - 1 - SEP

APT14HC - 2 - SEP

APT14SHC - 2 - SEP

DCV10

DN40 PN25 rated - SEP - SEP

DN50 Class 300 rated - 1 - SEP

Motive strainer DN15 SEP SEP SEP SEP

Product marking per ATEX Directive 94/9/EC II 2G CT3.

i) The products have been designed for use on steam, air and water/condensate

which are in Group 2 of the above mentioned Pressure Equipment Directive. The

products’ use on other fluids may be possible but, if this is contemplated, Spirax

Sarco should be contacted to confirm the suitability of the product for the

application being considered.

ii) Check material suitability, pressure and temperature and their maximum and

minimum values. If the maximum operating limits of the product are lower than

those of the system in which it is being fitted, or if malfunction of the product

could result in a dangerous overpressure or overtemperature occurrence, ensure

a safety device is included in the system to prevent such over-limit situations.

iii) Determine the correct installation situation and direction of fluid flow.

iv) Spirax Sarco products are not intended to withstand external stresses that may

be induced by any system to which they are fitted. It is the responsibility of the

installer to consider these stresses and take adequate precautions to minimise

them.

v) Remove protection covers including cardboard support flanges from all

connections before installation.

1. Safety information

IM-P612-04 ST Issue 12

3

1.2 Access

Ensure safe access and if necessary a safe working platform (suitably guarded)

before attempting to work on the product. Arrange suitable lifting gear if required.

1.3 Lighting

Ensure adequate lighting, particularly where detailed or intricate work is required.

1.4 Hazardous liquids or gases in the pipeline

Consider what is in the pipeline or what may have been in the pipeline at some

previous time. Consider: flammable materials, substances hazardous to health,

extremes of temperature.

1.5 Hazardous environment around the product

Consider: explosion risk areas, lack of oxygen (e.g. tanks, pits), dangerous gases,

extremes of temperature, hot surfaces, fire hazard (e.g. during welding), excessive

noise, moving machinery.

1.6 The system

Consider the effect on the complete system of the work proposed. Will any proposed

action (e.g. closing isolation valves, electrical isolation) put any other part of the

system or any personnel at risk?

Dangers might include isolation of vents or protective devices or the rendering

ineffective of controls or alarms. Ensure isolation valves are turned on and off in a

gradual way to avoid system shocks.

1.7 Pressure systems

Ensure that any pressure is isolated and safely vented to atmospheric pressure.

Consider double isolation (double block and bleed) and the locking or labelling of

closed valves. Do not assume that the system has depressurised even when the

pressure gauge indicates zero.

1.8 Temperature

Allow time for temperature to normalise after isolation to avoid danger of burns.

1.9 ools and consumables

Before starting work ensure that you have suitable tools and/or consumables available.

Use only genuine Spirax Sarco replacement parts.

1.10 Protective clothing

Consider whether you and/or others in the vicinity require any protective clothing

to protect against the hazards of, for example, chemicals, high/low temperature,

radiation, noise, falling objects, and dangers to eyes and face.

IM-P612-04 ST Issue 12

4

1.11 Permits to work

All work must be carried out or be supervised by a suitably competent person.

Installation and operating personnel should be trained in the correct use of the

product according to the Installation and Maintenance Instructions.

Where a formal 'permit to work' system is in force it must be complied with. Where

there is no such system, it is recommended that a responsible person should know

what work is going on and, where necessary, arrange to have an assistant whose

primary responsibility is safety.

Post 'warning notices' if necessary.

1.12 Handling

Manual handling of large and/or heavy products may present a risk of injury. Lifting,

pushing, pulling, carrying or supporting a load by bodily force can cause injury

particularly to the back. You are advised to assess the risks taking into account the

task, the individual, the load and the working environment and use the appropriate

handling method depending on the circumstances of the work being done.

Please note

For specific details relating to the weight and internal mechanism of these products,

see Section 2.

Product specific - safe lifting information

Please note that the Spirax Sarco APT14 automatic pump trap units come complete

with holes which may be tapped or untapped. These holes may be used for lifting

purposes at the sole risk and responsibilty of the purchaser.

The purchaser is responsible for the selection and use of the correct eye-bolt or

shackle combination and is, in whole, responsible for all lifting operations and

operator competency at their location. Spirax Sarco will ensure that any tapped hole

will have a spot face larger than the shoulder of a standard eye-bolt to allow seating

down to the shoulder. However, it should not be assumed that an eye-bolt is suitable

for lifting the product simply on the basis of shoulder size.

Spirax Sarco will accept no responsibility for loss or damage real or imagined, caused

by incorrect or inappropriate lifting of our products.

Spirax Sarco will ensure that the tapped holes provided are clearly marked with the

exact size and thread form. We will also carry out in conjunction with a third party,

a test on a sample of each product so provided and make available a copy of the test

procedure and test certificate on request.

Furthermore and without obligation Spirax Sarco will attach to each product provided

with such holes, threaded or otherwise, a disclaimer affixed to the product explaining

the purchaser's duty under the LOLER regulations for safe off-loading and lifting of

the product at their premises.

