Page 1

®

Spicer

Driveshafts, and Wheel Ends

Drive Axles, Steer Axles,

Lubrication

Manual

July 2012

Page 2

Table of Contents

General Information

Dana Lubrication Philosophy . . . . . . . . . . . . 3

Standard Drain Lubricants . . . . . . . . . . . . . 3

Extended Drain Lubricants . . . . . . . . . . . . . 3

Introduction to Manual . . . . . . . . . . . . . . . . 4

Linehaul - 500,000 Mile Extended Lube

Drain Interval . . . . . . . . . . . . . . . . . . . . . . 4

Vocational - 180,000 Mile Lube

Drain Interval . . . . . . . . . . . . . . . . . . . . . . 4

Warnings and Cautions . . . . . . . . . . . . . . . . 5

Vehicle Application Definitions. . . . . . . . . . . 5

Line Haul . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Vocational . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Severe Duty Service . . . . . . . . . . . . . . . . . . 5

Drive Axle

Drive Axle Lubricants

Heavy-Duty . . . . . . . . . . . . . . . . . . . . . . . 6

Medium-Duty . . . . . . . . . . . . . . . . . . . . . 6

Drive Axle Lubricant Capacities. . . . . . . . . . . 7

Single Drive Axle Lubricant Capacities . . . . . 7

Tandem Drive Axle Lubricant Capacities . . . . 8

Drive Axle Lubrication Procedure . . . . . . . . . 9

Check Drive Axle Lubricant Level . . . . . . . . . 9

Change Drive Axle Lubricant. . . . . . . . . . . . . 9

Drain Axle Sump . . . . . . . . . . . . . . . . . . . . . 9

Fill Axle Sump . . . . . . . . . . . . . . . . . . . . . . . . 9

Steer Axle

Steer Axle Lubricants . . . . . . . . . . . . . . . . . . 10

Steer Axle Lubrication Procedure . . . . . . . . . 11

Kingpins, Thrust Bearings and Tie

Rod Ends . . . . . . . . . . . . . . . . . . . . . . 11

On-Highway Applications - Standard . . . 11

Wheel Bearings . . . . . . . . . . . . . . . . . . . 11

Oil Bath . . . . . . . . . . . . . . . . . . . . . . . . . 11

Grease Packed . . . . . . . . . . . . . . . . . . . . 11

LMS Bearing System . . . . . . . . . . . . . . . 11

Driveline

Driveline Lubrication Intervals . . . . . . . . . . . 12

Driveline Lubrication Procedure . . . . . . . . . . 13

Lubrication Procedure for Universal Joints. . 13

Lubrication for Slip Splines . . . . . . . . . . . . . 14

Wheel End

Wheel End Lubricants . . . . . . . . . . . . . . . 15-16

Wheel End Lubrication Procedure. . . . . . . . . 17

2

Page 3

General Information

General Information

Dana Lubrication Philosophy

In promoting component reliability and longevity, proper lubrication is the key to a sound and effective maintenance program.

Without effective lubricants at proper levels, remaining maintenance procedures will not keep components functional.

We believe synthetic lubricants have proven to be superior to petroleum products and represent opportunities to promote superior maintenance and bottom line operating performance while significantly extending component service life and reliability.

Certain products and applications, as noted in this manual, require the use of approved synthetic lubricants.

A

list of approved lubricants and suppliers can be found at www.dana.com/commericalvehicle in the ApprovedLubricant

Supplier Manual, DALSM072012.

It is important to perform a daily pre-trip inspection of drivetrain components for lubricant leak

the attention of maintenance and immediate corrective action should be taken.

s. Leaks should be brought to

Standard Drain Lubricants

Drive Axle lubricants must meet specific lubricant industry requirements. Refer to the enclosed charts to select the proper

lubricant for your application.

Extended Drain Lubricants (Synthetic Lubricants)

Extended Drain synthetic lubricants offer superior thermal and oxidative stability for extended product performance and

reliability. The superior performance characteristics of these lubricants enable Dana to offer extended drain and extended

warranties. Added benefits include a more efficient drivetrain that translates into proven fuel economy savings over mineral

based lubricants.

hetic lubricants are recommended for severe duty applications and in cold climates.

Synt

It is important to use the lubricants that meet the current specifications set forth by Dana. Look for the appropriate approval

code on the container.

Drive Axle - Dana Specification: SHAES-256 Rev C

Drive Axle - Dana Specification: SHAES-429

Use of lubricants meeting these specifications will ensure the highest performing lubricants for maximum performance.

Note: Dana discontinued the use of the E500 logo in 2006.

3

Page 4

General Information

Introduction to Manual

This Lubrication Manual, organized by product, provides easy access to the following lube information:

• Type of lubricant

• Change intervals

• Capacities

• General lubrication procedures

• Warnings and Cautions

Note: Refer to the Approved Lubricant Supplier Manual, DALSM072012, to verify approved lubrication trade name and product.

Linehaul - 500,000 Mile Extended Lube Drain Interval

The extended drain interval program applies to the Dana axles listed below that meet the following conditions:

• Heavy-Duty and Medium-Duty axles

• Line haul service (On-highway)

• Lubricant approval levels

• Drive Axle – SHAES-256 Rev C

• Factory filled with lubricants approved for 500,000 mile drain cycles (US/Canada); 250,000/400,000Km (Outside US/

Canada)

• Refer to charts listed in this manual for axle drain intervals when using “Extended Drain Lubrican

• A Dana-approved lubricant must be used to keep the extended warranty in place. The extended drain program

and any extended warranty program are separate programs.

Note: For specific detail

Note: For a complete list of Dana “approved lubricants” for extended drain, refer to Approved Lubricant Suppliers Manual,

DALSM072012.

on Dana extended warranty programs refer to the Dana Warranty Guide or call 1-877-777-5360.

ts”

Vocational - 180,000 Mile Lube Drain Interval

This will outline the performance requirements of lubricants intended for use in vocational Spicer®drive axles that are allowed

the 180,000 mile or three year extended drain interval. The approved lubricants may be factory installed at the truck manufacturer,

or service filled up to 500 miles, and may rema

comes first.

