SpillTech

Sales & Marketing

5440 McGinnis Village Place

Suite 102

Alpharetta, GA 30005

Phone: 1-800-228-3877

Fax: 1-800-872-3764

Polyethylene Chemical Compatibility Guide Page 1 of 5

SpillTech

Manufacturing

Brookley Industrial Complex

1627 O’Donoghue Street

Mobile, AL 36615

Phone: 1-251-694-0102

Chemical Compatibility Guide

For Polyethylene Items

This Chemical Compatibility Guide is offered for informational purposes only and was developed from information sources

other than SpillTech. The information from such third party sources is believed to be reliable and accurate; however,

Purchaser should make its own determination of compatibility before using any SpillTech product.

It is the sole responsibility of the Purchaser to determine whether any product is suitable for Purchaser’s actual or

intended uses.

This listing was prepared to provide guidance to the chemical compatibility molded polyethylene. Polyethylene is

susceptible to attack by some chemicals which may cause stress cracking, swelling, oxidation or may permeate the

polyethylene. These reactions may reduce the physical properties of polyethylene.

When considering a polyethylene product for use in secondary containment applications, it is important to note that most

secondary containment products are designed to hold leaked chemicals for only hours, a day, at most a week. These

secondary containment units would then be cleaned of any chemical. In these short term applications, a greater variety

of chemicals may be used with the polyethylene since the exposure time of the chemical to the polyethylene is limited.

NO GUARANTEE, WARRANTY, OR REPRESENTATION IS MADE, INTENDED, OR IMPLIED AS TO THE CORRECTNESS OR

SUFFICIENCY OF THE CHEMICAL COMPATABILITY GUIDE OR ANY INFORMATION SUPPLIED HEREIN. THE PRODUCTS

DISCUSSED HEREIN ARE SOLD WITHOUT ANY WARRANTY AS TO MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE OR ANY OTHER WARRANTY, EXPRESSED OR IMPLIED. NO WAIVER, ALTERATION, ADDITION OR

MODIFICATION OF THE FOREGOING CONDITIONS SHALL BE VALID UNLESS MADE IN WRITING AND MANUALLY

SIGNED BY AN OFFICER OF SPILLTECH. IT IS THE PURCHASER’S SOLE RESPONSIBILITY TO CONDUCT TESTING TO

ESTABLISH THE SUITABILITY OF ANY PRODUCT FOR PURCHASER’S INTENDED USE. LIABILITY OF SPILLTECH FOR ALL

CLAIMS, WHETHER ARISING OUT OF A BREACH OF CONTRACT, WARRANTY, NEGLIGENCE, STRICT LIABILITY, OR

OTHERWISE, IS LIMITED TO THE PURCHASE PRICE OF THE MATERIAL SUPPLIED.

