Page 1

Spicer

Reference:

®

Axles & Brakes

P/N: SHAIS133

WORK INSTRUCTIONS – DANA KIT PART NUMBER: 326837

Kenworth Campaign Number: 01KW7

Kenworth Recall Bulletin Number: C-E-101

Below are work instructions for the replacement of specific tie rod end crosslink and brake assemblies from vehicles equipped with Dana E-1000I

or E-1200I steer axles and Dana ES165-5L ES brakes.

Tie Rod Assembly Replacement

1. Disconnect the tie rod end.

2. If the cross tube is being replaced, count the number of

exposed threads on the tie rod end.

3. Loosen the clamp nut and unscrew the tie rod end.

4. Install new tie rod ends or new cross tube.

NOTE: Cross tube has right-hand and left-hand threads for

corresponding sides of the vehicle.

5. Thread tie rod end into cross tube past the tube split. The

number of threads exposed from the tube should be equal

on both left and right tie rod ends.

CORRECT

The threaded portions of both

tie rod ends must be completely

inserted in cross tube split

Equal threads exposed on

left and right tie rod ends

INCORRECT

Threaded end is not completely

inserted in cross tube split

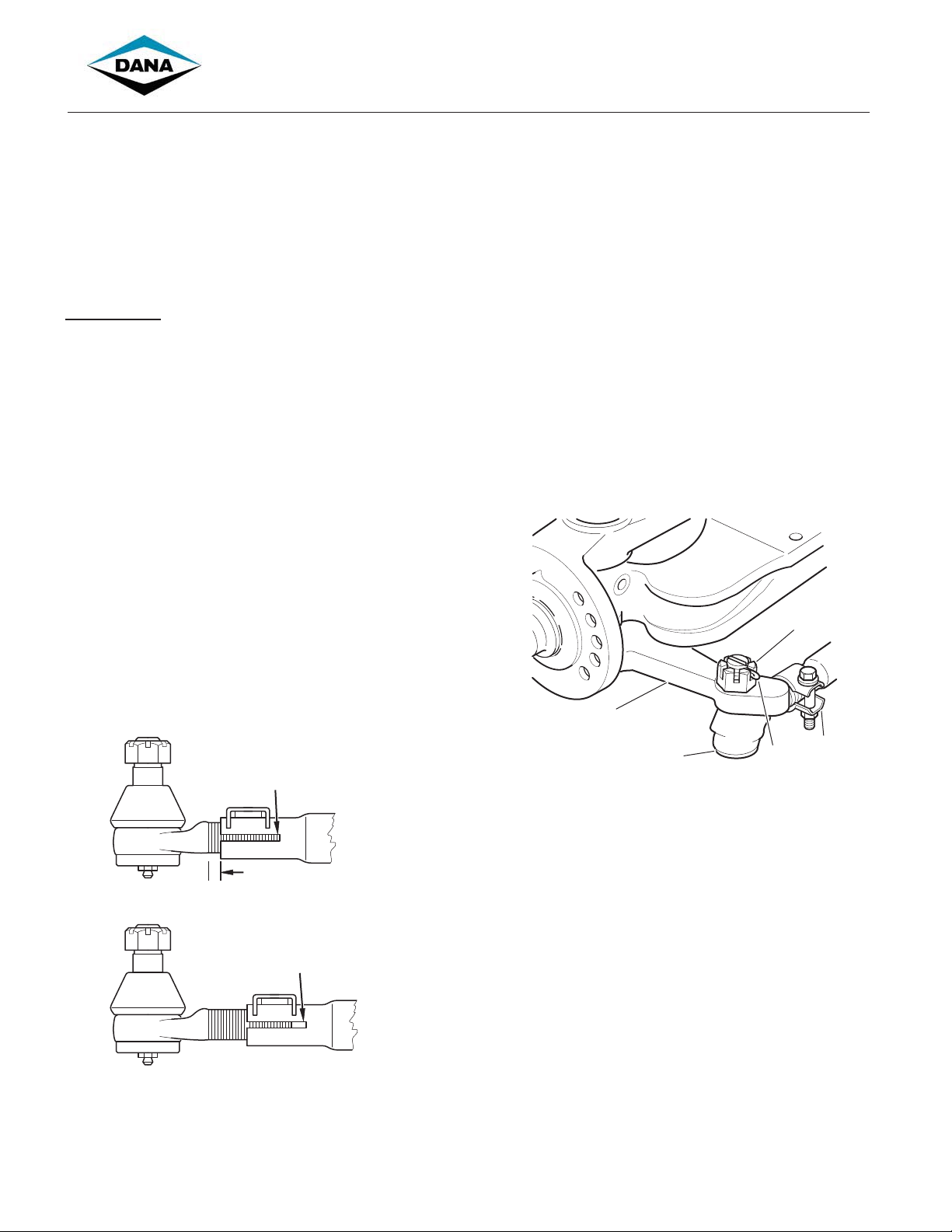

7. Install tie rod end into knuckle tie rod arm. Secure with

slotted nut and tighten to 120-160 ft. lbs. (163-217 N€m).

