Page 1

Spicer® Tandem Drive Axles

Service Manual

Spicer® Tandem Drive Axles

AXSM-8661

September 2007

Page 2

TABLE OF CONTENTS

Identification

Axle .............................................................................. 1

Model Numbering System ........................................... 2

Gear Set ........................................................................ 2

Axle Lubricant Recommendations .......................................... 3

General Precautions ................................................................4

Components

Power Divider ............................................................... 5

Axle (Forward Rear) .....................................................6

Axle (Rear Rear) ........................................................... 7

Removal of Differential Carrier from Axle Housing ............... 8

Removal of Differential from Carrier ...................................... 9

Disassembly

Differential .................................................................... 10

Inter-Axle Differential ................................................... 12

Intermediate Case ........................................................ 13

Pinion ............................................................................ 14

Output Shaft ................................................................. 15

Cleaning and Inspection ......................................................... 16

Assembly

Pinion ............................................................................ 17

Pinion Position ..............................................................18

Pinion Setting ................................................................20

Assembly

Ring Gear and Pinion Tooth Contact Pattern ........................ 29

Installation of Inter-Axle Differential to Carrier ..................... 30

Yoke Removal and Seal Replacement .................................... 30

Installation of Differential Carrier to Axle Housing ............... 31

Wheel Bearing Adjustment ..................................................... 32

Axle/Torque Specifications ............................................. 33-34

Recommended Service Tools .......................................... 35-36

(Continued)

Differential .................................................................... 22

Differential Installation ................................................ 23

Output Shaft ................................................................. 24

Intermediate Case ........................................................ 25

Inter-Axle Differential ................................................... 27

GENUINE SPICER SER VICE PARTS

Should an axle assembly require replacement component

parts, it is recommended that Spicer Heavy Axle Service

Parts be used. Spicer Heavy Axle Service Parts are

manufactured under the same rigid specification as are

original equipment axle components. This assures the

customer who uses genuine Spicer service parts, maximum reliability for a Spicer Heavy Axle assembly. They

may be obtained through your vehicle manufacturer.

The use of non-original Spicer service parts may cause

premature component failure and may void the warranty.

The items included in this book are currently being

offered as service parts at the time of printing. The part

numbers and illustrations are provided specifically for

reference purposes only. Therefore, Spicer reserves the

right to update this manual without notice or liability.

i

Page 3

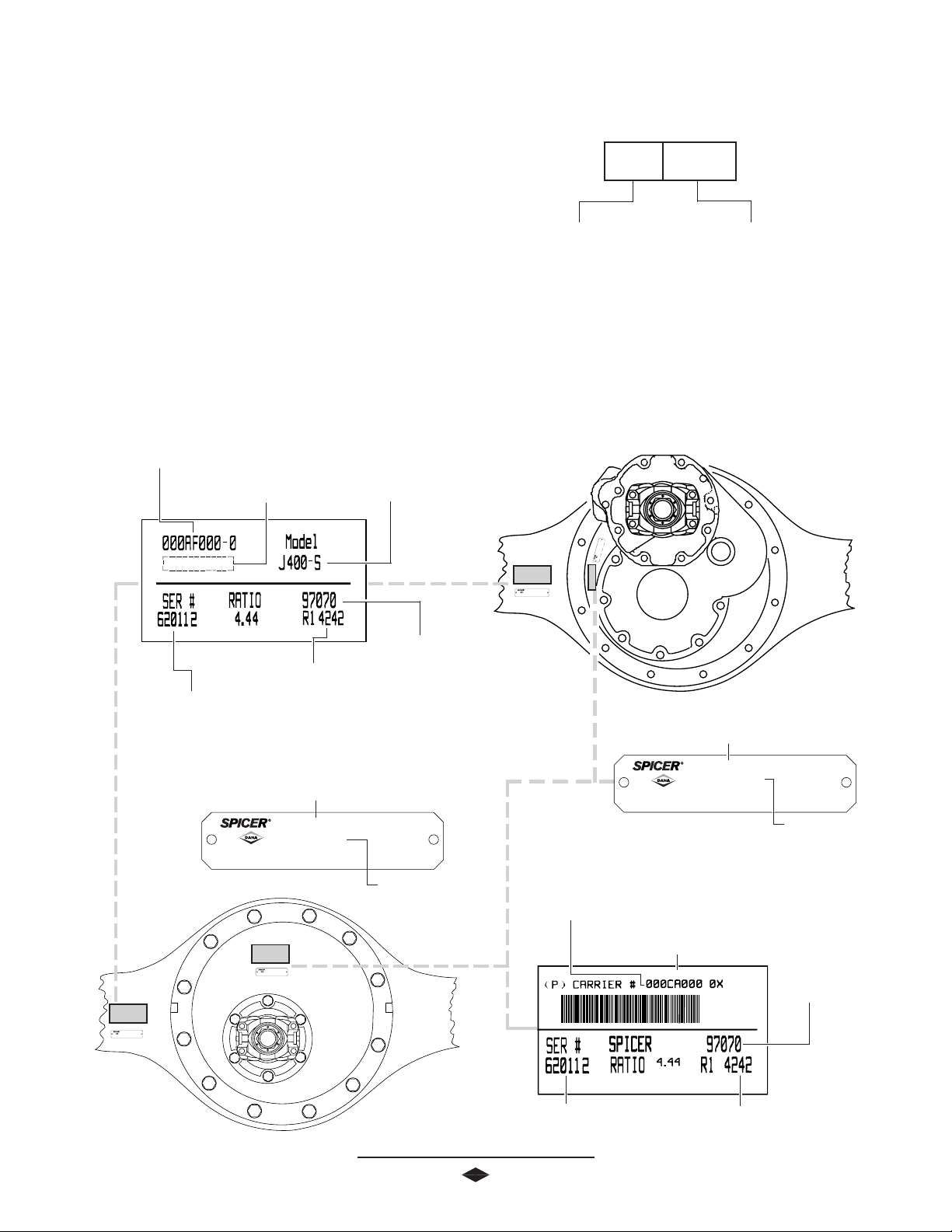

All axle assemblies are identified with two tags. One located

on the differential carrier, and the other located on the right

hand side of the axle housing. Two types of tags may be found

on the axle, an aluminum tag that is riveted on the assembly or

a coated mylar tag.

JULIAN DJULIAN D

JULIAN D

JULIAN DJULIAN D

MODEL YEARMODEL YEAR

MODEL YEAR

MODEL YEARMODEL YEAR

AXLE IDENTIFICA TION

AA

TE CODETE CODE

A

TE CODE

AA

TE CODETE CODE

99

7 17 1

9

7 1

99

7 17 1

77

7

77

00

0

00

DD

AA

Y OF YEARY OF YEAR

D

A

Y OF YEAR

DD

AA

Y OF YEARY OF YEAR

The aluminum axle assembly tag contains the following items:

serial number, according to the julian date, Dana part number,

and the model. The mylar axle assembly tag contains the

following items: Dana part number, julian date code, axle

model, and ratio. Optional items include customer part

number, line set number, and the last six digits of the vehicle

serial number.

DD

ANA PANA P

ARAR

D

ANA P

DD

ANA PANA P

NUMBERNUMBER

NUMBER

NUMBERNUMBER

LASLAS

LAS

LASLAS

VEHICLE SERIAL NUMBERVEHICLE SERIAL NUMBER

VEHICLE SERIAL NUMBER

VEHICLE SERIAL NUMBERVEHICLE SERIAL NUMBER

(OPTIONAL)(OPTIONAL)

(OPTIONAL)

(OPTIONAL)(OPTIONAL)

TT

AR

T

ARAR

TT

CUSCUS

CUS

CUSCUS

PP

P

PP

(OPTIONAL)(OPTIONAL)

(OPTIONAL)

(OPTIONAL)(OPTIONAL)

T SIX DIGITS OFT SIX DIGITS OF

T SIX DIGITS OF

T SIX DIGITS OFT SIX DIGITS OF

Axle Assembly Tags

TT

OMEROMER

T

OMER

TT

OMEROMER

ARAR

T NUMBERT NUMBER

AR

T NUMBER

ARAR

T NUMBERT NUMBER

SERIAL NUMBERSERIAL NUMBER

SERIAL NUMBER

SERIAL NUMBERSERIAL NUMBER

LINE SETLINE SET

LINE SET

LINE SETLINE SET

NUMBERNUMBER

NUMBER

NUMBERNUMBER

(OPTIONAL)(OPTIONAL)

(OPTIONAL)

(OPTIONAL)(OPTIONAL)

000000

000AF000-0

MODELMODEL

MODEL

MODELMODEL

JULIAN DJULIAN D

JULIAN D

JULIAN DJULIAN D

CODECODE

CODE

CODECODE

MODELSN

DD

ANA PANA P

D

ANA P

DD

ANA PANA P

NUMBERNUMBER

NUMBER

NUMBERNUMBER

J400-S

ARAR

AR

ARAR

AA

TETE

A

TE

AA

TETE

TT

T

TT

The aluminum differential carrier tag contains the following

items: serial number, according to the julian date code, the Dana

part number, and ratio. The mylar differential carrier tag

contains the following: Dana part number, julian date code, and

ratio. Optional items include customer part number, line set

number, and the last six digits of the vehicle serial number.

SERIAL NUMBERSERIAL NUMBER

SERIAL NUMBER

SERIAL NUMBERSERIAL NUMBER

SN 00000

000CA000-0X

RATIO

4.44

DD

ANA PANA P

ARAR

AR

ARAR

TT

T

TT

DD

ANA PANA P

D

ANA P

DD

ANA PANA P

NUMBERNUMBER

NUMBER

NUMBERNUMBER

ARAR

AR

ARAR

TT

T

TT

Carrier Tags

CUSCUS

TT

OMEROMER

CUS

T

OMER

CUSCUS

TT

OMEROMER

PP

ARAR

T NUMBERT NUMBER

P

AR

T NUMBER

PP

ARAR

T NUMBERT NUMBER

(OPTIONAL)(OPTIONAL)

(OPTIONAL)

(OPTIONAL)(OPTIONAL)

D

ANA P

DD

ANA PANA P

NUMBERNUMBER

NUMBER

NUMBERNUMBER

JULIAN DJULIAN D

JULIAN D

JULIAN DJULIAN D

LASLAS

T SIX DIGITS OFT SIX DIGITS OF

LAS

T SIX DIGITS OF

LASLAS

T SIX DIGITS OFT SIX DIGITS OF

VEHICLE SERIAL NUMBERVEHICLE SERIAL NUMBER

VEHICLE SERIAL NUMBER

VEHICLE SERIAL NUMBERVEHICLE SERIAL NUMBER

(OPTIONAL)(OPTIONAL)

(OPTIONAL)

1

(OPTIONAL)(OPTIONAL)

LINE SETLINE SET

LINE SET

LINE SETLINE SET

NUMBERNUMBER

NUMBER

NUMBERNUMBER

(OPTIONAL)(OPTIONAL)

(OPTIONAL)

(OPTIONAL)(OPTIONAL)

AA

TETE

A

TE

AA

TETE

CODECODE

CODE

CODECODE

Page 4

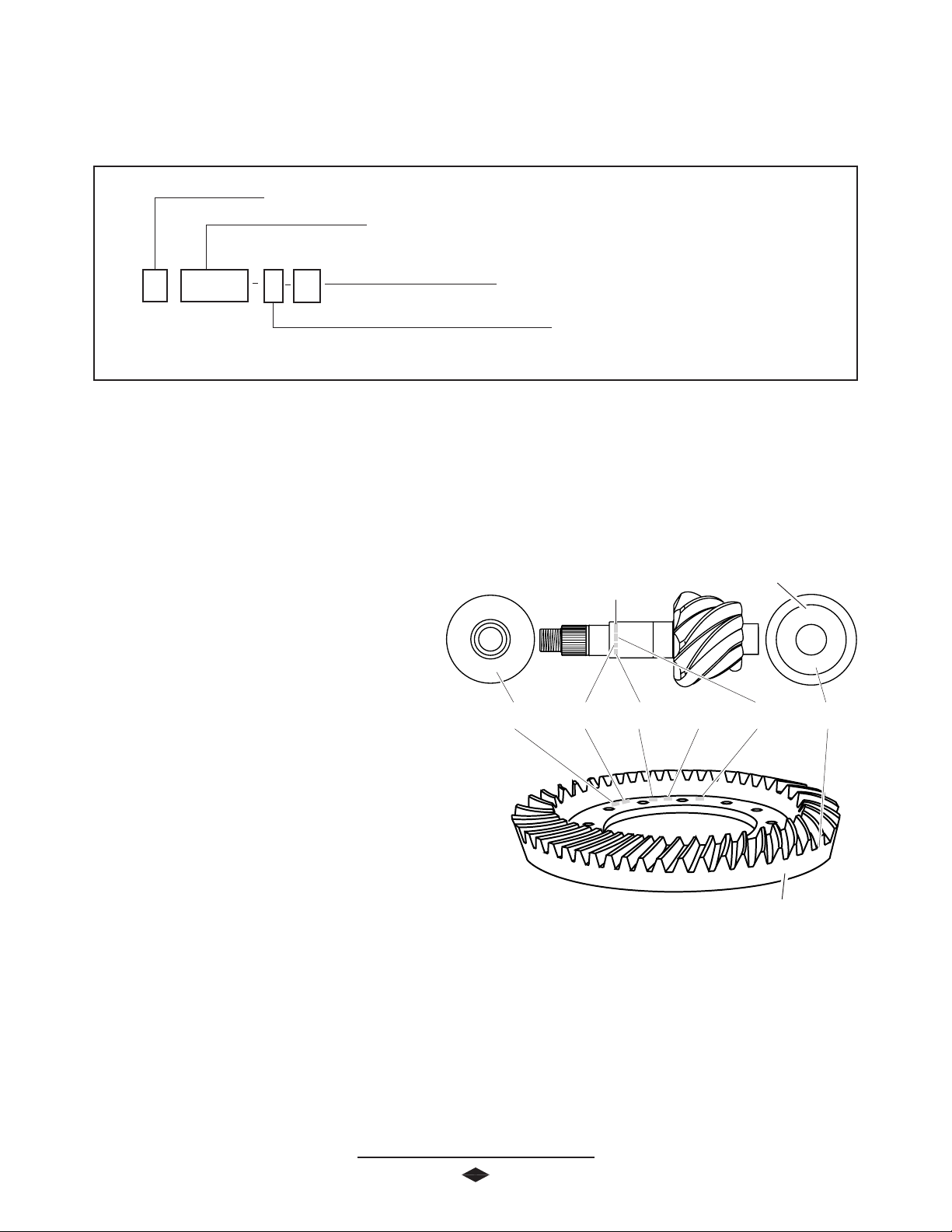

MODEL IDENTIFICA TION NUMBERING SYSTEM

Load Carrying Capacity

(340 = 34,000 Lbs.)