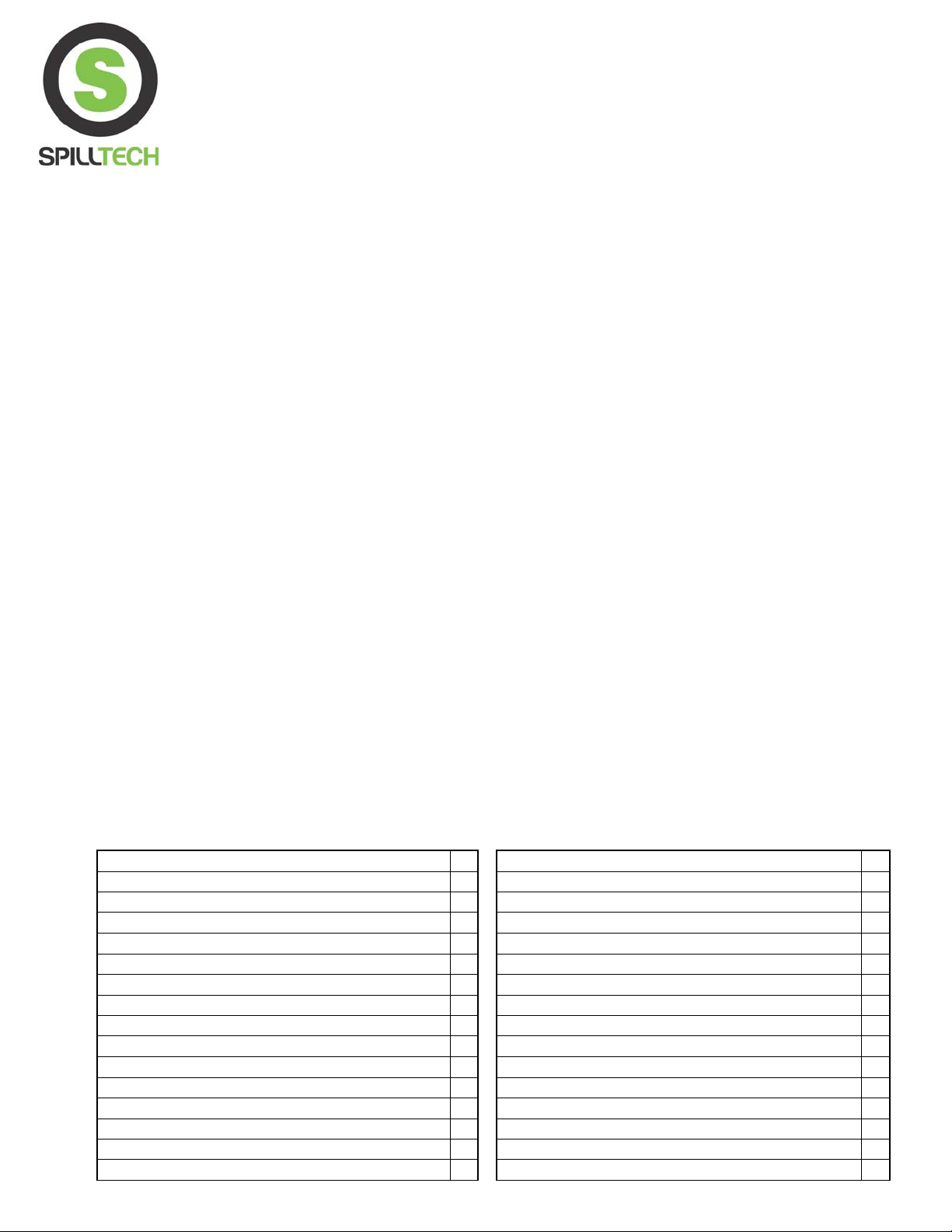

Rating Key:

L = Products should be suitable for

S =These substances may adversely affect the polyethylene. Products may be suitable for intermittent contact; however,

some deterioration in properties may occur. The user should perform qualification tests before or during usage of the

container.

N =These substances aggressively attack polyethylene or have vapor pressures incompatible with closed containers. Do

not use polyethylene containers in these applications.

Acetaldehyde (40%) L Hydrofluorisilicic Acid (All Conc.) L

Acetamide L Hydrogen Bromide (10%) L

Acetic Acid (50%) L Hydrogen Peroxide (90%) L

Acetic Acid (100%) N Hydrogen Phosphide 100% L

Acetic Acid Anhydride S Hydroquinone L

Acetic Ether S Hydrogen Sulfide L

Acetone L Hypochlorous Acid L

Acetylene Tetrabromide S Inks L

Acrylic Emulsions S Iodine (Alc. Sol.) Conc. L

Acrylonitrile L Iron Salts L

Adipic Acid L Iso-Octane S

Aliphatic Hydrocarbons (Hexane, Octane, etc) L Isopropyl Acetate L

Allyl Alcohol (96%) L Isopropyl Alcohol L

Alum (Aqueous Solutions) L Isopropyl Ether N

Aluminum Chloride (20%) L Jetfuel S

Aluminum Fluoride L Kerosene S

prolonged or repeated contact with these substances, under the conditions specified.

