Page 1

Spicer

®

Driveshafts

Service Manual

DSSM3264

September 2007

Page 2

Table of Contents

Safety . . . . . . . . . . . . . . . . . . . . . . 1

General Safety . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Component Safety . . . . . . . . . . . . . . . . . . . . . . 2

Driveline . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

End Fitting . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Universal Joint . . . . . . . . . . . . . . . . . . . . . . 2

Slip Member . . . . . . . . . . . . . . . . . . . . . . . . 2

Yoke (Includes Slip Yoke, Yoke Shaft,

and Tube Yoke) . . . . . . . . . . . . . . . . . . . . . . 2

Tubing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Midship Nut . . . . . . . . . . . . . . . . . . . . . . . . 3

Center Bearing . . . . . . . . . . . . . . . . . . . . . . 3

Foreign Material . . . . . . . . . . . . . . . . . . . . . 3

Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Lubrication (When Applicable) . . . . . . . . . . 4

Inspection . . . . . . . . . . . . . . . . . . . 5

End Fitting Inspection . . . . . . . . . . . . . . . . . . . . 5

Bearing Plate (Full Round) Yoke

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Quick Disconnect™ (Half Round) End

Yoke Inspection . . . . . . . . . . . . . . . . . . . . . 7

Universal Joint Inspection . . . . . . . . . . . . . . . . . 8

Re-lubable Style Universal Joints . . . . . . . . 8

Permanently Greased Plug Style

Universal Joints . . . . . . . . . . . . . . . . . . . . . 8

Slip Member Assembly . . . . . . . . . . . . . . . . . . . 9

Tubing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Center Bearings . . . . . . . . . . . . . . . . . . . . . . . 10

Midship End Fitting . . . . . . . . . . . . . . . . . . 10

Lubrication . . . . . . . . . . . . . . . . . . .11

Spicer 10 Series™ Universal Joint and

Slip Members Lubrication Intervals . . . . . .11

Lubrication for Universal Joints . . . . . . . . . . . .12

Grease Compatibility . . . . . . . . . . . . . . . . .12

Lubrication Procedure for Universal Joints 12

Quick Disconnect™ (Half Round)

Universal Joints . . . . . . . . . . . . . . . . . . . . .13

Bearing Plate (Full Round) Universal

Joints . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Snap Ring Universal Joints . . . . . . . . . . . .14

Lubrication for Slip Members . . . . . . . . . . . . .15

Lubrication of Center Bearing Assemblies . . . .15

Disassembly and Reassembly . . . . .16

Universal Joint . . . . . . . . . . . . . . . . . . . . . . . . .16

Disassembly - Snap Ring Design . . . . . . . .16

Reassembly - Snap Ring Design . . . . . . . .17

Disassembly - Bearing Plate Style . . . . . . .18

Reassembly - Bearing Plate Style . . . . . . .18

Center Bearing Assembly . . . . . . . . . . . . . . . . .20

Disassembly - Inboard Slip Style . . . . . . . .20

Midship Nut Specifications Table . . . . . . . .22

Disassembly - Outboard Slip Style . . . . . . .23

Reassembly - Inboard Slip Style . . . . . . . .24

Recommended Center Bearing

Lubricants . . . . . . . . . . . . . . . . . . . . . . . . .24

Midship Nut Installation Procedure . . . . . .24

Reassembly - Outboard Slip Style . . . . . . .25

Recommended Center Bearing

Lubricants . . . . . . . . . . . . . . . . . . . . . . . . .25

Grease Zerk (Nipple) Fittings or Plugs . . . . . . .26

Universal Joints and Slip Member

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . .26

Universal Joint Grease Zerk (Nipple)

Fitting and Plug Torque . . . . . . . . . . . . . . .26

Glossary . . . . . . . . . . . . . . . . . . . .27

Page 3

Safety

Safety

Note: Spicer 10 Series™ Driveshafts are found on vehicles

throughout the world. Therefore, this manual includes

worldwide terminology.

General Safety

The following WARNINGS and CAUTIONS should be read and

understood before attempting any service or repair on the various components of the driveshaft assembly.

CAUTION

Under no circumstances should individuals attempt to perform driveline service and/or maintenance procedures for

which they have not been trained or do not have the proper

tools or equipment.

WARNING

Failure to take common sense, precautionary measures

when working on a vehicle or other machinery could result

in property damage, serious personal injury, or death. To

avoid property damage, serious personal injury, or death,

please follow basic safety rules as noted below.

1. ALWAYS wear safety glasses when performing

maintenance or service. Failure to do so can result in

personal injury and/or partial or complete vision

loss.

2. NEVER perform service or maintenance tasks under-

neath a vehicle while the engine is running. Be sure

the vehicle engine is off and the keys are removed

from the ignition.

Safety

CAUTION

Spicer 10 Series™ Driveshaft assemblies can weigh in

excess of 100 pounds (46 kilograms). Be sure to use proper

lifting techniques when handling Spicer 10 Series™ Driveshaft assemblies. More than one person may be needed

when handling driveshaft assemblies.

8. ALWAYS use support straps to prevent the driveshaft

from falling out of the vehicle during the removal and

installation process.

Note: This manual does not discuss the removal and installa-

tion of Spicer 10 Series™ Driveshaft assemblies from

the vehicle. It only covers the disassembly and reassembly of component parts of the driveshaft assembly.

Please refer to the original-equipment manufacturer’s

service documentation for removal and installation procedures.

9. NEVER heat components, and never use sledgeham-

mers or floor jacks to remove the driveshaft from the

vehicle.

Note: For driveshaft applications that have pillow blocks,

dampers, parking brakes, or retarders, refer to these component manufacturers’ or the original equipment manufacturer’s

service manuals for the proper procedures. NEVER perform

any unauthorized procedures that will change the disconnected properties of Spicer products.

3. NEVER perform service or maintenance tasks under-

neath a vehicle that is not on a level or flat surface.

4. NEVER work on a driveshaft without blocking the

vehicle wheels and releasing all parking brakes.

5. ALWAYS wear gloves when handling parts with

sharp edges or abrasive surfaces.

6. NEVER lift a vehicle without the appropriate weight-

rated vehicle-lift equipment. Always properly support

the vehicle with appropriate weighted support equipment.

7. NEVER remove a driveshaft from a vehicle without

keeping the transmission in neutral.

