Sperian SURVIVAIR Opti-Fit 7641, SURVIVAIR Opti-Fit 7540, SURVIVAIR Opti-Fit 7640, SURVIVAIR Opti-Fit 7741, SURVIVAIR Opti-Fit 7740 Operation And Maintenance Manual

...Page 1

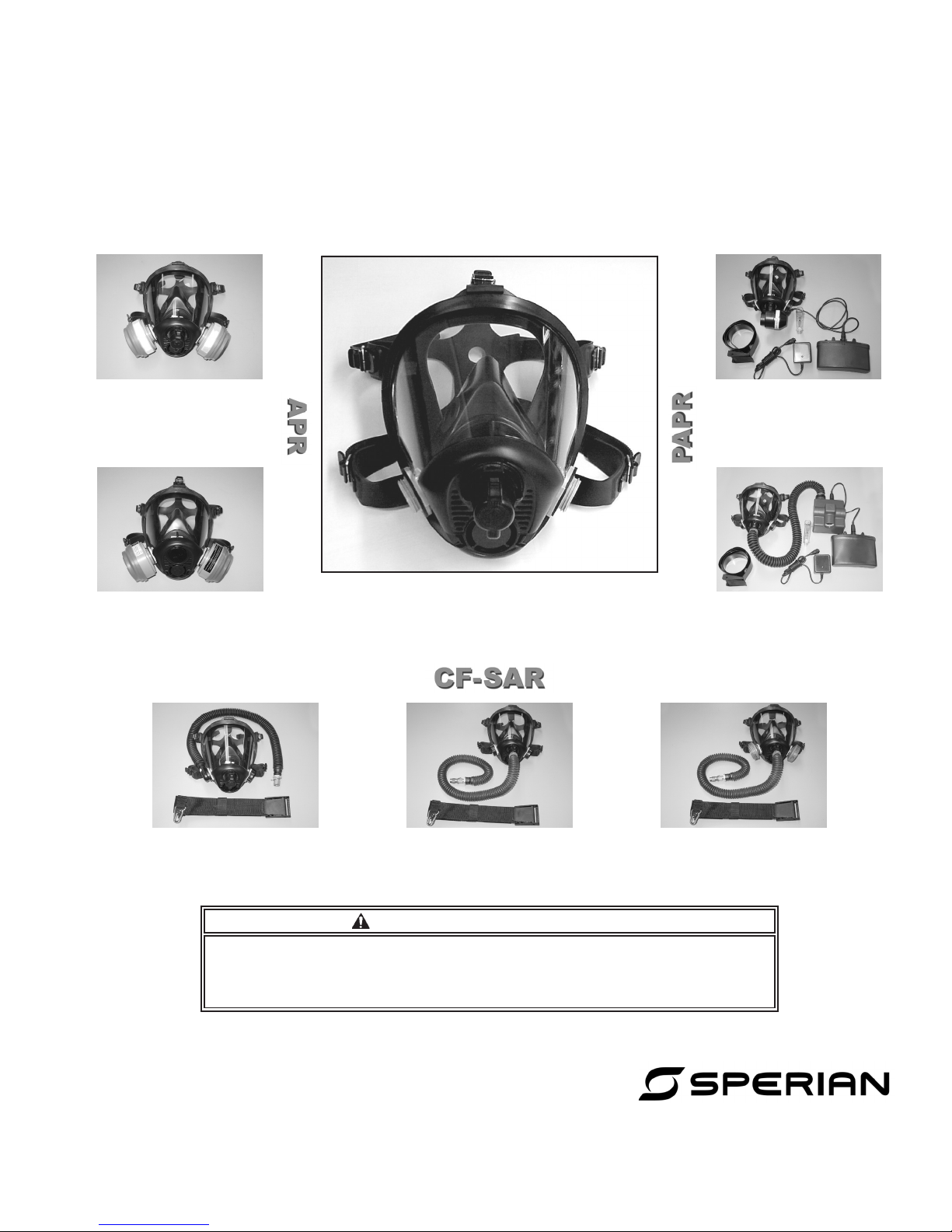

SURVIVAIR Opti-Fit™ Convertible Facepiece

Models 7540/7640/7740/7541/7641/7741

OPERATION and MAINTENANCE MANUAL

for Air Purifying Respirator (APR), Continuous Flow Supplied Air Respirator

(CF–SAR), and Powered Air Purifying Respirator (PAPR) Congurations

Air Purifying Respirator

Front Adapter Cap

Air Purifying Respirator

Low Prole Nozzle Plug

CF-Supplied Air Respirator

Side-mount Breathing Tube

SURVIVAIR Opti-Fit

™

Convertible Facepiece

CF-Supplied Air Respirator

Front-mount Breathing Tube

Powered Air Purifying

Respirator Mask-mount Blower

Powered Air Purifying

Respirator Belt-mount Blower

CF-Supplied Air Respirator

P100 Filter Escape

DO NOT USE your respirator until you read and completely understand this

instruction manual. You are required to inspect the adapter prior to putting it

into service. Please refer to the inspection procedures in this manual. Failure

to comply with this warning may result in personal injury, illness, or death.

©

Copyright SPERIAN Respiratory Protection USA, LLC

April 2008 All Rights Reserved

P/N 764099 REV D 03/09

WARNING

AN ISO 9001

REGISTERED

COMPANY

SPERIAN Respiratory Protection USA, LLC

3001 South Susan St., Santa Ana, CA 92704

Toll-Free 888.APR.SCBA or 714.545.0410

Fax 714.850.0299

www.sperianprotection.com

Page 2

NIOSH APPROVAL CAUTIONS AND LIMITATIONS

The Cautions and Limitations applicable to the air purifying respirator (APR), continuous ow supplied air respirator

(CF-SAR), and powered air purifying respirator (PAPR) congurations are listed below:

Operating Conguration Cautions and Limitations

Air Purifying Respirator (APR) ABCHJLMNOPS

Continuous Flow Supplied Air Respirator (SAR) ABCDEGHJLMNOPS

Powered Air Purifying Respirator (PAPR) ABCFHIJLMNOPS

Cautions and Limitations Key:

A - Not for use in atmospheres containing less than 19.5 percent oxygen.

B - Not for use in atmospheres immediately dangerous to life or health.

C - Do not exceed maximum use concentrations established by regulatory standards.

D - Air line respirators can be used only when the respirators are supplied with respirable air meeting the requirements

of CGA G-7.1 Grade D or higher quality.

E - Use only the pressure ranges and hose lengths specied in the User’s Instructions.

F - Do not use respirator if airow is less than four cfm (115 lpm) for tight tting facepieces or six cfm (170 lpm) for hoods

and/or helmet.

G - If airow is cut off, switch to lter and/or cartridge and immediately exit to clean air.

H - Follow established cartridge and canister change schedules or observe ESLI to ensure that cartridges and canisters

are replaced before breakthrough occurs.

I - Contains electrical parts which have not been evaluated as an ignition source in ammable or explosive atmospheres

by MSHA/NIOSH.

J - Failure to properly use and maintain this product could result in injury or death.

L - Follow the User’s Instructions for changing cartridges, canisters and/or lters.

M - All approved respirators shall be selected, tted, used, and maintained in accordance with MSHA, OSHA, and other

applicable regulations.

N - Never substitute, modify, add, or omit parts. Use only exact replacement parts in the conguration as specied by

the manufacturer.

O - Refer to Users Instructions, and/or maintenance manuals for information on use and maintenance of these respirators.

P - NIOSH does not evaluate respirators for use as surgical masks.

