Page 1

Spicer

®

TPCS

(

Tire Pressure Control System

Troubleshooting Guide

AXTS0020

)

April 2007

Page 2

Warnings and Cautions

General Information

The descriptions and specifications contained in this service

publication are current at the time of printing.

Dana reserves the right to discontinue or modify its models

and/or procedures and to change specifications at any time

without notice.

IMPORTANT NOTICE

This symbol is used throughout this

manual to call attention to procedures

where carelessness or failure to follow

specific instructions may result in

personal injury and/or component

damage.

Departure from the instructions, choice

of tools, materials and recommended

parts mentioned in this publication

may jeopardize the personal safety

of the service technician or vehicle

operator.

Any reference to brand name in this publication is made as an

example of the types of tools and materials recommended for

use and should not be considered an endorsement. Equivalents may be used.

WARNING: Failure to follow indicated

procedures creates a high risk of personal

injury to the servicing technician.

CAUTION: Failure to follow indicated

procedures may cause component

damage or malfunction.

IMPORTANT: Highly recommended

procedures for proper service of this unit.

Note: Additional service information not

covered in the service procedures.

Always use genuine Spicer replacement parts.

Every effort has been made to ensure the accuracy of all information in this guide. However, Dana Commercial Vehicle

Systems Division makes no expressed or implied warranty

or representation based on the enclosed information.

Any errors or omissions may be reported to:

Marketing Services

Dana Commercial Vehicle Systems Division

P.O. Box 4097

Kalamazoo, MI. 49003

Tip: Helpful removal and installation

procedures to aid in the service of this unit.

Page 3

Table of Contents

General Information

Tire Pressure Control System 1

Key Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Component Description . . . . . . . . . . . . . . . . . . . . . . . . 2

Simplified System Schematic . . . . . . . . . . . . . . . . . . . . 4

Operator Instructions

Driver Display Module (DDM) . . . . . . . . . . . . . . . . . . . 5

Operator Control Panel (OCP) . . . . . . . . . . . . . . . . . . . 8

OCP Programming Chart . . . . . . . . . . . . . . . . . . . . . . 12

Diagnostics

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Troubleshooting Tips . . . . . . . . . . . . . . . . . . . . . . . . . 16

Service Code Summary . . . . . . . . . . . . . . . . . . . . . . . 17

Service Codes

Group: 1C! (Code 17) . . . . . . . . . . . . . . . . . . . . . . . . . 19

Group: 3C! (Codes 18, 76, 77) . . . . . . . . . . . . . . . . . . 21

Group: 4C! (Code 15) . . . . . . . . . . . . . . . . . . . . . . . . . 23

Group: 5C! (Codes 33, 34) . . . . . . . . . . . . . . . . . . . . . 25

Group: 12C! (Codes 51, 52, 53, 54, 55, 56) . . . . . . . . 27

Group: 1P! (Codes 11, 12, 13, 16, 22) . . . . . . . . . . . . 29

Group: 2P! (Code 14) . . . . . . . . . . . . . . . . . . . . . . . . . 31

Group: 3P! (Code 21) . . . . . . . . . . . . . . . . . . . . . . . . . 33

Group: 4P! (Codes 23, 24, 25) . . . . . . . . . . . . . . . . . . 35

Group: 5P! (Codes 26, 27, 28) . . . . . . . . . . . . . . . . . . 37

Group: 7P! (Codes 31, 32) . . . . . . . . . . . . . . . . . . . . . 39

Group: 8P! (Code 35) . . . . . . . . . . . . . . . . . . . . . . . . . 41

Group: 9P! (Codes 36, 37, 38) . . . . . . . . . . . . . . . . . . 43

Group: 10P! (Codes 41, 42, 43) . . . . . . . . . . . . . . . . . 45

Group: 11P! (Codes 44, 45, 46) . . . . . . . . . . . . . . . . . 47

Group: 12P! (Codes 61, 62, 63, 64, 65, 66) . . . . . . . . 49

Code: No Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Service Procedures

Final System Checkout . . . . . . . . . . . . . . . . . . . . . . . .55

Pneumatic Control Unit - Cleaning and Inspection . . .57

Solenoid Assembly and Cartridge . . . . . . . . . . . . . . . .59

Service Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

Joint Compounds and Fittings . . . . . . . . . . . . . . . . . . .61

Air Filter Change . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

Troubleshooting Wheel End Seals . . . . . . . . . . . . . . . .63

Hose and Supply Tank Selection Chart . . . . . . . . . . . .65

Wire Harness

Connector Illustrations . . . . . . . . . . . . . . . . . . . . . . . .67

Electrical Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . .68

Configuration Connections . . . . . . . . . . . . . . . . . . . . .70

Table of Contents

i

Page 4

Tire Pressure Control System

General Information

Spicer Tire Pressure Control System features driver control of

tire air pressure through:

• Simple push button operation.

• Independent Front, Rear, and Trailer operation.

• Electronic braking priority for air system.

• Vehicle speed sensing and response capability.

• Self-diagnostics.

Key Features

Depressurized Control Lines

The only time the system is pressurized is when changing tire

pressures or during pressure checks. Wheel valves isolate the

tires from the rest of the system.

Electronic Braking Priority

A pressure switch, installed in the supply tank, controls the

TPCS’s use of air. This optimizes and protects the brake system’s primary tank pressures during system operation.

Self-Diagnostic and Auto Shut-Down

The Spicer TPCS provides self-diagnosis during operation. If

the system detects a problem, it will display a service code on

the driver interface to alert the driver. If necessary, it will close

the wheel valves and shut down.

Diagnostic Capability

The Spicer TPCS provides for easy troubleshooting using PCbased or industry standard tools. PC-supported diagnostics

improve troubleshooting, reduce maintenance time, provide

manual control of TPCS test sequences, and give historical

and active service code data.

Speed / Pressure Control and Warning

If truck speed exceeds the maximum allowable speed for a

given setting, a warning is activated by TPCS to alert the

driver. If speed is not reduced, the system automatically

inflates the tires to the appropriate pressure.

Manual Tire Inflation / Deflation

A valve stem has been included on each wheel valve and may

be used for manual inflation, deflation or measurement of tire

pressures.

Run Flat Operation

The TPCS normally checks tire pressures at intervals of 15

minutes. If possible tire damage is detected, the system will

activate Auto RUN FLAT. RUN FLAT reduces the pressure

check interval to 15 seconds, helping to assure that the tire

will remain inflated despite minor tire damage.

1

Page 5

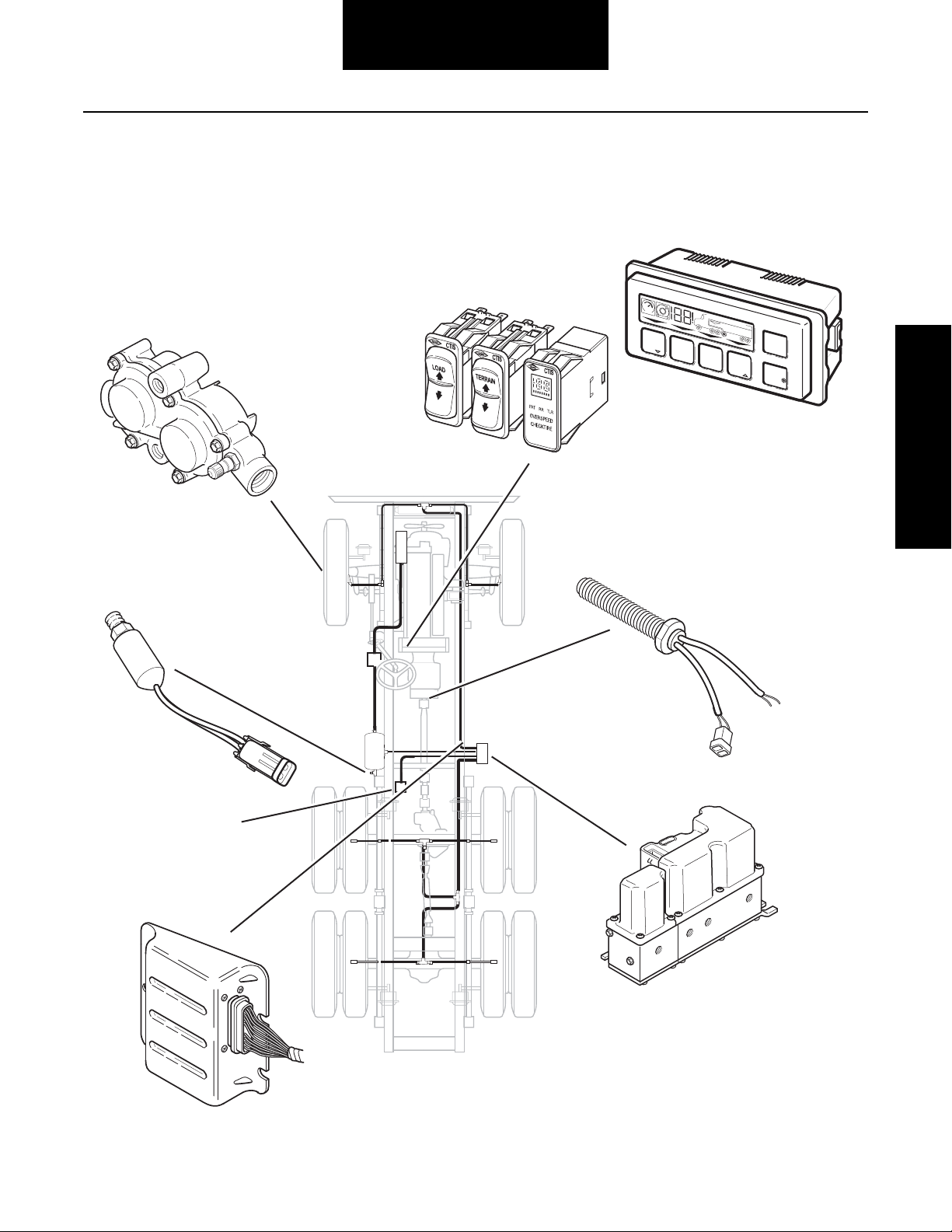

Component Description

Tire Pressure Control System Components

Wheel

Valve

General Information

Driver Display Module (DDM)

OR

mph

kph

L/U HWY OFF HWY

bar psi

Tire Pressure Control

EMER RUN FLAT

Operator Control Panel (OCP)

SELECT

Component Description

Pressure

Switch

Trailer

Connector

Speed Sensor

(or Alternate Speed Inputs)

Pneumatic Control Unit

(shown with optional 3rd channel)

Electronic

Control Unit

2

Page 6

General Information

Wheel Valve

All axles use a Wheel Valve (WV) at each end. Dual wheels are

typically connected through one WV to provide tire pressure

balance, although individual wheel valves for each tire may be

installed. When the system is idle, the wheel valve isolates the

tire(s), ensuring fail-safe operation. A standard valve stem is

included on the WV for manual inflation / deflation / pressure

checking.

Electronic Control Unit (ECU)

The Electronic Control Unit (ECU) is the control center for the

entire Tire Pressure Control System. The ECU receives commands from the driver through the Driver

(DDM) or Operator Control Panel (OCP) and transmits and

monitors appropriate signals throughout the system.

Display Module

Driver Interface

Options are available for the TPCS driver interface. The Driver

Display Module (DDM) includes two rocker switches and a

multi-function display. The Operator Control Panel (OCP) uses

a six-button keypad and graphic display.

Vehicle Speed

Speed is read from the vehicle data link or a separate speed

sensor.

Pressure Switch

The Pressure Switch (PS) acts as an electronic brake priority

switch. It prevents the Tire Pressure Control System from

using air from the supply tank until the brake system is fully

charged. The PS also ensures that enough pressure exists for

the system to operate properly.

Air Lines

The Tire Pressure Control System uses a dedicated pneumatic

system plumbed from the vehicle’s existing supply tank.

Wiring

A wiring harness (Dana or OEM supplied) provides for electrical signals between appropriate components.

Pneumatic Control Unit (PCU)

The Pneumatic Control Unit (PCU) is a solenoid controlled

manifold that controls the air system. It also contains the

Pressure Sensor (transducer) which reads tire pressures.