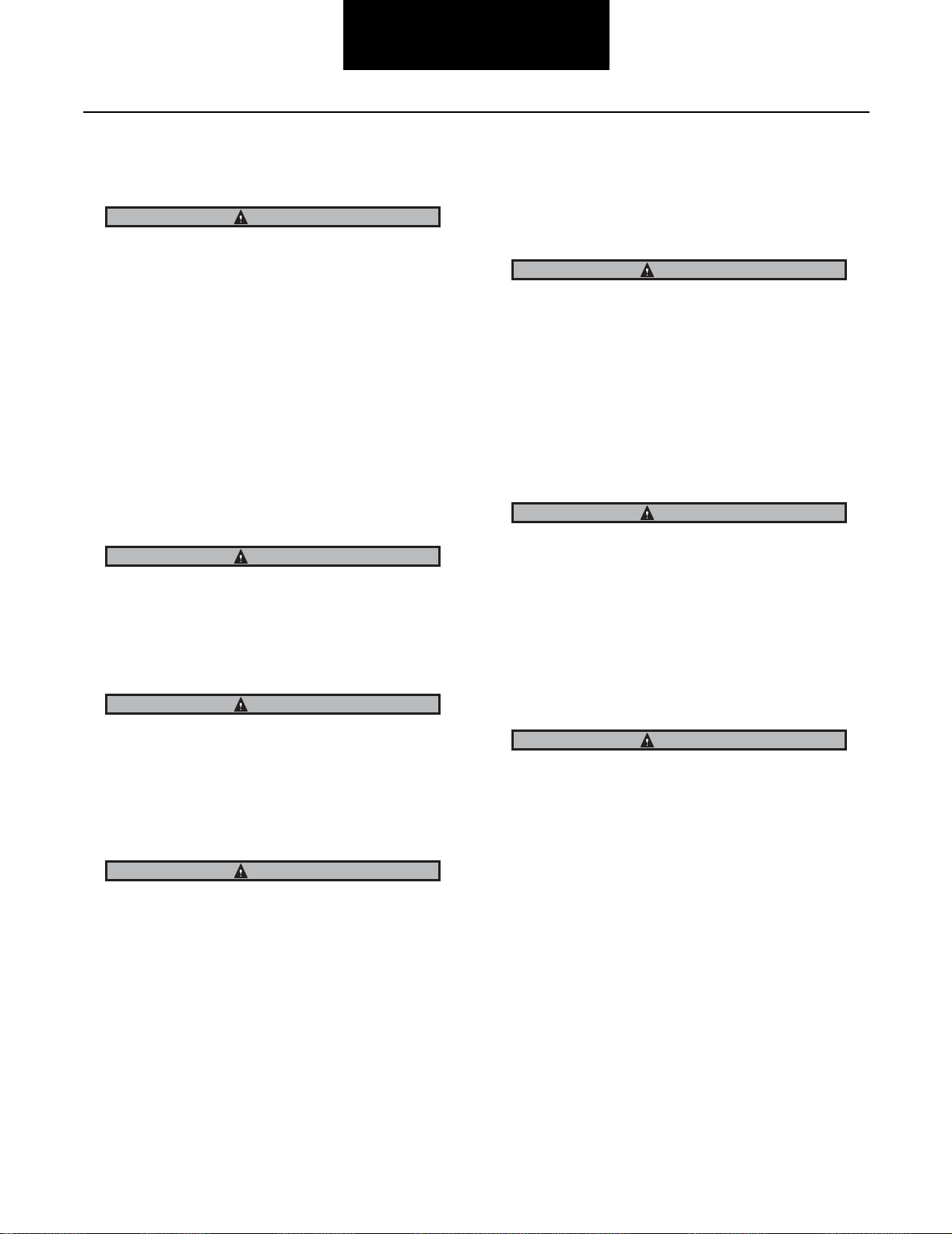

WARNING

ROTATING DRIVESHAFTS

• Rotating auxiliary driveshafts are dangerous. You

can snag clothes, skin, hair, hands, etc. This can

cause serious injury or death.

• Do not go under the vehicle when the engine is running.

• Do not work on or near an exposed shaft when

engine is running.

• Shut off engine before working on power take-off or

driven equipment.

• Exposed rotating driveshafts must be guarded.

1

Page 4

Component Safety

Safety

Driveline

WARNING

Failure to replace damaged driveline components can cause

driveline failure, which can result in separation of the driveline

from the vehicle. A separated driveline can result in property

damage, serious personal injury, or death.

Reassembly of a driveline out of original phase can cause

vibration and failure of the driveline and attaching components. Driveline failure can result in separation of the driveline

from the vehicle, resulting in property damage, serious personal injury, or death.

Driveshaft assemblies can weigh in excess of 100 pounds (46

kilograms). Be sure to use proper lifting techniques when

handling driveshafts. More than one person may be needed

when handling driveshaft assemblies.

CAUTION

Never heat components, never use sledge hammers, and

never use floor jacks to disassemble driveshafts. This can

result in damaged, weakened, or bent components.

End Fitting

WARNING

Failure to torque bolts to specification can cause driveline failure, which can result in separation of the driveline from the

vehicle. A separated driveline can result in property damage,

serious personal injury, or death.

CAUTION

Use a journal locator to avoid nicking journal cross trunnions

or damaging oil seal slingers.

If a bearing assembly or journal cross is worn or damaged,

the universal joint assembly must be replaced.

Be sure the snap rings are properly seated in the snap ring

grooves.

Slip Member

WARNING

Excessive radial looseness in the slip member assembly can

cause imbalance or vibration in the driveshaft. Imbalance or

vibration can cause components to wear, which in turn can

result in separation of the driveline from the vehicle. A separated driveline can cause property damage, serious personal

injury or death.

Yoke (Includes Slip Yoke, Yoke Shaft, and Tube

Yoke)

A loose end-fitting can result in driveline failure, which can in

turn lead to separation of the driveline from the vehicle. A separated driveline can lead to property damage, serious personal injury, or death.

Universal Joint

WARNING

Excessive looseness across the end of universal joint bearing

cup assemblies can cause imbalance or vibration in the driveshaft assembly. Imbalance or vibration can cause component

wear, which can result in separation of the driveline. A separated driveline can lead to property damage, serious personal

injury, or death.

DO NOT reuse bolts or use inferior grade bolts. Reuse of bolts

and/or use of inferior grade bolts can cause driveline failure,

which can result in separation of the driveline from the vehicle. A separated driveline can result in property damage, serious personal injury, or death.

2

WARNING

A loose or damaged slip yoke seal allows contaminants to

invade the slip member assembly. Invasion of contaminants

into the slip member assembly can degrade the grease, and

damage slip member components, which can result in driveline separation. A separated driveline can result in property

damage, serious personal injury, or death.

DO NOT deform yoke cross holes by removing excessive

metal. Raised metal or deformed yoke cross holes can be a

cause of cross and bearing failure, which can result in separation of the driveline from the vehicle. A separated driveline can

result in property damage, serious personal injury, or death.

Yoke shaft assemblies can weigh in excess of 50 pounds

(23 kilograms). Be sure to use proper lifting techniques when

handling yoke shafts.

Page 5

Safety

Tubing

WARNING

Bent or dented tubing can cause imbalance or vibration in the

driveshaft assembly. Imbalance or vibration can cause component wear, which can result in separation of the driveline

from the vehicle. A separated driveline can result in property

damage, serious personal injury, or death.

CAUTION

Do not bend or dent the tube when handling or servicing

driveshaft.

Midship Nut

WARNING

DO NOT reuse the midship nut. Reuse of the midship nut can

cause driveline failure, which can result in separation of the

driveline from the vehicle. A separated driveline can result in

property damage, serious personal injury, or death.

DO NOT touch or disturb the micro-encapsulated adhesive

found on the midship nut threads. Doing so may initiate the

curing process and impair the installation of the nut. Premature curing of the micro-encapsulated adhesive will result in

the improper installation of the midship nut. Improper installation of this nut can cause driveline failure, which can result

in a separation of the driveline from the vehicle. A separated

driveline can result in property damage, serious personal

injury, or death.

Center Bearing

WARNING

Loose center bearing bracket bolts can result in driveline failure, which can result in separation of the driveline from the

vehicle. A separated driveline can result in property damage,

serious personal injury, or death.

Damaged center bearings or center bearing components can

cause imbalance or vibration in the driveshaft assembly.

Imbalance or vibration can cause component wear, which can

result in separation of the driveline from the vehicle. A separated driveline can result in property damage, serious personal injury, or death.

Foreign Material

WARNING

Build-up of foreign material, excessive paint, or undercoating

on a driveshaft can cause imbalance or vibration in the driveshaft assembly. Imbalance or vibration can cause component

wear, which can result in separation of the driveline from the

vehicle. A separated driveline can result in property damage,

serious personal injury, or death.

A contaminated slip member can result in separation of the

driveline from the vehicle. A separated driveline can result in

property damage, serious personal injury, or death.

Hardware

WARNING

Safety

Failure to torque the midship nut to required specifications

can cause driveline failure, which can result in separation of

the driveline from the vehicle. A separated driveline can result

in property damage, serious personal injury, or death.

