Page 1

Spicer

®

Single Drive Axles

Service Manual

S140 Series

AXSM0030

September 2013

Page 2

General Information

General Information

The description and specifications contained in this service

publication are current at the time of printing.

Dana reserves the right to discontinue or to modify its models

and/or procedures and to change specifications at any time

without notice.

Important Notice

This symbol is used throughout this

manual to call attention to procedures

where carelessness or failure to follow

specific instructions may result in

personal injury and/or component

damage.

Departure from the instructions, choice

of tools, materials and recommended

parts mentioned in this publication

may jeopardize the personal safety

of the service technician or vehicle

operator.

Any reference to brand name in this publication is made

simply as an example of the types of tools and materials

recommended for use and should not be considered an

endorsement. Equivalents, if available, may be used.

WARNING: Failure to follow indicated

procedures creates a high risk of personal

injury to the servicing technician.

CAUTION: Failure to follow indicated

procedures may cause component

damage or malfunction.

IMPORTANT: Highly recommended

procedures for proper service of this unit.

NOTE: Additional service information not

NOTE:

covered in the service procedures.

TIP: Helpful removal and installation

procedures to aid in the service of this unit.

Refer to the OEM vehicle specifications

OEM

Always use genuine Spicer replacement parts.

i

Page 3

General Information

General Information ..........................................................i

Introduction .....................................................................1

Ring Gear and Pinion .......................................................3

Inspection ........................................................................4

Prepare the Parts for Inspection ......................................5

Differential Carrier Assembly ...........................................8

Differential Carrier Assembly -

Parts Exploded View ....................................................9

Remove Differential Carrier ............................................ 10

Install Differential Carrier ............................................... 11

Remove Wheel Differential ............................................. 12

Pinion - Parts Exploded View ......................................... 13

Pinion Removal .............................................................. 14

Drive Pinion ...................................................................15

Pinion Installation ..........................................................16

Wheel Differential Assembly - Parts Exploded ...............18

Disassemble, Overhaul, and

Assemble Wheel Differential ..................................... 19

Measure and Adjust Carrier Assembly ...........................24

Adjust Ring and Pinion Tooth Contact Pattern ............... 26

Install Axle Housing Breather .........................................28

Wheel End Seal - Parts Exploded View ......................... 29

Remove and Overhaul Wheel End Seal .......................... 30

Adjust Wheel Bearing.....................................................31

Wheel End .................................................................... 33

Lubricate Wheel End ..................................................... 34

Lubrication ................................................................... 36

Change Lube ................................................................ 38

Proper Vehicle Towing ....................................................39

Torque Chart ................................................................. 40

Page 4

Introduction

Introduction

Dana Commercial Vehicle Division, presents this publication to aid in maintenance and overhaul of Spicer single drive axles.

Instructions contained cover the models listed. Their design is common, with differences in load capacity. Capacity variations

are achieved by combining basic differential carrier assemblies with different axle housings, axle shafts and wheel equipment.

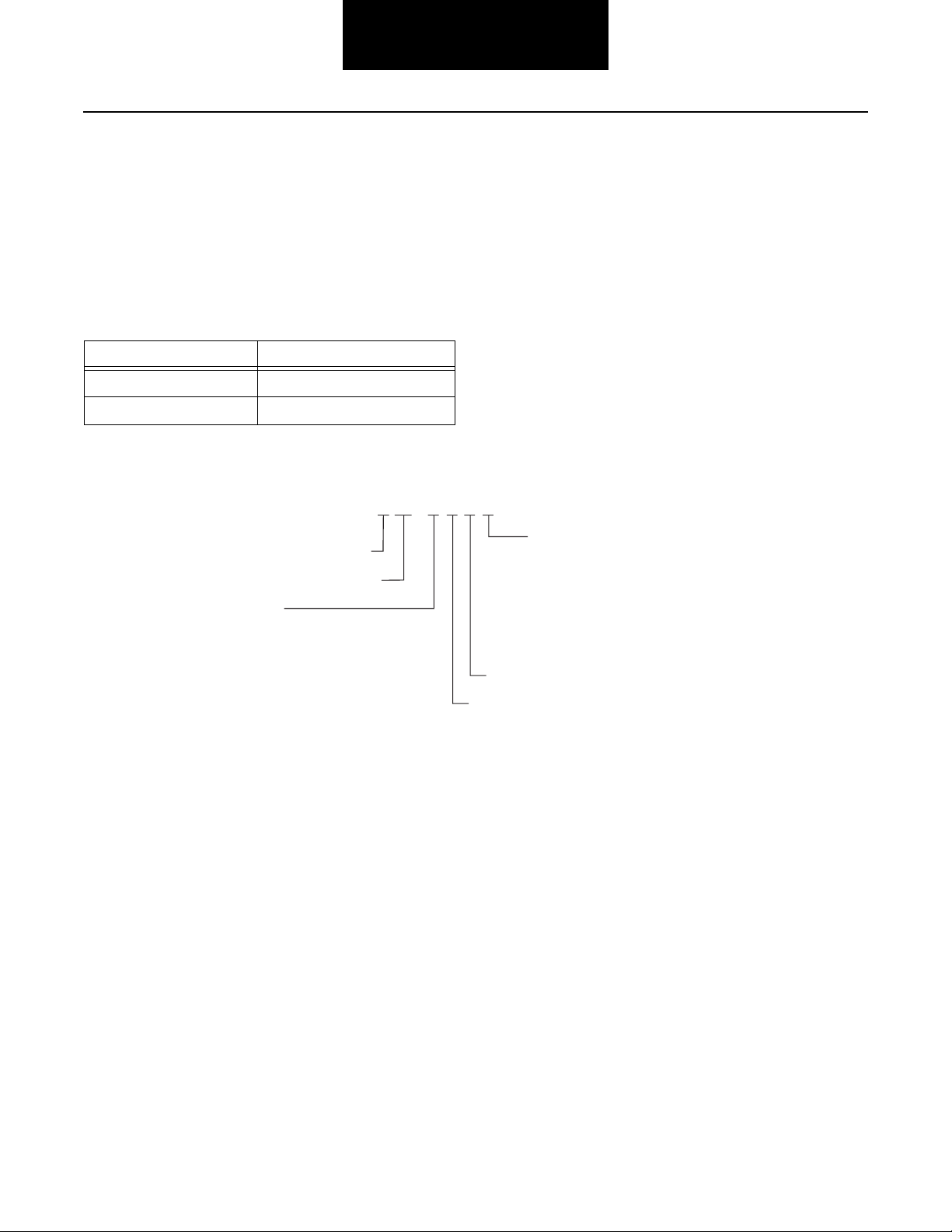

Model Listing

Rear Axle Load Capacity

S19-140 19,000

S17-140 17,000

Model Information

S 19 - 1 4 0 L

S - S i n gle R e a r Axle

G A W R at in g x 1000 l bs .

Gea r Ty p e

1 - S t a n d a r d S i n gle R e d u c t i o n

2 - D u a l R a n g e

3 - Pla n e t a r y Do uble R ed uc ti on

4 - C o n t r olled Tr act io n Differ en tial

5 - H elical R e d u c t i o n

O p t i o n s

L - L imit e d - S lip

W - W i d e -t r ack

F - Rolled Ove r

R - P a r k i n g B r ake

D e s i g n L evel

H ead A s s e mbl y S e r i e s

1

Page 5

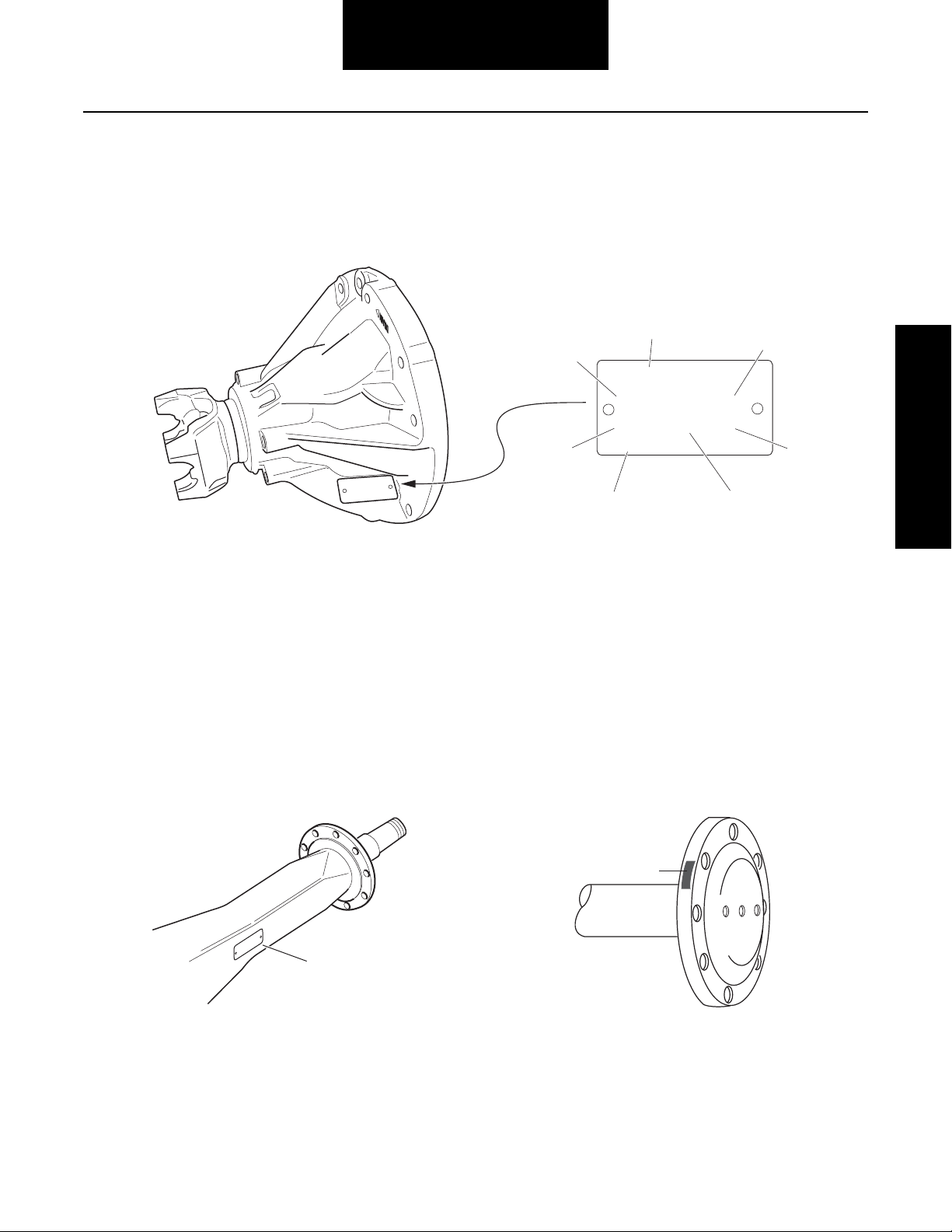

Model Identification

Drive Axle

Introduction

®

Spicer

CUST. PART NO.