3

1

2

1 – Tie rod arm

2 – Tie rod end

3 – Slotted nut

4– Cotter pin

5 – Position clamp fastener away from beam

Figure 2

8. Install the cotter pin in the slotted nut and bend the ends to

secure. If necessary, tighten the nut until the holes align.

9. Adjust toe-in.

NOTE: On tie rods with rotating clamp, position clamp with fastener

away from beam.

4

5

Figure 1

6. Tighten the clamp nut to 45-60 ft. lbs. (61-81N€m). Make

sure the tab on the clamp holds the end of the cross tube.

1

06SE01TBC6298

Page 2

General Information

DANGER: Avoid creating dust possible cancer and lung

!

disease hazard

While Dana does not offer asbestos brake linings, the long-term

effects of some non-asbestos fibers have not been determined.

Current OSHA Regulations cover exposure levels to some

components of non-asbestos linings but not all. The following

precautions must be used when handling these materials.

1. AVOID CREATING DUST. Compressed air or dry brushing

must never be used for cleaning brake assemblies or the

work area.

2. DANA RECOMMENDS THAT WORKERS DOING BRAKE

WORK MUST TAKE STEPS TO MINIMIZE EXPOSURE TO

AIRBORNE BRAKE LINING PARTICLES. Proper procedures

to reduce exposure include working in a well ventilated

area, segregation of areas where brake work is done, use

of local filtered ventilation systems or use of enclosed cells

with filtered vacuums. Respirators approved by the Mine

Safety and Health Administration (MSHA) or National

Institute for Occupational Safety and Health (NIOSH)

should be worn at all times during brake servicing.

3. Workers must wash before eating, drinking or smoking;

shower after working, and should not wear work clothes

home. Work clothes should be vacuumed and laundered

separately without shaking.

4. OSHA Regulations regarding testing, disposal of waste and

methods of reducing exposure for asbestos are set forth in

29 Code of Federal Regulations §1910.001. These

Regulations provide valuable information which can be

utilized to reduce exposure to airborne particles.

5. Material safety data sheets on this product, as required by

OSHA, are available from Dana.