(380 = 38,000 Lbs.)

(400 = 40,000 Lbs.)

(440 = 44,000 Lbs.)

(460 = 46,000 Lbs.)

J 400J 400

J 400

J 400J 400

Family

(J,W)

S N S N

S N

S N S N

GEAR SET IDENTIFICA TION

Manufacturer's Date- Date gear set was made.

Spicer Trademark- Dana Diamond and location of manufac-

turing facility.

047GP000- Part number of pinion. (TYPICAL)

047GR000- Part number of ring gear. (TYPICAL)

Options

(N= No-SPIN® option)

Gearing Type

(S= Single Reduction)

TRADEMARK

41-11

SPICER

* No-SPIN® is a registered trademark of Tractech

PINION

ETCH

+15

472

Tooth Combination(i.e. 41-11)- Indicates the pinion has 11

teeth and the ring gear has 41 teeth which results in a 3:73:1

ratio.

Matched Set Number- Spicer ring gears and pinions are

manufactured as matched sets. Both ring gear and pinion are

marked with a corresponding number (i.e. 472), which

identifies them as a matched set.

A gear set that does not have the same match set numbers

should not be run together. If either ring gear or pinion

require replacement,

a new matched set must be used.

Backlash Etch- Indicates backlash setting for assembly.

Pinion Etch- Indicator for proper pinion position shim stack

up. See Pinion Position Section.

2

TOOTH

COMBINATION

PART

NUMBER

HEAT

CODE

SPICER

TRADEMARK

MFG.

DATE

L10

BACKLASH

ETCH

MATCHED

SET NUMBER

472

Page 5

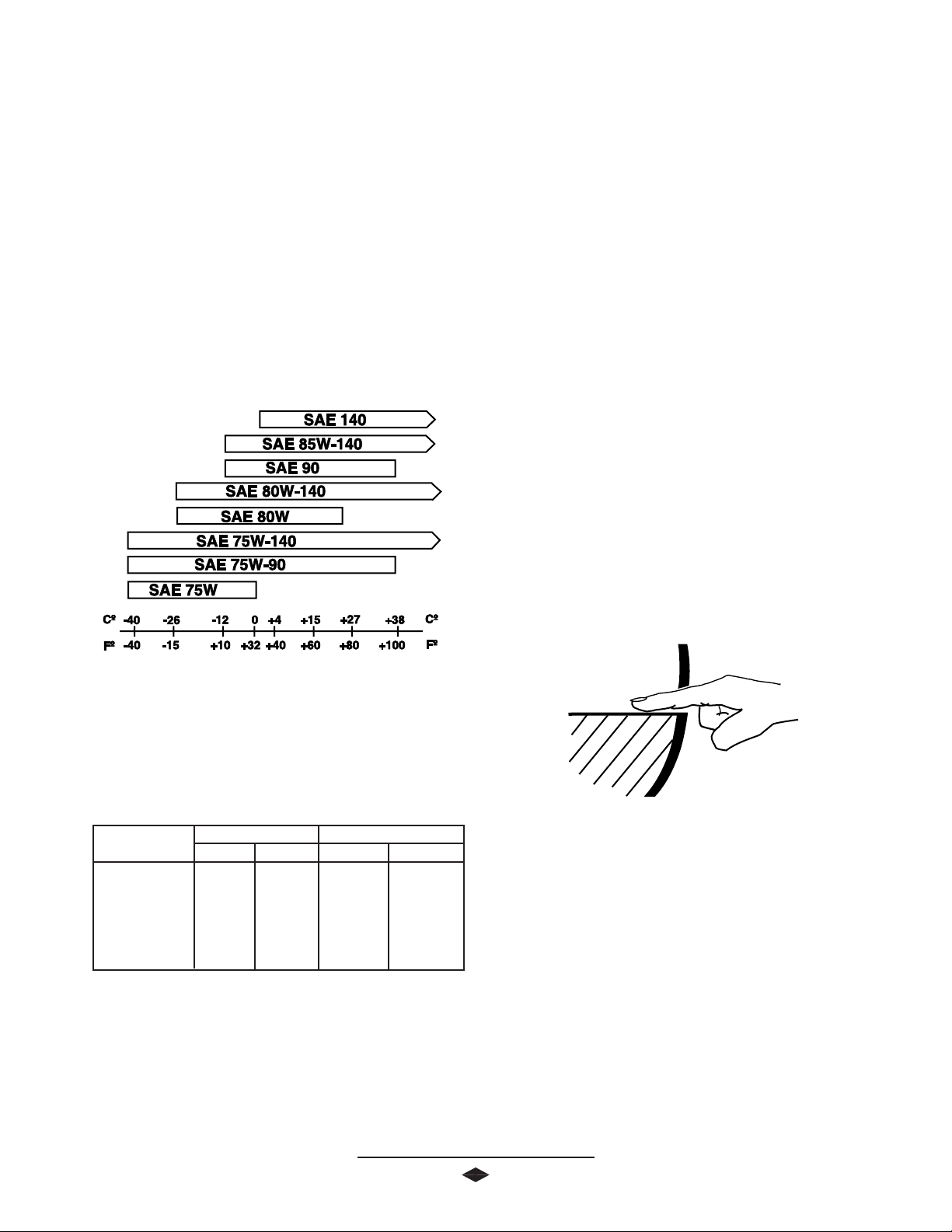

AXLE LUBRICANT RECOMMENDA TIONS

To ensure proper lubrication and operating temperature,

correct lubricants and lubricant levels must be obtained.

RECOMMENDED LUBRICANTS

Mineral or Synthetic based hypoid gear lubricants that meet

or exceed military specification MIL-L-2105D, and API service

classification GL-5, are the minimum requirements for use in

Spicer medium and heavy duty drive axles.

The table below indicates which SAE viscosities are recommended for various temperature ranges the vehicle will

encounter.

SUBMERSION OR DEEP WATER FORDING

In the event the axle assembly should become

submerged in water, particularly if over the vent or breather, it

is recommended that the lubricant be drained and all parts be

inspected for water damage and/or contamination. Reassemble the carrier to the housing and refill with specifed gear

lubricant.

AFTER OVERHAUL OR CHANGE INTERVALS

Fill the axle assembly to the bottom of housing fill hole as

shown in the illustration below. It is recommended that

following an overhaul, each side of the axle be jacked up

seperately to approximately six inches and held into position

for one minute. This procedure will allow adequate lubricant

to flow into the wheel ends and help eliminate the possibility

of premature damage to wheel bearings and seals. Lower the

vehicle to the floor and allow ten minutes for lube to return to

normal level. Check and refill assembly to bottom of fill hole to

replace the lubricant that was directed into the wheel ends.

Ambient Air Temperature

SERVICE

Recommended lubricant change intervals are dependent on

the application and operating environment. The following

chart should be used to establish proper change intervals.

PETROLEUM BASED PETROLEUM BASED

PETROLEUM BASED

APPLICAAPPLICA

APPLICA

APPLICAAPPLICA

On Highway 100,000 1 Year 250,000 3 Year

* Severe Service

and 50,000 1 Year 100,000 1 Year

On-Off Highway

PETROLEUM BASED PETROLEUM BASED

TIONTION

TION

TIONTION

MILES INTER MILES INTER

MILES INTER

MILES INTER MILES INTER

SYNTHETIC BASED** SYNTHETIC BASED**

SYNTHETIC BASED**

SYNTHETIC BASED** SYNTHETIC BASED**

VV

AL MILES INTERAL MILES INTER

V

AL MILES INTER

VV

AL MILES INTERAL MILES INTER

VV

ALAL

V

AL

VV

ALAL

* Severe service includes any applications operating at

or near maximum GVW or GCW ratings. This

includes normally wet or dusty environments, or

consistent heavy load and low speed applications.

** Includes Semi-Synthetic blends that meet

MIL-L-2105D specifications.

NOTE: Lubricant close enough to the bottom of the fill hole to be seen or touched

is not sufficient. Lubricant must be level with the fill hole.

3

Page 6

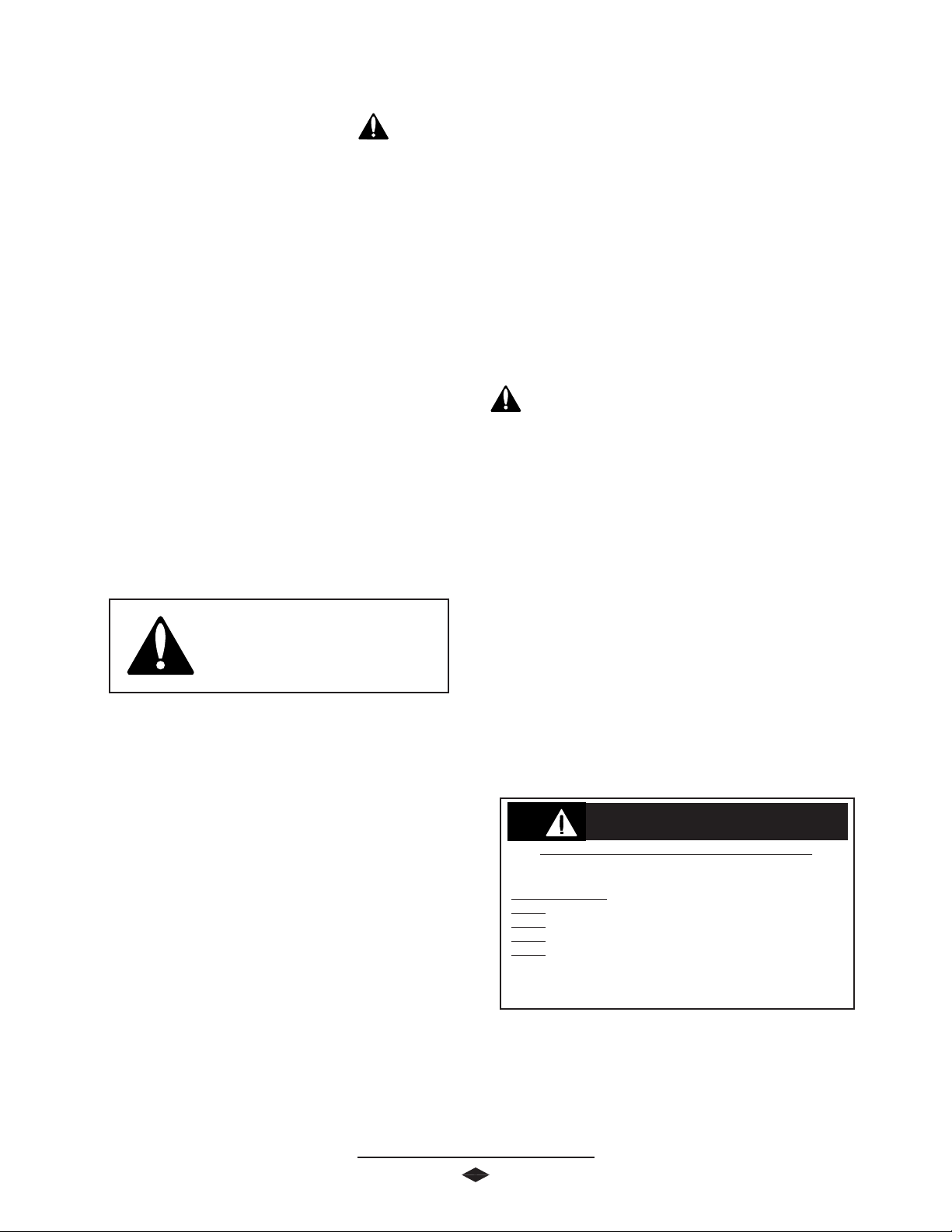

GENERAL PRECAUTIONS

READ THIS SECTION BEFORE STARTING

GENERAL AXLE DESCRIPTION

IMPORTANT

ANY SERVICE PROCEDURES

This manual covers maintenance and rebuild procedures for the

Spicer J340-S, J380-S, J400-S, W440-S and W460-S rear

drive tandem axle assemblies.

Accordingly, anyone who uses a service procedure or tool

different than shown must insure that their safety, and the

vehicle's safety, will not be jeopardized by the service method

selected.

The Spicer heavy duty single reduction rear drive axle is a full

floating axle assembly, with a hypoid gear carrier assembly,

END YOKES AND FLANGES

using a High Strength Low Alloy (HSLA) steel axle housing.

The hypoid pinion is straddle mounted with two tapered roller

bearings behind the pinion teeth for thrust and radial loads. A

pilot bearing is located on the nose of the pinion for radial

load. The differential itself uses four precision forged pinion

mate gears, a forged cross, and precision forged side gears.

bearing bores or misalign yoke lugs and result in early failures

of journal needle bearings or other driveline components.