SPEC. SERIAL NO.

MODEL PART NO. RATIO

MADE IN:

1 - Country of origin

2 - Axle model identification

3 - Specification number assigned to the axle built by Spicer.

Identifies all component parts of the axle including special

OEM requirements such as yokes or flanges.

4 - OEM part number assigned to the axle build

5 - Carrier assembly serial number assigned by the

manufacturing plant

6 - Axle gear ratio

7 - Carrier assembly production or service part number

Part Identification

Axle Housing Axle Shaft

4

3

CUST. PART NO.

SPEC. SERIAL NO.

MODEL PART NO. RATIO

2

MADE IN:

1

Spicer

7

5

®

Introduction

6

®

Spicer

PT. NO.

HSG. CAP. LBS.

. I.D. NO.

ADE IN

HSG

HOUSING M

1

1 - ID Tag 2 - Axle shaft part number

2

2

Page 6

Introduction

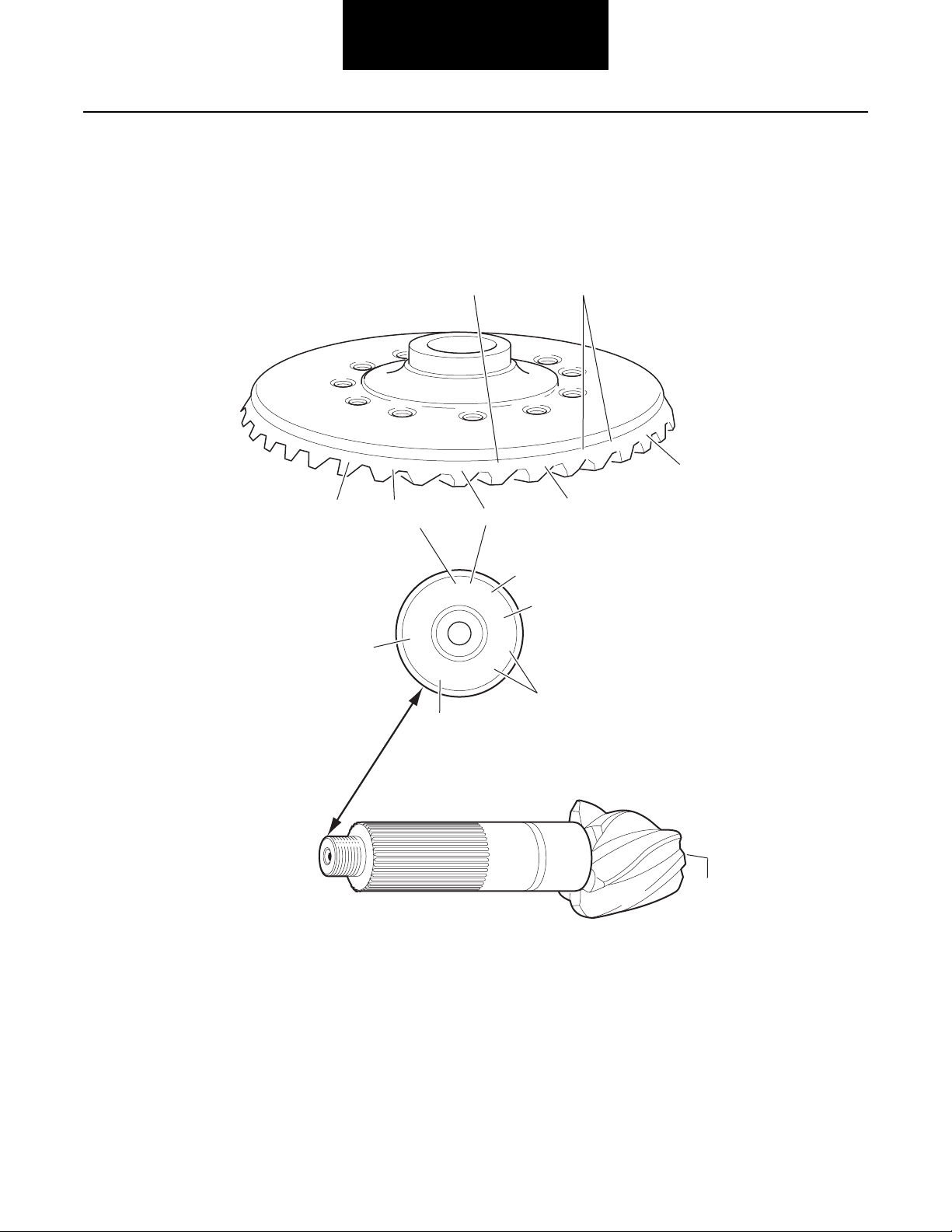

Ring Gear and Pinion

Note: Ring gear and drive pinion are matched parts and must be replaced in sets.

127381

1

3

L7038

G

17

OF

4

6

SPICER

7

8

41-8

NL2

5

2

8

8-41

127428

127

6

0H

17

G

127

7

SPICER

3

1

1 - Part number

2 - Number of ring gear teeth

3 - Manufacturing numbers

3

6-39

JD77

85405

86

4

4 - Matching gear set number

5 - Number of pinion teeth

7 - Indicates genuine Spicer parts

8 - Heat Code

6 - Date code

Page 7

Inspection

Inspection

Failure Analysis

Failure analysis is the process of determining the original

cause of a component failure in order to keep it from happening again. Too often, when a failed component is replaced

ut determining its cause, there will be a recurring failure.

witho

If a carrier housing is opened, revealing a ring gear with a broken tooth, it is not enough to settle on the broken tooth as the

cause of the carrier failure.

examined. For a thorough understanding of the failure and

possible insight into related problems, the technician needs to

observe the overall condition of the vehicle.

No one benefits when a failed component goes on the junk

cause unknown. Nothing is more disturbing to a

case of

n.

e

a rebuilt rear axle, mismatched gears may have

pile with th

customer than a repeat failure. Systematically analyzing a failure to prevent a repeat occurrence assures quality

avoiding unnecessary downtime and further expense to the

customer.

The true cause of a failure can be better determined by knowing what to look for, determining how a piece of the equipment was running and learning about previous problems. In

the

been installed. The more successful shops prevent repeat

equipment failures by developing good failure analysis practices. Knowing how to diagnose the cause of a premature failure is one of the prerequisites of

technicia

Other parts

of the carrier must be

ser

vice by

a good heavy-equipment

How to Diagnose a Failure

The following five steps are an effective approach to good failure diagnostics.

1. Document the problem.

2. Make a preliminary investigation.

3. Prepare the parts for inspection.

4. Find the cause of the failure.

5. Correct the cause of the problem.

4. Ask: In what type of service is the truck being used?

5. Ask: Has this particular failure

6.

Ask: How was the truck working p

You need to be a good listener. Sometimes, insignificant or unrelated symptoms can point to the cause of the failure:

7. Ask: Was the vehicle operating at normal temperatures?

8. Ask: Were the gauges showing normal ranges of

operation?

9. Ask: Was there any unusual noise or vibration?

After listening, review the previous repair and maintenance

records. If th

and compare their observations for consistency with the service and maintenance records. Verify the chassis Vehicle

entificat

Id

cation plate, as well as the mileage and hours on the vehicle.

Make a Preliminary Investigation

These steps consist of external inspections and

that will be valuable when combined with the results of the

parts examination.

1. Look for leaks, cracks or other damage that can

2. Make note of obvious leaks around

3. Look for cracks in the carrier housing (harder to see,

4. Does the general mechanical condition of the vehicle

5. Are the tires in good condition and do the

6. If equipped with a torque-limiting device, is it work-

ere is more than one driver, talk to all of them

ion Number (VIN) number from the vehicle identifi-

point to the cause of

A missing fill or drain plug would be an obvious

cause for concern.

metimes visible).

but so

indi

cate proper maintenance or are there signs of

neglect?

match?

ing properly?

the failure.

occurred before?

rior to the failure?

obser

vations

plugs and seals.

sizes

Inspection

Document the Problem

Here are some guidelines for starting to learn about a failure,

including questions to ask:

1.

Talk to the operator of the truck.

2. Look at the service records.

3. Find out when the truck was last serviced.

During the preliminary investigation, wr

of the ordinary for later reference. Items that appear insignificant now may take on more importance when the subassemblies are torn down.

ite down anything out

4

Page 8

Prepare the Parts for Inspection

Inspection

After the preliminary investigation, locate the failure and prepare the part for examination. In carrier failure analysis, it may

be necessar

y to disassemble the unit.

1. When disassembling subassemblies and parts, do

not clean the parts immediately since

destroy some of the evidence.

