Spheros Thermo S 160, Thermo S 230, Thermo S 400, Thermo S 300, Thermo S 350 Workshop Manual

Water Heater

Workshop Manual

Thermo S 160

Thermo S 230

Thermo S 300

Thermo S 350

Thermo S 400

with Control Unit 1586

Status: 01/2012

Ident.-no. 11114913B

1 Introduction

1.1 Content and purpose 101

noitiddA4.1

hev yawliar rof snoitaluger noitallatsnI2.5.1

tpadA4.5.1

2 Technical data

2.1 Electrical components 201

2.2 F

uel 201

3 Assemblies and components descriptions

3.1 Burner 302

3.1.1 Combustion air fan 302

3.1.2 Fuel pump 302

3.1.4 Control unit 303

3.1.6 Temperature sensors with water temperature sensor and integrated overheating protection 304

3.2 Heat exchanger 305

3.3 Combustion chamber 306

3.4 Circulating pump 307

3.4.1 Aquavent 5000 (U4814) and Aquavent

3.4.2 Aquavent 6000C (U4855) and Aquavent 6000SC (U4856) circulating pumps 308

3.5 Fuel lter 308

5000S (U4854) circulating pumps 307

noitcudortnI1004/053/003/032/061 SomrehT

101 ytidilav launam pohskroW2.1

101 tnetnoc dethgilhgih fo gninaeM3.1

101 noitatnemucod elbacilppa la

101 snoitaluger ytefas dna noitallatsnI5.1

101 snoitaluger noitallatsni lageL1.5.1

201 selci

201 snoitaluger ytefas lareneG3.5.1

401 ssenrah gniriw re

501 egnahc dna tnemevorpmI rof snoitsegguS6.1

303 retaeherp kcolb elzzoN3 .1.3

403 sedortcele noitingi htiw tinu noitingi cinortcelE5.1.3

4 Heater functions

4.2.1 Switching on and start 402

4.2.2 Heating operation 402

4..3 Switching o 403

4.3 Diagnosis interfac 404 sisongaid-

4.3.1 Test plug 405

4.5 Malfunction interlock 406

4.5.1 Malfunctions during switch 406 e rudecorp trats dna no-gni

5.4

4.6 Heater interlock 407

4.7 Error output 408

TTS dna e

epo retaeh gnirud snoitcnuflaM2.5.4

er kcolretni noitcnuflaM4.

5 Troubleshooting and error correction

5.1 General 501

104 noitpircsed ytilanoitcnuf retaeh lareneG1.4

204 ecneuqes retaeh lanoitarepO2.4

604 kcolretni retaeh dna kcolretni noitcnuflaM4.4

604 noitar

704 nwod-nur gnirud snoitcnuflaM3.5.4

704 ecnaraelc rorre dna esael

704 esaeler kcolretni retaeH1.6.4

1

1 Introduction Thermo S 160/230/300/350/400

5.2 General error symptoms 501

5.3 Malfunction code output via flash code 503

5.4 Error symptoms during functional tests with malfunction code output or diagnosis 505

5.4.1 Error symptom "No start within safety period" 505

5.4.2 Error symptom "Flame interruption" 505

5.4.3 Error symptom "Low voltage" 507

5.4.4 Error symptom "Extraneous light detected prior to ignition or during run-down" 508

5.4.5 Error symptom "Flame detector defective" 509

5.4.6 Error symptoms "Temperature sensor / overheating protection defective" and "Overheating" 509

5.4.7 Error symptom "Circulating pump interruption" 509

5.5 Individual component tests 510

5.5.1 General visual inspection 510

5.5.2 Heat exchanger visual inspection 510

5.5.3 Combustion chamber visual inspection 510

5.5.4 Resistance check of the temperature sensor with integrated overheating protection 511

5.5.5 Adapter wiring harness inspection 512

5.5.6 Fan and combustion air intake line visual inspection 512

5.5.7 Burner motor inspection 512

5.5.8 Electronic ignition unit inspection 513

5.5.9 Ignition electrode inspection 514

5.5.10 Flame detector inspection 515

5.5.11 Fuel pump inspection 516

5.5.12 Solenoid valve inspection 517

5.5.13 Nozzle block preheater inspection 518

5.5.14 Circulating pump inspection 519

6 Schematic diagrams

6.1 General 601

7 Servicing

7.1 General 701

7.1.1 Heater servicing 701

7.2 Servicing 701

7.2.1 CO2 content adjustment 702

8 Burner, components and heater removal and installation

8.1 General 801

8.2 Burner removal and installation 802

8.3 Removal and installation of the temperature sensor with integrated overheating protection 803

8.4 Hood removal and installation 803

8.5 Combustion air fan removal and installation 804

8.6 Electronic ignition unit and ignition electrode removal and installation 806

8.7 Control unit removal and installation 808

8.8 Fuel pump removal and installation 808

8.9 Solenoid valve removal and installation 810

8.10 Atomiser nozzle removal and installation 810

8.11 Combustion chamber removal and installation 811

8.12 Heat exchanger removal and installation 811

8.13 Heater removal and installation 811

8.14 Start-up after burner or heater installation 812

8.14.1 Bleeding of the fuel system 812

8.14.2 Bleeding of the water circulation 812

2

Thermo S 160/230/300/350/400 1 Introduction

9 Modifications and retrofits

10 Packing / storage

and shipping

10.1 General 1001

Appendix A 1

Periodic heater maintenance A-2

3

1 Introduction Thermo S 160/230/300/350/400

4

noitcudortnI1004/053/003/032/061 SomrehT

1 Introduction

1.1 Content and purpose

This workshop manual is used to support personnel

briefed and/or trained by Spheros during

maintenance and repair of water heaters Thermo

S160, S230, S300, S350 and S400.

1.2 Workshop manual validity

The workshop manual applies to heaters listed on the title

page of this document.

It may be subjected to modifications and amendments.

The respectively currently val

This version can be found on the Spheros homepage

under Service / Technical Documents.

1.3 Meaning of highlighted content

WARNINGS, CAUTIONS, and NOTES in this manual have

the following meaning:

This heading is used to highlight that non-compliance

with instructions or procedures may cause injuries or

lethal accidents to personnal.

This heading is used to highlight that non-compliance

with instructions or procedures may cause damage

to equipment.

id version is binding.

WARNING

CAUTION

1.5 Installation and safety regulations

1.5.1 Legal installation regulations

For the heaters exist type appr ovals according to the ECE

Regulations

R10 (EMC): No. 03 5266 and

R122 (Heater) No. 00 0208 for Thermo S 160

No. 00 0226 for Thermo S 230

No. 00 0227 for Thermo S 300

No. 00 0228 for Thermo S 350

No. 00 0225 for Thermo S 400

Installation is governed abov

Annex 7 of the

The provisions of these Regulations are binding within

the

territory governed by ECE Regulations and should

similarly be observed in

regulations.

(Extract from ECE Regulation R122, Annex 7)

4. The heater must have a manufacturer’s label showing

the manufacturer’s name, the model number and type

together with its rat

must also be stated and, where relevant, the operating

voltage and gas pressure.

7.1. A clearly visible tell-tale in the operaqtor’s field of view

shall inform when the combustion heater is switched on or

off.

(Extract from ECE Regulation R122, Part I)

ECE Regulation R122.

ed output in kilowatts. The fuel type

e all by the provisions in

NOTE

1.5.2 Installation regulations for railway

vehicles

NOTE

This heading is used to highlight and draw specific

attention to information.

1.4 Additional applicable documentation

We recommend the use of additional documentation.

References are provided in the workshop manual at

appropriate locatio

The following documents can be consulted during

operation and maintenance of the heaters listed on the

title page:

t Operating instruction

t Installation instruction

t Technical communications

t Technical information

t Spare parts list

ns.

For heater models Thermo S 230 / 300 / 350 / 400 Rail a

design certification acc. to § 33 EBO (= Federal Railway

Authority) has been issued with the following approval

number: EBA 32AZ3/0006/10.

Particular attention must be given to incidental provision

1.6 of the design certification:

Should the manufacturer, operator or service technician

gain knowledge of any accidents and damage (caused by

fire, explosion, escape of Diesel fuel or heating oil EL) that

may have occurred despite proper use of the heater, he is

required to immediately notify the certifying body thereof.

1.5.3 General safety regulations

General accident prevention regulations must be

observed.

"General safety regulations" beyond the scope of these

regulations are listed below.

101

SomrehTnoitcudortnI1 160/230/300/350/400

The safety regulations must be observed during

operation, maintenance and repair of heaters of the

Thermo S series.

For heaters in vehicles, which are not subjected to the

European Directive, inspection and approval by the

respective inspection authority is required, if applicable

regulations are in place.

The year of first start-up must be permanently marked

on the type plate by removal of not applicable dates.

The heaters are registered and licensed for the use in

vehicles according to the respective EU Directive 70/156/

.g. 2001/56/EC). When using the heater for other

ECC (e

applications not subjected to this EU Directive (e.g. ships),

respective applicable r egulations must be fulfilled.

CAUTION

The heaters are not approved for vehicles subjected to

Directive 94/55/EC (ADR).

The heater may only be installed in the driver's cab or

passenger compartment, if an installation box is used,

which can be tightly sealed vs. the vehicle interior. The

installation box must be sufficiently vented from the

outside.