Serious damage can also be done internally to the ring and

pinion set or pinion bearings by hammering on external parts.

End yokes or companion flanges should be removed or

installed using the recommended methods outlined in this

manual.

Safety glasses should be worn

at all times when assembling or

disassembling axles.

CLEANLINESS

Axle components should be steam cleaned prior to removal

from the vehicle. Dirt is abrasive and will cause premature wear

of otherwise serviceable parts. Service personnel should use a

wash tank for thorough cleaning of parts just prior to assembly.

CAUTION: Hammering on end yokes can close in the

SAFETY PRECAUTIONS

Proper service and repair of vehicle components is important

to the safe and reliable operation of all motor vehicles. This

applies particularly to driving axles such as the ones described

in this manual. The procedures recommended and described

in this manual are tested, effective methods for performing

service operations. Follow each procedure closely, making use

of both the text and illustrations. Some of these service

procedures show the use of certain tools designed specifically

for the operation being performed. They are shown as a

preferred means of performing the operation. It is not practical

to anticipate and advise the service trade of all possible

alternative methods, and of all possible hazardous consequences that could occur.

4

CAUTION

BRAKE LININGS CONTAIN NON-ASBESTOS FIBERS

BRAKE LININGS CONTAIN NON-ASBESTOS FIBERS

BREATHING BRAKE DUST MAY BE HAZARDOUS TO YOUR HEALTH AND

MAY CAUSE SERIOUS RESPIRATORY OR OTHER BODILY HARM.

AVOID CREATING DUST

DO NOT REMOVE BRAKE DRUM WITHOUT PROPER PROTECTIVE EQUIPMENT.

DO NOT WORK ON LININGS WITHOUT PROPER PROTECTIVE EQUIPMENT.

DO NOT REPLACE LININGS WITHOUT PROPER PROTECTIVE EQUIPMENT.

DO NOT ATTEMPT TO SAND, GRIND, CHISEL, FILE, HAMMER OR ALTER BRAKE

LININGS IN ANY MANNER WITHOUT PROPER PROTECTIVE EQUIPMENT.

FOLLOW 0.S.H.A. STANDARDS FOR PROPER PROTECTIVE DEVICES TO BE USED

WHEN WORKING WITH BRAKE MATERIALS.

Page 7

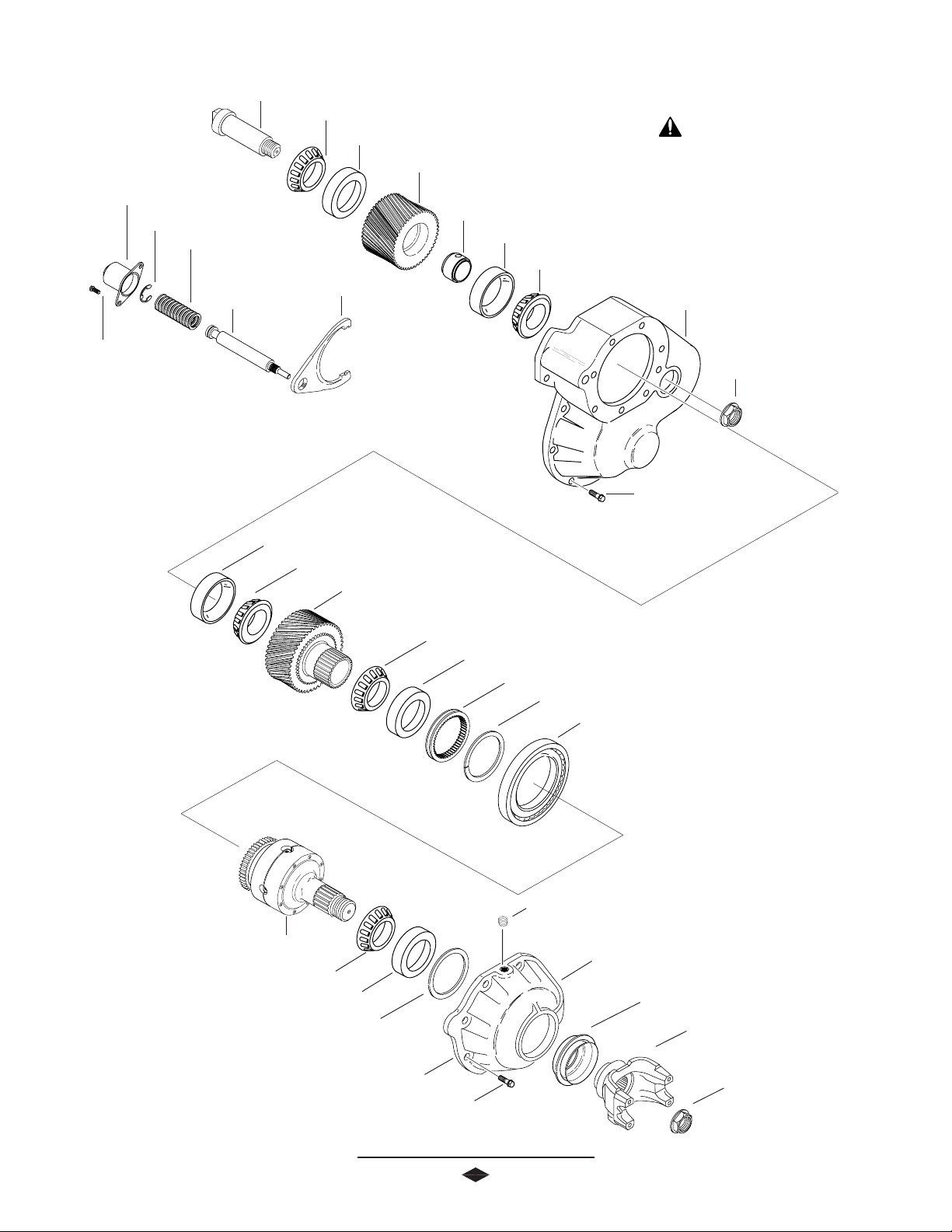

Air Shift Cylinder

Retainer Clip

Retainer Spring

Idler Gear Shaft

Shift Fork Shaft

(30-38 Lb-Ft)

(41-51 N-m)

Idler Gear Front Bearing Cone

Idler Gear Front Bearing Cup

Idler Gear

Idler Gear Bearing Spacer (Selective)

Shift Fork

POWER DIVIDER COMPONENTS

IMPORTANT: Torque

specifications, shown on illustration,

apply only to J Model. See Page 3334 for W Model torque specifications.

Idler Gear Front Bearing Cup

Idler Gear Front Bearing Cone

Intermediate Housing

Air Shift Cylinder Bolt

(30-40 Lb-Ft)

(41-55 N-m)

Idler Shaft Nut

(500-600 Lb-Ft)

(678-813 N-m)

Intermediate Housing Bolt

(75-90 Lb-Ft)

(102-122 N-m)

Drive Gear Bearing Cup

Drive Gear Bearing Cone

Input Drive Gear

Inter-Axle Differential Bearing Cone

Inter-Axle Differential Bearing Cup

Shift Collar

Spiral Snap Ring

Inter-Axle Differential Rear Bearing

Inter-Axle Differential Case Assembly

Input Bearing Cone

Input Bearing Cup

Shim (Selective)

Inter-Axle Differential Cover

Inter-Axle Differential Cover Bolt

(75-90 Lb-Ft)

(102-122 N-m)

Fill Plug

Pinion Oil Seal

End Yoke Assembly

Flanged Hex Nut

(900-1,200 Lb-Ft)

(1,220-1,627N-m)

5

Page 8

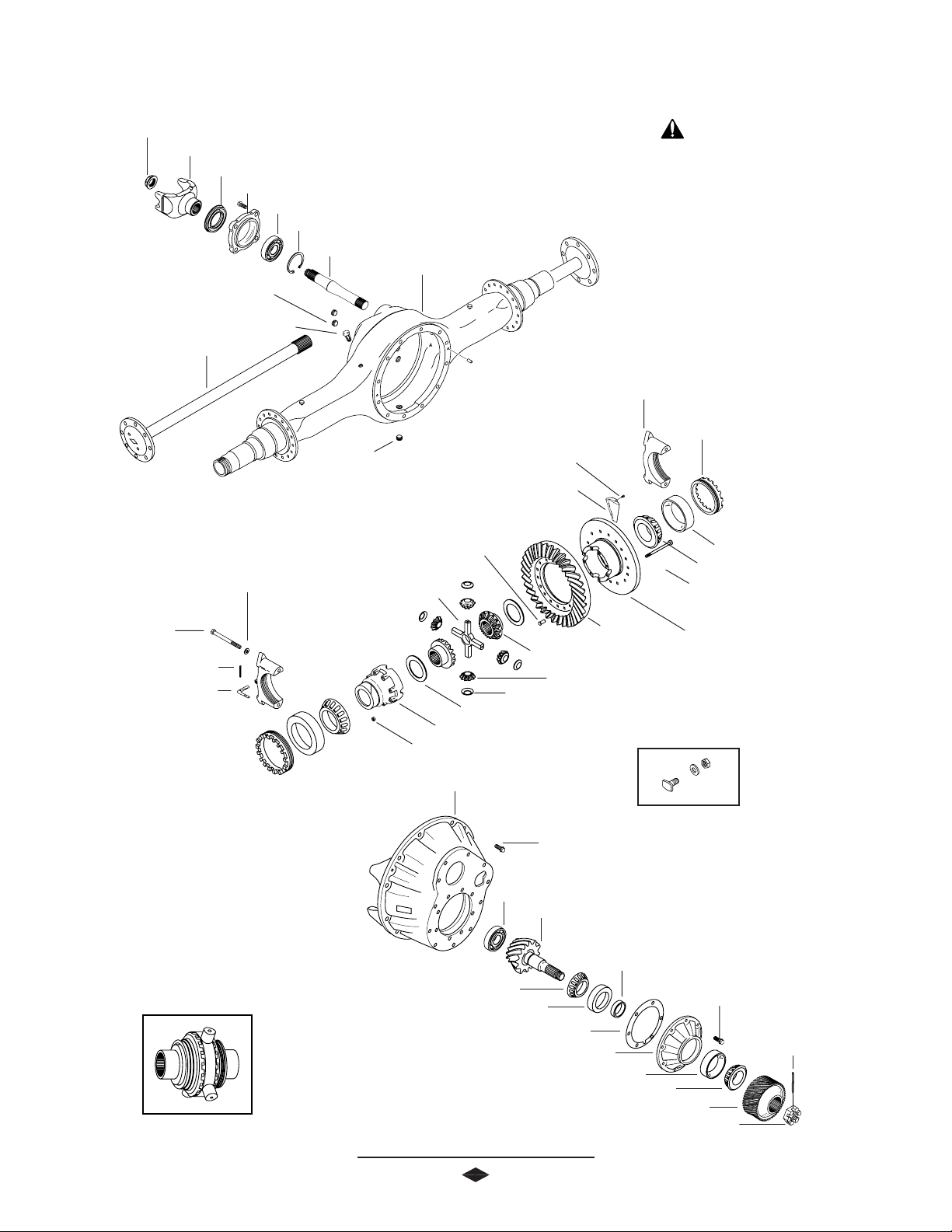

FORW ARD REAR AXLE COMPONENTS

Flanged Hex Nut

(500-600 Lb-Ft)

(680-816 N-m)

Output Yoke Assembly

Output Oil Seal

Bearing Retainer

Output Shaft Bearing

Snap Ring

Output Shaft

Fill Plug

(35-45 Lb-Ft)

(47-61 N-m)

Vent Plug

Axle Shaft

Housing

IMPORTANT: Torque

specifications, shown on illustration,

apply only to J Model. See Page 3334 for W Model torque specifications.

Differential Bearing Cap

Differential Bearing

Cap Washer

Differential Bearing Cap Bolt

(295-340 Lb-Ft)

(397-460 N-m)

Cotter Pin

Adjusting Ring Lock

Magnetic Drain Plug

(35-45 Lb-Ft)

(47-61 N-m)

Ring Gear Rivet

(45-50 tons)

(41-45 metric tonnes)

Differential Cross Shaft

Differential Case Nut

Oil Scoop Bolt

(7-9 Lb-Ft)

(10-12 N-m)

Oil Scoop

Differential Side Gear

Differential Pinion Mate

Differential Gear Thrust Washer

Differential Case Half

Carrier Housing

Carrier Mounting Bolt

(240-260 Lb-Ft)

(325-352 N-m)

Pinion Pilot Bearing

Pinion

Adjusting Ring

Differential Bearing Cup

Differential Bearing Cone

Differential Case Bolt

(115-135 Lb-Ft)

Ring Gear

Differential Pinion Mate Thrust Washer

(156-183 N-m)

Differential Case Flange Half

Ring Gear Bolt Kit

(300-320 Lb-Ft)

(407-433 N-m)

No-Spin® Differential

Inner Pinion Bearing Cone

Inner Pinion Bearing Cup

Pinion Position Shim(s)

Pinion Bearing Cage

Outer Pinion Bearing Cup

6

Bearing Preload Spacer (Selective)

Pinion Bearing Cage Bolt

(115-135 Lb-Ft)

(156-183 N-m)

Roll Pin

Outer Pinion Bearing Cone

Pinion Driven Gear

Castillated Pinion Nut

*(600 Lb-Ft Min.)

(816 N-m Min.)