2. When tearing down the drive axle, do it in the recom-

ded manner. Minimize any further damage to the

men

unit.

Ask more questions when examining the interior of

3.

the carrier

specifications regarding quality, quantity and viscosity? As soon as you have located the failed part, take

time

. Does the lubricant meet the manufacturer

to analyze

the data.

cleaning may

Find the Cause of the Failure

Here begins the real challenge to determine the exact cause of

the failure. Keep in mind that there is no benefit to replacing a

failed part without determining the cause of the failure. For

example, after examining a failed part and finding that the fail-

o

ure is caused by a lack of lubricati

there was an external leak. Obviously, if there is an external

leak, just replacing the failed gear is not going to correct the

situation.

Another important consideration is

type of failure which can be a valuable indicator for the cause

of failure. The following pages show different types of failures

and possible causes. Use this as a guide in determining types

of failures and in correcting problems.

n, you must determine if

to determine the

specific

Correct the Cause of the Problem

Once the cause of the problem has been determined, refer to

the appropriate service manual to perform the repairs.

5

Page 9

Inspection

Inspection

Clean

1. Wash steel parts with ground or polished surfaces in

solvent. There are many suita

vents available. Kerosene and diesel fuel are acceptable.

WARNING

Gasoline is not an acceptable solvent because of its

em

e combustibility. It is unsafe in the workshop envi-

extr

ronment.

2. Wash castings or other rough parts in solvent or

clean in hot solution tanks usi

tions.

Note: If a

hot solution tank is used, make sure parts are

heated

thoroughly before rinsing.

3. Rinse thoroughly to remove all traces of the cleaning

ion.

solut

4.

Dry parts immediately with clean rags.

5. Oil parts.

• If parts are to be reused immediately: Lightly oil.

• If parts are to be stored: Coat

sion resistant paper and store in a clean, dry place.

ble commercial sol-

ng mild alkali solu-

with oil, wrap in

corro-

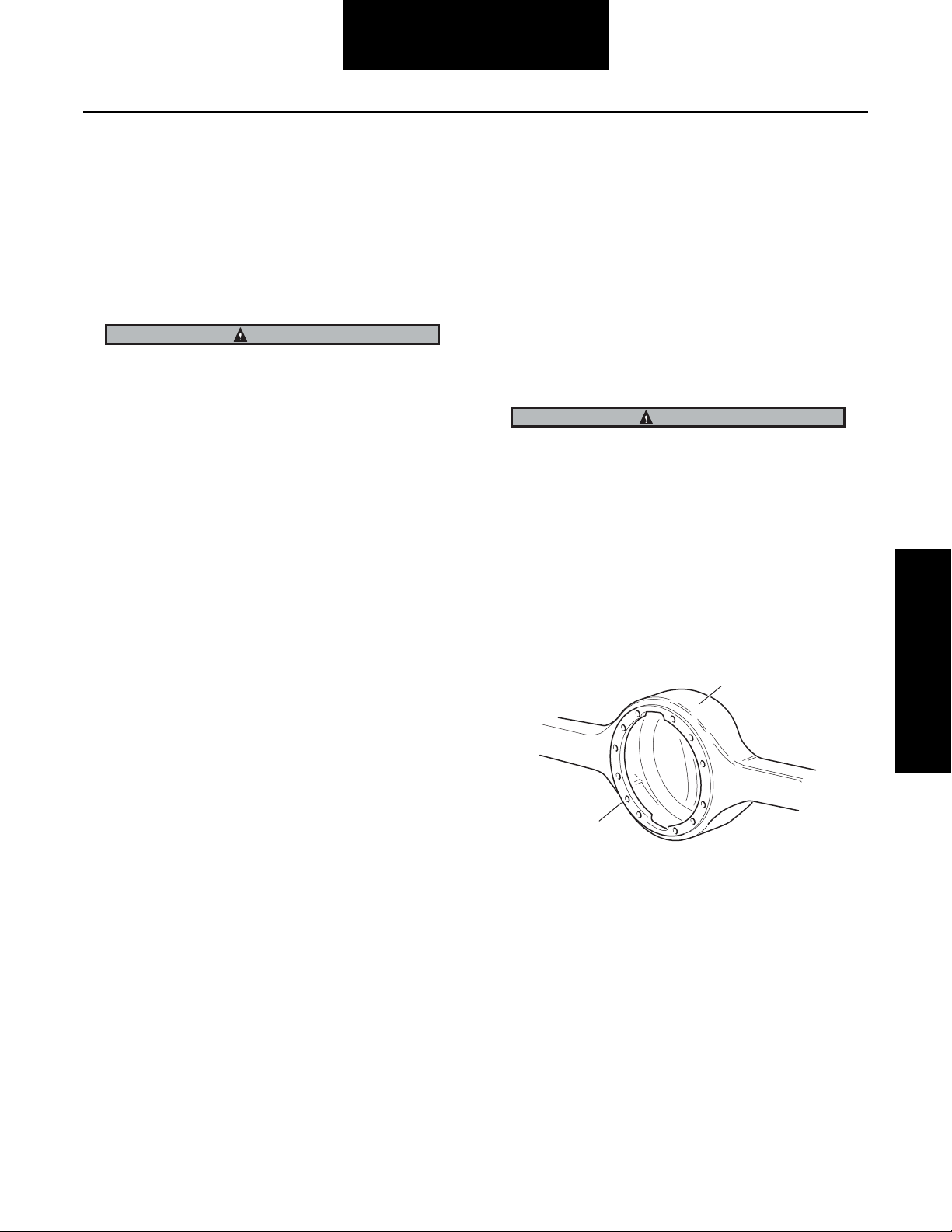

Inspect Axle Housing

Axle housing inspection and repairs are limited to the following checks or repairs.

• Visually inspect axle housing for cracks, nicks and

burrs on

• Check carrier bolt holes and studs for foreign material.

• Replace damaged fasteners. Look for loose bolts

cross-threaded holes

Any damage which affects the alignment or structural integrity of the housing requires housing replacement. Do not

r by bending or straightening. This process can affect

repai

the material’s properties and cause it to fail completely

under load.

• Check all seals and gaskets.

Note: Replace

ket compound (included in many repair kits). The compound provides a more effective seal against lube

seepage and is easier to remove from

when replacing parts.

machined surfaces.

conventional

or

CAUTION

gaskets with silicone rubber gas-

mating surfaces

1

Inspection

2

1 - Axle housing

2 - Machined surface

6

Page 10

Inspect Components

Inspect all steel parts for:

• Notches, visible steps or grooves created by wear.

• Pitting or cracking along gear contact lines.

• Scuffing, deformation or discolorations. These are

signs of

related to low lubrication levels or improper lubrication practices.

In addition, inspect the following for damage:

• Differential gearing

• Bearings for loose fit on drive pinion, and differential

bearings.

All fasteners for rounded heads, bends, cracks or

•

dama

excessive heat in the axle

ged threads.

and are usually

Inspection

• Inspect machined surfaces of cast or malleable

parts. They must be free of nicks, burrs

scoring, and wear.

• Look for elongation of drilled holes, wear on surfaces machined for bearing fits and nicks or burrs in

mating surf

aces.

, cracks,

Inspect Primary Gearing

Before reusing a primary gear set, inspect teeth for signs of

excessive wear. Check tooth contact pattern for evidence of

incorrect adjustment.