Aluminum Hydrogen Solution (10%) L Lactic Acid (All Conc.) L

Aluminum Hydroxide L Lanolin L

Alums (All Types) L Latex L

Ammonia (Anhydrous) L Lead Salts L

Ammonia (Aqueous) L Lead Acetate Sat’d L

Ammonia (100% Dry Gas) L Lime L

Ammonium Salts L Linseed Oil L

Ammonium Acetate L Lithium Salts L

Ammonium Biflouride L Lube Oil L

Ammonium Carbonate 50% L Magnesium Salts L

Ammonium Chloride L Magnesium Carbonate L

Ammonium Hydrogen Fluoride (50%) L Magnesium Hydroxide L

Ammonium Hydroxide L Magnesium Nitrate L

Ammonium Metaphosphate Sat’d L Magnesium Oxide L

Ammonium Nitrate (10%) L Magnesium Sulfate L

Ammonium Nitrate Sat’d L Maleic Acid L

Ammonium Persulfate Sat’d L Malic Acid (1%) L

Ammonium Phosphate L Mercuric Salts L

Ammonium Sulfate (1)%) L Mercurous Salts L

Ammonium Sulfate Sat’d L Mercury L

Ammonium Sulfide Sat’d L Methanol L

Ammonium Thiocyanate Sat’d L Methyl Acetate L

Amyl Acetate L Methyl Alcohol (100%) L

Amyl Alcohol (100%) L Methyl Amine (32%) L L

Amyl Chloride N Methyl Bromide N

Aniline (100%) S Methyl Chloride N

Aniline Hydrochloride S Methylene Chloride N

Animal Fats L Methyl Ethyl Ketone S

Anti-Freeze L Methyl Isobutyl Ketone S

Antimony Salts L Methyl Isopropyl ketone S

Antimony Trichloride 90% L Methyl Sulfate L

Aqua Regia N Methyl Sulfuric Acid (All Conc.) L

Aqueous Salt Solutions (NaCl) L Milk L

Aqueous Alkalies (NaOH) L Mineral Oils L

Arsenic Acid L Molasses L

Arsenic Salts L Monochloroacetic Acid Ethyl Ester L

Barium Salts L Monochloroacetic Acid Methyl Ester L

Barium Carbonate L Morpholin L

Barium Chloride L Mowilith D L

Barium Cyanide L Muriatic Acid L

Barium Hydroxide L Naptha S

Barium Nitrate L Napthalene S

Barium Sulfate L Nickel Salts L

Barium Sulfide L Nicotine Dilute L

Battery Fluid Acid S Nicotinic Acid L

Beef Tallow Emulsion, Sulfonated L Nitric Acid <50% L

Beer L Nitrobenzene S

Benzaldehyde L Nitrotoluene S

Benzene L Octyl Cresol L

Benzene Sulfonic Acid S Oils and Fats L

Benzoic Acid L Oleic Acid (All Conc.) L

Benzyl Alcohol L Oleum Conc. N

Benzyl Chloroformate L Olive Oil L

Bismuth Salts L Orange Extract L

Polyethylene Chemical Compatibility Guide Page 2 of 5

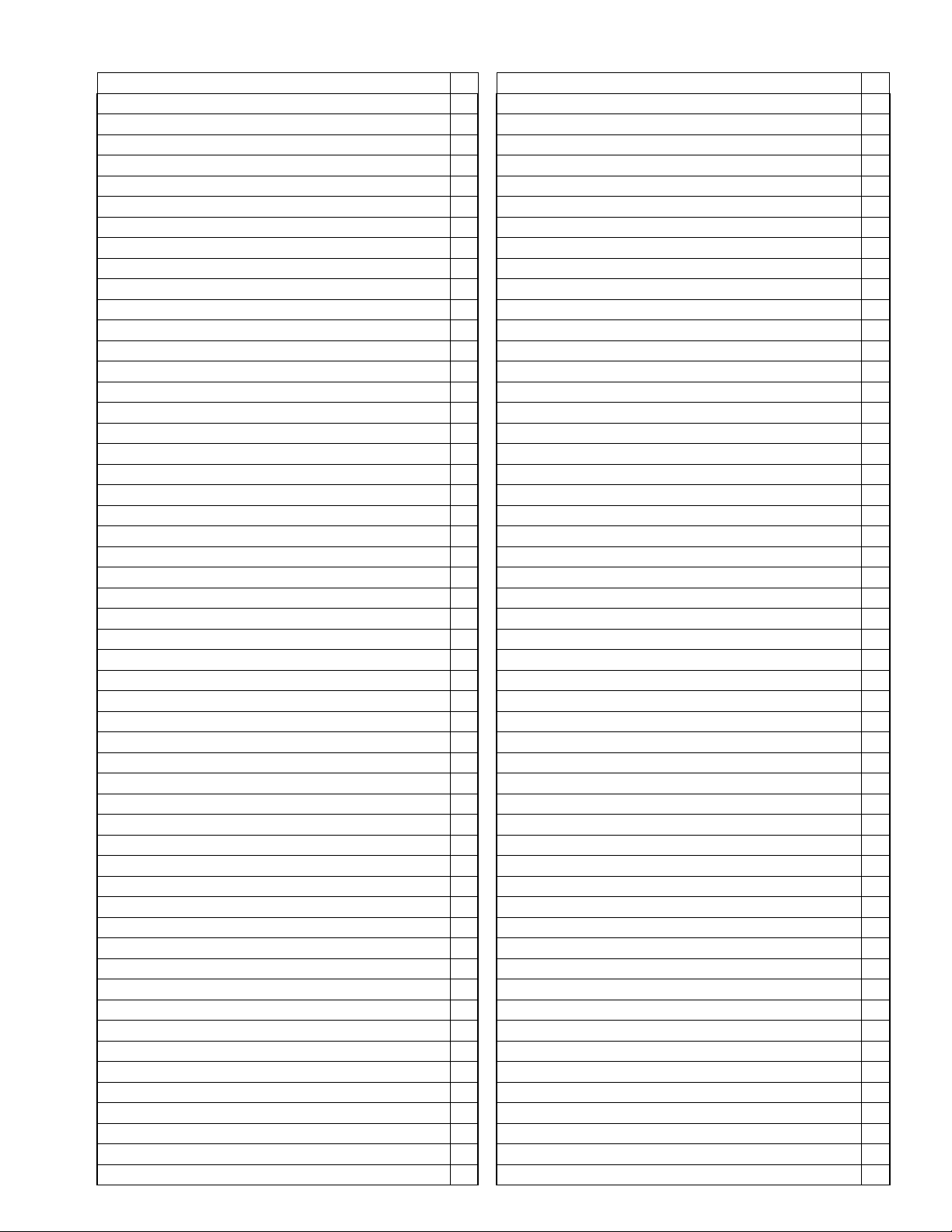

Bleach Lye (10%) S Oxalic Acid (All Conc.) L

Black Liquor L Palmitic Acid N

Borax Cold Sat’d L Palm Oil S

Boric Acid Dilute L Paraffin Emulsions L

Boric Acid Conc. L Paraffin Oil L

Bromine Liquid N Perchloric Acid (50%) L

Bromine Water N Perchloroethylene N

Bromobenzene N Petroleum L

Bromoform N Petroleum Ether S

Butadiene L Phenol (90%) N

Butane L Phenylhydrazine N

Butanediol (100%) L Phosphoric Acid All Conc L

Butanol L Phosphorous Chlorides S

Butyl Acetate L Phosphorous Yellow (100%) L