IM-P612-04 ST Issue 12

5

1.13 Residual hazards

In normal use the external surface of the product may be very hot. If used at the

maximum permitted operating conditions the surface temperature of these products

may reach temperatures of 200 °C (392 °F).

These products are not self-draining. Take due care when dismantling or removing

the product from an installation (refer to 'Maintenance instructions').

1.14 Freezing

Provision must be made to protect products which are not self-draining against

frost damage in environments where they may be exposed to temperatures below

freezing point.

1.15 Disposal

Unless otherwise stated in the Installation and Maintenance Instructions, this product

is recyclable and no ecological hazard is anticipated with its disposal

providing due care is taken.

1.16 Returning products

Customers and stockists are reminded that under EC Health, Safety and Environment

Law, when returning products to Spirax Sarco they must provide information on any

hazards and the precautions to be taken due to contamination residues or mechanical

damage which may present a health, safety or environmental risk. This information

must be provided in writing including Health and Safety data sheets relating to any

substances identified as hazardous or potentially hazardous.

IM-P612-04 ST Issue 12

6

2.1 General description

The Spirax Sarco automatic pump trap is a flanged or screwed displacement receiver

pressure rated to PN16. The unit is capable of automatically trapping or pumping, depending

on pipeline conditions. The unit is operated by steam and is used to remove condensate

from process plant under all operating conditions including vacuum.

2. Product information

Fig. 1 APT14 shown

Design compliance

The shell of the product has been designed in accordance with A.D. Merkblatter/ASME VIII.

IM-P612-04 ST Issue 12

7

Optional extra

Both the APT14 and APT14HC are available with the body and cover coated with

electroless nickel plate (ENP). This option, when required, will be denoted as APT14

ENP and APT14HC ENP respectively and must be stated at the time of order placement.

The APT14, APT14HC and APT14SHC are available with the body drilled, tapped

and plugged to accept sight level gauges. Note: Sight level gauges can not be fitted

retrospectively to the standard APT14, APT14HC or APT14SHC.

Sight level gauges, supplied separately, are available for the APT14, APT14HC or

APT14SHC. For further details contact Spirax Sarco.

Standards

These products fully comply with the requirements of the European Pressure Equipment

Directive 97/23/EC, ATEX Directive 94/9/EC and carry the and marks when

so required.

Certification

These products are available with certification to EN 10204 3.1. Note: All certification /

inspection requirements must be stated at the time of order placement.

2.2 Sizes and pipe connections

Model

and body

material

Inlet and outlet sizes

and pipe connections

Motive/exhaust

APT14

SG iron

Flanged

DN40 inlet x DN25 outlet

EN 1092 PN16 BSP or NPT DN15 (½")

ASME B 16.5 (ANSI) 150 NPT DN15 (½")

JIS 10 (JIS B 2210) BSP DN15 (½")

KS 10 (KS B 1511) BSP DN15 (½")

Screwed

1½" inlet x 1" outlet

BSP (BS 21 parallel) BSP DN15 (½")

NPT NPT DN15 (½")

APT14HC

SG iron

Flanged

DN50 inlet x DN40 outlet

EN 1092 PN16 BSP DN15 (½")

ASME B 16.5 (ANSI) 150 NPT DN15 (½")

APT14SHC

Carbon

steel

JIS 10 (JIS B 2210) BSP DN15 (½")

KS 10 (KS B 1511) BSP DN15 (½")

IM-P612-04 ST Issue 12

8

2.3 Pressure / temperature limits APT14 and APT14HC (SG iron) - see Section 2.4 for the APT14SHC

The product must not be used in this region.

The product should not be used in this region or beyond its operating range as

damage to the internals may occur.

A - D Flanged PN16.

B - D Flanged JIS/KS 10.

C - D Flanged ANSI 150.

Temperature °C

Pressure bar g

A

Steam

saturation

curve

C

D

Pressure psi g

Temperature °F

B

IM-P612-04 ST Issue 12

9

Body design conditions

PN16

Maximum motive inlet pressure

13.8 bar g (200 psi g)

PMA Maximum allowable pressure

16 bar g @ 120 °C (232 psi g @ 248 °F)

TMA Maximum allowable temperature

300 °C @ 12.8 bar g (572 °F @ 186 psi g)

Minimum allowable temperature

Note: For lower temperatures consult Spirax Sarco.

-10 °C (14 °F)

PMO

Maximum operating pressure for

saturated steam service

13.8 bar g @ 198 °C (200 psi g @ 388 °F)

Maximum backpressure - for standard pumps

Note: For higher backpressures contact Spirax Sarco

5 bar g (72.5 psi g)

TMO

Maximum operating temperature for

saturated steam service

198 °C @ 13.8 bar g (388 °F @ 200 psi g)

Minimum operating temperature

Note: For lower temperatures consult Spirax Sarco.