7

Page 11

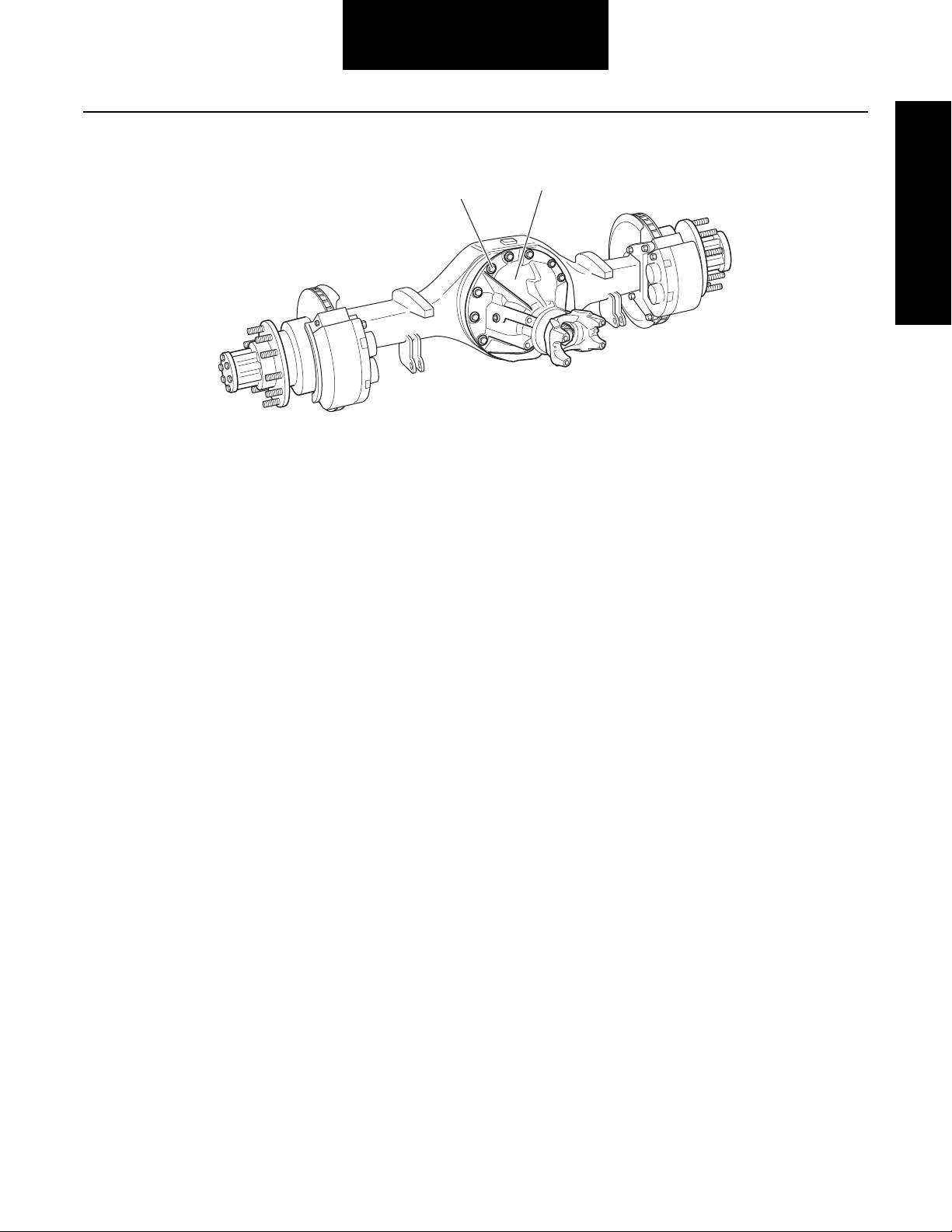

Differential Carrier Assembly

y

Differential Carrier Assembly

1 - Carrier fastener

2 - Carrier assembly

Differential Carrier

1

2

Assembl

8

Page 12

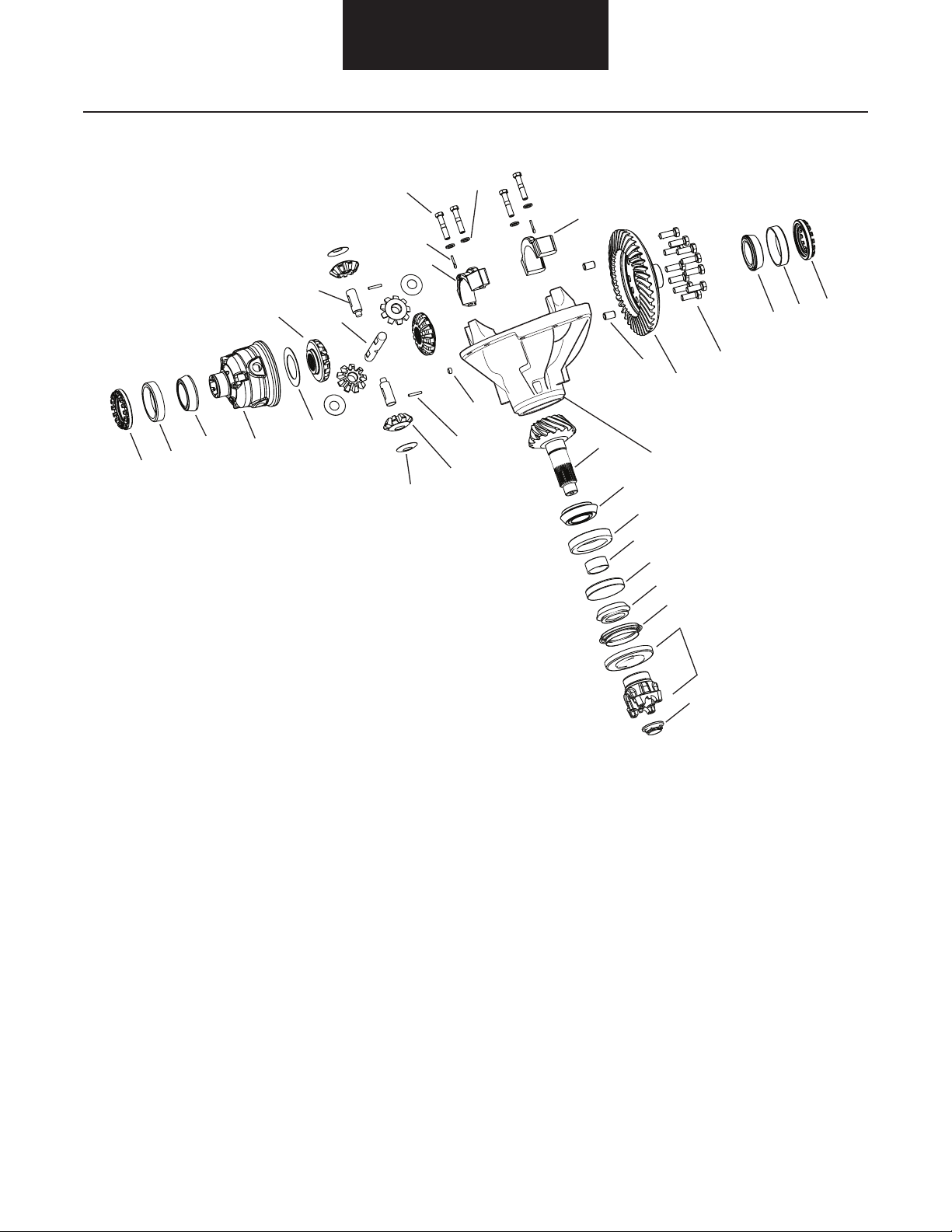

Differential Carrier Assembly

Differential Carrier Assembly - Parts Exploded View

31

30

29

28

19

20B

27

20A

22

17

26

25

18

21

23

32

24

16

15

14

11

9

10

8

7

6

5

4

3

13

12

1 - Pinion Nut

2 - End Yoke and Slinger

3 - Oil Seal

4 - Outer Pinion Bearing Cone

5 - Outer Pinion Bearing Cup

6 - Pinion Spacer

7 - Inner Pinion Bearing Cup

8 - Inner Pinion Bearing Cone

9 - Drive Pinion

10 - Carrier Housing

11 - Diff Case Dowels

12 - Ring Gear

13 - Ring Gear Bolts

14 - Flange Half Bearing Cone

15 - Flange Half Bearing Cup

2

1

16 - Flange Half Bearing Adjuster

17 - Side Pinion Thrust Washer

18 - Side Pinion

19 - Side Gear

20A,B - Differential Shaft

21 - Pin

22 - Capscrew

23 - Flat Washer

24 - Flange Half Cap

25 - Plain Half Cap

26 - Cotter Pin

27 - Side Gear Thrust Washer

28 - Plain Half Diff Case

29 - Plain Half Bearing Cone

30 - Plain Half Bearing Cup

31 - Plain Half Bearing Adjuster

32 - Pipe Plug

9

Page 13

Differential Carrier Assembly

y

Remove Differential Carrier

Standard Differentials

1. Block the vehicle.

2. Drain axle lubricant. Remove bottom two (2) capscrews.

3. Disconnect driveline.

4. Remove axle shafts. (If used, remove lock washers

and tap

Do not lie under carrier after fasteners are removed. Use

transmi

prior to loosening fasteners.

ssion jack to support differential carrier assembly

r dowels.)

e

WARNING

WARNING

CAUTION

CAUTION

Do not strike the shaft head with a steel hammer. Do not

s

use chi

els or wedges to loosen shaft or dowels.

5. Remove carrier capscrews and washers.

6. Remove differential carrier assembly.

Differential Carrier

Assembl

10

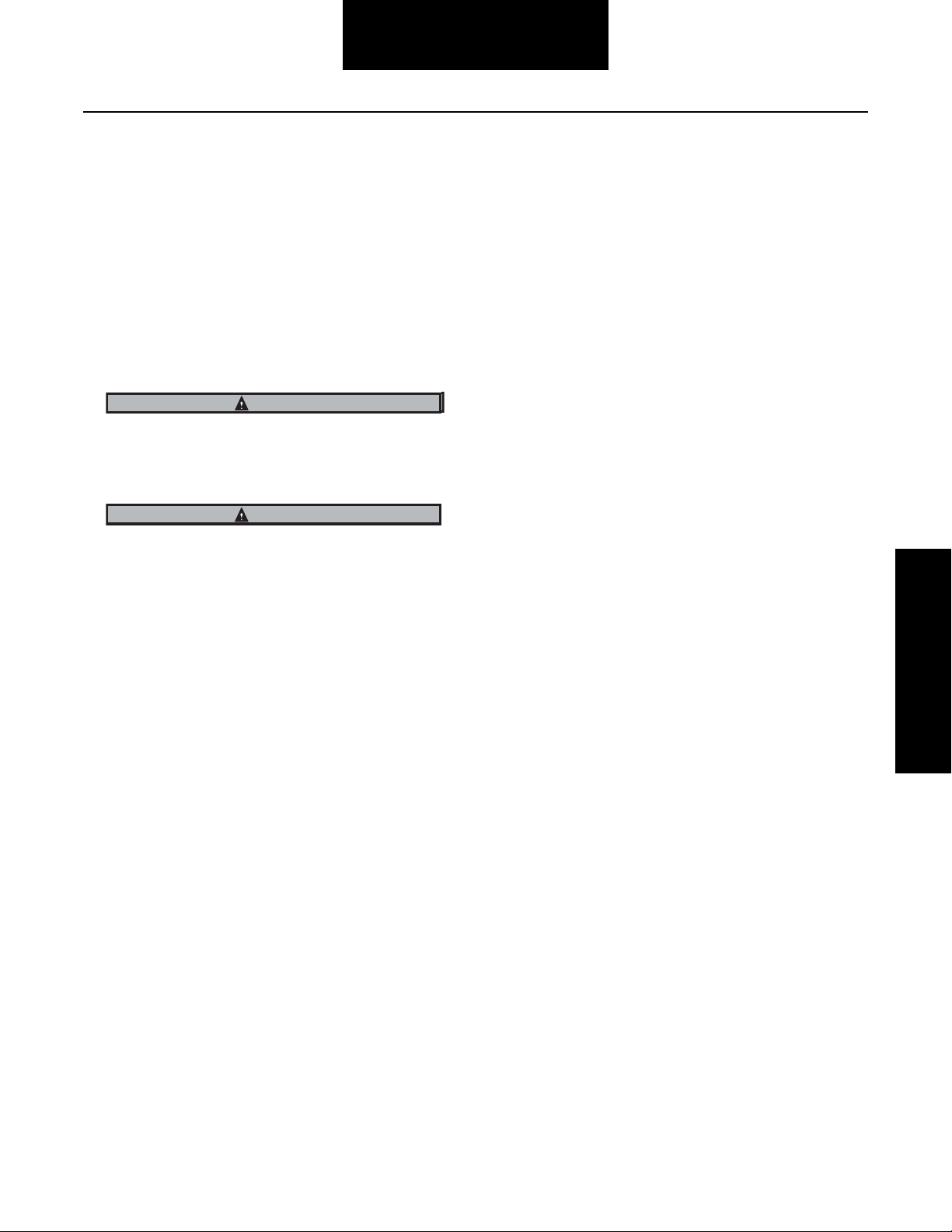

Page 14

Differential Carrier Assembly

Install Differential Carrier

IMPORTANTIMPORTANT

Before installing carrier assembly, inspect and thoroughly

clean interior of axle housing using an appropriate solvent

and clean rag.