Lubricant approval levels

• Axle – SHAES-429

in in the drive axles for the 180,000 mile or three year drain interval, whichever

4

Page 5

General Information

Warnings and Cautions

WARNING

Before working on a vehicle, place transmission in neutral, set brakes, and block wheels.

When switching between types of lubricants, all areas of each affected component must be thouroughly drained.

Do not introduce additives and friction modifiers.

Do not mix lubricants of different grades.

Do not mix mineral and synthetic lubricants.

Do not mix heavy-duty, multi-purpose lithium based (#2 grade) grease with sodium- based grease.

Vehicle Application Definitions

Line Haul (On-highway)

• High mileage operation (over 60,000 miles [96,500 Km] per year).

• On-highway or good to excellent concrete or asphalt.

• More than 30 miles [48 Km] between starting and stopping.

• 4x2, 6x2, 6x4 tractor/trailer combinations and straight trucks.

• Check fluid levels and inspect for leaks at regular PM maint

Vocational

• Low mileage operation (under 60,000 miles [96,500 Km] per year).

• Off-highway or areas of unstable or loose unimproved road surfaces.

• Less than 30 miles [48 Km] between starting and stopping.

• Heavy-Duty, off-road or specialized application type vehicles.

• Check fluid levels and inspect for leaks every 50 hours.

enance intervals, not to exceed 12,000 miles.

Severe Duty Service

• Consistent operation at or near maximum GCW or GVW ratings.

• Dirty or wet environments.

• Consistent operation on grades greater than 8%.

5

Page 6

Drive Axle

Drive Axle Lubricants

Dana Recommends the Use of Dana-Approved Lubricants for Extended Drain

Use the chart to locate the correct lubricant and change interval.

Note: For line haul and vocational definitions, see page 5.

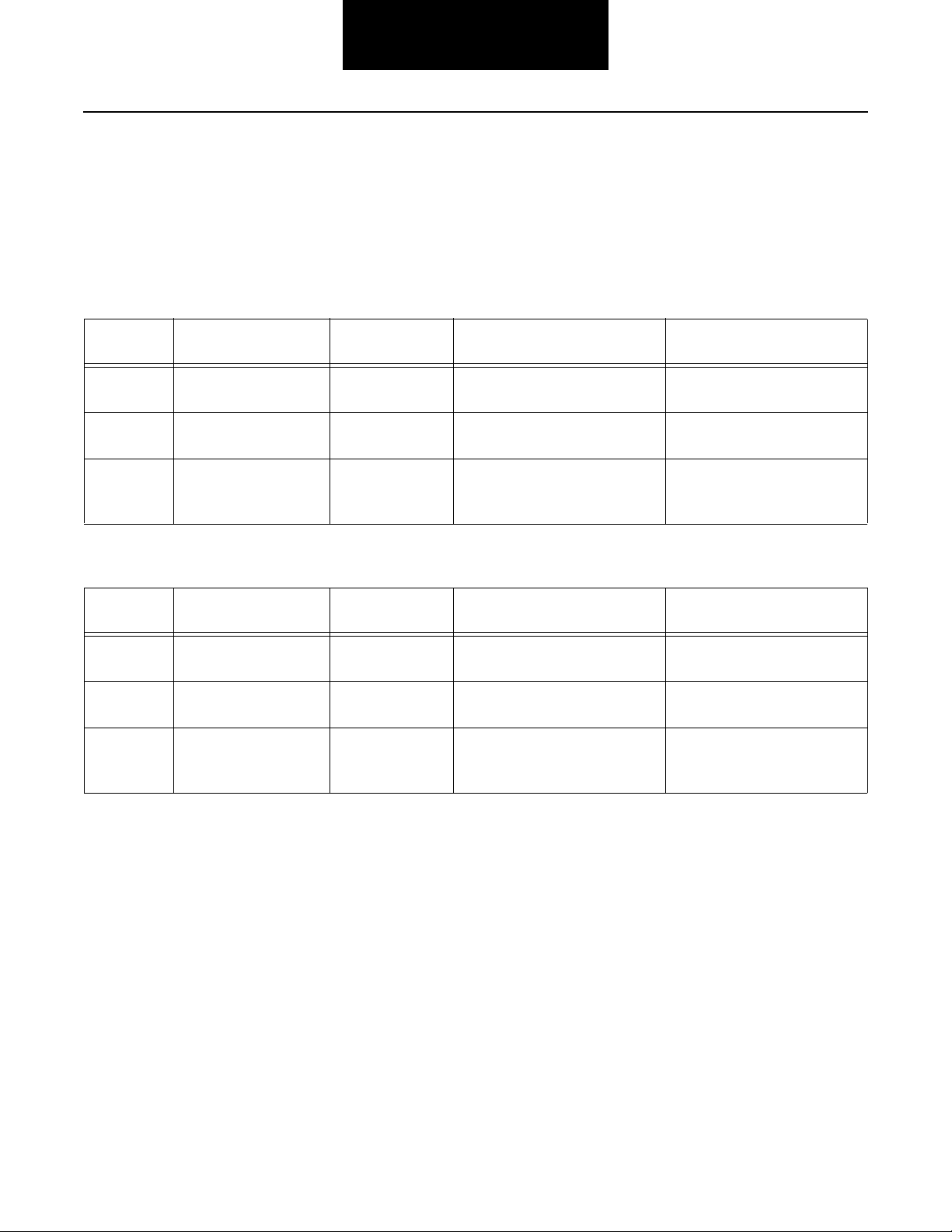

Heavy-Duty

Synthetic or

Mineral

Synthetic SHAES-256 Rev C SAE 75W-90 500,000 miles [800,000 Km]