Page 9

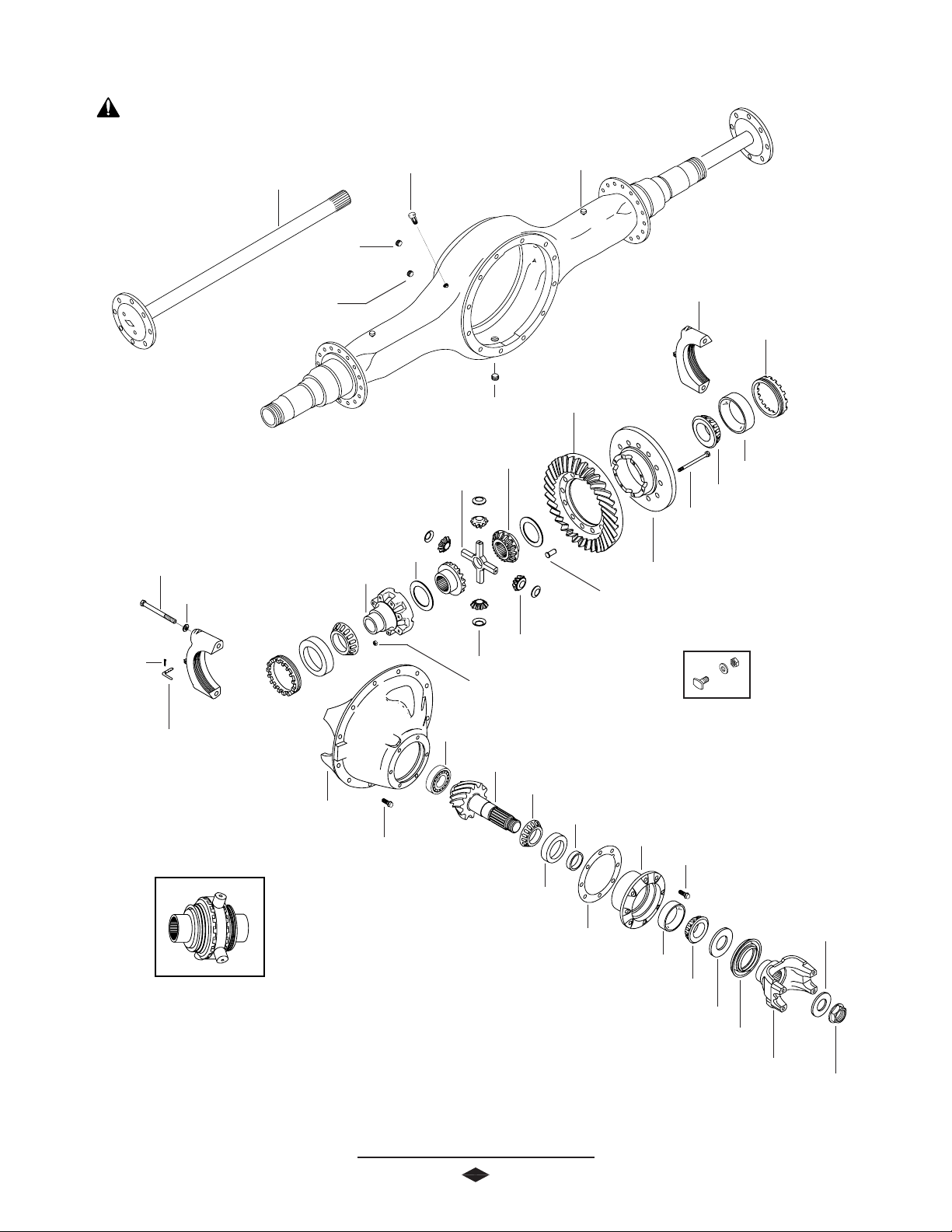

IMPORTANT: Torque

specifications, shown on illustration,

apply only to J Model. See Page 3334 for W Model torque specifications.

Axle Shaft

Temperature Sensor Plug

Pinion-Up Components

Differential Bearing Cap Bolt

(295-340 Lb-Ft)

(397-460 N-m)

Differential Bearing Cap Washer

Cotter Pin

Adjusting Ring Lock

Differential Case Cap Half

Vent Plug

Fill Plug

(35-45 Lb-Ft)

(47-61 N-m)

(35-45 Lb-Ft)

(47-61 N-m)

Differential Cross Shaft

Differential Gear Thrust Washer

Magnetic Drain Plug

(35-45 Lb-Ft)

(47-61 N-m)

Differential Side Gear

Differential Pinion Mate

Differential Pinion MateThrust Washer

Differential Case Nut

Pinion Pilot Bearing

REAR REAR AXLE COMPONENTS

Housing

Differential Bearing Cap

Adjusting Ring

Ring Gear

Differential Bearing Cup

Differential Bearing Cone

Differential Case Bolt

(115-135 Lb-Ft)

(156-183 N-m)

Differential Case Flange Half

Ring Gear Rivet

(45-50 tons)

(41-45 metric tonnes)

Ring Gear Bolt Kit

(300-320 Lb-Ft)

(407-433 N-m)

No-Spin® Differential

Carrier Housing

Carrier Mounting Bolt

(240-260 Lb-Ft)

(325-352 N-m)

Pinion

Inner Pinion Bearing Cone

Inner Pinion Bearing Cup

Pinion Position Shim(s)

Outer Pinion Bearing Cup

7

Pinion Bearing Spacer (Selective)

Pinion Bearing Cage

Pinion Bearing Cage Bolt

(160-180 Lb-Ft)

(217-244 N-m)

Washer

Outer Pinion Bearing Cone

Bearing Preload Spacer

Pinion Oil Seal

End Yoke Assembly

Flanged Hex Nut

(900-1,200 Lb-Ft)

(1,220-1,627 N-m)

Page 10

REMOV AL OF DIFFERENTIAL CARRIER FROM AXLE HOUSING

FORWARD REAR CARRIER

(WITH POWER DIVIDER)

NOTE: Steam clean axle assembly.

1. Block wheels.

2. Remove axle housing drain plug and drain lubricant.

3. Disconnect drive shafts from input and output shaft

end yokes.

NOTE: If end yoke and/or seal is to be replaced, loosen

flanged hex nut at this time.

4. Remove axle shaft flange nuts.

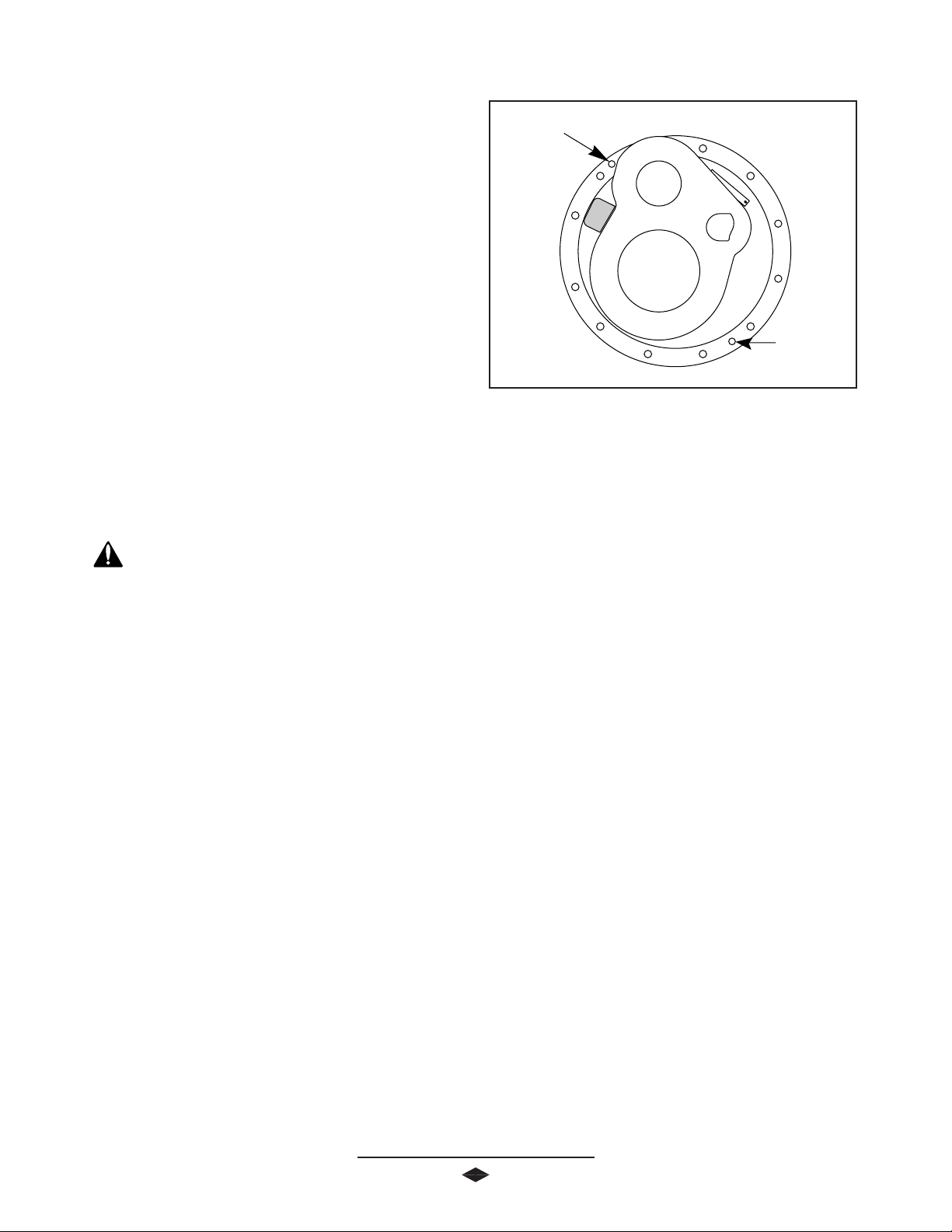

Threaded

Removal Hole

FF

F

FF

igurigur

igur

igurigur

e 1e 1

e 1

e 1e 1

Threaded

Removal Hole

5. Hold a large brass drift or a brass hammer against

the center of the axle shaft flange. Strike the drift

with sharp blows from a large hammer or sledge

until the axle shaft separates from the hub.

CAUTION: Do not strike the flange directly with a steel

hammer or sledge. This may crack and splinter material,

possibly causing serious or fatal injury. Do not pry or chisel

axle flange away from hub or damage to sealing surfaces

could occur.

6. Remove axle shafts.

7. Disconnect air line from power divider control.

8. Remove output shaft bearing retainer bolts. Use a

soft hammer to loosen bearing retainer from axle

housing. Remove bearing cage and output shaft

from axle housing.

9. Support the differential carrier assembly on a roller

jack. Secure as necessary to prevent it from

falling off the jack when removed from the housing.

10 . Use a breaker bar to loosen the differential carrier-

to-housing mounting bolts. Remove all bolts except

top two. These two bolts will prevent the carrier

assembly from falling.

NOTE: Removal holes are provided in the areas shown in the

illustration. See Figure 1.

certain carrier is balanced properly on jack, and

remove top two carrier-to-housing mounting bolts.

Remove differential carrier assembly from the axle

housing.

12 . Remove carrier assembly from under the vehicle.

13 . Mount carrier assembly in a suitable rebuild stand.

(Refer to Recommended Service Tools, Pgs. 35-36).

Differential Carrier Removal Complete

REAR REAR CARRIER

NOTE: Steam clean axle assembly.

1. Block wheels.

2. Remove axle housing drain plug and drain lubricant.

3. Disconnect drive shaft at rear U-joint.

NOTE: If end yoke and/or seal is to be replaced, loosen

flanged hex nut at this time.

4. Remove axle shaft flange nuts.

5. Hold a large brass drift or a brass hammer against

the center of the axle shaft flange. Strike the drift

with sharp blows from a large hammer or sledge

until the axle shaft separates from the hub.

11. Separate differential carrier from the housing. Be

6. Remove axle shafts.

8

Page 11

REMOV AL OF DIFFERENTIAL CARRIER FROM AXLE HOUSING

7. Support the differential carrier assembly on a roller jack.

Secure as necessary to prevent it from falling off the jack

when removed from the housing.

8. Use a breaker bar to loosen the differential carrier-

to-housing mounting bolts. Remove all bolts except

top two. These two bolts will prevent the carrier

assembly from falling.

CAUTION: Do not strike the flange directly with a steel

hammer or sledge. This may crack and splinter material,

possibly causing serious or fatal injury. Do not pry or chisel

axle flange away from hub as damage to sealing surfaces

could occur.