1. Apply Spicer approved RTV compound on axle

housing mating surface as shown in the illustration.

Completely remove all old gasket material prior to

applying new material. Compound will set in 20 minutes. Install carrier before compound sets or reapply.

1

1 - Apply RTV gasket in this pattern

TIP: To assist in installing complete differential carrier use

two pieces of threaded rod (M14 X 2) threaded into carrier

capscrew holes. Rod should be approximately 4" (102 mm)

long. Use these to pilot the carrier into the housing.

2. Install carrier to housing, lock washers and capscrews. Torque to proper specification. Torque to

142–158 lbs. ft. (193–214 N•m).

3. Install axle shafts and axle

d axle lubricant. Fill to bottom of filler hole in car-

4. Ad

rier.

5. Connect main driveline and lubricate joints.

stud nuts.

11

Page 15

y

Remove Wheel Differential

Differential Carrier Assembly

Note: Omit this step if the gear set is to be replaced. If gear

set is to be reused, check tooth contact pattern and ring

gear backlash before disassembling differential carrier.

When checking backlash, a yoke must be installed and

torqued to get an accurate reading. Best results are

obtained when established wear patterns are maintained

in used gearing.

1. Mount differential carrier in repair stand.

,

Note: For easier disassembly

ion (self-locking) nut.

loosen but do not remove pin-

3. Remove capscrews and bearing caps. Back

ing adjusters and remove adjusters and bearing

.

cups

4. Lift ring gear and differential

assembly out of

off bear-

carrier.

Differential Carrier

Assembl

2. Punch mark bearing caps. If reusing

punch mark bearing adjusters for reference during

assembly.

1

1 - Punch Marks

gear set,

also

12

Page 16

Pinion - Parts Exploded View

11

Differential Carrier Assembly

1 - Pinion Nut

2 - End Yoke

3 - Slinger

4 - Oil Seal

5 - Outer Pinion Bearing Cone

6 - Outer Pinion Bearing Cup

10

9

8

7

6

5

4

3

2

1

7 - Pinion Spacer

8 - Inner Pinion Bearing Cup

9 - Inner Pinion Bearing

10 - Drive Pinion

11 - Carrier

13

Page 17

y

Pinion Removal

Differential Carrier Assembly

1. Remove yoke nut.

2. Remove yoke using a yoke puller service tool.

1

1 - Yoke puller

3. Remove oil seal.

4. Place carrier in a press with

threaded end of

pinion

face up.

5. Place a wood block under pinion to avoid damage to

gear teeth.

1

2

3

6. Press pinion through outer bearing and out

of carrier

casting.

7.

Remove bearing preload spacer and save for use in

reassembly.

8.

Remove inner bearing cone from pinion using a

split-type puller.

Use two procedure steps to remove

each bearing.

a. Mount puller vertically to separate the bearing. This

action will force puller

halves under bearing and start

moving bearing off pinion.

b. Mount puller horizontally to press pinion out of bear-

ing.

1

Differential Carrier

Assembl

6

5

4

1 - Press

2 - Outer bearing

3 - Inner bearing

1 - Press

4 - Wood block

9. If bearings are to be replaced, remove bearing cups

5 - Drive pinion

6 - Bearing preload spacer

from carrier

complete.

casting at this time. Pinion removal

14

Page 18

Drive Pinion

Drive Pinion

Rear Axle Pinion Assembly - Parts Exploded View

10

9

8

7

6

5

4

3

1 - Pinion Nut

2 - End Yoke

3 - Slinger

4 - Oil Seal

5 - Outer Pinion Bearing Cone

2

1

6 - Outer Pinion Bearing Cup

7 - Pinion Spacer

8 - Inner Pinion Bearing Cup

9 - Inner Pinion Bearing Cone

10 - Drive Pinion

15

Page 19

Drive Pinion

Pinion Installation

Final Buildup

Note: Do not install oil seal in carrier until bearing preload is

correctly adjusted.

1. Press inner bearing cone on pinion.

3. Press inner and outer bearing cups into the carrier

until seated. Use

approx.) to make sure that bearing cups are fully

seated in bearing bores. Apply lubricant to both cup

and cone.

4. Place carrier housing in press with the pinion supported by wood block (6" x 6" x 6" [152 x 152 x 152

m

]), so the inner pinion bearing is mated to the

m

cone.

3

a feeler gage (.0015" [.038 mm]

1

2

5

4

Drive Pinion

IMPORTANTIMPORTANT

To prevent bearing damage, use suitable sleeve that only

contacts inn

2. Install preselected bearing spacer.

er race of bearing cone.

1 - Press

2 - Outer pinion bearing

3 - Wood block

4 - Drive pinion

5 - Bearing preload spacer

5. Press outer bearing onto pinion until completely

seated. Rotate carrier during

6. Use torque multiplier and torque pinion nut to 7101040

lbs. ft. (848-1410 N•m).

seating process

.

16

Page 20

Drive Pinion

7. Measure torque to rotate the pinion with an inchpound torque wrench. Torque measurements should

be taken every fourth (4th) revolution and should

read between 34-42 in.lbs. of bearing preload.

Note: If bearing preload does not fall within allowed limits,

preload can be increased by using a thinner spacer and

decreased by using a thicker spacer.

Always measure each spacer before assembly to

ensure correct thickness.

8. Repeat process until torque to rotate is between 3442 in. lbs. After proper preload is achieved, remove

yoke and install new seal with proper service tool.

11. Use a rubber mallet to drive the seal tool in until the

flange bottoms on the housing cover bore face. The

flange will locate the seal at the proper depth.

1

2

3

12. Install end yoke.

Note: Spicer recommends that new torque prevailing

nuts be used.

13. Use torque multiplier and torque pinion nut to 7101040 lbs. ft. (848-1410 N•m).

1 - Seal Driver

2 - Oil Seal

3 - Pinion Cage

CAUTIONCAUTION

Do not use any silicone or permatex-type bore sealant with

this seal.

9. Remove the new seal from its package and install

with the proper driver:

R-Pinion-Use drive #126917 only

WARNINGWARNING

Due to the resiliency of the plastic driver, hammer rebound

may occur when the seal is seated. Kee

rebound path!

mer

p clear of the ham-

10. Handle the seal by its outside diameter avoiding any

contact with the seal lips. During installation, use the

proper driver to make sure that the seal is mounted

properly.

17

Page 21

Wheel Differential Assembly

y

Wheel Differential Assembly - Parts Exploded

9

8

10

9

1

1 - Diff. Case Bearing Adjuster

2 - Diff. Bearing Cup

3 - Diff. Case Bearing Cone

4 - Differential Case

5 - Side Gear Thrust Washer

6 - Side Gear

7 - Differential Shaft

8 - Side Pinion

7

6

6

10

5

9

9

13

14

15

12

16

11

Wheel Differential

Assembl

3

2

4

9 - Side Pinion Thrust Washer

10 - Pin

11 - Ring Gear

12 - Ring Gear Bolt

13 - Ring Gear Bearing Cone

14 - Ring Gear Bearing Cup

15 - Ring Gear Bearing Adjuster

16 - Locating Dowels

18

Page 22

Wheel Differential Assembly

Disassemble, Overhaul, and Assemble Wheel Differential

Disassemble Wheel Differential

1. Remove capscrews fastening ring gear to differential

case.

2. The ring gear to differential case interface is a press

fit. Place the assembly in

ing downward. Support the assembly on eitiher side

of the ring gear

the case holes by hand. Press down on the head of

the capscrew, you may need to press in more than

one position to free the ring gear from the case.

. Thread a capscrew back into one of

a press with the case fac-

CAUTIONCAUTION

The differential case and gears will fall after separation.

Support

ferential or bodily injury.

the case so that it will not cause damage to the dif-

3. Remove the outer side gear.

4. Remove the differential shaft locking pins by turning

the differen

hammer to lightly tap on the side of the case to free

the locking pins.

tial case opening facing down. Use a

IMPORTANTIMPORTANT

Do not press on the wheel differential shaft to free the ring

gear fro

may cause it to bend and/or fatigue.

19

m the case. Pressing on the wheel differential shaft

5. The locking pins are slip fit and should fall from the

case easily

.

Page 23

Wheel Differential Assembly

y

6. Remove the half shafts first and then remove their

side pinions and thrust washers.

Half

Differential

Shaft

7. Remove the full shaft, side pinions and thrust washers.

9. Remove bearing cones from ring

gear and differential case in two steps:

A. Mount puller vertically to split bearing. This action

will start moving the bearing off case and gear.

B. Mount puller horizontally to remove cone.

Wheel Differential

Assembl

8. Remove inner side gear and thrust washer.

20

Page 24

Wheel Differential Assembly

Assemble Wheel Differential

10. Press new bearing cone on the differential case.

11. Place thrust washer on the side gear. Lubricate both

sides of the thrust

washer before installing.