-10 °C (14 °F)

Temperature limits (Ambient )

-10 °C to 200 °C (14 °F to 392 °F)

Designed for a maximum cold hydraulic test pressure of:

24 bar g (348 psi g)

Filling/

Installation

head

Recommended filling head above the pump

(from the base of the receiver/process)

0.3 m (12")

Maximum recommended installation head

(from the base of the pump) for higher

installation heads refer to Spirax Sarco

1 m (39")

Minimum installation head required (from the

base of the pump)

0.2 m (8")

IM-P612-04 ST Issue 12

10

2.4 Pressure / temperature limits APT14SHC (Carbon steel) - see Section 2.3 for the APT14 and APT14HC

Temperature °C

Pressure bar g

Pressure bar g

Temperature °C

D

Pressure psi g

Temperature °F

Steam

saturation

curve

Pressure psi g

D

C

B

A

Steam

saturation

curve

Temperature °F

The product must not be used in this region.

The product should not be used in this region or beyond its operating range as

damage to the internals may occur.

A - D Flanged PN16.

B - D Flanged JIS/KS 10.

C - D Flanged ANSI 150.

IM-P612-04 ST Issue 12

11

Body design conditions

PN16

Maximum motive inlet pressure

13.8 bar g (200 psi g)

PMA Maximum allowable pressure

16 bar g @ 120 °C (232 psi g @ 248 °F)

TMA Maximum allowable temperature

300 °C @ 12.8 bar g (572 °F @ 186 psi g)

Minimum allowable temperature

Note: For lower temperatures consult Spirax Sarco.

-10 °C (14 °F)

PMO

Maximum operating pressure for

saturated steam service

13.8 bar g @ 198 °C (200 psi g @ 388 °F)

Maximum backpressure - for standard pumps

Note: For higher backpressures contact Spirax Sarco

5 bar g (72.5 psi g)

TMO

Maximum operating temperature for

saturated steam service

198 °C @ 13.8 bar g (388 °F @ 200 psi g)

Minimum operating temperature

Note: For lower temperatures consult Spirax Sarco.

-10 °C (14 °F)

Temperature limits (Ambient )

-10 °C to 200 °C (14 °F to 392 °F)

Designed for a maximum cold hydraulic test pressure of:

24 bar g (348 psi g)

Filling/

Installation

head

Recommended filling head above the pump

(from the base of the receiver/process)

0.3 m (12")

Maximum recommended installation head

(from the base of the pump) for higher

installation heads refer to Spirax Sarco

1 m (39")

Minimum installation head required (from the

base of the pump)

0.2 m (8")

IM-P612-04 ST Issue 12

12

2.4 Nominal capacities

For full capacity details for a specific application consult Spirax Sarco. To accurately size

the pump trap, the following data is required.

1.Installation head available, from the base of the pump trap to the centre line of the heat

exchanger / process condensate outlet (metres, feet or inches). If the outlet is mounted

vertically, then this should be from the base of the pump to the face of the outlet.

2. Motive steam pressure available to power the pump trap (bar g or psi g).

3. Total backpressure in the condensate return system (bar g or psi g). See note below.

4. Heat exchanger full-load operating pressure (bar g or psi g).

5. Heat exchanger maximum steam load (kg/h or lb/h).

6. Minimum temperature of secondary fluid. ( °C).

7. Maximum controlled temperature of secondary fluid ( °C or °F).

Model APT14 APT14HC and APT14SHC

Pump discharge/cycle

5 litres

(1.1 gallons)

8 litres

(1.76 gallons)

At:

1 metre installation head

5 bar g motive pressure

1 bar g total

backpressure

Maximum trapping

capacity

4 000 kg/h

(8 820 lb/h)

Maximum trapping

capacity

9 000 kg/h

(19 845 lb/ h)

Maximum pumping

capacity

1 100 kg/h

(2 425 lb/h)

Maximum pumping

capacity

2 800 kg/h

(6 174 lb / h)

Note:

The capacities detailed within the above Table are only given as a guide. They are based

on the installation parameters shown in the left hand column.

Achieved capacities will differ if any of the installation parameters change. For specific

capacities and application details, contact Spirax Sarco.

The total lift or backpressure BP (static head plus pressure head in the return system)

must be below the motive fluid inlet pressure to allow pump capacity to be achieved.

BP (backpressure) = (H x 0.098 1 m) + (P) + (Pf)

Height (H) in metres x 0.098 1 plus pressure (P) bar g in the return line, plus downstream

piping friction pressure drop (Pf) in bar.

(Pf can be ignored if the downstream pipework is less than 100 metres to a non-flooded

condensate return and has been sized to take into account the effect of flash steam at the

heat exchanger's full-load operating conditions.)