Synthetic

Mineral SAE J2360 75W, 75W-90,

Lubricant

Specification

SHAES-429 SAE 75W-90

SAE

Viscosity Grade

SAE 80W-140

75W-140, 80W90, 85W-140

Change Interval for

Line Haul

or 5 years

120,000 miles [193,000 Km]

or 1 year

Medium-Duty

Synthetic or

Mineral

Synthetic SHAES-256 Rev C SAE 75W-90 250,000 miles [400,000 Km]

Synthetic

Mineral

Lubricant

Specification

SHAES-429 SAE 75W-90,

SAE J2360 75W, 75W-90,

SAE

Viscosity Grade

SAE 80W-140

80W-90,

85W-140

Change Interval for

Lin

e Haul

or 3 years

100,000 miles [160,000 Km]

or 1 year

Change Interval for

Vocational

N/A

]mK 000,882[ selim 000,081A/N

or 3 years

60,000 miles [96,500 Km]

or 1 year

Change Interval for

Vocational

N/A

]mK 000,882[ selim 000,081A/N

or 3 years

60,000 miles [96,500 Km]

or 1 year

Note: Extended warranties require the use of synthetic lubricant approved to SHAES-256 Rev C.

6

Page 7

Drive Axle

Drive Axle Lubricant Capacities

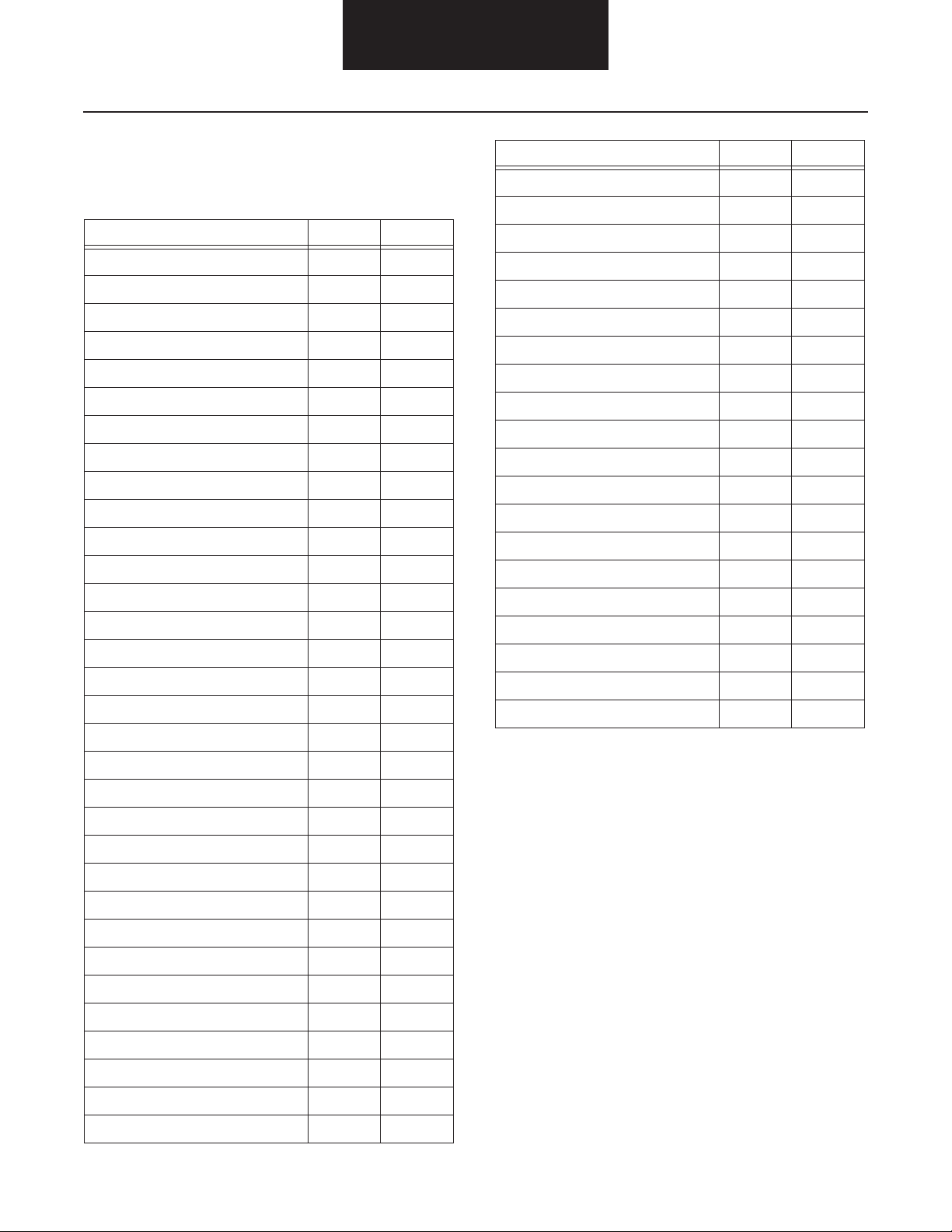

Single Drive Axle Lubricant Capacities

Capacities are sorted by model number. The suffixes are

included when necessary.

Single Axle Model Number Pints Liters

6.641011S

4.66.31031S

4.1142531S

4.1142051S

5.7173071-12S

5.7173D071-12S

5.7173071-32S

5.7173D071-32S

5.7173071-52S

5.7173D071-52S

5.7173091-32S

5.7173D091-32S

5.7173091-62S

5.7173D091-62S

9.8104091-03S

9.8104D091-03S

5245)BS( 062S

Single Axle Model Number Pints Liters

21070 (D, S) 40 18.9

21080 (A, D, S) 40 18.9

22060 (A, D, S) 28 13.2

22060 (P, T) 35 16.6

22065 (D, S) 34 16.1

22065 (P, T) 35 16.6

22080 (A, D, S) 40 18.9

23070 (D, S) 40 18.9

23070 (P, T) 39 18.5

23080 (A, D, S) 40 18.9

23080 (P, T) 41 19.4

23085 (C, D, S) 40 18.9

23085 (P, T) 41 19.4

23105 (A, D, S) 48 22.7

26080 (A, D, S) 40 18.9

26080 (P, T) 41 19.4

26085 (P, T) 41 19.4

26105 (A, D, S) 48 22.7

30055 (P) 36 17

30105 (A, D, S) 46 21.5

35055 (P) 36 17

15040 (P, T) 24 11.4

9.912)S( 04051

17060 (A, D, S) 28 13

19050 (P, T) 33 15.6

19055 (D, S) 34 16.1

19055 (P, T) 35 16.6

19060 (A, D, S) 28 13.2

19060 (P, T) 35

21060 (A, D, S) 28 13.2

21060 (P, T) 35 16.6

21065 (D, S) 34 16.1

21065 (P, T) 35 16.6

16.6

8.1152)S( 05091

7

Page 8

Drive Axle

Tandem Drive Axle Lubricant Capacities

Capacities are sorted by model number. The prefixes are

included when necessary.