13. Start the full differential shaft into

the shaft bores in

the case that does not have a locking pin hole.

Side Pinion

and Thrust

Washer

Full

Differential

Shaft

Locking

Pin Holes

14. Install a side pinion and thrust washer and push the

shaft t

hrough the side pinion.

Side Pinion

and Thrust

Washer

12. Install the side gear and thrust washer in the differential case.

15. Install the side pinion and thrust washer to the other

full

side of the

shaft.

16. Install a side pinion and thrust washer on the half

shaft side.

Side Pinion

and Thrust

Washer

21

Page 25

Wheel Differential Assembly

y

17. Install the half shaft so that the pin is facing upward

and push it in until it stops.

Half

Differential

Shaft

Pin Hole

Facing

Upward

18. The end of the half shaft should fit into the slot of

the full shaft at the same time as the hole in the case

lines up with the hole in the half shaft.

Align Pin

Holes

Fit End

Into Slot

Note: No thrust washer is us

ed at this location.

21. Lower the ring gear onto the case assembly aligning

the locking dowels.

Wheel Differential

Assembl

19. Install the locking pins to both sides of the

tial case.

differen-

22. Install and hand-tighten all new ring gear capscrews.

Locking

Pin

20. Install outer side gear.

22

Page 26

Wheel Differential Assembly

23. The interface of the ring gear to differential case is a

press fit. Put the assembly in a press with the ring

gear facing upward. Make certain that the ring gear

is flush and square to the differential case before

pressing. Press until ring gear bottoms out on the

case.

IMPORTANTIMPORTANT

DO NOT use the capscrews to draw the ring gear into place.

Only use a press.

tool should have a slit cut if the ID is the same as the

bearing boss OD.

25. Tighten and torque ring gear capscrews in an altering pattern. 435-465 lbs. ft. (589-630 N•m).

nat

26. Install differential case assembly into carrier. Be

careful no

ing the assembly.

t to damage the differential bearings lower-

24. Press new ring gear bearing cone.

IMPORTANTIMPORTANT

When pressing differential case bearing cones, note that

bearing is beyond flush with the top of the case. The

the

cone must be fully seated. To prevent bearing damage, use

suitable sleeve that only contacts the inner race of the

cone. A used bearing race would be a suitable tool. This

27. Lubricate the differential bearings and install bearing

and differential bearing adjusters.

cups

23

Page 27

Wheel Differential Assembly

y

Measure and Adjust Carrier Assembly

Adjust Backlash and Preload

1. Turn the flange half-bearing adjuster in until the ring

gear contacts the pinion (zero backlash) then back

the adjuster out two (2) notches from the adjuster

lugs.

1

1 - Flange half

2 - Plain half

2. Tighten the plain half-adjuster until the bearing cup

just starts to turn, this is a zero bearing preload.

4. Use a rubber mallet to make certain that both bearing adjusters are fully seated.

5. Measure backlash. Make sure it is within specification of .008"–.018” (.15-.46 mm).

TIP: To give yourself room to adjust contact pattern, set it

ween .012"–.014” (.30-.36 mm).

bet

2

Wheel Differential

Assembl

Tighten the plain half-adjuster two lug notches. Start

3.

e notch at the top, count two notches coun-

with th

terclockwise on the adjuster, turn the adjuster so

that the notch is

two-notch preload.

1 - Lugs

2 - One notch

facing straight up. You now have a

2

1

24

Page 28

Wheel Differential Assembly

Change Backlash Setting

If you have too much backlash, the ring gear needs to move

closer to the pinion. Back off the plain half-adjuster, counting

the number of notches you back it off (each notch equals

about .003" [.08 mm] of backlash).

IMPORTANTIMPORTANT

In order to maintain the differential bearing preload, you

l

need to turn the flange half-bearing adjuster the same

wil

amount in the same direction. If you need more backlash,

reverse this procedure.

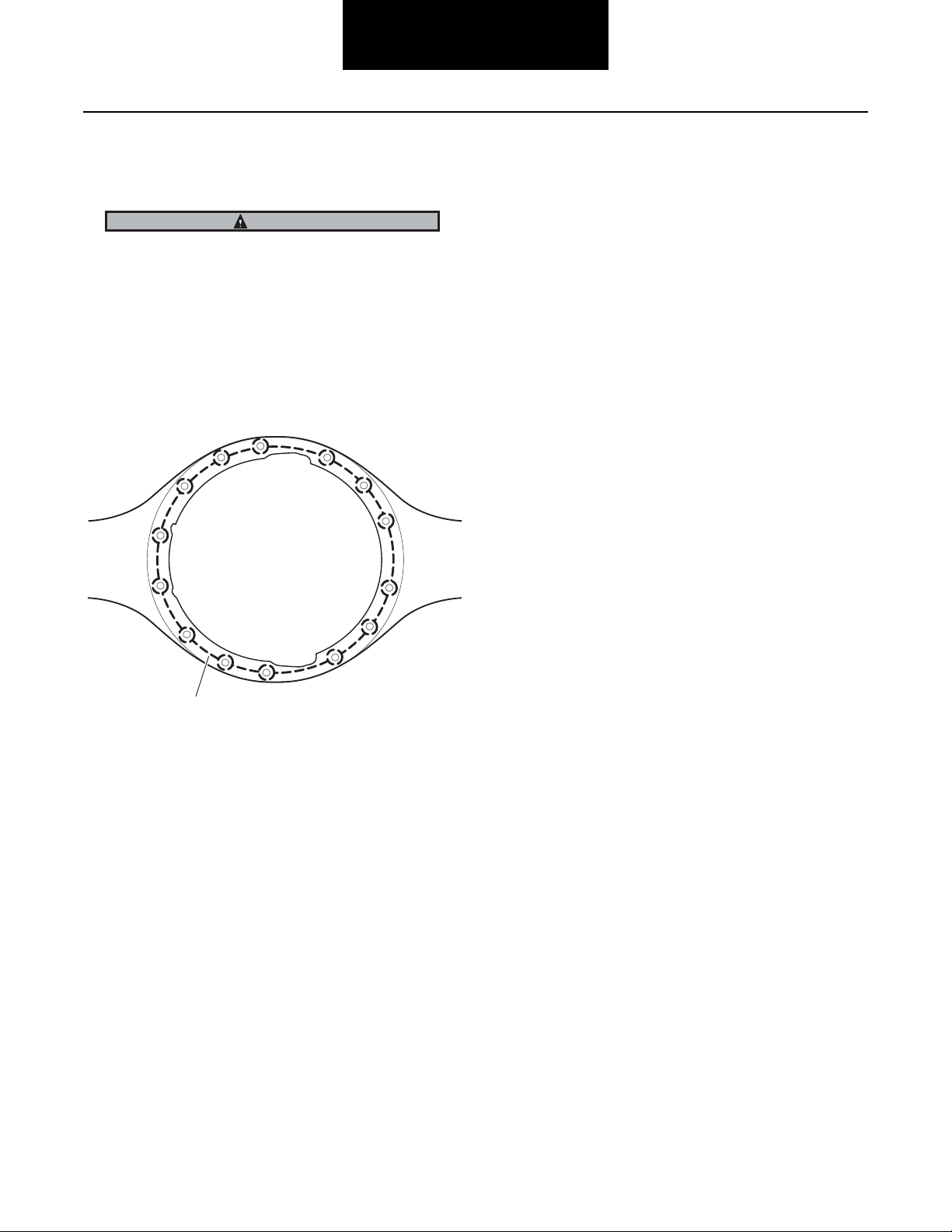

1. Install carrier bearing caps and torque carrier

bolts to 350-428 lbs. ft. (475-580 N•m).

2. Recheck backlash: If the bearing adjusters were not

in straight or

a. Used Gearing:

before disassembly.

b. New Gearing: Backlash

.008” and .018" (.15-.46 mm).

fully seated, the backlash will change.

Reset to backlash recorded

should be between

cap

Measure Ring Gear Runout

Measure Ring Gear Total

1. Measure ring gear total radial runout. (Indicator

reading shou

2. Measure ring gear total backface runout.

read

ing should not exceed .010" [.25 mm]).

ld not exceed .010" [.25 mm]).

(Indicator

3. Check ring gear tooth contact pattern. Paint ring

teeth and check tooth contact pattern. Correct tooth

patterns, see "Adjust Tooth Contact Pattern."

4. Install bearing adjuster cotter pins.

25

gear

Page 29

Adjust Tooth Contact Pattern

Adjust Ring and Pinion Tooth Contact Pattern

Used Gearing - Correct Pattern

2

1

1 - Face width

2 - Tooth depth

3 - Heel

4 - Top land

5 - Root

6 - Toe

1. Identify if new or used gearing.

2. Check tooth contact pattern (new or use

New Gearing - Correct Pattern

• Paint six ring gear teeth 180° apart and roll the

to obtain a contact pattern. The correct pattern is

slightly below center on the ring gear tooth with

lengthwise contact up off the toe. The length of the

pattern in an unloaded condition is approximately

one-half (1/2) to two-thirds

(2/3) of the ring gear tooth in most models and

ios.

rat

The pattern could vary in length and should cover

•

half (1/2) of the tooth or

tern should be evenly centered between tooth top

land and

root and should be up off the tooth toe.

more (face width). The pat-

3

4

5

6

d gearing).

gear

• Used gearing will not usually display the square,

even contact pattern found in new gear sets. The

will normally have a “pocket” at the heal end of

gear

the gear tooth. The more use a gear has had, the

more the line becomes the dominant characteristic

of the pattern.

• Adjust used gear sets to display the same contact

obser

pattern

tern is up off the toe and centers evenly along the

face width between the top

the length and shape of the pattern are highly variable and is considered acceptable as long as it does

t run

no

1 - Pattern along the face width could be longer

Adjust Contact Pattern

• If necessary, adjust the contact pattern by changing

the ring

•

Ring gear position controls the backlash. This

adjust

width of the gear tooth.