If the temperature within the installation box exceeds the

permissible ambient temperature of the heater, the

venting opening must be increased after consultation with

Spheros.

WARNING

For risk of poisoning and suffocation the heater may

not be used in closed rooms such as garages or

workshops without exhaust fume extraction. This

also applies when pre-set times/timers are used. This

also applies for burner operation during adjustment

of the CO content in the exhasut dumes.

For explosion risk the heater must be switched off at

gas stations and gas systems.

For explosion risk the heater must be switched off,

when combustible fumes or dust can be generated

(e.g. in the proximity of fuel, coal, wood dust, grain

storage/silos

2

or similar).

CAUTION

The heaters may only be installed in horizontal

position.

WARNING

If operated without coolant (overheating!), the heaters

outer enclosure may reach the ignition temperature of

diesel fuel during operation!

Dripping or evaporating fuel should not accumulate

or ignite on hot parts or electrical equipment.

The heater should be installed as low as possible to

ensure automatic venting of heater and circulating

pump. This in particular applies for the circulating

pump, which does not automatically draw.

CAUTION

Prior to opening the heater it must be disconnected

from the vehicle electrical system.

NOTE

The heater should always be disconnected from the

vehicle electrical system prior to disconnecting the

temperature sensor plug.

If the order is reversed, t he heater will automatically

be interlocked.

Prior to removing the burner from the heat exchanger,

the temperature sensor plug must be removed.

CAUTION

A temperature of 110°C may not be exceed

heater areas (storage temperature).

Exceeding the temperature may cause heater

malfunctions and permanent damage to the

electronics.

Electrical cables must be routed avoiding isolation

damage (e.g. by pinching, heat development,

bending, fraying, etc.).

ed in the

After coolant replacement sufficient purging of the

cooling system must be ensured. Insufficient venting

heating operation can cause malfunctions due to

overheating.

Proper venting can be recognised by almost noise-free

operation of the circula

The opening pressure in the vehicle cooling system,

usually indicated on the cooler lid, may not exceed 2.0 bar

working overpressure (also applies to separate heating

circulations).

Hose connections must be secured with hose clamps

against slipping.

ting pump.

CAUTION

The tightening torques of the used hose clamps must

be observed.

102

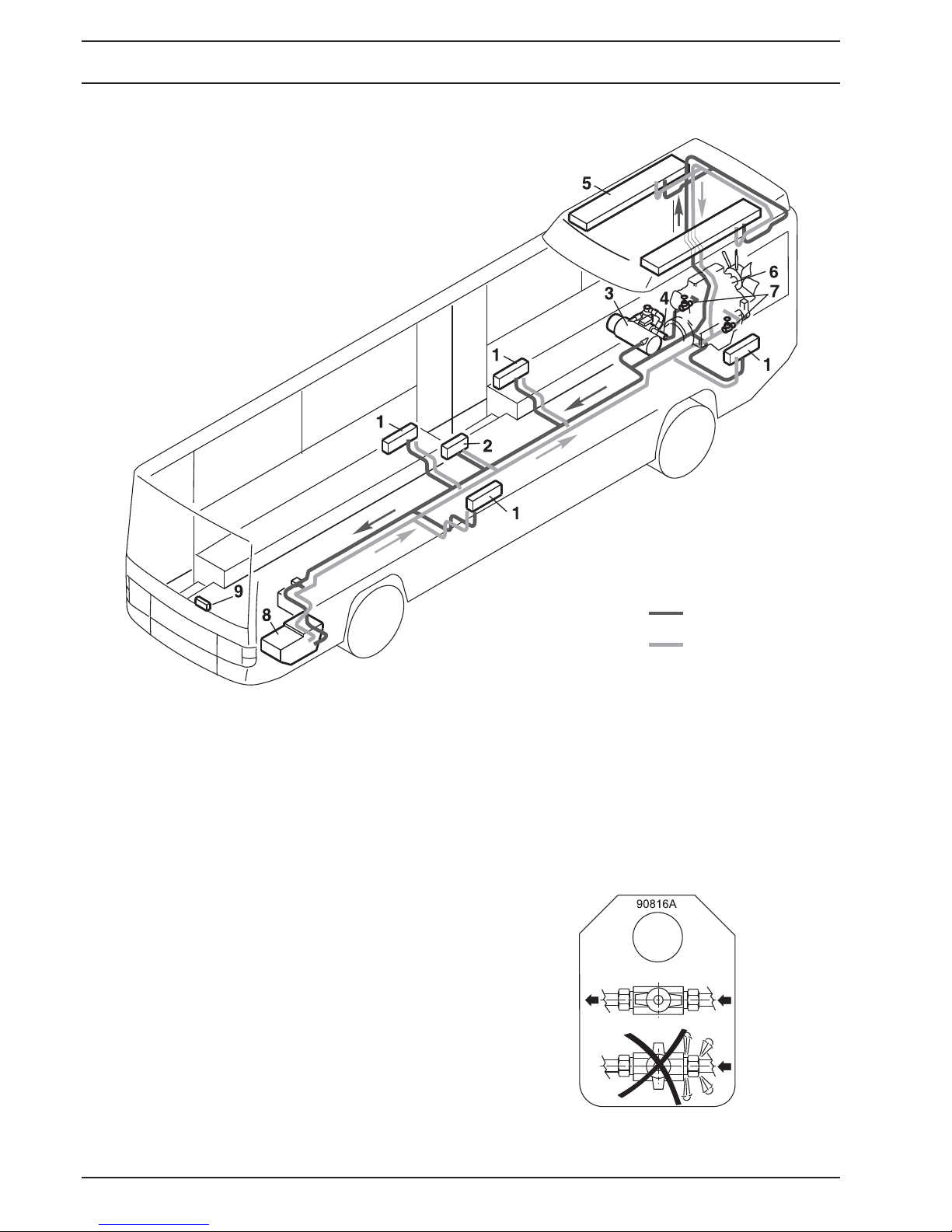

Water heating circulation system - wall heater and roof channel heater

1 Wall heater with fan

2 Heat exchanger at the entrance

3 Heater

4 Circulation pump

5 Roof heat exchanger

6 Vehicle engine

7 Shut-o valve

8 Driver seat heater

9 Control element

SomrehTnoitcudortnI1 160/230/300/350/400

Fig. 101 Heater installation example in a bus

Coolant level verification and cooling system purging

must be performed acco rding to the vehicle

manufacturer's specifications. The coolant in the heating

circulation system should contain at least 20 % of an antifreezing agent recommended by the vehicle

manufacturer.

The anti-freezing agent content should not exceed 60 %.

Fuel hoses may not be bent or twisted during installation.

In order to avoid sagging, they should secured using

clamps in 10 inch (25 cm) distances.

Fuel lines must be protected against temperature

exposure.

Permissible fuel line dimensions must be o

btained from

the installation instruction.

Supply

Return

If a shut-off fitting is installed in the return line, an

information plate must be installed at a well visible

location.

Fig. 102 Information plate

103

1.5.4 Adapter wiring harness

CAUTION

Do not put strain on the adapter wiring harness or

adapter plugs installed for testing purposes.

1.6 Suggestions for Improvement

and change

Please direct any complaints, improvement or

modification suggestions regarding this manual to:

noitcudortnI1004/053/003/032/061 SomrehT

Spheros North America, Inc.