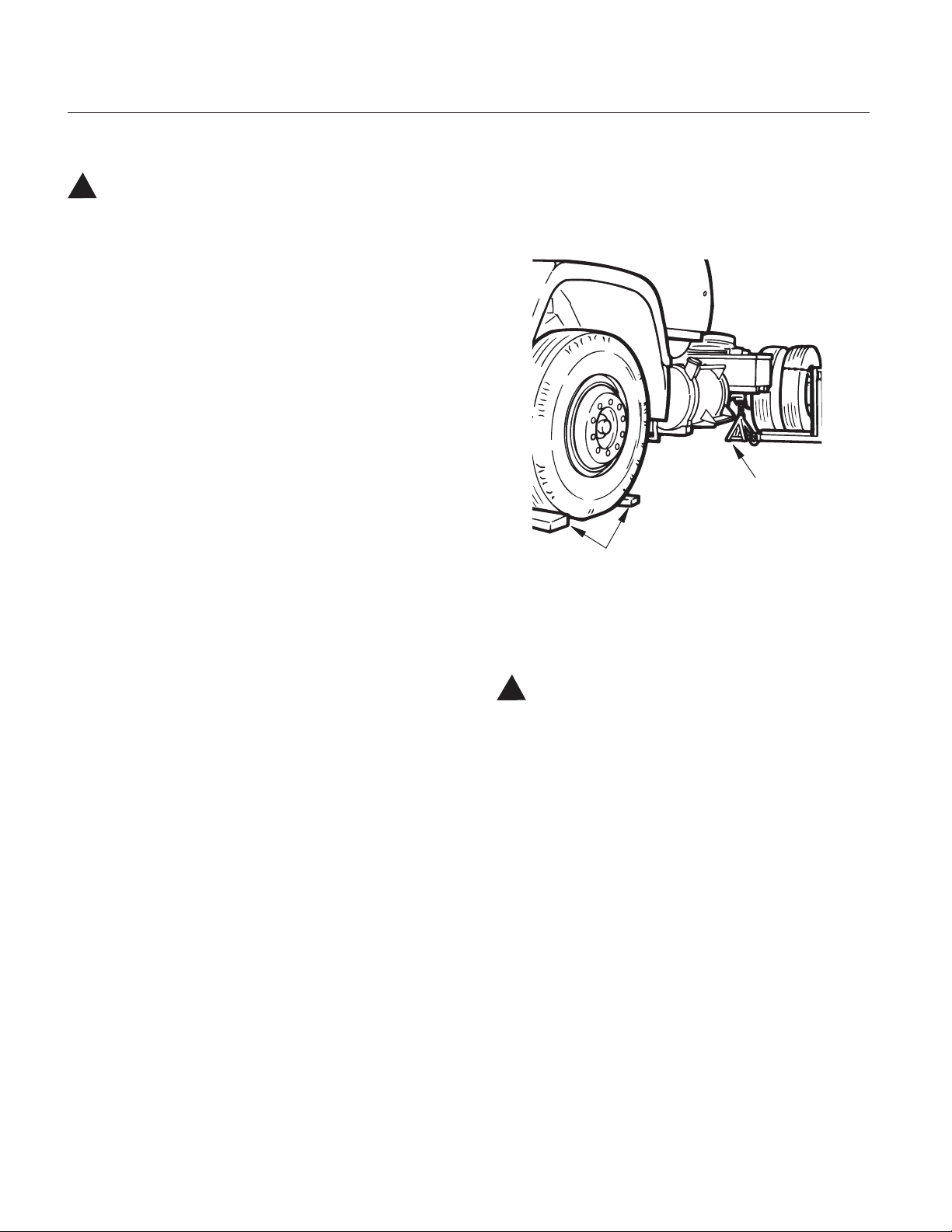

Brake Maintenance Preliminary Steps

Prior to performing any maintenance requiring removal of the tire

and wheel, the following preliminary steps must be taken to ensure

your safety. Refer to Figure 3.

Support On

Jack Stands

of Adequate

Capacity

Block Wheels

Figure 3

1. Set parking brake and block wheels to prevent vehicle

movement.

2. Raise drive axle with a jack and support on suitable stands.

WARNING: Never work under a vehicle supported by a

!

jack.

3. Cage spring-type brake chamber following vehicle

manufacturer’s instructions.

2

06SE01TBC6298

Page 3

Removal/Disassembly

Drum Removal

1. Perform “Brake Maintenance Preliminary Steps”.

2. While depressing locking sleeve, back off brake adjuster

adjustment nut on manual brake adjusters. Refer to

Figure 4. Continue turning until shoes are fully returned to

released position and clear of drum. On self adjusting

brake adjusters, follow manufacturer’s instructions.

NOTE: With outboard mounted drums go to step 6.

Turn Adjuster Nut to

Back-Off Adjustment

Figure 4

3. On drive axles, remove stud nuts and axle shafts. If used,

remove Iockwashers and taper dowels. If necessary,

loosen dowels by holding a brass drift in the center of the

shaft head and striking it a sharp blow with a hammer. On

trailer and steer axles, remove hub cap.

WARNING: Do not strike the axle shaft flange with a

!

hammer. Do not use chisels or wedges to loosen shaft or

dowels.

4. Remove axle spindle nut(s) and washer.

5. While rocking drum, pull outboard enough to allow

removal of outer wheel bearing.

6. Remove drum by pulling outboard while rocking from side

to side. If shoes are not clear of drum, return to Step 2

above.

CAUTION: If difficulty is found on removal, do not force

!

drum. Excessive pulling force may damage brake

components.

06SE01TBC6298

3

Page 4

Brake Shoe Removal

EB models (except EB-150-4L)/ ES-165-5D,L / ES-165-6D,L /

ES-165-7D, F, L / ES-150-8D, F / ES-150-4D / ES-150-6D /

ES-165-8D, F, L

1. Perform steps in Removal/Disassembly: Drum Removal.

2. ES-165-5,6,7,8,D,L,F, ES-150-4D, ES-150-8D, F & 6D

ONLY: Pry roller retainer coiled loops out of both shoe web

holes as shown in Figure 5. Pivot roller retainer to swing

loops clear of shoe webs.

NOTE: EB models do not have roller retainers.

3. Using a large screwdriver or lever, lift upper shoe to stretch

return spring as shown in Figure 6.