S - Special or critical User’s Instructions and/or specic use limitations apply. Refer to User’s Instructions before donning.

i

Page 3

SURVIVAIR Opti-Fit™ Convertible Facepiece

TABLE OF CONTENTS

NIOSH APPROVAL CAUTIONS AND LIMITATIONS ....................................................i

TABLE OF CONTENTS .........................................................................ii

I. INTRODUCTION.............................................................................1

II. SAFETY PRECAUTIONS......................................................................1

III. DESCRIPTIONS OF RESPIRATOR OPERATING CONFIGURATIONS .................................1

A. Air Purifying Respirator (APR) Conguration ...................................................1

B. Supplied Air Respirator (CF-SAR) Conguration ................................................1

C. Powered Air Purifying Respirator (PAPR) Conguration ...........................................2

IV. General Warnings for All Respirator Congurations .................................................2

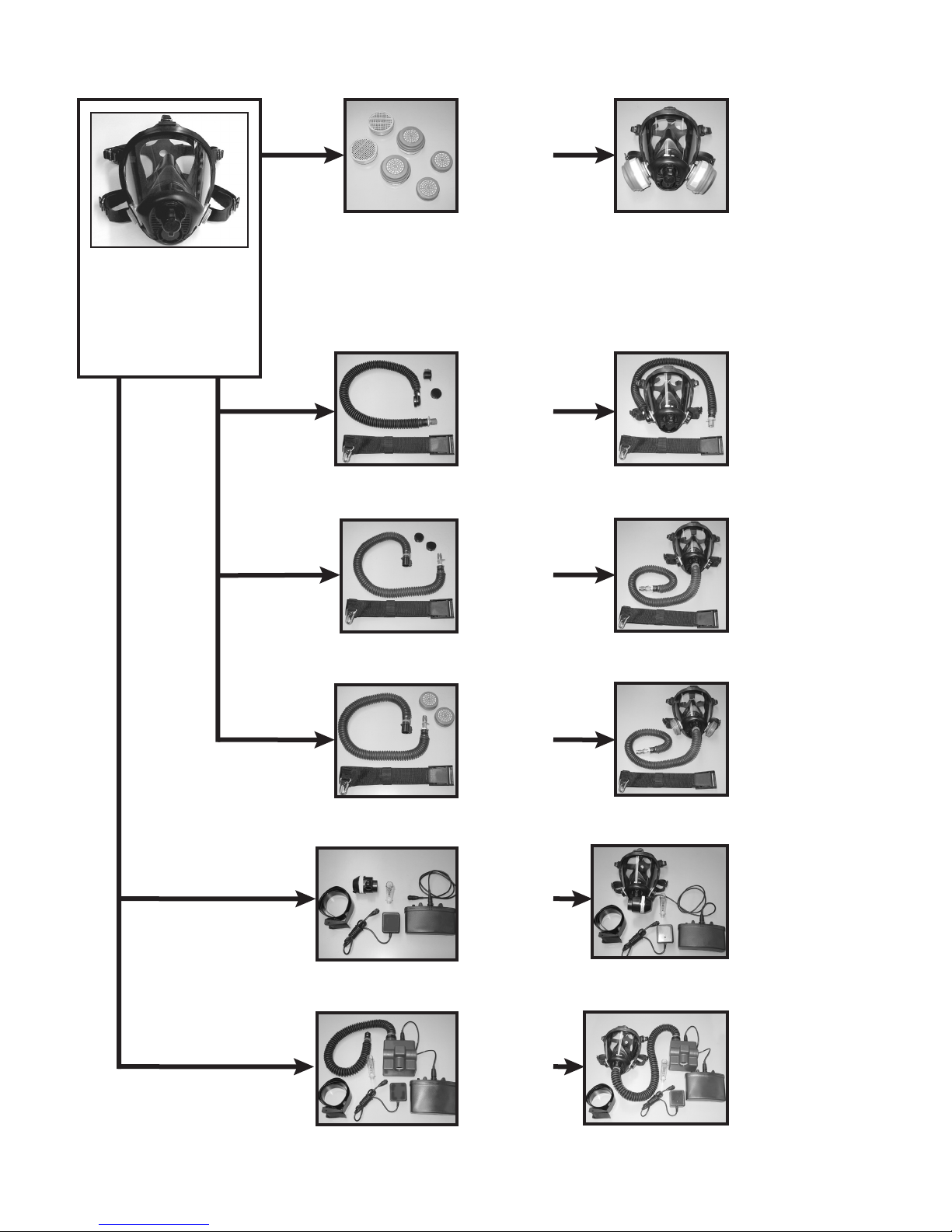

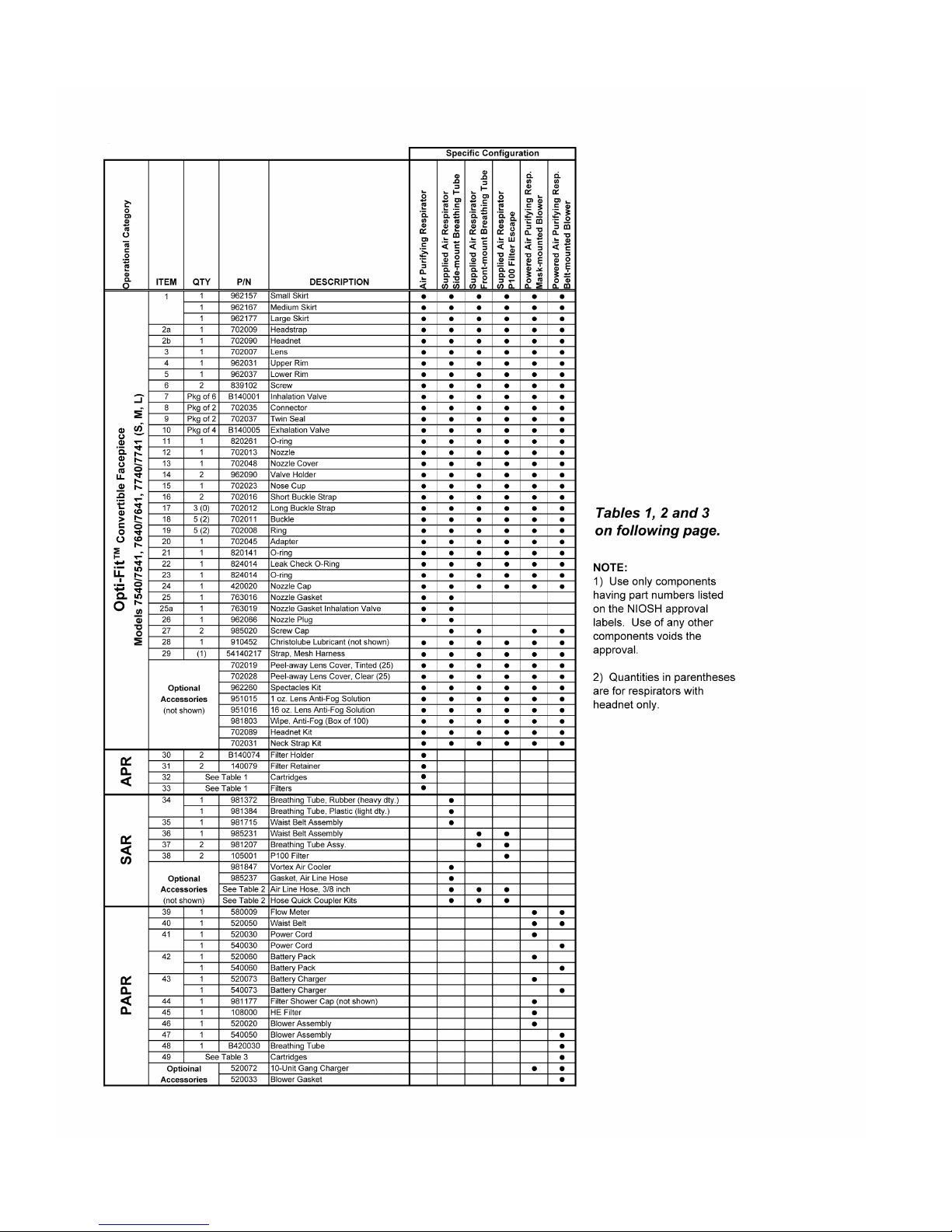

V. RESPIRATOR OPERATING CONFIGURATIONS SCHEMATIC ........................................5

VI. PARTS LIST ...............................................................................6

Table 1. Air Purifying Respirator (APR) Filters and Cartridges ........................................8

