Spheros DBW 230, DBW 160, DBW 300, DBW 2020, DBW 350 Workshop Manual

Water heaters Workshop Manual

DBW 160

DBW 230(2020)

DBW 300

DBW 350

Status: 07/2010

Visit www.butlertechnik.com for more technical information and downloads.

www.butlertechnik.com

Visit www.butlertechnik.com for more technical information and downloads.

www.butlertechnik.com

DBW 160 / 230 (2020) / 300 / 350 Contents

2

Contents

1 Introduction

1.1 Contents and purpose .......................................................................................................................... 101

1.2 Applicability of the manual.... ... ... ... ....................................................................................................... 101

1.3 Meaning of accentuations..................................................................................................................... 101

1.4 Further documentation to be used........................................................................................................ 101

1.5 Safety information and regulations....................................................................................................... 101

1.5.1 General safety regulations......................................................................................................... 101

1.6 Legal requirements regarding the installation.................... ... ... .... ... ... ... ................................................ 102

1.7 Suggestions for improvements and modifications ................................................................................ 103

2 General Description

2.1 Combustion air fan................................................................................................................................ 204

2.2 Motor..................................................................................................................................................... 204

2.3 Fuel pump............................................................................................................................................. 204

2.3.1 Nozzle-block preheater.............................................................................................................. 205

2.4 Heat exchanger .................................................................................................................................... 205

2.5 Combustion chamber............................................................................................................................ 206

2.6 Control unit ........................................................................................................................................... 206

2.7 Flame sensor........................................................................................................................................ 207

2.8 Electronic ignition unit with ignition electrodes ..................................................................................... 207

2.9 Temperature limiter /thermal fuse......................................................................................................... 208

2.10 Control thermostat................................................................................................................................ 208

2.11 Fan thermostat...................................................................................................................................... 209

2.12 Circulation pump................................................................................................................................... 209

3 Function Description

3.1 General................................................................................................................................................. 301

3.2 Operation.............................................................................................................................................. 301

3.2.1 Activation................................................................................................................................... 301

3.2.2 Heating operation...................................................................................................................... 301

3.2.3 Deactivation............................................................................................................................... 301

3.2.4 Malfunction cut-out................. ... ... ... ... .... ... ... ............................................................................. 301

4 Technical data

Electrical components..................................................................................................................................... 401

Fuel .............................................................................................................................................................. 401

Visit www.butlertechnik.com for more technical information and downloads.

www.butlertechnik.com

Contents DBW 160 / 230 (2020) / 300 / 350

3

5 Troubleshooting

5.1 General................................................................................................................................................ 501

5.2 General fault symptoms....................................................................................................................... 501

5.3 Troubleshooting – quick diagnostic...................................................................................................... 503

5.4 Fault symptoms........................ .... ........................................................................................................ 504

5.4.1 Heater does not start when being switched on......................................................................... 504

5.4.2 Heater repeatedly switches into malfunction mode approx. 30 s after bein g switched on ....... 505

5.4.3 Heater requires several attempts to start ................................................................................. 506

5.4.4 Heater turns off by itself during operation................................................................................. 506

5.4.5 Heater creates black smoke..................................................................................................... 507

5.4.6 Heater creates white smoke................................ ..................................................................... 508

5.4.7 Heater cannot be switched off.................................................................................................. 508

6 Function Checks

6.1 General................................................................................................................................................ 601

6.2 Settings................................................................................................................................................ 601

6.2.1 Adjusting CO

2

contents ............................................................................................................ 601

6.3 Checks of individual components ........................................................................................................ 602

6.3.1 Check of flame-sensor resistance ............................................................................................ 602

6.3.2 Check and adjustment of ignition electrodes............................................................................ 603

6.3.3 Check of electronic ignition unit................................................................................................ 603

6.3.4 Check of fuel pump................................................................................................................... 603

6.3.5 Check of burner motor.............................................................................................................. 604

6.3.6 Check of solenoid valve............................................................................................................ 604

6.3.7 Check of nozzle-block preheater.............................................................................................. 604

7 Wiring diagrams

7.1 General................................................................................................................................................ 701

8 Service and Maintenance

8.1 General................................................................................................................................................ 801

8.2 Heater servicing................................................................................................................................... 801

8.3 Vehicle servicing.......................................... ... ..................................................................................... 801

8.4 Heater test run..................................................................................................................................... 801

8.5 Maintenance work................................................................................................................................ 801

8.5.1 Swinging the burner head open and closed ............................................................................. 802

8.6 Visual inspections /

installation specifications 803

8.6.1 Connection to the vehicle's cooling system.............................................................................. 803

8.6.2 Connection to the vehicle's fuel system.................................................................................... 803

8.6.3 Combustion air supply.............................................................................................................. 805

8.6.4 Exhaust pipe............................................................................................................................. 805

Visit www.butlertechnik.com for more technical information and downloads.

www.butlertechnik.com

DBW 160 / 230 (2020) / 300 / 350 Contents

4

8.7 Removal and installation....................................................................................................................... 806

8.7.1 Heater, removal and installation................................................................................................ 806

8.7.2 Replacing the temperature limiter.............................................................................................. 806

8.7.3 Replacing the control thermostat............................................................................................... 806

8.7.4 Replacing the fan thermostat..................................................................................................... 806

8.7.5 Replacing the thermal fuse........................................................................................................ 806

8.7.6 Replacing the burner head........................................................................................................ 806

8.7.7 Replacing the electronic ignition unit......................................................................................... 806

8.7.8 Replacing the flame sensor....................................................................................................... 806

8.7.9 Replacing the combustion chamber.......................................................................................... 807

8.8 Start-up................................................................................................................................................. 808

8.8.1 Bleeding the coolant circuit........................................................................................................ 808

8.8.2 Bleeding the fuel-supply system................................................................................................ 808

9Repair

9.1 General................................................................................................................................................. 901

9.1.1 Measures on components in disassembled condition............................................................... 902

9.1.2 Carrying out modifications......................................................................................................... 902

9.2 Disassembly and assembly.................................................................................................................. 907

9.2.1 Replacing the temperature limiter.............................................................................................. 907

9.2.2 Replacing the control thermostat............................................................................................... 907

9.2.3 Replacing the fan thermostat..................................................................................................... 909

9.2.4 Replacing the thermal fuse........................................................................................................ 909

9.2.5 Replacing the control unit.......................................................................................................... 909

9.2.6 Replacing the burner head........................................................................................................ 909

9.2.7 Replacing the motor .................................................................................................................. 911

9.2.8 Replacing the high-pressure nozzle.......................................................................................... 912

9.2.9 Replacing the nozzle-block preheater....................................................................................... 912

9.2.10 Replacing the electronic ignition unit......................................................................................... 912

9.2.11 Replacing the flame sensor....................................................................................................... 912

9.2.12 Replacing the ignition electrodes............................................................................................... 912

9.2.13 Replacing the fuel pump............................................................................................................ 914

9.2.14 Replacing the solenoid valve..................................................................................................... 914

9.2.15 Replacing the combustion chamber.......................................................................................... 914

9.2.16 Thermostat of the nozzle-block preheater................................................................................. 914

9.2.17 Replacing the heat exchanger................................................................................................... 916

9.2.18 Replacing the nozzle block........................................................................................................ 917

9.2.19 Replacing the combustion air fan.............................................................................................. 917

10 Packaging / Storage and Shipping

10.1 General............................................................................................................................................... 1001

A Appendix

Regular maintenance of heater....................................................................................................................... A-2

Visit www.butlertechnik.com for more technical information and downloads.

www.butlertechnik.com

List of Figures DBW 160 / 230 (2020) / 300 / 350

5

List of Figures

301 Function sequence (heaters with control unit 1553)...................................................................................... 302

501 General fault symptoms ............................................... .................................................................................. 501

701 Au tomatic wiring diagram, DBW 160 with control unit 1553 and switch, system variants and pin allocation 702

702 Automatic wiring diagram, DBW 230/300 with control unit 1553, 24 volts..................................................... 704

703 Automatic wiring diagram, DBW 300/350 with control unit 1553, 24 volts..................................................... 706

704 Application ex ample for DBW 160/230/300, 12 and 24 volts, operation with timer and battery switch.......... 708

801 Swinging the burner head open and closed................................................................................................... 802

802 Example of heater installation in a bus .......................................................................................................... 804

901 Replacement of temperature limiter, control thermostat, fan thermostat and thermal fuse ........................... 908

902 Replacement of the control unit..................................................................................................................... 910

903 Replacement of the burner head.................................................................................................................... 910

904 Replacement of the motor.............................................................................................................................. 911

905 Replacement of nozzle block, nozzle-block preheater, high-pressure nozzle and flame sensor................... 913

906 Replacement of the thermostat of the nozzle-block preheater....................................................................... 915

907 Replacement of the solenoid valve................................................................................................................ 915

908 Replacement of the combustion chamber and the heat exchanger............................................................... 916

909 Replacement of the combustion air fan.......................................................................................................... 918

Visit www.butlertechnik.com for more technical information and downloads.

www.butlertechnik.com

DBW 160 / 230 (2020) / 300 / 350 1Introduction

101

1Introduction

1.1 Contents and purpose

This workshop manual serves to support trained personnel in the repair of coolant heaters DBW 160/230/300 /350.