Lift Upper Shoe

to Stretch Spring

Figure 5

Shoe

Web

Disengage

Retainer Coiled

Loops From

Shoe Webs

Pivot Retainer to

Swing Loops Clear

of Shoe Web

Roller

Retainer

Remove Roller and Pin, Then

Repeat for Lower Shoe.

For ES Brakes, See Note Below

Figure 6

4. Remove upper cam roller and pin.

NOTE: ES-165-5,6,7,8D, L, F, ES-150-4D, ES-150-8D, F & 6D

ONLY: Remove roller and roller retainer as a unit.

5. Repeat Steps 2 through 4 to remove lower shoe roller and

pin.

NOTE: Dana recommends the use of a suitable brake tool when

removing rollers and return springs.

WARNING: The long term effects of non-asbestos fibers

!

have not been determined. Therefore, precautions should

be used when handling these materials.

See General Information / Lining Material Warning

4

06SE01TBC6298

Page 5

6. Push cam end of both shoes toward cam and unhook shoe

return spring. Remove and discard spring.

NOTE: To remove return spring, position a lever or suitable tool

with notch to engage spring rod. Refer to Figure 7. Apply downward

force to stretch spring, allowing removal of upper spring hook.

Remove and discard spring.

Stretch Using Suitable

Tool Positioned

As Shown

Figure 7

7. Rotate both shoes around anchor pin and remove from

vehicle. Refer to Figure 8.

8. Clean and inspect remaining parts as outlined in removal/

disassembly section of this manual.

Rotate Both Shoes

Around Anchor

Pin and Lift Off

Brake Shoes

NOTE: ES-165-5,6,7L,D/ES-150-6D steer axle brakes may use two

return springs with a horse collar or dual spring post. To remove

return springs, position a lever or suitable tool with notch to engage

spring. Return to Figure 7. Apply downward force to stretch upper

spring, allowing removal of upper spring hook. Remove and

discard. Repeat procedure for lower spring.

Figure 8

Figure 9

06SE01TBC6298

5

Page 6

Installation/Assembly

Brake Shoe Installation and Adjustments

All EB (except EB-150-4L) and ES-165 5/6/7/8D, F, L

NOTE: The following procedures are divided into sections,

identified by brake model numbers.

1. See Inspection & Repair / Replacement to verify that

spider camshaft, bracket, and brake adjuster are

serviceable and properly installed.

2. During shoe installation, lubricate:

• Shoe roller recess - one-piece roller.

• Roller I.D. - two-piece roller.

CAUTION: Use only grease conforming to NLGI grade #1,

!

high-temperature, waterproof.

Do Not Lubricate:

• Cam head surface. For efficient operation, this surface

must remain free of oil, grease or other contaminants.

3. Hook ends of new retainer springs into holes in both shoe

tables, hooks pointing out.

4. Position upper and lower shoes around anchor pin. Refer

to Figure 10.

WARNING: The long term effects of non-asbestos fibers,

!

have not been determined. Therefore, precautions should

be used when handling these materials.

See General Information / Lining Material Warning

With Retainer Springs

Installed, Position

Upper and Lower Shoes

Around Anchor Pin

Figure 10

ES-165-D,L,F Only:

Stetch Spring Using Suitable

Tool Positioned as Shown

5. Install a new shoe return spring. Refer to Figure 11.

NOTE: On ES-165-D, 1, F, a lever may be required to assist in

hooking shoe return spring.

Figure 11

6

06SE01TBC6298

Page 7

6. For ES-165 5/6/7/8D, L, F, ES-150-4D, ES-150-8D, F & 6D

only:

Assemble roller retainer on ends of roller as shown in Figure 12.

Install Retainer

on Roller

8. For ES-165 5/6/7/8D, L, F, ES-150-4D, ES-150-8D, F &

6D only:

Position assembly in roller recess as shown. Squeeze loops and

swing retainer into position to snap loops into web holes. Refer to

Figure 14. Verify that both retainer loops are engaged in web holes

before proceeding.

Web

Hole

Figure 12

7. Using a lever or large screwdriver, stretch shoe return

spring to allow insertion of new pin and roller, (or roller

and retainer assembly) on the lower shoe web. Refer to

Figure 13.

NOTE: If drums are oversized, use oversize rollers, see InspectionDrum Inspection.

Stretch

Return Spring,

Install Roller

And Retainer

Figure 13

Install Retainer

Loops in Shoe

Web Holes

Figure 14

9. Repeat process on upper shoe.

NOTE: For all EB Models a roller retainer is not used.