IM-P612-04 ST Issue 12

13

2.5 Dimensions / weights

Metric (approximate) in mm and kg

Model

A B C D E F G H I J Weight

PN16 ANSI

APT14

Screwed 350 19 8 246 385 304 258 57 250 - - 19 8 45

Flanged 389 198 246 385 304 258 57 250 - - 198 45

APT14HC Flanged 476 198 270 400 335 261 57 275 31.5 45 198 65

APT14SHC Flanged 508 206 278 407 351 261 57 275 31.5 45 206 105

Imperial (approximate) in inches and lbs

APT14

Screwed 13.78 7. 8 9.69 15.16 11. 97 10.16 2.24 9.84 - - 7. 8 0 99.26

Flanged 15. 31 7. 8 9.69 1 5.16 11. 9 7 10.16 2.24 9.84 - - 7. 8 0 99.26

APT14HC Flanged 18.74 7. 8 10.63 15.75 13.1 9 10.27 2.24 10.83 1.24 1.77 7. 8 0 143.33

APT14SHC Flanged 99.9 8.1 10.94 16.62 13.82 10.27 2.24 10.83 1.24 1.77 8 .11 231.53

Motive

steam

supply

B

D

F

E

H

I

Exhaust

C

J

Fig. 2

A

G

Note:

Installation of

a DN40 outlet

check valve

type DCV10

is required

for the

APT14HC and

APT14SHC

only

S E

Withdrawal

distance

IM-P612-04 ST Issue 12

14

2.6 Materials

No. Part Material

1 Cover

APT14 SG iron en js 1025 or ASTM A395

APT14HC SG iron en js 1025 or ASTM A395

APT14SHC Carbon steel en 1.0619+N or ASTM A216 WCB

2 Cover gasket Graphite laminated with stainless steel insert

3 Body

APT14 SG iron en js 1025 or ASTM A395

APT14HC SG iron en js 1025 or ASTM A395

APT14SHC Carbon steel en 1.0619+N or ASTM A216 WCB

4

Cover bolts Stainless steel ISO 3506 Gr. A2 70

4 x location pins

(APT14SHC only)