3

Page 7

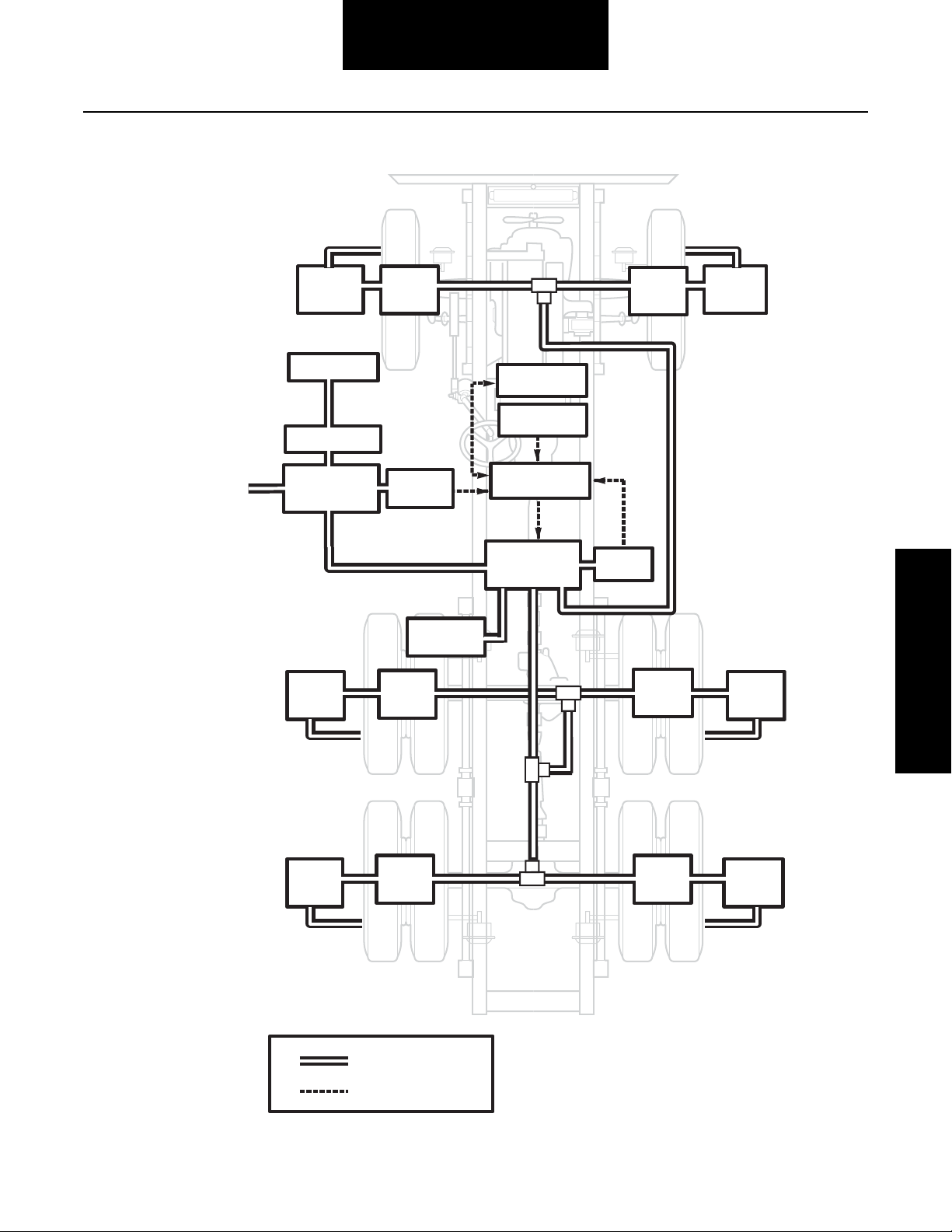

Simplified System Schematic

General Information

TireTire

To Primary

and Secondary

Tanks

Wheel

Valve

Compressor

Air Dryer

Supply Tank

Wheel

Valve

Rotary

Joint

Pressure

Switch

Connector

Seal

Assembly

Trailer

User

Interface

Speed Sensor

Electronic

Control Unit

Pneumatic

Control

Unit

PCU

Sensor

Rotary

Joint

Seal

Assembly

Wheel

Valve

Simplified System

Schematic

Wheel

Valve

Wheel

Valve

System Key

Seal

Assembly

Pneumatic

Electrical

Seal

Assembly

TireTire

Wheel

Valve

TireTire

4

Page 8

Operator Instructions

Operator Instructions - Driver Display Module (DDM)

TPCS may be equipped with one of two driver interface

devices: a Driver Display Module (DDM) or an Operator Control Panel (OCP). The Driver Disp

trated below and the following sec

and use.

lay Module (DDM) is illus-

tion explains the features

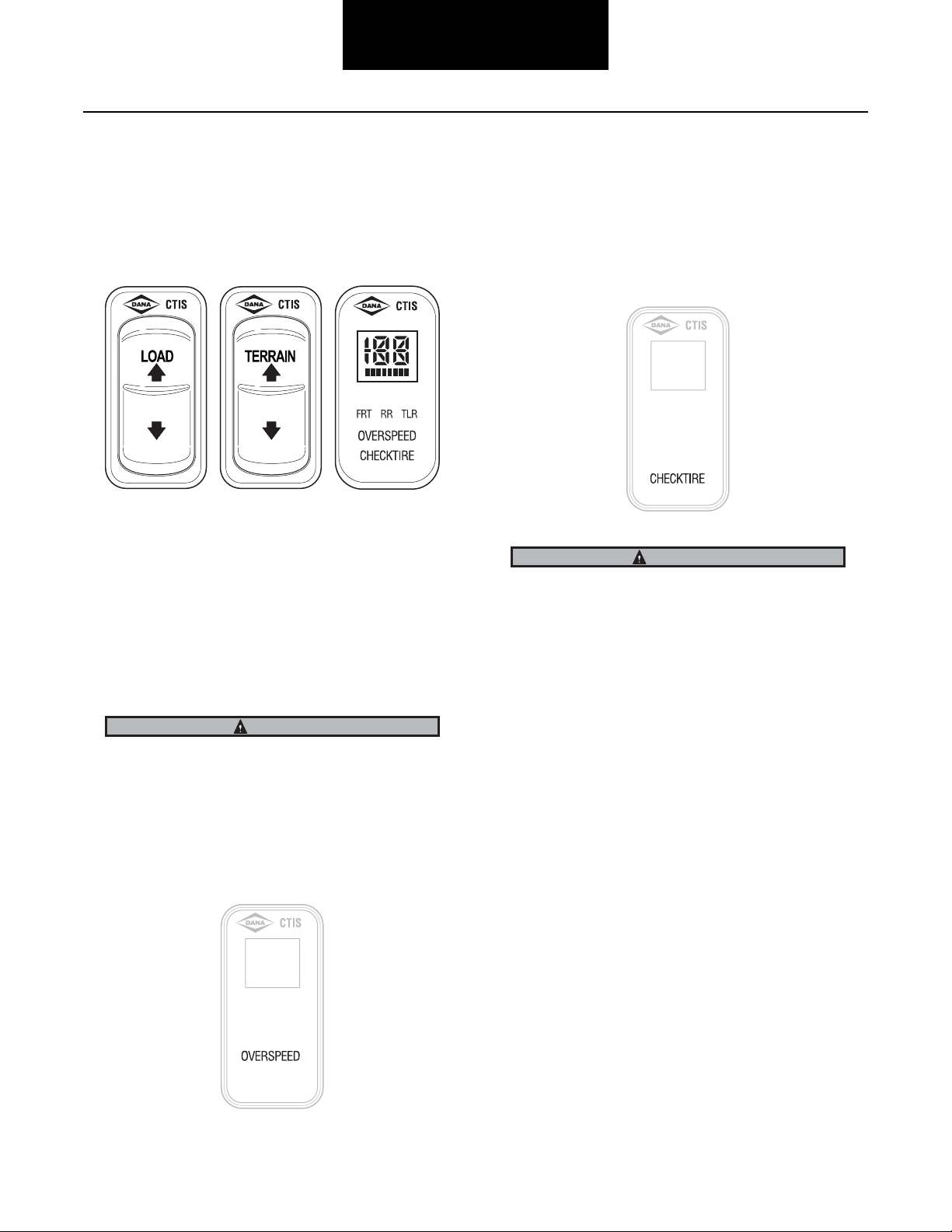

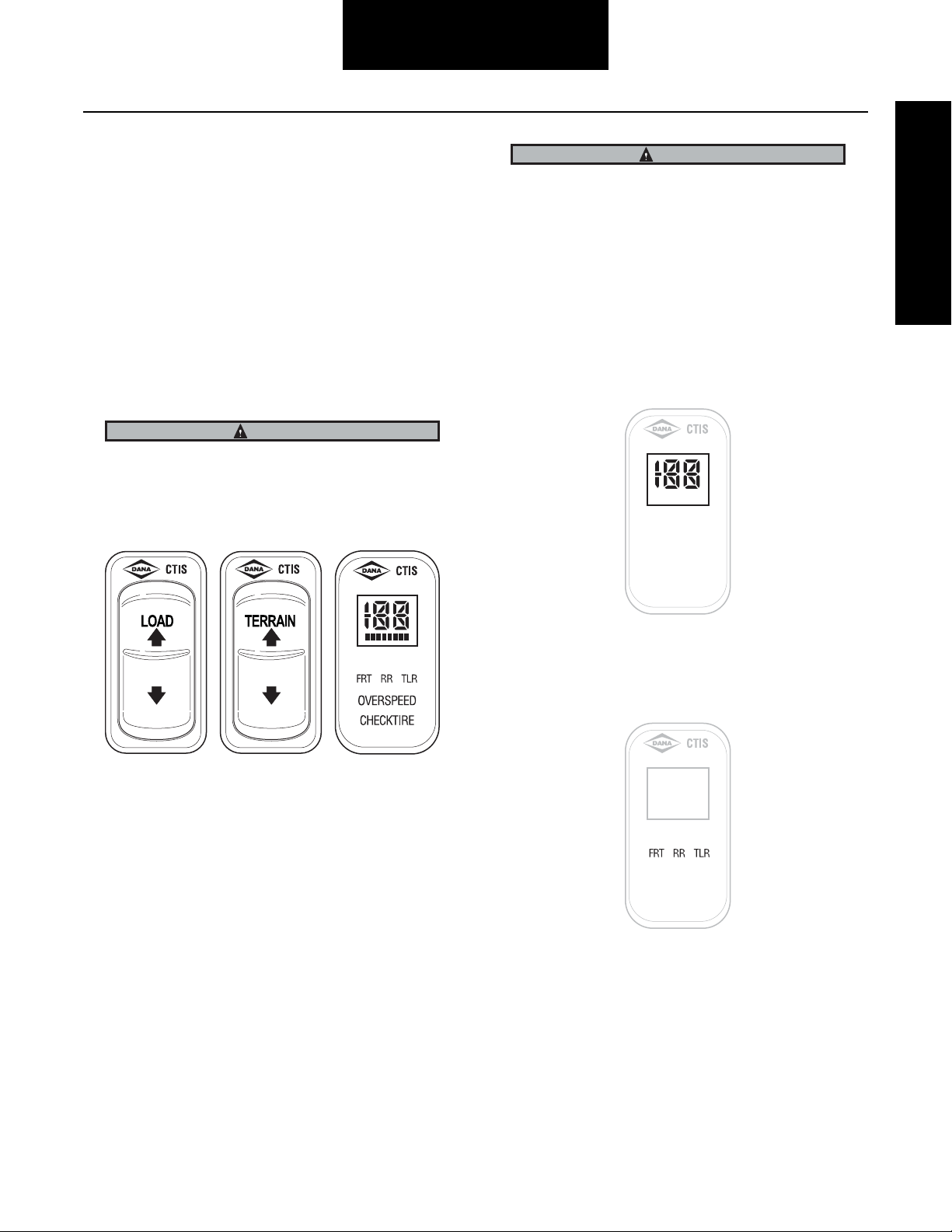

Warning Icons

TPCS includes two distinct warnings to report possible tire

problems and inappropriate vehicle operation. You must take

immediate action to either reduce vehicle speed or check tire

condition whenever these warnings are displayed.

Reduce Vehicle Speed

CAUTION

Failure to respond may result in overheated tires and

possible tire failure.

This signal reports that the vehicle speed is too fast for the

sure selected. You must either reduce speed or select a

pres

higher pressure by pressing the appropriate key. Continued

operation in this mode will result in the system automatically

selecting a more appropriate pressure setting.

Check Tire Condition

This signal reports that one or more tires may be at a significantly lower pressure than the others and could indicate that a

is not holding pressure. Stop the vehicle immediately in a

tire

safe place and identify the extent of tire damage.

IMPORTANT

Tires can still go flat! Although the Tire Pressure Control

is designed to identify under-inflated tires and fill

System

these tires to the desired operating pressure, you can still

expect that tires will occasionally be punctured or otherwise damaged during normal use and no longer retain air

liably. A daily walk-around inspection of the vehicle at the

re

start of the day, including a manual check of the tires, is

still an important responsibility of the vehicle operator. Tire

damage is more apparent after the vehicle has been idle

overnight and will be more difficult to detect visually once

the TPCS equipped vehicle is in operation. Although observation of excessive inflation periods through the driver

terface can help identify a tire problem, you should have

in

damaged tires replaced prior to placing the vehicle in operation.

5

Page 9

Terrain and Load Pressure Selection

Operator Instructions

Driver Display Module

CAUTION

TPCS displays both the selected terrain and load, and may be

configured to display numerical tire pressures in PSI, if

desired. Tire pressures for the following terrain modes can be

programmed and may be selected by the operator:

• Highw

• Off Highway (

• Em

The Emergency selection is for extreme conditions only and

ld not be used for normal driving.

shou

ay (Hy) - For travel on paved surfaces at

higher speeds.

OH) - For reduced speed operation on

secondary roads and unpaved surfaces.

ergency (E) - For selection of extremely low tire

pressures to help free a stuck vehicle.

CAUTION

System Operation

Operating a loaded vehicle at unloaded tire pressures may

sult in tire overheating and reduced tire life or blowout.

re

• Pressure Display - If the terrain switch

up position for >5 seconds, numerical tire pressures

(in PSI) for each channel will alternate in the display

with the selected mode.

Note: The system

due to heat buildup during vehicle use. This system will

not automatically deflate these pressure buildups—

lower pressure mode selection by the operator must be

selected to initiate a deflate.

is designed to allow tire pressure increase

is held in the

• Display - The DDM uses a multi-function display to

indicate the current selections. The display will show

HY for highway pressures, OH for off-highway pressures, and E for emergency pressures.

errain Selection - The terrain selection is changed

• T

by depressing the terrain rocker switch, up to

increase pressures and down to decrease pressures.