5536 Research Drive

Canton MI. 48188

Telephone: 1-734-218-7350

Fax: 1-734-487-1569

website: www.spheros.us / info@spheros.us

104

SomrehTnoitcudortnI1 160/230/300/350/400

105

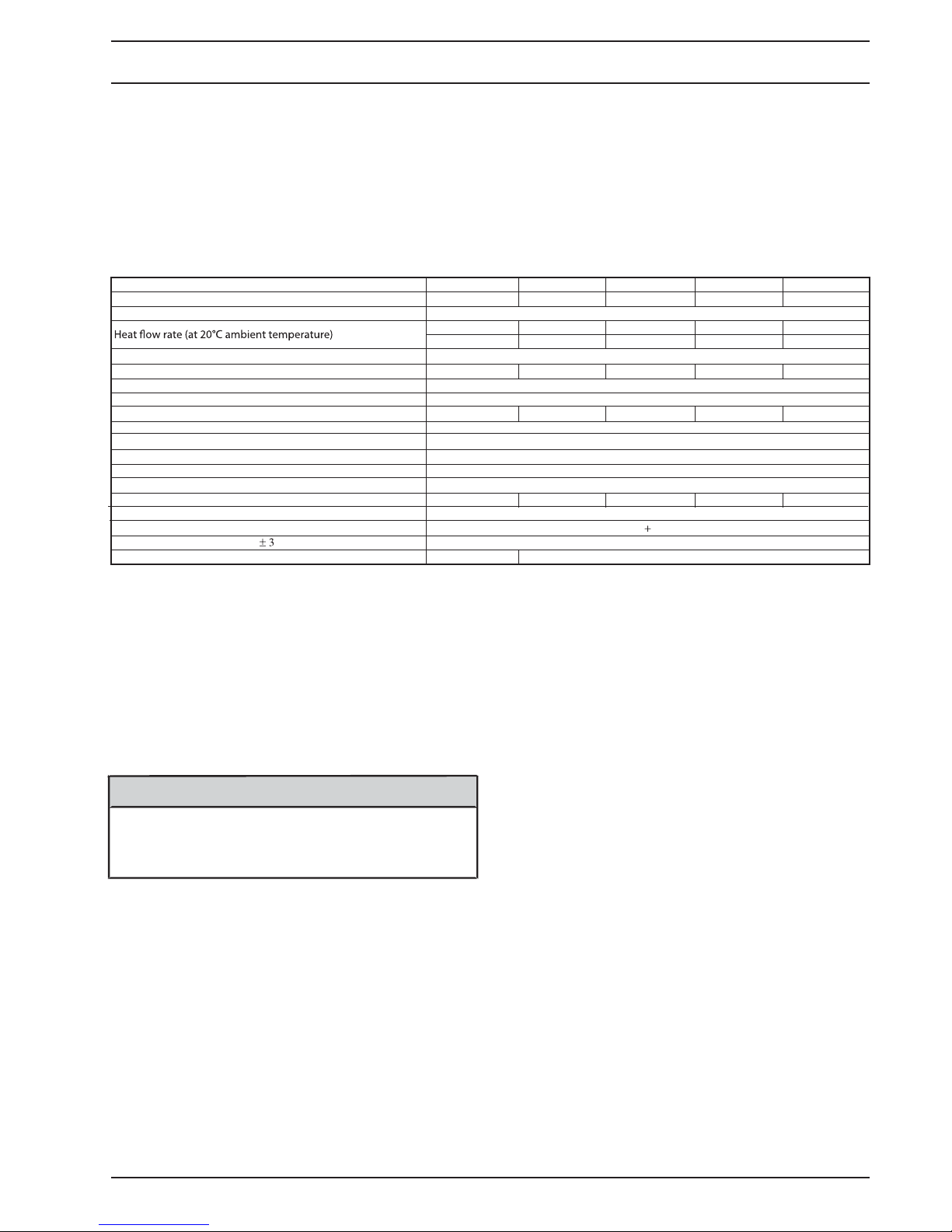

2 Technical data

Unless limiting values are de fined, the technical data

should be understood with tolerances of ±10% common

for heaters at an ambient temperature of 68° F (+20° C)

and at nominal voltage.

Table 201 Technical data

Design High-pressure atomizer

Fuel Diesel / light fuel oil

Electrical power consumption at 24 V Amps (W) 2.08 (50) 2.7 (65) 3.75 (90) 5.0 (120) 7.5 (180)

Max. permissible combustion air intake temperature

Permissible ambient temperature during operation

CO

2

Heater dimensions (tolerance

t lb (kg) 40.5 (18.4) 41.5 (18.8) hgieW

n Gal/h (kg/h) 0.51 (1.92) 0.79 (2.5) 0.95 (3.0) 1.14 (3.6) 1.29 (4.1)oitpmusnoc leuF

e US Quart (L) 1.9 (1.8)mulov gnillif regnahcxe taeH

e US Gallon (L) 10 (37.8) mulov noitalucric muminiM

mm) in (mm) 23.6” x 9.73” x 8.66” (600 x 247 x 220)

Btu/h 50,000 80,000 104,000 120,000 137,000

KW 16 23 30 35 40

42 Vegatlov lanimoN

03...02 Vegnar egatlov gnitarepO

°F (°C) 185 (85)

°F (°C) -40...+212 (-40...+100)

Permissible storage temperature °F (°C) -40...+230 (-40...+110)

Permissible operating pressure Psi (Bar) max. 29 (2.0)

5.9% loVagetlov lanimon ta tsuahxe ni 1.5

5220822072206220802000 R221 1E rebmun timrep epyt ECE

atadlacinhceT2004/053/003/032/061SomrehT

004SomrehT053SomrehT003SomrehT032SomrehT061SomrehTretaeH

002 ± 0023002 ± 0072002 ± 0042002 ± 0091002 ± 0041h/l… ±wolf retaw muminiM

* without circulating pump

Max. continuous current of the circulating pump 10 A, maximum peak current for 0.5 s duration = 90 A - We recommend the use o

efficiency and reliability. In order to reduce starting currents the circulating pump can be synchronized by the control unit f or a short time period during activation.

Confirm compatibility in case pumps provid ed by different manufacturers are used!

2.1 Electrical components

– Diesel -water emulsions: 0 .. - 5 °C without preheating

f Spheros circulation pumps for highest

system, - 10 .. - 15 °C with nozzle block preheater and

Control unit, circulating pump, solenoid valve, electronic

ignition and the digital timer are designed for 24V nominal

voltage. Motor nozzle block preheater and temperature

sensor voltages are controlled by the control unit.

NOTE

Recirculating pumps must be assigned to the heaters

according to the flow resistance in the coolant circulation

system. Voltages

directly app lied to the burner motor for

testing purposes may not exceed 12 V.

2.2 Fuel

heated fuel filter (use limitations depending on fuel

quality/water content).

– 100% Paraffin: - 10°C with nozzle block preheater and

heated fuel filter, the use of lubrication-improving

additives is recommended.

– Mixture of 70 Vol-% diesel fuel (winter diesel)

according to DIN EN 590 or DIN 51628 and 30 Vol-%

Bio diesel according to DIN EN 14214: - 5 .. - 10 °C

without preheating system, - 15°C with nozzle block

preheater a

nd heated fuel filter (use limitations

depending on fuel quality).

– Mixture of 75 Vol-% diesel fuel (winter diesel) according

to DIN EN 590 or DIN 51628 and 25 Vol-% vegetable oil

(rapeseed oil): 0 .. - 5 °C without preheating system,

Only fuels listed on the type plate as well as fuels

approved by Spheros may be used. The fuel use

limitations in the heater listed below must be observed.

– Diesel fuel according to DIN EN 590 and DIN 51628: The

limitations of use of the standard apply, hence winter

diesel down to - 20°C, Arctic diesel down to - 40°C

- 5 .. - 10 °C with nozzle block preheater and heated fuel

filter (use limitations depending on fuel quality).

– Mixture of 75 Vol-% diesel fuel according to DIN EN

590 or DIN 51628 and 25 Vol-% ethanol:

0 .. - 5 °C without preheating system, -5 .. - 10 °C with

with nozzle block preheate r and heated fuel filter

– Light fuel oil according to DIN 51603 (above 0°C)

– Bio diesel fuel according to DIN EN 14214: 0 .. - 5 °C

without preheating system, -10 .. - 15 °C with nozzle

block preheater and

heated fuel filte

r (use limitations

depending on fuel quality).

201

CAUTION

The listed temperature ranges, hence minimum

permissible temperatures strongly depend on the

respective fuel quality. In case of bad-quality fuel the

use limitations may deviate, e.g. in case of too high

water content.

At temperatures below 32°F (0°C ) commercially available

winter

diesel should be used. This especially applies for

fuel

extraction from a separate fuel tank.

The use of lubrication and flow improving additives is

permitted. No negative impact is known at time of the

preparation of this workshop manual.

CAUTION

When fuels are used, their respective limi

use must be observed and appropriate measures

(nozzle block preheater, electrically heated filter)

must be applied as needed.

In case fuel is extracted from the vehicle tank, the

vehicle manufacturer's mixing regulations shall apply.