06SE01TBC6298

7

Page 8

Brake Adjustment - Manual Brake Adjuster

NOTE: An assistant is required to make a brake adjustment.

WARNING: Block all wheels before beginning this

!

adjustment procedure

To determine whether Dana Brakes require adjustment, applied

stroke is measured and compared to the maximum value for the air

chamber size in use on the vehicle.

1. Perform “Brake Maintenance Preliminary Steps”

described earlier.

2. With air chamber pushrod fully retracted, measure

distance from face of air chamber to centerline of clevis pin

hole. Refer to Figure 15. If the measurement is not within

ranges shown in Table 1, reposition clevis. Remeasure the

distance and repeat until within range. Record exact

measured distance as dimension “A”.

B

Measure This

Distance

at 80 psi,

Dimension B

Figure 15

Distance: Clevis Pin Hole

Centerline to Air Chamber Face

All brakes (except Mack and

Trailer Axle)

2-5/8” ± 1/16”

(66.7 ± 1.59 mm)

Mack brakes 4-3/8” ± 1/16”

(111.1 ± 1.59 mm)

Trailer Axle brakes 6-1/2” ± 1/8”

(165.1 ± 3.175 mm)

Table 1

A

0HDVXUH7KLV

'LVWDQFHZLWK

&KDPEHUu$W5HVWv

'LPHQVLRQu$v

Figure 14

3. Apply and hold an 80 psi brake application, and again

measure from face of air chamber to clevis pin centerline.

Refer to Figure 16. Record distance as dimension “B”.

4. Subtract dimension “A” from “B”. The difference is applied

stroke. Compare applied stroke to maximum value in

Table 2. If applied stroke equals or exceeds maximum

applied stroke shown, adjust brakes. If less than the

maximum, no adjustment is required and you may perform

Brake Operation Check.

80 - 90 PSI

Air Chamber Size Maximum

Applied

Desired Free

Stroke

Stroke

Type 30” Long Stroke

Type 30”

Type 24”

Type 24” (with 2-1/2”

2.5”

2”

1-3/4”

2”

3/8” to 5/8”

(Without Drag)

extended stroke)

Type 24 (with 3”

2.5”

extended stroke)

Type 20” and 16” 1-3/4” 3/8” to 1/2”

Type 12” 1-3/8” 3/8” to 1/2”

Table 2

NOTE: If adjustment is necessary, Dana Brakes are adjusted to

achieve proper free stroke. The difference between free stroke and

applied stroke is merely the method used to move the brake adjuster

from rest. Applied stroke uses an 80 psi brake application; free

stroke is measured using a lever to move the brake adjuster until the

brake shoes contact the drum. If applied stroke exceeded the

maximum and adjustment is necessary, adjust the brakes as

described in steps 5 through 8 below.