The heater may only be operated with the specified fuel

(diesel) and only with the type of electrical connection

specified for the respective model.

1.2 Applicability of the manual

The manual is applicable for the heaters listed on the title

page. The heaters mainly differ with regard to their technical data (see Section 4).

1.3 Meaning of the warning and safety

notices

In this manual, the signal words DANGER, CAUTION and

NOTE have the following meanings:

DANGER

This heading is used when incorrect compliance or noncompliance with instructions or procedures may result in

injuries or lethal accidents.

CAUTION

This heading is used when incorrect compliance or non-

compliance with instructions or procedures may result in

damage to components.

NOTE

This headline is used to indicate particularly useful or

special information.

1.4 Further documentation to be used

This workshop manual contains all information and instructions required for the repair of coolant heaters DBW

160/230/300/350.

The use of additional documentation is normally not required.

If required, the installation instructions and the operating

instructions can be used in addition.

1.5 Safety information and

regulations

As a rule, the applicable general regulations and instructions concerning accident prevention and work safety

must be observed.

"General safety regulations" beyond the scope of these

regulations are listed in the following.

The special safety regulations of importance for this

manual are indicated in the relevant sections or process

descriptions in the form of signal words (warnings, cautions, notes).

1.5.1 General safety regulations

For the heaters DBW 160/230/300/350, type approvals

according to EC directives 72/245/EEC (EMC) and 2001/

56/EC (heater systems) have been granted, with the EC

approval number:

e1*2001/56*0006xx

For installation, primarily the provisions of Annex VII to di-

rective 2001/56/EC must be observed.

CAUTION

Non-compliance with the installation instructions and the

notes contained will lead to exclusion of liability by Spheros. The same applies to repairs not carried out by experts

or without the use of genuine spare parts. This will result

in the invalidation of the General Build-Type Approval of

the heater and hence the General Certification (German

'ABE').

The year the heater was initially commissioned must

be permanently marked on the type label

by removing the relevant year.

The heaters are approved for heating the vehicle engine

and the passenger compartment. When the heater is used

in vehicles not subject to the StVZO [German road-traffic

licensing regulations] (e.g. ships), locally applicable regulations must be complied with.

The heater may only be installed in vehicles or in independent heating systems with a minimum coolant volume

of 10 litres.

Visit www.butlertechnik.com for more technical information and downloads.

www.butlertechnik.com

1Introduction DBW 160 / 230 (2020) / 300 / 350

102

The heater may not be installed in the driver's or passenger's compartments of vehicles. If the heater is nevertheless installed in such a compartment, the installation case

must be tightly sealed towards the vehicle interior. From

the outside, the installation case must be sufficiently

vented so that a maximum temperature of 85 °C in the installation case is not exceeded. If this temperature is exceeded, malfunctions may occur.

DANGER

Because of danger of poisoning and suffocation, the

heater must not, not even with a timer, be operated in

enclosed rooms such as garages or workshops

without exhaust-gas extraction systems.

Because of explosion hazard, the heater must be

switched off at filling stations and filling systems.

CAUTION

Wherever flammable fumes or dust can form (e.g.

near fuel, carbon, wood-dust, cereal storage sites or

similar), the heater must be switched off due to explosion hazard.

The heater may not be operated in the vicinity of flammable materials, such as dry grass, leaves, cardboard

boxes, paper etc.

In the vicinity of the control unit, an ambient temperature

of 110°C (storage temperature) must not be exceeded

(e.g. when paint work is carried out on the vehicle).

If the specified temperature is exceeded, permanent

damage to the electronics may occur. When checking the

coolant level, proceed according to the vehicle manufac-

turer's instructions. The coolant in the heating circuit must

contain at least 10% of a brand-name anti-freeze agent.

Additives in the heating circuit may not be aggressive

against metals, plastics and rubber and may not cause

any deposits.

The opening pressure in the vehicle cooling syst em usually indicated on the radiator cap – must range

between 0.4 and 2.0 bar allowable working pressure (also

applies to separate heating circuits).

1.6 Legal requirements regarding the

installation

For installation, primarily the provisions of Annex VII to directive ECE R122 must be observed.

NOTE:

The provisions of these directives are binding in the

area of application of the ECE directive and should

also be observed in countries without specific regula-

tions!

(Excerpt from directive ECE R122, Appendix VII)

7.1 A clearly visible operation indicator in the operator's

field of vision must inform about the heater being switched

on or off.

Regulations regarding the installation in the vehicle

5.3.1 Area of application

5.3.1.1 As stipulated in Section 5.3.1.2, combustion

heaters must be installed according to the provisions of

Section 5.3.

5.3.1.2 In class-O vehicles with heaters for liquid fuel, it is

assumed that they comply with the pr ovisions of Section

5.3.

5.3.2 Positioning of the heater

5.3.2.1 Parts of the vehicle body and other components

in the vicinity of the heater must be protected from excessive heating and possible fuel or oil-induced soiling.

5.3.2.2 Even in the event of overheating, no fire hazard

may be caused by the combustion heater. This provision

is considered to be complied with if, during installation, relevant clearance to all components is maintained, sufficient ventilation is provided for or fire-resistant materials

or heat shields have been used.

5.3.2.3 In class-M2 and M3 vehicles, the combustion

burner may not be located in the passenger compartment.

Its installation in the passenger compartment is, however,

permissible when it is located in a properly se aled casing

which also complies with the provisions of Section 5.3.2.2.

5.3.2.4 The label named in Appendix 7, Section 1.4 or a

duplicate must be positioned to allow for easy reading

when the heater is installed in the vehicle.

5.3.2.5 The heater must be installed in a location where

the risk of injuring persons and damaging items carried is

as small as possible.

5.3.3 Fuel supply

5.3.3.1 The fuel-filler neck may not be located in the passenger compartment and must be equipped with a tigh tlysealing cap which prevents fuel from escaping.

5.3.3.2 In heaters for liquid fuel, where the fuel supply is

separated from the vehicle's fuel supply, the type of fuel

and the filler neck must be clearly marked.

5.3.3.3 On the filler neck, a note must be visible, saying

that the heater must be switched off before refuelling it. A

corresponding instruction must also be included in the

Visit www.butlertechnik.com for more technical information and downloads.

www.butlertechnik.com

DBW 160 / 230 (2020) / 300 / 350 1Introduction

103

manufacturer's operating manual.

5.3.4 Exhaust system

5.3.4.1 The exhaust outlet must be positioned so that no

exhaust fumes can get into the vehicle's interior via

venting devices, hot-air inlets or window openings.

5.3.5 Combustion air inlet

5.3.5.1 The air for the heater's combustion chamber must

not be drawn in from the vehicle's passenger compartment.

5.3.5.2 The air inlet must be protected and positioned in

a way that it cannot be blocked by garbage or luggage.

5.3.6 Heating air inlet

5.3.6.1 The combustion air supply may consist of ambient

air or circulating air and must be drawn in from a clean

area which can presumably not be contamina ted by

exhaust gas from the engine, the combustion heater or

another source in the vehicle.