Table 2. Continuous Flow Supplied Air Respirator (CF-SAR) Air Hose Components .......................8

Table 3. Powered Air Purifying Respirator (PAPR) Belt-Mounted Cartridges .............................8

VII. FACEPIECE PREPARATION USING INCLUDED ITEMS............................................9

VIII. OPERATING INSTRUCTIONS FOR SPECIFIC RESPIRATOR CONFIGURATIONS .....................10

A. Air Purifying Respirator (APR) Conguration ..................................................10

1. Installing Chemical Cartridges and Particulate Filters ......................................... 11

2. Donning Instructions for APR Conguration.................................................12

3. Fit Check Instructions for APR Conguration ................................................13

4. How to Use the Respirator ..............................................................13

5. Dofng Instructions for APR Conguration..................................................13

6. Chemical and Particulate Filter Service Life and Replacement ..................................13

B. Continuous Flow Supplied Air Respirator (CF-SAR) Congurations.................................15

1. Air Supply ...........................................................................16

2. Quick Coupler Assembly ...............................................................16

3. Breathing Tube Setup..................................................................17

4. Donning Instructions for CF-SAR Congurations .............................................18

5. Fit Check Instructions for CF-SAR Congurations ............................................19

6. How to Use the Respirator ..............................................................20

7. Dofng Instructions for CF-SAR Congurations ..............................................21

8. Pressure Tables for Continuous Flow Supplied Air Respirator (CF-SAR) ..........................21

9. P100 Filter Service Life and Replacement ..................................................22

C. Powered Air Purifying Respirator (PAPR) Congurations .........................................22

1. Battery Pack Charging .................................................................22

2. Cartridge and Filter Installation...........................................................23

3. Pre-operational Flow Check .............................................................24

4. Donning Instructions for PAPR Congurations ...............................................26

5. Fit Check Instructions for PAPR Congurations ..............................................27

6. How to Use the Respirator ..............................................................28

7. Dofng Instructions for PAPR Congurations ................................................28

8. Chemical and Particulate Filter Service Life and Replacement ..................................28

9. Decontamination......................................................................30

IX. MAINTENANCE ...........................................................................30

A. Cleaning ..............................................................................30

B. Inspection .............................................................................31

C. Repair ................................................................................32

D. Storage ...............................................................................32

X. SHIPMENT................................................................................32

XI. OVERHAUL FREQUENCY...................................................................32

XII. ADDITIONAL INFORMATION ................................................................32

XIII. WARRANTY AND LIMITATION OF LIABILITY ...................................................33

XIV. RESPIRATOR INSPECTION TABLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

ii

Page 4

SURVIVAIR Opti-Fit™ Convertible Facepiece

I. INTRODUCTION

This manual provides instructions for the use and maintenance of the various respirator operating congurations achievable with the SURVIVAIR Opti-Fit™ Convertible full facepiece respirator models 7540, 7640, 7740,

7541, 7641, and 7741. The base conguration of the

SURVIVAIR Opti-Fit facepiece allows use as an air purifying respirator (APR) in conjunction with S Series par-

ticulate lters, gas and vapor cartridges, and cartridge/

lter combinations as required for specic contaminant

protection. Additional components can be attached to

the SURVIVAIR Opti-Fit Convertible to easily convert it

to a front or side hose connection continuous ow supplied air respirator (CF-SAR) and mask or belt mounted

powered air purifying respirator (PAPR) congurations.

Before using a respirator in a contaminated work

place, you must, at a minimum, understand the elements of a respirator program, your work place, and

the contaminants you are trying to protect yourself

against. Determining the applicability of a respirator

is difcult. You must be able to calculate the service

life of the cartridges, determine the type and concentration of contaminants, and determine whether

the contaminants have poor warning properties,

etc. If you do not have a complete understanding

of the use of respirators, you must seek the aid of

a certied industrial hygienist or contact SPERIAN.

You must read and understand this manual and be

trained in the proper use of the respirator before

wearing it in a contaminated atmosphere.

II. SAFETY PRECAUTIONS

The Warnings, Cautions, and Notes contained in this

instruction sheet have the following signicance

WARNING

Maintenance or operating procedures

and techniques that may result in serious personal injury, serious personal illness, or death if not carefully followed.

CAUTION

Maintenance or operating procedures and

techniques that may result in damage to

equipment and/or minor to moderate personal injury if not carefully followed.

NOTE

Maintenance or operating procedures and

techniques or information considered impor-

tant enough to emphasize.

III. DESCRIPTIONS OF RESPIRATOR OPERATING

CONFIGURATIONS

The SURVIVAIR Opti-Fit full facepiece contains two

connectors on each side of the lens for attaching par-

ticle lters, gas/vapor cartridges or air hoses, as well

as a front adapter for a supplied air breathing hose or

powered air purifying blower. This range of connections

allows the SURVIVAIR Opti-Fit Convertible facepiece

to be congured, through the use of additional components, as a supplied air respirator (CF-SAR) or powered

air purifying respirator (PAPR).

The full facepiece is designed with a wide lip silicone

skirt and ve point head strap harness (models 7540,

7640, and 7740). The facepiece is also available with

a Headnet™ retention system (models 7541, 7641, and

7741). All facepieces contain a lens treated with an

abrasion resistant coating. The facepiece is available

in three sizes, small, medium and large. While a nose

cup is standard, the facepiece may be equipped with an

optional spectacles kit, clear or tinted lens covers and

neck strap kit.

The connection versatility of the SURVIVAIR Opti-Fit™

Convertible full facepiece and available components and

accessories (see Section VI, Parts List) allow it to be as-

sembled into the following operating congurations:

A. Air Purifying Respirator (APR) Conguration

The side port connectors are used to attach S series

particulate lters, gas and vapor cartridges, and cartridge/lter combinations as required for a specic con-

taminant protection. The front adapter can be removed

and replaced with a plug to reduce the front prole of

the mask.

B.Continuous Flow Supplied Air Respirator

(CF-SAR) Conguration

With one side port connector port capped with a supplied screw cap, a high volume, low pressure breathing tube can be attached to the second side connector

to provide a constant ow of air to the facepiece when

connected to an external air source. An alternate connection option uses a breathing tube connected to the

front adapter with both side port connectors capped. An

optional Vortex air cooler may also be connected in-line

to provide cool air to the facepiece.

NOTE

The Vortex air cooler cannot be used in

conjunction with ambient air pump supply

systems.

The SURVIVAIR Opti-Fit™ Convertible can also be con-

gured as a CF-SAR with P100 lter cartridges and the

breathing tube connected to the front adapter. When the

air line hose is disconnected from the air line quick coupler, a check valve in the air line couple assembly prevents leakage of contaminated air through the facepiece

hose, and the wearer’s air is drawn through the P100

lters. This feature allows for safe entry, exit or escape

from a dangerous area in case of air supply failure.

For all CF-SAR congurations, when used at pressures

specied in the tables in Section VIII, Part B.8, air is de-

livered to the facepiece at a rate between 115 and 425

liters per minute (4-15 cubic feet per minute [cfm]).

1

Page 5

SURVIVAIR Opti-Fit™ Convertible Facepiece

WARNING

The pressure within the full facepiece

continuous ow supplied air respirator

(CF-SAR) remains positive under most

working conditions, but as with all respirators, negative pressure excursions are

possible. Conditions when a respirator

can experience negative facepiece pressures include, but are not limited to:

1) the respirator is improperly worn,

2) the respirator is not used in accordance with the instructions, or

3) the respirator is over-breathed during

heavy work rates. The respirator will

provide reduced protection when operated in a negative pressure mode. Failure to comply with this warning may result in personal injury, illness, or death.

The ANSI Z88.2-1992 assigned protection factor (APF)

for full facepiece continuous ow atmosphere supplying respirators is 1000. An APF of 1000 means that this

device, when properly used, will reduce exposure by a

factor of 1000.

