Page 1

Pattern should range from just clear of the toe end to about

pattern observed before disassembly. A correct pattern is up

Spicer

Drive Axles

P/N: SHAIS168B

Ring and Pinion Tooth Contact Pattern Information

Affected Models: All Dana Drive Axle Models

Dana drive axles require adjustment of the ring gear and pinion tooth contact at overhaul or anytime the axle has been

disassembled. Most axles require the same distinctive pattern, described in our service publications.

After differential preload and gear backlash adjustments are complete, check the tooth contact pattern and adjust if

necessary. Tooth contact patterns are a function of the relative positions of the ring gear and the pinion. An improper

pattern will require a relocation of either or both. Always adjust pinion position first, if necessary, then the ring gear

position. Always check backlash when done.

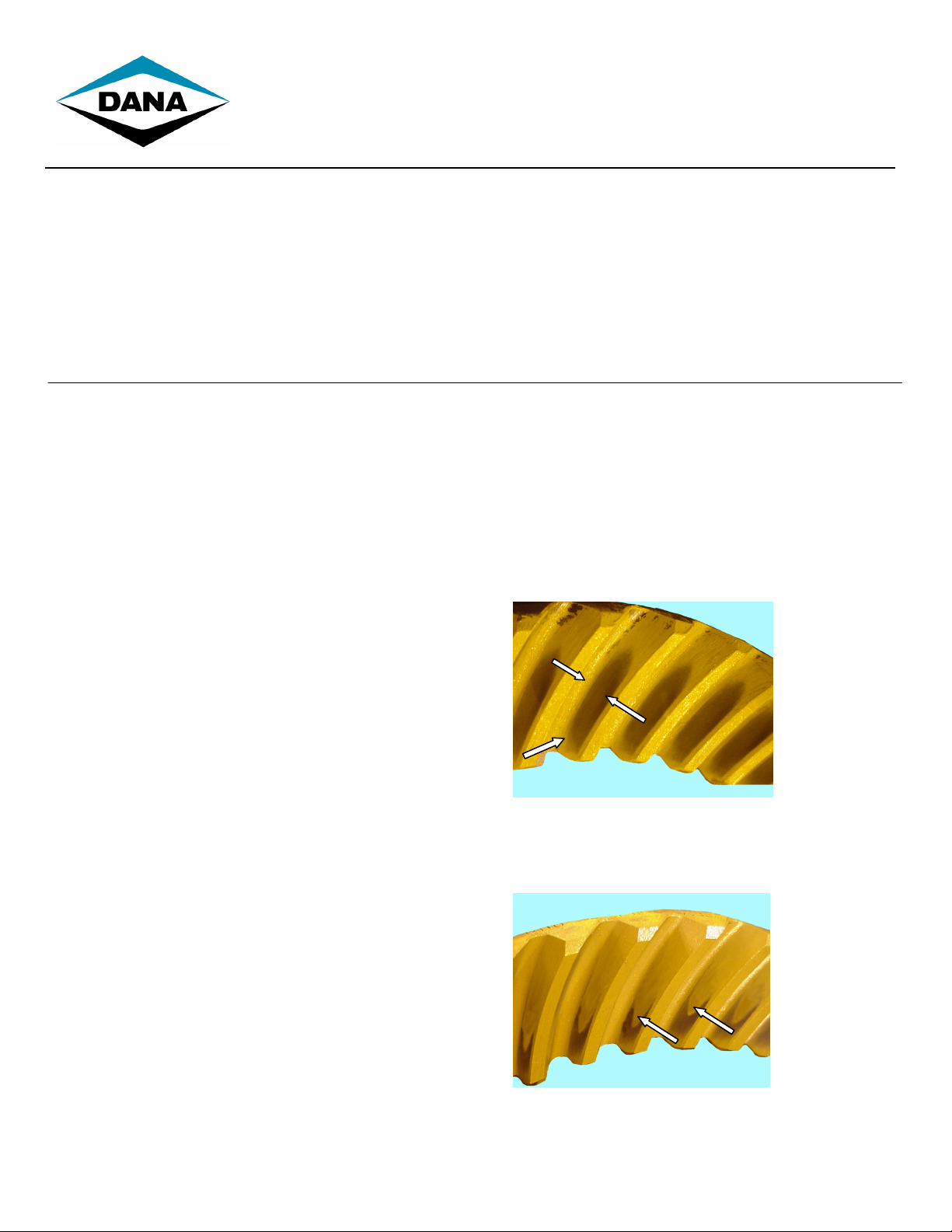

New Gearing

Paint ring gear with marking compound and roll the gear to

obtain a contact pattern as shown in the photograph. The

length of the pattern in a unloaded condition is

approximately one-half to two-thirds of the ring gear tooth

in most models and ratios.

3/8” off the toe end. The pattern should be evenly centered

between tooth top land and root.

Used Gearing

Used gearing may not display the round, even contact

pattern found in new gear sets. The gear may have a

“pocket” at the heel end of pattern. The more “use” a gear

has had, the more dominate characteristic of the pattern.

Adjust used gearing so as to display the same contact

slightly off the toe and centers evenly along the face width

between the top land and the root. Otherwise, the length

and shape of the pattern are highly variable and are

considered acceptable as long as there is some pattern on

toe end of the tooth.