Stainless steel 304

5 Pump lever Stainless steel BS 1449 304 S15

6 Float Stainless steel BS 1449 304 S15

7 Trap lever Stainless steel BS 1449 304 S15

8 Tra p 2nd stage valve Stainless steel ASTM A276 440 B

9 Trap housing Stainless steel BS 3146 ANC 2

10 Ball (APT14 only) Stainless steel ASTM A276 440 B

11 Seat (inlet check valve) Stainless steel AISI 420

12 Flap (inlet check valve) Stainless steel BS 3146 ANC 4B

13 Pump mechanism bracket Stainless steel BS 3146 ANC 4B

14 Spring (pump) Stainless steel BS 2056 302 S26 Gr. 2

15 Split pin Stainless steel BS 1574

16 Exhaust seat Stainless steel BS 970 431 S29 or ASTM A276 431

For parts 17 to 29, go to pages 16 and 17

IM-P612-04 ST Issue 12

15

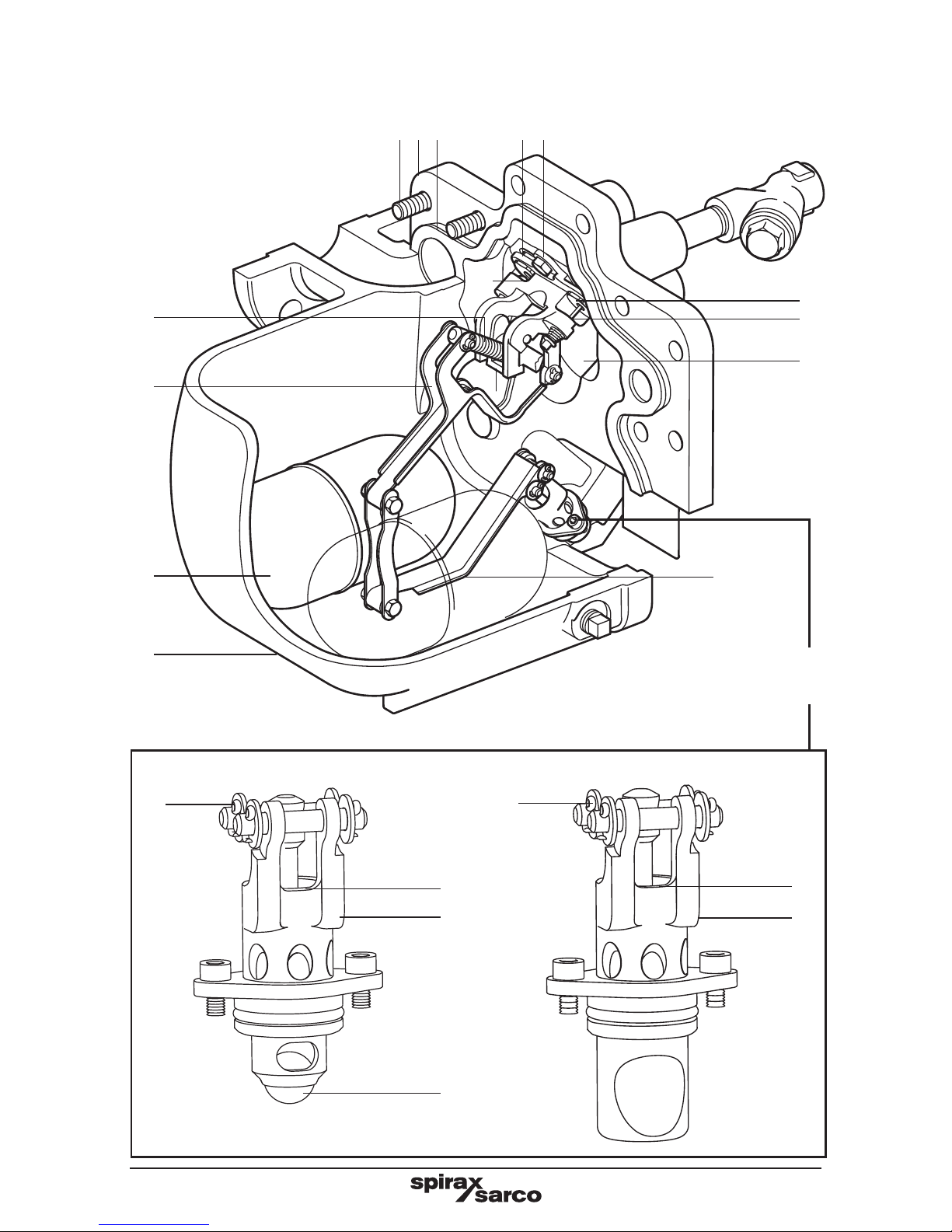

3

6

14

5

1

24

13

16

7

9

8

10

15

APT14

11

APT14HC and APT14SHC

9

8

15

Trap

mechanism

Fig. 3

IM-P612-04 ST Issue 12

16

For parts 1 to 16, go to pages 14 and 15

2.6 Materials

No. Part Material

17 Inlet valve and seat assembly Stainless steel

18 Exhaust valve Stainless steel BS 3146 ANC 2

19 Valve seat gasket Stainless steel BS 1449 409 S19

20 Pump mechanism bolt Stainless steel ISO 3506 Gr. A2 70

21 Trap housing bolt Stainless steel BS 6105 A4 80

22 Tr a p 1st stage valve Stainless steel BS 970 431 S29 or ASTM A276 431

23 'O' ring EPDM

24 Actuator arm Stainless steel BS 3146 ANC 2

25 Name-plate Stainless steel BS 1449 304 S16

26 Drain plug Steel DIN 17440 1.4571

27 Inlet valve spring Stainless steel

28 Motive strainer

APT14 SG iron

APT14HC SG iron

APT14SHC Carbon steel

29

DCV10

(APT14HC and APT14SHC only)

Stainless steel

(not shown)

2.7 Disposal

There are no hazardous materials used in the construction of this product. Any unwanted

material should be recycled or disposed of in an environmentally friendly manner as specified

in Section 1, Safety information.

IM-P612-04 ST Issue 12

17

18

19 28

20

21

24

25

26

27

22

23

APT14

21

17

APT14HC and APT14SHC

22

23

15

21

Trap

mechanism

Fig. 4

IM-P612-04 ST Issue 12

18

3. Operation

Step 1 (Figure 5)

The APT14, APT14HC and

APT14SHC automatic pump trap

operates on a positive displacement

principle. Condensate enters the

body through the inlet swing check

valve causing the float to rise.

The float is connected to the trap

mechanism via a multi-link pivot.

If the upstream system pressure

PS is sufficient to overcome the

backpressure PB (Figure 4), the

build up of condensate will be

discharged through the opening two

stage trap mechanism.

In this way, the float will

automatically modulate according to

the rate of condensate entering the

unit, controlling the rate of opening

and closure of the trap.

Step 3 (Figure 7)

However, with the APT14, APT14HC and

APT14SHC, the condensate simply fills

the main chamber - lifting the float until the

changeover linkage is engaged, opening

the motive inlet and closing the exhaust

valve.

Step 2 (Figure 6)

With some temperature controlled

equipment, it is possible for the

system pressure PS to be lower

than the backpressure at PB

(Figure 6).

If this occurs a standard trap will

stall allowing the condensate to

flood the equipment being drained.

Fig. 5 APT14 shown

Fig. 6 APT14 shown

Fig. 7 APT14 shown

Condensate

inlet PS

Exhaust

Condensate

outlet PB

Condensate

inlet PS

Exhaust

Condensate

outlet PB

Motive

steam

inlet

IM-P612-04 ST Issue 12

19

Step 4 (Figure 8)

The snap action mechanism ensures

a rapid change from the trapping

mode to the active pumping mode.

With the motive inlet valve open, the

pressure in the APT14, APT14HC

and APT14SHC increases above

the total backpressure and the

condensate is forced out through

the trap seat into the plant’s return

system.

Step 5 (Figure 9)

As the condensate level falls

within the main chamber, the

float re-engages the change

over linkage, causing the motive

inlet to close and the exhaust

valve to open.

Step 6 (Figure 10)

As the pressure inside the APT14

equalises with the condensate inlet

pressure through the open exhaust

valve, condensate re-enters via

the inlet swing check valve. At the

same time the outlet ball check

valve (APT14 only) ensures no

condensate can drain back into the

main chamber and the trapping or

pumping cycle begins again.

Note: The APT14HC and

APT14SHC requires an external

Spirax Sarco DN40 disc check

valve to be fitted to the condensate

outlet, between the flanges.