C. Powered Air Purifying Respirator (PAPR)

Conguration

The SURVIVAIR Opti-Fit™ Convertible full facepiece

can be congured into a mask-mounted or belt-mounted powered air purifying respirator. In the mask-mount-

ed conguration, a high efciency (HE) lter/blower

mounts directly to the nozzle of the facepiece and deliv-

ers air to the facepiece at a ow rate greater than 115

liters per minute (4 cubic feet per minute). The blower

is powered by a belt mounted rechargeable nickel cadmium battery pack equipped with an ON/OFF switch.

This conguration is NIOSH approved and SPERIAN

recommended for respiratory protection against dusts,

fumes and mists, including asbestos-containing dusts

and mists, particulate radionuclides, and radon daughters attached to dusts, fumes and mists.

The belt-mounted PAPR respirator uses the SURVIVAIR

Opti-Fit™ Convertible facepiece, a rubber breathing

tube, a belt mounted blower with three (3) cartridges or

lters and a rechargeable Nickel Cadmium (NiCad) battery pack. Filtered breathing air is provided to the face-

piece at a ow rate greater than 170 liters per minute

(6 cubic feet per minute). To maintain NIOSH approval,

only the equipment and accessories listed on the appropriate NIOSH approval label may be used together.

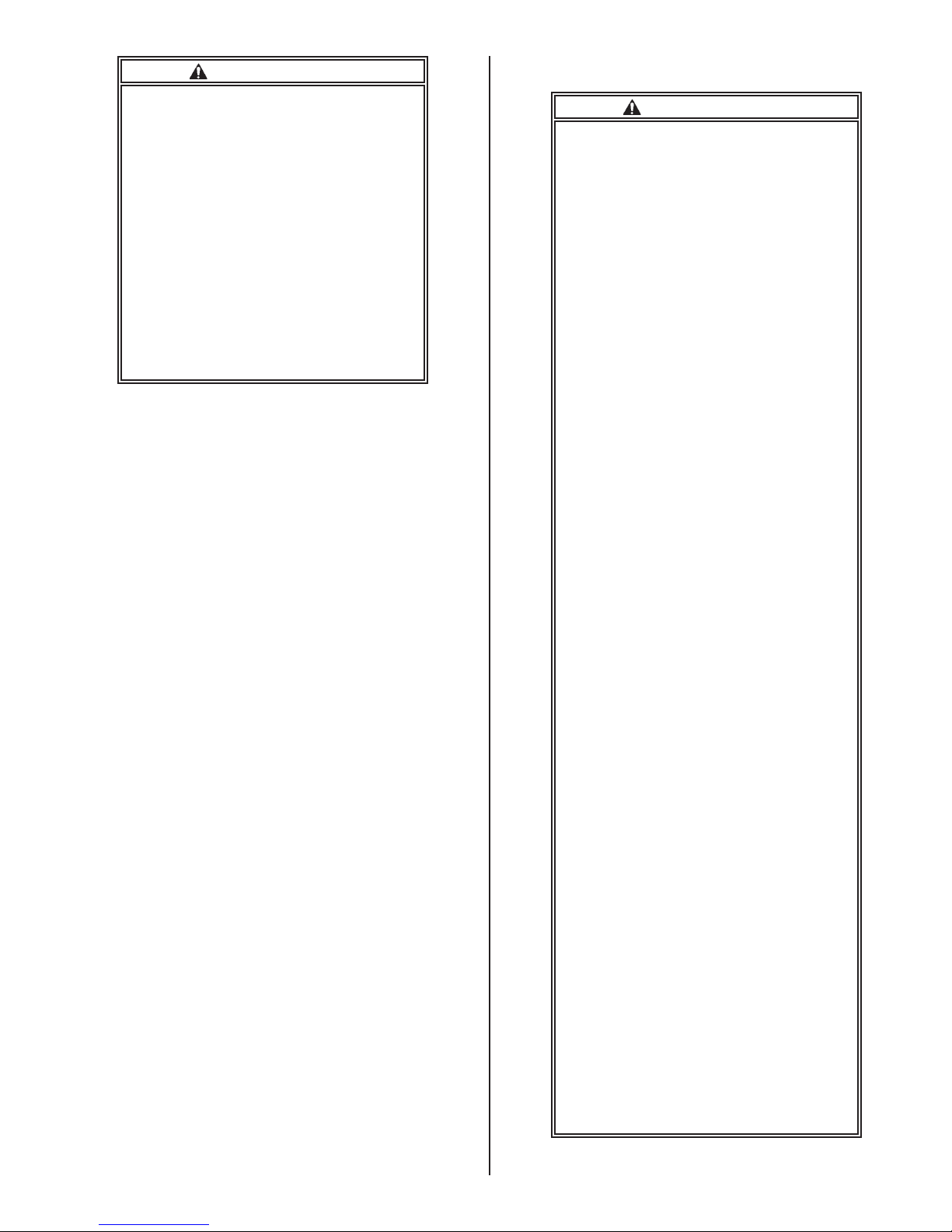

IV. GENERAL WARNINGS FOR ALL RESPIRATOR

CONFIGURATIONS

The following general warnings must be observed for

proper operation of all air purifying (APR), continuous

ow supplied air (CF-SAR) and powered air purifying

(PAPR) respirator congurations. Additional warnings for

specic operating congurations are listed in Section VIII,

Parts A, B, and C, and must also be observed for proper

operation of the respective respirator conguration.

General Warnings for All Respirator Congurations:

WARNING

● Your employer (or you, if you do not

have an employer) is responsible for

establishing that this respirator is

suitable for the user’s application.

● SPERIAN cannot predict what will

happen to this respirator in every potential environment. Materials can be

chemically attacked if exposed to the

wrong environment and may exhibit

excessive corrosion or other forms

of damage. Permeation or penetration

of gases, liquids or particles through

the materials could be excessive. Extremes of temperature might cause

thermal degradation. Each of these

things, or a combination of them, could

create conditions in which this respirator would be dangerous to use.

● Before entering a hazardous environment while wearing this respirator,

you must conduct safe, scientic

tests to determine if the environment

could render the equipment unsafe.

Results of this testing should be well

documented. Seek the help of a certi-

ed safety professional or industrial

hygienist. DO NOT USE this equipment if the user would be endangered

in any way through environmentally

induced degradation of the materials

in the apparatus.

● All persons using this SPERIAN

breathing apparatus must be made

aware of its limitations. We cannot

be responsible for any damage to

property, personal injury, or death in

which environmental exposure is a

contributing factor.

● Do not use this respirator if anything

comes between the facepiece and

your face (e.g., hair, bandanna, head

covering, etc.). This condition will

prevent a good facepiece seal and

may allow the leakage of contaminants into the facepiece.

● Do not use this respirator in environments where the concentrations of contaminants are unknown or are immediately dangerous to life or health (IDLH).

IDLH atmospheres are dened as:

a. Those that the wearer could not

breathe for short periods.

b. Those from which the wearer

could not escape without the aid

of a respirator.

c. Those which have an immediate or

delayed adverse effect on health.

● Do not use this respirator at ambient

temperatures above 130°F (55°C).

2

Page 6

SURVIVAIR Opti-Fit™ Convertible Facepiece

WARNING─Continued

● Do not use this respirator where en-

vironmental conditions could cause

the respirator facepiece to be dislodged or slip.

● Immediately return to a non-contaminated area if:

You taste or smell contaminants, a.

or if your eyes, nose, or throat

become irritated.

Breathing becomes difcult.b.

The air you are breathing be-c.

comes uncomfortably warm.

You feel nauseous or dizzy.d.

You notice a loss or decrease in e.

airow.

The facepiece moves, slips, or f.

leaks.

● This respirator does not protect exposed areas of the body. Some contaminants can be absorbed directly

through the skin while others may

irritate exposed areas.

● This respirator does not provide protection from hazardous rays or harm-

ful noise. Always wear proper head

and ear protection.

● This respirator must not be used

underwater, for fumigation, interior structural fire fighting, abrasive

blasting operations, or in areas where

high heat, sparks, or flames could

contact the respirator. If this respirator will be used during welding, it

is the user’s responsibility to obtain

the proper equipment for protection

against sparks, optical radiation, and

impact. This respirator will not pro-

tect you against these hazards.