Tandem Axle Model Number Pints Liters

5.8193071-04D

5.7173071-04R

5.8193071-64D

5.7173071-64R

5.8193071-05D

5.7173071-05R

9.9124091-25D

9.8104091-25R

9.9124091-06D

9.8104091-06R

9.9124095-25D

9.8104095-25R

40 DDS(P), DSS(P) 40 18.9

40 DDH(P), DSH(P) 31 14.7

40 RDS, RSS 37 17.5

40 RDH, RSH 28 13.2

7.4113)P(HSD 44

44 RDH, RSH 28 13.2

Tandem Axle Model Number Pints Liters

454 DA(P), DD(P), DS(P) 31 14.7

454 RA, RD, RS 28 13.2

461 DD(P), DS(P) 43 20.3

461 DP(P), DT(P) 46 22

461 RC, RP, RT 39 18

461 RD, RS 40 18.9

462 DD(P), DS(P) 40 18.9

462 RD, RS 37 17.5

463 DD(P), DP(P), DS(P), DT(P) 40 18.9

463 RD, RP, RS 37 17.5

521 DD(P), DP(P), DS(P), DT(P) 42 19.9

521 RC, RD, RP, RS, RT 39 18.5

581 DD(P), DP(P), DS(P) 42 19.9

581 RD, RP, RS 39 18.5

601 DC(P), DD(P), DP(P) 42 20

5.8193PR 106

4.9114)P(PD 156

8173PR 156

9114)P(PD 256

8173PR 256

341 DC, DP, DT(P), DS(P) 39 18.5

341 RC, RP, RS, RT 36 17

344 DA(P), DD(P), DS(P) 31 14.7

402 DP, DT(P), RP, RT 34 16.1

404 DA(P),

404 RA, RD, RS 28 13.2

405 DA(P), DD(P), DS(P) 31 14.7

405 RA, RD, RS 28 13.2

451 DP(P), DT(P), RP, RT 34 16.1

451 DC(P), DS(P) 39 18.5

451 RC, RS 36 17

8

DD(P), DS(P) 31 14.7

2.3182SR 443

5.8193)P(SD 204

7163SR 204

Page 9

Drive Axle

Drive Axle Lubrication Procedure

Check Drive Axle Lubricant Level

1. Remove fill hole plug, located in the axle housing

cover.

2. Lubricant must be level with the hole.

Hole

Hole

Improper Oil Level

Proper Oil Level

Fill Axle Sump (and Wheel Ends, if necessary)

Note: If wheel ends were removed, they must be filled with

the same lubricant as the axle sump.

1. Wipe clean all internal cavities or the hubs.

2. Lubricate the wheel bearings using the same lubricant as in the housing.

Note: Do not use wheel bearing grease.

3. Fill inner hub cavities before installing onto axle

housing spindles.

4. If the hub has

5. If hub does not have a fill hole, raise the opposite

axle end 8 in. [203 mm] for at least 1 minute.

6. If the wheel ends were filled by jacking up the axle

ends, recheck the main sump and top off if necessary until oil reaches the bottom of the fill hole.

a fill hole, add 1.5 pints [0.7 liters].

Oil will run into Wheel End

3. Check housing breather. Clean if dirty and replace if

damaged.

Change Drive Axle Lubricant

Drain Axle Sump

1. Before draining, lubricant temperature must be

between 60° and 120° F [15.5° and 48.8° C].

2. Put drain pan under drain plug located on the

underside of the axle housing.

3. Unscrew magnetic drain plug and drain the lubricant.

4. Inspect plug for large quantities of metal particles.

If present, inspect entire unit.

Oil will run into Wheel End

Fill Housing with oil to bottom of Plug

Temperature Sensor Mounting Hole

9

Page 10

Steer Axle Lubricants

The standard lubricants specified by the Steer Axle Product

Engineering group are as follows

Note: For line haul and vocational definitions, see page 5.

Steer Axle

Type of Lubricant

System

Lubricant SAE Change Interval for

Line Haul

Wheel End Mineral Oil SAE 75W-90 100,000 miles

[161,000 km] or 1 year

Wheel End Mineral Grease - NLGI #2 #2 grade 100,000 miles

[161,000 km] or 1 year

LMS-Low Lube

LMS-Lube Free

LMS-Low Lube

1

1

1

Synthetic Oil SAE 50

PS-164 Rev 7

Synthetic Oil SAE 50

PS-164 Rev 7

250,000 miles

[400,000 km] or 1 year

None (only needed if

tear down)

Semi-Fluid Synthetic Grease Chevron Delo SF50,000 miles [800,000

km] or 3 years

LMS-Low Lube

1

King Pin Joint Grease /

Tie Rod Ends

1

For easy identification, note that the Dana LMS-Low Lube

Semi-Fluid Synthetic Grease Mobilith SHC

007

Heavy-Duty, multipurpose

lithium based

#1 grade or

#2 grade

50,000 miles [800,000

km] or 3 years

25,000 miles [40,000

Km] or 6 months

brake uses a special “button head” grease fitting and the

Dana LMS-Lube Free brake does not have a grease fitting.