Fig. 10 APT14 shown

Fig. 9 APT14 shown

Fig. 8 APT14 shown

Motive

steam

inlet

Condensate

inlet PS

Exhaust

Condensate

outlet PB

Condensate

inlet PS

Exhaust

Condensate

outlet PB

Return to Step 1.

IM-P612-04 ST Issue 12

20

4. Installation

Important - safety note

Please read Section 1.12 regarding the safe lifting of this product before actioning

any installation or maintenance procedure.

Before any installation or maintenance procedure, always ensure that all steam or

condensate lines are isolated.

Ensure any residual internal pressure in the product or connecting lines is carefully

relieved. Also ensure any hot parts have cooled to prevent risk of injury from burns.

Always wear appropriate safety clothing before carrying out any installation or

maintenance work.

Note: If pumping a potentially explosive media, the motive supply media must be an

inert gas with no oxygen present.

IM-P612-04 ST Issue 12

21

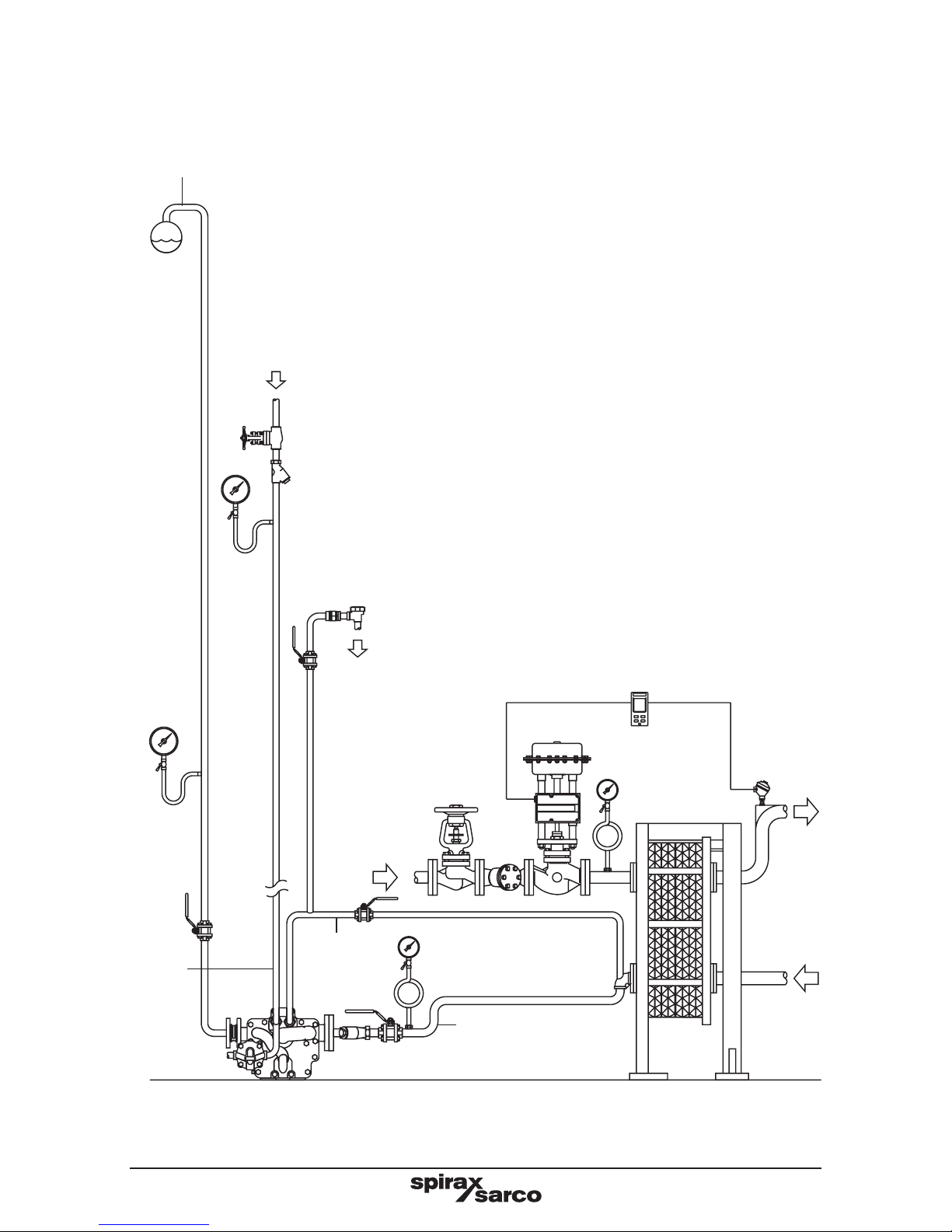

Motive IN

Strainer fitted with 100 mesh screen.

Note: The APT's are all supplied with a strainer close coupled

to the steam inlet connection.

† Minimum installation head

0.2 m (8") from base of pump.

Recommend minimum 0.3 m,

maximum 1 m.

Condensate

outlet

Spirax Sarco sized length

of pipe to act as a reservoir

Balance

line

Exhaust

OUT

Condensate

inlet

Strainer

Outlet DCV10 between flanges (APT14HC and

APT14SHC only)

An air vent must be fitted higher than the inlet to the process.

