Page 1

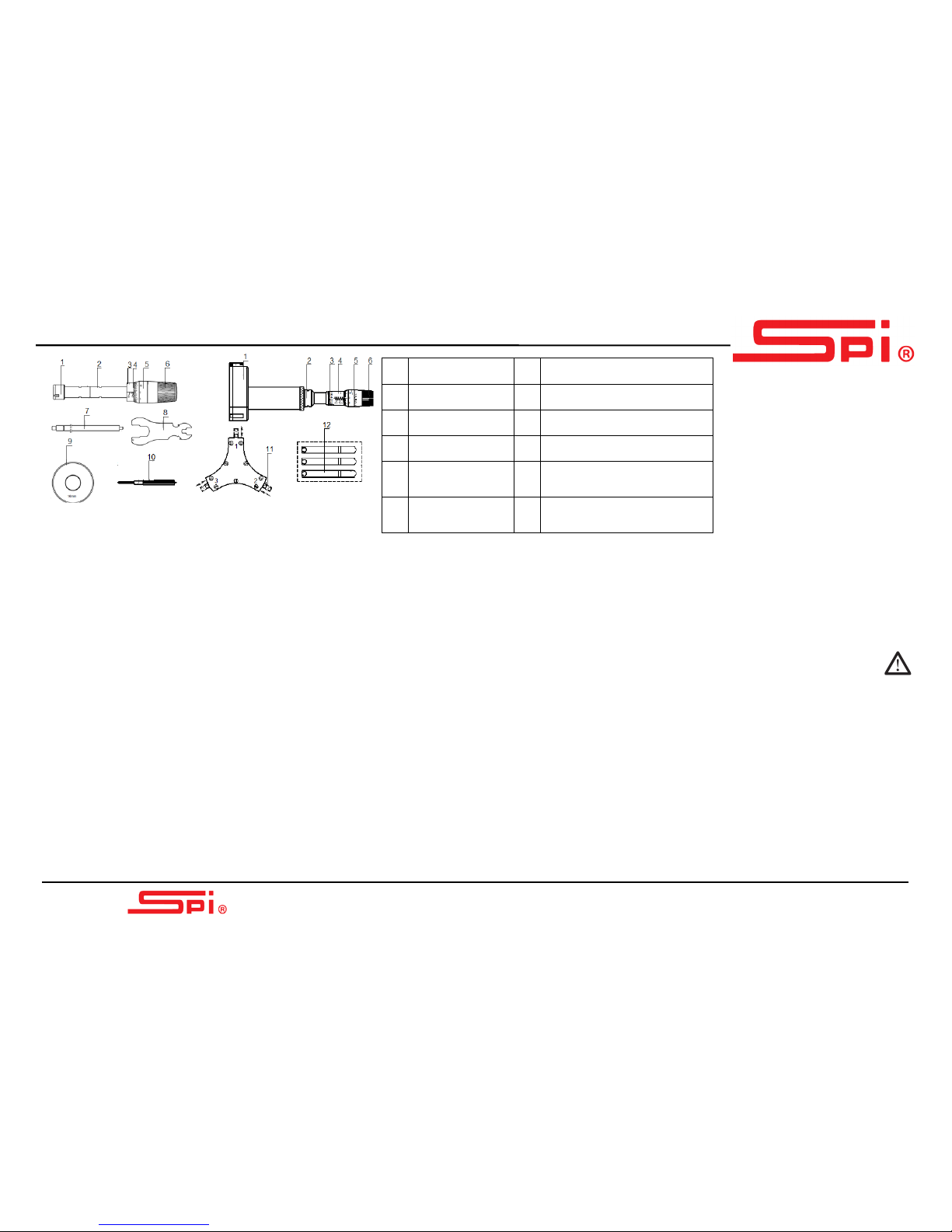

THREE POINT INTERNAL MICROMETER

swissprec.com

1

Measuring head

7

Extension Rod

2

Inside sleeve

8

Spanner

3

Adjusting Screw

9

Setting Ring

4

Fastness Sleeve

10

Screwdriver

5 Thimble

11

The first set Interchangeable

anvil

6

Ratchet

12

The second set Interchangeable

anvil

THREE POINT INTERNAL

MICROMETER

OPERATION MANUAL

SPI20G02

IMPORTANT NOTICE

• Clean all spindle and body prior to use.

• Clean the battery before installation.

• Zero set the indicators after installing

the battery.

Specifications

• Graduation:Inch: .0001"

Metric: 0.001mm

• Carbide tipped measuring faces

• Ratchet Stop.

• Models Up to and including 6mm or .24 inch have two

measuring points and models 7mm or .275 inch and above

are with three measuring points.

Zero setting

Clean the measuring jaws and the hole of the setting ring

with soft cloth. Rotate ratchet stop until the measuring jaws

Repeat the above process until indicator value is identical with

the setting ring.

Remark: Need to zero setting again after install or remove

extension rod.