Any switch operation which does not change pressures will command the system to do a pressure

check.

• Loa

d Selection - Vehicle load selection is repre-

sented by a horizontal bar graph under the mode display. Depress the load rocker switch to change the

selection, up for increasing load and dow

decreasing load.

n for

• Chann

el Indicators - The DDM indicates FRT, RR or

TLR respectively for front, rear or trailer axle groups.

If a channel indicator is on continuously, that channel has achieved the target pressure.

6

Page 10

Operator Instructions

• Service Code Indication - The DDM will not display

service codes directly but will exhibit two dashes if

service is required. (Accessing the service codes will

require a diagnostic tool).

Note: See the Service Codes Section to diagnose and repair.

• RUN FLAT Indicator - If the TPC System determines

that a tire or tires may not be holding air, it may

reduce the pressure check interval to minimize the

possibility of air loss from the tire by switching to

RUN FLAT operation. (See RUN FLAT in the Key Features section).

If RUN FLAT is activated, the DDM will alternate the

display of the terrain setting and RF and the CHECK

TIRE indicator will be illuminated.

Tire Pressure Control System Programming

Spicer's Tire Pressure Control System is fully programmable,

allowing the technician to program tire pressures for each

channel (axle group) and maximum speeds for each terrain

mode. If equip

programming must be done with a diagnostic tool.

Programmable settings include:

• Individual pressure settings for the front, rear, and

• Loaded and unloaded axle group programming for

• Over speed warning threshold for highway,

ped with

trailer axle groups.

highway, off-highway, and emergency conditions.

off-highway and emergency conditions.

the Driver Display Module (DDM),

CHECKTIRE

7

Page 11

Operator Instructions

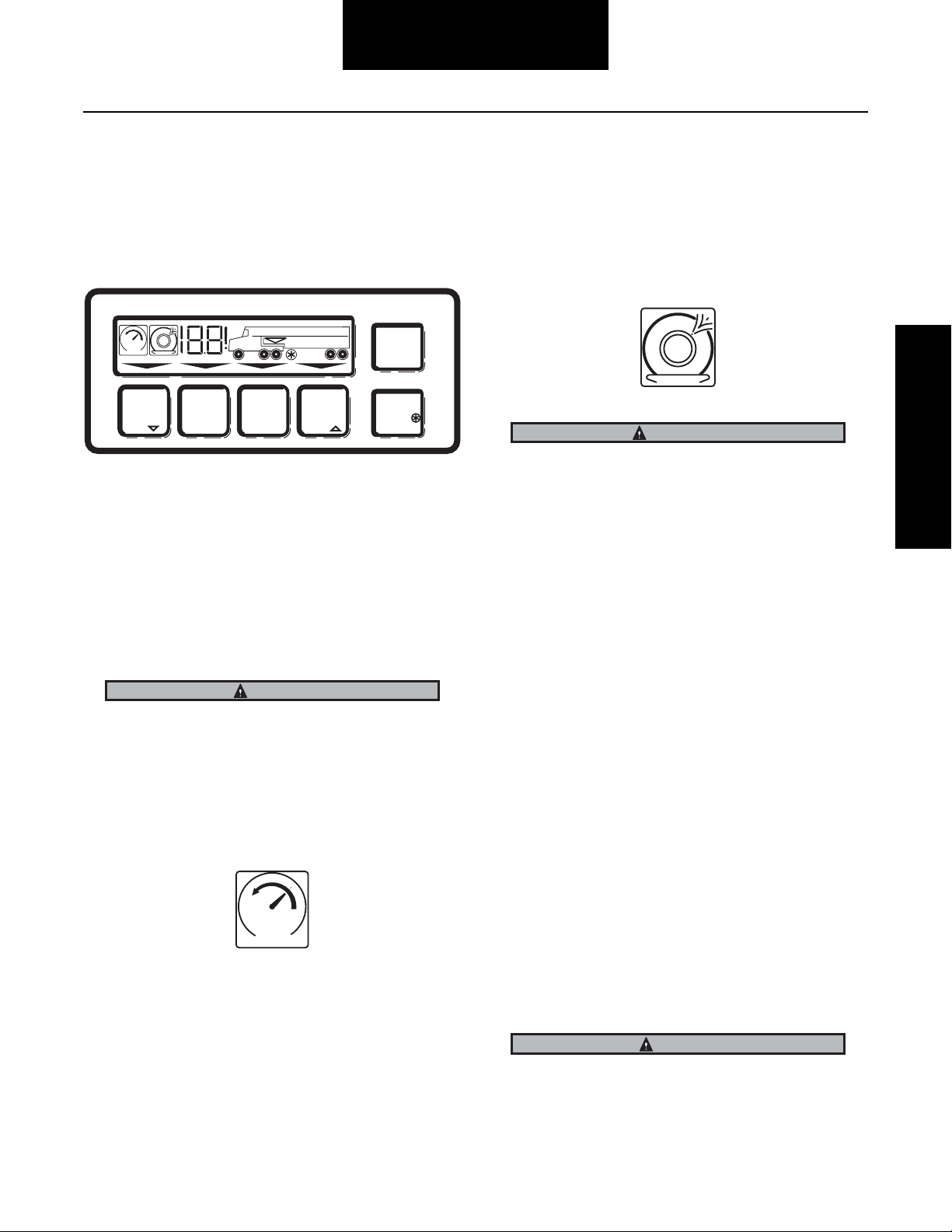

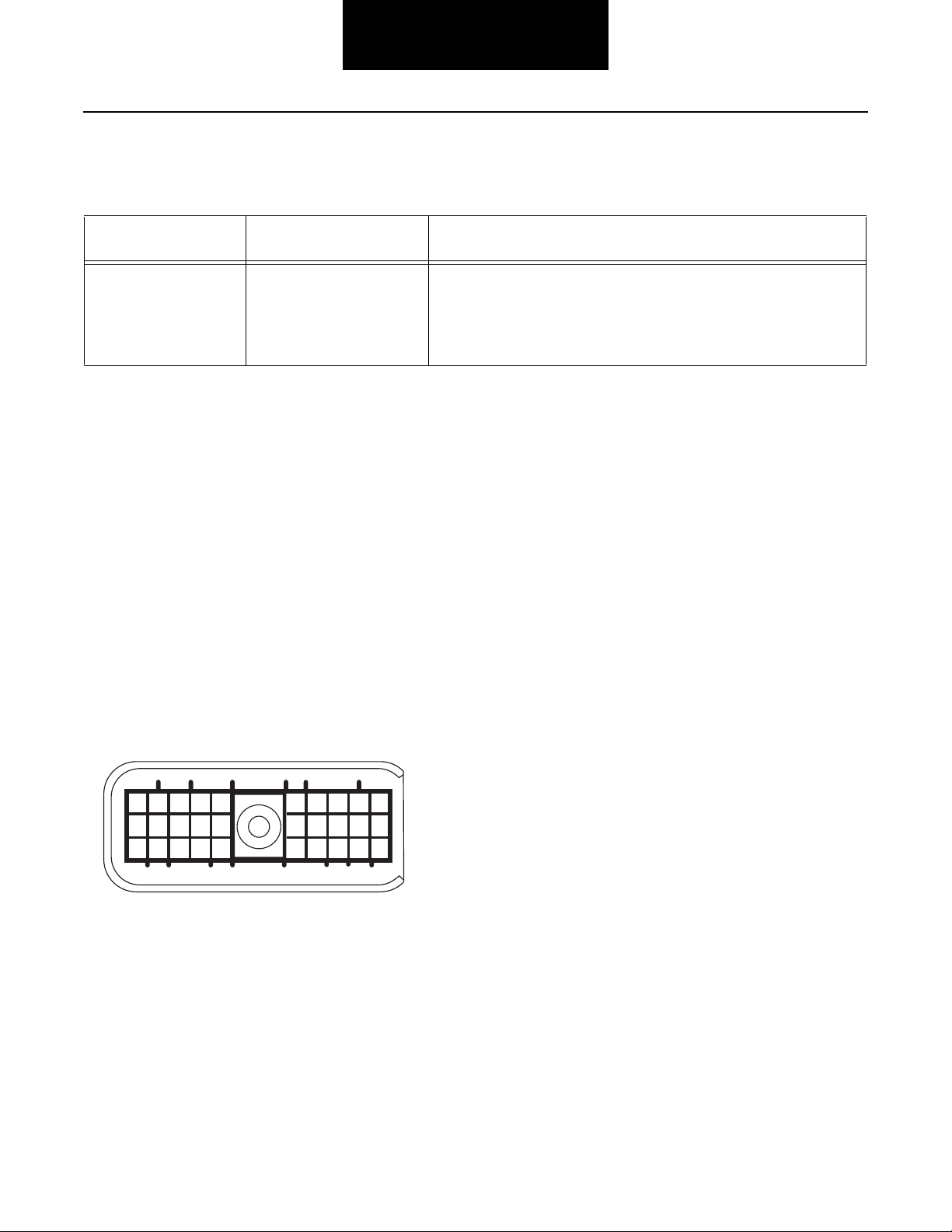

Operator Instructions - Operator Control Panel (OCP)

TPCS may be equipped with one of two driver interface

devices: a Driver Display Module (DDM) or an Operator Control Panel (OCP). The Operator Control Panel (OCP) is illustrated below and the following sec

tion explains the features

and use.

mph

kph

L/ U HWY OFF HWY EMER RUN FLAT

bar psi

SELECT

Warning Icons

TPCS includes two distinct warnings to report possible tire

problems and inappropriate vehicle operation. You must take

immediate action to either reduce vehicle speed or check tire

condition whenever these warnings are displayed.

Reduce Vehicle Speed

CAUTION

Failure to respond may result in overheated tires and possible tire failure.

Check Tire Condition

This signal reports that one or more tires may be at a significantly lower pressure than the others and could indicate that a

is not holding pressure. Stop the vehicle immediately in a

tire

safe place and identify the extent of tire damage.

IMPORTANT

Tires can still go flat! Although the Tire Pressure Control

is designed to identify under-inflated tires and fill

System

these tires to the desired operating pressure, you can still

expect that tires will occasionally be punctured or otherwise damaged during normal use and no longer retain air

liably. A daily walk-around inspection of the vehicle at the

re

start of the day, including a manual check of the tires, is

still an important responsibility of the vehicle operator. Tire

damage is more apparent after the vehicle has been idle

overnight and will be more difficult to detect visually once

the TPCS equipped vehicle is in operation. Although observation of excessive inflation periods through the driver

terface can help identify a tire problem, you should have

in

damaged tires replaced prior to placing the vehicle in operation.

Operator Control Panel

This signal reports that the vehicle speed is too fast for the

sure selected. You must either reduce speed or select a

pres

higher pressure by pressing the appropriate key. Continued

operation in this mode will result in the system automatically

selecting a more appropriate pressure setting.

mph

kph

Terrain and Load Pressure Selection

TPCS displays both the selected terrain and load, and may be

configured to display numerical tire pressures in PSI, if

desired. Tire pressures for the following terrain modes can be

programmed and may be selected by the operator:

• HWY - For

speeds.

• OFF HWY

secondary roads and unpaved

• EM

ER - For selection of extremely low tire pressures

to help free a stuck vehicle.

The EMER key is for extreme conditions only and should not

used for normal driving.

be

travel on paved surfaces at higher

- For reduced speed operation on

surfaces.

CAUTION

8

Page 12

Operator Instructions

System Operation

mph

kph

L/ U HWY OFF HWY EMER RUN FLAT

• Display - The OCP uses a graphic display to indicate

the selection for both terrain mode and vehicle load.

Above the selector keys labeled HWY (highway), OFF

HWY (off-highway), and EMER (emergency), an illuminated arrow designates the current selection.

• T

by depressing the desired mode on the keypad.

When the system is actively changing tire pressure,

the arrow above the target mode will flash. Pressing

the key for a current mode will command a pressure

check.

• Loa

represented by an arrow above the rear w

graphic display. Depress the keypad

button labeled L/U to change from loaded to

unlo

Operating a loaded vehicle at unloaded tire pressures may

sult in tire overheating and reduced tire life or blowout.

re

• Pressure Display

Select is pressed after vehicle start, numerical pressures will be displayed sequentially for each active

channel. Subsequent actuation of the

lock the display on individual channels, or turn it off

again.

Note: The sys

due to heat buildup during vehicle use. This system will

not automatically deflate these pressure buildups—

lower pressure mode selection by the operator must be

selected to initiate a deflate.

bar psi

SELECT

errain Selection - The terrain selection is changed

d Selection - Vehicle load selection is

heels in the

aded.

CAUTION

- If the keypad button labeled

Select key will

tem is designed to allow tire pressure increase

• Chann

inside the tires of the truck graphic. The pressure

shown in the display reflects the channel with the

lighted rings.

mph

kph

rvice Code Indication - The OCP will display ser-

• Se

vice codes using a number and letter combination

followed by an excla

Note: See the Ser

etric/English Indicator - The OCP may be pro-

• M

grammed to display pressure in metric (BAR) or

English (PSI) units

• RUN F

that a tire or tires may not be holding air, it may

reduce the pressure check interval to minimize the

possibility of air loss from the tire by switching to

RUN FLAT operation. (See RUN FLAT in the Key Features section).