Note: This is a shimless pinion designed carrier

shows an

sure the inner pinion cup is fully seated. Use a feeler

gauge.

ved before disassembly. A correct pat-

land and root. Otherwise,

off the tooth at any point.

gear position.

ment moves the contact pattern along the face

. If the pattern

incorrect pinion cone position, check to make

Adjust Tooth Contact

Pattern

26

Page 30

Adjust Tooth Contact Pattern

Adjust Ring Gear Position (Backlash)

If the ring gear pattern shows incorrect face width contact,

change backlash by

If the pattern is too close to the edge of the tooth toe, move the

ring gear away

1. Loosen the bearing adjuster on the teeth side of the

ring

adjusting the ring gear.

from the pinion to increase backlash.

gear several notches.

2.

Loosen the opposite adjuster one notch.

3. Return to adjuster on teeth side of the ring gear and

tigh

ten adjuster until it contacts the bearing cup.

4. Continue tightening the same adjuster two (2) or

three (3) notches and recheck backlash.

If

the pattern is concentrated at the heel (too far up the tooth),

the

move

ring gear toward the pinion to decrease backlash.

5. Loosen the bearing adjuster on the teeth side of the

ring gear several notches.

Tighten the opposite adjuster one notch.

6.

7. Return to adjuster on teeth side of ring gear and

tigh

ten adjuster until it contacts the bearing cup.

8. Continue tightening the same adjuster two (2) or

three (3) notches and recheck backlash.

27

Page 31

Install Axle Housing Breather

1. Install fitting in breather hole.

2. Tighten fitting finger tight.

Housing Breather

4. Insert hose onto fitting, long end down.

3. Torque to 5 lbs. ft. (7 N•m) and align the nose of the

breather to the

rear.

5. Push hose firmly against fitting. Rotate hose to point

wn.

do

Housing Breather

28

Page 32

Wheel End Seal - Parts Exploded View

Wheel End Seal

1

1 - Installation tool

2 - Seal

3 - Rear hub

2

3

29

Page 33

Remove and Overhaul Wheel End Seal

Wheel End Seal

WARNINGWARNING

Never work under a vehicle supported by only a jack.

Always supp

make sure the vehicle will not roll before releasing the

brakes.

Wheel end seals can be easily damaged during handling.

ve the sea

Lea

damage or contamination.

1. Remove outer nut and locking washer.

2. Remove inner nut.

3. Remove outer bearing and wheel.

4. Remove oil seal.

5. Remove inner bearing.

6. Inspect spindle journal and hu

ort vehicle with stands. Block the wheels and

IMPORTANTWARNING

l in its package until installation to prevent

b bore for scratch

burrs. Recondition with an emery cloth as required.

es or

Install Wheel End Seal

1. Before installation, lubricate the following with the

same

lubricant used in the axle sump.

• Inner bearing.

• Wheel seal (follow the directions pro

the seal supplier).

2. Place seal on installation tool.

3. Drive seal with installation tool onto hub.

vided by

Wheel End Seal

Note: Deep

Always use the seal installation tool specified by the seal

manuf

age the seal and cause premature seal failure.

gouges can be repaired by filling gouge with hard-

ening gas

7. Clean hub cavity and bearing bores before reassem-

8. Clean bearings thoroughly with solvent and examine

acturer. Using an improper tool can distort or dam-

ket cement and smoothing

. Be sure to remove contaminants from all

bly

recesses and corners.

for damage. Replace damaged

IMPORTANTIMPORTANT

with emery cloth.

or worn bearings.

30

Page 34

Adjust Wheel Bearing

Wheel Adjustment Systems

WARNINGWARNING

Do not mix spindle nuts and lock washers from different

systems. Mixing spindle nuts and lock washers can

cause

wheel separation.

Note: The lock

washer

for a four-piece tang/dowel-type wheel

nut system is thinner than the lock washer for a threepiece tang-type wheel nut system and is not designed to

bear against the inner nut.

1. Inspect the spindle and nut threads for

and clean thoroughly or

Note: Proper assembly and

replace as required.

adjustment is

corrosion

not possible if the

spindle or nut threads are corroded.

2. Inspect the tang-type washer (if used).

washer

if the tangs are broken, cracked, or dam-

Replace the

aged.

3. Install the hub and drum on the spindle with care to

prevent damage

or distortion to the wheel seal.

CAUTIONCAUTION

Never use an impact wrench to adjust wheel bearings. A

torqu

e wrench is required to assure the nuts are properly

tightened.

8. Back off the inner nut one full turn. Rotate the wheel

hub.

Retighten the inner nut to 50 lbs. ft. (68 N•m) while

9.

rotatin

g the wheel hub.

10. Back off the inner nut exactly 1/4 turn.

Note: This adjustment procedure allows th

e wheel to rotate

freely with 0.001" -.005” (0.025 mm–0.127 mm) endplay.

Install the correct lock washer for the wheel nut sys-

11.

tem being used.

Three-piece Dowel-type Lock Washer System

WARNINGCAUTION

A wheel dolly is recommended during installation to make

sure that

the wheel seal is not damaged by the weight of the

hub and drum. Never support the hub on the spindle with

just the inner bearing and seal. This can damage the seal

and cause premature failure.

4. Completely fill the hub cavity between the inner and

used

outer bearing races with the same lubricant

in

the axle sump.

5. Before installation, lubricate the outer bearing with

the same lubricant used in the

Note: Lubricate only with clean axle

type used in the

axle sump. Do not pack the bearings

axle sump.

lubricant of the same

with grease before installation. Grease will prevent the

proper circulation of axle lubricant and may cause wheel

seal failure.

6. Install the outer bearing on the spindle.

7. Install the inner nut on the spindle. Tighten the inner

to 20

nut

0 lbs. ft. (271 N•m) while rotating the wheel

hub.

1

2

3

4

1 - Inner nut

2 - Dowel pin

3 - Dowel-type lock washer

4 - Outer nut

• Install the Dowel-type lock washer on the spindle.

Note: If the dowel pin and washer are not

aligned, remove

washer, turn it over and reinstall. If required, loosen the

inner nut just enough for alignment.

IMPORTANTIMPORTANT

Never tighten the inner nut for alignment. This can preload

bearing and cause premature failure.

the

31

Page 35

Wheel Adjustment Systems

y

• Install the outer nut on the spindle and tighten to

350 lbs. ft. (475 N•m).

• Verify end-play, see “Verify Wheel End Play Proce-

dure."

Three-piece Tang-type Lock Washer System

1

2

3

1 - Inner nut

2 - Tang-type lock washer .123” thick

3 - Outer nut

• Install the Tang-type lock washer on the spindle.

IMPORTANTIMPORTANT

Never tighten the inner nut for alignment. This can preload

earing and cause premature failure.

the b

Four-piece Tang/Dowel-type Lock Washer System

3

4

5

1

2

1 - Inner nut

2 - Dowel pin

3 - Dowel-type lock washer

4 - Tang-type lock washer

5 - Outer nut

• Install the Dowel-type lock washer on the spindle.

Note: If the dowel pin and washer are not

washer, turn it over and reinstall. If required, loosen the

inner nut just enough for alignment.

8” thick

.047

aligned, remove

Wheel Adjustment

S

stems

• Install the outer nut on the spindle and tighten to 250

lbs. ft

. (339 N•m).

• Verify end-play, see “Verify Wheel End Play Proce-

dure."

• After verifying end-play, secure wheel nuts by bend-

ing one of the locking washer tangs over the outer

wheel nut and

• Go to step 12.

another tang over the inner wheel nut.

Never tighten the inner nut for alignment. This can preload

bearing and cause premature failure.

the

• Install the Tang-type lock washer on the spindle.

• Install the outer nut on the spindle and tighten to 250

lbs. ft. (

• Verify end-play, see “Verify Wheel End Play Procedure."

• After verifying end-play, secure the ou

bending (180° apart) two opposing tangs of the

locking washer over the outer nut.

12. Install the following:

• New gasket at axle shaft flange.

• Axle shaft.

• Axle flange nuts and tighten to specified torque.

13. Lubricate axle wheel ends.

339 N•m).

IMPORTANTIMPORTANT

ter nut by

32

Page 36

Wheel End

Wheel Adjustment

Verify Wheel End-play Procedure

Verify end-play meets specification using a dial indicator. An

indicator with .001" (.03 mm) resolution is required. Wheel

end-play is the free movement of the tire and wheel assembly

along the spindle

Correct end-play is .001-.005” (.025-.125 mm).

1. Attach a dial indicator with its magnetic base to the

hub

2. Adjust the dial indicator so that its plu

is against the end of the spindle with its line of action

approximately parallel to the axis of the spindle.

3. Grasp the wheel assembly at the 3 o’clock and

9 o’clock positions. Push the wheel assembly in and

out while oscillating

bearing end-play as the total indicator movement.

If end-play is not within specification, readjustment is

quired.

re

axis.

or brake drum as shown below.

nger or pointer

it to seat the bearings. Read

WARNINGCAUTION

Adjust End-play with Wheel Hub

With indicator mounted at bottom, push / pull at sides of

drum.

Readjust Wheel End-play Procedure

Excessive End-play: If end-play is greater than .005"

(.127 mm), remove the outer nut and pull the lock washer

away from

inner nut to the next alignment hole of the dowel-type washer

(if used). Reassemble the washer and retorque the outer nut.

Verify end-play with a dial indicator.

the inner nut, but not off the spindle. Tighten the

Adjust End-play with Tire and Wheel Assembly

Insufficient End-play: If end-play is

outer nut and pull the lock washer away from the inner nut,

but not off the spindle. Loosen the inner nut to the next

adjustment hole of the dowel-type washer (if used). Reassemble the washer and retorque t

with a dial indicator.

