08/04 Form # 409

OPERATING INSTRUCTIONS

V.O. mA MULTIMETERS

PLEASE READ THESE

OPERATING INSTRUCTIONS

CAREFULLY

MISUSE AND OR ABUSE OF

THESE INSTRUMENTS CANNOT

BE PREVENTED BY ANY

PRINTED WORD AND MAY

CAUSE INJURY AND OR

EQUIPMENT DAMAGE PLEASE

FOLLOW ALL THESE

INSTRUCTIONS AND

MEASUREMENT PROCEDURES

FAITHFULLY AND ADHERE TO

ALL STANDARD INDUSTRY

SAFETY RULES AND

PRACTICES.

MODEL

SP-10A

PRINTED IN CHINA

MADE IN CHINA

A.W. SPERRY INSTRUMENTS INC.

Byram Laboratories, Inc. 1 Columbia Rd, Branchburg, NJ 08876

Phone: 800-766-1212 or 908-252-0852

Fax: 908-252-0822

www.byramlabs.com

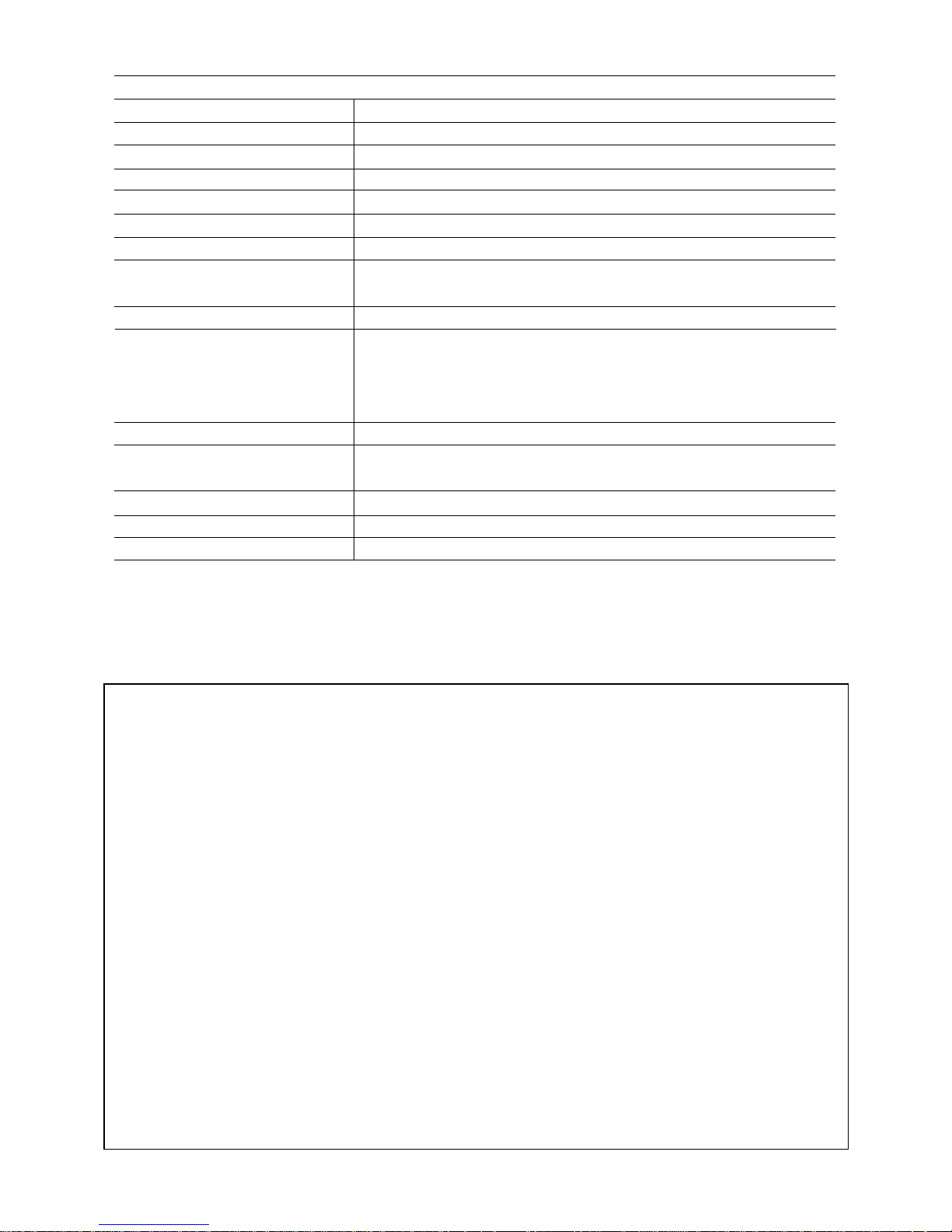

SPECIFICATIONS

SP–10A

SENSITIVITY 2 kΩ/V AC & DC

AC V 10/50/250/500

DC V 10/50/250/500

DC MA 250

OHMS FULL RANGE 1K/10K/100KΩ

OHMS MID SCALE 5/50 /500Ω

dB -20 T0 +56

SPECIAL FEATURES SEPARATE 1.5V TO 9V

BATTERY CHECK RANGES

ACCURACY DC ± 3% FS - OHMS ± 3% OF ARC

INDOOR USE

TEMPERATURE 5

0

C TO 400C

MAXIMUM RELATIVE HUMIDITY 80% @ 31

0

C

MINIMUM 50% @40

0

C

BATTERY COMMERCIAL ELECTRIC ™ PART # B - 1, TYPE AA, 1.5VDC

FUSE COMMERCIAL ELECTRIC ™ PART # F - 7. MINIATURE GLASS

TYPE, 5x20MM1/2 AMP, 250VAC, FF

DIMENSIONS 4”H x 2.9”W x 15/16”D (100H x 63W x 34DMM)

WEIGHT 3.6OZ. (102GMS)

TEST LEADS TL-34

ONE YEAR LIMITED WARRANTY

A.W Sperry Instruments Inc. warrants that this A.W Sperry Instruments Inc. has been carefully tested,

inspected and warranted for one (1) year from the date of purchase by the original end user, provided the

