Page 1

J300P-GI

J300-P SAFETY MESSAGES AND

GENERAL INFORMATION

GENERAL SAFETY INFORMATION

To prevent injury to yourself and/or damage to the equipment:

• Read carefully all owners manuals, service manuals, and or other instructions.

• Always follow proper procedures and use proper tools and safety equipment.

• Be sure to receive proper training.

• Never work alone while under a vehicle or while repairing or maintaining equipment.

• Always use proper components in applications for which they are approved.

• Be sure to assemble components properly.

• Never use worn-out or damaged components.

• Always block any raised or moving device that may injure a person working on or under a vehicle.

• Never operate the controls of the power take-off or other driven equipment from any position that could result in

getting caught in the moving machinery.

ROTATING AUXILIARY DRIVESHAFTS

• Rotating auxiliary driveshafts are dangerous. You can snag clothes, skin, hair, hands, etc. This can cause

serious injury or death.

• Do not go under the vehicle when the engine is running.

• Do not work on or near an exposed shaft when the engine is running.

• Shut off engine before working on power take-off or driven equipment.

• Exposed rotating driveshafts must be guarded.

WARNING: USING SET SCREWS

Auxiliary driveshafts may be installed with either recessed or protruding set screws. If you choose a square head

set screw, you should be aware that it will protrude above the hub of the yoke and may be a point where clothes,

skin, hair, hands, etc. could be snagged. A socket head set screw, which may not protrude above the hub of the

yoke, does not permit the same amount of torquing as does a square head set screw. Also, a square head set

screw, if used with a lock wire, will prevent loosening of the screw caused by vibration. Regardless of the choice

made with respect to a set screw, an exposed rotating auxiliary driveshaft must be guarded.

WARNING: GUARDING AUXILIARY DRIVESHAFTS

We strongly recommend that a power take-off and a directly mounted pump be used to eliminate the auxiliary

driveshaft whenever possible. If an auxiliary driveshaft is used and remains exposed after installation, it is the

responsibility of the vehicle designer and P.T.O. installer to install a guard.

This symbol warns of possible injury.