A loose midship nut can result in driveline failure, which can

result in separation of the driveline from the vehicle. A separated driveline can result in property damage, serious personal injury, or death.

Loose, missing, or damaged bearing retainers or stamped

straps, retaining bolts, nuts, end fitting tangs, snap rings, or

rotating bearing cups can result in driveline failure. A separated driveline can lead to property damage, serious personal

injury, or death.

DO NOT reuse bolts, straps, nuts, or damaged bearing retainers, or use inferior grade bolts. Reuse of bolts, straps, nuts,

or damaged bearing retainers, or use of inferior grade bolts,

can cause driveline failure, which can result in separation of

the driveline from the vehicle. A separated driveline can result

in property damage, serious personal injury, or death.

CAUTION

If loosening or removing bolts, always install a new strap and

bolts and torque bolts to specification.

3

Page 6

Safety

Lubrication (When Applicable)

WARNING

A missing, loose, or fractured grease zerk (nipple) fitting or

plug eliminates the ability to lubricate the universal joint.

Improper or inadequate lubrication can cause driveline failure,

which can result in separation of the driveline from the vehicle. A separated driveline can result in property damage, serious personal injury, or death.

Improper lubrication techniques can cause driveline failure,

which can result in separation of the driveline from the vehicle. A separated driveline can result in property damage, serious personal injury, or death.

A missing, loose, damaged, or fractured plug or grease zerk

(nipple) fitting can allow contaminants to invade the universal

joint. Invasion of contaminants into the universal joint can

degrade grease and cause universal joint damage, which can

result in separation of the driveline from the vehicle. A separated driveline can result in property damage, serious personal injury, or death.

Incompatible greases that are applied to universal joints and/

or slip members can result in driveline failure and can result in

separation of the driveline from the vehicle. A separated driveline can result in property damage, serious personal injury, or

death.

Hand tightening of grease zerk (nipple) fittings or plugs is

NOT recommended. Failure to torque grease zerk (nipple) fittings to specifications can result in separation of the driveline

from the vehicle. A separated driveline can cause property

damage, serious personal injury, or death.

CAUTION

In cold temperatures, be sure to drive the vehicle immediately

after lubrication. This activates the slip spline and removes

excess grease. Failure to do so could cause excess grease to

stiffen in the cold weather and force the plug out. The end of

the spline would then be open to collect contaminants and

cause the spline to wear and/or seize.

All slip yoke and universal joint seals should be completely

purged.

4

Page 7

Inspection

Inspection

Spicer 10 Series™ Driveshafts should be carefully inspected

at recommended original-equipment manufacturer’s service

intervals and/or at Spicer recommended lubrication intervals

as shown in the Lubrication section on page 11.

End Fitting Inspection

This information refers to axle, transmission, transfer case,

and center bearing end fittings. Please refer to the End Fitting

information in Component Safety on page 2.

1. Visually inspect all end-fitting retaining nuts or bolts

for any gaps or looseness between mating surfaces.

If gaps are present, consult transmission, axle, or

transfer case original-equipment manufacturer’s service and maintenance manual for proper fastener

specifications. If looseness is evident between the

nut, yoke, or center bearing, take the driveshaft to a

qualified driveshaft facility for further inspection and

repair.

2. Check all end fittings for looseness. Grasp the end

fitting with both hands and try to move it vertically

and horizontally to feel any looseness.

3. Grasp the end fitting with both hands and rotate left

to right, feeling for play and backlash. There should

not be any movement in the end fittings relative to

the output or input shafts to which they are connected. If looseness is evident, consult transmission,

axle, or transfer case original-equipment manufacturer’s service and maintenance manuals for proper

end fitting to shaft specifications.

Inspection

4. Visually inspect for:

• damaged half round bearing straps

• loose bearing strap bolts

• loose companion flange bolts and nuts

• damaged or worn tangs on end fittings

• damaged or missing snap rings

• rotating bearing cups

If any of these conditions are present, component replacement is necessary. Refer to the original-equipment manufacturer’s recommendations for removal instructions.

5

Page 8

Inspection

Bearing Plate (Full Round) Yoke Inspection

Please refer to the End Fitting information in the Component

Safety section on page 2.

1. Refer to original-equipment manufacturer for

removal of the driveshaft from the vehicle.

2. Place the driveshaft in v-blocks to remove the cross

and bearing assemblies. Completely remove the

cross and bearings from the yokes at both ends of

the driveshaft using a universal joint removal tool.

Next, disassemble the bearing assemblies from the

slip yoke (and flange yoke, where applicable), using

a tool kit.

4. Check the yoke lug cross holes with a No-Go Wear

Gauge, and then use a Spicer Alignment Bar to

inspect for damage by sliding through both cross

holes simultaneously.

The alignment bar will identify yoke lugs that have

taken a set because of excessive torque. The raised

metal or distorted lugs can be a cause of premature

cross and bearing problems.

5. If, after proper cleaning of the cross holes, the alignment bar will not pass through both cross holes

simultaneously, the yoke lugs are distorted, and the

yoke or yokes should be replaced.

3. Clean the cross holes on the yoke, and inspect the

cross hole surfaces for damage or raised metal.

Raised metal or fretting can be removed from yoke

cross holes with a fine-toothed file and/or emery

cloth.

WARNING

DO NOT deform yoke cross holes by removing excessive

metal. Raised metal or deformed yoke cross holes can

cause cross and bearing failure, which can result in separation of the driveline from the vehicle.

6

Page 9

Inspection

Quick Disconnect™ (Half Round) End Yoke Inspection

Please refer to the End Fitting information in the Component

Safety section on page 2.

1. Remove the universal joint assembly from the end

yoke, and clean the cross hole surfaces for inspection.

2. Inspect the cross hole surfaces for damaged or

raised metal. Raised metal or fretting can be

removed from yoke cross holes with a fine-toothed

file and/or emery cloth.

WARNING

DO NOT deform yoke cross holes by removing excessive

metal. Raised metal or deformed yoke cross holes can

cause cross and bearing failure, which can result in separation of the driveline from the vehicle.

Inspect the bearing caps for any indication of rotation within the cross holes. If rotation is apparent,

the yoke should be replaced.

3. Check the yoke for cross hole alignment using the

Spicer alignment gauge. Place the correct bushing in

each lug ear, allowing a .030" (.75 mm) to .060"

(1.5 mm) clearance between the tang and the bushing.

4. Assemble bearing straps and bolts, tightening bolts

a minimum of 30 lbs. ft. (41 N•m). Insert the alignment bar into one bushing. If the bar enters and

passes through the opposite bushing, alignment is

correct. If the alignment bar will not enter the opposite bushing, re-inspect for yoke seat burrs.

Inspection

5. If, after proper cleaning, the alignment bar still does

not pass through both bushings, the yoke lugs are

distorted, and the yoke should be replaced.

7

Page 10

Universal Joint Inspection

Inspection

Please refer to the Universal Joint information in the Component Safety section on page 2.

1. Check for excessive looseness between the ends of

the universal joint bearing cup assemblies and trunnions.

2. Grasp the inboard yoke on the driveshaft with both

hands and attempt to move the yoke horizontally and

vertically. There should be less than .006" (.15 mm)

movement in the universal joint relative to the

inboard or outboard yokes. If looseness is greater

than .006" (.15 mm) in either direction, the universal

joint must be replaced. See Disassembly and Reassembly on page 16.

Re-lubable Style Universal Joints

1. With re-lubable style universal joints, check for the

presence of all grease zerk (nipple) fittings. Grease

zerk (nipple) fittings should not be missing, loose, or

fractured.

2. If a grease zerk (nipple) fitting is loose, tighten it to

required specifications. See the Universal Joint

Grease Zerk (Nipple) Fitting and Plug Torque table on

page 26.