5.3.6.2 The inlet opening must be protected by grilles or

other suitable means.

5.3.7 Heating air outlet

5.3.7.1 Hot air pipes in the vehicle must be protected and

positioned so touching them will not result in injuries or

damage.

5.3.7.2 The air outlet must be protected and positioned in

a way that it cannot be blocked by garbage or luggage.

5.3.8 Automatic control of the heating system

5.3.8.1 When the engine stalls, the heating system must

automatically be switched off and the fuel supply interrupt-

ed within five seconds. If a manually operated control

device has already been activated, the heating system

can remain in operation.

CAUTION:

Non-compliance with the installation instruction s and

the notes contained will lead to exclusion of liability

by Spheros. The same applies to repairs not carrie d

out by experts or without the use of original spare

parts. This results in the invalidation of the heater's

type approval and hence the ECE type approval.

Installation instructions for separate fuel tanks with regard

to the fuel supply of coolant heaters in vehicles:

• In busses, the installation in the passenger's or driv-

er's compartment is not permissible.

• In no vehicle may the fuel-filler neck be located in the

passenger's or driver's compartment.

• The fuel tanks must either be equipped with a vent ilat-

ed cap or any other type of ventilation (vent line).

Only caps in compliance with DIN 73400 may be used.

1.7 Suggestions for improvements and

modifications

Please address any complaints, improvements or suggestions for correction of this technical manual to:

Spheros GmbH

Friedrichshafener Straße 9 - 11

82205 Gilching

Phone: +49 (0) 8105 7721-201

Fax: +49 (0) 8105 7721-199

Visit www.butlertechnik.com for more technical information and downloads.

www.butlertechnik.com

1Introduction DBW 160 / 230 (2020) / 300 / 350

104

Notes

Visit www.butlertechnik.com for more technical information and downloads.

www.butlertechnik.com

DBW 160 / 230 (2020) / 300 / 350 2 General Description

201

2 General Description

The Spheros DBW 160, 230, 300 and 350 coolant heaters

supplement the vehicle's heating system

– to heat the passenger compartment

– to defrost the windows, and

– to preheat liquid-cooled engines.

The coolant heater functions independently of the vehicle

engine and is connected to the cooling system, fuel

system and electric system.

The heater is designed for heat transfer a nd is contr olled

by a temperature sensor. It's operation is intermittent.

The heaters of the type DBW 160, 230, 300 and 350 com-

prise the following main components:

– combustion air fan

– fuel pump

– heat exchanger

– combustion chamber

– electronic ignition unit with ignition electrodes

Some heater variants are equipped with a nozzle- blo ck

preheater.

The heater is controlled by

– a control unit

– a flame sensor

integrated in the device.

The control units are fitted laterally at the rear or on the

top, depending on the heater variant.

The heater may comprise

– a temperature limiter

– a thermal fuse

– a fan thermostat

depending on variant.

An external circulation pump is installed in the vehicle.

Visit www.butlertechnik.com for more technical information and downloads.

www.butlertechnik.com

2 General Description DBW 160 / 230 (2020) / 300 / 350

202

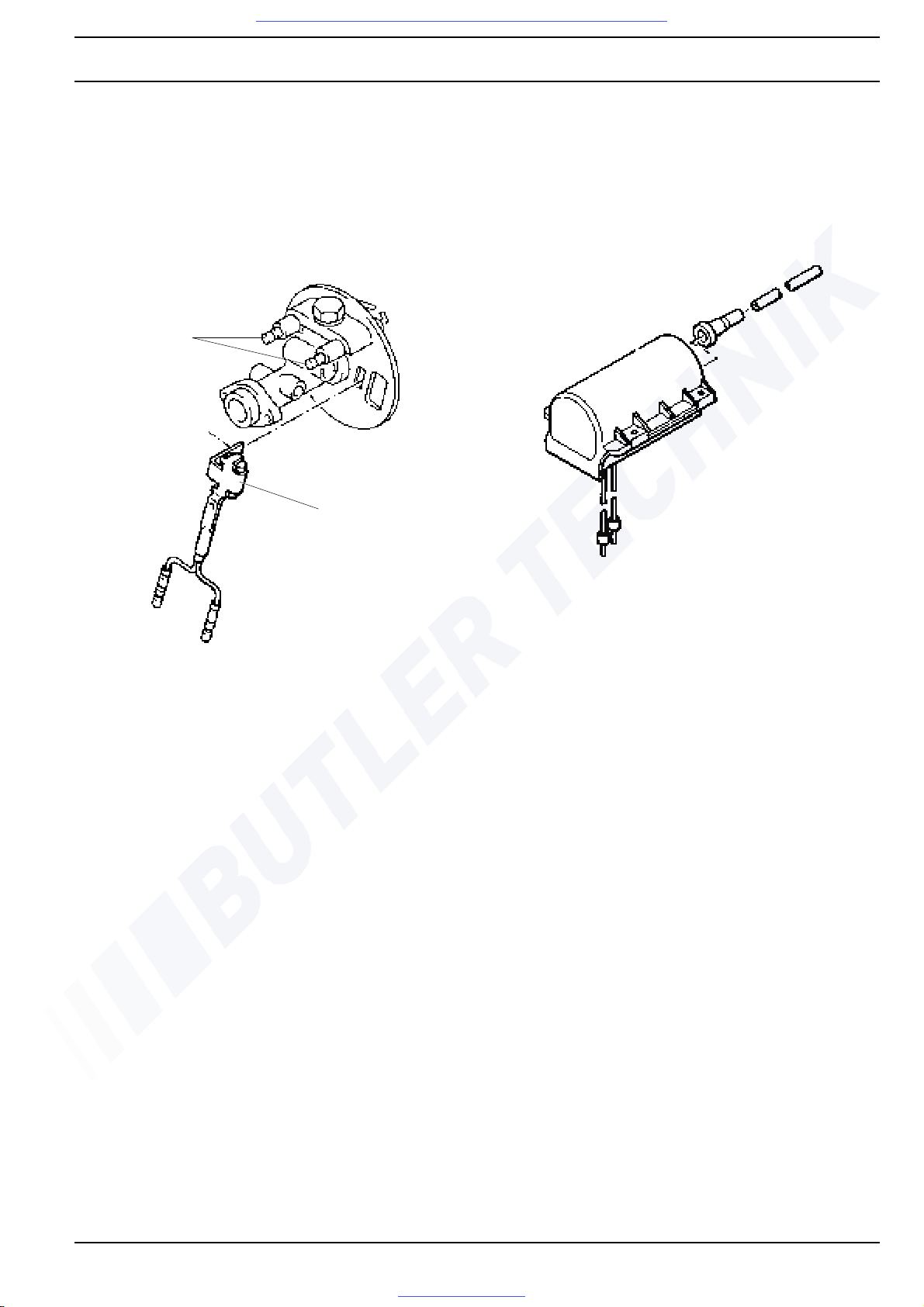

Heater DBW 160

1 Burner head

2 Electronic ignition unit

3 Coolant outlet

4 Control thermostat

5 Fusible link

6 Temperature limiter

7 Fan thermostat

8 Heat exchanger

9 Exhaust outlet

10 Control unit

8

7

6

4

3

2

1

9

10

5

Visit www.butlertechnik.com for more technical information and downloads.