instrument has not been misused, damaged due to negligence, neglect or unauthorized repair, abused or

used contrary to the operating instructions.

Instruments and proof of purchase in the form of a legible copy or original of the sales receipt clearly

identifying the distributor, model number and date of purchase must be returned to A.W Sperry

Instruments Inc., Attention: Customer Service Center, 245 Marcus Boulevard, Hauppauge, NY 11788

postage prepaid for examination and verification of manufacturing defect under warranty. A.W Sperry

Instruments, Inc. shall be the sole judge of such defect. The liability of A.W Sperry Instruments, Inc. shall

be limited to the repair or replacement at its sole option of any defective product.

THIS WARRANTY AND THE OBLIGATIONS AND LIABILITIES OF SELLER THEREUNDER ARE

EXCLUSIVWE AND IN LIEU OF AND BUYERS HEREBY WAIVES ALL OTHER REMEDIES, EXPRESS

WARRANTIES, GUARANTEES OR LIABILITIES OF AND FOR INCIDENTAL OR CONSEQUENTIAL

DAMAGES OR WHETHER OR NOT OCCASIONED BY SELLER’S NEGLIGENCE. THIS WARRANTY

SHALL NOT BE EXTENDED, ALTERED OR VARIED EXCEPT BY A WRITTEN INSTRUMENT SIGNED

BY SELLER AND BUYER. SOME STATES ALLOW LIMITATIONS ON HOW LONG AND IMPLIED

WARRANTY LASTS, SO THE ABOVE LIMITATION ON HOW LONG AN IMPLIED WARRANTY LASTS,

SO THE ABOVE LIMITATIONS MAY NOT APPLY TO YOU. THIS WARRANTY GIVES YOU SPECIFIED

LEGAL RIGHTS AND YOU MAY ALSO HAVE OTHER RIGHTS WHICH VARY STATE TO STATE.