tations of

omrehTatad lacinhceT2 S 160/230/300/350/400

202

Thermo S 160/230/300/350/400 3 Assemblies and components

3 Assemblies and components

descriptions

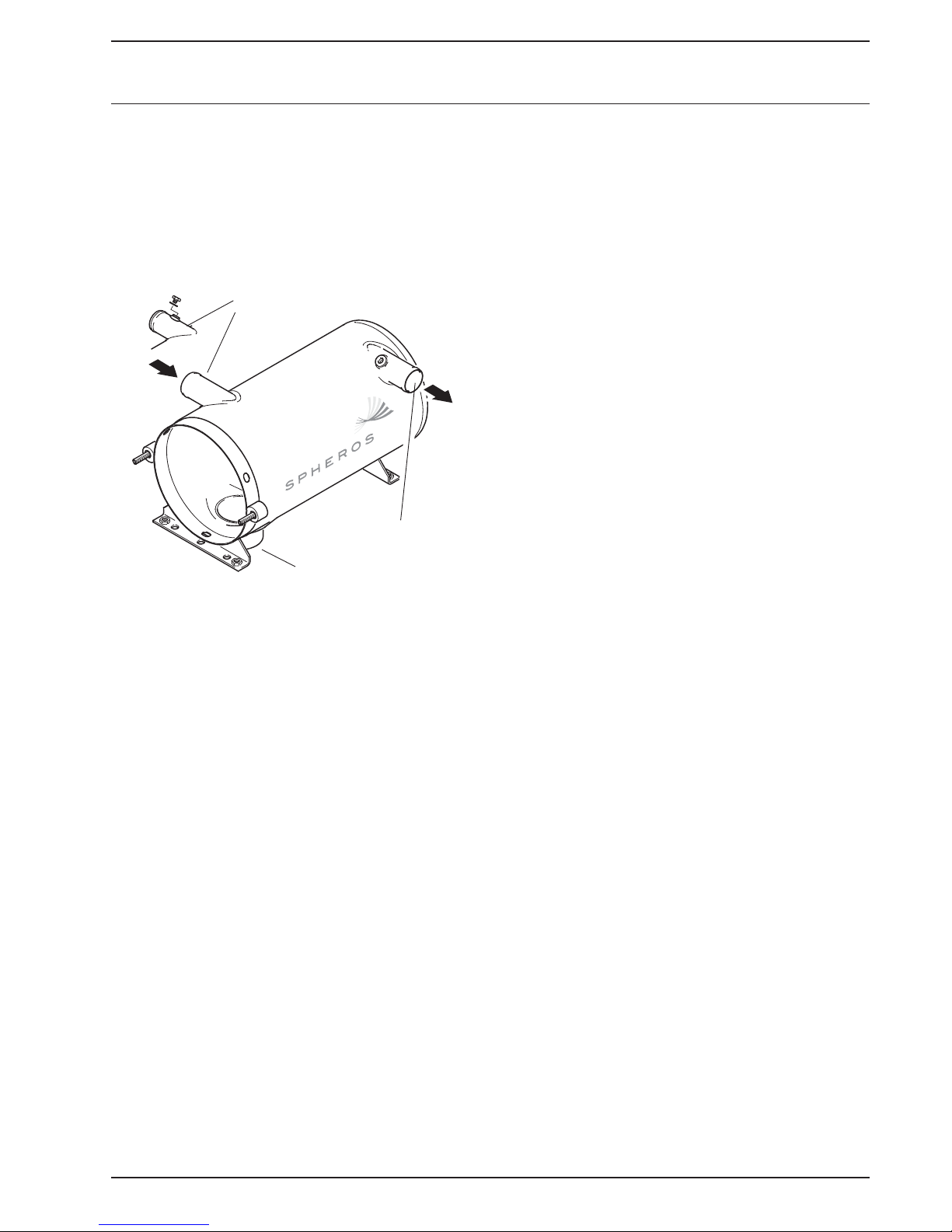

The Spheros Thermo S 160, S 230, S 300, S 350 and

S 400 water heater systems are used in conjunction with

the vehicle heating system

– to heat the passenger compartment

– to defrost the windows

– to preheat water-cooled vehicle engines.

The water heater operates independently from the vehicle

engine and is connected to the cooling system, the fuel

system and the electrical system of the vehicle. It is bolted

down to the vehicle chassis or is secured using an

additional cross beam.

3

2

Heat is generated by combusti on of liquid fuels. The heat

it transfe

heater's heat exchanger. In termittent operation adjusts

the heater to changing heat demand (cyclic operation).

The control unit controls heater activation and

deactivation based on the te mperature sensor signals.

The heaters of the Thermo S series mainly consist of the

following main components:

– Burner Head

– Combustion chamber

– Heat exchanger

A circulating pump is externally installed in the system, or

for compact devices directly on the heater.

rred to a coolant circulation system via the

4

5

Version for additional

sensor

10

12

11

13

1

6

7

9

8

1 Burner

2 Coolant, intake

3 Sensor plug

4 Temperature sensor with

integrated overheating protection

5 Coolant, outlet

6 Heat exchanger

7 Exhaust outlet

8 Fuel, return

9 Combustion air, intake

10 Fuel, flow

11 Splashguard

(screen alternative)

12 Screen

13 Hot air elbow

(incl. adapter)

(screen alternative)

301

3 Assemblies and components Thermo S 160/230/300/350/400

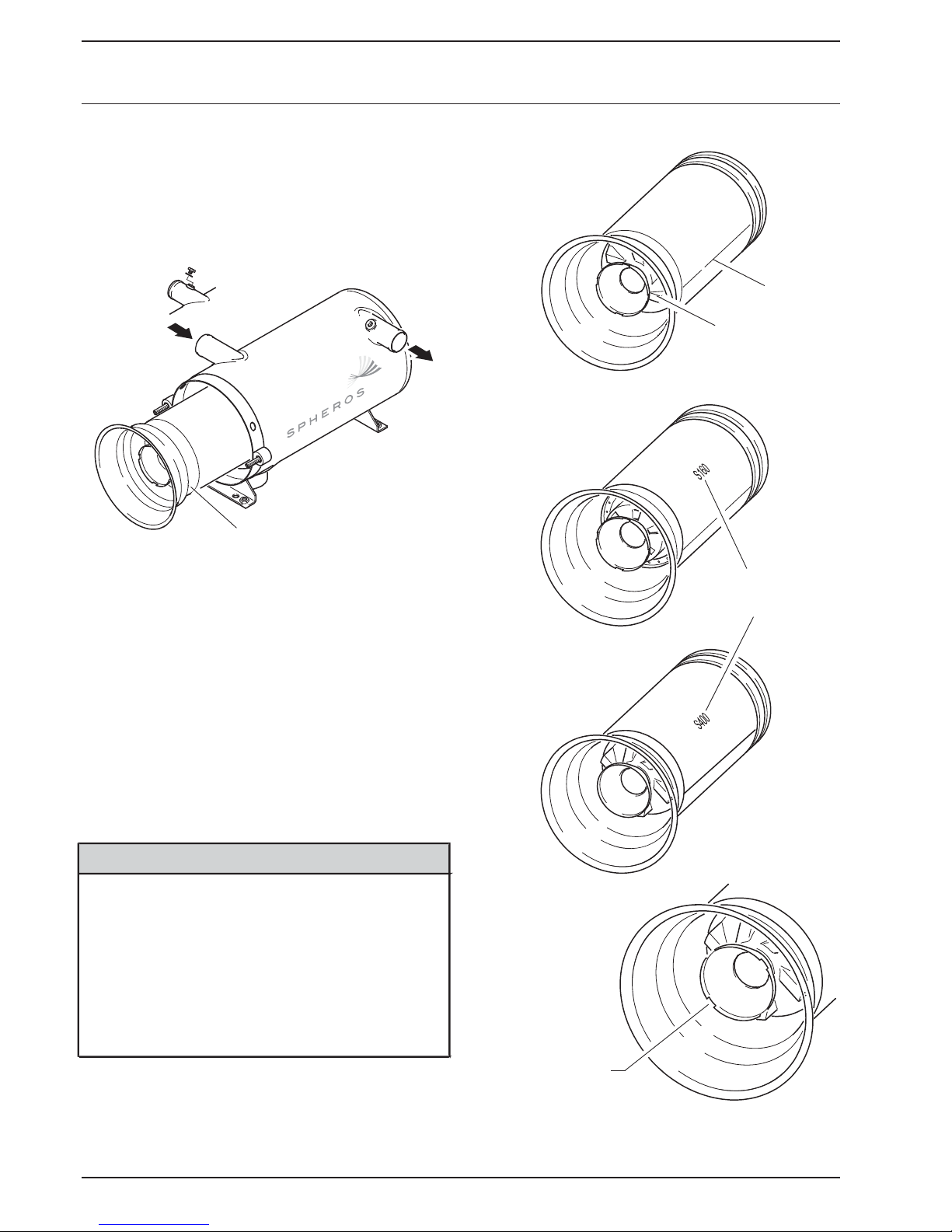

3.1 Burner

The burner consists of components

t Burner motor

t Combustion air fan

t Fuel pump with solenoid valve and atomiser nozzle

t Electronic ignition unit with ignition electrode

t Nozzle block preheater, optional

t Control unit with flame detector

t Disc with inspection glass

t Adapter wiring harness as interface to the

temperature sensor system

3.1.1 Combustion air fan

The combustion air fan transports the air required for

combustion from the combustion air intake to the

combustion chamber.

The combustion air fan consists

motor cross member. Air is

opening in the hood. The air intake opening is equipped

with a splashguard, a protective screen and a hot air

elbow.

Motor cross member

of burner motor, fan and

drawn in through the air intake

Coupling with

magnets

3.1.2 Fuel pump

The fuel pump is responsible for fuel supply.

The pump is driven by the burner motor via a coupling.

Fuel is compr

atomised via the atomiser nozzle.

The solenoid valve integrated into the fuel pump opens

and closes the fuel supply to the atomiser nozzle.

Three different fuel pumps are assigned to the different

heating capacity classes of the Thermo S series.

These are identified by the heating capacity class

specification as well as colour dots:

t 16 KW: 1 colour dot

t 23-35 KW: 2 colour dots

t 40 KW: 3 colour dots

essed in the fuel pump to approx. 10 bar and

Solenoid valve

Nozzle block

preheater (optional)

Burner motor

Shaft

circlip

Two dierent motors are assigned to the dierent heating

capacity classes of the The

heating capacity classes are indicated on the motor. In

addition the motors are dierentiated by colour.

t 16 kW - 30 KW: Motor housing

colour: silver

t 35 kW - 40 KW: Motor housing

colour: black

Fan

rmo S series. The respective

Screen

O-ring

Fuel pump

Colour dots for

identification

of the heating

capacity class

302

Thermo S 160/230/300/350/400 3 Assemblies and components

The fuel pump can be used in dual-line operation (fuel

supply and return line).

If the heater is operated with

– a long fuel supply line

– check valves in the fuel supply and return line

– a fuel filter in the fuel supply line

– single-line operation

the fuel supply line must be filled prior to first heater startup (see 8.14.1).