3. If a grease zerk (nipple) fitting is fractured or missing, the entire universal joint must be replaced. Refer

to Disassembly and Reassembly on page 16 for

removal and replacement instructions.

Permanently Greased Plug Style Universal Joints

Please refer to the Universal Joint information in Component

Safety on page 2.

1. Permanently greased plug style universal joints have

a plug rather than grease zerk (nipple) fittings. Make

sure the plug is not missing, loose, or fractured. If

the plug is loose, tighten it to required specifications.

See the Universal Joint Grease Zerk (Nipple) Fitting

and Plug Torque table on page 26.

2. If a plug is missing or fractured, the entire universal

joint must be replaced. Refer to recommendations in

the Disassembly and Reassembly on page 16 for

removal and replacement instructions.

8

Page 11

Inspection

Slip Member Assembly

This information refers to slip yokes and tube shaft assemblies. Please refer to the Slip Member information in the Component Safety section on page 2.

1. Check all slip yoke assemblies to be sure the slip

yoke plug is not loose, missing, or damaged. If any

of these situations are evident, replacement of the

yoke assembly is necessary.

2. Visually inspect for the presence of the grease zerk

(nipple) fitting, if applicable, on the slip yoke. Grease

zerk (nipple) fittings should not be missing, loose, or

fractured.

Tubing

Please refer to the Tubing information in the Component

Safety section on page 2.

1. Check the driveshaft for bent or dented tubing or

missing balance weights. If any of these conditions

is evident, replacement of the complete driveshaft

assembly or tube is necessary.

2. Make certain there is no build-up of foreign material

on the driveshaft. If found, build-up should be

removed carefully to avoid damaging the driveshaft.

CAUTION

Do not allow solvents to come in contact with seals or

greasible areas of the driveshaft assembly. If foreign material cannot be removed without complete assurance that the

driveshaft will not be damaged, the complete driveshaft

should be replaced with a new OEM driveshaft.

Inspection

3. If a grease zerk (nipple) fitting is loose, tighten it to

required specifications. See the Universal Joint

Grease Zerk (Nipple) Fitting and Plug Torque table on

page 26.

4. If a grease zerk (nipple) fitting is missing or damaged, the slip member assembly must be replaced.

5. Check the slip yoke seals and dust caps. Make sure

the seal is properly attached to the slip yoke and is

not loose or damaged. If any of these situations are

evident, replacement of the slip member and/or seal

may be necessary.

6. For an inboard and outboard slip yoke assembly

design, check to be sure the slip yoke welch plug is

not loose, missing, or damaged.

7. If there is excessive looseness between the mating

components, with the presence of vibration, all slip

assembly components should be replaced.

9

Page 12

Center Bearings

Inspection

Please refer to the Center Bearing information in the Component Safety section on page 2.

1. Inspect the center bearing bracket bolts for looseness. If looseness is evident, re-tighten the center

bearing bracket bolts. Consult the vehicle manufacturer’s documentation for proper bolt torque. Check

the alignment of the bracket before tightening the

bolt. Bracket should not be skewed more than 3° in

relation to the centerline of the driveshaft.

2. Visually inspect the center bearing rubber cushion

for damage. Make sure the slingers are not rubbing

against the rubber cushion. Verify that the rubber

cushion is properly seated in the metal bracket. If

any of these conditions are evident, replacement of

the center bearing assembly is necessary. Refer to

recommendations in the Disassembly and Reassembly on page 16 for proper center bearing replacement procedures.

Midship End Fitting

Please refer to the safety information in the General Safety

section and the Midship Nut information in the Component

Safety section on page 2.

1. Inspect the center bearing end fitting and bolt hole

threads for damage. If the bolt hole threads are damaged, the end fitting must be replaced.

2. Check the center bearing end fitting and fitting nut

washer for any looseness. Grasp the end fitting with

both hands, and try to move it both vertically and

horizontally to feel for looseness. There should NOT

be any movement in the center bearing end fitting

relative to the midship tube shaft to which it is connected. If any of these conditions are present, the

center bearing end fitting and midship tube shaft

must be replaced as a pair.

3. Refer to the End Fitting Inspection section on page 5

for proper procedures.

10

Note: Repeat the same inspection steps for all center bearings

within the driveline.

Page 13

Lubrication

Lubrication

Lack of proper lubrication is among the most common causes

of universal joint and slip member problems. Properly sized

Spicer universal joints that are adequately lubricated at recommended intervals will normally meet or exceed vehicle

operation requirements.

Note: Spicer 10 Series™ relube style universal joints contain

only enough grease to provide needle roller bearing protection during storage and shipment. It is therefore necessary to completely lubricate each replacement

universal joint after assembly into the end fitting.

Inadequate service intervals and failure to properly lubricate

the universal joints will cause universal joint failures. Proper

lubrication purges all universal joint seals, thus removing

abrasive contaminants from the bearing assemblies. Slip

members must also be adequately lubricated to prevent slip

member failure.

Members Lubrication Intervals

1. Carefully review the lubrication specifications found

in this manual.

2. Be sure to lubricate at the recommended intervals.

See the table below.

3. Be sure to use only recommended greases that meet

the listed criteria. See “Lubrication for Universal

Joints” on page 12.

4. Carefully follow driveshaft inspection procedures as

outlined in this manual.

Note: It is essential that all bearing seals be completely

purged of old grease and contaminants. If only fresh

grease can be seen at all seals, the purging process is

complete, and the universal joint is properly lubricated.

Spicer 10 Series™ Universal Joint and Slip

The Spicer 10 Series™ Driveshafts include 1310 through 1880.

City Highway Line Haul On/Off Highway Off-Highway

and Industrial*

Lubrication

5,000/8,000 Miles

(8,000/12,000Km)

or

3 months

(whichever comes first)

*Grease cycles for off-highway and industrial uses vary depending on the application and operating conditions. In general, to

obtain maximum life, lubrication should occur every 500 hours for normal service and every 200 hours for continuous service

or severe environmental conditions.

Spicer Driveshaft recommends lubricating with a compatible grease meeting N.L.G.I. Grade 2 specifications with an operating

range of +325° F to -10° F (163° C to -23° C). For more information on Spicer Driveshaft lubrication intervals, please refer to

Form #3283-SDD.

• City is defined as all applications requiring a mini-

mum of 90 percent of operation time within city limits.

• Highway is defined as all applications requiring less

than 10 percent of operating time on gravel, dirt, or

unpaved roads.

• Line Haul is defined as 100 percent of operating

time on smooth concrete or asphalt.

10,000/15,000 Miles

(16,000/24,000Km)

or

3 months

(whichever comes first)

10,000/15,000 Miles

(16,000/24,000Km)

or

30 days

(whichever comes first)

• On/Off Highway is defined as all applications operat-

• Off-Highway and Industrial is defined as 100 per-

5,000/8,000 Miles

(8,000/12,000Km)

or

3 months

(whichever comes first)

ing primarily on paved roads but requiring more than

10 percent of operating time on gravel, dirt, or

unpaved roads.

cent on gravel, dirt, or unpaved roads, or stationary

applications.

500/200 Hrs.

11

Page 14

Lubrication for Universal Joints

Lubrication

Spicer recommends the following requirements be met for

any grease used to service most vehicular and industrial

applications and all auxiliary driveshaft applications:

• Use a good quality E.P. (extreme pressure) grease

(Timken Test Load - 50 lbs. / 23 kg. minimum), and

that

• Meets N.L.G.I. (National Lubricating Grease Institute) Grade 2 specifications, and has an

• Operating range of +325° F to -10° F (163° C to 23° C), which is

• Compatible with commonly used multi-purpose

greases. For information about grease compatibility,

see the Grease Compatibility section below. Consult

your local grease source for greases that meet these

specifications.