● This respirator must be used in con-

junction with a written respirator

program meeting the requirements

of the OSHA Standard for Respiratory Protection, 29 CFR 1910.134,

available from the U.S. Department

of Labor, Occupational Safety and

Health Administration. The program

must include procedures for evaluating air contaminants and selecting

appropriate respirators; procedures

for proper use of respirators; procedures for testing the facepiece fit of

respirators; procedures for cleaning,

disinfecting, inspecting, maintaining,

and storing respirators; procedures

for determining if workers are physically and medically capable of wearing respirators; and procedures for

training employees in the use and

care of respirators and in recognizing the hazards associated with con-

taminants in the work place.

WARNING─Continued

● Do not wear this respirator if a satis-

factory fit, as determined by a qualitative or quantitative fit test, cannot

be obtained. See ANSI Z88.2, latest

issue, and OSHA 29 CFR 1910.134,

latest edition. Beards, stubble, or

sideburns will prevent a good facepiece seal, and facial hair may interfere with valve function. Do not use

this respirator unless you are clean

shaven. Absence of one or both dentures can seriously affect the fit of

the respirator.

● This respirator will reduce, but will

not eliminate the inhalation of contaminants. Some sensitive individuals may experience health problems when exposed to even minute

amounts of contaminants. This respirator will not prevent health problems to those individuals.

● Use of components other than those

listed on the NIOSH approval label

and in this manual, or as authorized

by SPERIAN, or modification of this

respirator in any manner will void

the NIOSH certification and invalidates all SPERIAN’s warranties for

the respirator.

● Always read and follow the instructions listed in the Material Safety

Data Sheet for the chemicals that are

present in the work area.

● Do not use if you have a preexisting

skin condition (for example, folliculitus or vitiligo) until you obtain clearance from a medical doctor.

● This respirator must be worn and

used as specified in SPERIAN’s instructions. No respirator can provide complete protection from all

conditions. Use extreme care for

emergency conditions.

● Some individuals are sensitive to

chemicals (e.g., isocyanates, latex,

oil mists, etc.) or may have some

type of respiratory disorder (e.g.

asthma, chronic obstructive airway

disease, etc.). If you are sensitive to

any chemical or have a respiratory

disorder, you may have a severe reaction at contaminant levels well below

accepted health levels, such as the

OSHA Permissible Exposure Limit

(PEL), ACGIH Threshold Limit Value

(TLV), or the NIOSH Recommended

Exposure Limits (REL). Many chemicals (e.g., isocyanates, Mercury, etc.)

have no physical warning properties

and you cannot taste or smell the

contaminants even though they may

3

Page 7

SURVIVAIR Opti-Fit™ Convertible Facepiece

WARNING─Continued

be present in the respirator facepiece. This respirator will reduce, but

will not eliminate the possibility of

contaminants entering the facepiece

and causing a severe reaction. Do not

use this respirator until you obtain

clearance from a medical doctor.

● Users must clean and maintain this

respirator only in accordance with

SPERIAN’s instructions. Accessories

not offered by SPERIAN may degrade

performance, and will void NIOSH

certification.

● The respirator facepiece assembly

contains natural rubber latex, which

may cause allergic reactions in some

individuals. Discontinue use if you

experience an allergic reaction.

● Discontinue use if you experience

skin irritation or discoloration.

● This product may provide less than

adequate protection if improperly

used, which may result in personal

injury, illness, or death.

● For use by trained, qualified personnel

only.

● Do not use this respirator if it has

been left exposed in a contaminated

environment as contaminants could

collect on the inside of the facepiece

and be inhaled when the gas mask is

donned.

● Routinely used respirators must be

inspected before and after each use.

Stored emergency respirators must

be inspected after each use and at

least every 30 days. A written record

must be kept of emergency respirator inspections.

FAILURE TO OBSERVE ALL WARNINGS MAY RESULT IN PERSONAL INJURY, ILLNESS, OR DEATH.

4

Page 8

SURVIVAIR Opti-Fit™ Convertible Facepiece

V. RESPIRATOR OPERATING CONFIGURATIONS SCHEMATIC

Cartridges and

Filters See

cartridge table

in Section VI

for available

cartridge part

numbers.

Side-mount

Tube and Belt

Kits*:

Light Duty

P/N 981415

Heavy Duty

P/N 981416

SURVIVAIR Opti-Fit

Convertible Facepiece

5-Pt. Strap

Small/Medium/Large

754000/764000/774000

Mesh Headnet

Small/Medium/Large

754100/764100/774100

™

APR

Air Purifying

Respirator (APR)

SURVIVAIR Opti-Fit

Facepiece

Side-mount Tube

CF-Supplied Air

Respirator (CF-SAR)

PAPR

CF-SAR

Front- mount

Tube and

Screw Caps

Kit*:

P/N 981205

Front- mount

Tube and P100

Filters

Kit*:

981209

Mask- mount

PAPR

Kit

520075

SURVIVAIR Opti-Fit

Facepiece Front-

mount Tube CF-SAR

5-Pt. Strap S/M/L

981500/981501/981503

Mesh Headnet™ S/M/L

981550/981551/981553

SURVIVAIR

Opti-Fit Facepiece

P100 Escape

CF-Supplied Air

Respirator (CF-SAR)

SURVIVAIR Opti-Fit

Facepiece

Mask-mount PAPR

5-Pt. Strap S/M/L

520500/520600/520700

Mesh Headnet™ S/M/L

520520/520620/520720

* All continuous ow supplied air respirator (CF-SAR) and powered air purifying respirator (PAPR) kit components are

available individually. See Parts List in Section VI.

Belt- mount

PAPR

Components

Blower Kit*:

500085

Breathing Tube:

