Page 1

Quick Reference GuideQuick Reference Guide

Spicer Life Series® Heavy-Duty (SPL) U-Joint Service

Note: This document is intended as a “quick reference” only.

Refer to service manual DSSM-0100 (3264-SPL) for detailed

warnings and instructions.

WARNING

• Always follow all safety practices when servicing,

removing and/or installing a driveshaft.

• Always use support straps to prevent the driveshaft

from falling out of the vehicle during removal and

installation.

• Always put the transmission in neutral before

working on the driveshaft.

• Never heat components or use a sledgehammer or

floor jack to remove the driveshaft from the vehicle.

• Do not reuse quick disconnect stamped caps.

• Do not reuse bearing plate bolts.

• Only replace U-joints with genuine Dana / Spicer

service parts.

Inspection Recommendations

• U-joint inspections should be performed every time a

vehicle comes in for scheduled maintenance.

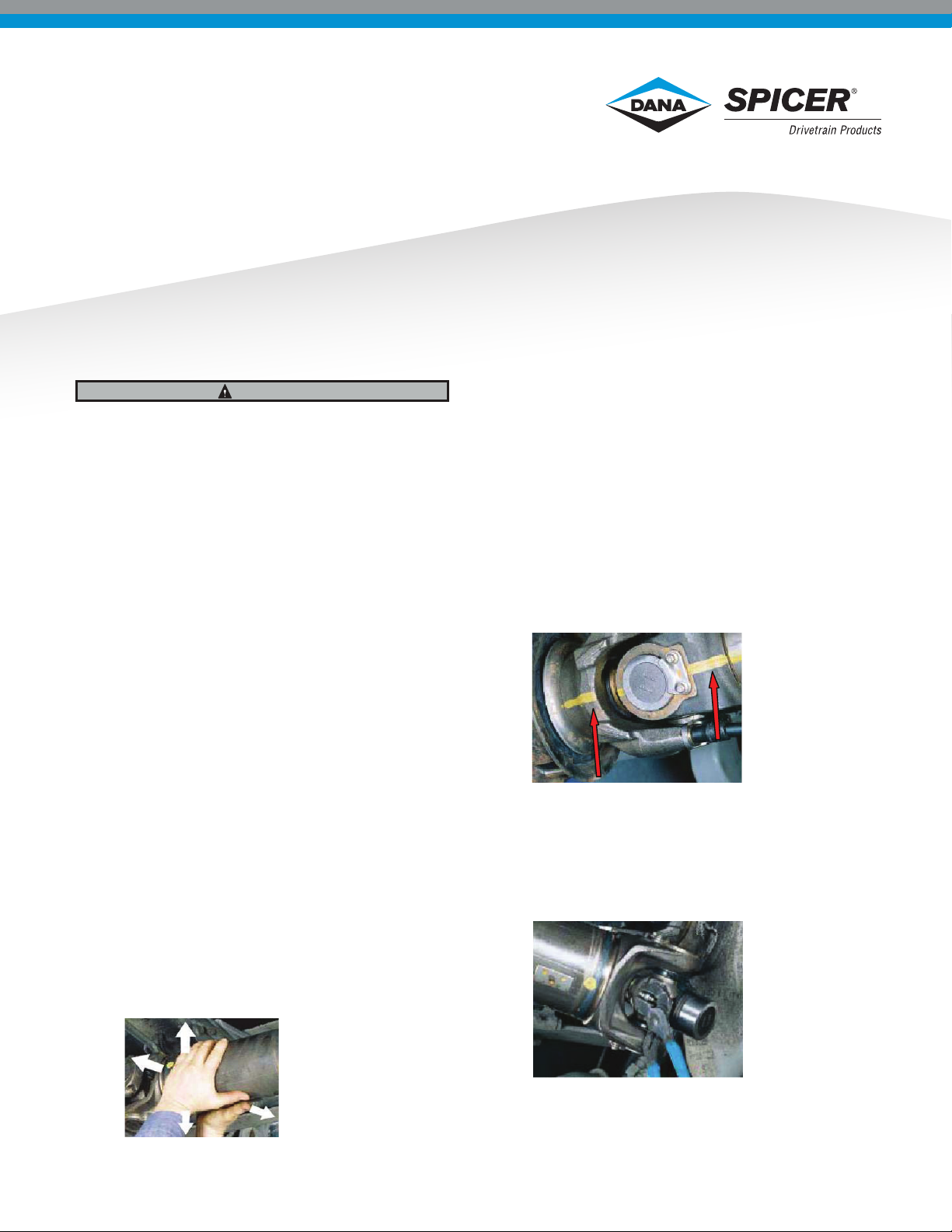

• Visually inspect for damaged bearing retainers or

stamped straps, loose bearing retainer or strap bolts,

loose companion flange bolts and nuts, loose or

missing spring tabs or spring tab bolts, damaged

tangs on end fittings, damaged or missing snap rings

and rotating bearing cups.

• If any of these situations are evident, replacement of

the component is necessary.

• Check all input a

Take hold of the end fitting with both hands.

Try to move it vertically and horizontally to feel

any looseness.

• There should be less than .006” movement in the

U-joint relative to the end yoke. If looseness in greater

than .006” the U-joint should be replaced.

• Check for the presence

of all grease zerks

fittings. Damaged zerks

should be replaced.

Loose zerks should

be tightened.

nd outpu

t end fittings for looseness.

Lubrication Intervals

For (on-highway) applications, Spicer Life XL U-joints do not

need to be greased until 3 years/ 350,000 miles. After this time

U-joints should be greased every 6 months/ 100,000 miles.

Recommended Lubricant

• Use a quality EP (extreme pressure) grease

• Meeting N.L.G.I.; EP., Grade 2 specifications

• Grease must have operating range of +325°F to -10°F

• Must be compatible with Lithium soap types

Mark Driveshaft (Phasing Marks)

• Mark all mating driveshaft components with a paint