3.1.3 Nozzle block preheater

In case of very low temperatures fuel may exhibit severely

modified viscosity. Due to in sufficient fuel atomisation

functional heater malfunctions may occur.

Depending on the fuel used, these temperatures vary.

When used in

fuel are used, we recommend the use of a nozzle block

preheater.

The nozzle block preheater co nsists of a heating element

with an integrated temperature sensor.

At a temperature of < 5°C the heating element heats the

nozzle holder and thus, fuel and atomizer nozzle. Fuel

viscosity is reduced and atomisation improved.

The control unit defines the preheating time depending on

vehicle electrical system voltage and starting temperature.

cold regions or if fuels different from diesel

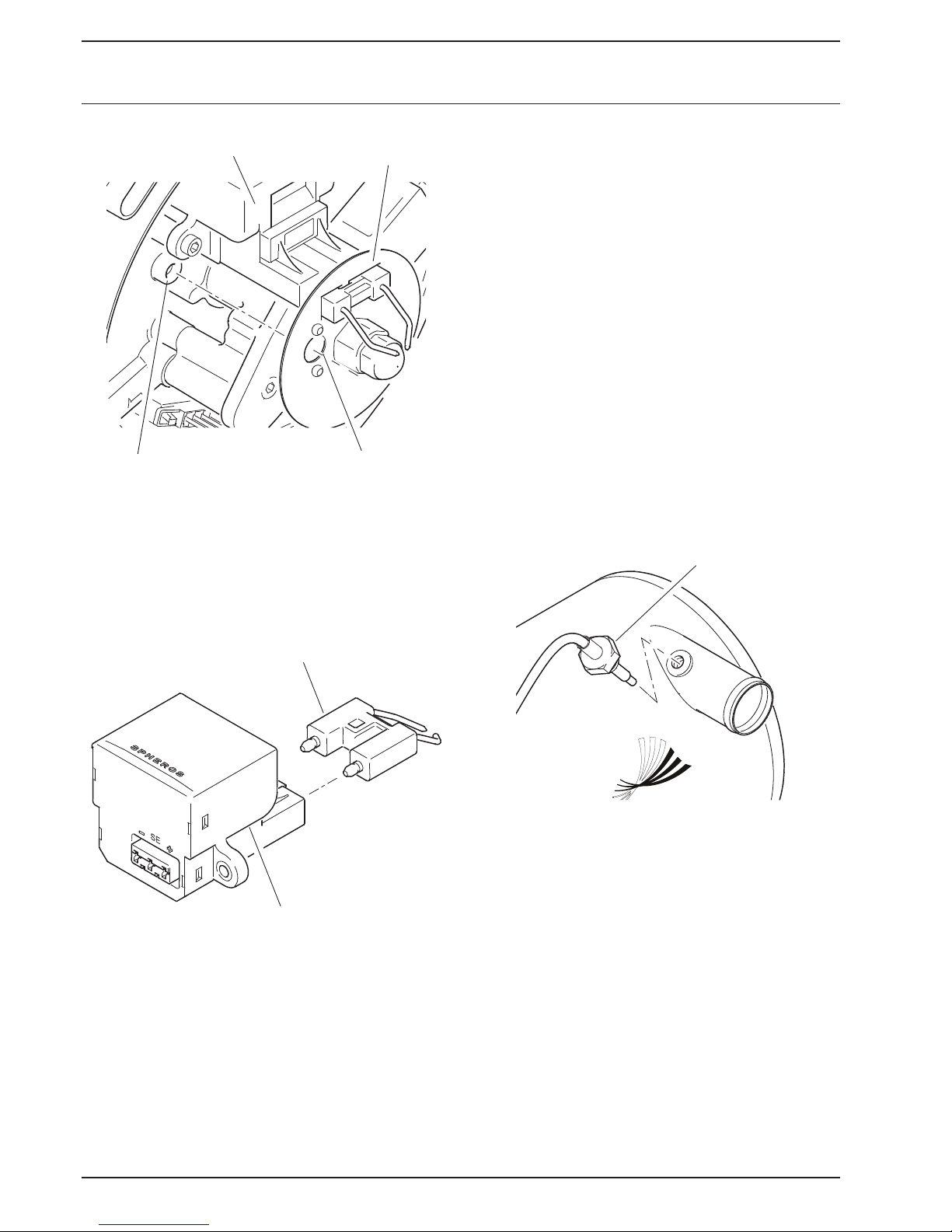

3.1.4 Control unit

The control unit 1586 ensures the operating sequence

and burner operation monitoring.

The flame detector is integrated into the control unit.

Different control units are assigned to the different heating

capacity classes.

The control units are assigned via the ID number and the

performance class indicated on the type plate of the

control unit.

Type plate with

ID number and

heating capacity

class identification

Control unit 1586

The use of the nozzle block preheater is optional. It is

possible to

the control unit.

retrofit this capability without modifications to

Heating element

Nozzle block preheater

Flame detector

3.1.4.1 Flame detector

The flame detector monitors the flame conditions during

heater operation.

e fame detector is a photo

Th

resistance as a function of flame luminous intensity and

thus, the voltage applied.

transistor, which changes its

303

3 Assemblies and components Thermo S 160/230/300/350/400

3.1.6 Temperature sensors with water

Electronic ignition unit

Flame detector

Disc

Window

3.1.5 Electronic ignition unit with ignition

electrodes

The electronic ignition unit induces the high voltage

required for ignition of the fuel-air mixture. Ignition is

triggered by a high voltage spar k, which is initiated on the

ignition electrode.

The water temperature sensor captures the coolant

temperature at the heat exchanger outlet as electrical

resistance.

This signal is transmitted to the control unit, where it is

processed.

The overheating protection integrated into the temperature

sensor is responsible for temperature limitation.

Similar to the water temperature sensor, the coolant

temperature is captured at the heat exchanger outlet as

electrical resistance and transmitted to the control unit.

Overheating protection prevents inadmissibly high heater

operating temperatures.

At a temperature greater than 125°C heater deactivation

and interlocking is initiated.

It is not necessary to man ually reset the overheating

protection.

temperature sensor and integrated

overheating protection

Temperature

sensor

Ignition electrode

Electronic ignition unit

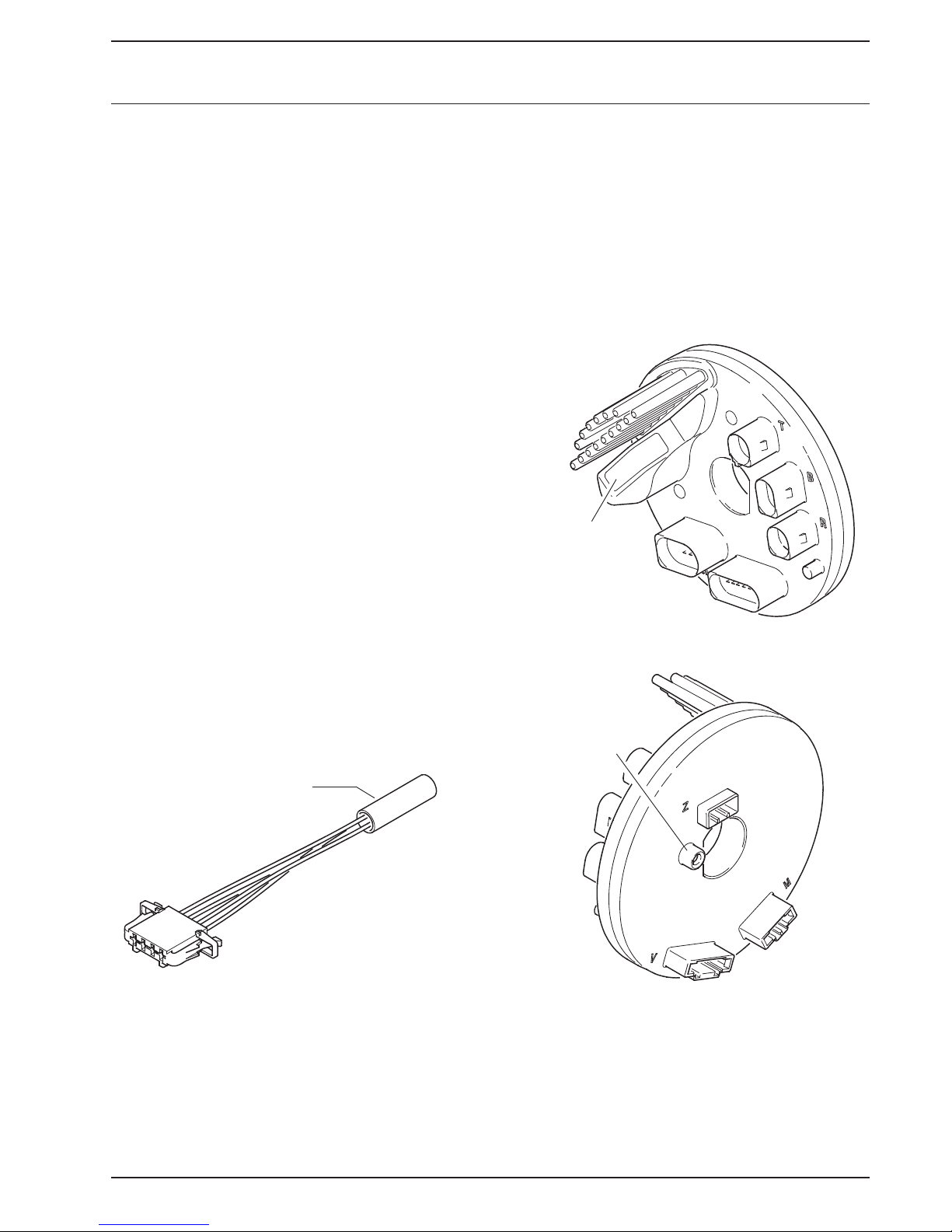

3.1.6.1 Adapter wiring harness

It is possible to disconnect the temperature sensor plug

from the adapter wiring harness. Thus, the hood does not

need to be removed for burn

er head removal.