Note: There are instances when special lubrication is required

due to original-equipment manufacturer specifications

or customer requests. The lubrication recommendations

listed in this manual are authorized by Spicer Driveshaft

engineering. Any alternate greases or lubrication procedures are the responsibility of the user.

Grease Compatibility

To help reduce the effects of incompatible greases, be sure to

thoroughly purge all four bearing seals on each universal joint

with the new grease. Purge seals until the fresh grease is visible on the outside of all four bearing seals. It is recom-

mended that all purged grease be wiped clean to prevent

discharge into the general environment. Contact your local

grease supplier for grease compatibility information.

Lubrication Procedure for Universal Joints

Please refer to the Lubrication information in the Component

Safety section.

Required Materials:

• N.L.G.I. Grade-2, E.P. Grease

• Grease gun

May Need If Bearing(s) Will Not Purge:

•C-Clamp

• New straps

•New bolts

1. Use the proper grease to purge all four seals of each

universal joint. This flushes abrasive contaminants

from each bearing assembly and assures all four

bearings are filled. Purge the seals. Spicer seals are

made to be purged. Make sure fresh grease is evident at all four universal joint bearing seals.

2. If any of the seals fail to purge, try to push the driveshaft away from the seal that will not purge, while

applying grease gun pressure. There will occasionally be one or more bearing assemblies that will not

purge.

12

Page 15

Quick Disconnect™ (Half Round) Universal Joints

Lubrication

Series Strap Kit

Assemblies

1310 2-70-18X 13-18 lbs. ft. 17.6 - 24.4

1330 2-70-18X 13-18 lbs. ft. 17.6 - 24.4

1350 3-70-18X 30-35 lbs. ft. 40.7 - 46.5

1410 3-70-18X 30-35 lbs. ft. 40.7 - 46.5

1480 3-70-28X 45-60 lbs. ft. 61 - 81.3

1550 3-70-28X 45-60 lbs. ft. 61 - 81.3

1610 5-70-28X 45-60 lbs. ft. 61 - 81.3

1710 6.5-70-18X 115-135 lbs. ft. 162.7 - 183

1760 6.5-70-18X 115-135 lbs. ft. 162.7 - 183

1810 6.5-70-18X 115-135 lbs. ft. 162.7 - 183

The bolt torque specifications refer to Spicer bearing straps and bearing plates only. If using original-equipment bearing straps

and bearing plates, refer to manufacturer’s service manual for proper bolt torque specifications.

Note: Unless otherwise noted all recommended bolt torques are with dry threads.

1. If any of the bearing assemblies fail to purge removal

of the driveshaft is necessary. See the originalequipment manufacturer for proper driveshaft

removal procedures.

2. Place the driveshaft in v-blocks and apply a C-clamp

across the half round bearings. Apply grease gun

pressure. Completely purge both bearings.

3. If outboard bearings fail to purge, slightly loosen Cclamp and reapply grease gun pressure until both

half round bearings purge.

Recommended

Bolt Torque

4. After all four bearings purge fresh grease, re-tighten

the C-clamp to squeeze out excess grease and wipe

clean. This will ease installation of universal joint kit

back into yoke. Install universal joint kit in the yoke

using new straps and bolts, and torque bolts to the

required specifications. Reference bolt torque specifications in the above table.

5. If the bearings still will not purge, complete removal

of the universal joint kit is needed to determine the

cause of blockage. Refer to original-equipment manufacturer's service manual for removal procedures.

N•m

Lubrication

13

Page 16

Bearing Plate (Full Round) Universal Joints

Lubrication

Series Bolt

Part Number

1610 5-73-709 26-35 lbs. ft. 35.3 - 47.5

1710 6-73-209 38-48 lbs. ft. 51.5 - 65.1

1760 6-73-209 38-48 lbs. ft. 51.5 - 65.1

1810 6-73-209 38-48 lbs. ft. 51.5 - 65.1

1880 7-73-315 60-70 lbs. ft. 81.3 - 94.9

The bolt torque specifications refer to Spicer bearing straps and bearing plates only. If using original-equipment bearing straps

and bearing plates, refer to manufacturer’s service manual for proper bolt torque specifications.

Note: Unless otherwise noted all recommended bolt torques are with dry threads.

1. There will occasionally be one or more bearing

assembly seals that will not purge. Release seal tension by loosening the bolts holding the bearing

assembly that does not purge. It may be necessary

to loosen the bearing assembly approximately 1/16"

minimum. If loosening it does not cause purging,

remove the bearing assembly to determine the cause

of blockage.

Note: It is essential that all seals be completely purged of old

grease and contaminants. If fresh grease can be seen at

these seals, the purging process is complete, and the

universal joint is properly lubricated.

Recommended

Bolt Torque

Snap Ring Universal Joints

1. There will occasionally be one or more bearing

assembly seals that will not purge. If any of the seals

will not purge, replacement of the universal joint kit

is necessary. See the Reassembly - Inboard Slip

Style under “Center Bearing Assembly” on page 20

for proper replacement procedures.

N•m

Note: Spalling and/or brinelling can be caused if contami-

nants (water, air, etc.) are left in the universal joint and/

or the bearing seals. Purge old grease thoroughly.

2. Install new bolts, and torque to specifications in the

above table.

14

Page 17

Lubrication for Slip Members

Lubrication

Please refer to the Lubrication information in the Component

Safety section on page 2.

The grease used for universal joints is satisfactory for slip

members. Glidecote® and steel splines both use a high quality E.P. grease meeting N.L.G.I. Grade 2 specifications.

Grease splines at the intervals recommended in the Lubrication Intervals table page 11.

1. Apply grease gun pressure to the grease zerk (nipple) fitting until grease appears at the pressure relief

hole in the plug.

Lubrication of Center Bearing Assemblies

Spicer center bearings are lubricated for life. No attempt

should be made to add to or change grease within the bearing

itself.

Note: For pillow blocks, use original-component manufac-

turer’s recommended greases and lubrication intervals.

Lubrication

2. Now cover the pressure relief hole with your finger

and continue to apply pressure until grease appears

at the slip yoke seal.

Note: Use caution to prevent seal damage when using high

pressure lubrication systems.

15

Page 18

Disassembly and Reassembly

Disassembly and Reassembly

For procedures used in the removal and installation of Spicer

Driveshafts from the vehicle, please consult the vehicle manufacturer’s service manual. This manual concerns itself only

with the disassembly and reassembly of driveshaft components.

Universal Joint

Disassembly - Snap Ring Design

Please refer to the Universal Joint information in the Component Safety section on page 2.

With the driveshaft removed, the following procedure should

be followed:

1. Using snap ring pliers, remove the snap rings from

the yoke ears.

2. Set the yoke in the arbor press with a piece of tube

stock beneath it. Position the yoke with the universal

joint grease zerk (nipple) fitting pointing up to prevent interference during disassembly. Place an

appropriate push rod on the upper bearing assembly,

and press it through to release the lower bearing

assembly.

CAUTION

Do not distort yoke ears with excessive force while in the

arbor press.

3. If the bearing assembly will not pull out by hand after

pressing, grip the bearing cup and pull from the

yoke.

4. Place the yoke in the arbor press with the remaining

bearing cup face down. Using an appropriate push

rod, press on the end of the journal cross trunnion.

Continue to press down on the journal cross trunnion until the shoulder of the journal cross makes

contact with the inside of the yoke ear.

5. Repeat steps three and four on the remaining bearing assemblies to remove the cross from the yoke.

6. Inspect all yoke cross hole surfaces for damage.

Raised metal or fretting can be removed from yoke

cross holes with a fine-toothed file and/or emery

cloth.

16

Page 19

Disassembly and Reassembly

y

Reassembly - Snap Ring Design

Please refer to the Universal Joint information in the Component Safety section on page 2.

