Page 1

®

Spicer

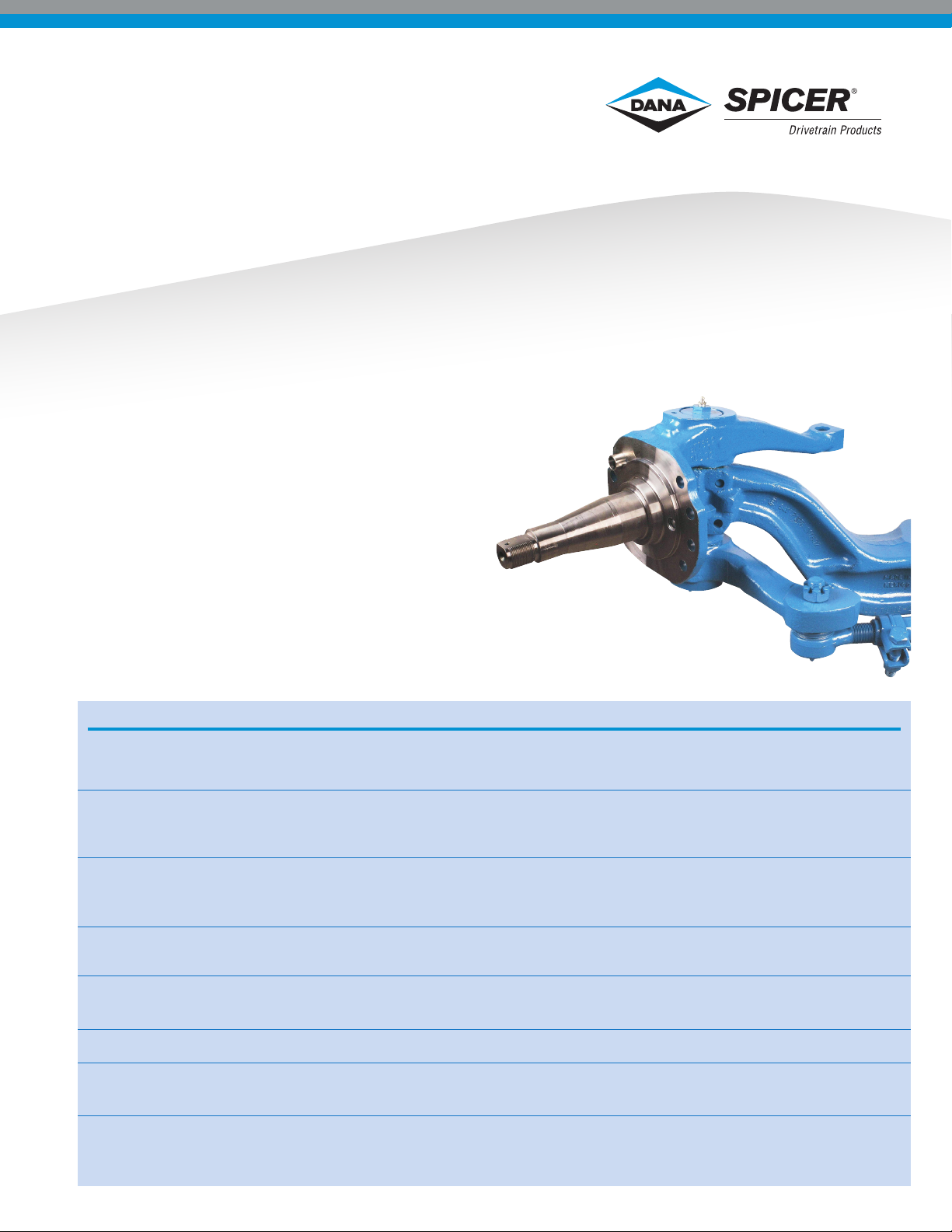

Integral Arm

Steer Axles

E-1002I

E-1002W

10,000 lbs. [4,536 kg] – 12,000 lbs. [5,443 kg]

Improved Vehicle Performance is Available for On-Highway,

City Delivery and Bus Chassis Applications

The exclusive combination of larger kingpin bushings

and a kingpin sealing system, which includes the

pressure reducing compressible inserts, helps ensure

long service life and reduced maintenance.