8

06SE01TBC6298

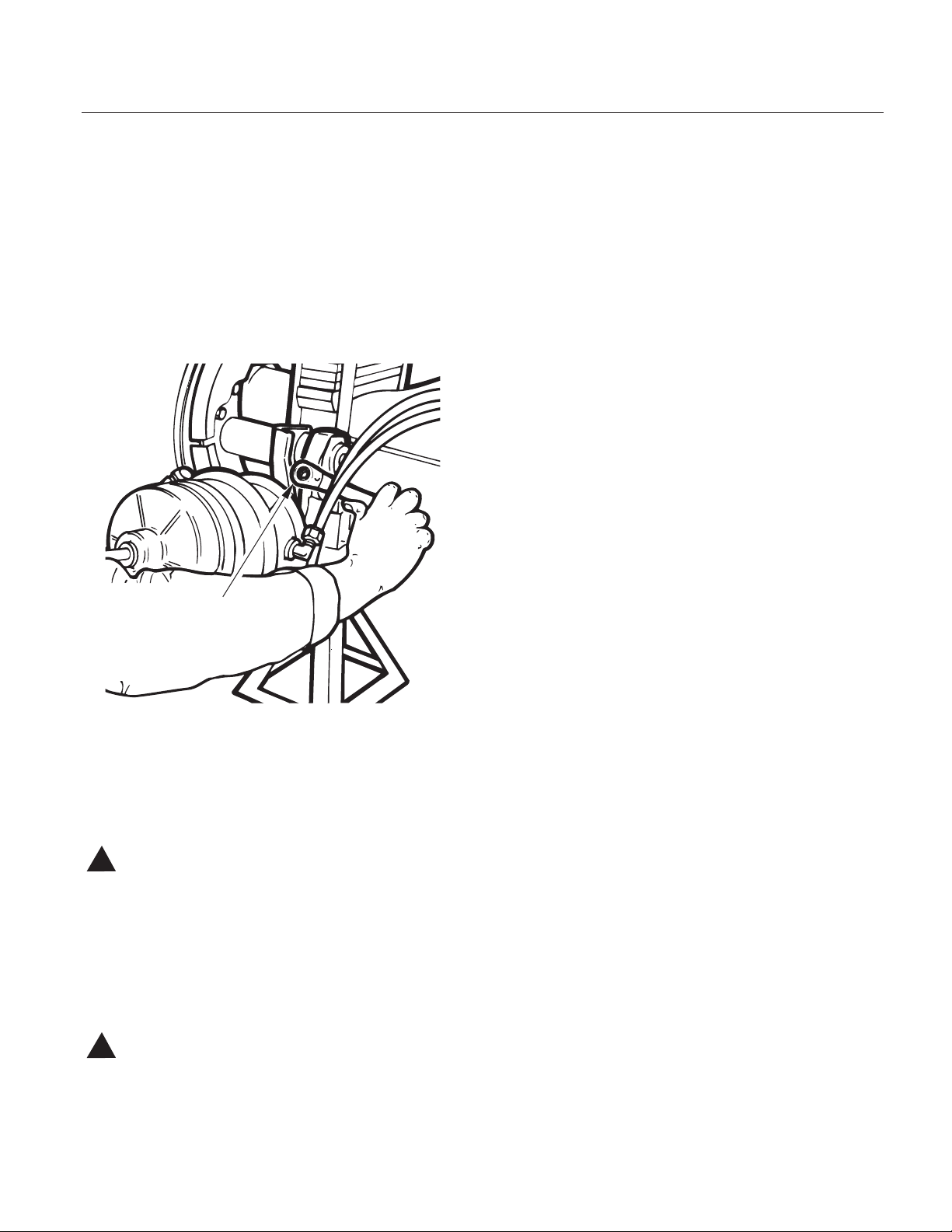

Page 9

5. Take “A” dimension exactly as before. Take “B”

measurement using a lever to move brake adjuster as

shown until the shoes contact drum. Refer to Figure 17.

The result of “B” - “A” is brake free stroke. Adjust free

stroke to within range specified in Table 2.

B

Measure with

Brake Applied

Using Lever,

Lever

Figure 16

6. To adjust free stroke, depress locking sleeve on brake

adjuster adjustment nut and turn in direction required.

Recheck free stroke to verify it is within range. Make sure

sleeve is “locked” when adjustment is completed.

7. Verify that brakes are not dragging by spinning wheels by

hand or tapping drum lightly with a hammer and listening

for a sharp ringing sound.

8. Perform Brake Operation Check, to verify proper

operation of brakes before releasing vehicle for service.

Dimension B

Brake Adjustment - Self Adjusting Brake

Adjuster

1. Brake adjustment for self adjusting brake adjusters is the

same as for manual brake adjusters.

2. Refer to the Self Adjusting Brake Adjuster Manufacturer’s

Instructions for proper installation.

Brake Operation Check

NOTE: An assistant is required to make a thorough brake operation

check.

1. Apply brakes to 80 psi and hold. Check all air line fittings

and air chambers for leakage.

2. Apply and release brakes while observing operation of

brake adjusters on each axle. As brakes are applied and

released, brake adjusters should move in unison visually.

3. Investigate source and make corrections for any

discrepancies found in Steps 1 and 2.

4. Drive vehicle at low speeds in a safe area and make several

brake applications to verify safe operation and absence of

pulling, grabbing, or noise. If any of these are noted,

investigate and repair prior to releasing vehicle for service.

CAUTION: Never release a vehicle for service if any brake

!

discrepancy - no matter how minor - is evident.

06SE01TBC6298

9

Page 10

For spec’ing or service assistance, call 1-800-ÈÓ£nän{ 24 hours a day, 7 days a week, for more time on the road.

Or visit our web site at http://www.ëViÀ«>ÀÌÃ.com.

SHAIS133A September 2001 Copyright Dana Corporation, 2001 Dana Corporation

Printed in U.S.A. All Rights Reserved Commercial Vehicle Axle Division

www.dana.com ККККККККККККККККККP.O. Box ÎÓ£

/i`]Ê"Ê{ÎÈÇäÎÓ£

Loading...

Loading...