1. Using a high quality N.L.G.I., grade 2 extreme pressure (E.P.) grease, apply adequate grease to each

bearing cup assembly. Fill all the cavities between

the needle rollers, and also apply a liberal coating of

grease in the bottom of each bearing cup and on the

lip of the seal. Be careful not to get grease on the

outside machined surface of the bearing cup.

2. Position the journal cross in the yoke cross holes

with the grease zerk (nipple) fitting inward toward

the tubing. Failure to properly position the univer-

sal joint may result in the inability to lubricate the

universal joint. If using an arbor press, proceed to

Step 3. If using a universal joint installation tool, follow the tool manufacturer’s instructions.

3. Move one end of the journal cross to cause a trunnion to project through the cross hole beyond the

outer machined face of the yoke ear. Check the bearings for skewed or dropped needle rollers. Place the

bearing cup assembly over the protruding trunnion

diameter and align it to the yoke cross hole. Align the

yoke in an arbor press with the bearing assembly

resting on the base of the press. Cover the yoke ear

with a metal plate that has .150" (6.4 mm) minimum

thickness. Push the yoke onto the bearing cup

assembly until it is flush with the cross hole face.

Disassembly and

Reassembl

4. Place a push rod that is smaller than the diameter of

the bearing cup assembly under the bearing cup

assembly, and continue pressing into the yoke cross

hole until a snap ring can be installed.

5. Remove the yoke from the arbor press. Install a snap

ring using snap ring pliers.

17

Page 20

Disassembly and Reassembly

6. Flip the yoke 180°. Check the bearings for skewed or

dropped needle rollers. Place another bearing cup

assembly over trunnion diameter, and align it to the

yoke cross holes. Align the yoke in arbor press with

previously installed bearing cup assembly resting on

the base of the press. Place a push rod that is

smaller than the bearing cup assembly on top of the

bearing cup assembly. Press bearing cup assembly

into the yoke cross hole until a snap ring can be

installed.

7. Remove the yoke from the arbor press. Install a snap

ring using snap ring pliers.

Disassembly - Bearing Plate Style

Please refer to the Universal Joint information in the Component Safety section on page 2.

With the driveshaft removed, see “Inspection” on page 5 for

Bearing Plate (Full Round) Yoke Inspection disassembly procedures.

Reassembly - Bearing Plate Style

Please refer to the Universal Joint information in the Component Safety section on page 2.

1. Remove the cross and bearings from the box and

remove all four bearing assemblies. Rotate the cross

to inspect for the presence of a positive purging

valve in each grease hole of all four trunnions. Then

position the cross into the end yoke with its grease

fitting in line as near as possible with the slip spline

grease fitting. Keep the grease fitting on the inboard

side.

2. Using a high quality N.L.G.I., grade 2 extreme pressure (E.P.) grease, apply adequate grease to each

bearing cup assembly. Fill all the cavities between

the needle rollers, and also apply a liberal coating of

grease in the bottom of each bearing cup and on the

lip of the seal. Be careful not to get grease on the

outside machined surface of the bearing cup.

8. Ensure snap rings are seated into the snap ring

grooves.

9. Flex the journal cross to make sure it moves freely

by hand. Some resistance is acceptable. If it does

not move freely, tap the yoke ear as shown.

3. Position one end of the cross to cause a trunnion to

project through the hole beyond the outer machined

face of the yoke lug.

18

Page 21

Disassembly and Reassembly

y

4. Place a bearing assembly over the trunnion diameter

and align it to the cross hole.

5. Holding the trunnion in alignment with the cross

hole, install the bearing assembly by hand until it is

flush with the face of the end yoke. If the universal

joint bearing cap is pressed into place, the bearings

and bearing surfaces could be damaged.

6. If the bearing assembly binds in the cross hole, tap it

with a soft-faced hammer directly on the center

bearing assembly. Do not tap the outer edges of the

bearing assembly.

7. When the bearing assembly is completely seated,

put the lock plate tab (if used) in place and use the

"Grade 8" cap screws furnished with the universal

joint and insert them through the cap screw holes in

both the lock strap and/or the bearing plate assembly. Thread by hand or with a wrench into the tapped

holes in the yoke. Do not torque down the bolts.

Note: The self-locking bolt design for full round yokes uses

serrated bolts with lock patch and does not require a

lock strap. DO NOT reuse any retaining bolt. If loosening

or removal of a bolt is necessary, replace it with a new

one.

Disassembly and

Reassembl

CAUTION

Exact fit of all driveline components is extremely important.

The correct parts and clean mating services are essential

for safe operation, long life, and good repair.

8. Move the cross laterally to the opposite side and

through the cross hole, beyond the machined surface of the yoke lug. Place a bearing assembly over

the cross trunnion and slide it into the cross hole,

seating the plate to the face of the lug. Thread the

bolts by hand or with a wrench into tapped holes in

the yoke.

Note: Projecting the trunnion through a cross hole beyond the

machined surface of the lug will provide a surface to

help align the bearing assembly with the cross hole.

9. For flange yoke applications, install the flange yoke,

bearing assemblies, and bolts at this time.

19

Page 22

Disassembly and Reassembly

Center Bearing Assembly

Disassembly - Inboard Slip Style

Please refer to the Center Bearing information in the Component Safety section on page 2.

3. Mark the counterbore of the coupling shaft end yoke

to midship “nose” with a marking stick, paint marker

or other legible marking device. This assures proper

reassembly of the coupling shaft end yoke in its original phased position.

This information includes procedures for disassembling SAE,

DIN, and T-Type Companion Flange / Flange Yoke, Quick Disconnect, and Bearing Plate Styles.

1. Remove the midship nut. Reference the midship nut

specification in the Midship Nut Specifications table.

Discard the nut. If the washer is damaged, discard

and replace it. Otherwise, reuse the washer.

Note: The midship nut can be removed when the coupling

shaft is still in the vehicle. For coupling shaft removal,

please refer to original-equipment manufacturer’s service document.

4. Using a puller, follow the tool manufacturer’s

instructions to remove the end fitting. The end fitting

has a press fit and should NOT be removed with a

hammer. If the end fitting is loose enough to be

removed by hand, the entire coupling shaft must be

replaced. Remove and discard the slinger from the

yoke.

5. Visually inspect the splines of the center bearing end

yoke. If the yoke splines are damaged, missing or

twisted, the yoke must be replaced. If the yoke hub

has cracked, the yoke must be replaced.

2. Remove driveshaft per original-equipment manufacturers instructions, and then place the driveshaft in

v-blocks.

20

6. Visually inspect the midship splines and threads. If

the splines or threads are damaged, missing or

twisted, replacement of the entire coupling shaft is

necessary.

Page 23

Disassembly and Reassembly

y

7. On some Spicer center bearing assemblies, a metal

retainer spans the outside center bearing bracket. If

the metal retainer is present, remove it and discard.

8. Remove and discard the center bearing bracket.

10. Using a puller, follow the tool manufacturer’s

instructions to remove the bearing assembly from

the midship. Discard the center bearing.

11. Inspect the midship for wear on the bearing diameter. If the midship is damaged from a seized bearing,

replacement of the entire coupling shaft is necessary.

Disassembly and

Reassembl

9. Remove and discard the rubber cushion.

12. If no damage is apparent, remove the slinger, and

proceed to the installation of the center bearing,

described in the "Reassembly - Inboard Slip Style"

section.

21

Page 24

Disassembly and Reassembly

Midship Nut Specifications Table

Series Nut Nut Washer Head Size Nut Torque

Part Number Catalog Color Part Number N•m lbs. ft.