Butyl Alcohol (100%) L Phosphorous Pentoxide L

Butylene N Photographic Solutions L

Butylene Glycol L Phthalic Acid (All Conc.) L

Butylene Liquid N Phthalic Anhydride L

Butyl Phenol N Pickling Baths Sulfuric Acid L

Butyric Acid L Pickling Baths Hydrochloric Acid L

Calcium Carbonate L Picric Acid (1%) L

Calcium Chloride L Plating Solutions L

Calcium Hydroxide L Potash L

Calcium Hypochlorite L Potassium/Aluminum Sulfates (50%) L

Calcium Nitrate (50%) L Potassium Bichromate L

Calcium Sulfate L Potassium Borate (10%) L

Camphor Oil N Potassium Bromide L

Carbon Disulfide N Potassium Chlorate L

Carbonic Acid (Aq.CO2) L Potassium Chloride L

Carbon Monoxide L Potassium Chromate L

Carbon Tetrachloride N Potassium Cyanide L

Castor Oil Conc. L Potassium Dichromate 40% L

Caustic (Aqueous) L Potassium Ferri/ Ferro Cyanide Sat’d L

Caustic Potash Sol. (50%) L Potassium Fluoride L

Caustic Soda Sol. (10%) L Potassium Hydroxide L

Chloral Hydrate L Potassium Iodide L

Chloroethanol L Potassium Nitrate Sat’d L

Chloric Acid (10%) L Potassium Perborate Sat’d L

Chloroacetic Acid L Potassium Perchlorate L

Chlorobenzene L Potassium Permanganate L

Chloroform N Potassium Persufate Sat’d L

Chloromethane N Potassium Phosphates L

Chlorosulfonic Acid 100% N Potassium Sulfate L

Chrome Alum Sat’d L Propanol L

Chromic Acid (50%) S Propargyl Alcohol (7%) L

Cider L Propionic Acid (50%) L

Citric Acid (All Conc.) L Propyl Alcohol L

Clorox Bleach L Propylene Dichloride (100%) L

Coconut Oil Alcohols L Propylene Glycol L

Cola Concentrates L Propylene Oxide L

Compressed Air Conditioning Oil L Pyridine S

Copper Salts L Rayon Coagulation Salts L

Copper Cyanide L Rust Inhibitors L

Copper Nitrate L Sea Water L

Polyethylene Chemical Compatibility Guide Page 3 of 5

Copper Sulfate L Selenic Acid L

Corn Oil L Sewage L

Cottonseed Oil L Shortening L

Cresol (90%) L Silicic Acid L

Cresylic Acid L Silicone Oil L

Crotonic Aldehyde L Silver Salts L

Cuprous Chloride Sat’d L Silver Nitrate L

Cyclohexane L Soda Solution (All Conc.) L

Cyclohexanol L Soda Ash L

Cyclohexanone S Sodium Salts L

Detergents (General) L Sodium Acetate Sat’d L

Developer, Photographic L Sodium Acrylates L

Dextrin Sat’d L Sodium Benzoate L

Dextrose Sat’d L Sodium Bicarbonate L

Dibutyl Ether N Sodium Bisulfate (10%) L

Dibutylphthalate S Sodium Bisulfite L

Dibutyl Sebacate S Sodium Bromate S

Dichloroacetic Acid S Sodium Bromide L

Dichloroacetic Acid / Methyl Ester S Sodium Bromide Dilute Sol. L

Dichlorobenzene Liquid N Sodium Carbonate L

Dichloroethylene N Sodium Chlorate L

Diesel Fuel S Sodium Chloride L

Diesel Oil S Sodium Chlorite L

Diethyl Carbonate L Sodium Chromate L