304

Thermo S 160/230/300/350/400 3 Assemblies and components

3.2 Heat exchanger

The heat exchanger transfers the heat generated by

combustion to the coolant circulation system.

Depending on the system integration a heat exchanger

with or without thread in the coolant inlet socket can be

installed.

Coolant inlet

Coolant outlet

Exhaust outlet

305

3 Assemblies and components Thermo S 160/230/300/350/400

3.3 Combustion chamber

The combustion chamber is used for generation and

combustion of the fuel air mixture. The generated exhaust

gas heats the coolant flowing through the heat exchanger.

23 - 35 KW

Welding seam

Swirl plate

16 KW

Combustion chamber

Three different combustion chambers are used for heaters

of the Thermo S series. Deviating from the standard

combustion chamber variant for Thermo S 230, S 300 and

S 350, the Thermo S 160 is equipped with a combustion

chamber with a sheet metal swirler and the Thermo S 400

is equipped with a burner pipe with increased wall

thickness (1.5 mm).

The combustion chambers of Thermos S 160 and Thermo

S 400 are each fitted with a stamping to di

individual combustion chambers.

NOTE

If possible, the combustion chamber should be inserted

into the heat exchanger in such a way, that the burner

pipe welding seam is between 60° and 300° in the lower

area.

At the same time it must be ensured that none of the

4 cut-outs of the combustion-chamber head points

vertically downwards (see figure on the right).

It is permissible to change t he position during maintenance

or after combustion chamber r eplacement vs. the previous

installation position.

stinguish the

Identication

of the heating

capacity class

40 KW

Cut-out positions

on the combustion

chamber head

in installe d condition

306

Thermo S 160/230/300/350/400 3 Assemblies and components

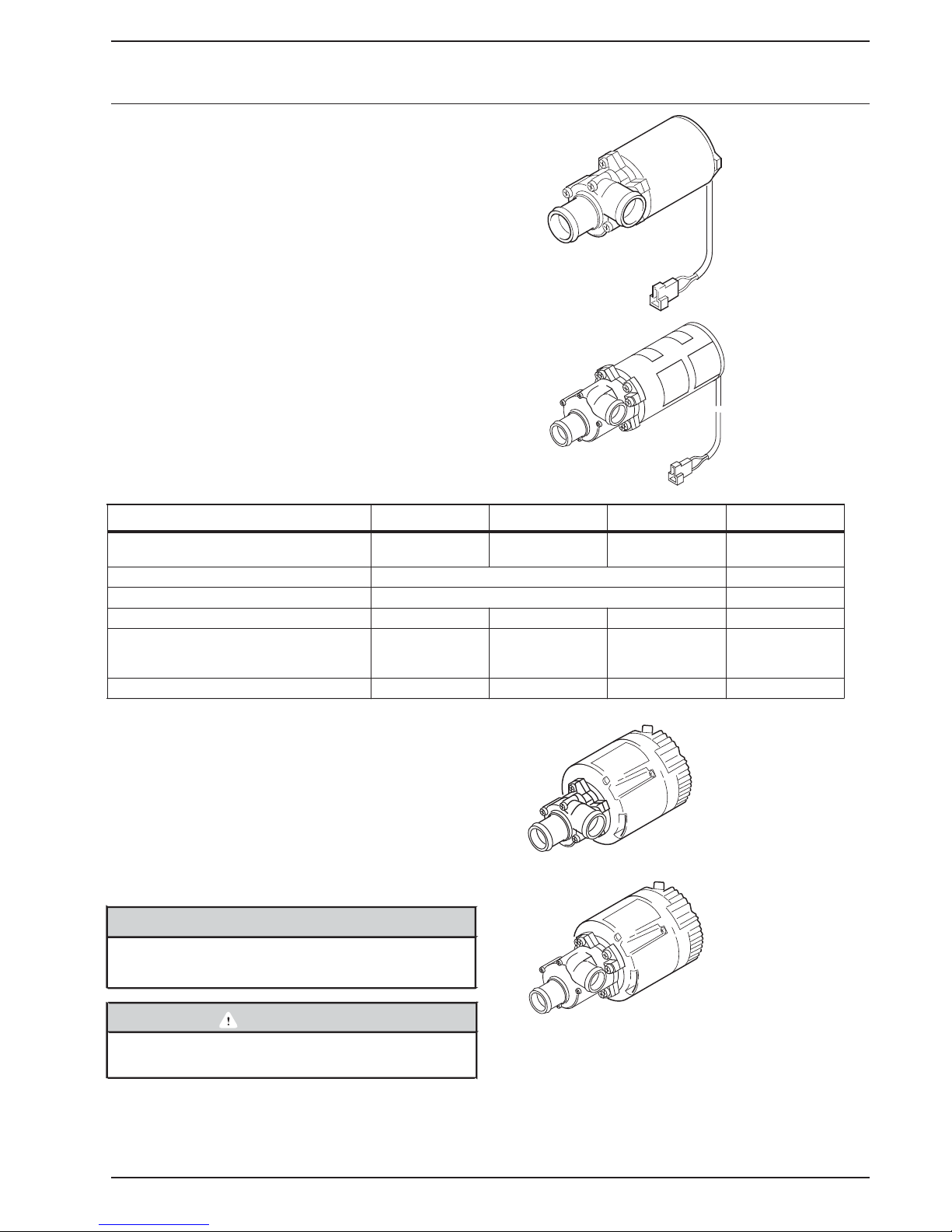

3.4 Circulating pump

Aquavent 5000

The externally arranged circulating pump ensures coolant

transport within the vehicle and/or heater circulation

system.

Depending on the application, the circulating pump is

switched on via the control unit or directly via the vehicle

electrical system and operated during the entire heater

operation duration.

Heaters can be operated wit h Aquavent 5000 (U4814),

Aquavent 5000S (U4854), Aquavent 6000C (U4855) or

Aquavent 6000SC (U4856) circulating pumps.

(U4814)

Aquavent 5000S

(U4854)

h/lwolf fo emuloV

US Gal/m

Nominal power consumption Watts 104 104 210 210

).ni( mmsnoisnemiD

mm (in.)

mm (in.)

5200

23

Length 229 (9)

Width 100 (3.9)

Height 105 (4.1)

5200

6000 6000

23

26.4 26.4

12 ... 24stloVegatlov lanimoN

10 ...14/20 ... 28stloVegatlov gnitarepO

Length 249 (9.8)

Width 100 (3.9)

Height 105 (4.1)

Length 224 (8.8)

Width 115 (4.5)

Height 110 (4.3)

Length 229 (9)

Width 115 (4.5)

Height 110 (4.3)