Fine Tuning the End-play: If,

ment procedures, end-play is still not within the .001"-.005”

27 mm) range, disassemble and inspect the compo-

(.025-1

ts. If parts are found to be defective, replace the defective

nen

parts, reassemble and repeat

cedure. Verify end-play with a dial indicator.

not present, remove

h

e outer nut. Verify end-play

after per

wheel bearing adjustment pro-

forming the readjust-

the

33

Page 37

Lubricate Wheel End

Wheel Adjustment

IMPORTANTIMPORTANT

Before operating the axle, the wheel hub cavities and bearings must be lubricated to prevent failure.

When wheel ends are serviced, follow Spicer’s wheel

end lubrication procedure before operating the axle.

Spicer axles may be equipped with either of two (2)

wheel-end designs:

• Wheel ends with an oil fill hole.

• Wheel ends without an oil fill hole .

Wheel Ends with an Oil Fill Hole

1. Remove the oil fill plug.

2. Pour half (1/2) a pint of axle sump lubricant into

each hub through the wheel end fill hole.

3. Install oil fill plug and tighten to specified torque.

Wheel End with Oil Fill Hole

1

2

1 - Wheel end oil fill hole

2 - Proper lubricant level

Wheel End without Oil Fill Hole

Wheel End

1 - Lubricant flow from sump

1

34

Page 38

Wheel Adjustment

Wheel Ends without Oil Fill Hole

1. With axle level and wheel ends assembled, add lubricant through filler hole in carrier until fluid is

with the bottom of filler hole.

2. Raise the right side of the axle six (6) inches (152

mm) or more.

minute.

3. Lower the right side.

4. Raise the left side of the axle six (6) inches (152

mm) or more.

minute.

5. Lower the left side.

6. With axle on a level surface, add lubricant through

carrier oil filler hole until fluid is level

tom of the hole.

Note: Axles witho

mately 2.5 additional pints of lubricant to bring the lube

level even with

Hold axle in this position for one (1)

Hold axle in this position for one (1)

with the bot-

u

t wheel end fill holes will require approxi-

the bottom of fill hole.

level

1 - Oil will run into wheel end

2 - Oil will run into wheel end

1

2

35

Page 39

Lubrication

Lubrication

The ability of a drive axle to deliver quiet, trouble-free operation over a period of years is largely dependent upon the use

of good-quality gear lubrication in the correct quantity. The

most satisfactory results can be obtained by following the

directions contained in this manual.

The following lubrication instructions represent the most current recommendations from the Axle & Brake Division of Dana.

Approved Lubricants

General - Gear lubrications acceptable under military specifi-

cation (MILSPEC) MIL-L-2105D (Lubricating Oils, Gear, Multipurpose) are approved for use in Spicer Drive Axles.

The MIL-L-2105D specification defines performance and viscosity requirements for multigrade oils. It su

MIL-L-2105B, MIL-L-2105C and cold weather specification

MIL-L-10324A. This specification applies to both petroleumbased and synthetic based gear lubricants if they appear on

the most current “Qualified Products Lis

MIL-L-2105D.

Note: The use of separate oil additives and/or friction modifi-

ers are not approved in Spicer Drive Axles.

persedes both

t” (QPL-2105) for

Recommendations for Viscosity/Ambient

Temperature

The following chart lists the various SAE Grades covered by

MIL-L-2105D and the associated ambient temperature range

from each. Those SAE grades shown with an asterisk (*) are

available in the Spicer family of synthetic gear lubricants.

The lowest ambient temperatures covered by this chart are

-40°F and -40°C. Lubrication recommendations for those

applications which consistently operate below this temperature range must be obtained through Dana by contacting

your local Dana representative.

Grade Ambient Temperature Range

75W -40°F to -15°F (-40°C to -26°C)

75W

-80 -40°F to 80°F (-40°C to 21°C)

75W-90* -40°F to 100°F (-40°C to 38°C)

75W-140 -40°F and

80W-90 -15°F to 100°F (-26°C to 38°C)

above (-40°C and above)

Lubrication

Synthetic Based - Synthetic-based gear lubricants exhibit

superior thermal and oxidation stability, and generally

degrade at a lower rate when compared to petroleum-based

lubricants. The performance characteristics of these lubricants include extended change intervals, improved

omy, better extreme temperature operation, reduced wear and

cleaner component appearance. The family of Spicer gear

lubricants represents a premium quality synthetic lube

which fully meets or exceeds the requirements of

MIL-L-2105D. These products, available in both 75W-90

and 80/W-140, have demonstrated superior performance in

comparison to others qualified under the MILSPEC, as demonstrated by extensive laboratory and field testing. For a complete list of Spicer-approved synthetic lubricants, contact

your local Dana

manual for appropriate phone number.

Makeu

p Lube - Maximu

lube is 10%.

representative. See back cover of this

m amount of non-synthetic makeup

fuel econ-

80W-140* -15°F and above (-26°C and above)

85W-140 10°F and above (-12°C and above)

* Available in the Spicer family of synthetic gear lubricants.

36

Page 40

Lube Change Intervals

Lubrication

This product combines the latest manufacturing and part

washing technology. When filled with a Spicer-approved

synthetic lubricant at the factory, the initial drain is

not required.

Change the lubricant within the first 5,000 miles of operation when not using a Spicer-approved synthetic lubricant

in either a new axle or after a carrier head replacement.

Base subsequent lubricant changes on a combination of

the following chart and user assessment of the application

and operating environment.

Synthetic or

Mineral

Synt

hetic* SHAES-256 SAE 75W-90 500,000 miles [800,000 Km] or

Synthetic** SHAES-256 SAE 75W-90,

Mineral

Base

* Axles using LMS wheel end system

Lubricant SAE Change Interval for Line Haul Change Interval for Voca-

75W-140

MIL-L-2105E/J02360,

API GL-5 Gear Oil,

PRF-2105E

MIL-

75W, 75W-90,

75W-140, 80W90, 85W-140

Severe Service Lubrication Change Intervals - Severe service applications are those where the vehicle consistently

operates at or near its maximum GCW or GVW ratings, dusty

t environments, or consistent operation on grades

or we

greater than 8%.

WAY portion of the chart should be used. Typical applications

are construction, logging, mining and refuse removal.

Note: Clean metallic particles from the magnetic filler plug

and drain plugs. Clean or replace the breather yearly to

avoid lube contamination due to water ingestion.

5 years

250,000 miles (400,000 Km) or

3 years

120,000 miles [193,000 Km] or

1 year

For these applications, the ON/OFF HIGH-

tional

120,000 miles (193,000 Km)

or 1year

60,000 miles [96,500 Km] or 1

year

60,000 miles [96,500 Km] or

1 year

** Axles using adjustable wheel bearing system

37

Page 41

Change Lube

Lubrication

Lubrication

Drain

1. Drain when the lube is at normal operating temperature (150°-200°F [66°-93°C]). It will run

minimize the time necessary to fully drain the axle,

this insures the axle is flushed.

2. Remove the bottom two carrier to h

screws and allow the lube to drain into a suitable

container

Note: Dispose

posal

oils.

Inspect breather for clogging or corrosion. Clean or

3.

repla

.

of all used lubricants properly by following dis-

methods approved for mineral- or synthetic-based

ce as necessar

y.

freely and

ousing cap-

Fill

1. Reinstall bottom two carrier to housing capscrews –

use Loctite 270 and torque to 142–158 lbs. ft. (193214 N•m).

2. Remove the filler hole plug from the side of the carrier and fill the axle with the approved lubricant until

ith the bottom of the hole.

level w

3. If wheel ends were removed, follow instructions in

the wheel end servicing

Always use the filler hole as the final reference. If lube is level

with the bottom

Note: Lube fill capacities are basic guid

based on the angle the axle is installed in a particular

chassis. Torque fill plug to 40–60 lbs. ft. (54–82 N•m).

e axle can be filled through the axle housing breather

TIP: Th

hole

. Fill until lube level is even with the bottom of filler hole in

side of carrier.

of the hole, the axle is properly filled.

section.

e

lines and will vary

Fill

Drain

38

Page 42

Proper Vehicle Towing

Proper Vehicle Towing

Lift the drive wheels completely off of the ground or damage

will occur.

WARNINGWARNING

Do not lift the front wheels (non-drive wheels). This alters

oil’s position in the drive axle, draining it away from the

the

drive pinion and its bearings. If the pinion is rotated under

these conditions for any period of time, bearings will overheat resulting in axle damage or failure.

If it is impossible to lift the drive wheels, remove all axle

shafts to prevent gear

vent loss of lubricant and a possible road hazard. See

lowing section Proper Vehicle Towing with Wheel Differential

Lock for removal procedure.

rotation and cap the

wheel hubs to pre-

the fol-

39

Page 43

Torque Chart

Torque Chart

Location Thread Size Class/Grade Torque Secifications

Pinion End Nut M36 x 1.5 10.9 710-1040 lbs. ft. (848-1410 N•m)

Ring Gear to Diff Case Capscrew M20 x 1.5 10.9 435-465 lbs. ft. (589-630 N•m)

Carrier Cap Capscrew M20 x 2 10.9 350-428 lbs. ft. (475-580 N•m)

Fill Plug 1 x 1.11.5 – 40-60 lbs. ft. (54-81 N•m)

Carrier to Housing Capscrew M14 x 2 10.9 142-158 lbs. ft. (193-214 N•m)

Parking Brake Capscrew M16 x 1.5 10.9 180-220 lbs. ft. (244-298 N•m)

40

Page 44

For spec‘ing or service assistance, call 1-877-777-5360 or visit our website at www.dana.com

Dana Commercial Vehicle Products Group

3939 Technology Drive

Maumee, Ohio, USA 43537

www.dana.com

All applications must be approved by the Application Engineering Department. Specifications and/or design are subject to change without notice or obligation. Printed in USA AXSM-0030 09/13

Loading...

Loading...