1310 231781 cadium plate

& wax

1310

(Toyota Only)

1410 16-74-101 silver 230123-15 1-5/16" 373-440 275-325

1480 16-74-101 black 230123-15 1-5/16" 542-610 400-450

1480 16-74-101 silver 230123-15 1-5/16" 373-440 275-352

1550 231502 black none 1-5/8" 644-712 475-530

1610 231502 black none 1-5/8" 644-712 475-525

1710 20-74-91 black 230123-6 1-5/8" 644-712 475-525

1710 231502 black none 1-5/8" 644-712 475-525

1760 20-74-91 black 230123-6 1-5/8" 644-712 475-525

1810 20-74-91 black 230123-6 1-5/8" 644-712 475-525

Disassembly - Outboard Slip Style

1. Mark the slip yoke barrel and midship tube shaft with

a marking stick, paint marker, or other legible marking device. This ensures proper reassembly of the

mating components in their original phased position.

10-74-101 cadium plate

& wax

230123-12

230123-14

230123-12

230123-14

5. Remove and discard the center bearing bracket.

15/16" 136-163 100-120

15/16" 136-163 100-120

2. Refer to original-equipment manufacturer's instructions for removal of the coupling shaft.

3. Visually inspect midship tube shaft, looking for wear

on spline surface. If splines are damaged, missing or

twisted, or Glidecote® is missing, replacement of

entire coupling shaft is necessary.

4. On some Spicer center bearing assemblies, a metal

retainer spans the outside center bearing bracket. If

the metal retainer is present, remove it and discard.

22

6. Remove and discard the rubber cushion.

Page 25

Disassembly and Reassembly

y

7. Using a puller, follow the tool manufacturer’s

instructions to remove the bearing assembly from

the midship. Discard the center bearing.

8. Inspect the midship for wear on the bearing diameter. If the midship is damaged from a seized bearing,

replacement of the entire coupling shaft is necessary.

Reassembly - Inboard Slip Style

Please refer to the Center Bearing information in the Component Safety section on page 2.

This information pertains to SAE, DIN, and T-Type Companion

Flange/Flange Yoke, Quick Disconnect, and Bearing Plate

styles.

1. Wipe the bearing surface of the midship tube shaft

with a fine emery cloth.

2. Install a new slinger (included in the center bearing

replacement parts kit) on the midship tube shaft. Use

a section of tubing to avoid damaging the slinger.

Make sure the slinger is completely seated against

the midship tube shaft shoulder.

3. Before installing the new center bearing assembly,

be sure to fill the entire cavity around the bearing

with a waterproof lubricant.

Enough lubricant must be applied to fill the cavity to

the extreme edge of the slinger surrounding the

bearing. Lubricants must be waterproof.

Disassembly and

Reassembl

9. If no damage is apparent, remove the slinger and

proceed to the installation of the center bearing,

described in the "Reassembly - Outboard Slip Style"

section.

Recommended Center Bearing Lubricants

Lubricants Source

Rykon Premium No. 3 Amoco Oil Company

Amolith 8516 Amoco Oil Company

Van Talgar No. 4 Exxon Company

23

Page 26

Disassembly and Reassembly

4. Carefully align the new center bearing assembly with

the ground surface of the midship tube shaft. Install

the center bearing onto the midship tube shaft. Minimal force should be necessary to push the center

bearing onto the midship tube shaft, provided the

shaft and bearing are in alignment.

5. Install the remaining slinger on the end yoke using a

section of tubing to avoid damaging the slinger.

6. Make sure that the phasing marks from driveshaft

removal are aligned, and using an installation tool,

press the yoke onto the midship tube shaft. Do not

strike yoke with hammer or use midship nut to

install yoke.

7. Installation of the driveshaft onto the vehicle can

now proceed. Refer to the vehicle manufacturer’s

documentation for installation procedures. See the

Midship Nut information in the Component Safety

section on page 2.

Midship Nut Installation Procedure

Only work on components when they are cool to the touch.

Installing the midship nut onto a threaded midship which is

above the ambient temperature will cause the adhesive to cure

too rapidly, and the midship nut may not install correctly.

Do not use the midship nut to pull the end fitting onto the

midship. This may result in improper seating of the end fitting

and will begin the curing of the midship nut adhesive. As a

result, the midship nut may not install correctly.

1. Visually inspect the midship washer (if applicable)

for flatness, corrosion, or cracks. If the washer is

bent, corroded, or cracked, the washer must be

replaced.

2. Thoroughly clean midship threads with mineral spirits. Wipe the midship threads dry with a clean, dry

rag. Do not use a wire brush to clean threads. This

may distort the midship threads and result in the

midship not being able to properly retain the midship

nut.

3. Thoroughly clean the midship washer (if applicable)

and the inboard, machined face of the end fitting

with mineral spirits. Wipe components with a clean,

dry cloth.

4. Do not apply any additional compounds to midship

threads, washer (if applicable), or nut. These compounds may interfere with the adhesive that is preapplied to the midship nut and will be detrimental to

its effectiveness. Unacceptable compounds include,

but are not limited to:

• thread lockers, such as Loctite.™

• anti-seizing compounds, such as Never-Seez.™

• lubricants, such as oil, grease, silicone, graph-

ite, or soap.

5. Install the midship washer (if applicable) onto the

midship and up against the machined surface of the

end fitting.

24

6. By hand, start the midship nut onto the midship

threads until it will no longer spin freely. Use a

socket and a torque wrench with a suggested range

of 600 lbs. ft. (800 N•m) or equivalent device capable of installing the midship nut to a final torque at a

maximum rate of 120 rpm. (Refer to the Midship Nut

Specifications table for proper socket size and

torque specs.)

Page 27

Disassembly and Reassembly

y

Reassembly - Outboard Slip Style

1. Wipe the bearing surface of the midship tube shaft

with a fine emery cloth.

2. Install a new slinger (included in the center bearing

replacement parts kit) on the midship tube shaft,

using a section of tubing to avoid damaging the

slinger. Make sure the slinger is completely seated

against the midship tube shaft shoulder.

3. When replacing a center bearing assembly, be sure

to fill the entire cavity around the bearing with a

waterproof lubricant. Enough lubricant must be

applied to fill the cavity to the extreme edge of the

slinger surrounding the bearing. Refer to the below

table.

Disassembly and

Reassembl

Recommended Center Bearing Lubricants

Lubricants Source

Rykon Premium No. 3 Amoco Oil Company

Amolith 8516 Amoco Oil Company

Van Talgar No. 4 Exxon Company

4. Carefully align the new center bearing assembly with

the ground surface of the midship tube shaft. Physically push the center bearing onto the midship tube

shaft. Minimal force should be necessary to push the

center bearing onto the midship tube shaft provided

the shaft and bearing are in alignment.

5. Press the remaining slinger on the midship tube

shaft using a section of tubing to avoid damaging the

slinger.

6. Installation of the driveshaft onto the vehicle can

now proceed. Refer to the vehicle manufacturer's

documentation for installation procedures. Ensure

phasing marks are aligned on mating components.

25

Page 28

Disassembly and Reassembly

Grease Zerk (Nipple) Fittings or Plugs

For procedures used in the removal and installation of Spicer

Driveshafts from the vehicle, please consult the vehicle manufacturer’s service manual.

Once the driveshaft has been removed or the defective grease

zerk (nipple) fitting or plug is accessible, follow the steps

listed in the Disassembly - Universal Joint section on page 16

for replacement. Please refer to the Lubrication information in

the Component Safety section page 2.

Universal Joints and Slip Member Assembly

1. Tilt the universal joint or flange yoke and universal

joint to allow access to the defective grease zerk

(nipple) fitting or plug. Using pliers or an openended wrench, turn the grease zerk (nipple) fitting or

plug counter-clockwise until it is removed from the

journal cross or slip member assembly. Discard the

grease zerk (nipple) fitting or plug.