In addition, the unique two-drawkey and spring

washer kingpin retention system along with a

robust beam forging design provides improved

total vehicle alignment capability and axle durability.

E-1202I

E-1202W

The state-of-the-art Power Rib beam was engineered

to meet the latest camber, toe setting, and braking

requirements while maintaining light weight.

FEATURES BENEFITS

Integral Arm Knuckle – Exclusive one-piece forging design

including the steer arm, tie rod arm and spindle.*

Larger Diameter Kingpin – Includes 15% larger bushing

area, sealed thrust bearings and compressible kingpin

inserts.*

Two-Drawkey Kingpin Retention – Same-side location with

spring washer tensioning and a widened and more rigid

beam kingpin boss.*

Tie Rod End Sealing – Improved design with sealed boot

and new grease purge valve.*

Power Rib Beam – A new design to achieve optimal

toe-change-with-load and camber.*

Standard and Wide Beam Widths.

Forged knuckle reliability for up to 55° turn angle and

lightweight compact package.

Improved durability and reduced maintenance. Common

components with E-1462I/W.

Improved durability, alignment capability and reduced

maintenance in a compact package.

Improved durability and reduced maintenance.

Forged beam reliability design for optimum deflections and

lightweight, which results in improved alignment capability.

Maximum maneuverability.

Hub Compatibility Options – Standard, Spicer

LMS™ Hub

New Options – ABS wire or hydraulic hose attachment,

1-1/2 12 UNF D-Flat spindle threads and 30-50 degree

stop screw assembly.

*Patented or Patent Pending Features

®

Wheel bearing adjustment and component serviceability

choices affecting life-cycle costs.

Compatibility with varying OEM design and assembly

requirements.

Page 2

®

Spicer

Integral Arm Steer Axles

Specifications:

KINGPIN SPRING PAD

MODEL GAWR INTERSECTION DROP CENTER DROP AXLE WEIGHT

E-1002I 10,000 lbs. [4,545 kg] 69 in. [1,753 mm] 3.5 in. [88.9 mm] 1.25 in. [32 mm] 314 lbs. [142 kg]

E-1002W 10,000 lbs. [4,545 kg] 71 in. [1,803 mm] 3.5 in. [88.9 mm] 1.25 in. [32 mm] 319 lbs. [145 kg]

10,000 lbs. [4,545 kg] 71.5 in. [1,816 mm] 3.74 in. [95 mm] 1.25 in. [32 mm] 319 lbs. [145 kg]

E-1202I 12,000 lbs. [5,442 kg] 69 in. [1,753 mm] 3.5 in. [88.9 mm] 1.25 in. [32 mm] 314 lbs. [142 kg]

E-1202W 12,000 lbs. [5,442 kg] 71 in. [1,803 mm] 3.5 in. [88.9 mm] 1.25 in. [32 mm] 319 lbs. [145 kg]

12,000 lbs. [5,442 kg] 71.5 in. [1,816 mm] 3.74 in. [95 mm] 1.25 in. [32 mm] 319 lbs. [145 kg]