Disodium Phosphate L Sodium Disulfite L

Diazo Salts L Sodium Dithionite (10%) L

Diethylene Glycol L Sodium Ferricyanide L

Diethanolamine S Sodium Ferrocyanide Sat’d L

Diglycolic Acid (30%) L Sodium Fluoride Sat’d L

Di-Isobutyl Ketone S Sodium Hydroxide Conc. L

Dimethylamine S Sodium Hypochlorite L

Dimethyl Formamide S Sodium Iodide L

Dinonyl Phthalate N Sodium Nitrate L

Dioctyl Phthalate N Sodium Oxalate L

Dioxane L Sodium Persulfate L

Diphenyl Oxide N Sodium Phosphate L

Electrolyte L Sodium Silicate L

Emulsions, Photogtraphic L Sodium Sulfate L

Ethanol L Sodium Sulfide L

Ether N Sodium Sulfite L

Ethyl Acetate (100%) S Sodium Sulfonates L

Ethyl Alcohol L Sodium Thiosulfate L

Ethyl Butyrate S Spindle Oil L

Ethyl Chloride N Stannic Salts L

Ethyl Ether N Stannous Salts L

Ethylene Chloride N Starch Solution Sat’d L

Ethylene Chlorohydrin L Stearic Acid (All Conc.) L

Ethylene Diamine L Succinic Acid L

Ethylene Dichloride N Sugar Solutions (Glucose, Lactose, Sucrose, etc) L

Ethylene Glycol L Sulfur L

Ethylene Oxide N Sulfuric Acid (98%) S

Fatty Acids L Sulfuric Acid Fuming N

Fatty Alcohol Sulfonate L Sulfurous Acid L

Ferric Salts L Sulfuryl Chloride N

Polyethylene Chemical Compatibility Guide Page 4 of 5

Polyethylene Chemical Compatibility Guide Page 5 of 5

Ferric Sulfate L Tallow L

Ferrous Salts L Tannic Acid L

Ferrous Sulfate L Tanning Extracts L

Fertilizer Salts L Tartaric Acid Sat’d L

Fish Solubles L Tetrachloroethane N

Fluoboric Acid L Tetrachloroethylene N

Fluosilicic Acid (All Conc.) L Tetraethyl Lead L

Formaldehyde (40%) L Tetrahydrofuran N

Formamide L Tetrahydronaphthalene N

Formic Acid (All Conc.) L Thionyl Chloride N

Fruit Pulp L Tin Salts L

Fuel Oil L Titanium Salts S

Furfural (100%) L Toluene S

Furfuryl Alcohol N Toluene Sulfonic Acid S

Gallic Acid Sat’d L Transformer Oil L

Gasoline L Tributylphosphate L

Gasohol L Trichloroacetic Acid S

Gelatine L Trichloroethane N

Gin L Trichloroethylene N

Gluconic Acid (All Conc.) L Tricresyl Phosphate L

Glucose L Triethanolamine L

Glycerine L Trioctyl Phosphate N

Glycol L Trisodium Phosphate Sat’d L

Glycol Ethers L Trichloroethylene N

Glyocolic Acid (All Conc.) L Turpentine Oil N

Grape Sugar Sat’d Aq. L Urea L

Heptane L Urine L

Hexane L Vegetable Oils L

Hexanol Tert L Vinegar L

Hydrazine Hydrate L Vanilla Extract L

Hydrosulfite (10%) L Wax Alcohol N

Hydroxylamine Sulfate L Wetting Agents L

Hydrazine (35%) L Whisky L

Hydrazine Hydrochloride L White Acid (75%) L

Hydroiodic Acid (All Conc.) L Wine L

Hydrobromic Acid (50%) L Xylene N

Hydrocyanic Acid Sat’d L Yeast L

Hydrochloric Acid (All Conc.) L Zinc Salts L

Hydrofluoric Acid (All Conc.) L Zinc Sulfate L

Loading...

Loading...