If RUN FLAT is activated, an asterisk (*) will be illuminated in the display of the OCP. This asterisk

matches the symbol on the RUN FLA

indicates that the RUN FLAT feature is selected. The

OCP also allows the driver to select RUN FLAT, by

depressing that key, to manually reduce the pressure

check interval. This may be desirable when operating

under conditions (i.e. sharp rocks or construction

debris) where tire punctures may be anticipated. The

RUN FLAT feature will automatically de-select after

10 minutes, but may be re-selected.

mph

kph

el Indicators - The OCP display includes rings

Tire Pressure Control

Tire Pressure Control

bar psi

mation point (!).

vice Codes Section to diagnose and repair.

(see Programming section).

LAT Indicator - If the TPC System determines

T key and it

bar psi

SELECT

RUN FLATL /U HWY OFF HWY EMER

mph

kph

bar psi

bar psi

9

Page 13

Operator Instructions

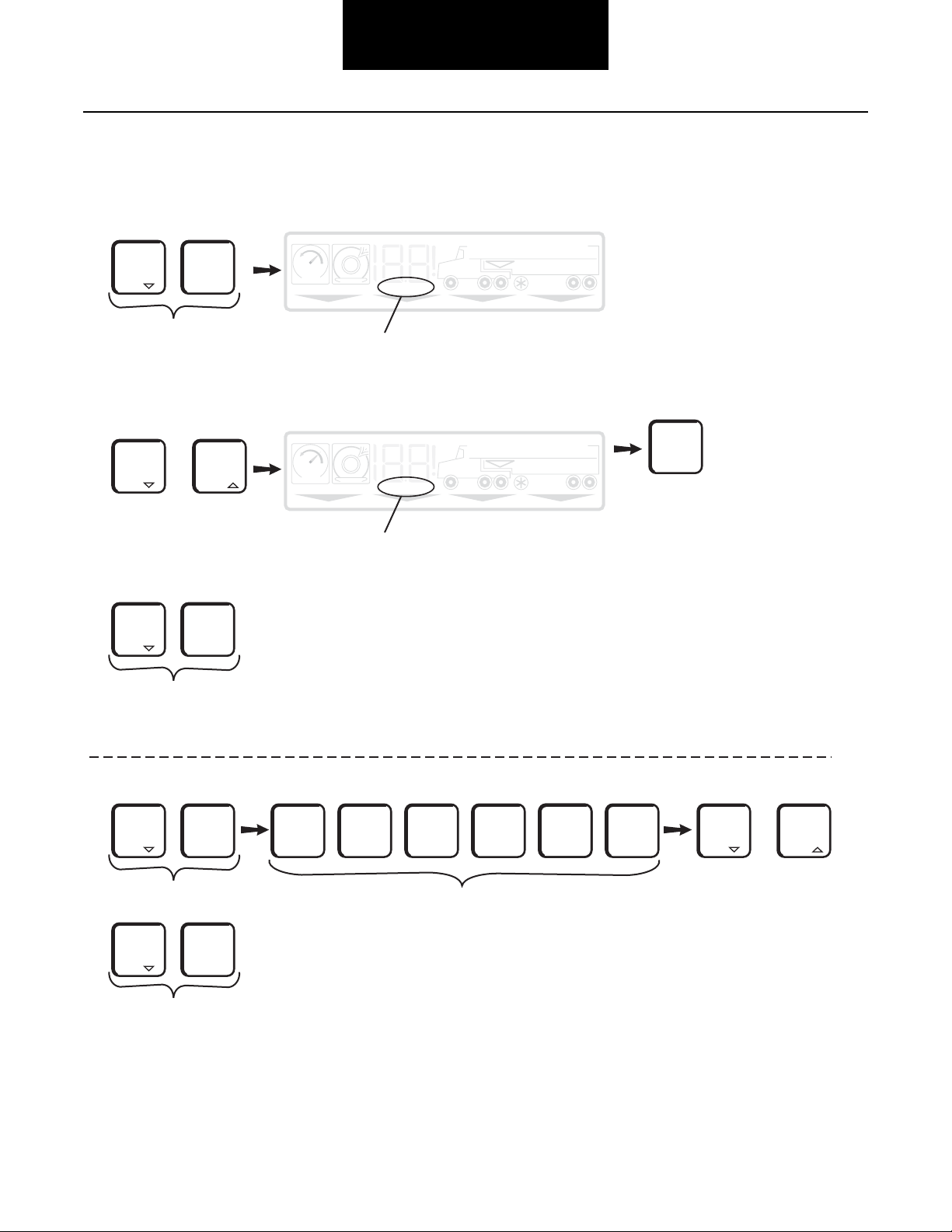

Tire Pressure Control System Programming

Spicer's Tire Pressure Control System is fully programmable,

allowing the technician to program tire pressures for each

channel (axle group) and maximum speeds for each terrain

mode. The system allows programming directly through the

Operator Control Panel, or with a diagnostic tool.

Programmable settings include:

• Individual pressure settings for the front, rear, and

trailer axle groups.

• Loaded and unloaded axle group programming for

highway, off-highway, and emergency conditions.

• Over speed warning threshold for highway,

off-highway and emergency conditions.

To program the system, follow these steps:

1. Enter the Tire Pressure Control System programming sequence by pressing the SELECT and L/U buttons at the same time. A flashing bar or PSI verifies

that you are in the programming mode and also indicates that the first selection, English or metric values, is ready for programming. Refer

Panel Programming Sequence" for sample

Control

procedure.

2. Press the up/down arrows (on the L/U and EMER

keys) to select options or change settings (pressure

or speed) and press the SELECT button to record a

selection in memory and move to the next step.

3. Press the SELECT button repeatedly to move

through the program steps, one step for each time

the SELECT button is pressed. Refer to the programming reference chart for specific Tire Pressure Control System pressure and speed programming steps.

4. To complete the programming sequence, or exit the

programming mode, continue to press the SELECT

button to step through to the end of the procedure,

or press the SELECT and L/U buttons at the same

time.

to "Operator

Operator Control Panel

Note: If no buttons are pressed for more than one minute, the

Operator Control Panel will end the programming

sequence, saving any changes made during

programming.

10

Page 14

Operator Instructions

Operator Control Panel Programming Sequence

Example for Step 1 Programming (see OCP Programming Chart)

L/U

+

SELECT

mph

kph

bar psi

bar psi

Tire Pressure Control

Press at the same

time to enter

programming

down

arrow

up

arrow

or

L/U

between metric

and English

EMER

Toggle

+

L/U

Press at the same

time to exit

programming

SELECT

Flashing "bar" or "psi"

indicates you have

entered programming

mph

kph

bar psi

bar psi

Make selection

Tire Pressure Control

SELECT

Press to record a selection

in memory and move to

the next step

Example for Step 7 Programming (see OCP Programming Chart)