www.butlertechnik.com

DBW 160 / 230 (2020) / 300 / 350 2 General Description

203

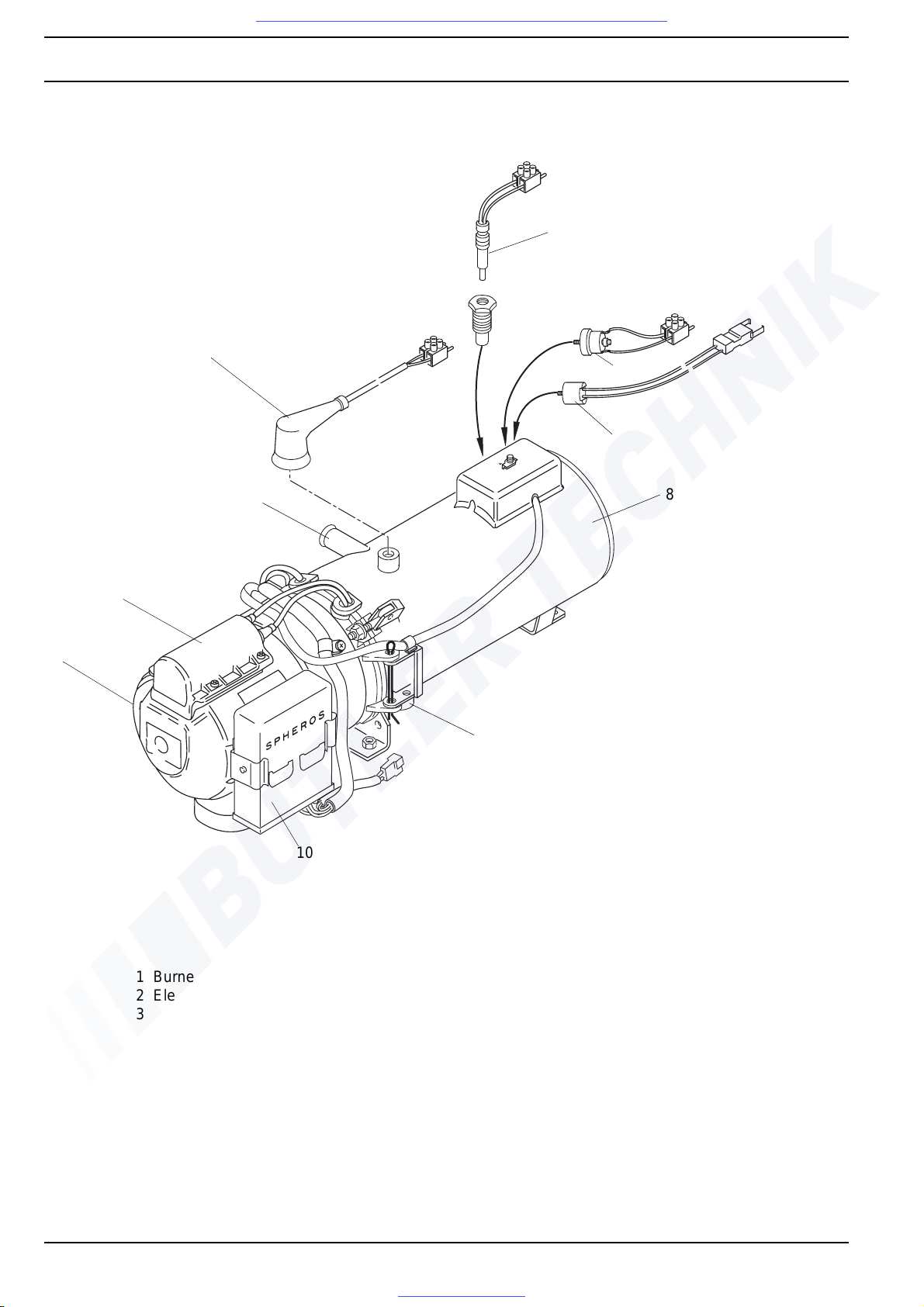

Heater DBW 230, DBW 300 and DBW 350

1 Burner head

2 Electronic ignition unit

3 Coolant inlet

4 Fusible link *

5 Control thermostat *

6 Temperature limiter *

7 Coolant outlet

8 Heat exchanger

9 Fuel return

10 Fuel supply

11 Exhaust outlet

12 Control unit

* for components installed in applicable

heater variants

3

2

1

4

5

6

8

7

9

10

12

11

Visit www.butlertechnik.com for more technical information and downloads.

www.butlertechnik.com

2 General Description DBW 160 / 230 (2020) / 300 / 350

204

2.1 Combustion air fan

The combustion air fan supplies the air required for combustion from the air intake into the combustion chamber.

Heaters are fitted with the following fan types:

DBW 160 – side-channel fan,

DBW 230 / 300 – radial fan,

DBW 350 – two-stage radial fan.

2.2 Motor

The motor drives the combustion air fan via a co up ling

and the fuel pump via a gearset.

2.3 Fuel pump

The fuel pump supplies fuel for combustion. It is driven by

the combustion air fan motor via a coupling. Inside the fuel

pump, the fuel is pressurised to approx. 10 bar (DBW 160

11.5 bar) and is vaporised by the high-pressure atomiser.

Fuel supply to the atomiser is controlled by a solenoid

valve.

DBW 160

DBW

230 / 300

DBW 350

DBW

300.62

DBW 160 /

230 / 300 /

350

Visit www.butlertechnik.com for more technical information and downloads.

www.butlertechnik.com

DBW 160 / 230 (2020) / 300 / 350 2 General Description

205

2.3.1 Nozzle-block preheater

The nozzle-block preheater heats the fuel flowing to the

high-pressure nozzle.

Heaters without nozzle-block preheaters may show malfunctions at extremely low temperatures.

At temperatures < 0° C, the heating element in the nozzle

block is actuated via a thermostat.. Heating duration

depends on the heat reflected in the combustion chamber,

and the heater switches off when the thermostat reaches

a temperature of +8° C.

Heaters without nozzle-stock preheaters can be retrofitted.

For parts required please refer to parts list.

2.4 Heat exchanger

The heat exchanger transfers the heat generated by combustion into the cooling system.

DBW 160

Heating element

Nozzle block

Thermostat

DBW 230 /

300 / 350

Heating element

Nozzle block

Thermostat

DBW 160

to DBW

230(2020).32

to DBW

300.15

from DBW 230(2020).33

from DBW 300.15

from DBW 350.01

Visit www.butlertechnik.com for more technical information and downloads.

www.butlertechnik.com

2 General Description DBW 160 / 230 (2020) / 300 / 350

206

2.5 Combustion chamber

The fuel/air mixture is distributed in the combustion

chamber where it is burned, thus heating the he at

exchanger.

2.6 Control unit

The control unit is the core control element ensurin g th e

system function and the monitoring of the combustion.

Control unit 1553

DBW 160

to

DBW 300.15

from

DBW 230(2020).33

DBW 300.16

DBW 300.62 without flame pipe

DBW 350.01

to

DBW 230(2020).32

Visit www.butlertechnik.com for more technical information and downloads.

www.butlertechnik.com

DBW 160 / 230 (2020) / 300 / 350 2 General Description

207

2.7 Flame sensor

The flame sensor monitors the flame during the entire

combustion process. The flame sensor acts as a photoelectric resistor detecting the absence of a flame or as a

photoelectric transistor detecting the presence of a flame

and responding to its luminous intensity.

Its signals are received and processed by the control unit.

Flame sensor for control unit 1553

2.8 Electronic ignition unit with ignition

electrodes

The electronic ignition unit creates the high voltage

required to ignite the fuel/air mixture. Ignition is then realised by high-voltage spark-over between the two ignition

electrodes.

Ignition

electrodes

Flame sensor

Visit www.butlertechnik.com for more technical information and downloads.

www.butlertechnik.com

2 General Description DBW 160 / 230 (2020) / 300 / 350

208

2.9 Temperature limiter / Thermal fuse

Temperature limiter

The temperature limiter (bi-metal) protects the heater

against excessive operating temperatures. The temperature limiter trips when a temperature of 107° C or 117° C

is exceeded, turning off the heater. The temperature

limiter is resetable or self-resetting.

Thermal fuse

The thermal fuse protects the heater against excessive

operating temperatures. It comprises a fusible link that

trips at excessive temperatures, turning off the heater.

Heaters can be retrofitted with temperature limiters

replacing the thermal fuses.