B420030

5

SURVIVAIR Opti-Fit

Facepiece Kit Belt-mount

PAPR 5-Pt. Strap S/M/L

540510/540610/540710

Mesh Headnet™ S/M/L

541510/541610/541710

Blower/Battery Kit 500085

Page 9

SURVIVAIR Opti-Fit™ Convertible Facepiece

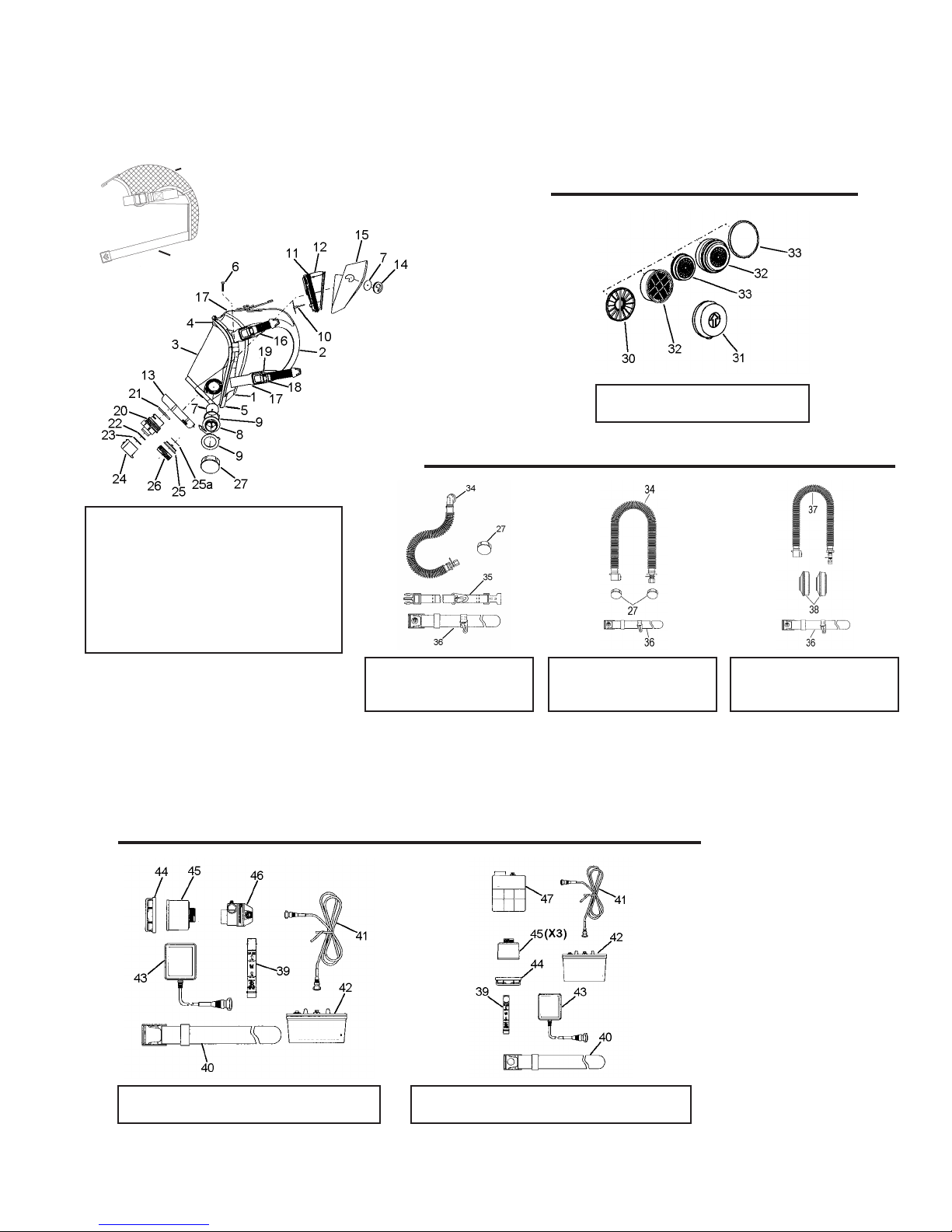

VI. PARTS LIST

A. Please refer the Parts List Matrix in Part B for component descriptions and identication of their use with the

various operating congurations of the SURVIVAIR Opti-Fit Convertible Facepiece.

2b

APR

29

Headnet

™

Air Purifying Respirator

Cartridges

CF-SAR

SURVIVAIR Opti-Fit Convertible

Facepiece Models

5 Pt. Headstrap

7540/7640/7740

Mesh Headnet

™

7541/7641/7741

CF-Supplied Air

Respirator

Side-mount Breathing Tube

PAPR

CF-Supplied Air

Respirator

Front-mount Breathing Tube

CF-Supplied Air

Respirator

P100 Escape

Powered Air Purifying Respirator

Mask-mounted Blower

Powered Air Purifying Respirator

Belt-mounted Blower

6

Page 10

SURVIVAIR Opti-Fit™ Convertible Facepiece

B. Parts List Matrix

SURVIVAIR

7

Page 11

SURVIVAIR Opti-Fit™ Convertible Facepiece

Table 1. Air Purifying Respirator (APR) Filters and

Cartridges

Part No. Protection/Description

Filters

1050 P100

1060 Filter Pad, N95

1070 Filter Pad, N99/R95

1190 P100 Slimline

1195 P100 Disk

Cartridges

100100 Organic Vapors

100200 Acid Gases

100300 Organic Vapors and Acid Gases

100400 Ammonia and Methylamine

100600 Mercury Vapor and Chlorine

100800 Multi-contaminant

1051 Combination Organic Vapors and P100

1052 Combination Acid Gases and P100

1053 Combination Organic Vapors, Acid Gases, and P100

1054 Combination Ammonia, Methylamine, and P100

1056 Combination Multi-contaminant and P100

1058 Combination Multi-contaminant and P100

Table 2. Continuous Flow Supplied Air Respirator

(CF-SAR) Air Hose Components

Part No. Item Description

930861 High performance hose—25 feet (requires quick coupler kit)

930862 High performance hose—50 feet (requires quick coupler kit)

930864 High performance hose—100 feet (requires quick coupler kit)

930801 Light weight hose—25 feet (requires quick coupler kit

930802 Light weight hose—50 feet (requires quick coupler kit

930804 Light weight hose—100 feet (requires quick coupler kit

985241 Light weight hose with OBAC couplings—25 feet

985242 Light weight hose with OBAC couplings—50 feet

985244 Light weight hose with OBAC couplings—100 feet

930810 Quick coupler kit—style: Foster

930820 Quick coupler kit—style: Schrader

930830 Quick coupler kit—style: Hansen

930840 Quick coupler kit—style: OBAC

Table 3. Powered Air Purifying Respirator (PAPR)

Belt-Mounted Cartridges

Part No. Item Description

150100 OV Cartridge

150200 AG Cartridge

150300 OV/AG Cartridge

150400 AM/MA Cartridge

158100 OV/HEPA Cartridge

158200 AG/HEPA Cartridge

158300 OV/AG/HEPA Cartridge

158400 AM/MA/HEPA Cartridge

108000 HEPA Filter

APR Cartridge Considerations:

WARNING

The following is a partial list of materials

that have either poor warning properties, will develop high heats of reaction

with the sorbent in the canister, have

extremely short service times, or will

not be absorbed at all. Respirators cannot be used to protect you against many

of these chemicals. Contact a certied

industrial hygienist or SPERIAN if you

have any of these materials present in

the work place. The use of a respirator

for these materials may lead to personal

injury, illness, or death.

Acroline Carbonyls Hydrogen

Aniline Cyanogen Isocyanates:

Arsine Dimethylaniline Methanol Phosphine

Boron

Hydrides

Bromine Ethyl Cyanide Nitro

Carbon

Dioxide

Carbon

Monoxide

Dimethyl Sulfate Methyl

Fluorine Sulfur Chloride

Hydrogen

Cyanide

Selenide

TDI, HDI, MDI

Bromide

Methyl

Chloride,

Methylene

Chloride

Compounds:

Nitrogen

Oxides

Nitroglycerin

Nitrobenzene

Nitromethane

Ozone

Phosgene

Phosphorous

Trichloride

Stibine

Vinyl Chloride

VII. FACEPIECE PREPARATION USING INCLUDED

ITEMS

The SURVIVAIR Opti-Fit Convertible is shipped with

side connector port screw caps and a nozzle plug kit

that must be used to congure the facepiece for the

various operating congurations as detailed below.