J300P-GI © Dana Holding Corporation, 2011

1

Page 2

J300P-GI

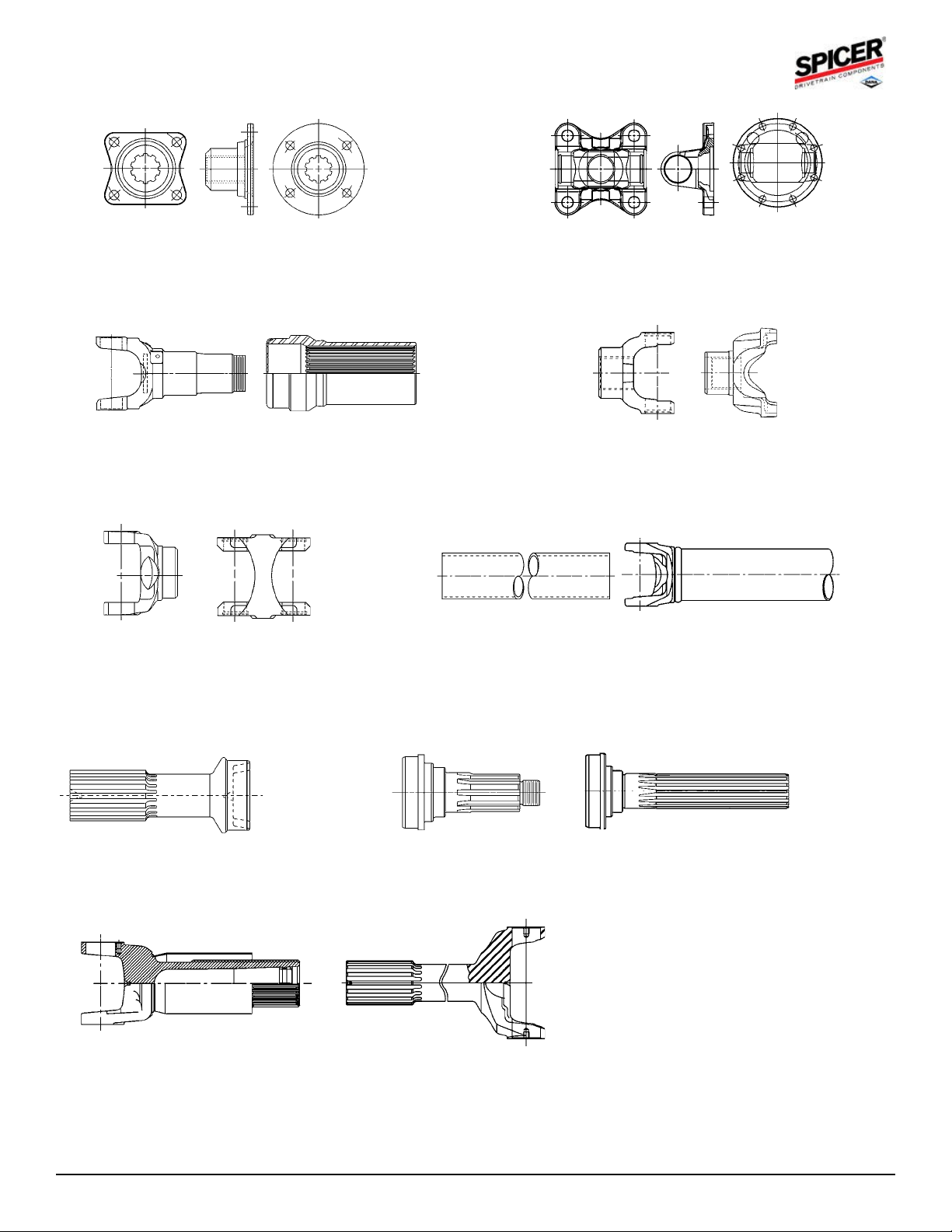

SPICER PART NAMES,

TYPES & NUMBERS

Rectangular Circular

J300P SECTION 1

Companion Flanges

(Part Type Number Set = 1)

®

J300P SECTION 2

Flange Yokes

(Part Type Number Set = 2)

J300P SECTION 3

Slip Yokes Splined Sleeves

(Part Type Number Set = 3) (Part Type Number Set = 55)

J300P SECTION 5

Tube Yokes Center Yokes &

(Part Type Number Center Plates

Set = 26 or 28) (Part Type Number

Set = 26)

J300P SECTION 7 J300P SECTION 7

Tube Shafts Midship Tube Shafts

(Part Type Number Set = 40 or 42) (Part Type Number Set = 53 or 54)

J300P SECTION 6

Tubing Yoke & Tube Assemblies

(Part Type Number Set = (Part Type Number Set = 27)

30 or 32)

J300P SECTION 4

End Yokes

(Part Type Number Set = 4)

J300P SECTION 9

Miscellaneous Parts

• bolts

• nuts

• dust caps

• balance weights

J300P SECTION 8

Yoke Shafts

(Part Type Number Set = 82)

OLD STYLE: Identify the part by the 2nd (center) number set (as shown on the previous page) of the complete part number. In the complete part

number, with the exception of Journal & Bearing Kits, Support Bearing Assemblies, Driveshaft Assemblies, and Tubing, the:

1st Number Set — Indicates the Joint Series

2nd Number Set— Indicates the Part Type

3rd Number Set— Indicates the Serial Number

4th Number Set— Indicates Additional Information

2

• keys

• tube deadeners

• snap rings

Page 3

J300P-GI

22 SPL22 1 Companion Flanges X Sub-assembly

25 SPL25 2 Flange Yokes KX Slip yoke including dust cap

30 SPL30 3 Slip Yoke Assy KXM Slip yoke w/ dust cap &

36 SPL36 4 End Yokes metric bolt holes

55 SPL55 7 Snap Rings SB Super bulk pricing available

70 SPL70 14 Dust Caps 1 Half-round

90 SPL90 15 Dust Cap Washers 1X Half-round assembly

100 SPL100 16 Seals

140 SPL140

170 SPL170 26 Center Yokes

250 SPL250 27 Tube & Yoke Assy

28 Tube Yokes

10 1000 30 & 32 Tubing

1 1100 40 & 42 Tube Shafts

2 1210-1330 & 7290 53 & 57 Midship Tube Shafts

3 1340-1480 55 Spline Sleeves

4 1550 68 Caps & Plugs

5 1610 &1650 70 Bearing Strap Kits

6 1710 73 Bearing Cap Hardware

6.3 1760 82 Yoke Shafts

6.5 1810 83 Socket Yokes

8 1820 & 1880 86 One Piece Dust Caps

9 1950 (See GWB) 94 U-Bolt Assm

95 Center Bearing Retainers

4C 4C Wing Bearing 98 Lock Straps

5C 5C Wing Bearing

6C 6C Wing Bearing

7C 7C Wing Bearing

8.5C 8.5C Wing Bearing

8C 8C Wing Bearing

9C 9C Wing Bearing

10C 10C Wing Bearing

SPICER® DRIVELINE PART

NUMBER NOMENCLATURE

Use the chart to identify Genuine Spicer® driveline parts except for:

- Journal & Bearing Kits

- Support Bearing Assemblies

- Driveshaft Assemblies

- Tubing

1st Number 2nd (Center) 4th Number

Set = Joint Number Set = 3rd Number Set = Set =

Series Part Type Serial Number Additional

Information

3 - 4 - 6561 - 1x

Actual Part Number Example

3

Page 4

J300P-GI

NOTES

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

4

Loading...

Loading...