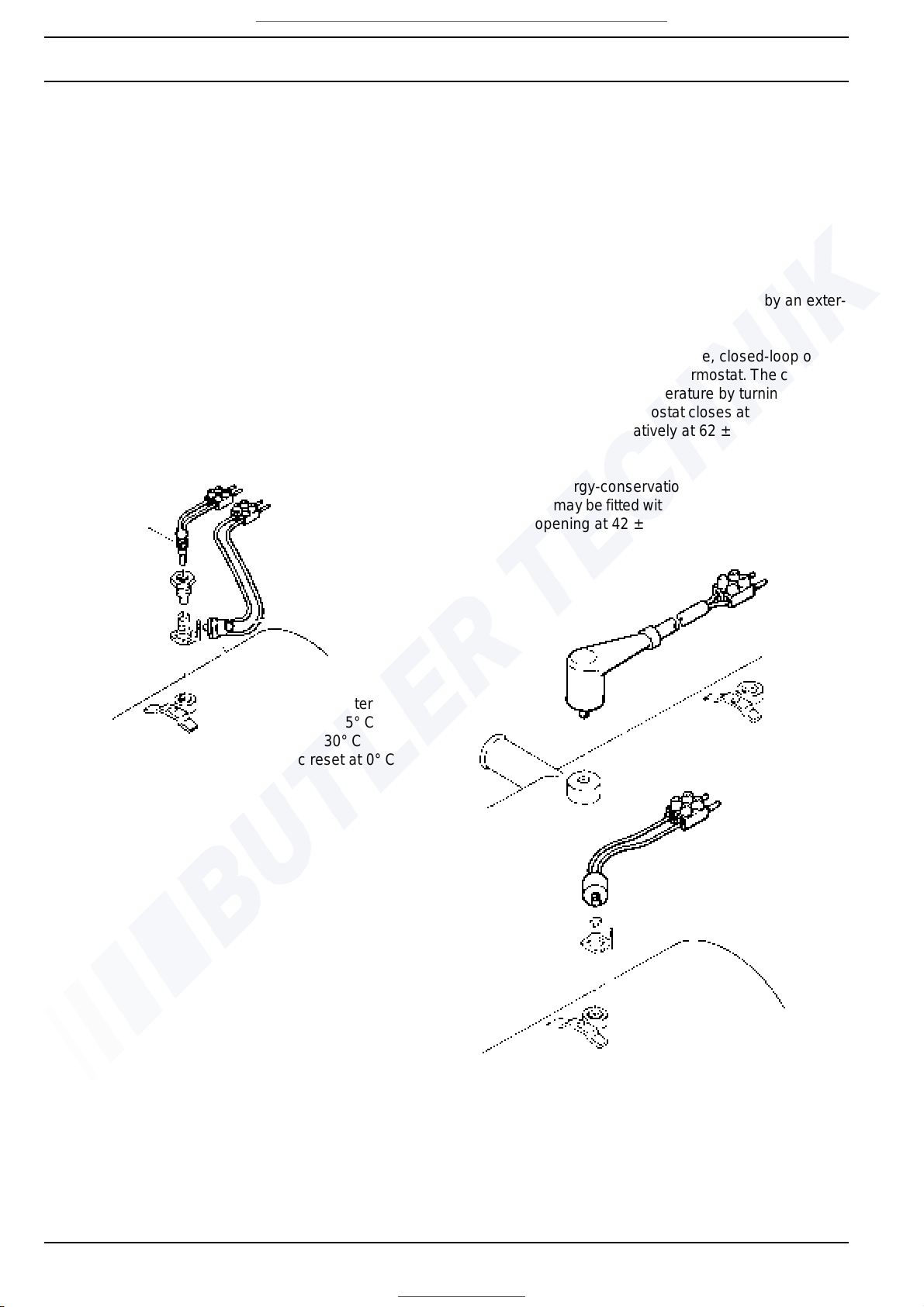

2.10 Control thermostat

Control thermostat at heater

After reaching operating temperature, closed-loop operation is performed by the control thermostat. The coolant is

maintained at a constant temperature by turning the

heater on and off. The thermostat closes at 63 ± 5° C and

opens at 70 ± 3° C.

External control thermostat

Closed-loop operation can also be executed by an exter-

nal control thermostat.

After reaching operating temperature, closed-loop operation is performed by the control thermostat. The coolant is

maintained at a constant temperature by turning the

heater on and off. The thermostat closes at 71 ± 2° C and

opens at 78 ± 2° C; alternatively at 62 ± 2° C and

70 ± 2° C.

Heaters with energy-conservation function (temperature

conservation) may be fitted with a thermostat closing at 35

± 2° C and opening at 42 ± 2° C.

Thermal

fuse

Reset

button

Temperature limiter

opens at 107 ± 5° C

resetable at 30° C

automatic reset at 0° C

DBW 160

DBW 230 / 300 / 350

Control thermostat at heater

Visit www.butlertechnik.com for more technical information and downloads.

www.butlertechnik.com

DBW 160 / 230 (2020) / 300 / 350 2 General Description

209

2.11 Fan thermostat

The fan thermostat turns the vehicle heater's fan on and

off at coolant temperatures between 30° C and 40° C. The

thermostat closes at 40 ± 3° C and opens at 30 ± 5° C.

Fan thermostat at heater

– Fan thermostat in coolant system

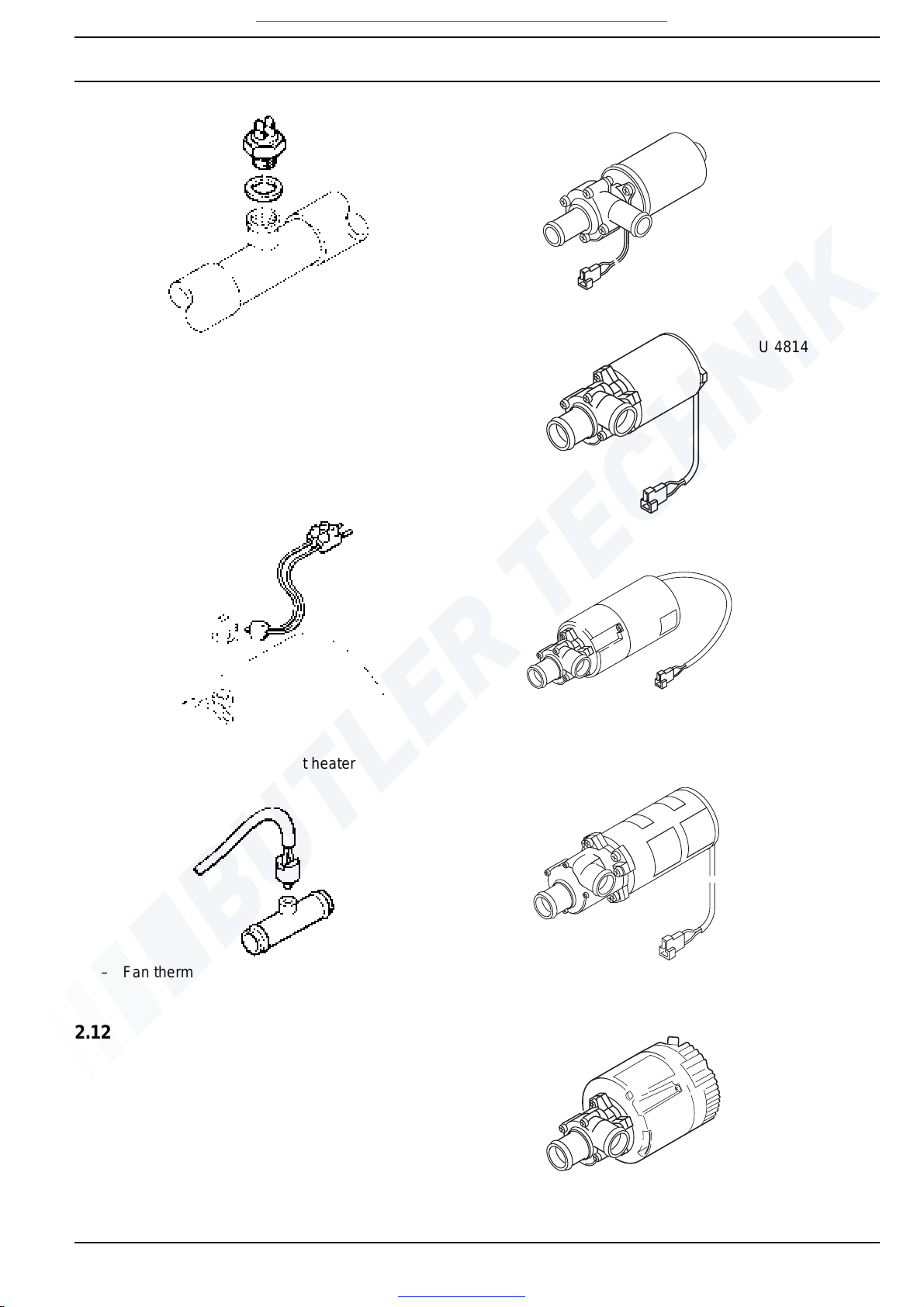

2.12 Circulation pump

The external circulation pump circulates the coolant in the

cooling system of the vehicle and in the heater. The pump

is activated by the control unit and runs througho ut the

entire operating period of the heater. Heaters are compatible with pumps of the type U 4810 (DBW 160 only),

U 4814, U 4851, U 4854, U 4855 or U 4856.