2

OPERATING

ENVIRONMENT

Instrument complies with insulation category (over voltage category II)

Pollution degree 2 in accordance with IEC-644

This equipment has been evaluated to INSTALLATION CATEGORY (OVERVOLTAGE

CATEGORY II)

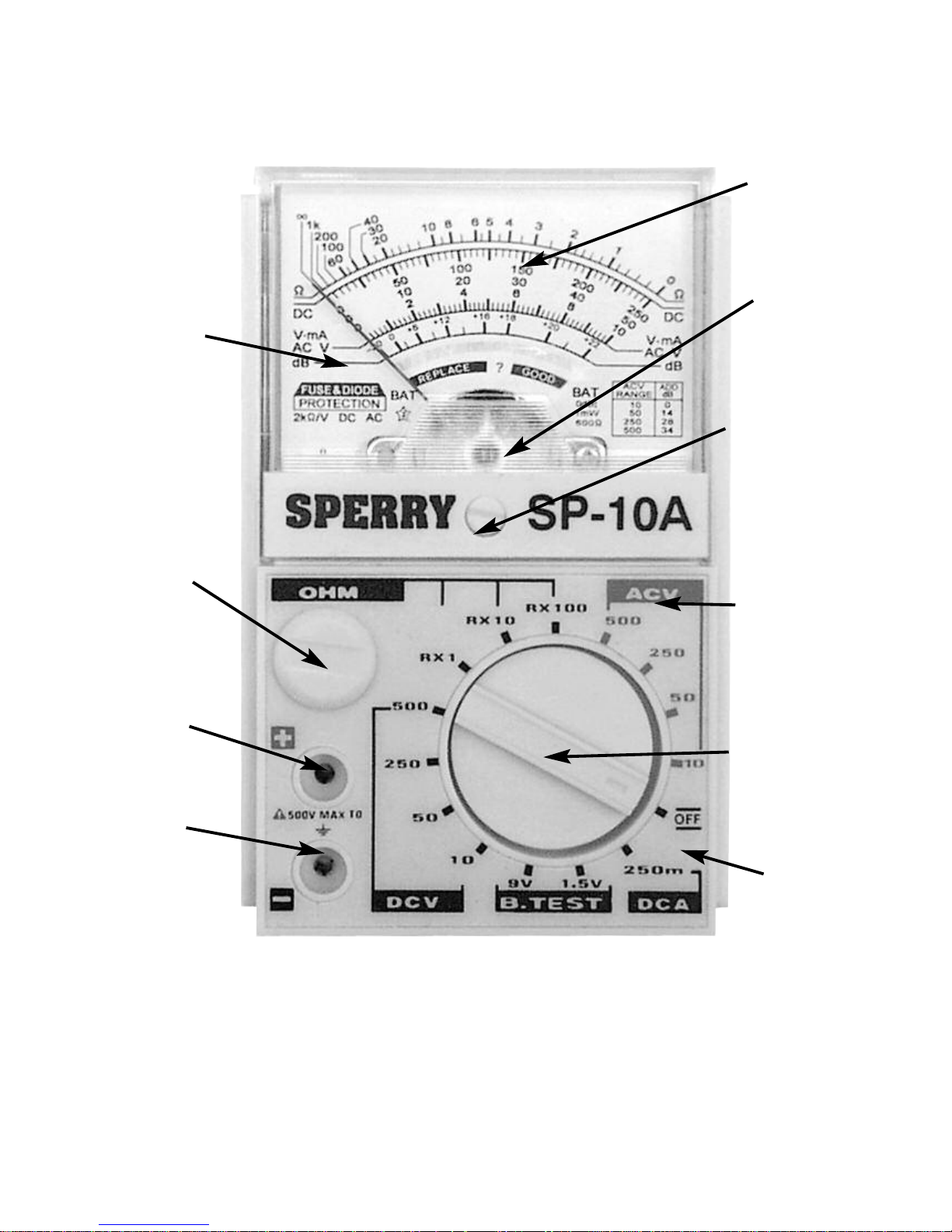

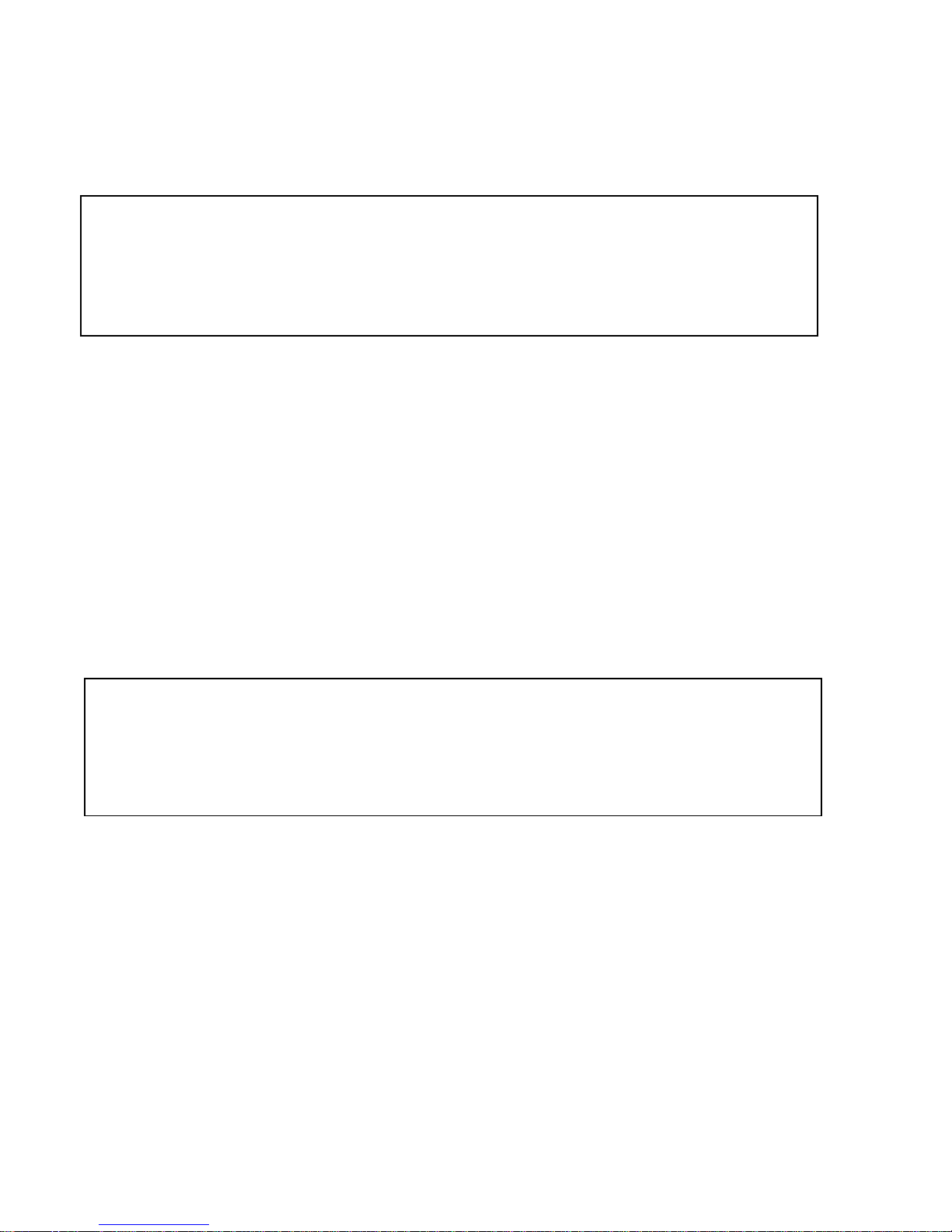

POINTER

ZERO

OHM

ADJUST

+ JACK

- JACK

RANGE

DECAL

RANGE

SWITCH

CASE

SCALE

PLATE

COVER

ZERO

ADJUST

FIG. 1

3

Always inspect your meter, test leads and accessories for any signs of damage or abnormality

before every use. If any abnormal condition exist: e.g. broken test lead, cracked case etc., do

not attempt to take any measurements. Return for repair to 245 Marcus Boulevard,

Hauppauge, NY 11788

DOUBLE INSULATION

WARNING:TO AVOID ELECTRIC SHOCK, DISCONNECT

MEASURING TERMINALS BEFORE REMOVING BACK COVER.

CAUTION:FOR CONTINUED PROTECTION AGAINST FIRE, REPLACE

ONLY WITH FUSE OF THE SPECIFIED VOLTAGE, CURRENT, AND RUPTURE

SPEED RATINGS.

TO PLACE MINI-METER™ IN OPERATION:

A. BATTERY

1. A battery is furnished with each instrument. Remove back case and make certain it is in

place, in proper polarity + and – is molded in well under battery.