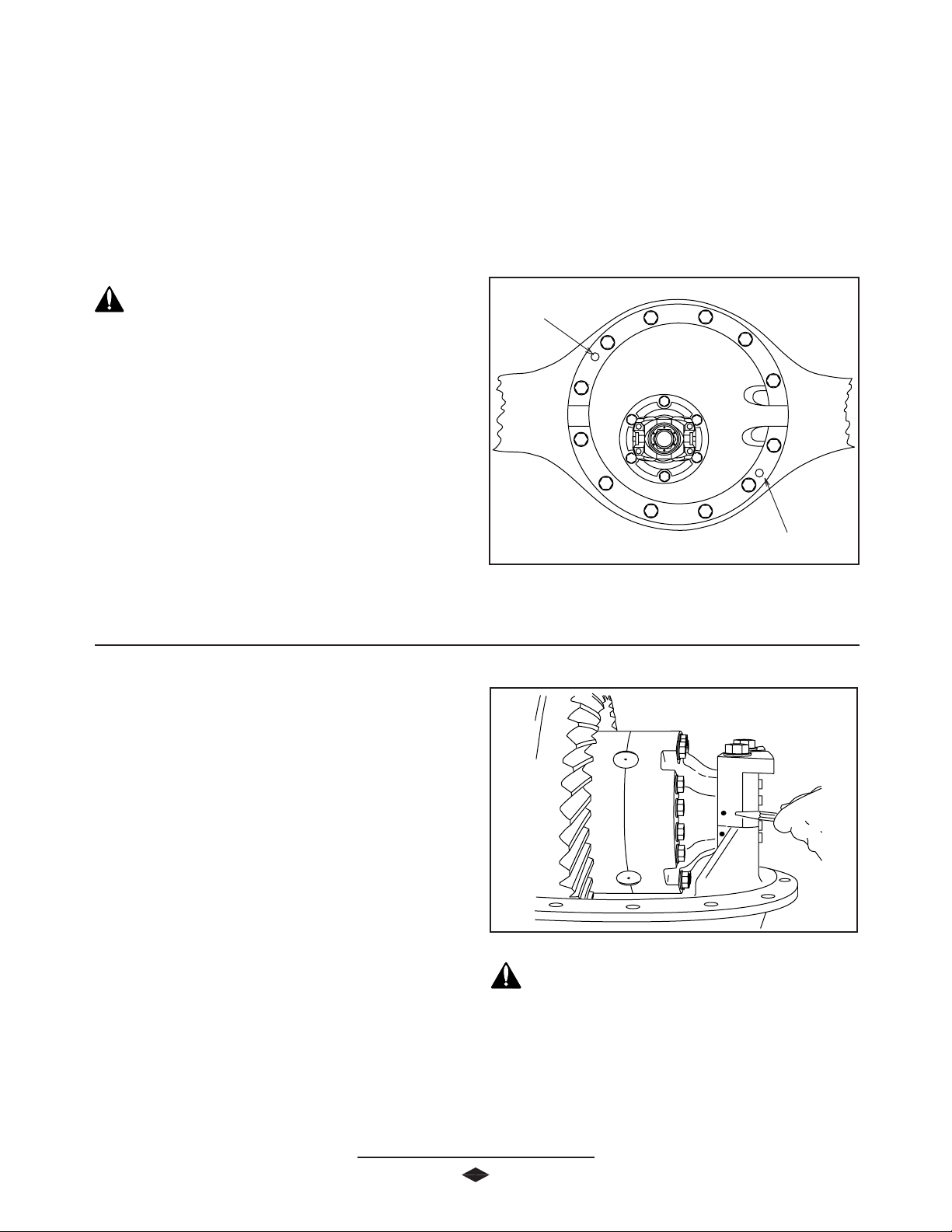

NOTE: Removal holes are provided in the areas shown in the

illustration See Figure 1 & 2.

9. Install two 1/2”-13 bolts into threaded holes provided

in carrier housing flange. See Figure 2. Turn puller bolts

in to break carrier away from housing. Be certain carrier is

balanced properly on the jack, and remove top two

carrrier-to-housing mounting bolts. Remove differential

carrier assembly from the axle housing.

10 . Remove carrier assembly from under the vehicle.

11 . Mount carrier assembly in a suitable rebuild stand. (Re-

fer to Recommended Service Tools, Pgs. 35-36)

Differential Carrier Removal Complete

Threaded

Removal

Hole

Threaded

Removal

Hole

FF

igurigur

e 2e 2

F

igur

e 2

FF

igurigur

e 2e 2

REMOV AL OF DIFFERENTIAL FROM CARRIER

NOTE: The following service procedures apply to both the

forward rear and rear rear axles, unless otherwise noted.

1. Remove adjusting ring locks from bearing caps.

2. Match mark one differential bearing cap and leg of carrrier

with center punch or chisel for use during reassembly.

See Figure 3.

. Loosen four bearing cap retaining bolts.

3

4. Loosen adjusting ring, relieving bearing preload.

5. Remove four bearing cap retainer washers and bolts.

6. Remove bearing caps.

7. Remove adjusting rings and bearing cups.

NOTE: The ring gear side of the subassembly must be tipped

up for the ring gear to clear pinion roller bearing retainer.

8. Carefully lift the ring gear and differential subassembly

out of the carrier.

9

FF

igurigur

e 3e 3

F

igur

e 3

FF

igurigur

e 3e 3

CAUTION: Use care not to damage the ring gear and

pinion. If either ring gear or pinion show signs of damage,

they must be replaced as a matched set.

Removal of Differential Complete

Page 12

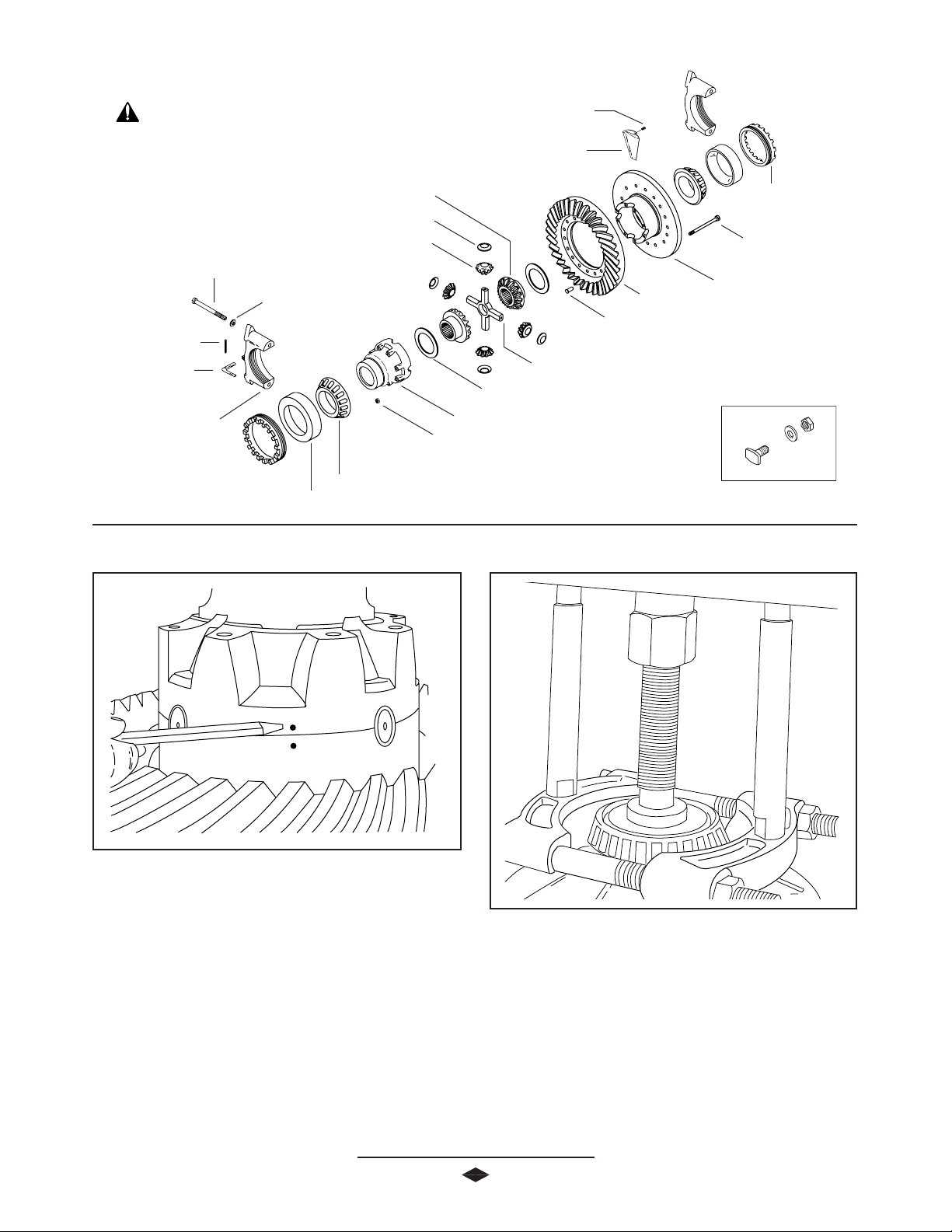

DIFFERENTIAL DISASSEMBL Y

IMPORTANT: Torque

specifications, shown on illustration,

apply only to J Model. See Page 3334 for W Model torque specifications.

Differential Pinion Mate Thrust Washer

Differential Bearing Cap Bolt

(295-340 Lb-Ft)

(370-435 N-m)

Cotter Pin

Adjusting Ring

Lock

Differential Bearing Cap

Differential Side Gear

Differential Pinion Mate

Differential Bearing

Cap Washer

Differential Bearing Cone

Differential Bearing Cup

Oil Scoop Bolt

(7-9Lb-Ft)

(9-12 N-m)

Oil Scoop

Differential Cross Shaft

Differential Gear Thrust Washer

Differential Case Cap Half

Differential Case Nut

(115-135 Lb-Ft)

(156-183 N-m)

Adjusting Ring

Differential Case Bolt

(115-135 Lb-Ft)

(156-183 N-m)

Differential Case Flange Half

Ring Gear

Ring Gear Rivet

(40-45 tons)

(41-50 metric tonnes)

Ring Gear Bolt Kit

(300-320 Lb-Ft)

(406-434 N-m)

(Optional)

FF

igurigur

e 4e 4

F

igur

e 4

FF

igurigur

e 4e 4

1. Match mark differential case halves with punch or chisel

for correct alignment during reassembly. See Figure 4.

2. Remove differential case bolts and lift off the differential

case half.

3. Remove thrust washer and differential side gear.

4. Lift out cross shaft, pinion mates, and thrust washer.

10

FF

igurigur

e 5e 5

F

igur

e 5

FF

igurigur

e 5e 5

5. Remove second differential side gear and thrust washer.

6. If differential side bearings are to be replaced, remove old

bearings using suitable puller. See Figure 5.

NOTE: Inspect all parts, including the machined surfaces of the

case itself.

Page 13

DIFFERENTIAL DISASSEMBL Y

IMPORTANT: If any gears are to be replaced, they must be

replaced in sets. Inspect thrust washers for scoring and

excessive wear. Replace all worn or damaged parts.

7. When it is necessary to remove ring gear from differential

case, carefully center punch each rivet head. Use a 9/16"

drill bit on the J model carrier rivets and a 11/16” drill bit

for the W model carrier rivets. Drill through the rivet

heads to a depth as shown through rivet heads. See

Figure 6.

CORRECT PROCEDURE

Case

Ring Gear

8. Next, use a round type punch to drive out the remaining

portion of the rivet.

CAUTION: Always use a soft hammer or H.D. plastic

head hammer to strike punch.

NOTE: Do not use a chisel to remove rivet heads, damage to

differential case may result. See Figure 7.

Differential Disassembly Complete

INCORRECT PROCEDURE

Case

Ring Gear

FF

igurigur

F

igur

FF

igurigur

e 6e 6

e 6

e 6e 6

FF

igurigur

F

igur

FF

igurigur

e 7e 7

e 7

e 7e 7

11

Page 14

INTER-AXLE DIFFERENTIAL DISASSEMBL Y

Spiral Snap Ring

Inter-Axle Differential Rear Bearing

Inter-Axle Differential Case

Assembly

Input Bearing Cone

Input Bearing Cup

Shim (Selective)

Inter-Axle Differential

Cover Bolt

(75-90 Lb-Ft)

(102-122N-m)

1. Remove the inter-axle shift cylinder assembly, compress

spring and remove retainer clip. Remove spring.

Fill Plug

Inter-Axle Differential Cover

Pinion Oil Seal

End Yoke

Assembly

Flanged Hex Nut

(900-1,200 Lb-Ft)

(1,220-1,627N-m)

2. Screw shift fork shaft out and remove from differential

carrier.

3. Remove inter-axle differential cover bolts

NOTE: One bolt is larger than the others and must be

replaced in the same postion.

4. Lift inter-axle differential assembly from power

divider case. Use of an overhead crane or hoist is

recommended.

5. Remove input flanged hex nut.

NOTE: Use of torque multiplier is recommended as torque

specification on the input nut is 900-1,200 Lb-Ft (1,2201,627 N-m).

6. Remove input yoke using suitable puller. See Figure 8.

7. Lift off inter-axle differential cover housing.

8. Remove bearing cup and shims from inter-axle differential

housing. Retain shims for possible use during reassembly

9. To remove spiral snap ring, use a small bladed screwdriver. Insert tip into slot of snap ring and lift away from

case. Apply pressure under snap ring and lift away from

case. Apply pressure under snap ring and rotate around

case until snap ring is free.

FF

igurigur

e 8e 8

F

igur

e 8

FF

igurigur

e 8e 8

10 . Remove ball bearing from inter-axle differential case using

a suitable puller.

11 . Match mark differential case halves to assure correct

alignment upon reassembly. Remove differential case

bolts and separate case halves.

12 . Remove pinion mates, front and rear side gears, cross

shaft, and thrust washers.

13 . If tapered roller bearing is to be replaced, remove

bearing using a suitable puller. See Figure 9.

Inter-axle Differential Disassembly Complete

12

Page 15

Idler Gear Shaft

Air Shift Cylinder

Retainer Clip

Retainer Spring

Idler Gear Front Bearing Cone

Idler Gear Front Bearing Cup

Idler Gear

Idler Gear Bearing Spacer (Selective)

INTERMEDIA TE CASE DISASSEMBLY

IMPORTANT: Torque

specifications, shown on illustration,

apply only to J Model. See Page 3334 for W Model torque specifications.

Idler Gear Front Bearing Cup

Idler Gear Front Bearing Cone

Inter-Axle Differential Case

Air Shift Cylinder Bolt

(30-40 Lb-Ft)

(41-55 N-m)

Shift Fork Shaft

(30-38 Lb-Ft)

(41-51 N-m)

Shift Fork

Inter-Axle Differential

Case Bolt

(75-90 Lb-Ft)

(102-122 N-m)

1. Remove intermediate case to carrier housing mounting

bolts. Lift intermediate case from differential carrier

housing using a hoist or overhead crane. If necessary, use

soft hammer to break seal between case and carrier.