2. Check the threads in the journal or slip member. If

threads are damaged, replacement of the universal

joint or slip member is necessary. See disassembly

procedures for universal joints and slip member in

the Disassembly and Reassembly section on

page 16.

3. Thoroughly wipe the grease zerk (nipple) fitting or

plug threaded hole.

4. Install the new grease zerk (nipple) fitting or plug.

Tighten to a minimum 40-55 lbs. in. (4.5 - 6.2 N•m).

Continue to turn only until the grease zerk (nipple)

fitting is correctly positioned.

Universal Joint Grease Zerk (Nipple) Fitting and Plug

Torque

Minimum Zerk Torque

Part Number Description N•m lbs. in.

500174-1 .250-28 NF

Tapered Thread

500168-2 .125-27 PTF 4.5 - 6.2 40 - 55

4.5 - 6.2 40 - 55

26

Page 29

Glossary

Glossary

Alignment Bar A device (gauge) used to check yoke cross hole alignment.

Ball Yoke See Tube Yoke.

Bearing Cross Hole See Cross Hole.

Bearing Cup Assembly Consists of a bearing cup with needle rollers, generally held in place by a seal guard and bear-

ing seal. Sometimes the assembly includes a thrust washer.

Bearing Cup A cup-shaped member used as the bearing bore of a bearing cup assembly and for positioning

a thrust end of a cross trunnion.

Bearing Seal A flexible member of a bearing cup assembly that prevents the escape of grease from or entry

of foreign matter into a bearing.

Bearing Strap A narrow, stamped metal plate used to retain a bearing cup assembly in a half round end yoke

or flange yoke design.

Center Bearing Consists of a rolling element bearing isolated in rubber and a bracket configuration for attach-

ment to the vehicle frame.

Glossary

Companion Flange A fixed flange member that attaches a driveshaft to another drivetrain component.

Coupling Shaft The coupling member or members of a multiple-piece driveline, which consists of a universal

joint, tube, center bearing, and a slip or fixed spline shaft.

Coupling Shaft Length

(Centerline to Centerline)

Cross See Journal Cross.

Cross Hole A through hole in each lug ear of a yoke used to locate a bearing assembly.

Deflector See Slinger.

Driveline An assembly of one or more coupling shafts and a driveshaft with provisions for axial move-

Driveshaft An assembly of one or two universal joints connected to a tubular shaft member, which

Driveshaft Length

(Centerline to Centerline)

Ear One of two projecting parts of a yoke symmetrically located with respect to the rotation axis of

End Fitting An end yoke or companion flange (including SAE, DIN, and T-Type styles) that attaches a

The distance between the outermost universal joint centers on a driveshaft. On coupling shafts

with fixed centers, it is the nominal dimension.

ment, which transmits torque and/or rotary motion at a fixed or varying angular relationship

from one drivetrain component to another.

accommodates axial movement.

The distance between the outermost universal joint centers on a driveshaft. On driveshafts with

variable length centers, driveshaft length is usually measured in the compressed or installed

lengths.

the yoke.

driveshaft to another drivetrain component.

End Yoke A half round yoke that attaches a driveshaft to another drivetrain component.

Flange Yoke A full round or half round style yoke that attaches a driveshaft to a companion flange.

Flinger See Slinger.

Glidecote® The blue, nylon, wear-resistant coating on Spicer yoke shafts and tube shafts.

Grease Zerk (Nipple) Fitting The fitting on the shoulder or center of a journal cross or on a greaseable slip spline that allows

for lubrication.

27

Page 30

Glossary

Half Round Cross Hole A semicircular hole located on the end of each lug ear of some end yoke and flange yoke

designs used to locate a bearing cup assembly.

Inboard Bearing Assembly Contained in inboard yoke.

Inboard Yokes Yokes that make up the ends of a driveshaft or coupling shaft assembly, i.e. tube yokes, slip

yokes, yoke shafts, and center bearing end yokes.

Journal Cross The core component of a universal joint, which is an intermediate drive member with four

equally spaced trunnions in the same plane.

Lug Ear See Ear.

Midship Shaft A machined element consisting of spline teeth, a pilot for a center bearing, and a piloting hub

that attaches to the tube of a coupling shaft assembly.

Needle Rollers One of the rolling elements of a bearing cup assembly.

Nib See Tang.

Outboard Bearing Assembly Contained in an outboard yoke.

Outboard Yokes Yokes that are not a part of a driveshaft or coupling shaft assembly, i.e. transmission, axle,

transfer case end yokes.

Phase Angle The relative rotational position for each yoke on a driveshaft or driveline.

Pillow Block Consists usually of a rolling element bearing and a bracket configuration for attachment.

Pressure Relief Hole A hole in the welch plug of Spicer slip yokes that allows air to escape from the slip member

assembly.

Purge The act of flushing old grease and contaminants from universal joints and slip member assem-

blies with fresh grease.

Retaining Ring See Snap Ring.

Retaining Ring Groove See Snap Ring Groove.

Round Bearing Assembly See Bearing Cup Assembly.

Seal Guard A covering member used to protect a bearing seal on the bearing cup assembly.

Serrated Flange See T-Flange.

Shaft Support Bearing See Center Bearing.

Slinger A stamped metal or non-metal ring, which prevents the entry of foreign matter into a center

bearing, transmission, axle, or transfer case.

Slip The total permissible length of axial travel.

Slip Yoke A yoke that accommodates axial movement.

Slip Yoke Plug See Weld Plug.

Slip Yoke Seal Pop-on or threaded ring that contains a seal that protects the slip member assembly from envi-

ronmental contaminants and retains grease.

Snap Ring A removable member used as a shoulder to retain and position a bearing cup assembly in a

yoke cross hole.

Snap Ring Groove A groove used to locate a snap ring.

Spline A machined element consisting of integral keys (spline teeth) or keyways (spaces) equally

spaced around a circle or portion thereof.

28

Page 31

Glossary

Stub Shaft See Tube Shaft.

Tang A nib of metal found on half round end yoke and/or flange yoke style cross holes, used to

locate a bearing cup assembly.

T-Flange A companion flange and flange yoke design, which has a serrated flange face. Found most

often in European applications.

T-Type Flange See T-Flange.

Thrust Washer A washer found in the bottom of a bearing cup assembly that reduces needle roller friction and

bearing heat, and guards against end galling on the journal cross trunnions.

Tube The tubular connecting member of a driveshaft. Pipe or piping is not an equivalent.

Tubing See Tube.

Tube O.D. The outside diameter (O.D.) of a tube.

Tube Yoke An inboard yoke with a piloting hub for attachment to a tube or spline sleeve.

Tube Shaft A machined element consisting of spline teeth and a piloting hub that attaches to the tube of a

driveshaft assembly.

Glossary

Trunnion(s) Any of four projecting journals of a cross.

Universal Joint A mechanical device that can transmit torque and/or rotary motion from one shaft to another at

fixed or varying angles of intersection of the shaft axes. Usually consisting of a journal cross,

grease zerk (nipple) fitting, and four bearing cup assemblies.

U-Joint See Universal Joint.

Welch Plug A plug in the slip yoke face that seals off one end of the spline opening. Also known as a slip

yoke plug.

Weld Yoke See Tube Yoke.

Yoke Lug Ear Cross Hole See Cross Hole.

Yoke Shaft A slip member yoke with a male machined spline used for axial movement.

29

Page 32

For spec‘ing or service assistance, call 1-877-777-5360 or visit our website at www.dana.com

Dana Commercial Vehicle Products Group

3939 Technology Drive

Maumee, Ohio, USA 43537

www.dana.com

All applications must be approved by the Application Engineering Department. Specifications and/or design are subject to change without notice or obligation. Printed in USA DSSM-3264 09/06

Loading...

Loading...