+

L/U

Enter programming

SELECT

SELECT

+

+ +

SELECT

Press SELECT six times to go to step 7

+

SELECT

+

L/U

Exit programming

11

SELECT

SELECT

SELECT+SELECT

down

arrow

+

SELECT

L/U

or

arrow

EMER

up

Press to set highway

unloaded drive pressure

Page 15

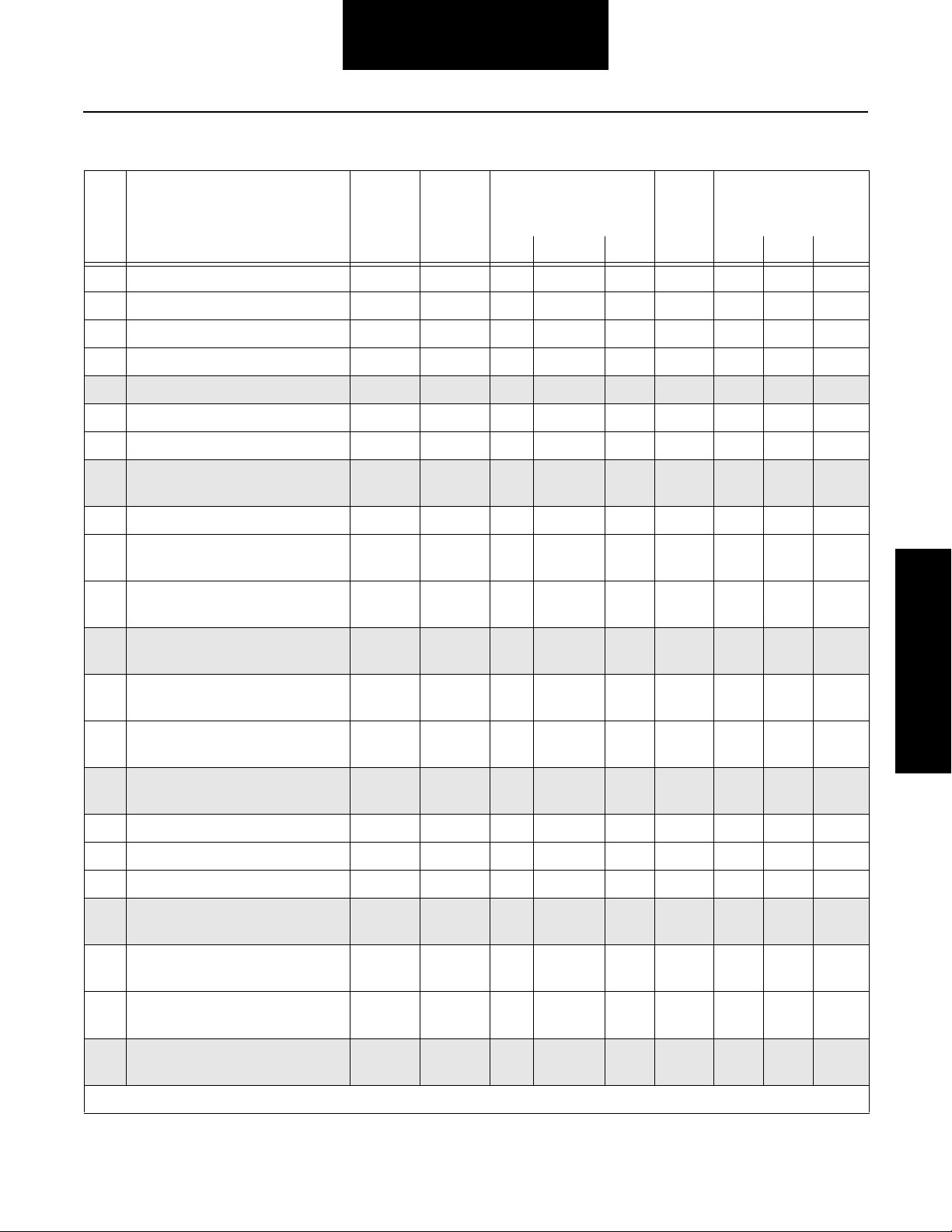

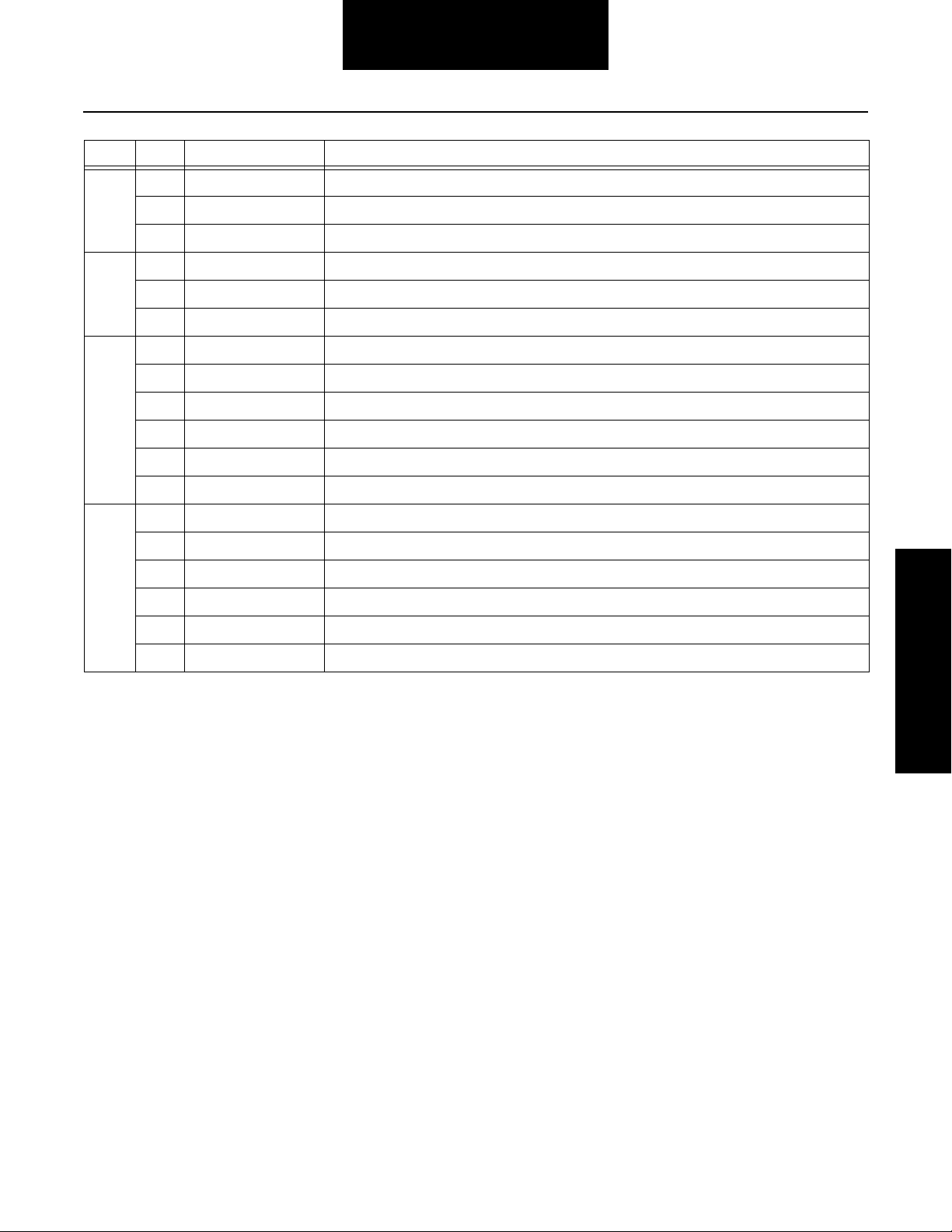

OCP Programming Chart

Operator Instructions

Step Setting Metric

English

Indicator

1 Metric / English On

2 Highway Over Speed On On

3 Highway Loaded Front Pressure On On On

4 Highway Loaded Rear Pressure On On On

5* Highway Loaded Trailer Pressure On On On

6 Highway Unloaded Front Pressure On On

7 Highway Unloaded Rear Pressure On On

8* Highway Unloaded Trailer

Pressure

9 Off-Highway Over Speed On On On On

10 Off-Highway Loaded Front

Pressure

11 Off-Highway Loaded Rear

Pressure

SpeedIndicator

Terrain Arrows Loaded

Arrow

HWY OFF HWY EMER Front Rear Trailer

On On

On On On

On On

OCP Channel Indicator

On

OCP Programming Chart

12* Off-Highway Loaded Trailer

Pressure

13 Off-Highway Unloaded Front

Pressure

14 Off-Highway Unloaded Rear

Pressure

15* Off-Highway Unloaded Trailer

Pressure

16 Emergency Over Speed On On

17 Emergency Loaded Front Pressure On On On

18 Emergency Loaded Rear Pressure On On On

19* Emergency Loaded Trailer

Pressure

20 Emergency Unloaded Front

Pressure

21 Emergency Unloaded Rear

Pressure

22* Emergency Unloaded Trailer

Pressure

On On

On On

On

On

On On On

On On

On On

On On

On

* 3 Channel Only

12

Page 16

Diagnostics

Diagnostics

This section covers the equipment and procedures used to

find and correct Tire Pressure Control System problems.

Test Equipment

Tire Pressure Control System troubleshooting can be

performed at three levels:

1. PC diagnostics.

2. Handheld tester.

3. Operator Control Panel service codes (if vehicle is

equipped with an OCP).

Regardless of the testing equipment used, the troubleshooting procedures will be based upon the diagnostic service

codes. Diagnostic tools offer the advantages of computeraided testing without interpreting service codes.

Tire Pressure Control System Diagnostics

The onboard system diagnostics are an important feature of

Spicer’s Tire Pressure Control System. This section describes

the use of service codes to identify Tire Pressure Control

System operating problems.

Service Codes

The Service Codes are described in the Troubleshooting

section. Some service codes also identify the component that

is associated with the problem. A list of possible causes is

shown in order of most likely occurrence.

Test Modes

Diagnostic tools allow the system to be placed in several

diagnostic modes:

Info - Display ECU information and configuration.

Codes - Active and historic codes are listed as reported by the

ECU.

Monitor (Normal) - TPCS operates normally, while status of

system components is observed.

Test - The following operations can be performed on each

channel (axle group):

• Check & Hold - System checks and

displays the pressures, then holds pressure in air

lines (quick test of control line and seal integrity).

The Tire Pressure Control System uses a code to identify service issues. The codes can be extracted from the ECU memory using a diagnostic service tool

appropriate

Operator Control Panel (OCP) will report codes directly on the

display. Refer to the service code chart for more detailed

information on service codes.

software. In addition, systems equipped with an

equipped with the

Historical Service Codes

Any time a fault occurs the system will log a fault in memory

of the ECU. If the system becomes inoperative, the Driver Display Module (DDM) will report two dashes (- -) or an actual

service code will be displayed on the Operator Control Panel.

(Only the most recent code is displayed by the

Operator Control Panel). Historical codes are stored in

memory. Historical codes can only be accessed by a

diagnostic tool. Historical codes are automatically cleared

after 50 ECU resets with no active faults.

• Deflate - System "manually" deflates (test the

deflation signal).

• Inflate - System "manually" inflates (test for large

leaks).

• Hold - Pressure is held in control lines (test for small

leaks).

Setup - Allows the technician to modify parameters such as

target tire pressures, etc.

13

Page 17

Diagnostics

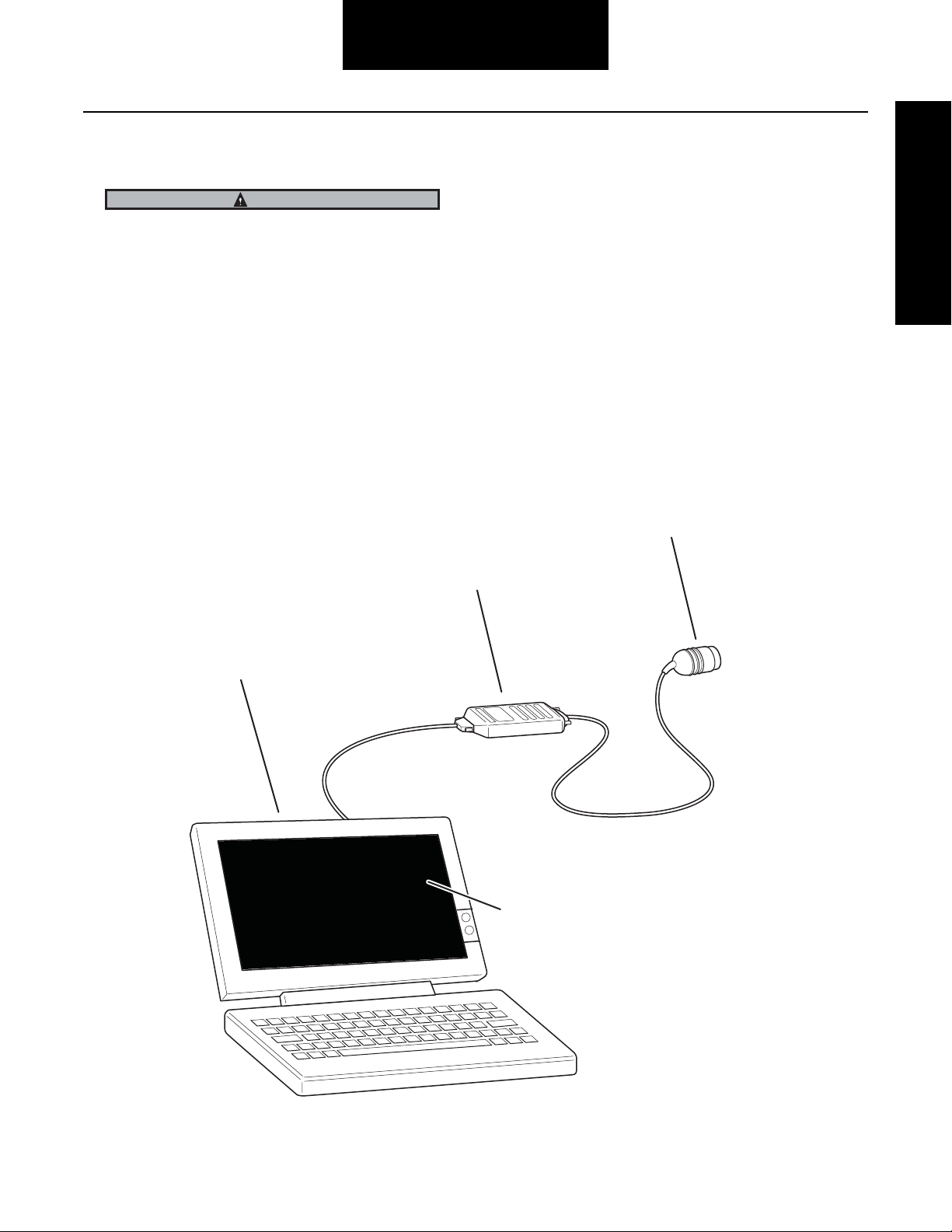

PC Diagnostics

CAUTION

A battery charger is not an adequate source of power.

Visit www.dana.com for free download of Dana Diagnostic

Tool (DDT).

PC diagnostics are easy to use and provide the quickest

diagnostic capabilities.

• Retrieve historical data, faults and tire pressures.

• Pressurize system to detect leaks.

• Access troubleshooting flowcharts and service

procedures.

Attach computer to RP1210A

communications box.

Download free Dana Diagnostic

Tool from dana.com.

To use this program, an RP1210A compatible interface box

and cables are needed to connect the PC to the vehicle.

For these types of interface boxes to work with the Dana

Diagnostic Tool program, you must install a "RP1210 driver"

program provided by the manufacturer of the interface box.

If you do not have this program, it can normally be obtained

from the manufacturer's web site. Please contact the

manufacturer of your interface box if you have any questions

regarding this process.

Connect to diagnostic

connector.

Diagnostics

Note: Program requires

Windows 98 or newer.

Follow on-screen

instructions.

14

Page 18

Diagnostics

Handheld Tester

A Prolink handheld tester may be used to read and clear

service codes and to obtain a short description of failures. The

tester can initiate test sequences for controller outputs and

can also read system parameters when equipped with the

Dana program card.

KENT-MOORE

MICRO PROCESSOR SYSTEMS INC.

Pro-Link

9

7 8

6

4 5

2 3

1

ENTER

0

FUNC

Multimeter

Based upon system schematics and aided by component

specific service codes, a multimeter can be used to check

sensor and solenoid resistances and to find wiring harness

faults. The multimeter can be used to check the Tire Pressure

Control System wiring and components for:

• Continuity

• Ground

• Broken wires

• Open circuits

• Shorted circuits

• Incorrect battery voltage

15

Page 19

Troubleshooting Tips

Diagnostics

This checklist outlines some general hints and guidelines that

will be helpful in tracking down and correcting operating

problems.

Operator Control Panel only displays one active code.

Only the most recent service code

Control Panel. In troubleshooting, be alert for related codes.

Use of a diagnostic tool offers the advantages of spotting multiple active codes as well as retrieving historical codes.

A cleared code alone does not indicate a corrected

problem.

A code is set by a specific fault condition and may be cleared

switching the ignition off. It's possible to clear a code (i.e.,

by

remove it from the driver interface) only to have it display

again when the fault condition reoccurs. To ensure that a

problem is fixed, you must run the system through the same

operating modes that caused the problem and verify that the

service code does not appear.

Disconnect the Electronic Control Unit connector with ignition off.

To avoid setting electrical service codes, make sure that the

ignition is

at the Electronic Control Unit module.

Reconnect the connector before switching on the ignition.

off before unplugging the wire harness connection

displays on the Operator

C! Service Codes are often connection problems.

The most likely cause of component faults will be damaged

wires or co

service codes, switch off vehicle ignition, then disconnect

applicable connectors and inspect for damage. (Switching off

the ignition is required before disconnecting the harness at

the Electronic Control Unit, but is also a recommended practice before all other electrical system disconnections.) Clean

or repair all

System is not continually pressurized.

When troubleshooting P! service code faults, keep in mind

that

ple, in the inflate mode). This means that such

checking for leaks require the system to be in an active,

pressurized state. This can be accomplished most easily by

using

Basic vehicle air and power systems

guide.

The Tire Pressure Control System requires air pressure and

electrical power

Diagnosis and service of these systems is outside the scope

this manual.

of

Some faults will halt inflate or deflate sequences.