New Gearing

Used Gearing

®

1

Page 2

SHAIS168B – Ring and Pinion Contact Pattern Information

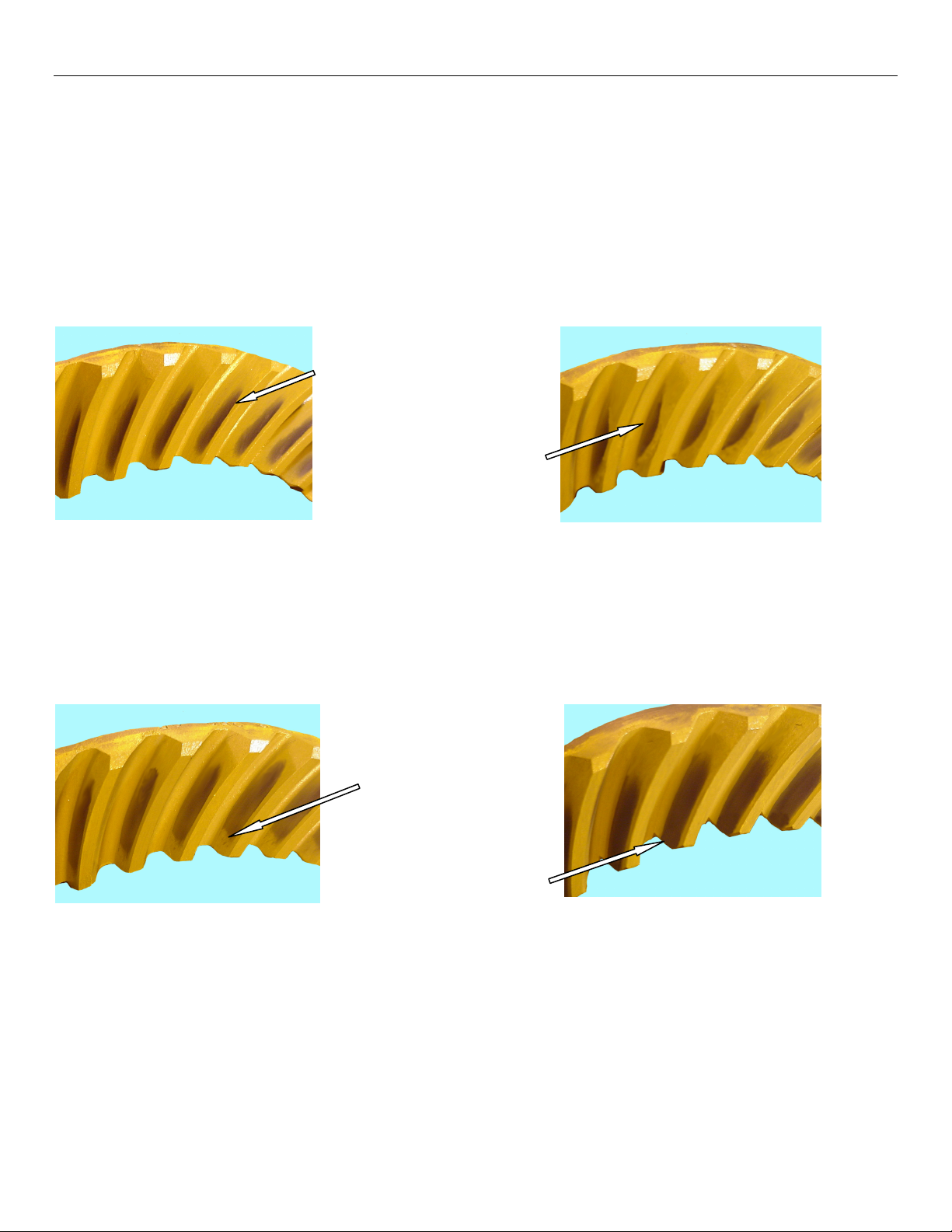

Remove Shim

Add Shim

Decrease Backlash

Increase backlash

Decrease Backlash

then the backlash.

If necessary, adjust the contact pattern by moving the ring gear or drive pinion. Ring gear position

controls the backlash. This adjustment moves the pattern along the face width or up and down the

gear tooth. Pinion position is determined by the size of the shims behind the pinion bearing cage,

and controls tooth depth contact.

These adjustments are interrelated. As a result, they must be considered together even though

the pattern is altered by two distinct operations. When making adjustments, first adjust the pinion,

If the contact pattern shows incorrect tooth depth contact, change drive pinion position by altering the shim

pack. Used gearing should achieve proper contact with the same shims removed form the axle at disassembly.

Always recheck backlash after shim changes.

Loosen the opposite adjuster one notch. Return to adjuster on the tooth side of the ring gear and tighten adjuster

until it contacts the bearing cup. Continue tightening the same adjuster 2 or 3 notches. Recheck backlash.

Tighten the opposite adjuster one notch. Return the adjuster on the tooth side of the gear and tighten adjuster

until it contacts the bearing cup. Continue tightening the same adjuster 2 to 3 notches. Recheck backlash.

Incorrect Pattern - Adjust Pinion Position

Pattern to close to

tooth top land and

off center.

Pattern to close to

tooth root.

Incorrect Pattern - Adjust Backlash

Pattern is more

than 3/8” off the

toe of tooth.

Pattern is running

off the toe of the

tooth.

by loosening the bearing adjuster on the tooth side of the ring gear several notches.

by loosening the bearing adjuster on the tooth side of the ring gear several notches.

Increase Backlash

2

Page 3

SHAIS168B – Ring and Pinion Contact Pattern Information

Face

Tooth Depth

Copyright Dana Limited, 2013 Dana Aftermarket Group

SHAIS168B FEB 2013 All Rights Reserved. P.O. Box 321

Printed in U.S.A. Dana Limited Toledo, OH 43697-0321

Refer to this illustration for proper ring gear nomenclature.

Heel

Top land

Root

Toe

3

Loading...

Loading...