2. For replacement, use "AA" battery.

3. If instrument is not in service for a long time, remove battery and store separately.

4. To avoid battery drain, always set Range knob at OFF position.

B. FUSE

1. A fuse is furnished with each instrument, installed in a fuse holder. Check to make sure

the fuse is securely in its clips at the time you check the battery.

2. For replacement, use A.W. Sperry Instruments Inc. Part # F-7 fuse.

CAUTION: DO NOTshort fuse out of the circuit, or use a fuse with a higher rating

than Ω amp., or alter circuit to eliminate fuse. These actions negate the safety purpose of the

Fuse, can cause damage to the instrument and or equipment being measured and or injury to

the user.

C. ZERO ADJUSTMENT

1. Before use and for greatest accuracy, make certain that the pointer is set exactly on the

Zero Line, at the extreme left of the arc.

2. If not on zero, rotate the Zero Adjuster Screw, at middle bottom of window, until pointer

is directly over the line zero.

3. It is good practice to check the zero adjustment daily, since changes in atmospheric

conditions can cause it to drift in position.

D. TESTLEADS

1. One (1) pair consisting of a Red Lead and a Black Lead, is furnished with

each instrument.

2. The short insulated probe tips fit into the two receptacles on the front cover.

3. The long insulated prod handles are used to make contact with the circuit

being measured.

4

!

!

Before taking any measurements, ALWAYS REMEMBER TO

CAREFULLY CHECK THE FUNCTION DESIRED, THE POSITION OF THE ROTARY

SWITCH AND THE RANGE TO BE USED. START WITH THE HIGHEST RANGE AND WORK

DOWN TO LOWER RANGES UNTIL POINTER READS IN UPPER HALF OF SCALE.

MEASUREMENT PROCEDURE

To minimize possibility of damage to the instrument and to obtain a long trouble-free field

life, the following procedure is recommended.

E. ACCURACY

1. For best accuracy, the pointer should read in the upper half of the scale, preferably in

the fourth quadrant of the arc, where accuracy is best.

F. SWITCH POSITION

1. Prior to use, SET THE SWITCH TO THE HIGHEST RANGE OF THE FUNCTION TO

BE MEASURED.

Work down to lower successive ranges of this function until the pointer reads in the

upper half of the scale.

.

For example, in preparing to read AC volts, set the switch to highest range then take

measurement. Work the switch down to lower ranges of AC volts until the pointer reads in

the upper half of the arc.

.

In this fashion, the instrument is protected against overloads where circuit values are

not known.

2. When finished with measurements of one function, remove Test Leads COMPLETELY

from the circuit, if another different function is to be measured, FIRST set switch to the

highest range of the new function, THEN take measurements.

HOW TO READ AC VOLTS

1. Connect Red short probe in + Jack, Black in – Jack. Read all AC Volt Ranges on the

third arc down.

2. Voltage measurements are taken by connecting the instrument in parallel with thecircuit

being checked. The long insulated prod handles are used to make contact with the circuit.

NOTE: For maximum safety, do NOT hold the Mini-Meter in your hand on the two highest

AC Volt ranges. (250 & 500V AC)

HOW TO READ DC VOLTS

1. Connect Red short probe into + Jack, Black in - Jack.

2. Read all DC volt range on the second arc down.

3. Voltage measurements are taken by connecting the instrument in parallel with the circuit

being checked. The long insulated prod handles are used to make contact with the circuit.

NOTE: For maximum safety do NOT hold the Mini-Meter in your hand on the two

highest DC Volt ranges. ( 250 & 500 VDC)

5

6

HOW TO READ DC MILLAMPS

1. Connect Red short Probe in + Jack, Black in - Jack.

2. Read all DC Milliamp Ranges on the second arc down.

3. For current measurements, open the circuit and connect the instrument in series with

the circuit being measured.

CAUTION

Make certain that the circuit to be measured is completely De-Energized

(

DEAD)with NO

live voltage in the circuit whatsoever.

Before taking any resistance measurement, disconnect line voltage fro circuit being

measured, or feeder voltage from any component being checked.

HOW TO READ OHMS

1. Set Range knob selector to suitable OHM Range.

2. Connect Red short Probe in + Jack, Black in – Jack

3. Short the Long Prod handles and adjust the Zero Ohm adjust pot (see Fig. 1) until the

pointer is directly over the Zero position on the Ohm Range (at extreme right).