Idler Shaft Nut

Drive Gear Bearing Cup

Drive Gear Bearing Cone

Input Drive Gear

Inter-Axle Differential Bearing Cone

Inter-Axle Differential Bearing Cup

Shift Collar

2. Lift clutch shift collar and shift fork from case. Inspect shift

fork for wear and misalignment.

3. Remove input gear assembly from intermediate case.

4. Remove bearing from input gear using a suitable puller.

See Figure 9.

FF

F

FF

igurigur

igur

igurigur

e 9e 9

e 9

e 9e 9

5. Turn gear over and remove opposite bearing.

6. Place intermediate case in soft jawed vise clamping on the

flats of the idler shaft. Remove idler shaft nut using a

torque multiplier wrench.

7. Remove intermediate case from vise. Tap idler shaft with a

soft hammer to free case and remove idler shaft.

8. Slide idler gear to large opening and remove idler gear,

bearings and bearing spacer for possible use during

reassembly.

Intermediate Case Disassembly Complete

13

Page 16

PINION DISASSEMBL Y

ID Tag

REAR REAR AXLE COMPONENTS

Carrier Housing

Pinion Pilot Bearing

IMPORTANT: Torque

specifications, shown on illustration,

apply only to J Model. See Page 3334 for W Model torque specifications.

Carrier Mounting Bolt

(240-260 Lb-Ft)

(325-352 N-m)

Pinion

Inner Pinion Bearing Cone

Inner Pinion Bearing Cup

Bearing Preload Spacer (Selective)

Pinion Bearing Cage

Pinion Bearing Cage Bolt

(115-135 Lb-Ft)

(156-183 N-m)

Washer

Pinion Nut

Pinion Seal

End Yoke

Used in place of

pinion driven gear,

castillated pinion

nut,and roll pin, that

are used on the

forward rear axle

carrier assembly.

1. Remove pinion bearing cage mounting bolts.

2. Remove pinion bearing cage and cage assembly from

carrier housing. If difficulty is encountered in removing

pinion assembly from carrier, place a brass drift on inner

end of pinion and tap lightly.

NOTE: Retain shims for possible use during reassembly.

3. Mount pinion assembly in a soft jawed vise or fixture,

holding yoke or pinion stationary. Remove roll pin, nut,

and washer.

4. Remove the end yoke or drive gear using a suitable press.

Pinion Position Shim(s)

Outer Pinion Bearing Cup

Outer Pinion Bearing Cone

Pinion Driven Gear

Castillated Pinion Nut

(600- Lb-Ft)Min.

(217 N-m) Min.

Roll Pin

6. Located between pinion bearings is a selective spacer,

used for pinion bearing preload. Retain this spacer for

possible use in reassembly.

7. Lift out the outer pinion bearing cone.

8. Remove inner pinion bearing cup, using a suitable

adapter and press or puller.

9. Remove roller bearing from end of pinion.

10 . Remove inner bearing cone from pinion.

Pinion Disassembly Complete

5. Remove pinion from cage assembly.

14

Page 17

Flanged Hex Nut

(500-600 Lb-Ft)

(678-813 N-m)

End Yoke Assembly (Output)

Output Shaft Bearing

Snap Ring

OUTPUT SHAFT DISASSEMBL Y

IMPORTANT: Torque

specifications, shown on illustration,

apply only to J Model. See Page 3334 for W Model torque specifications.

Output Shaft Oil Seal

Output Shaft Bearing Cage

Bolt

(30-40 Lb-Ft)

(41-55 N-m)

Output Shaft

1. Remove rear drive shaft.

2. Remove output shaft bearing cage assembly from forward

rear axle housing.

3. Mount output shaft in vise by clamping yoke in jaws of

vise.

4. Remove nut and yoke.

5. Use snap ring tool to remove snap ring from bearing

retainer.

6. Remove bearing and retainer from shaft.

7. Using a suitable sleeve to support bearing inner race,

press bearing from shaft.

8. Using suitable sleeve, press seal from retainer.

9. Clean and inspect all components. Replace all worn or

damaged components with genuine Spicer replacement

parts.

Output Shaft Disassembly Complete

15

Page 18

CLEANING AND INSPECTION

CLEANING

1. Parts should be cleaned with emulsion cleaners or

petroleum base cleaning solvent.

NOTE: Alkaline type solutions may cause damage to machined

surfaces and should be avoided.

2. Make sure interior of axle housing is clean prior to

reassembly.

3. Clean all gasket surfaces of old material.

DRYING

Use soft, clean, lintless towels or rags to dry components

after cleaning. Bearings should

not

be dried by spinning

with compressed air. This can damage mating surfaces

due to the lack of lubrication.

After drying, parts should be coated with a light coat of

lubricant or rust inhibitor to prevent damage from

corrosion. If parts are to be stored for a prolonged

period, they should be wrapped in wax paper.

GEARS

Inspect gears for excessive wear or damage. Replace

gears that are pitted, scored, broken, or worn.

SHAFTS

INSPECTION

Prior to reassembly, inspect parts for signs of excessive

wear or damage. Replacement of these parts can prevent

premature failure and costly downtime.

BEARINGS

Bearing surfaces should be inspected for pitting,

excessive wear, or overheating.

Inspect shafts for nicks or scoring.

SPLINES

Inspect all splines for excessive wear, distortion from

twisting, and cracking.

HOUSINGS

THRUST WASHERS

Inspect thrust washers for scoring and cracking.

Inspect housing for stripped threads and bending

16

fatigue.

Page 19

IMPORTANT: Torque

specifications, shown on illustration,

apply only to J Model. See Page 3334 for W Model torque specifications.

ID Tag

REAR REAR AXLE COMPONENTS

PINION ASSEMBLY

Carrier Housing

Carrier Mounting Bolt

(240-260 Lb-Ft)

(325-352 N-m)

Pinion Pilot Bearing

Pinion

Inner Pinion Bearing Cone

Inner Pinion Bearing Cup

Bearing Preload Spacer (Selective)

Pinion Bearing Cage

Pinion Bearing Cage Bolt

(115-135 Lb-Ft)

(156-183 N-m)

Washer

Pinion Nut

Pinion Seal

End Yoke

Used in place of

pinion driven gear,

castillated pinion

nut,and roll pin, that

are used on the

forward rear axle

carrier assembly.

1. Press inner pinion bearing cone onto the pinion.

2. Press roller bearing onto nose of pinion.

NOTE: Bearing must be installed with radius in bearing bore

toward pinion.

3. Stake roller bearing in nine places (See illustration

below), using a center punch or equivalent tool. This

operation will move gear shaft material outward into

bearing chamfer.

Pinion Position Shim(s)

Outer Pinion Bearing Cup

Outer Pinion Bearing Cone

Pinion Driven Gear

FF

igurigur

e 1e 1

00

F

igur

e 1

0

FF

igurigur

e 1e 1

00

Castillated Pinion Nut

(600- Lb-Ft)Min.

(217 N-m) Min.

bores See Figure 10. This is necessary for proper pinion

position.

NOTE: Make sure all cage bores are free of nicks, dirt, or any

other contaminants.

4. Install inner pinion bearing cup into pinion cage.

5. Install outer pinion bearing cup into pinion cage.

6. Use a feeler guage or shim stock .0015 in. (.0381mm) to

ensure bearing cups are completely seated in bearing

7. Press inner pinion bearing onto pinion stem.

8. Place selective preload spacer that was removed during

disassembly onto pinion.

9. Place pinion cage onto pinion inner bearing.

10 . Install outer pinion bearing cone onto pinion.

11 . Inspect rear rear carrier end yoke seal surface for grooves

caused by lip of seal. If grooves can be detected with

fingernail, it should be replaced.

12 . Install gear onto pinion of forward rear carrier. Place

assembly in a hydraulic press and seat gear on spline.

Torque castillated nut to 600 Lb-Ft Min. If hole in pinion

17

Page 20

PINION ASSEMBLY

does not align with slots in nut, tighten nut until they are

aligned. Do not install roll pin at this time.

On rear carriers, install end yoke onto pinion using yoke

installer service tool, (See Figure 11 and Recommended

Service Tools Pgs. 35-36), without seal to allow proper

setting of bearing preload. Tighten pinion nut to 9001200 Lb-Ft (1,220-1,627 N-m).

NOTE: Pinion cage should be rotated while tightening pinion

nut to seat and align the pinion bearings.

CAUTION: Wash spacer thoroughly of emery cuttings

before installing on pinion.

14 . After proper preload is achieved, install new roll pin into

forward carrier pinion. If roll pin cannot be installed,

tighten pinion nut until roll pin can be installed. Pinion

and cage assembly are now ready to be installed into the

carrier housing.

15 . After proper preload is achieved on rear carriers, remove

end yoke, and install new seal.

16 . Clean and dry threads on pinion.

17. Install pinion oil seal. (See Recommended Service Tools,

Pgs. 35-36)

18 . Install end yoke using yoke installer service tool. Coat

threads with Loctite #680 adhesive compound. See

Figure 11.

19 . Use torque multiplier and tighten flanged hex nut to 900-

1,200 Lb-Ft (1,220-1,627 N-m).

FF

igurigur

e 1e 1

11

F

igur

e 1

1

FF

igurigur

e 1e 1

11

12 . Measure torque to rotate with the torque wrench,

assemble pinion cage into the carrier housing and install

two mounting bolts to anchor the unit. Rotate pinion with

the torque wrench. See Figure 12. Torque measurement

will be taken during fourth revolution and must be

between 10-40 Lb-in (1.1-4.5 N-m) without pinion seal.

NOTE: When torque to rotate reading does not fall within

allowable limits, bearing preload can be increased by using a

thinner spacer or decreased by using a thicker spacer. A .001

in. (.025 mm) change in preload spacer thickness, changes

scale reading by approximately 10 lbs, .001 in. change in

preload spacer will change torque to rotate by approximately

30 Lb- in. This is only a guide, individual carriers may vary

slightly.

Pinion Assembly Complete

FF

igurigur

e 1e 1

22

F

igur

e 1

2

FF

igurigur

e 1e 1

22

The pinion bearing spacers are available in the following

thicknesses. Measure spacer with micrometers before

assembly to ensure correct thickness.

NOTE: Closer adjustment can be made by sanding next thicker

spacer to desired thickness using emery cloth on a flat

surface. Surfaces must be parallel to each other and square to

bore diameter.

18

J Model W Model

Inches MM Inches MM

.718 18.24 .893 22.68

.719 18.26 .894 22.71

Page 21

PINION ASSEMBLY

J Model W Model

Inches MM Inches MM

.720 18.29 .895 22.73

.721 18.31 .896 22.76

.722 18.34 .897 22.78

.723 18.36 .898 22.81

.724 18.39 .899 22.84

.725 18.41 .900 22.86

.726 18.44 .901 22.89

.727 18.47 .902 22.91

.728 18.49 .903 22.94

.729 18.52 .904 22.96

.730 18.54 .905 22.99

.731 18.57 .906 23.01

Ring gears and pinions are supplied in matched sets only.

Matching numbers on both the pinion and ring gear are etched

for verification. If a new gear set is being used, verify the

numbers of each pinion and ring gear before proceeding with

assembly. (See Gear Set Identification, Pg. 2)

J Model W Model

Inches MM Inches MM

.732 18.60 .907 23.04

.733 18.62 .908 23.06

.734 18.64 .909 23.09

.735 18.67 .910 23.11

.736 18.69 .911 23.14

.737 18.72 .916 23.27

.738 18.75

.739 18.77

.740 18.80

.741 18.82

.742 18.85

.745 18.92

PINION POSITION

3. Remove any burrs and wipe clean differential bearing

bore I.D.'s. Turn micrometer 90º to step plate. Install

assembled pinion setting gauge into bearing bores of

carrier housing until fully seated. Adjust micrometer so it

Pinion position is based on the nominal mounting distance

measured from the centerline of the ring gear to the nose of

the pinion. This dimension is controlled by selectively

shimming between the pinion cage assembly and the carrier

housing. The nominal dimension is 3.976 in. (100.990 mm).

NOTE: Be sure mounting surfaces and shims are free of burrs

and dirt prior to assembly as they will affect pinion position.

1. To establish the correct nominal dimension by using a

pinion setting gauge, install pinion and cage assembly

into the carrier housing without shims. Tighten pinion

cage bolts to correct torque specifications. (See Torque

Specification Chart, Pgs. 33-34) Failure to tighten

properly may result in incorrect gear adjustment.

2. Attach the step plate clamp assembly to the carrier

mounting flange. Locate step plate clamp screw over

center of pinion. Install step plate under clamp screw and

tighten to hold step plate securely in position.

NOTE: Be sure lugs on bottom of step plate straddle the

bearing staking indentions on end of pinion, or false reading

may occur. Also, make sure differential side bearing bores

are clean and free of nicks.

19

FF

igurigur

e 1e 1

33

F

igur

e 1

3

FF

igurigur

e 1e 1

33

is directly over end of step plate. Run the micrometer

thimble down to measure the distance between the center

of the ring gear and the step plate. Make a note of this

dimension. See Figure 13.

NOTE: Because the step plate must be taken into consideration, the thickness of the step plate (.400 in. (10.16 mm))

needs to be added to the measured value for the correct

micrometer distance.

4. On the machined end of each pinion either a plus (+),

minus (-), or a zero (0) will be etched. (See Gear Set

Identification, Pg. 2) This number represents the amount

Page 22

PINION POSITION

in thousandths of an inch (.001) to be added or

subtracted from the nominal dimension for the best

running position for that particular gear set.

and nicks prior to assembly or leaks will occur and pinion

position can be affected.