Upon sensing some service codes, the Tire Pressure Control

System will immediately go

cause mode arrows to stop flashing before the system has

actually attained the pressures for the indicated mode.

nnections. As a first step in troubleshooting all C!

suspicious connections before proceeding.

the air system is only pressurized as needed (for exam-

procedures as

a diagnostic tool.

are not covered in this

supply from the base vehicle systems.

to the "maintain" mode. This may

Troubleshooting Tips

16

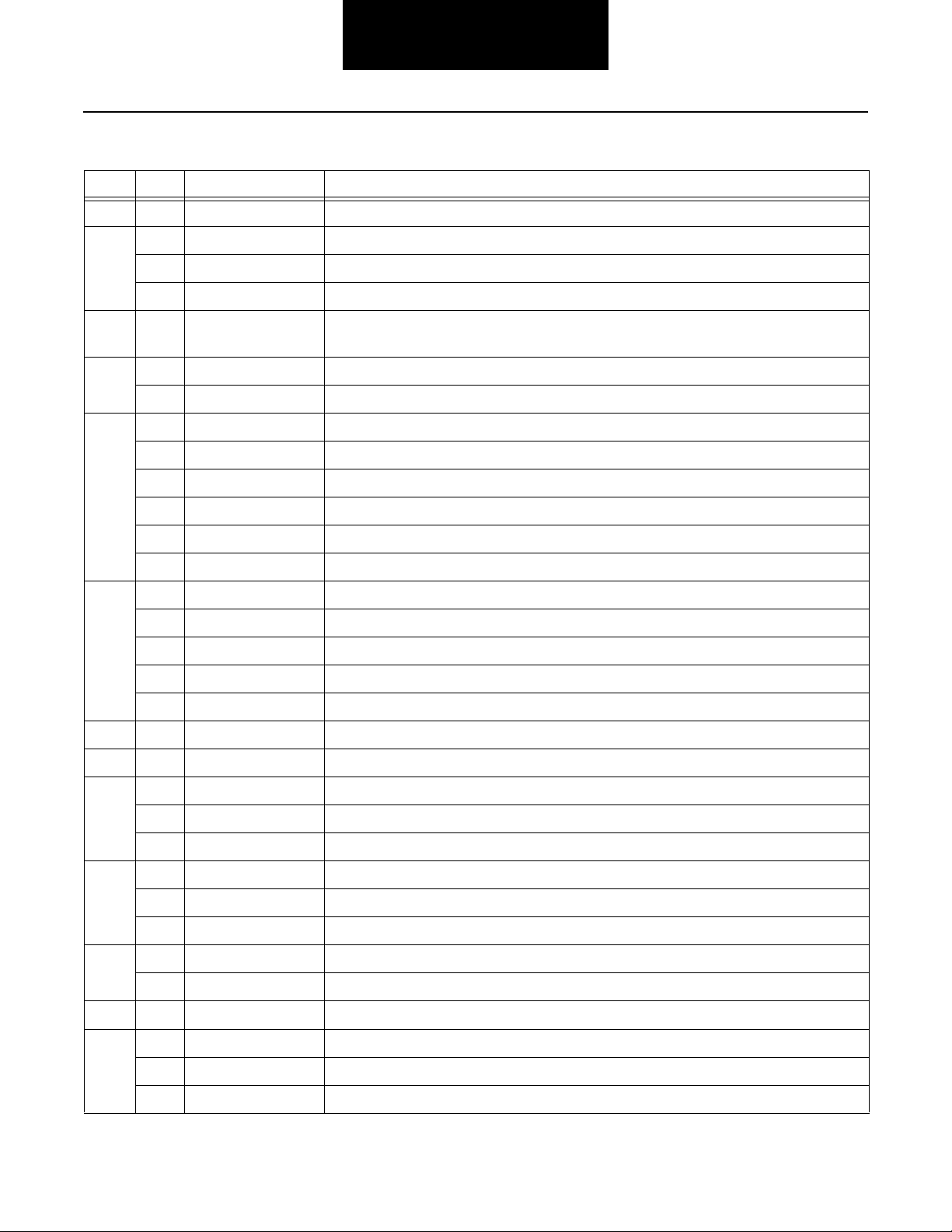

Page 20

Diagnostics

Service Code Summary

Group Code System Status Description

1C! 17 No Operation Power - battery voltage out of range at the ECU

3C! 18 Normal Operation Speed Signal - no speed detected during multiple ignition cycles

76 Normal Operation J1587 Speed Message - not

77 Normal Operation J1939 Speed Message - not

4C! 15 Inflate Only Display Control Communications - ECU not receiving

interface

5C! 33 No Operation PCU Sensor - signal voltage too high

34 No Operation PCU Sensor - connector unplugged; signal voltage too low

12C! 51 No Operation PCU Solenoid, Front - connector unplugged; faulty wiring or solenoid

52 No Operation PCU Solenoid, Rear - connector unplugged; faulty wiring or solenoid

53 No Operation PCU Solenoid, Trailer - connector unplugged; faulty wiring or solenoid

54 No Operation PCU Supply Solenoid - connector unplugged; faulty wiring or solenoid

55 No Operation PCU Deflate Solenoid - connector unplugged; faulty wiring or solenoid

56 No Operation PCU Control Solenoid - connector unplugged; faulty wiring or solenoid

1P! 11 No Deflation Deflate Signal, Front - could not generate a

12 No Deflation Deflate Signal, Rear - could not generate a vacuum in control lines

13 No Deflation Deflate Signal, Trailer - could not generate a vacuum in control lines

16 Normal Operation Deflate Signal - could not generate a vacuum in one or

22 Inflate Only Deflate Signal, PCU - could not generate

receiving expected messages on J1708 data link

receiving expected messages on data link

communications from user

vacuum in control lines

more channel's control lines

a vacuum in pneumatic control unit

2P! 14 Inflate Only Deflate Trend - tire pressure did not decrease properly

3P! 21 Inflate Only Vacuum - unintentional vacuum in PCU

4P! 23 Pressure Check Only Between Modes, Front - inflated or

24 Pressure Check Only Between Modes, Rear - inflated or deflated too slowly

25 Pressure Check Only Between Modes, Trailer - inflated or deflated too slowly

5P! 26 Pressure Check Only Low Pressure, Front - open line or large seal leak

27 Pressure Check Only Low Pressure, Rear - open line or large seal leak

28 Pressure Check Only Low Pressure, Trailer - open line or large seal leak

7P! 31 Pressure Check Only Pressure Switch - failed closed or wiring shorted

32 Pressure Check Only Low Air Supply - pressure switch did not close

8P! 35 Pressure Check Only Atmospheric - PCU sensor reading out of range

9P! 36 Channel Inoperative Inflate Trend, Front - tire pressure decreased

37 Channel Inoperative Inflate Trend, Rear - tire pressure

38 Channel Inoperative Inflate Trend, Trailer - tire pressure decrea

17

deflated too slowly

during an inflate

decreased during an inflate

sed during an inflate

during deflate

Page 21

Diagnostics

Group Code System Status Description

10P! 41 Inflate Only Tire Leak, Front - not passing tire pressure confirm check (multiple attempts)

42 Inflate Only Tire Leak, Rear - not passing tire pressure confirm c

43 Inflate Only Tire Leak, Trailer - not passing tire pressure confirm check (multiple attempts)

11P! 44 Pressure Check Only Tire Leak, Front - tire pressure imbalance or line leak

45 Pressure Check Only Tire Leak, Rear - tire pressure imbalance or line leak

46 Pressure Check Only Tire Leak, Trailer - tire pressure imbalance or line leak

12P! 61 Normal Operation Sluggish Shut Off, Front - lost minor pressure during wheel valve

62 Normal Operation Sluggish Shut Off, Rear - lost

63 Normal Operation Sluggish Shut Off, Trailer - lost minor pressure

64 Normal Operation Shut Off Failure, Front - cannot close wheel valve(s) and vent lines

65 Normal Operation Shut Off Failure, Rear - cannot close wheel valve(s) and vent lines

66 Normal Operation Shut Off Failure, Trailer - cannot

- 47-48 Reserved (47, 48)

57 Spare #1 - connector unplugged; faulty wiring or component

58 Spare #2 - connector unplugged; faulty wiring or component

67-68 Reserved (67, 68)

71-75 Reserved (71-75)

78 Reserved (78)

minor pressure during wheel valve shut off

close wheel valve(s) and vent lines

heck (multiple attempts)

during wheel valve shut off

shut off

Service Code Summary

18

Page 22

Service Codes

Group: 1C! (Code 17)

Type: Power

System Mode Condition Possible Causes

(Listed in Likely Order of Occurrence)

No Operation Power out of range - Low battery voltage.

- Poor ground connection to Electronic Control Unit.

- Poor switched ignition connection to Electronic Control Unit.

- High vehicle electrical system voltage.

- Faulty Electronic Control Unit.

Code Description

Group 1C! (17) indicates a power fault and sets when the system power is outside the acceptable range of 9 to 32 volts.

fault could be caused by low battery power or some other

The

problem with the basic vehicle electrical system.

If the vehicle power system checks out

possible causes include bad Electronic Control Unit (ECU)

connections, or a faulty Electronic Control Unit.

In inspecting circuits and connections for a Code 1C! fault,

pay part

be causing the fault.

See "Troubleshooting Tips" for general

diagnostics.

icular attention to a bad ground connection that could

satisfactorily, other

guidelines on system

ECU Harness Connector

C

AB

A

ABB

D

E

D

E

C

D

E

C

GHJK

F

F

G

H

F

G

HJJKK

3

2

1

19

Page 23

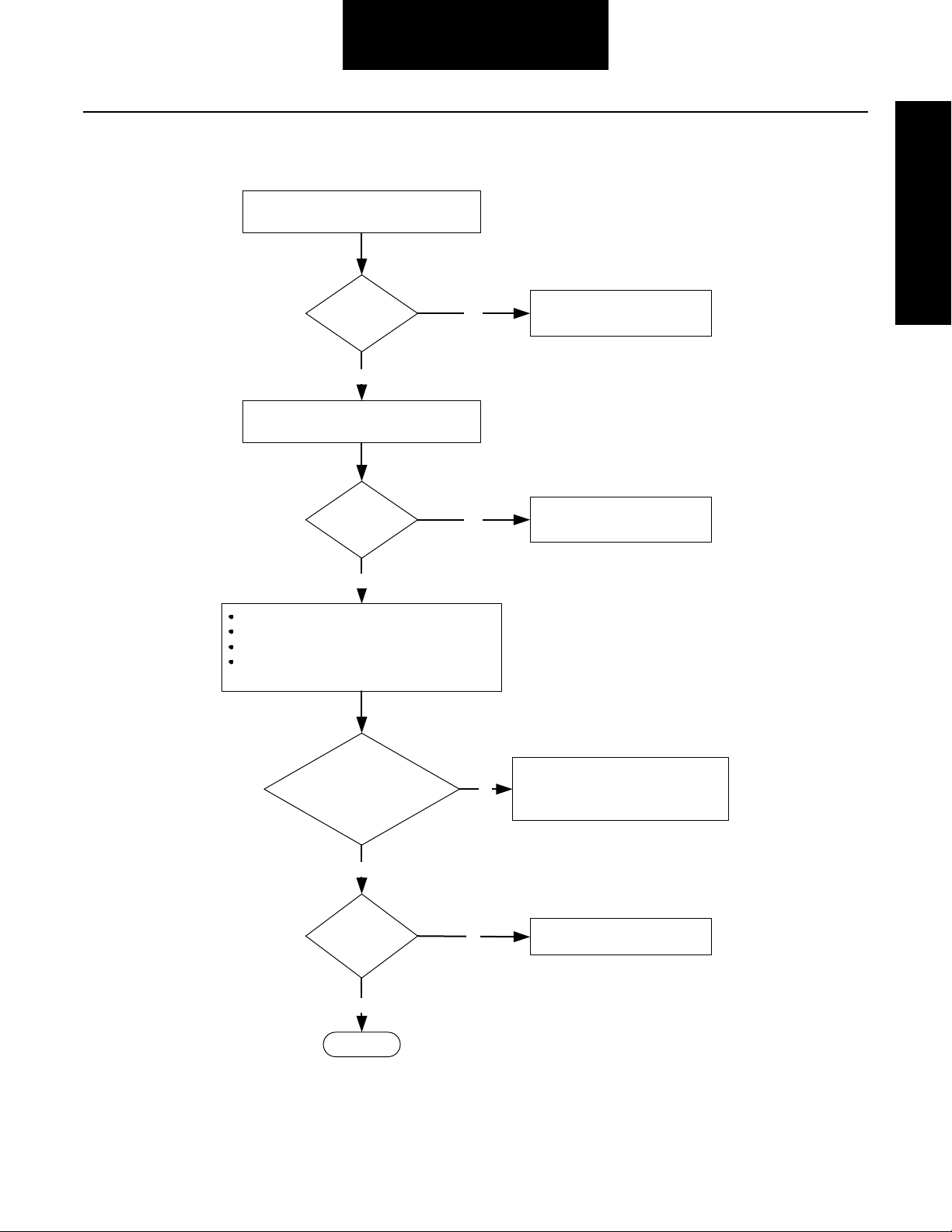

Power (Code 17)

Service Codes

Group: 1C! (Code 17)

With ignition switched on and engine running,

measure battery voltage across battery terminals.

Is voltage

reading > 32

volts?

No

With ignition switched on but engine not running,

measure battery voltage across battery terminals.

Is voltage

reading

< 9 volts?

No

Switch off ignition.

Disconnect ECU connector.

Switch on ignition.

Check SWACC circuit by measuring voltage

between ECU harness connector pins K1 and K2.

Yes

Yes

Base vehicle power is out of range.

Refer to Service Manual

Base vehicle power is out of range.

Refer to Service Manual

Does

measured

voltage match battery voltage

reading obtained in

previous

step?

Yes

Is code 1C!

fault cleared?

Yes

Complete

No

Inspect for failure in SWACC circuit including

No

vehicle power panel and/or ground

connections. Repair or replace as indicated.

Inspect wire sockets and ECU pins.

If okay, replace ECU.

20

Page 24

Service Codes

Group: 3C! (Codes 18, 76, 77)

Type: Speed Signal

System Mode Condition Possible Causes

(Listed in Likely Order of Occurrence)

Normal Operation No speed signal - ECU power cycled 50 times without vehicle being moved.

- Sensor disconnected or loose plug.

- Either speed sensor wire is open (broken wire).

- Either speed sensor wire is shorted to ground

(bare wire is touching the frame).

- Faulty speed sensor.

- Sensor actuation failure.

- Tang drive broken/disconnected on

- Gap not adjusted correctly on pole sensor.

- Sensor wires shorted together.

mechanical sensor.

Code Description

Group 3C! indicates a faulty speed sensor signal. In general,

the system is configured to accept speed signals from any

one of several sources (analog or digital; J1708/J1587,

J1939). In this standard configuration, a loss of speed signal

fault is indicated by code 18. In some specific instances, a

vehicle may be configured to only accept speed from a specific data link. In these cases, codes 76 (SAE J1708/J1587)

and code

signal fault.

Note: These codes will occur

See "Troubleshooting Tips" for general

diagnostics.

77 (SAE J1939) may be used to indicate a speed

• A wiring or sensor connection.

• A misadjusted or faulty sensor.