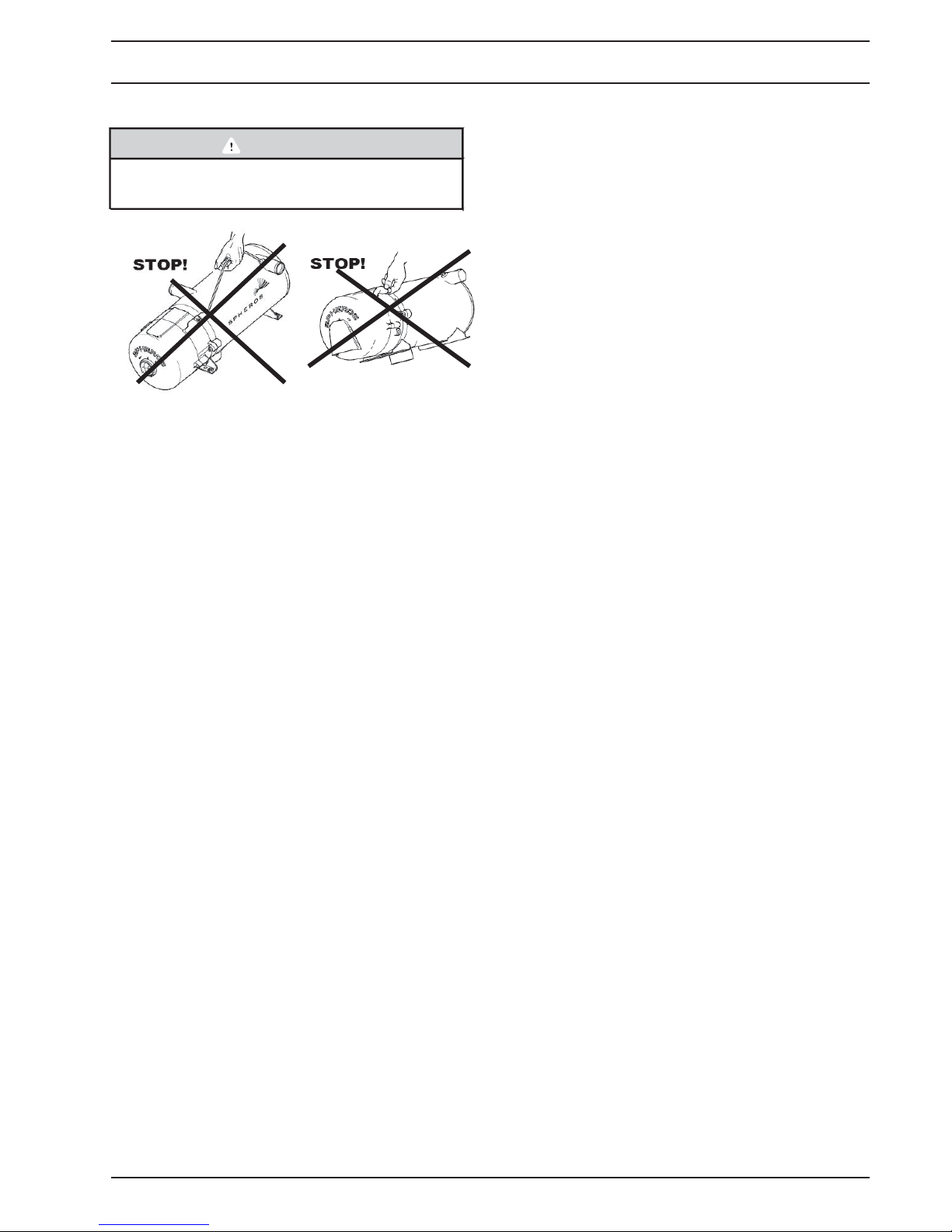

The safety device of the circulating pump may never be

lled, while the pump is running, and may not be

pu

replaced, when the pump is switched on.

Aquavent 6000C

(U4855)

3.4.1 Aquavent 5000 (U4814) and Aquavent

5000S (U4854) circulating pumps

The Aquavent 5000 (U4814) and 5000S (U4854)

circulating pumps are equipped with a brush motor.

NOTE

Aquavent 5000 (U4814) with floating-ring type shaft seal.

Aquavent 5000S (U4854) magnetic drive (no seal)

Aquavent 6000SC

(U4856)

SC 0006 tnevauqA Aquavent 6000C S 0005 tnevauqA Aquavent 5000 pmup gnitalucriC

5.5 (2.5) 5.3 (2.4)4.8 (2.2) (2.1) .4.6 thgieW

CAUTION

The circulating pump motor is not equipped with an

internal inverse-po

larity protection

307

3 Assemblies and components Thermo S 160/230/300/350/400

3.4.2 Aquavent 6000C (U4855) and Aquavent

6000SC (U4856) circulating pumps

The Aquavent 6000C (U4855) and

Aquavent 6000SC (U4856) circulating pumps are

equipped with a brushless motor.

Inverse-polarity protection

The circulating pump motor is not equipped with an

internal inverse-polarity protection.

3.5 Fuel filter

NOTE

The Aquavent 6000C (U4855) has a floating-ring type

shaft seal.

The Aquavent 6000SC (U4856) is equipped wit a

magnetic coupling (no seal)

Soft start

The circulating pump motor starts slowly and gently. Max.

rotational speed is only reached after approx. 5 seconds.

Protection against dry running

Protection against dry running is integrated into the

circulating

If the circulating pump motor consumes within a time

period of approx. 45 minutes significantly less current, dry

running is detected. The circulating pump motor is

switched off.

After approx. 2 minutes and circulating pump motor

reactivation, the operation can be continued.

Blocking protection

If the pump wheel is blocked, the motor will be switched

off via the error mode directly prior to standstill of the

pump wheel.

pump motor.

A heatable fuel filter is available as an option. The

temperature switch switches the integrated filter heating

on at a temperature of <

a temperature of <

0.5 ± 2.5 °C and switches it off at

5.5 ± 2.5 °C.

Overload protection

Overload protection is activa ted after the soft start is

completed. The current consumption will be limited.

In case of hydraulic ove

pump, the circulating pump motor will not be damaged.

Error mode

In case of malfunctions the circulating pump motor is

switched off via the error mode. After approx. 5 seconds

the error mode switches the circulating pump motor into

energy-saving sleep mode.

Sleep mode

In sleep mode internal electronics consumers of the

circulating pump motor are switched off.

Reactivation of the circulating pump motor

It is possible to reactivate the circulating pump motor from

sleep mode. For this purpose the power supply is

disconnected fo

reconnected, the circulating pump motor restarts in softstart mode.

r > 2 min. Af ter the power supply is

rpressuring of the circulating

308

snoitcnuf retaeH4004/053/003/032/061 SomrehT

4 Heater functions

4.1 General heater functionality

description

The heater principle is based on a high-pressure atomizer

burner and is monitored by an integrated control unit.

The burner motor powers the fan and the fuel pump. The

fuel pump is coupled to the motor using a plastic coupling.

The fan produces the required combustion air, the combustion

air volume is impacted by the burner motor speed.

The speed is monitored by a sensor in the control unit, which

analyses the changing magnetic field of the magnets in the

couplings.

The speed required for the CO

first calibration at Sphero

In a maintenance event the workshop can adjust the CO

setting using the STT diagnosis (Spheros-Thermo-TestDiagnosis) (see 4.2).

The fuel pressure is generated in the fuel pump and reduced

to the required pressure using a pressure limiting valve.

A solenoid valve releases the fuel via the atomizer nozzle

for combustion in the combustion chamber.

-content is determined during

2

s and is stored in the control unit.

-

2

As an option, the fuel pump can be equipped with a nozzle

block

block preheater. The nozzle

preheater heats the

nozzle holder with the atomizer nozzle at low temperatures,

and thus the fuel. Th

e fuel air mixture is ignited in the

combustion chamber via a high-voltage ignition spark.

The flame is monitored by a flame detector integrated into

the control unit.

Depending on the equipment, the heater is switched on

and off using a

t digital timer

t switch

t or climate control.

During heating operation the burner is automatically

switched on and off. The heater is switched on, when the

temperature falls short of a lower temperature threshold,

and is switched off, if the upper temperature threshold is

reached (see table 401).

The switching

and the heating operation type. They cannot be changed

and are programmed into the control unit.

For overheating protection of the heater the switching

thresholds are modified by the control unit, if specified

temperature gradients are exceeded.

If the specified minimum burning duration is not reached,

the switching thresholds will be reduced. This protects the

heater against sooting of the heat exchanger.

thresholds depend on the heater variant

An operating display is available for monitoring the operating

status. A flame indication can be optionally installed.

The operating display is also used to output error

messages in flash code.

so possible to read the flash code via the two-pin

It is al

plug in the heater wiring harness (see 4.7 and 5.3).

Use max. 2W lamps.