External control thermostat

U 4810

Recommended

for heater DBW

160

U 4814

Recommended

for heater DBW

230, 300 and

350

U 4851

Recommended

for heater DBW

230, 300 and 350

U 4854

Recommended

for heater DBW

230, 300 and

350

U 4855

(replaces

U 4851)

Recommended

for heater DBW

230, 300 and

350

Visit www.butlertechnik.com for more technical information and downloads.

www.butlertechnik.com

2 General Description DBW 160 / 230 (2020) / 300 / 350

210

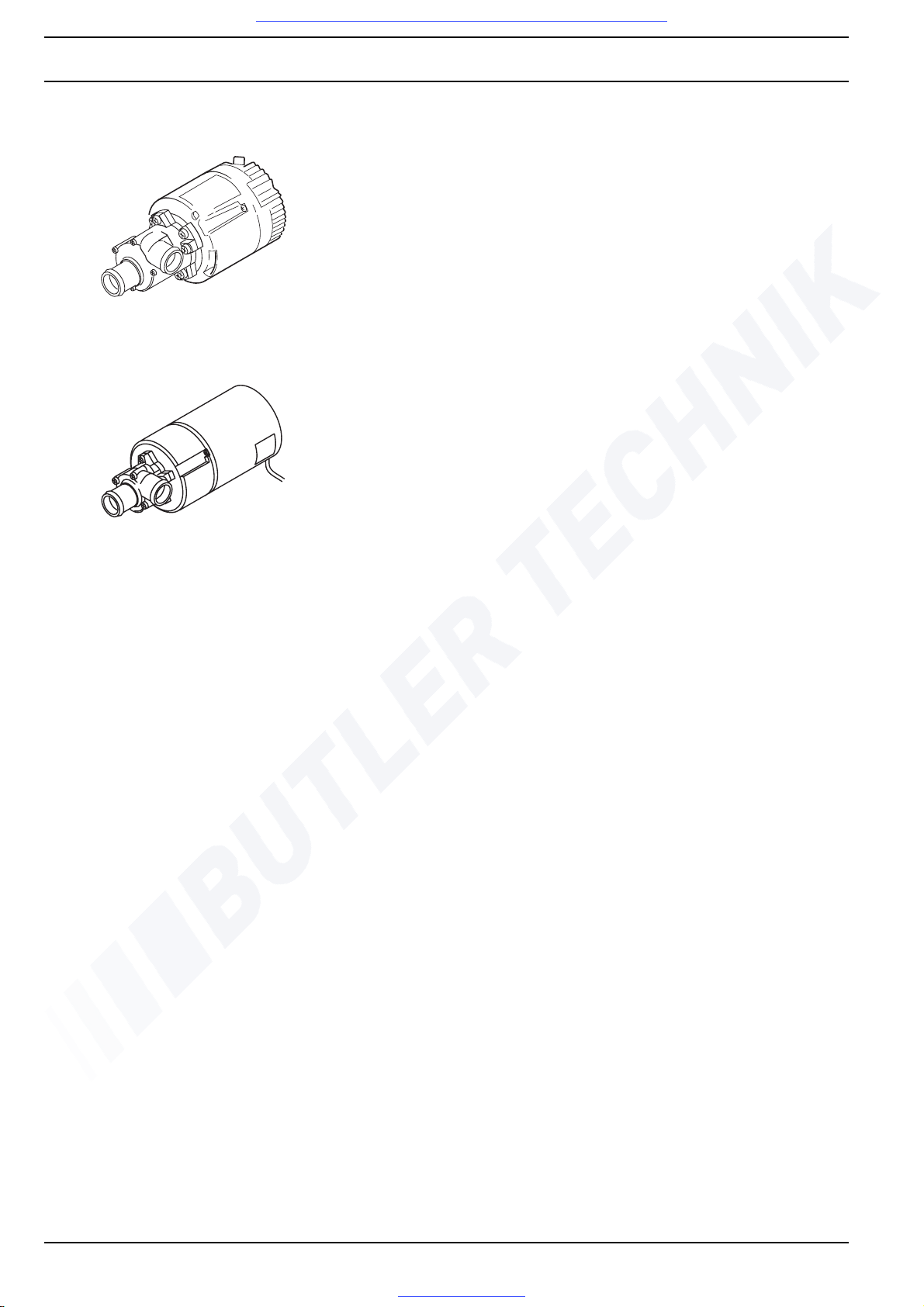

U 4856

(replaces

U 4852)

Recommended

for heater DBW

230, 300 and 350

U 4852

Recommended

for heater DBW

230, 300 and 350

Visit www.butlertechnik.com for more technical information and downloads.

www.butlertechnik.com

DBW 160 / 230 (2020) / 300 / 350 3 Function Description

301

3 Function Description

3.1 General

The heaters are equipped with burners using high-pressure atomisers and run in intermittent operation. They are

thermostatically controlled (control unit 1553).

3.2 Operation

The heater is switched on and off at the

– switch (On/Off) or

– by the timer.

Its operating mode is shown by an operation indicator in-

tegrated in the timer or by a separate indicator light.

Heaters can be fitted with optional nozzle-block pre-

heaters and heater elements for operatio n at extremely

low temperatures.

Operation (see Fig. 301)

3.2.1 Switch on

When the system is switched on, the operation indicator

lights up. Combustion air fan, fuel pump and circ ulation

pump start. After approx. 15 seconds, the solenoid valve

opens and fuel is injected into the combustion chamber

via the atomiser. At the same time, a high-voltage ignition

spark is generated. When the flame sensor detects a

flame, it outputs a signal to the control unit which switches

the electronic ignition unit off.

If no flame is detected, please refer to 3.2.4.

3.2.2 Heating operation

After reaching operating temperature, closed-loop operation is performed by the control thermostat.

Coolant temperature is then maintained at a constant

level by switching the heater on and off. When the temperature exceeds the upper switch point, the solenoid valve

shuts of the fuel supply, causing the flame to extinguish.

The combustion air fan then runs on for approx. 150 seconds, switching off automatically. The circulation pump

keeps on running during the burner's off-periods, and the

operation indicator remains on. When the temperature

falls below the lower switch point, the heater is restarted.

3.2.3 Switch off

When the heater is switched off, combustion is stopped.

The operation indicator is turned off, and the purge cycle

begins. Combustion air fan and circulation pump are

switched off after approx. 150 seconds.

The heater cannot be restarted during purge cycle.

3.2.4 Malfunction cut-out

Heaters with control unit 1553

A malfunction cut-out occurs

– if no combustion is detected within approx. 30

seconds after the heater is switched on,

– if the fuel supply is interrupted for more than 10

seconds during heating operation,

– if thermal fuse or temperature limiter detect over-

heating of the heater. The thermal fuse must always

be replaced by a fuse of the identical type (observe

colour code). Reset the button of the temperature

limiter (once the heater has cooled down to below

60° C).

– if undervoltage is detected approx. 10 – 25 seconds

after the temperature falls below the switch point.

Once the cause of the malfunction has been eliminated,

the heater can be unlocked by switching it off and back on.