Change Interval for

Vocational

30,000 miles [48,000

km] or 6 months

30,000 miles [48,000

km] or 6 months

250,000 miles

[400,000 km] or 1 year

None (only needed if

tear down)

50,000 miles [800,000

km] or 3 years

50,000 miles [800,000

km] or 3 years

Every 50 hours

10

Page 11

Steer Axle

Steer Axle Lubrication Procedure

Lubrication

Proper lubrication practices are important in maximizing the

service life of your steer axle assembly.

CAUTION

Do not mix lubricants of different grades. Do not mix mineral and synthetic lubes. Different brands of same grade

may be mixed. Do not pack bearings with grease when

using an oil bath system. This practice can restrict the flow

of lubricant to the wheel seal.

Kingpins, Thrust Bearings, and Tie Rod Ends

On-Highway Applications - Standard

Pressure lubricate every 6 months or 25,000 miles (40,000

km).

A more frequent lubrication cycle is required for axles used

in on/off highway, refuse, or other severe service applications.

Use heavy-duty, multipurpose lithium base (#2 grade)

grease. Do not mix with sodium base grease.

Note: If it is difficult to grease either the upper or lower bush-

ing, try greasing the bushings with the vehicle jacked

up and supported on axle stands to improve grease

flow and help flush out contamination.

Wheel Bearings

Lubricate wheel bearings with an approved drive axle lubricant (oil bath) or heavy duty grease (grease packed) depending on the type of axle lube system. Identify the type of

lubrication system on your vehicle before servicing wheel

bearings. Improper lubrication can result in reduced seal life

and potential damage to bearings and spindles.

Grease Packed

Thoroughly clean bearings, spindle, hub cap, and hub cavity.

Parts may be washed in a suitable commercial solvent. Be

certain parts are free of moisture or other contaminants.

Refer to vehicle and/or wheel seal manufacturer’s recommendations when using grease. Fill wheel hub with grease to

inside diameter of bearing cups. Fill hub cap. Grease bearing

es by forcing grease between rollers, cones, and cage.

con

CAUTION

Never mix oil bath and grease packed wheel ends.

LMS Bearing System

Refer to Dana Spicer information Bulletin ABIB-9606.

Oil Bath

Lubricate wheel end assembly with a drive axle lubricant that

meets MIL-L-2105D specifications. Either 80W-90 mineral

based or 75W-90 synthetic lube is acceptable. Check lubricant level at each greasing interval. Maintain lube level to

center-line of axle or fill line on hub cap. Always check lube

level on flat ground.

11

Page 12

Driveline

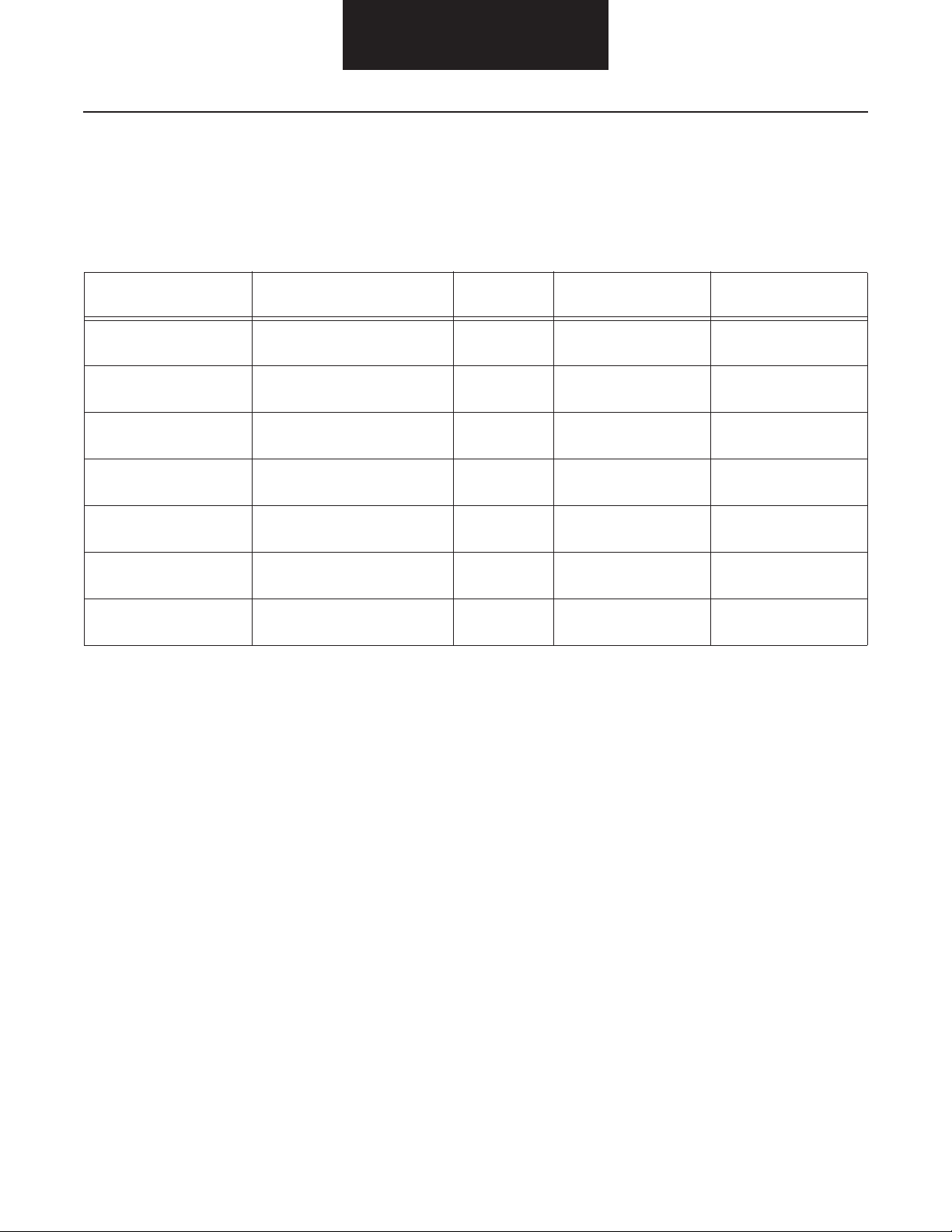

Driveshaft Lubrication Intervals

For assistance identifying the driveshaft model, see DSMT0100.