8

Page 12

SURVIVAIR Opti-Fit™ Convertible Facepiece

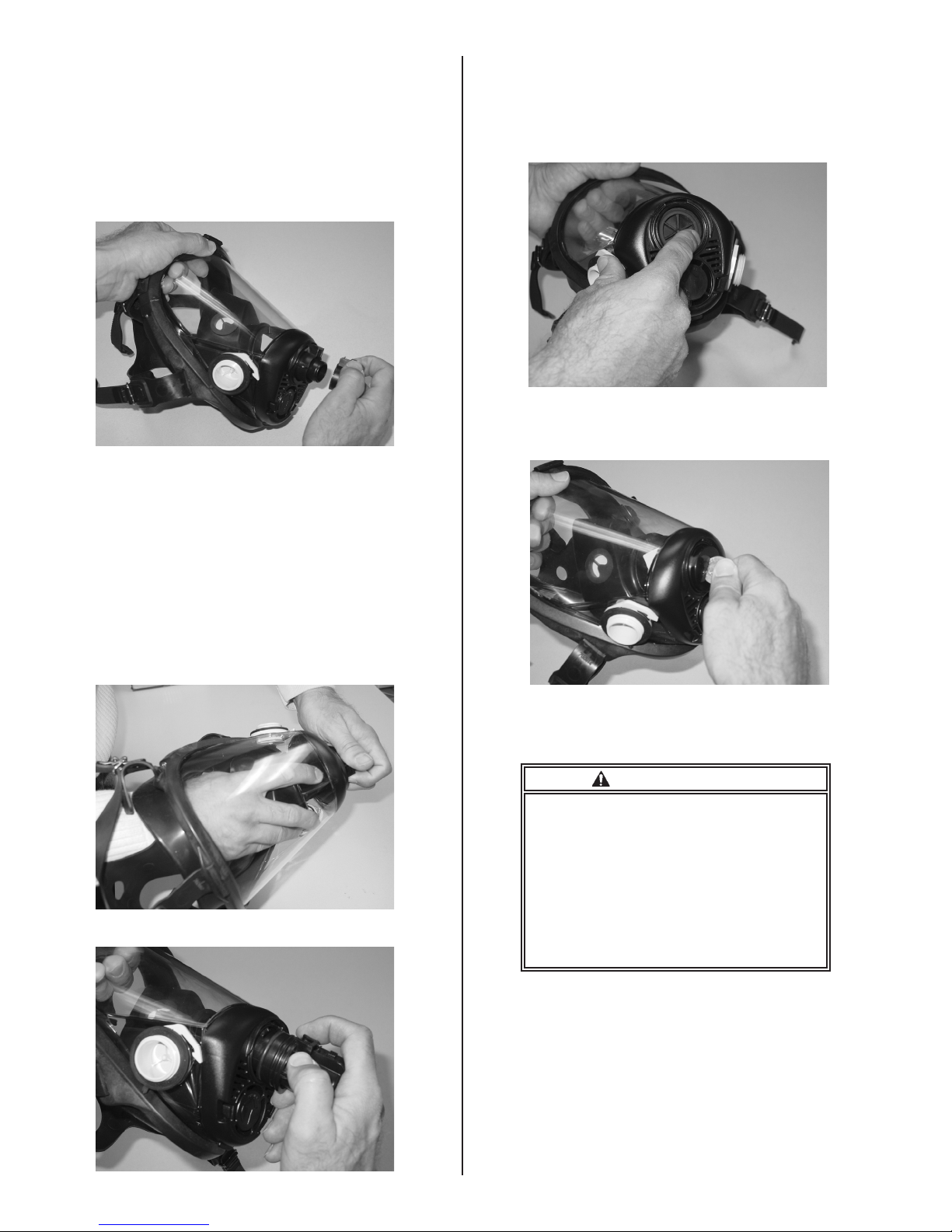

A. Air Purifying Respirator (APR)

The SURVIVAIR Opti-Fit Convertible is shipped from the

factory with the nozzle adapter (item 20, P/N 702045)

installed in the facepiece nozzle. This adapter must be

capped using the included adapter cap (item 24, P/N

420020) for the facepiece to be used as an APR respirator. When attaching the adapter cap, an audible click

should be heard (Figure 1).

Figure 1. Adapter Cap

Figure 4. Insert Nozzle Gasket into Facepiece

If a low prole nozzle setup is desired, the nozzle

adapter can be removed from the facepiece and the

nozzle plug kit installed in its place. Unscrew the nozzle

adapter from the facepiece by pressing down on the

adapter locking tab from inside the lens and turning the

adapter counterclockwise (Figures 2 and 3). Insert the

nozzle gasket (item 25, P/N 763016) into the nozzle

port (Figure 4). Thread in the nozzle plug (item 26, P/N

962066), using a quarter or similar item in the molded

slot to hand-tighten (Figure 5).

Figure 2. Push Down on Adapter Locking Tab

Figure 5. Tighten Nozzle Plug with Coin

in Molded Slot

WARNING

The included screw caps (item 27, P/N

985020) are not to be used on the facepiece side ports when using the SURVIVAIR Opti-Fit Convertible in the air puri-

fying respirator (APR) conguration. See

Section VIII, Part A.1 for installing chemi-

cal cartridges and particulate lters to

the facepiece side connector ports. Failure to comply with this warning may lead

to personal injury, illness, or death.

Figure 3. Remove Adapter

9

Page 13

SURVIVAIR Opti-Fit™ Convertible Facepiece

B. Continuous Flow Supplied Air Respirator(CF-SAR)

1. Side-mounted Breathing Tube

When using the SURVIVAIR Opti-Fit Convertible

as a supplied air respirator (CF-SAR) with sidemounted breathing tube, the nozzle adapter and

the side port not in use by the breathing tube

must be capped for proper operation. Attach

the nozzle adapter cap (item 24, P/N 420020)

to the nozzle adapter, making sure to hear an

audible click has the cap is pushed into place

(Figure 1).

If a low prole nozzle setup is desired, the nozzle adapter can be removed from the facepiece

and the nozzle plug kit installed in its place. Unscrew the nozzle adapter from the facepiece by

pressing down on the adapter locking tab from

inside the lens and turning the adapter counterclockwise (Figures 2 and 3). Insert the nozzle

gasket (item 25, P/N 763016) into the nozzle

port (Figure 4). Thread in the nozzle plug (item

26, P/N 962066), using a quarter or similar item

in the molded slot to hand-tighten (Figure 5).

Thread one of the provided screw caps (item 27,

P/N 985020) onto the side connector port not

in use by the side-mounted breathing tube and

hand-tighten (Figure 6).

C. Powered Air Purifying Respirator (PAPR)

Both the mask-mounted and belt-mounted powered air

purifying respirator (PAPR) congurations require both

side connector ports to be capped with the included screw

caps (item 27, P/N 985020). Thread the screw caps onto

the side connector ports and hand-tighten (Figure 6).

Use of the nozzle adapter is necessary for connecting

the mask-mounted blower or breathing tube and there-

fore the low-prole nozzle plug kit cannot be used.

WARNING

● Do not attempt to use the SURVIVAIR

Opti-Fit Convertible with both the

nozzle adapter and the side connector ports capped.

● Failure to securely cap unused

threaded side port connectors and/

or the front adapter port for the APR,

CF-SAR or PAPR configuration you

are using can allow contaminants

to leak into the respirator and cause

personal injury, illness, or death.

VIII. OPERATING INSTRUCTIONS FOR SPECIFIC

RESPIRATOR CONFIGURATIONS

Figure 6. Thread Screw Cap onto Side Connection

Port (CF-SAR and PAPR Only)

2. Front-mounted Breathing Tube and P100

Escape

When using the SURVIVAIR Opti-Fit Convertible as a supplied air respirator (CF-SAR) with

front-mounted breathing tube, both of the side

connector ports must be capped with the included screw caps (item 27, P/N 985020). Thread

the screw caps onto the side connector ports

and hand-tighten (Figure 6). If the facepiece

is to be congured as an CF-SAR with P100

escape, the screw caps are not required, and

a P100 lter cartridge (item 38, P/N 105001)

should be screwed onto each side connector

port. Use of the nozzle adapter is necessary

for connecting the breathing tube and therefore

the low-prole nozzle plug kit cannot be used.

A. Air Purifying Respirator (APR) Conguration

In addition to the General Warnings listed in Section IV,

the following warnings apply to air purifying respirator

(APR) congurations:

WARNING

● When using this respirator for protection against any gas or vapor, including gases or vapors with poor warning properties (e.g., HDI, MDI, or TDI

isocyanates, paint hardeners, etc.),

OSHA 29 CFR 1910.134 requires the

canister to have an end-of-servicelife indicator (ESLI). If the canister

does not have an ESLI, OSHA requires the canister be changed at

intervals derived from a change-out

schedule that is based on objective

information or data that ensures the

canister is changed before the end of

its service life.

● Do not use for protection against

gases or vapors which generate high

heats of reaction with the sorbent

material or against gases or vapors

which are not readily absorbed by

the sorbent (e.g., methanol).

● There are gases and vapors (e.g., acetone, acetaldehyde, etc.) that have a

boiling point below 149ºF (65ºC). Gas

masks should not be used for protection against these chemicals

10

Page 14

SURVIVAIR Opti-Fit™ Convertible Facepiece

WARNING─Continued

for more than 8 hours or one shift,

even though the calculated service

life estimate is greater that 8 hours or

one shift. These contaminants can migrate through the canister even when

the canister is not in use (e.g., overnight) and collect in the facepiece.