• A missing data link speed signal. (J1939 or J1708/

J158

7)

if ECU power has been cycled 50

times and no speed signal is received. Fifty power

cycles can occur after 25 engine starts without moving

the vehicle, however the code will clear as soon as a

speed signal is received.

guidelines on system

Speed Sensor

Harness Connector

AB

ECU Harness Connector

AB

C

D

E

A

ABB

D

E

C

E

D

C

GHJK

F

F

G

H

F

G

HJJKK

3

2

1

21

Page 25

)

Speed Signal (Codes 18, 76, 77)

This fault is set when ECU power has been cycled 50 times without sensing any speed input. Move vehicle at greater than 5 mph.

Service Codes

Determine type of speed sensor input:

Check adjustment on threaded

pencil speed sensor or drive tang on

mechanical speed sensor.

Sensor problem?

No

Switch off ignition.

Disconnect speed sensor and ECU from harness.

Check for shorts on ECU connector:

- F2 to F3

- F2 to K2

- F3 to K2

Yes

Did fault clear?

No

Digital (TTL signal from engine ECU or speedometer)

Analog (pole sensor or VR type)

Data Link (SAE J1708/1587 or SAE J1939)

Analog

Repair as necessary.

Sensor type?

Digital

Yes

Data Link

Complete

Group: 3C! (Codes 18, 76,

77

Use industry standard tools to verify

data link signal is OK.

Switch off ignition.

Disconnect speed input from signal

source and ECU from harness.

Check for shorts on ECU connector

F1 to K2.

Check continuity of ECU

connector F1 to speed input.

Was a short found?

No

Check for opens:

Short speed sensor harness connector A

and B together.

Measure continuity between F2 and F3 on

ECU connector.

Was circuit open?

No

Replace speed sensor.

Yes

Yes

Repair harness

as necessary.

Repair harness

as necessary.

Note: ECUs are not a typical cause of problems. If an ECU

is replace, the system should be carefully rechecked to

make sure the problem has been fixed and does not reoccur.

Repair and verify speed signal source.

Move vehicle at

greater than 5 mph.

Did active

code clear?

No

Replace ECU.

Yes

Complete

22

Page 26

Service Codes

r

Group: 4C! (Code 15)

Type: Display Control Communications

System Mode Condition Possible Causes

(Listed in Likely Order of Occurrence)

Inflate Only Blank Display - No power to Driver Interface.

- No ground connection to Driver Interface.

- System voltage out of range

(9-19 volts DC).

Inflate Only Operator Control Panel

displays logo only

DDM displays dash dash

(nothing else on display)

- No power or ground to ECU.

- Driver Interface to Electronic

- Driver Interface to Electronic Con

- Driver Interface to Electronic Con

- Driver Interface to Electronic Con

- Faulty Driver Display Module/Operat

- Faulty Electronic Control Unit.

Code Description

Group 4C! indicates a communication problem between the

Electronic Control Unit (ECU) and the driver interface (either

the Driver Display Module or Operator Control Panel). Code

4C! will only be observable on a diagnostic tool as code 15. It

will not show on the Operator Control Panel. Instead, the

Operator Control Panel may be blank (indicating a power

problem).

All of the troubleshooting steps for

the condition of Electronic Control Unit and driver interface

circuits. If no circuit problems are found, Code 4C! indicates

either a faulty driver interface or a faulty Electronic Control

Unit.

code 4C! involve checking

Control Unit lines open.

trol Unit lines shorted to ground.

trol Unit lines shorted to power.

trol Unit lines shorted together.

or Control Panel.

DDM Display Harness Connecto

5

4

3

2

1

6

7

8

9

10

See "Troubleshooting Tips" for general

diagnostics.

ECU Harness Connector

AB

C

D

23

A

ABB

E

D

E

C

D

E

C

F

F

F

guidelines on system

GHJK

G

H

G

HJJKK

OCP Harness Connector

56

0

8

91

3

2

1

Page 27

Display Control Communications (Code 15)

Turn on ignition.

Service Codes

With vehicle running, measure battery

voltage across battery terminals.

Is voltage

reading > 19

volts?

No

With ignition switched on but engine

not running, measure battery

voltage across battery terminals.

Is voltage

reading < 9

volts?

No

Disconnect driver interface.

With ignition on, measure

voltage between:

DDM Display or OCP

Harness Pins Harness Pins

4 and 5 5 and 6

Does

measured

voltage match

battery voltage reading

obtained

in previous

step?

Yes

Replace driver interface.

Yes

Base vehicle power is out of range.

Yes

Yes

No

Refer to Service Manual

Base vehicle power is out of range.

Refer to Service Manual

Repair harness power or ground

connections to driver interface.

Note: ECUs are not a typical cause of

problems. If an ECU is replaced, the

system should be carefully rechecked

to make sure the problem has been

fixed and does not reoccur.

Is

driver interface

completely

blank?

Replace ECU.

No

Check continuity between:

ECU and DDM Display or OCP

Harness Pin Harness Pin Harness Pin

K3 6 9

J3 7 10

Check for communication circuits shorted to ground, power or

shorted to each other. Check between:

DDM Display Harness Pins or OCP Harness Pins

6 and 4 9 and 6

7 and 4 10 and 6

7 and 5 9 and 5

6 and 5 10 and 5

6 and 7 9 and 10

Switch ignition off.

Disconnect ECU connector.

Disconnect driver interface connector.

Switch ignition on.

Verify adequate voltage (9-32 Vdc) between

power (ECU harness connector pin K1) and

ground (ECU harness connector pin K2).

Is voltage within range?

Yes

No

Is there

continuity?

Yes

Is any circuit shorted?

No

Replace driver interface.

Switch on ignition.

Is driver

interface functioning

correctly?

No

Inspect fuses/

repair harness

No

to power ECU.

Inspect and repair

faulty

communications

circuit in harness.

Yes

Yes

Inspect and

repair faulty

wire or

connection.

Complete

Group: 4C! (Code 15)

24

Page 28

Service Codes

Group: 5C! (Codes 33, 34)

Type: PCU Sensor

System Mode Condition Possible Causes

(Listed in Likely Order of Occurrence)

No operation No PCU sensor reading - PCU Sensor electrically disconnected.

- PCU Sensor signal wire open.

- PCU Sensor signal wire shorted to ground.

- PCU Sensor XDCR VREF wire open.

- PCU Sensor XDCR VREF wire shorted to ground.

- PCU Sensor XDCR COMMON wire open.

- Faulty PCU Sensor.

- Faulty Electronic Control Unit.

No operation High pressure transducer

reading

- PCU Sensor signal wire shorted to VBATT or XDCR VREF.

- Faulty PCU Sensor.

- Faulty Electronic Control Unit.

Code Description

Group 5C! displays when the Electronic Control Unit (ECU)

receives an unusually high or low reading from the PCU

Sensor. A diagnostic tool will specify 33 for a high reading and

34 for a

Initial troubleshooting steps involve checking

shorted-to-ground or an open PCU Sensor circuit.

If the circuits check out OK, secondary causes could involve a

faulty transducer

See "Troubleshooting Tips" for general

diagnostics.

low reading.

for a

or a faulty Electronic Control Unit.

guidelines on system

PCU Sensor

Harness Connector

ABC

ECU

Harness Connector

C

AB

A

ABB

D

E

D

E

C

D

E

C

G H JK

F

F

G

H

F

G

HJJKK

3

2

1

25

Page 29

PCU Sensor (Codes 33, 34)

With ignition off, inspect socket connections at

ECU connector and at PCU sensor 3-way.

Service Codes

Group: 5C! (Codes 33, 34)

Replace ECU.

Repair

conditions as

necessary.

Inspect and

repair faulty

harness.

Are

No

PCU Sensor ECU Harness

Harness Pin Connector Pin

No

connections

mechanically and

electrically

sound?

Yes

Disconnect the ECU connector

and the PCU sensor connector.

Check continuity between the

following points:

C H1

B H2

A H3

Is there

continuity?

Yes

Is voltage

between 4.9 and

5.1V?

Yes

Check harness inside PCU

cover for continuity:

A to A

B to B

C to C

Is there

continuity?

Yes

Check harness inside

PCU cover for shorts:

A to B

B to C

C to A

Are any

shorted?

No

Yes

Note: ECUs are not a typical cause of

No

problems. If an ECU is replaced, the

system should be carefully rechecked

to make sure the problem has been

fixed and does not reoccur.

Repair mini-harness inside cover.

Repair mini-harness inside cover.

Inspect and

repair faulty

harness.

Check for short circuits between each

pair of PCU sensor harness pins:

A and B

B and C

C and A

No

Check voltage between PCU sensor harness

pin B and ground with ignition switch on.

Are any

shorted?

Yes

Reconnect ECU connector.

No

Replace PCU sensor.

Is the active

fault cleared?

Yes

Complete

No

Replace ECU.

Note: ECUs are not a typical cause of

problems. If an ECU is replaced, the

system should be carefully rechecked

to make sure the problem has been

fixed and does not reoccur.

26

Page 30

Service Codes

Group: 12C! (Codes 51, 52, 53, 54, 55, 56)

Type: PCU Solenoids

• Front (51)

• Rear (52)

• Trailer (53)

• Supply (54)

•Deflate (55)

• Control (56)

System Mode Condition Possible Causes

(Listed in Likely Order of Occurrence)

No operation Pneumatic Control Unit

solenoid failed electrical

diagnostic test

- Connector unplugged or faulty wiring.

- Solenoid wire open.

- Solenoid wire shorted to ground.

- Solenoid wire shorted to power.

- Faulty solenoid.

- Faulty Electronic Control Unit.

Code Description

Group 12C! indicates an electrical fault in the Pneumatic

Control Unit (PCU). Codes 51 through 56 specifically

designate which solenoid in the PCU

operation is disabled when this fault is detected.

is faulty. System

PCU Connector

EFDGCHBA

K

The system shuts down in a fail-safe mode

and turns off

power to the solenoids.

The troubleshooting tree first tests internal solenoid circuitry.

istance outside the specified range of 7 to 25 ohms

Res

indicates a defective solenoid. Successive steps check

continuity of the wire harness circuits between the Pneumatic

ntrol Unit and the Electronic Control Unit (ECU). If the

Co

problem can be traced to a faulty circuit or connector, make

the necessary repairs. If the troubleshooting routine leads to a

problem with the solenoid itself, the Pneumatic Control Unit

must be repaired or replaced. If both the solenoid and the

circuitry check out, the Electronic Control Unit is faulty.

See "Troubleshooting Tips" for general

guidelines on system

diagnostics.

PCU Harness

Connector

ABCDE

KHGF

ECU

Harness Connector

C

A B

A

ABB

D

E

D

E

C

D

E

C

F

GHJK

F

G

H

F

G

HJJKK

3

2

1

27

Page 31

Service Codes

,

,

,

,

)

PCU Solenoids (Codes 51, 52, 53, 54, 55, 56)

Code 12C! Indicates one or more solenoid faults. Use service tool to determine the

specific solenoid. When the troubleshooting instructions refer to connector test

points, use chart select the pin test point for use with the particular fault code you

are diagnosing.

Solenoid/

Code

PCU Harness

Connector

ECU Harness

Connector

Any

Code

Any

Front

Code

H F G E K A C B D

K2 K2 D1 D2 E1 K2 B1 B2 B3

(51)

Rear

(52)

Trailer

(53)

Supply

(54)

Deflate

(55)

Control

(56)

A

Are any pins

shorted to

ground?

Yes

Repair or replace

connections,

coils or PCU.

Group: 12C! (Codes 51,

52

53

54

Switch off ignition.

Disconnect harness at

PCU 10-way connector.

Measure solenoid coil resistance on PCU 10-way connector.

Front (51): F – G Supply (54): H – C

Rear (52): F – E Deflate (55): H – B

Trailer (53): A – K Control (56): F – D

Are all

resistance

measurements

7-25 ohms?

Yes

No

Repair or replace

connections, coils or PCU.

No

Disconnect ECU harness

connectors.

Check continuity of harness pins

shown in chart for given fault

code: PCU harness connector to

ECU harness connector.

Are circuits

continuous?

Yes

Measure at PCU harness connector.

Verify continuity between:

-A and F

-A and H.

Verify no continuity between any combination

of pins B, C, D, E, G, K on PCU harness

connector and K2 on ECU harness connector.

(Do not use multi-meter’s continuity “beep

mode,” as most meters will falsely identify the

7-25 ohm coils as shorted.)

No

55

56

Repair or replace

harness.

Check for shorts between PCU connector

pins B, C, D, G, E, K and vehicle ground.

(Do not use multi-meter’s continuity “beep

mode,” as most meters will falsely identify

the 7-25 ohm coils as shorted.)

A

Note: ECUs are not a typical cause of problems. If an

ECU is replaced, the system should be carefully

rechecked to make sure the problem has been fixed

Are

connections

OK?

Yes

Replace ECU.

and does not reoccur.

No

Repair or replace

harness.

28

Page 32

Group: 1P! (Codes 11, 12, 13, 16, 22)

Service Codes

Type: No Deflate Signal

System Mode Condition Possible Causes

(Listed in Likely Order of Occurrence)

Inflate Only Inadequate vacuum in the

Pneumatic Control Unit

Inflate Only No sustained vacuum in

trol lines

con

- Plugged or restricted Pneumatic Control Unit vent line.

- Faulty Pneumatic Control Unit.

- Line leaks.

- Air seals, oil lip seals.

Code Description

Group 1P! indicates inadequate vacuum in the Pneumatic

Control Unit (PCU) prior to channel selection, or failure to

sustain a vacuum in the control lines following channel

selection. These codes will be set when the nominal vacuum

" Hg drops to 17" Hg. Codes can be generated by one

of 26

channel, multiple channels or a combination of channels.