Spicer® Driveshaft Lubrication Intervals

Product City On Highway Line Haul On/Off Highway

10-Series

(1480 thru 1810 & SPL90)

Slip member also requires

Note:

lubrication.

Spicer Life Series

®

Medium Duty

(SPL55, 70, & 100)

Booted and permanently lubricated

slip member.

Spicer Life Series Heavy Duty

(SPL140, 170, & 250)

Standard

Spicer Life Series

U-Joint. Booted and permanently

5,000/8,000 miles

[8,000/12,000 Km]

or 3 months. (which

ever comes first)

25,000 miles

[40,000 Km]

or 6 months. (which

ever comes first)

25,000 miles

[40,000 Km]

or 6 months. (which

ever comes first)

lubricated slip member.

Spicer Life XL™ First Lubrication Cycle

Product City On Highway Line Haul On/Off Highway

Spicer Life XL

(SPL170XL & 250XL)

Extended lubrication U-Joint.

Booted and permanently lubricated

100,000 miles

[160,000 Km]

or 1 year. (which

ever comes first)

slip member.

Spicer Life XL™ Re-Lubrication Cycle

123

123

10,000/15,000 miles

[16,000/24,800 Km]

or 3 months. (which

ever comes first)

25,000 miles

[40,000 Km]

or 6 months. (which

ever comes first)

100,000 miles

[160,000 Km]

or 6 months. (which

ever comes first)

350,000 miles

[560,000 Km]

or 3 years. (which

ever comes first)

10,000/15,000 miles

[16,000/24,800 Km]

or 3 months. (which

ever comes first)

25,000 miles

[40,000 Km]

or 6 months. (which

ever comes first)

100,000 miles

[160,000 Km]

or 6 months. (which

ever comes first)

350,000 miles

[560,000 Km]

or 3 years. (which

ever comes first)

5,000/8,000 miles

[8,000/12,000 Km]

or 3 months. (which

ever comes first)

25,000 miles

[40,000 Km]

or 6 months. (which

ever comes first)

25,000 miles

[40,000 Km]

or 6 months. (which

ever comes first)

100,000 miles

[160,000 Km]

or 1 year. (which

ever comes first)

Product City On Highway Line Haul On/Off Highway

Spicer Life XL

(SPL170XL & 250XL)

Extended lubrication U-Joint.

Booted and permanently lubricated

25,000 miles

[40,000 Km]

or 6 months. (which

ever comes first)

100,000 miles

[160,000 Km]

or 6 months. (which

ever comes first)

100,000 miles

[160,000 Km]

or 6 months. (which

ever comes first)

25,000 miles

[40,000 Km]

or 6 months. (which

ever comes first)

slip member.

Spicer Life SF™ Lubrication Cycle

Product City On Highway Line Haul On/Off Highway

Spicer Life SF

(SPL170SF & 250SF) Service Free

1

Spicer Life XL universal joints are best identified by the rubber seal guards (a soft, pliable “boot”) fitted to the bearing cups.

Spicer Life XL universal joints have a plastic zerk cover attached prior to the required initial 350,000 mile re-lubrication. Standard

Spicer Life Series universal joints have a hard plastic slinger fitted to the bearing cups.

2

Spicer Driveshaft Division recommends re-lubrication with grease meeting NLGI Grade 2 specifications with an operating range

of +325°F/+163°C to -10°F/-23°C.

3

After initial miles (km) or time is reached, the plastic grease zerk cover must be removed and the joints re-lubricated. Once the

grease zerk cover has been removed, the “Re-Lubrication Cycle” interval must be followed.

12

Permanently lubricated for life of product

Page 13

Driveline

Driveline Lubrication Procedure

WARNING

Inadequate lubrication can cause driveline failure which can result in separation of the driveline from the vehicle. A separated driveline can result in serious injury or death. In order to avoid driveline failure, including driveline separation, you

must:

Among the most common causes of universal joint and slip spline failure is lack of proper lubrication. Properly sized Spicer universal joints that are adequately re-lubricated at recommended intervals will normally meet or exceed fleet operational requirements. Inadequate re-lube cycles and failure to lubricate the joints and slip spline properly not only cause joint failures, but lead

to other problems such as slip spline seizures. Proper re-lubrication flushes the universal joints, thus removing abrasive contaminants from the universal joint bearings.

1. Carefully review

2. Re-lubricate at recommended intervals.

3. Only use approved lubricants.

Spicer replacement universal joint kits contain only enough grease to provide needle bearing protection during storage. It is,

therefore, necessary to completely lubricate each replacement kit prior to assembly into the driveshaft yokes. Each journal cross

lube reservoir should be fully packed with a grease listed on the previous page. Each bearing assembly should also be wiped with

the same grease, filling all the cavities between the rollers and applying a liberal grease coating to the bottom of each race. After

the kits are installed into the driveshaft yokes and, prior to placing into service, they should be re-lubed, through the zerks, using

the same grease.

the lubrication specifications in the manual.

Lubrication Procedure for Universal Joints

1. Use the proper lubricant to purge all four bearing seals of each universal joint. This flushes abrasive contaminants from

each bearing and assures all four bearings are filled properly. Pop the seals. Spicer

2. If any of the seals fail to purge, move the driveshaft from side-to-side while applying gun pressure. This allows greater

clearance on the thrust end of the bearing that is not purging. (On two-headed zerk fittings, try greasing from the opposite lube fitting.)

3. Because of the superior sealing capability of the Spicer Seal design on the 1610, 1710, 1760, 1810, and 1880 Series,

there will occasionally be one or more bearing seals of a universal joint that may not purge. Seal tension then has to be

released. Bearing seals must purge to ensure adequate lubrication at all four universal joint bearings.

To Release Seal Tension:

seals are made to be popped.