7. Install pinion and pinion cage assembly into carrier.

EXAMPLE:

If pinion is etched +3, the required mounting distance is

more than nominal by .003 in. (.076 mm). This means

the pinion would require .003 in. (.076 mm) thicker shim

between pinion bearing cage assembly and carrier

housing that a pinion etched with "0". If the pinion is

marked -3, the shim required between pinion gearing

cage assembly and carrier housing would be .003 in

(.076 mm) thinner than if pinion was etched "0".

5. Pinion shims are available in the following thicknesses.

Inches MM

.005 .127

.010 .254

. 030 . 762

NOTE: Studs can be used to assist in alignment.

8. Tighten pinion cage to carrier bolts. (See Torque

Specifications Chart, Pgs. 33-34)

9. An alternative to using the pinion setting gauges is to

follow the procedure described in the following section.

Pinion Position Complete

When a new gear set is being installed, use a micrometer to

measure the thickness of the old pinion position shims.

Measure each shim separately and add together to get the

total thickness of the original build-up.

Pinion Positon Shims

Pinion

6. Position shims on carrier housing so oil return holes

align properly. Use a minimum of three shims in a

pack. If the pack is made of different shim thicknesses, install the thinnest shims on both sides of the

pack for maximum sealing.

NOTE: Be sure mounting surfaces and shims are free of dirt

PINION SETTING

NOTE: If old shims are bent or mutilated they should be

replaced.

If a new gear set is being used, notice the (+), (–) or "0"

etching on both the old and the new pinions, and adjust the

thickness of the shims to compensate for the difference of

these two figures (as shown in table on next page).

For example, if the old pinion is etched +2, and the new pinion

is –2, subtract .004 in. from the thickness of the original shims

used to position the pinion.

If either or both the pinions are etched beyond the values on

20

Nominal Mounting Distance

Ring Gear

this chart, follow the same procedure to establish correct

pinion position.

For example if the old pinion is etched –12 and the new pinion

is etched +9, add .021 in. to the thickness of the original

shims.

After determining the new total build up of pinion position

shims, round the figure off to the nearest multiple of .005 inch.

Use the Pinion Setting Chart on the next page as a guideline to

set the pinion.

Page 23

PINION SETTING CHART

21

Page 24

DIFFERENTIAL ASSEMBLY

IMPORTANT: Torque

specifications, shown on illustration,

apply only to J Model. See Page 3334 for W Model torque specifications.

Differential Side Gear

Differential Pinion Mate Thrust Washer

Differential Pinion Mate

Differential Bearing Cap Bolt

(295-340 Lb-Ft)

(370-435 N-m)

Cotter Pin

Adjusting Ring

Lock

Differential Bearing Cap

Differential Bearing

Cap Washer

Differential Bearing Cone

Differential Bearing Cup

Oil Scoop Bolt

(7-9Lb-Ft)

(9-12 N-m)

Oil Scoop

Differential Cross Shaft

Differential Gear Thrust Washer

Differential Case Cap Half

Differential Case Nut

(160-180 Lb-Ft)

(218-245 N-m)

Adjusting Ring

Differential Case Bolt

(160-180 Lb-Ft)

(218-245 N-m)

Differential Case Flange Half

Ring Gear

Ring Gear Rivet

(40-45 tons)

(41-50 metric tonnes)

Ring Gear Bolt Kit

(300-320 Lb-Ft)

(406-434 N-m)

(Optional)

1. If ring gear was removed from differential case, reinstall at

this time. Clean mating surfaces and bolt ring gear to

differential case at 3 locations, 120º apart to help

eliminate ring gear runout. Use hydraulic press and

suitable riveting fixture, as shown. Pressure requirement

per rivet is 45-50 tons (41-45 metric tonnes).

The ring gear is properly installed when a .0015” (.038

mm) feeler guage cannot be inserted between the

differential case flange and the ring gear backface. See

Figure 14.

NOTE: Ring gear and pinion must be replaced as a match set

only.

2. Install bearing cones to differential case halves.

Place bearing cups on cones during remainder of

assembly to prevent damage to bearings.

NOTE: Use of press and proper adapter is required to

eliminate possible damage to bearings.

3. Apply a small amount of lubricant to all mating surfaces.

This will keep thrust washers in place during assembly and

provide initial lubrication.

4. Place thrust washer and side gear in flange half of

differential case. Dimples in thrust washers go against

side gear.

5. Assemble differential pinions and thrust washers on cross

shaft. Place assembly in flange half differential case.

6. Place remaining side gear and thrust washers in position

on differential pinions.

7. Assemble case halves, making sure that both match marks

are lined up.

FF

F

igur

FF

igurigur

igurigur

e 1e 1

e 1

e 1e 1

8. Install differential case bolts. Tighten alternately and

evenly. (See Torque Specifications Chart, Pgs. 33-34)

Differential Assembly Complete

44

4

44

22

Page 25

Oil Pick-Up Plate

1. Three differential cases are used with the W Model

carriers, depending on the ratio. Two of the cases

have two oil pick-up plates attached. Clean and coat

bolts with Loctite #271 or its equivalent. Assemble

and torque bolts to 7-9 Lb-Ft (9-12 N-m)

CAUTION: Differential assembly must be aligned

within bearing bores before preload is applied or damage to

bearings could occur.

2. Install ring gear and differential assembly into carrier

housing.

CAUTION: To avoid damage of the ring gear and pinion, care

should be used when installing the ring gear differential

assembly into the carrier housing.

DIFFERENTIAL INSTALLATION

FF

igurigur

e 1e 1

55

F

igur

e 1

5

FF

igurigur

e 1e 1

55

6. Check ring gear and pinion backlash in four equally

spaced positions around the ring gear with a dial

indicator as shown. Acceptable backlash tolerance

is .006"-.012". See Figure 16.

NOTE: If backlash tolerance varies more than .003" (.080

mm) between the four positions, remove the differential and

determine the cause.

7. Once backlash is set, torque the differential bearing

cap bolts to 295-340 Lb-Ft (397-460 N-m). Check

backlash after torquing cap bolts.

3. Be sure side bearing cups are seated on bearing cones.

Assemble differential bearing caps, with match marks in

proper location. Clean differential bearing cap bolts and

washers and coat threads with Loctite #277 or its

equivalent. Install bearing cap bolts and tighten enough

to eliminate visible space between differential bearing cap

and carrier housing. Do not torque the cap bolts at this

time.

4. Install adjusting rings. Tighten both adjusting rings

until end play is eliminated and there is backlash

between the ring gear and pinion. See Figure 15.

5. Loosen adjusting ring on tooth side of ring gear 1 notch

and tighten adjusting ring on flange side of ring gear 1

notch. Repeat process until backlash is eliminated.

Tighten adjusting ring on tooth side of the ring gear 2 or

3 notches or until proper backlash and side bearing

preload are established.

23

FF

igurigur

e 1e 1

66

F

igur

e 1

6

FF

igurigur

e 1e 1

66

Differential Installation Complete

Page 26

OUTPUT SHAFT ASSEMBL Y

Flanged Hex Nut

(500-600 Lb-Ft)

(678-813 N-m)

Output Shaft Bearing

End Yoke Assembly (Output)

Output Shaft Oil Seal

Output Shaft Bearing Cage

Bolt

(30-40 Lb-Ft)

(41-55 N-m)

Snap Ring

Output Shaft

1. Support output shaft bearing and press output shaft into

bearing.

2. Install bearing cage over bearing and secure with snap

ring.

NOTE: To insure proper end play, both inner and outer

bearings are in matched sets with spacers. Do not mix

separate bearings.

CAUTION: Use only enough pressure to lightly seat

bearings against the thick spacer. Excessive pressure could

damage the assembly.

3. Install new seal using seal installer tool (See Recom-

mended Service Tools, Pgs. 35-36).

4. Install end yoke using yoke installer tool (See Recom-

mended Service Tools, Pgs. 35-36) and place washer

onto shaft. Clean and dry threads, then coat with Loctite

#680 and torque to 500-600 Lb-Ft (678-813 N-m).

5. Clean mating surface on axle housing and output shaft

bearing retainer. Apply a 1/16” bead of Loctite #518

Gasket Eliminator on housing mounting flange and around

bolt holes. Install output shaft, with lube trough to

bottom. See Figure 17. Tighten mounting bolts evenly to

30-40 Lb-Ft (41-55 N-m).

6. Install rear drive shaft.

Loctite #518

Lube Trough

24

FF

igurigur

e 1e 1

77

F

igur

e 1

7

FF

igurigur

e 1e 1

77

Output Shaft Assembly Complete

Page 27

Idler Gear Shaft

Air Shift Cylinder

Retainer Clip

Retainer Spring

Air Shift Cylinder Bolt

(30-40 Lb-Ft)

(41-55 N-m)

Shift Fork Shaft

(30-38 Lb-Ft)

(41-51 N-m)

Idler Gear Front Bearing Cone

Idler Gear Front Bearing Cup

Idler Gear

Idler Gear Bearing Spacer (Selective)

INTERMEDIA TE CASE ASSEMBLY

IMPORTANT: Torque

specifications, shown on illustration,

apply only to J Model. See Page 3334 for W Model torque specifications.

Idler Gear Front Bearing Cup

Idler Gear Front Bearing Cone

Inter-Axle Differential Case

Idler Shaft Nut

(500-600 Lb-Ft)

(678-813 N-m)

Shift Fork

Inter-Axle Differential

Case Bolt

(75 -90 Lb-Ft)

(101-122 N-m)

1. Install bearing cups into the idler gear. Be certain cups

are pressed completely into or improper measurement of

end play will result.

2. Install bearing spacer and bearings into idler gear. The

end play is controlled by the bearing spacer.

3. Install idler gear into intermediate case. Slide gear into

position.

4. Install idler shaft into idler gear and intermediate case.

Drive Gear Bearing Cup

Drive Gear Bearing Cone

Input Drive Gear

Inter-Axle Differential Bearing Cone

Inter-Axle Differential Bearing Cup

Shift Collar

The plate accomplishes two things:

A. It positions the idler shaft properly to facilitate assembly

of the intermediate case to the differential carrier housing.

B. It retains the input gear bearing cup in the

intermediatecase when checking end play of the inter-axle

differential.

8. Turn intermediate case over. Install a new prevailing

torque nut.

5. Install input gear bearing cup into intermediate case. Use

of Loctite to help retain bearing cup in case is recommended.

IMPORTANT: A special plate has been designed to aid in

assembly. A print of the special plate is provided for your

convenience. See Pg. 19.

25

9. Retain intermediate case to eliminate movement.

Use a torque multiplier wrench and torque idler

shaft nut to 500-600 Lb-Ft (675-800 N-m).

10 . The idler gear is designed to run with end play. Using a

dial indicator, check end play. End play should be .001”

to .006”. If it is not to specification, change bearing

Page 28

INTERMEDIA TE CASE ASSEMBLY

spacer. Use a thinner spacer to decrease end play or a

thicker spacer to increase end play. Any preload on the

gear bearing will cause premature bearing failure.

11 . Assemble bearing cones onto front and tear of input gear

and install input gear assembly into intermediate case.

Rotate to make sure it is seated properly.

12 . Assemble shift fork onto shift collar and install into

intermediate case. Be sure the boss on the shift fork is

pointing up or towards the inter-axle differential before

installing. Unit will not shift correctly if installed improperly.

13 . Apply Loctite #290 to threads of shift fork shaft.

FABRICATE SPECIAL PLATE FROM 3/8” STEEL

14 . Install shift fork shaft into intermediate case and thread

into shift fork. Torque shaft to 30 to 38 Lb- Ft (41-52 Nm). Place spring over shaft. Compress spring and install

retainer clip into groove in shaft. Intermediate case is now

ready for assembly of inter-axle differential.

Intermediate Case Assembly Complete

23.292mm

4.625"

117.475mm

54.381mm

1.96"

49.784mm

.917"

2.141"

2.290"

58.166mm

45

5.281"

134.137mm

5.063"

128.600mm

2.593"

65.862mm

3.78 DIA.

96.012mm

9.843"

250.012mm

81.737mm

1.187"

30.149mm

3.218"

48.412mm

3.968"

100.787mm

1.906"

25

3.052"

77.520mm

.323"

8.204mm

101.600mm

4.063"

103.200mm

4.000"

3.468"

88.087mm

7.531"

191.287mm

26

Page 29

Spiral Snap Ring

Inter-Axle Differential Rear Bearing

Input Bearing Cone

Input Bearing Cup

Shim (Selective)

INTER-AXLE DIFFERENTIAL ASSEMBLY

Inter-Axle Differential Case

Assembly

IMPORTANT: Torque

specifications, shown on illustration,

apply only to J Model. See Page 3334 for W Model torque specifications.

Fill Plug

Inter-Axle Differential Cover

Pinion Oil Seal

End Yoke

Assembly

Inter-Axle Differential

Cover Bolt

(75-90 Lb-Ft)

(102-122N-m)

1. Press input bearing cone onto inter-axle differential case

assembly. Install bearing cup into differential cover

without shims.

2. Install inter-axle differential case assembly into

intermediate case. Then place the inter-axle

differential cover on top of the inter-axle differential

assembly. (the inter-axle differential rear bearing should

not be installed at this time)

3. Secure inter-axle differential cover into place with

four bolts. Bolts do not have to be torqued, but

should be enough to prevent movement.

4. Position a dial indicator on input shaft of inter-axle

differential. See Figure 18. Use a lever arm and pry

differential up to measure end play. Record this

dimension. Remove inter-axle cover and inter-axle

differential. Remove bearing cup from cover.

5. End play for the inter-axle differential is .001-.005.

From the dimension recorded in step 4, subtract

.001-.005 for correct shim required.

Flanged Hex Nut

(900-1,200 Lb-Ft)

(1,220-1,627N-m)

FF

igurigur

e 1e 1

88

F

igur

e 1

8

FF

igurigur

e 1e 1

88

EXAMPLE

.080 in. (2.032 mm) Dial indicator measurement

-.003 in. (.076 mm) Preferred end play

.077 in. (1.956 mm) Shims required

Install proper shim and bearing cup into inter-axle cover.