†

Fig. 11

*Trapped motive steam supply

Soft sealing flanged or screwed DCV

0.2 m

(8")

It is recommended that the reservoir be installed at

least 1 pipe diameter below the process outlet, but

as high as possible above the APT14, APT14HC or

APT14SHC inlet (up to 1 metre (40")).

IM-P612-04 ST Issue 12

22

4.1 Inlet piping

To prevent condensate backing up into the equipment being drained, it is recommended that

the inlet pipework is sufficiently sized to accumulate condensate during the pump’s discharge

cycle. Generally a length and diameter of pipe to accommodate the following condensate

capacity will be sufficient: 4 litres (1.1 gallons) for an APT14 or 8 litres (1.76 gallons) for an

APT14HC and APT14SHC. It is recommended this condensate reservoir is situated at least

1 pipe diameter below the process outlet but as high as possible above the APT inlet (up to

1 metre (40")). It is essential that a Spirax Sarco Y-type strainer is fitted at the condensate

inlet of the APT14, APT14HC and APT14SHC, as shown in Figure 12.

4.2 Recommended installation head

An installation head of at least 0.3 m (12 ins) from the base of the unit is recommended.

Minimum 0.2 m (8") with reduced capacity; Maximum 1 m (40"). Note: During cold start-up

conditions, it is possible for hydraulic pulsing of the inlet check valve to occur. It is advisable

in this case to install a throttling isolation valve to reduce the filling pressure.

4.3 Connections (refer to the installation diagram, Figure 12)

The APT's have four connection ports. The DN40 (1½") - APT14 or DN50 (2") - APT14HC

and APT14SHC port should be connected to the outlet of the equipment being drained.

The DN25 (1") - APT14 or DN40 (1½") APT14HC and APT14SHC port should be connected

to the condensate return line. Flow arrows indicate the correct direction of flow. The DN15

(½") port marked (S) should be connected to a trapped motive steam supply. * It is

important to ensure this line is drained of condensate at all times using a Spirax

Sarco steam trap and filtered using a 100 mesh strainer as fitted (see Figure 11).

The screwed DN15 (½") port marked (E) should be balanced back as close as possible

to the condensate outlet of the equipment. This balance line must always be connected

to the top of the condensate pipe, as shown in Figure 11. Note: If a thermal cut out device

has been installed to protect the heat exchanger from excess temperature, then it is

important this is mounted upstream of the steam control valve and the take-off point for

the motive steam supply to the APT14, APT14HC or APT14SHC.

Filtered / trapped motive steam supply line

Removable flanged or union section for

ease of maintenance

Spirax

Sarco

APT14

•

Ensure this

steam line is

correctly drained

of condensate at

all times using a

Spirax Sarco steam

trap plus the 100

mesh strainer as

fitted to the pump

to prevent debris

entering the pump

mechanism.

Fig. 12

Suggested coupling of

motive supply and exhaust

lines

250 mm (APT14)

275 mm (apt14hc

275 mm (APT14SHC)

minimum withdrawal

distance

IM-P612-04 ST Issue 12

23

4.4 Outlet piping

It is important for the outlet piping to be correctly sized to prevent excessive backpressure

on the APT14, APT14HC or APT14SHC. This pipework should be sized to take into account

the effects of flash steam at the heat exchangers full load operating conditions and any

other equipment being discharged into the return line.

Note: A separate Spirax Sarco DN40 DCV10 check valve must be fitted to the outlet flange

of the pump body and the connecting pipework flange - APT14HC and APT14SHC only.

Ensure the DCV10 is mounted centrally between the flanges with the directional flow arrow

pointing in the direction of fluid flow. A gasket should be used both sides of the disc check

valve. For all other maintenance and technical information see IM-P601-32.

Motive IN

Strainer fitted with 100 mesh screen.

Note: The APT's are all supplied with a strainer close coupled

to the steam inlet connection.

Condensate outlet

Spirax Sarco sized length

of pipe to act as a reservoir

Balance

line

Exhaust

OUT

Condensate inlet

Strainer

Outlet DCV10 between flanges

(APT14HC and APT14SHC only)

An air vent must be fitted higher than the inlet to the process.

†

Fig. 13

*Trapped motive steam supply

Soft sealing flanged or screwed DCV

0.2 m

(8")

It is recommended that the reservoir be installed at least 1 pipe diameter below the

process outlet, but as high as possible above the APT14, APT14HC or APT14SHC inlet.

† Minimum installation head

0.2 m (8") from base of pump.

Recommend minimum 0.3 m,

maximum 1 m.

IM-P612-04 ST Issue 12

24

4.5 Pressure gauges

It is recommended that system pressure gauges are fitted to the motive supply, condensate

inlet and condensate outlet as shown in Figure 14.

4.6 Control of motive supply pressure

Although the APT is able to utilise motive pressures up to 13.8 bar g (200 psi g), it is highly

recommended that the motive pressure does not exceed 3 to 4 bar g (44 to 58 psi g) above

the backpressure applied to the pump. When specifying a pressure reducing valve to

reduce the motive supply pressure, the effects of pulsating flow on the pressure reducing

valve must be considered. Contact Spirax Sarco for details of recommended installation if

required. The motive supply must be drained by a suitable steam trap to ensure the motive

steam is dry. See Figure 14.