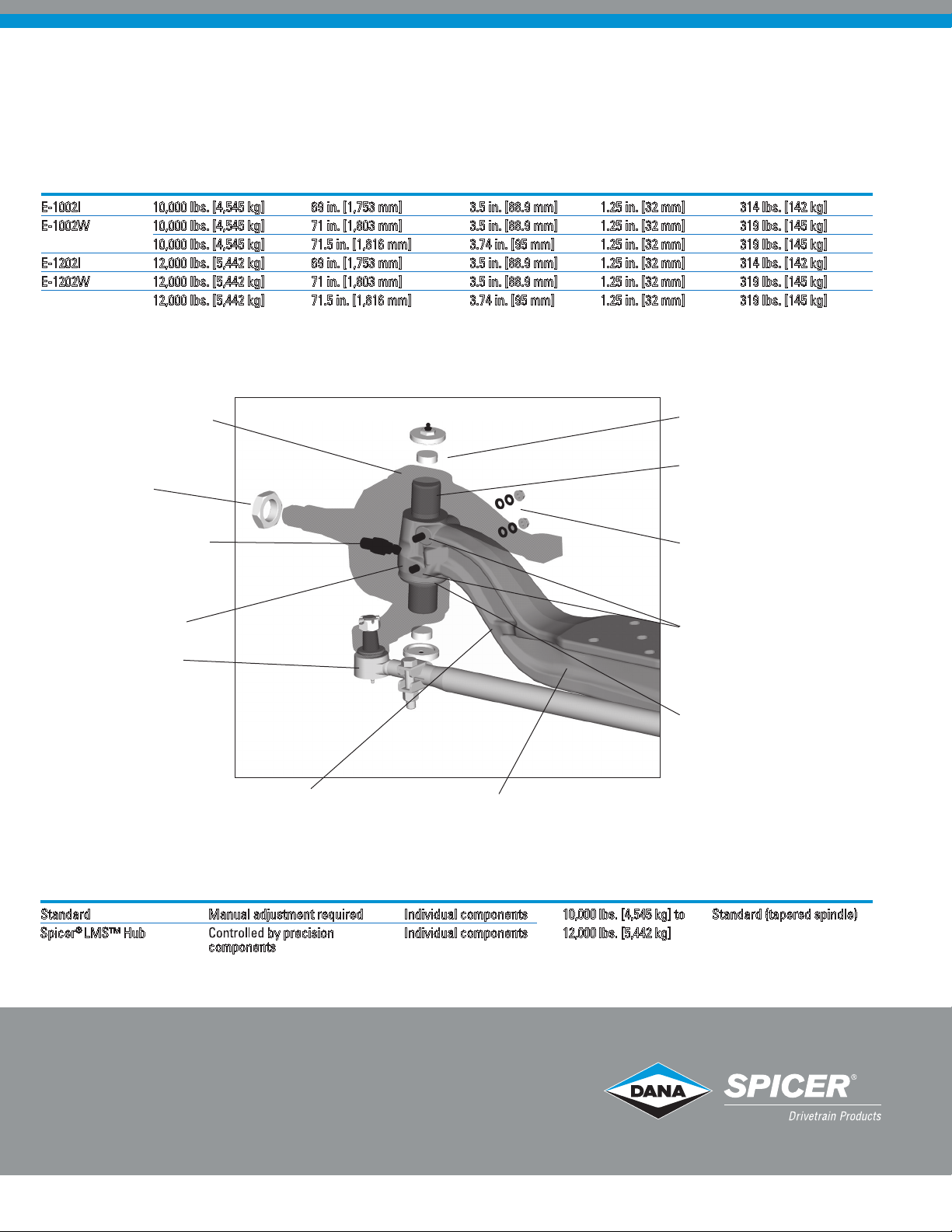

Product Features

Integral Arm Knuckle – Exclusive one-piece forging design including the steer arm, tie rod arm and spindle

ABS Wire/Hydraulic Hose

Mount Option

1-1/2 12 UNF D-Flat Spindle

Thread Option

30-50° Stop Screw Option

Wider Beam Boss with

Vertical Stiffening Rib

Improved Tie Rod End

Sealing

Hub Compatibility Options:

Power Rib Beam Forging

Compressible Kingpin Inserts

Larger Diameter Kingpin with

15% Greater Bushing Area

Spring Washer

Drawkey Tensioning

Two-Drawkey Kingpin

Retention System

Sealed Thrust Bearing and

Kingpin Seals

Standard or Wide

Beam Width

BEARING HUB/BEARING/SEAL AXLE SPINDLE

HUB TYPE ADJUSTMENT SERVICEABILITY GAWR CONFIGURATION

Standard Manual adjustment required Individual components 10,000 lbs. [4,545 kg] to Standard (tapered spindle)

Spicer® LMS™ Hub by precision Individual components 12,000 lbs. [5,442 kg]

For spec‘ing or service assistance, call 1-877-777-5360 or visit our website at www.dana.com

Dana Commercial Vehicle Products Group

3939 Technology Drive

Maumee, Ohio, USA 43537

www.dana.com

All applications must be approved by the Application Engineering Department. Specifications and/or design are subject to change without notice or obligation. Printed in USA AXSL-0470 06/10

components

Loading...

Loading...