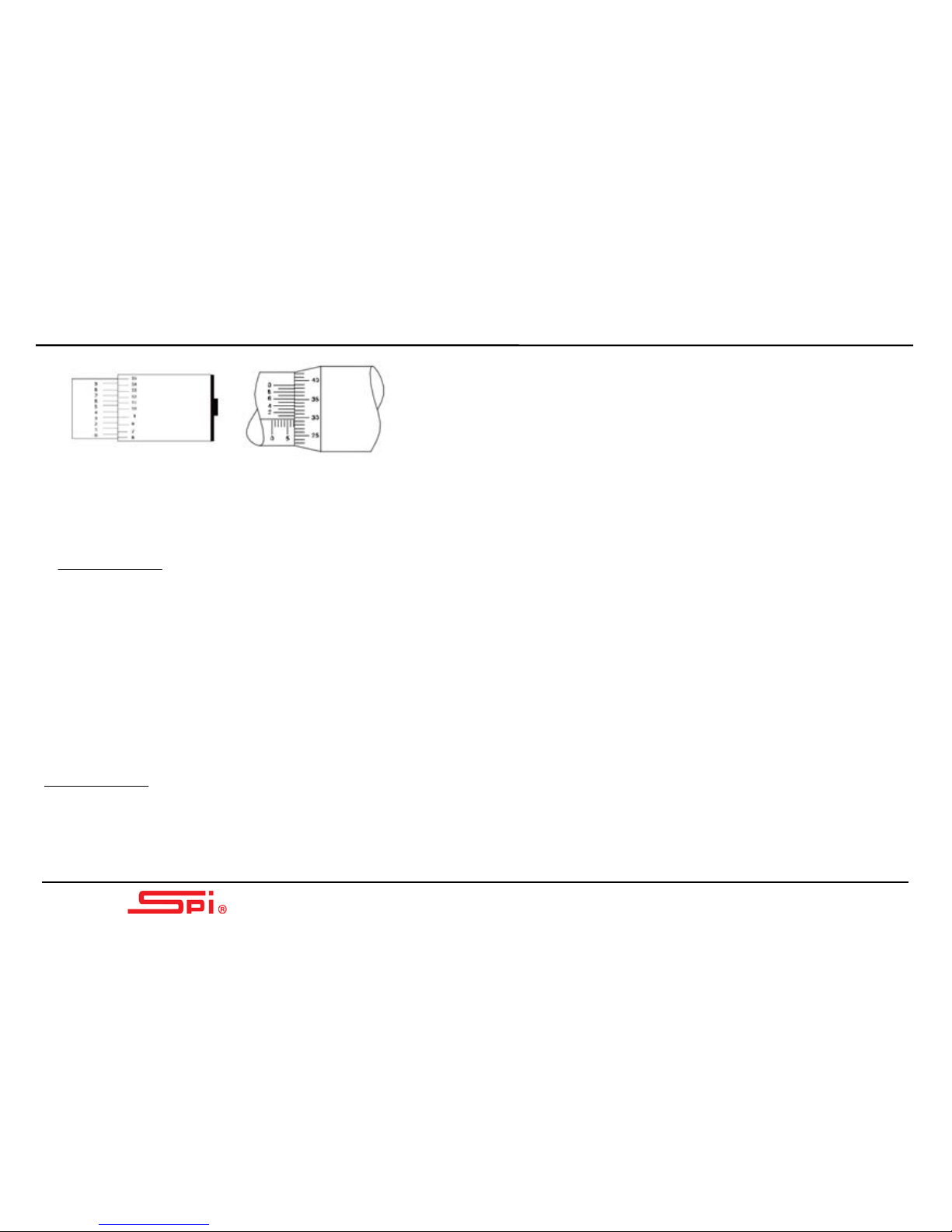

Method of Reading

• Metric

The standard micrometer with the vernier scale on the sleeve

can be read to 0.001mm. In reading of vernier scale, find which

graduation of the vernier scale coincides with that of the

thimble and multiply it by 0.001mm.

Page 2

THREE POINT INTERNAL MICROMETER

swissprec.com

Sleeve: 7.00 mm

Thimble: 0.29 mm

Vernier: 0.008 mm

Reading: 7.298 mm

• Inch

In this scenario the numbers on the left repress sent the readings from the

vernier scale. Each division counts as .0001 inch based on the division that

lines up with the line on the thimble.

Sleeve: 0.175ʺ

Thimble: 0.004ʺ

Vernier: 0.0003ʺ

Reading: 0.1793ʺ

Interchangeable anvil replacement instructions

• Product measuring ranges over 4 "(100 mm) is with Interchangeable anvil.

•

Rotate the thimble until the line marked “0” comes exactly in line with the

reference line on the sleeve. Pull out the measuring jaws; insert another set of

measuring jaws into the grooves in the measuring head in turn. Inspect the

measuring jaws by smaller pull.

• When changing the measuring jaws, number of the measuring jaws must fit the

relevant that of the three grooves in the measuring head.

• Prevent dust from getting inside the three grooves in the measuring head.

• Place tool into packaging box after apply antirust oil on the measuring jaws if the

micrometer not used for a long of time.

Precaution

• Clean all measuring surfaces and body prior to use.

• Zero set the tool using the following steps before use, and after installing the

extension rod.

• Check the zero point by measuring setting ring. If the reading doesn’t match the

setting ring:

• Unlock the adjusting screw; rotate the fastness sleeve till getting correct reading.

• Lock the adjusting screw.

Loading...

Loading...