Visit www.butlertechnik.com for more technical information and downloads.

www.butlertechnik.com

3 Function Description DBW 160 / 230 (2020) / 300 / 350

302

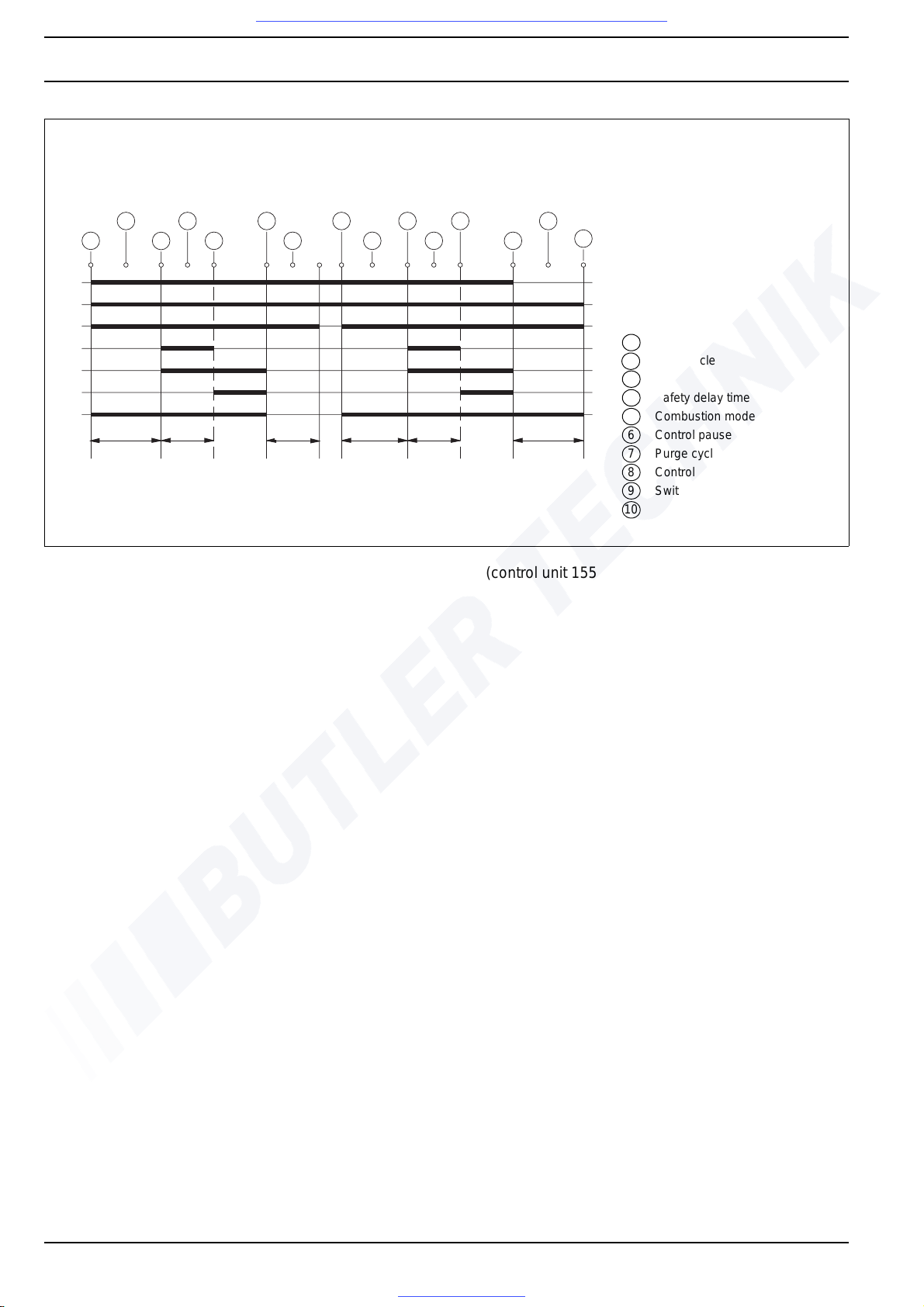

Fig. 301 Function sequence (control unit 1553)

1

10

3

5

82 4 6

7

3

2 4

5 7

9

10-25 s 5-25 s

ca.150 s

10-25 s

5-25 s

ca.150 s

A

B

C

D

E

F

G

A Operation indicator

B Circulation pump

C Combustion air fan

D Electronic ignition unit

E Solenoid valve

F Flame sensor

G Control thermostat

1 Activation

2 Initial cycle

3 Start

4 Safety delay time

5 Combustion mode

6 Control pause starts

7 Purge cycle

8 Control pause ends

9 Switch-off

10 Heater stops

Visit www.butlertechnik.com for more technical information and downloads.

www.butlertechnik.com

DBW 160 / 230 (2020) / 300 / 350 4 Technical Data

401

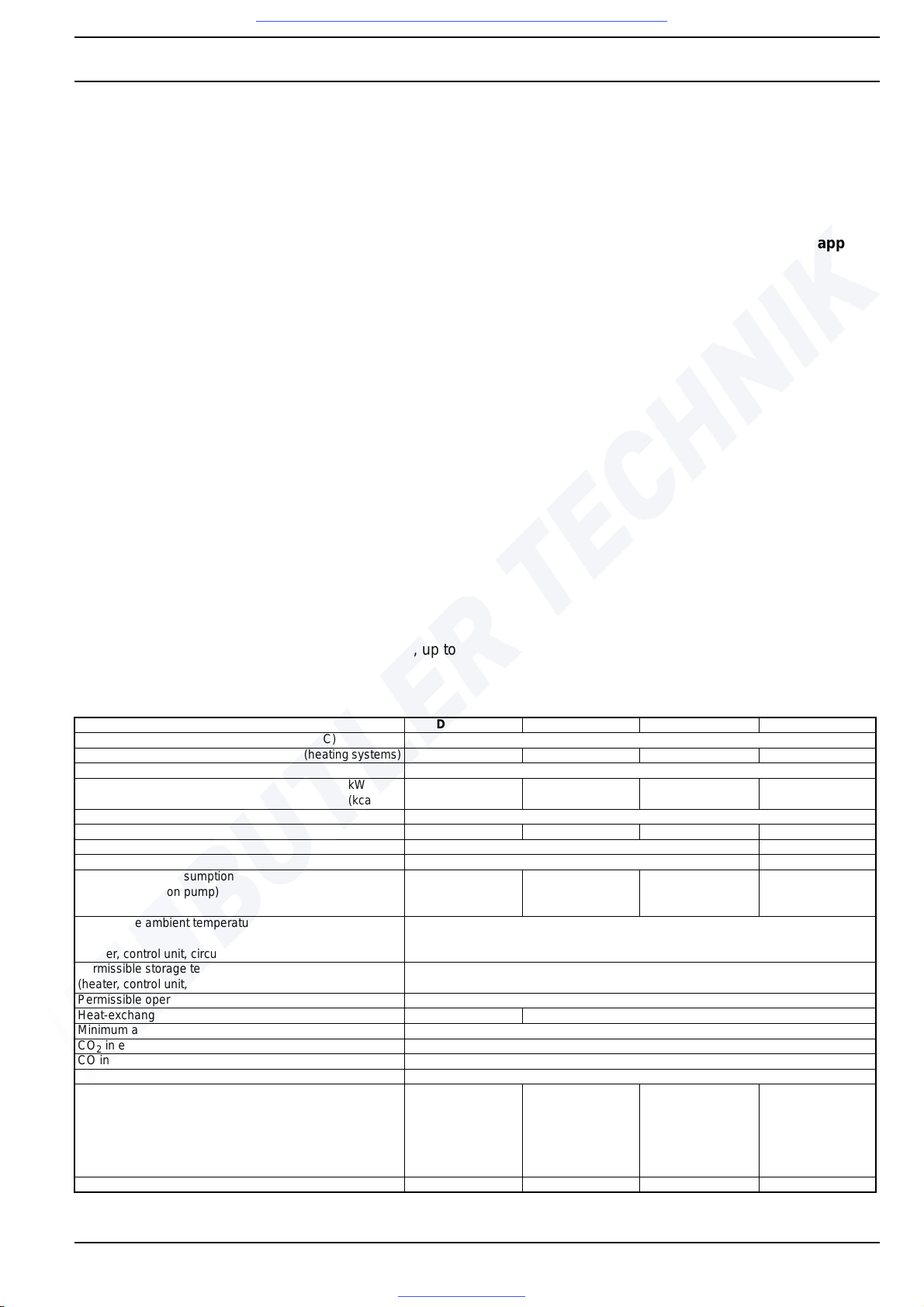

4 Technical data

Where no limit values are specified, technical data are understood to include standard tolerances for heaters of

±10% at an ambient temperature of +20° C and at nominal

voltage.