Note: If Ohm Zero position cannot be adjusted, change the battery

4. Touch the long prod handles across the circuit, or component to be measured and

read on the Ohm arc. (Top Arc).

IMPORTANT - PLEASE READ CAREFULLY

Impressing live voltage across the Ohm circuit by mis-use or abuse may result in injury to

the operator and/or damage to the instrument and the equipment being checked. The extent

of the damage will depend on the volts and amps going at time of measurement.

CAUTION

Make certain that the circuit to be measured is completely De-Energized

(

DEAD)with NO

live voltage in the circuit whatsoever.

Before taking any resistance measurement, disconnect line voltage for circuit being

measured, or feeder voltage from any component being checked.

HOW TO USE THE BATTERY CHECK RANGES

1. The SP-10A comes with two separate battery check ranges that enable you to test either

1.5VDC or 9VDC batteries

2. Connect Red short Probe to + Jack, Black to - Jack.

3. Set the range selector switch to the 1.5V battery test range

4. Connect the test leads to the 1.5VDC battery under test. A good 1.5VDC battery will

read in the green portion of the Arc.

5. To check 9V batteries follow the above procedures with the range selector switch set

to 9V.

6. The “REPLACE” section of the scale plate shows that the battery may be starting

to decay.

Note: May not read various 1.5VDC button cell batteries.

HOW TO READ DECIBLES (DB)

Note:

In order to eliminate the DC components I the circuit, connect a O. 1 microFarad

Capacitor, or larger, in series with one of the Test Leads.

1. The db arc is 4th down, in Red.

2. Connect Red Short probe to + Jack, Black to – Jack.

3. Set switch knob selector to 10V AC Range, read direct on upper db arc, -20 to 22.

4. For measurement above the basic db range, set switch to the next highest AC Voltage

range and add db as shown in the table on the scale plate.

ACCESSORIES

Battery-Replace with

"AA"

Battery.

Fuse-Replace with A.W. Sperry Instruments Inc. Part # F-7 Fuse.

Test Leads-Replace with A.W. Sperry Instruments Inc. Part # TL-34 Test Leads.

IN STOCK- AT YOUR LOCAL WHOLESALER

GENERAL USAGE & MAINTENANCE

THINK SAFETY - ACT SAFELY.

DO NOT SOLDER WIRE ACROSS THE FUSE CLIPS, OR RE-INSERT BURNED

OUT FUSE WITH METAL FOIL ENCLOSING IT OR BYPASS THE SAFETY FUSE IN

ANY WAY.

DO NOT exceed the published maximum for each function.

DO NOT polish the window or attempt to clean it with cleaning fluid, kerosene or

gasoline - damage will result.

When volt measurements are completed, FIRST remove the Test Leads from circuit

being checked, AND THEN remove Test Leads from instrument jacks.

Remove grease and grime with a clean dry cloth.

When instrument is NOT in use, set Switch knob to “OFF”.

When measuring OHMS, MAKE SURE the circuit being checked is DEAD, completely

DE-ENERGIZED.

Avoid severe continuous mechanical shock or vibration, extreme temperature or very

strong magnetic fields.

7

RETURN FOR REPAIRS

Before returning your analog multimeter for repair be sure to check that the failure to operate

is not due to the following:

1. Weak Battery

2. Open Fuse

3. Open, loose or intermittent test leads.

If these conditions do not exist and the instrument fails to operate properly, return the

instrument and accessories prepaid:

State in writing what is wrong with the instrument. All warranty repairs must include proof of

purchase in the form of a legible or original copy of the sales receipt, clearly identifying the

distributor, model number and date of purchase and must have a warranty card on file. See

warranty statement on page 2 for full warranty disclosure. Repair estimate will be furnished if

requested for out of warranty instruments. Be sure to include all accessories, which may be

related to the problem and a note describing the malfunction you observed.

8

A.W. SPERRY INSTRUMENTS INC.

Byram Laboratories, Inc. 1 Columbia Road, Branchburg, NJ 08876

Phone: 800-766-1212 or 908-252-0852

Fax: 908-252-0822

www.byramlabs.com

Loading...

Loading...