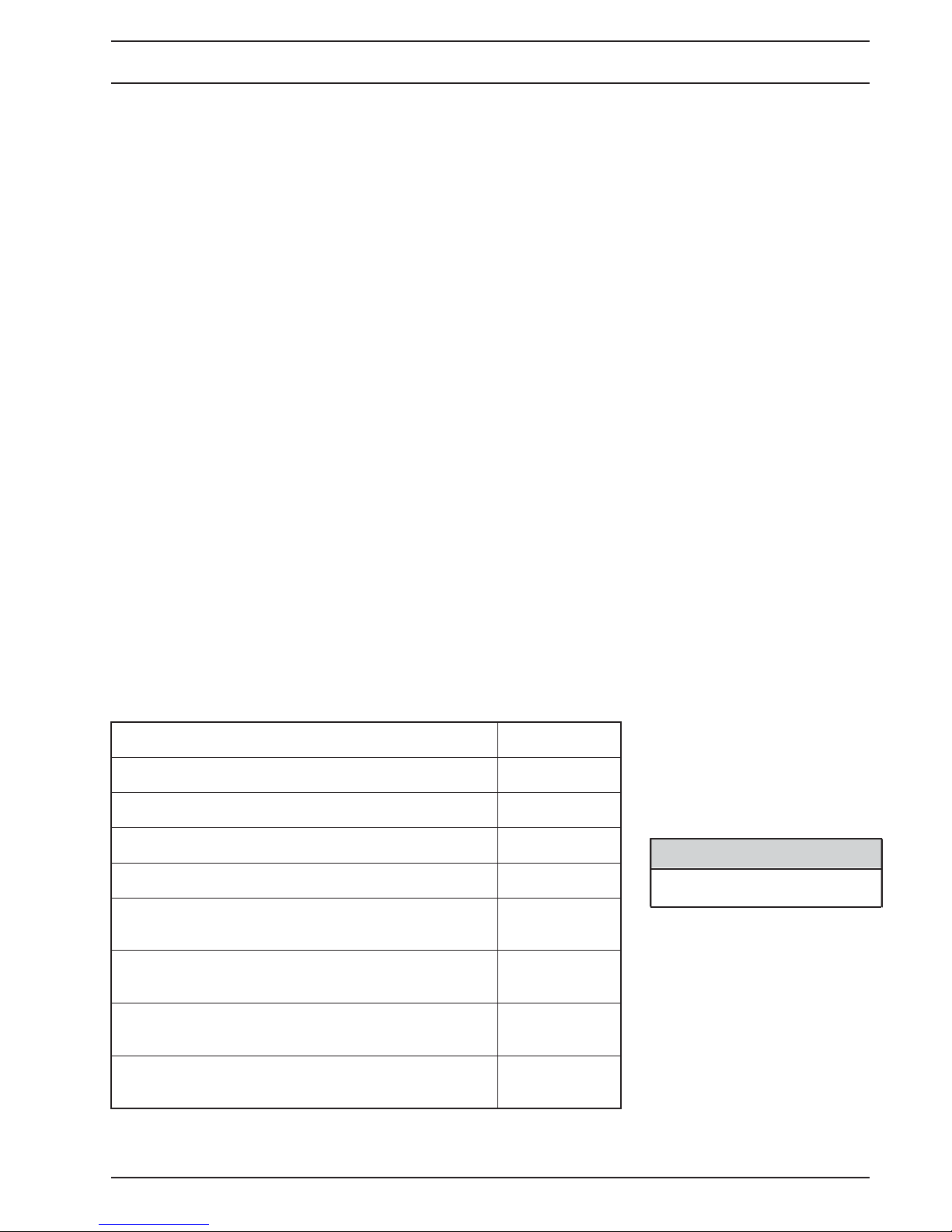

Table 401 Standard switching thresholds

Standard

Lower switching threshold: auxiliary heating in °F (°C) 172 (78)

Upper switching threshold: auxiliary heating in °F (°C) 185 (85)

Lower switching threshold: normal mode parking heating in °F (°C) 158 (70)

°

Upper switching threshold: normal mode parking heating in °F (

Lower switching threshold: saving mode 1 parking 131 (55)

heating in °F (°C)

Upper switching threshold: saving mode 1 parking 158 (70)

heating in °F (°C)

Lower switching threshold: saving mode 2

heating in °F (°C)

Upper switching threshold: saving mode 2 parking 140 (60)

heating in °F (°C)

parking 113 (45)

C) 185 (85)

Switching thresholds may deviate

NOTE

per customer.

401

mrehTsnoitcnuf retaeH4 o S 160/230/300/350/400

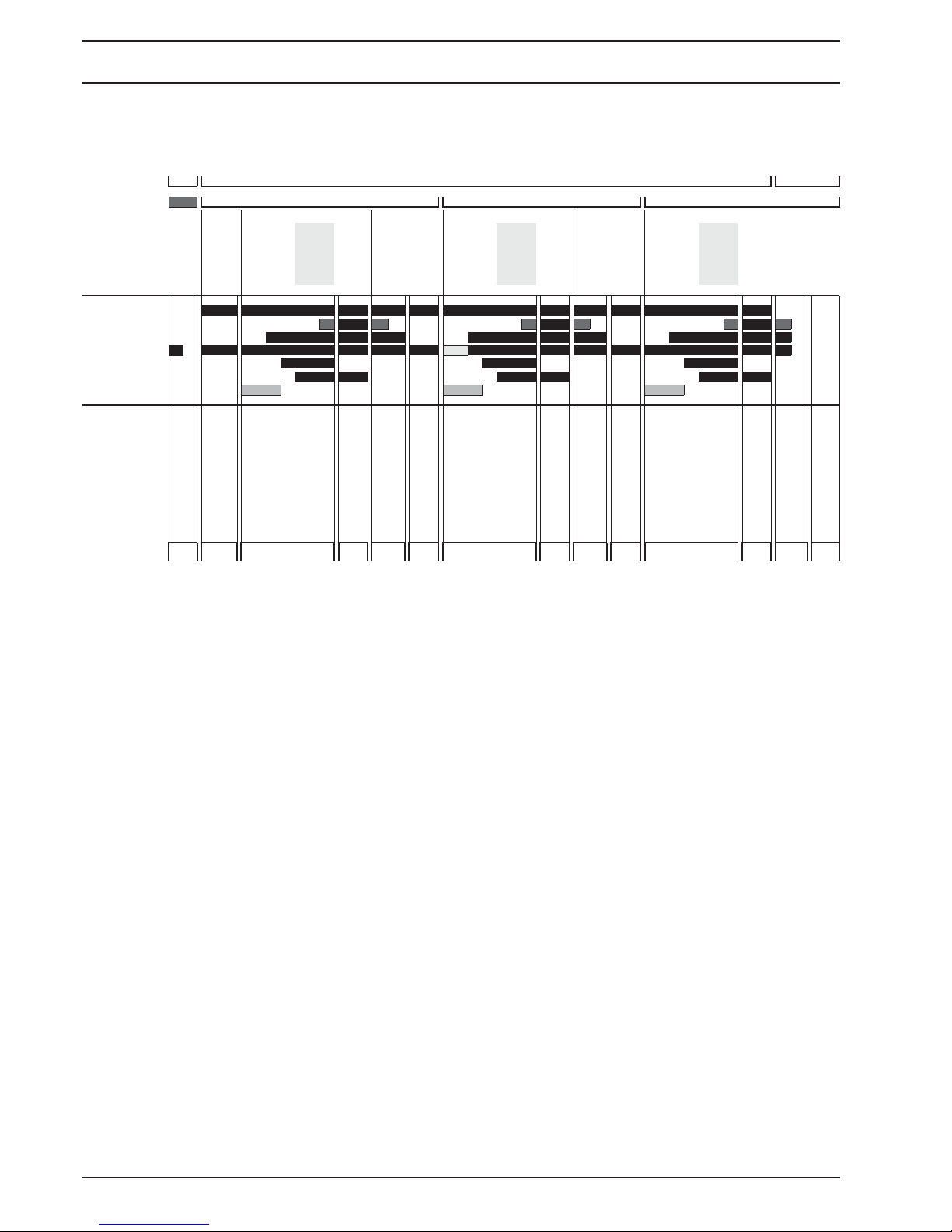

4.2 Operational heater sequence

Signals

Main switch o on o

Terminal 61

Tnim_T < Tnim_T > Terutarepmet tnalooC

nim_T < Txam_T => Tnim_T < Txam_T =>

)gnitaeh gnikrap( ffo)gnitaeh yrailixua( no)gnitaeh gnikrap( ffo

Flame

Initial cycle with light check

generation

Pre-ignition

Ignition

Stabilisation

Run-down with safety period

Run-down 2

down

Optional nozzle block

Standby Start Heating Run-

preheating

UPFA on

Actuators

Operating display

Flame display

Combustion air motor

Circulating pump

Electronic ignition unit

Solenoid valve

Nozzle block preheater

Time in s 0..108 12 1 0..15 5 ... 30 90 0..108 12 1 0..15 5 ... 30 90 0..108 12 1 0..15 5 ... 30 90

State

UPFA o

Look for

Optional nozzle block

OFF Standby Start Heating Run-

preheating

Initial cycle with light check

Flame

generation

Pre-ignition

Ignition

Stabilisation

Run-down with safety period

Run-down 2

down

Optional nozzle block

Standby Start Heating Run-

preheating

Initial cycle with light check

Flame

generation

Pre-ignition

Ignition

Stabilisation

Fig. 403 Operational sequence

4.2.1 Switching on and start

voltage the preheating time is determined. The duty cycle

is limited to a maximum of 120 seconds.

When switched on, the operating display is illuminated,

the control unit starts controlled operation and checks the

coolant temperature.

The burner motor does not run during the entire

preheating time. It starts latest 12 seconds prior to

expiration of the determined preheating time during initial

cycle.

If the coolant temperature is below the upper temperature

threshold, the initial cycle starts.

Combustion air fan and circulating pump are switched on.

The initial cycle time can be extended to a maximum of

120 seconds.

The further sequence takes place as described.

Run-down with safety period

down

Run-down 2

O

After approx. 12 seconds (initial cycle time) the highvoltage spark is ignited. Approx. 1 second later the

solenoid valve in the fuel pump is opened.

The fuel injected via the atomizer nozzle and mixed with

the air of the combustion air fan, is

ignited by the ignition

spark and burned in the combustion chamber.

The flame is monitored by a flame detector integrated into

the control unit.

A few seconds after a flame is detected, the control unit

switches the electronic ignition unit off. Until then the

flame is stabilised. The heater is not yet in heating mode.

With optional nozzle block preheater:

The integrated temperature sensor determines the

temperature on the nozzle holder as soon as the initial

cycle starts. Starting at a temperature of < 5°C the nozzle

block preheater is switched on. Depending

determined temperature and the vehicle electrical system

402

on the

4.2.2 Heating operation

After the flame is stabilised, the heater is in controlled

(normal) operation.

Depending on the coolant tempe

temperature is maintained at one level by switching the

burner alternately on and off.

Once the upper switching threshold is exceeded, heating

operation is finished and run-down initiated.

The solenoid valve is closed, the flame expires, however the

combustion air fan and circulating pump continue running.

The run-down ends approx. after 120 seconds. The

combustion air fan is switched off.

The heater is in a controlled break.

The operating disp lay is illuminated.

rature, the coolant

Loading...

Loading...