6. Press inter-axle differential rear bearing onto rear case of

inter-axle differential cover.

7. Assemble spiral snap ring onto differential case. Be sure

snap ring is completely seated into groove.

27

Page 30

INTER-AXLE DIFFERENTIAL ASSEMBLY

8. Install input seal into inter-axle cover. Apply a light coat

of lubricant onto seal prior to installation. Assemble end

yoke onto input shaft of inter-axle differential. Mount

end yoke in vise.

9. Clean and dry threads. Coat threads with Loctite

#680 and torque nut to 900-1,200 Lb-Ft

(1,220-1,627 N-m). See Figure 19.

10 . Apply 1/16" bead of Loctite #518 Gasket Eliminator to

mating surface on rear side of input shaft bearing retainer.

See Figure 20. Position retainer onto intermediate case.

Install bolts and tighten to 75-90 Lb-Ft (102-122 N-m).

Again check end play to assure proper setting.

Figure 20Figure 20

Figure 20

Figure 20Figure 20

12 . Torque mounting bolts to 30-40 Lb-Ft (41-55 N-m).

13 . As a check, connect air line to power divider control to be

certain it is operable. There should be a distinct “clunk”

sound when air is applied.

FF

igurigur

e 1e 1

99

F

igur

e 1

9

FF

igurigur

e 1e 1

99

11 . Apply 1/16" bead of Loctite #518 Gasket Eliminator

onto mounting surface next to cylinder and install onto

intermediate case. See Figure 21.

Inter-axle Differential Assembly Complete

FF

F

igur

FF

igurigur

igurigur

e 2e 2

e 2

e 2e 2

11

1

11

28

Page 31

RING GEAR AND PINION TOOTH CONT ACT PA TTERN

The procedures to the right are to be used to establish proper

gear tooth pattern after assembly of the carrier is complete.

NOTE: If matched sets are being reused, measure and record

backlash before disassembly, and reassemble to the same

backlash. This will match ring and pinion gears to the established wear patterns. Hand rolled patterns will cover less area

than the gear pattern established by previous service.

Gleason cut gears and Oerlikon cut gears can be identified by

using the following chart.

Example: Gleason cut Wmodel, 584282C1.

J Model W Model

Gleason 047GX1XX XXXXXXC1

XXXXXXR1

Oerlikon ------ 057GX2XX

STEP 1. Paint 1/4 ring gear with marking compound on

both the drive and coast side.

STEP 2. Rotate ring gear at least one complete revolution in

both directions while load is being applied.

CORRECT GEAR P ATTERNS FOR GLEASON CUT GEARS

LIGHTLY LOADED

HEAVILY LOADED

CORRECT GEAR P ATTERNS FOR ORLIKON CUT GEARS

LIGHTLY LOADED

HEAVILY LOADED

NOTE: Tooth contact pattern, on this axle model, can be moved only by adjusting backlash. The contact pattern can be moved in

the direction of heel-to-toe, and toe-to-heel; Depth of the pattern cannot be adjusted. If an acceptable tooth contact pattern

cannot be established within limits of backlash, contact Spicer Service at 1-800-666-8688.

29

Page 32

INST ALLATION OF INTER-AXLE DIFFERNETIAL TO CARRIER

1. Thoroughly clean mating face of carrier and apply an 1/8

inch bead of Loctite #518 Gasket Eliminator. See Figure

21 for correct bead pattern.

2. Align inter-axle differential case with carrier housing and

insert bolts and torque to 160-180 Lb-Ft (217-244 N-m).

#518 Gasket Eliminator Bead Pattern

FF

igurigur

e 2e 2

11

F

igur

e 2

1

FF

igurigur

e 2e 2

11

YOKE REMOV AL AND SEAL REPLACEMENT

1. Disconnect drive shaft at the rear U-joint.

2. Remove yoke nut.

NOTE: Use of torque multiplier is recommended as torque

specification on input flanged hex nut is 900-1,200 Lb-Ft

(1,220-1,627 N-m).

3. Remove end yoke using the yoke remover tool. See

Figure 22.

4. Remove oil seal.

5. Inspect end yoke seal surface for grooves. If grooves can

be detected with fingernail, it should be repaired with a

®

CR SPEEDI-SLEEVE

6. Clean and dry threads on input/ouput shaft or

pinion. Install oil seal using proper tools.

7. Install end yoke using yoke installer.

NOTE: Spicer recommends that new flanged hex nuts be used.

or replaced.

8. Apply Loctite #680 (green) to threads.

9. Use torque multiplier and torque flanged hex nut to 900-

1,200 Lb-Ft (1,220-1,627 N-m).

Yoke Remover

Figure 22Figure 22

Figure 22

Figure 22Figure 22

Yoke Removal and Seal Replacement Complete

30

Page 33

INST ALLATION OF DIFFERENTIAL CARRIER TO AXLE HOUSING

1. Thoroughly clean the inside of the carrier housing and

inspect the housing mounting surface for nicks and general

cleanliness. Stone the surface if necessary to remove burrs

or nicks. Bolt holes must also be checked to see that they

are free of contaminants.

Loctite #518

Gasket Eliminator

Figure 23Figure 23

Figure 23

Figure 23Figure 23

8. Install the axle shafts to proper location. Torque the axle

flange nuts to vehicle manufacturers specifications.

9. Clean drain plug and install. Torque drain plug to 35-45

Lb-Ft (47-61 N-m). Fill unit to proper level with hypoid

gear lubricant.

10. Install fill plug and torque to 35-45 Lb-Ft (47-61 N-m).

NOTE: Lubricant close enough to bottom of fill hole to be seen or

touched is not sufficient. Lubricant must be level with the fill hole.

2. Apply an 1/8“ (3.175 mm) diameter bead of Loctite

#518 Gasket Eliminator onto the axle housing mounting

flange and around each bolt hole. See Figure 23.

3. Thread two studs into the axle housing 180º

apart. This

will eliminate rotation of the carrier assembly after it

makes contact with the gasket material.

4. Install the carrier assembly into the axle housing. If

reinstalling used bolts, clean the mounting bolts, and coat

with Loctite #277, and install. Tighten bolts evenly in a

crossing pattern. Torque bolts 240-260 Lb-Ft (325-352

N-m).

5. Allow one hour cure time for gasket material before

adding hypoid gear lubricant.

6. Remove the old axle flange gasket and clean mating

surfaces of the hub and axle flange.

7. Install the new axle flange gasket.

CAPACITIES (Approximate*):

J Models Pints Liters

Forward Rear 33.5 16.0

Rear Rear Axle 26.5 12.7

W Models Pints Liters

Forward Rear 35.5 16.9

Rear Rear Axle 28.5 13.6

* Lube capacity will vary depending upon the housing angle in each

vehicle. Capacities given above are for an angle of 4 degrees. Fill to

the lower edge of the fill hole in the axle housing as shown above.

** Pour 1 Pint (0.5 Liter) of gear lube into the filler hole in top of

Inter-axle Differential cover.

31

Page 34

WHEEL BEARING ADJUSTMENT

,,,

,,

,

NOTE: Wheel bearings should be adjusted following vehicle

manufacturers recommended maintenance schedule.

1. Block wheels not being adjusted to insure that vehicle will

not roll. Release emergency brake.

2. Raise wheel to be adjusted off of the ground. Make certain

wheel rotates freely.

3. Remove axle shaft.

4. Remove outer adjusting nut and lock if tabs are broken.

5. Torque inner wheel nut to 50 Lb-Ft (68 N-m) while

rotating wheel one direction, then the other direction.

Back off inner nut 1/4 turn.

NOTE: When replacing wheel bearings, new bearings must be

seated to insure maximum service reliability. After the hub and

bearings are assembled in place on the spindle, install the

inner adjusting nut. Tighten the inner adjusting nut to 120 140 Lb-Ft (163-190 N-m), while rotating the hub to seat the

bearings. Back off the adjusting nut 1/2 turn and follow the

procedure outlined in step #5.

LUBRICANT LEVELLUBRICANT LEVEL

LUBRICANT LEVEL

LUBRICANT LEVELLUBRICANT LEVEL

6. Install lock against inner wheel nut, with locking portion

positioned on either the flat side of inner nut or peak of

inner nut, as shown.

7. Install outer wheel nut and torque to 250-275 Lb-Ft

(340-373 N-m). Rotate wheel in both directions. Wheel

must rotate freely, without binding.

8. Bend one tang of lock over flat portion of outer wheel to

secure.

9. Remove old axle flange gasket and clean mating surfaces

of hub and axle flange.

10 . Install new axle flange gasket.

11 . Install axle shaft. Torque axle nuts to specifications. (See

Axle/Torque Specifications, Pg. 33).

32

Page 35

Axle Specifications

AXLE / TORQUE SPECIFICA TIONS

Description

J Models

U.S. Metric

W Models

U.S. Metric

Pinion

Nominal Dimension 3.976 in. 95.745 mm 4.2845 in. 108.826 mm

Bearing Preload (Torque Wrench) 10-30 Lb-in 1.1-3.4 N-m 10-30 Lb-in 1.1-3.4 N-m

Differential

Ring Gear to Pinion Backlash .010-.013 in. .25-.33 mm .012-.016 in. .30-.40 mm

Ring Gear Rivet Pressure 45-50 tons 41-45 tonnes 50 tons 45 tonnes

Power Divider

Inter-axle Differential End Play .001-.005 in. .03-.12 mm .001-.005 in. .03-.12 mm

Idler Gear Bearing End Play .001-.006 in. .03-.15 mm .001-.006 in. .03-.15 mm

Lubrication (Approx.**)

Forward Rear Axle 33.5 16.0 35.5 16.9

Rear Rear Axle 26.5 12.7 28.5 13.6

* Pinion bearing preload is established prior to installation of pinion seal.

** Capacity will vary depending on the housing angle in each vehicle. Fill to lower edge of fill hole in rear of axle housing as shown on Page 30.

§ Pour 1 Pint (0.5 Liter) of gear lube into filler hole in top of inter-axle differential cover.

Axle Specifications

Position Model

Thread

Grade

Lb-Ft

N-m

Axle Flange to J340-S Only 5/8-18 5 Nylok 125-145 170-195

Wheel Hub Nuts*** J380-S thru W460-S 3/4-16 5 Nylok 217-240 290-325

Axle Flange to J340-S Only 5/8-18 8 Steel 160-185 220-250

Wheel Hub Nuts*** J380-S thru W460-S 3/4-16 8 Steel 275-320 370-435

NOTE: Refer to vehicle manufacturer specifications for axle Flange-Wheel Nut fastener torque.

*** Axle flange mounting nuts are either a grade 5 nylon (Nylok) locking nut, or a grade 8 steel locking nut. Torque to specification shown in

chart above.

33

Page 36

AXLE / TORQUE SPECIFICA TIONS

Power Divider Fasteners

Position Thread

Grade

Lb-Ft N-m

Flanged Hex Nut, Input 1 3/4-12 900-1,200 1,220-1,267

Flanged Hex Nut, Output 1 1/2-18 500-600** 680-816**

Idler Shaft Nut 1 1/4-18 500-600 680-816

Inter-axle Differential Cover Bolt (Hex) 1/2-13 8 75-90 101-122

Intermediate Case Bolts (Flanged) 1/2-13 8 75-90 101-122

Output Shaft Retainer Bolts 3/8-16 8 30-40 41-55

Shift Fork Shaft 1/2-13 30-38 41-52

Air Shift Cylinder Bolts 3/8-16 8 30-40 41-55

** Threads must be cleaned and dried, and coated with Loctite#518 adhesive compound, or its equivalent.

Forward/Rear Axle Common Fasteners

Position Thread

GradeModel

Lb-Ft N-m

Castillated Pinion Nut All Fwd Carriers 1 3/4-12 600 Min.* 815 Min.*

Flanged Hex Nut, Rear All 1 3/4-12 900-1,200** 1,220-1,627**

Pinion Bearing Cage Bolts (Hex) All Fwd Carriers 9/16-12 5 115-135 155-183

Pinion Bearing Cage Bolts (Hex) All 5/8-11 5 160-180 218-245

Pinion Bearing Cage Bolts (Flanged) All 5/8-11 8 240-260 326-352

Differential Bearing Cap Bolts (Hex) All 3/4-10 5 275-320 373-433

Differential Bearing Cap Bolts (Flanged) All 3/4-10 8 295-340 400-460

Differential Case Nuts J 9/16-18 8 115-135 155-183

Differential Case Nuts W 5/8-18 8 160-180 218-245

Carrier Mounting Bolts (Hex) All 5/8-11 5 160-180 218-245

Carrier Mounting Bolts (Flanged) All 5/8-11 8 240-260 326-352

Differential Case Oil Scoop Bolts All 1/4-20 8 7-9 9-12

Oil Pipe Plugs All 3/4-14 8 35-45 47-61

Ring Gear Bolt Kit All M16 x 1.5-6G 300-320 406-434

*

If roll pin cannot be installed after minimum torque is attained, the nut must be advanced until roll pin can be installed.

** Threads must be cleaned and dried, and coated with Loctite#518 adhesive compound, or its equivalent.

34

Page 37

RECOMMENDED SERVICE TOOLS

ILLUSTRA TION ORDER NUMBER

DESCRIPTION

DST1001 CARRIER STAND

DST1002

TORQUE MULTIPLIERS

Maximum 1,000 Lb-Ft

DST1003

Maximum 2,000 Lb-Ft

DST1004

DST1005

Maximum 4,000 Lb-Ft

Maximum 12,000 Lb-Ft

DST1006

DST1009