4. On Quick Disconnect™ half round end yokes, remove the universal joint kit from the yoke and apply grease. Re-install

the universal joint kit, with new bolts, in the yoke and torque to specifications as listed in DSSM-3264.

5. On full round closed hole yokes, loosen the bolts holding the bearing assembly that does not purge to release seal ten-

It may be necessary to loosen the bearing assembly approximately 1/16” minimum. If loosening does not cause

sion.

purging, remove the bearing assembly to determine cause of blockage.

6. Remove bolts and replace.

Note: The self-locking bolt design for full round yokes uses serrated bolts with lock patch and does not require a lock strap. DO

NOT reuse any retaining bolt. If loosening or removal of a bolt is necessary, replace it with a new one.

13

Page 14

Driveline

Lubrication for Slip Splines

Always use a good E.P. grease meeting NLGI Grade 2 specifications on Glidecote™ and steel splines. The same lubricant used for

universal joints is satisfactory for slip splines.

Re-lube splines as the interval prescribed in the “Driveline Lubricants” section. Apply grease gun pressure to lubrication zerk

until lubricant appears at pressure relief hole in welch plug at slip yoke end of spline (Photo 1). At this point, cover pressure

relief hole with finger and continue to apply pressure until grease appears at slip yoke seal (Photo 2). This will insure complete

lubrication of spline.

Figure 1 Figure 2

CAUTION

In cold winter months, activate the slip spline assembly by driving the vehicle sufficiently to cause displacement of the

grease prior to its stiffening. Otherwise, the slip yoke plug may be forced out due to hydraulic pressure causing loss of

grease

and allowing abrasive contaminants to enter the slip spline.

14

Page 15

Wheel End

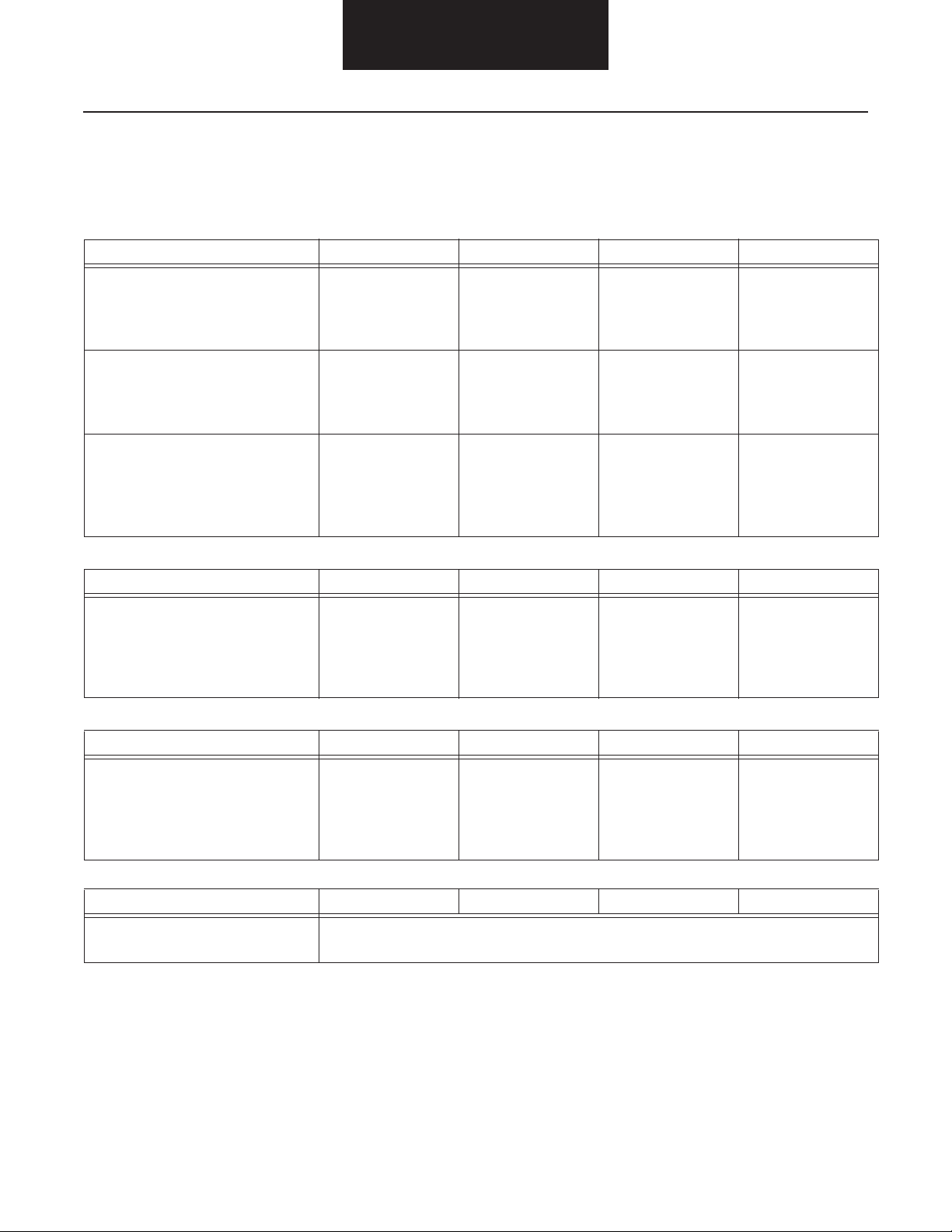

Wheel End Lubricants

Use the chart to locate the correct lubricant and change interval.

Note: For line haul and vocational definitions, see page 5.