marker to assure proper phasing during reassembly.

• Reassembly of a driveshaft that is out of phase can

cause vibration and failure to driveshaft components.

Grease Zerks

• Replace damaged zerks

•

• Zerk should be lined up with outboard bearings

• Clean zerk nipples before greasing

Zerk Torque 15 ft. lb. (20 Nm)

Page 2

Quick Reference Guide

Spicer Life Series® Heavy-Duty (SPL) U-Joint Service

Strap Torque Sequence

IMPORTANT

Failure to torque strap bolts in the proper sequence could result

in premature failure.

Torque bolts in a counter clockwise sequence starting with

either number one position.

Start Here

12

1

Start Here

2

Strap Bolt Torque (Half Rounds)

Series Head Size Size Bolt Torque

SPL 250,

170, 140

1/2 inch

12 point

12mm

1.25

115-135 ft lb

(156-183 Nm)

Spring Tab Bolt Torques

Lubrication Procedure

1. Use a recommended lubricant to purge all 4 seals of

each U-joint.This flushes abrasive contaminates from

each bearing assembly and assures proper filling.

2. Ensure fresh grease is evident at all U-joint

bearing seals.

IMPORTANT

If any of the seals fail to purge, move the driveshaft from side to

side while applying grease gun pressure.

a. If all 4 bearing positions still will not purge,

releasing seal tension may be necessary.

b. Remove the bearing plate bolts and straps.

Do not reuse bolts or straps.

c. Once the bearing cups are free, allow the

driveshaft to rest on support strap.

d. Apply a c-clamp around the inboard bearings.

e. Apply grease gun pressure. Completely purge

both bearings.

Spring Tab Torque (Full Round)

Series Head Size Size Bolt Torque

SPL 250,

170, 140

For spec‘ing or service assistance, call 1-877-777-5360 or visit our website at www.dana.com

Dana Commercial Vehicle Products Group

3939 Technology Drive

Maumee, Ohio, USA 43537

www.dana.com

All applications must be approved by the Application Engineering Department. Specifications and/or design are subject to change without notice or obligation. Printed in USA DSSM-0201 09/11

8 mm

6 point

8 mm

1.00

25– 30 ft lb

(35– 40 Nm)

removal of the U-joint and inspect for blockage.

g. If the U-joint will still not purge at all 4 positions

after following the steps in this procedure,

replace the U-joint.

f. If bearings will still not purge, complete the

Loading...

Loading...