Electrical components

Control unit, motors for combustion air fan and circulation

pump, solenoid valve, electronic ignition unit, heating element, nozzle-block preheater and timer are designed for

24 volts. The components temperature limiter, flame

sensor, temperature sensor and switch are voltage-independent.

NOTE

Combinations of circulation pumps and heaters must be

selected in accordance with coolant flow resistance

Fuel

Only the type of fuel indicated on the heater's type label

may be used.

Commercially available diesel fuels in accordance with

DIN EN 590 (diesel fuel) may be used.

According to the diesel-fuel standard DIN EN 590, up to

5% of biodiesel additive is also permissible.

At temperatures below 0°C, a commercially available

winter diesel fuel should be used.

The use of flow improvers or additives is permissible.

Adverse effects are not known.

CAUTION:

For fuel taken from the vehicle tank, the vehicle manufacturer's specifications regarding additives apply.

Heater DBW 160 DBW 230 DBW 300 DBW 350

ECE approval number according to R10 (EMC) 025038

ECE approval number according to R122 (heating systems) 000204 000205 000206 000207

Build type High-pressure atomiser

Heat flow kW

(kcal/h)

16

(13 800)

23.3

(20 000)

30

(26 000)

35

(30 000)

Fuel Diesel fuel as per DIN 51601

Fuel consumption kg/h 1.9 2.5 3.3 3.7

Nominal voltage V – 12 or 24 24

Nominal-voltage range V – 10...14 / 21...28 21...28

Nominal power consumption

(without circulation pump)

W 100 (12V)

90 (24V)

110 (12V)

110 (24V)

100 (12V)

130 (24V)

.62: 100 (24V)

170 (24V)

Permissible ambient temperature during operation

(heater, control unit, circulation pump)

°C -40... + 60

Permissible storage temperature

(heater, control unit, circulation pump)

°C -40... + 85

Permissible operating pressure bar 0.4...2.0

Heat-exchanger filling capacity l 1.1 2.4

Minimum amount of coolant in circuit l 10.00 I

CO

2

in exhaust gas at nominal voltage Vol % 10.5 ± 0.5

CO in exhaust gas Vol % max. 0.2

Bacharach smoke number Vol % < 4.0

Heater dimensions (tolerance ± 3 mm) mm

mm

mm

length 584

width 205

height 228

length 681 to .32

length 680 to .50

width 230 to .32

width 240 to .50

height 279 to .32

height 269 to .50

length 681 to .15

length 680 to .30

width 230 to .15

width 240 to .30

height 279 to .15

height 269 to .30

length 725

width 240

height 279 to .10

height 269 from .11

Weight kg 14.5 24 from .33: 22 24 from .33: 22 23

Visit www.butlertechnik.com for more technical information and downloads.

www.butlertechnik.com

4 Technical Data DBW 160 / 230 (2020) / 300 / 350

402

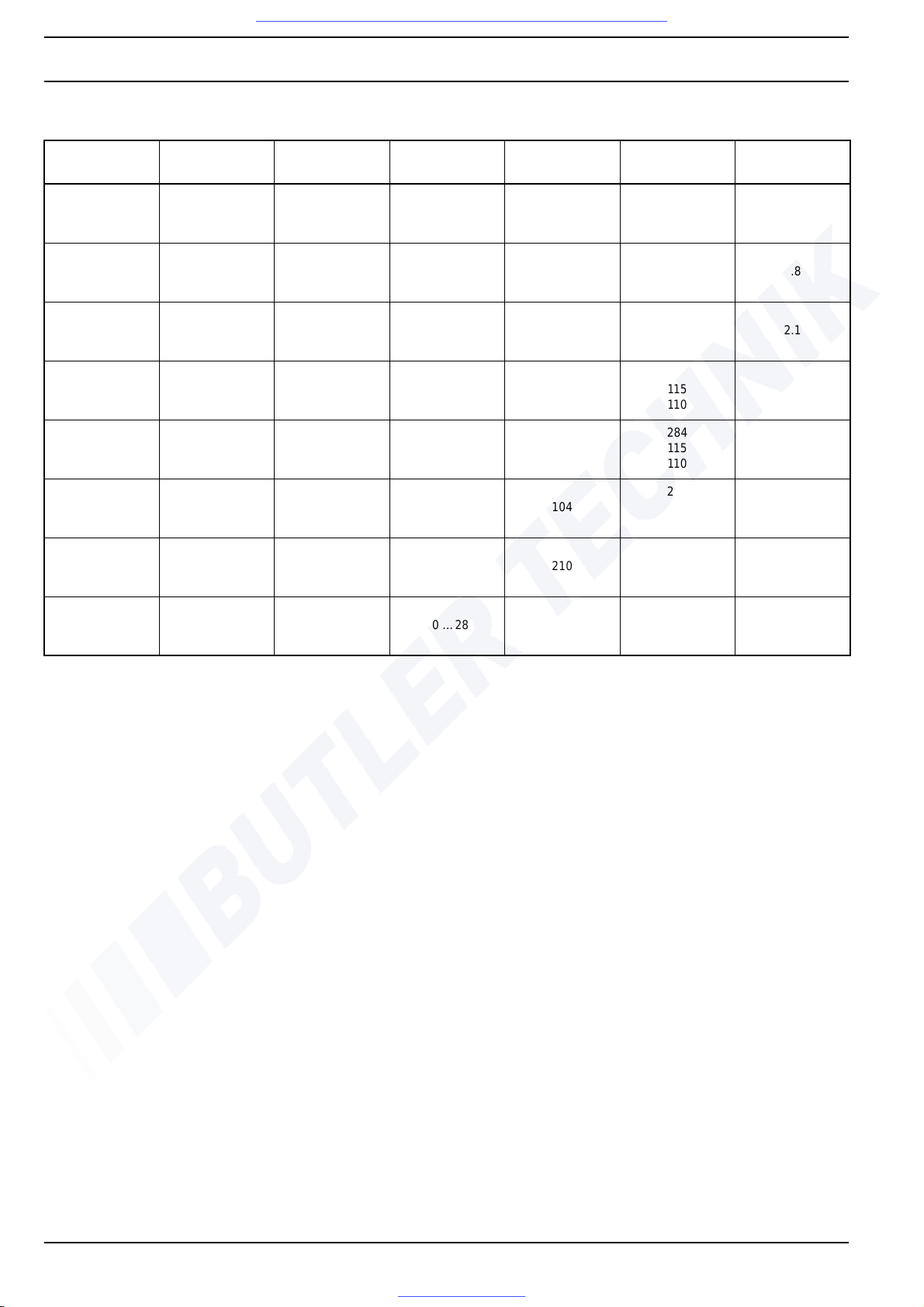

Circulationpump type

Volume flow Nominal voltage

Operating

voltage range

Nominal power

consumption

Dimensions Weight

l/h V – V – W

length

width

height

kg

U 4810

1600 (at approx.

0.15 bar)

12 or 24 10 …14 / 20 …28 25

173

94

77

0.8

U 4814

5000 (at approx.

0.2 bar)

12 or 24 10 …14 / 20 …28 104

228

100

105

2.1

U 4851

6000 (at approx.

0.4 bar)

24 20 …28 209

279

115

110

2.7

U 4852

6000 (at approx.

0.4 bar)

24 20 …28 209

284

115

110

2.95

U 4854

5200 (at approx.

0.15 bar)

24 20 …28 104

221

100

105

2.1

U 4855

6000 (at approx.

0.4 bar)

24 20 …28 210

225

110

115

2.4

U 4856

6000 (at approx.

0.4 bar)

24 20 …28 210

229

110

115

2.5

Visit www.butlertechnik.com for more technical information and downloads.

www.butlertechnik.com

Loading...

Loading...