Product Lubricant Type SAE Change Interval for

Drive Axle

LMS

Drive Axle

(Adjustable)

Drive Axle

(Adjustable)

Steer Axle

Oil Bath LMS

Steer Axle

Oil Bath

(Adjusted)

Steer Axle

Oil Bath

(Adjusted)

Steer Axle

Semi-fluid

(Adjusted)

Change Interval for

Line Haul

Synthetic

1

SHAES 256 Rev C

SHAES 429

Synthetic

5

SHAES 256 Rev C

SHAES 429

Mineral Base

5

SAE J2360

SAE 75W-90, 80W-140 500,000 miles

[800,000 Km]

or 5 years

SAE 75W-90, 80W-140 250,000 miles

[400,000 Km]

or 3 years

SAE 75W-90, 75W-140,

80W-90, 85W-140

120,000 miles

[193,000 Km]

or 1 year

Synthetic

1

SHAES 256 Rev C

SAE 75W-90 500,000 miles

0,000 Km]

[80

or 5 years

Synthetic

SHAES 256 Rev C

SHAES 429

Mineral Base

SAE J2360

SAE 75W-140, 75W-90 120,000 miles

[193,000 Km]

or 1 year

75W, 75W-90, 80W-90,

85W-140

120,000 miles

[193,000 Km]

or 1 year

3

Semi-fluid Synthetic

Grease

Delo SF, Mobil SHC 007

120,000 miles

[193,000 Km]

or 1 year

Vocational

180,000 miles

[288,000 Km]

or 3 years

180,000 miles

[288,000 Km]

or 3 years

60,000 miles

[96,500 Km]

or 1 year

120,000 miles

[193,000 Km]

or 2 years

60,000 miles

[96,500 Km]

or 6 months

60,000 miles

[96,500 Km]

or 6 months

60,000 miles

[96,500 Km]

or 6 months

Steer Axle

Grease Pack

(Adjusted)

Trailer Axle

Oil Bath LMS

Trailer Axle

Oil Bath

(Adjusted)

Trailer Axle

Oil Bath LMS

Trailer Axle

Grease LMS

Trailer Axle

Grease (Adjusted)

Heavy-Duty Multipurpose

Lithium Based

3

#2 Grade 120,000 miles

[193,000 Km]

or 1 year

Synthetic

4

SHAES 256 Rev C

SAE 75W-90 500,000 miles

0,000 Km]

[80

or 5 years

Synthetic

SHAES 256 Rev C

SHAES 429

SAE 75W-90, 80W-140 120,000 miles

[193,000 Km]

or 1 year

Mineral Base, J-2360 75W, 75W-90 120,000 miles

[193,000 Km]

or 1 year

Heavy-Duty Multipurpose

Lithium Based

3

#2 Grade 120,000 miles

[193,000 Km]

or 1 year

Heavy-Duty Multipurpose

Lithium Based

3

#2 Grade 120,000 miles

[193,000 Km]

or 1 year

60,000 miles

[96,500 Km]

or 6 months

180,000 miles

[288,000 Km]

or 3 years

180,000 miles

[288,000 Km]

or 3 years

60,000 miles

[96,500 Km]

or 1 year

60,000 miles

[96,500 Km]

or 6 months

60,000 miles

[96,500 Km]

or 6 months

15

Page 16

Wheel End

Product Lubricant Type SAE Change Interval for

Trailer Axle

Semi-fluid LMS

Trailer Axle

Semi-fluid LMS

Trailer Axle

Semi-fluid

Semi-fluid Synthetic

Grease

Semi-fluid Synthetic

Grease

Semi-fluid Synthetic

Grease

Chevron Delo SF

Mobil SHC 007

Delo SF, Mobil SHC 007

(Adjusted)

1

Only approved lubricant for LMS wheel ends

2

Use of this grease requires a signed waiver from the customer

3

Do not mix with sodium base grease

4

Specified by MGM-113 as only approved lubricants for LMS trailer axles

5

Refer to maintenance manual for inspection and adjustment intervals

Change Interval for

Line Haul

4

500,000 miles

[800,000 Km]

or 5 years

2

120,000 miles

[193,000 Km]

or 1 year

2

120,000 miles

[193,000 Km]

or 1 year

Vocational

120,000 miles

[193,000 Km]

or 2 years

60,000 miles

[96,500 Km]

or 6 months

60,000 miles

[96,500 Km]

or 6 months

16

Page 17

Wheel End Lubrication Procedure

Wheel End

CAUTION

Before operating the axle, the wheel hub cavities and

bearings must be lubricated to prevent failure.

When wheel ends are serviced, follow Dana’s wheel end

lubrication procedure before operating the axle.

Spicer axles may be equipped with either of two wheel end

designs:

• Wheel ends with an oil fill hole

Wheel end oil fill hole

Proper lubricant level

Wheel End Lubrication Procedure (without oil fill

hole)

1. With axle level and wheel ends assembled, add

lubricant through filler hole in axle housing cover

until fluid is

2. Raise the left side of the axle 6 in. [152 mm] or

more. Hold axle in this position for one minute.

Oil will run into Wheel End

3. Raise the right side of the axle 6 in. [152 mm] or

more. Hold axle in this position for one minute.

level with the bottom of filler hole.

Oil will run into Wheel End

• Wheel ends without an oil fill hole

Lubricant flow from sump

Proper lubricant level

Wheel End Lubrication Procedure

(with oil fill hole)

1. Rotate the wheel end hub until the oil fill hole is up.

2. Remove the oil fill plug.

3. Pour 0.5 pint [0.2 liter] of axle sump lubricant into

each hub through the wheel end fill hole.

4. With axle on a level surface, add lubricant through

housing cover oil filler hole until fluid is level with

the bottom of the hole.

Fill Housing with oil to bottom of Plug

Temperature Sensor Mounting Hole

Note: Axles without wheel end fill holes require approxi-

mately 2.5 pints [1.2 liters] of additional lubricant to

bring the lubricant level even with the bottom of the fill

hole.

4. Install oil fill plug and tighten to specified torque.

17

Page 18

For spec‘ing or service assistance, call 1-877-777-5360 or visit our website at www.dana.com

Dana Commercial Vehicle Products Group

3939 Technology Drive

Maumee, Ohio, USA 43537

www.dana.com

All applications must be approved by the Application Engineering Department. Specifications and/or design are subject to change without notice or obligation. Printed in USA LM072012

Loading...

Loading...