When a deflate is requested, the system

channel control lines and generates a vacuum in the Pneumatic Control Unit alone. A failure to generate thi

will result in Diagnostic Code 22.

first shuts off all the

s vacuum

Group1P! can be caused by:

• Line leak.

• Air seal or oil lip seal leaks.

• Plugged or restricted Pneumatic Control Unit vent

• Faulty Pneumatic Control Unit.

To identify the root cause of the problem, connect the

diagnostic tool (see Diagnostic Se

and descriptions) and follow the procedure in the 1P!

Troubleshooting Tree.

line.

ction for test equipment

Once the vacuum has been established in the Pneumatic

Control Unit, the individual channel control line(s)

and a vacuum is routed to them. If a vacuum is not sustained

in the control lines, a 1P! fault is logged as follows:

11 - Front Channel

12 - Rear Channel

13 - Trailer Channel

16 - Individual channels OK but a combination of

channels results in low vacuum.

Note: If a

vacuum loss occurs during an attempt to deflate

two or more channels at the same time, the system will

halt the deflate and re-attempt it one channel at a time.

This will result in a Code 16 being stored in the ECU.

are opened

See "Troubleshooting Tips" for general guidelines

diagnostics.

on system

29

Page 33

,

,

)

No Deflate Signal (Codes 11, 12, 13, 16, 22)

Using the diagnostic tool, test

vacuum in isolated PCU.

Service Codes

Initiate pressure check and hold on

steer channel.

Check all air lines and fittings for leaks

as well as exhaust port of wheel valves.

Make repairs to faulty components.

Initiate pressure check and hold on

drive channel.

Check all air lines and fittings for leaks

as well as exhaust port of wheel valves.

Make repairs to faulty components.

Is the vacuum

< 6" Hg?

Yes

Initiate deflate mode on the steer

channel. Record the reading.

No

No

Is the vacuum

> 20" Hg?

Yes

Initiate deflate mode on the drive

channel. Record the reading.

Is the vacuum

> 20" Hg?

Yes

No

vent line plugged or

Repair PCU restriction and

recheck system.

Refer to Service Manual

Is the PCU

restricted?

Yes

Replace PCU and recheck

No

Refer to Service Manual

Problem is a cumulative effect

of individual channel leaks.

system.

Group: 1P! (Codes 11, 12,

13

16

22

Initiate deflate mode on the trailer

Initiate pressure check and hold on

trailer channel.

Check all air lines and fittings for leaks

as well as exhaust port of wheel valves.

Make repairs to faulty components.

channel. Record the reading.

No

Is the vacuum

> 20" Hg?

Yes

Initiate inflate pressure hold on channel

with the lowest vacuum reading.

Check for leaks.

Make repairs to faulty components.

Verify by initiating deflate

mode on repaired channels.

Note: Line leakages occasionally occur which are unidirectional; i.e., they might occur under vacuum and not pressure (or vice-versa).

Inability to determine the cause of vacuum loss on an individual channel may dictate replacement of air lines and/or fittings on that

channel. Be sure all replaced air lines and fittings are identical in all respects, including length, to the parts replaced.

30

Page 34

Group: 2P! (Code 14)

Service Codes

Type: Deflate Trend

System Mode Condition Possible Causes

(Listed in Likely Order of Occurrence)

Inflate Only Pressure increased or failed

to drop appropriately

- Plugged or restricted control lines.

- Plugged or restricted Pneumatic Unit vent line.

- Plugged or restricted wheel valve exhaust port.

- Faulty Pneumatic Control Unit.

Code Description

Group 2P! is the result of a deflate that did not occur properly.

The system measures tire pressure before and after each

deflate. If the pressure readings indicate that the pressure

either increased or failed to drop properly, the system shuts

down the deflate sequence.

Group 2P! can be caused by:

• Plugged or restricted control lines.

• Plugged or restricted Pneumatic

line.

Control Unit vent

• Contaminated or faulty Pneumatic Control Unit.

To identify the root cause of the problem, connect the

diagnostic tool (see Diagnostics Section for

and descriptions) and follow the procedure in the 2P!

Troubleshooting Tree.

See "Troubleshooting Tips" for general

diagnostics.

test equipment

guidelines on system

31

Page 35

Deflate Trend (Code 14)

Use diagnostic tool to manually

deflate the tires on each channel.

Caution: Verify clean (no oil), dry air system on vehicle. This

condition can be caused by contamination in PCU. Reference

PCU Cleaning and Inspection for cleaning procedure.

All tires on each

channel deflate?

Yes

Replace or clean PCU.

Service Codes

Check for conditions preventing vacuum reaching tires:

No

Group: 2P! (Code 14)

Restrictions in valve stems (valve cores, filters, rubber, etc.)

Restricted PCU vent line

Loss of vacuum on channel (see 1P! flowchart)

Inoperative or restricted wheel valve

Verify repair by monitoring

system deflate.

32

Page 36

Group: 3P! (Code 21)

Service Codes

Type: Vacuum Fault

System Mode Condition Possible Causes

(Listed in Likely Order of Occurrence)

Inflate Only Inappropriate vacuum

generation

- Faulty or contaminated Pneumatic Control Unit.

Code Description

Group 3P! displays when the system is generating a

vacuum at a time when the Electronic Control Unit (ECU) is

not requesting

is highly unlikely.

The most likely cause of an unexpected vacuum is a

contaminated or faulty Pneumatic

Verify the problem before replacing the Pneumati

Unit. See the procedure in the 3P! Troubleshooting Tree.

See "Troubleshooting Tips" for general

diagnostics.

a vacuum. Creation of an unexpected vacuum

Control Unit (PCU).

c Control

guidelines on system

33

Page 37

Vacuum Fault (Code 21)

Service Codes

Verify the problem.

Replace or clean PCU.

Caution: Verify clean (no oil), dry air system on vehicle. This

condition can be caused by contamination in PCU. Reference

PCU Cleaning and Inspection for cleaning procedure.

Verify the repair.

Group: 3P! (Code 21)

34

Page 38

Group: 4P! (Codes 23, 24, 25)

Service Codes

Type: Channel Between Modes

System Mode Condition Possible Causes

(Listed in Likely Order of Occurrence)

Pressure Check Only Slow Inflate - Faulty compressor.

- Restricted flow at wheel valve air filters

- Crimped or plugged lines.

Slow Deflate - Restricted flow at wheel valve air filters

- Plugged or restricted Pneumatic Control Unit vent port.

- Leaking lines.

- Plugged or restricted wheel valve exhaust port.

Code Description

Group 4P! displays if any channel inflates or deflates too

slowly as shown below:

• 23 - Front Channel

• 24 - Rear Channel

• 25 - Trailer Channel

The maximum allotted time for each channel is 40 minutes for

an inflate, or 20

a faulty compressor or similar problem resulting in

inadequate air supply to the T

minutes for a deflate. The most likely cause is

ire Pressure Control System.

If the system air supply is function

4P! may indicate that a leak or restriction exists in an air

passage. The components that may contain a

leaking air passage include:

• Wheel valve air filters.

• Pneumatic Control Unit (PCU)

• Air supply lines.

• Wheel valve exhaust port (deflate mode only).

To identify the root cause of the problem, connect the

diagnostic tool (see Diagnostics Section for test equipment

and descriptions)

4P! Troubleshooting Tree.

or tire valve stems.

or tire valve stems.

ing properly, code group

restricted or

vent port restriction.

and follow the procedure in the

35

See "Troubleshooting Tips" for general guidelines

diagnostics.

on system

Page 39

)

Channel Between Modes (Codes 23, 24, 25)

Verify Tire Pressure Control System air system

capacity by checking air system pressure buildup.

Service Codes

Does the air

system build up to at

least 125 psi?

Yes

Using the diagnostic tool, check

faults to identify the faulty channel:

Front (23)

Rear (24)

Trailer (25)

Initiate deflate mode on the

identified channel.

Are the wheel

valves deflating

slowly?

No

Yes

Repair air system and retest system.

Refer to Service Manual

Group: 4P! (Codes 23, 24,

25

On the tire or axles that deflate slowly, check for:

Restricted wheel valve exhaust port

Clogged wheel valve filters

Plugged tire valve stem

Refer to Service Manual

No

Initiate inflate mode on the identified channel

and check for crimped or restricted lines.

36

Page 40

Group: 5P! (Codes 26, 27, 28)

Service Codes

Type: Low Pressure Reading

System Mode Condition Possible Causes

(Listed in Likely Order of Occurrence)

Pressure Check Only Extreme pressure loss - Leaking axle seals.

- Open line between Pneumatic Control Unit to channel.

- Crimped or plugged line between supply tank and Pneumatic Control Unit.

- Pressure switch failure, shorted closed.

- Pneumatic Control Unit failure, supply or control off.

- Faulty pressure transducer.

Air Pressure Check

The Tire Pressure Control System is not continuously pressurized; pressure checks occur on

tire pressure checks, the system delivers compressed air to

each channel for approximately two seconds while

monitoring the pressure in that channel.

a periodic basis. During

Code Description

Group 5P! indicates an extreme pressure loss on the front

(26), rear (27), or trailer (28) channels. Possible causes are

leaking axle air seals or an open line, which would be clearly

audible during pressure measurements.

Note: In extremely cold conditions

leak, resulting in a code 5P!. This code may clear by

simply driving the vehicle for a few minutes to "warm

up" the seals allowing proper system operation.

, air seals will sometimes

Other possible causes of a group 5P! are:

• Open line from Pneumatic Control Unit (PCU) to

channel.

• Restricted line between the supply tank and Pneumatic Control Unit.

• Faulty PCU Sensor.

• Faulty PCU.

To identify the root cause of the problem, connect the

diagnostic tool (see Diagnostics Section for test equipment

and descriptions)

5P! Troubleshooting Tree.

See "Troubleshooting Tips" for general guidelines

diagnostics.

and follow the procedure in the

on system

37

Page 41

)

Low Pressure Reading (Codes 26, 27, 28)

Service Codes

Group: 5P! (Codes 26, 27,

Using the diagnostic tool, check faults to

identify the faulty channel:

Front (26)

Rear (27)

Trailer (28)

Initiate inflate mode for the faulty channel.

Is there extreme

pressure loss?

No

Use the diagnostic tool to pressurize

and hold the faulty channel.

Does pressure

drop quickly?

Yes

Yes

Identify cause of air loss,

repair and recheck system.

Refer to Service Manual

Locate leak (check axle

vents for air leakage also),

repair and recheck system.

Is there a

restricted line between

the wet tank and

PCU?

No

After a pressure

check, is the pressure

reading <5 psi?

No

Check harness and PCU for open supply or

control solenoids. See Group 12C! PCU

Solenoids, Codes 54 or 56 for procedure.

Yes

Identify cause of air loss,

repair and recheck system.

Refer to Service Manual

Yes

Replace PCU sensor

and recheck system.

28

No

Verify that the pressure switch opens

when the supply tank is below 80 psi.

Note: Primary and secondary air brake

gauges do not reflect actual pressure in

the supply tank.

Does the

pressure switch

open?

No

Replace pressure switch

and recheck system.

Refer to Service Manual

Yes

Replace PCU and recheck system.

Note: While replacing the PCU, pay particular

attention to possible air line contamination (e.g.,

oil, water, particles) which may suggest further

air system maintenance needs.

Refer to Service Manual

Does fault

reoccur?

Yes

Replace ECU and recheck system.

Note: ECUs are not a typical cause of problems. If

an ECU is replaced, the system should be carefully

rechecked to make sure the problem has been

fixed and does not reoccur.

No

Complete

38

Page 42

Group: 7P! (Codes 31, 32)

Service Codes

Type: Low Air Supply

System Mode Condition Possible Causes

(Listed in Likely Order of Occurrence)

Pressure check only Pressure switch won’t

close (32)

Supply Tank pressure too

(32)

low

Pressure switch failed

closed (31)

- Compressor governor cut-out set too low.

- Air dryer needs service.

- Pressure switch unplugged.

- Open or broken line from supply ta

- Crimped or plugged line from supply tank to Pneumatic Control Unit.

- Faulty pressure switch.

- Faulty compressor.

- Governor cut-in too low.

- Faulty compressor.

- Leaking lines.

- Wiring to pressure switch shorted together.

- Faulty pressure switch.

Air Pressure Check

The Tire Pressure Control System is not continuously

pressurized; pressure checks occur on a periodic basis.

During tire pressure checks, the system delivers compressed

air to each channel

monitoring the pressure in that channel.

for approximately two seconds while

The components that can cause the pressure switch to remain

en include:

op

• Air dryer needs service.

• Pressure switch unplugged or damaged wire

• Faulty pressure switch.

nk to Pneumatic Control Unit.

harness.

Code Description

Group 7P! displays if the system air pressure supply is too

low to perform a valid tire pressure check.

This may occur because the pressure switch

(inadequate air supply, code 32) or because the pressure

switch or its wiring is shorted, allowing the actual supply

pressure to be lower than anticipated by the system.

o assure a nominal compressor output, code 32 will

Note: T

not be set unless the pressure switch does not close for

a preset period while the vehicle is being driven at a

speed of over 20 mph.

will not close

• Faulty compressor.

• Open or broken line from supply tank to Pneumatic

Control Unit.

• Crimped or plugged line from supply tank to Pneumatic Control Unit.

• Faulty Electronic Control Unit.

To identify the root cause of the problem, connect the