Motive IN

Strainer fitted with 100 mesh screen.

Note: The APT's are all supplied with a strainer close coupled

to the steam inlet connection.

Spirax Sarco sized length

of pipe to act as a reservoir

Balance

line

Exhaust

OUT

Condensate inlet

Strainer

Outlet DCV10 between flanges

(APT14HC and APT14SHC only)

An air vent must be fitted higher than the inlet to the process.

†

Fig. 14

Soft sealing flanged or screwed DCV

0.2 m

(8")

It is recommended that the reservoir be installed at least 1 pipe diameter below the

process outlet, but as high as possible above the APT14, APT14HC or APT14SHC inlet.

Condensate

outlet

*Trapped motive steam supply

† Minimum installation head

0.2 m (8") from base of pump.

Recommend minimum 0.3 m,

maximum 1 m.

IM-P612-04 ST Issue 12

25

4.6.1 Fail safe condition of motive supply.

When the APT14 is used to remove condensate from temperature controlled plant such

as heat exchangers, it is recommended that the motive supply to the APT is taken from a

point downstream of a fail safe high limit control valve, see Figure 15.

Fig. 15

APT motive

steam supply

Fail safe

high limit

valve

Temperature

control valve

IM-P612-04 ST Issue 12

26

5.1

After ensuring the inlet and outlet pipe connections and motive/exhaust connections

are coupled in accordance with Figures 15 and 16, slowly open the motive steam inlet

line to supply pressure to the APT14, APT14HC or APT14SHC. Ensure the exhaust/

balance line is open and not restricted in any way.

5.2

Slowly open the isolation valves in the condensate inlet and discharge lines, allowing

condensate to fill the body of the APT14, APT14HC or APT14SHC.

5.3

The APT14, APT14HC or APT14SHC is now ready to operate.

5.4

When the process plant is operational, the APT14, APT14HC or APT14SHC will

discharge condensate under all pressure conditions into the return line.

5.5

If any irregularities are observed, recheck the installation according to the

recommendations in Section 4. If the unit fails to operate, then consult the fault finding

guide Section 9.

5. Commissioning

Fig. 16

Filtered / trapped motive steam supply line

Spirax

Sarco

APT14

Ensure this steam line is correctly drained of condensate at

all times using a Spirax Sarco steam trap plus the 100 mesh

strainer as fitted to the pump to prevent debris entering the

pump mechanism.

IM-P612-04 ST Issue 12

27

Return

line

Fig. 17 APT14HC shown

Motive

IN

Condensate

outlet

Exhaust

OUT

Condensate

inlet

Trapped motive steam supply

IM-P612-04 ST Issue 12

28

6.1 Mechanisms inspection and repair (Important - safety note)

Please read Section 1.12 regarding the safe lifting of this product before actioning

any installation or maintenance procedure.

Before any installation or maintenance procedure, always ensure that all steam or

condensate lines are isolated.

Ensure any residual internal pressure in the product or connecting lines is carefully

relieved. Also ensure any hot parts have cooled to prevent risk of injury from burns.

Always wear appropriate safety clothing before carrying out any installation or

maintenance work.

When dismantling this product, care should be taken to prevent injury from the snap

action mechanism. Always handle with care.

The APT14, APT14HC and APT14SHC should be inspected periodically, intervals

dependant on application. Contact Spirax Sarco for details.

6.2 Removal and fitting of cover assembly

Please ensure the safety recommendations are observed before commencing with any

maintenance of this product.

6.3 To remove the cover assembly

1. Disconnect all connections to the cover. Remove the cover bolts using the correct

size socket, then carefully slide the cover assembly away from the body (a minimum

withdrawal distance of 250 mm for the APT14 or 275 mm for the APT14HC and

APT14SHC will be needed). Lift the cover assembly to a bench or other convenient

working surface and clamp securely, avoiding contact with the gasket face.

2. Visually inspect the mechanism for obvious damage. Check that it is free of dirt and

scale and operates freely when the floats are moved up and down.

3. Inspect the spring assembly for damage. Make sure the valves slide freely and the

spring loaded exhaust valve moves on its guide.

4. Inspect the floats to ensure they are undamaged. Check they pivot smoothly on the

pump and trap levers and they are not waterlogged.

5. Ensure the inlet swing check valve is free to move and the sealing faces of both the

seat and the flap are clean and undamaged. (If the seat is badly scored or damaged a

new cover assembly may be required).

6. Check the two stage trap module to ensure both the 1st and 2nd stage valves are free

from dirt and debris. Ensure they slide open and close smoothly.

7. It is not possible to visually check the outlet check valve without removing the trap

module (refer to Section 8 of this manual for correct removal and fitting of this part APT14 only).

8. If any of the parts appear damaged or fail to work correctly, then refer to Sections 8

and 9 of this manual for correct removal and fitting instructions.

6. Maintenance

Loading...

Loading...