● Do not use this respirator without the

appropriate SPERIAN cartridges and/

or lters securely attached onto the

facepiece. Always read cartridge labels prior to use and be certain that

you have cartridges and/or lters

that will provide the required protection. This respirator must be used

for protection against only those air

contaminants listed on the air purify-

ing cartridge, lter and/or the NIOSH

approval label. Respirators labeled

for protection against particulates

only shall not be used for gases/vapors. Respirators labeled for protection against gases/vapors only shall

not be used for particulates.

● This respirator does not supply oxygen. Do not use the respirator in

atmospheres containing less than

19.5% oxygen by volume.

● Failure to comply with this warning

may lead to personal injury, illness,

or death.

1. Installing Chemical Cartridges and Particulate

Filters

a. Mercury Vapor Cartridges

Special or Critical User’s Instructions: The mercury vapor cartridges incorporate passive endof-service-life indicators (ESLI). Each ESLI,

yellow in color when new, turns gray when

exposed to mercury vapor. Do no use these

cartridges unless you can distinguish between

the safe and discard colors of the ESLI. The

indicators must be visible when wearing the

respirator without having to manipulate either

the facepiece or the indicator. If the indicators

cannot be seen, do not wear the respirator. The

cartridges must be replaced when the ESLI

change color from yellow to gray, when the

ESLI become dirty or damaged, after 30 days

of use, or if removed from their original packaging and not used within 30 days. Never enter

or remain in a hazardous atmosphere if one or

more of the ESLI is gray.

b. Particulate Filters

Before using a particulate lter, you must conrm the atmosphere is non-IDLH and not oxygen decient, the contaminant is a particulate

hazard, and you must determine the hazard ratio (hazard concentration/exposure limit). If the

hazard ratio is less than 10, you may use a half

mask respirator with a lter efciency of 95% or

higher. If the hazard ratio is less than 20, you

may use a full facepiece respirator with a lter

efciency of 95% or higher. If the hazard ratio is

less than 100, you may use a full facepiece res-

pirator with a lter efciency of 99% or higher. If

the hazard ratio is greater than 100, you must

use another type of respirator.

N-series lters must only be used for non-oil

containing aerosols or particulates. R or P-

series lters can be used if the atmosphere

contains oil (e.g., lubricants, cutting uids,

glycerin, etc.). An R-series lter used in an oil-

containing atmosphere must be replaced after

each 8-hour shift. A P-series lter can be used

for more than one 8-hour shift. Please refer to

Section VIII, Part A.6, Chemical and Particulate

Filter Service Life and Replacement, for important additional information. Refer to the NIOSH

publication Guide to the Selection and Use of

Particulate Respirators Certied Under 42CFR

84 for additional guidelines on use limitations

for lters.

WARNING

Filters improperly used or improperly

assembled to the facepiece could cause

leakage, which could lead to personal

injury, illness, or death.

c. Cartridge/Filter Installation

Ensure that you have the correct cartridge and/

or lter type for the contaminants in your work

area. If you are not sure, consult your supervisor or safety professional.

Install cartridges and lters by threading i.

them onto the facepiece connectors and

hand tightening. Do not overtighten.

If using lter pads, insert the appropriate ii.

pad into the lter retainer so that the side

stamped with the model number will face

towards the facepiece when installed.

Completely snap the lter retainers onto

the cartridges or lter holders.

Inspect the lter through the retainer to iii.

ensure that the entire edge of the lter is

making contact with the retainer and the

lter is not bunched or folded. The outer

edge of the pad must be compressed be-

tween the top edge of the cartridge or lter

holder and the inner sealing rings of the

retainer. Install lter holders in the same

manner as cartridges.

11

Page 15

SURVIVAIR Opti-Fit™ Convertible Facepiece

2. Donning Instructions for APR Conguration

WARNING

● Your employer (or you, if you do not

have an employer) is responsible for

establishing that this respirator is

suitable for the user’s application.

● Always read cartridge labels prior to

use to be certain that you have car-

tridges and/or lters that will provide

the required protection. Filters labeled for protection against particulates only shall not be used for gases/vapors, and cartridges labeled for

protection against gases/vapors only

shall not be used for particulates.

Both cartridges/lters must be of the

same type.

● Ensure that the o-ring (Item 23, P/N

824014), is in the cap (Item 24, P/N

420020) and the cap plug is securely

seated on the adapter. If the nozzle

plug (Item 26, P/N 962066) is to be

used instead of the cap, be sure

that the Nozzle Gasket (Item 25, P/N

763016) is installed with an inhalation valve.

● The failure to comply with this warning may lead to personal injury, illness, or death.

7. Hold the facepiece against your face and pull

the straps over your head.

8. Tighten the two lower straps, temple straps, then

the top straps until a good seal is obtained and

all straps lie at on your head. Do not overtighten the straps. See Figure 8a. For respirators

with a Headnet, tighten the two lower straps and

the temple straps until a good seal is obtained

and all straps lie at on your head. Flatten the

Headnet with a wiping motion toward the back

of your head. See Figure 8b. Retighten straps

as necessary. Do not overtighten.

Figure 8a. Adjust Lower Straps First

1. Inspect the respirator as described in Section

IX, Part B.

2. Verify that unused ports are capped as detailed in

Section VII for the APR operational conguration.

3. Verify that two lters and/or cartridges are at-

tached to the threaded side connectors of the

facepiece.

4. Adjust the top straps until one inch of strap extends through each buckle. Fully loosen the

lower straps. For respirators featuring a Headnet, fully loosen all straps.

5. Place the neck strap (if installed) over your head.

6. Place your chin against the chin cup and center

the facepiece on your face. See Figure 7.

Figure 8b. Flatten Headnet with Wiping Motion

NOTE

When properly adjusted, the head strap hub

should be centered on the back of your head

and the lower straps should be below your

ears. See Figure 9a. For the Headnet version, the backstrap should be at the nape of

the neck. The Headnet should lie at on the

head and not bunch up. See Figure 9b.

Figure 7. Place Chin in Chin Cup

12

Page 16

SURVIVAIR Opti-Fit™ Convertible Facepiece

whether the cartridges are correctly seated against

the facepiece. It is your responsibility to ensure that

the face seal is not disturbed when reinstalling the

cartridges and that each cartridge is sealed against

the facepiece.

Inhale gently and hold your breath to slightly collapse

the facepiece. If air leakage occurs, readjust the

facepiece and head strap, then retest. If lter retainers are used, do not remove them after the t check

is completed. Removing the lter retainers may shift

the facepiece and break the face seal.

Figure 9a. Properly Center Head Strap Hub

Figure 9b. Properly Fitted Headnet

3. Fit Check Instructions for APR Conguration

You must perform the following t check each time

the respirator is worn or before entering the contaminated area.

WARNING

If a leak-tight seal is not obtained during

the following t check, do not wear the

respirator. Ask your supervisor or safety

professional for assistance. The failure

to comply with this warning may lead to

personal injury, illness, or death.

4. How to Use the Respirator

To receive the maximum protection available from

your respirator, you must read, understand, and

follow all the warnings, limitations, and instructions

contained in this manual and follow your employer’s

instructions on the use and maintenance of the respirator. Read and understand the following warnings

prior to using the respirator.

WARNING

● Never remove the respirator for any

reason while in the work area.

● You must leave the work area immediately if the facepiece-to-face seal is

disturbed for any reason such as:

a. Slippage due to sweating or ex-

cessive head movement.

b. The facepiece becomes dislodged

as a result of being knocked.

c. Sneezing or coughing while wear-

ing the facepiece.

d. You need to blow your nose,

scratch your face or adjust your

spectacles.

● For any other reason that would cause

the facepiece seal to be disturbed.

● You must restore the facepiece-to-

face seal and perform a fit check in

a non-hazardous environment before

re-entering the work area.

● Failure to comply with this warning

may lead to personal injury, illness,

or death.

Negative Pressure Fit Check

Cover the inlet of the cartridges and/or lters with the

palms of your hands or another suitable item, such

as a thin sheet of plastic or rubber. When the respi-

rator is equipped with cartridges, lter retainers may

be used as an aid. Alternatively, the cartridges may

be removed to perform the t check. If removed,

SPERIAN recommends someone other than you

reinstall them after a leak-tight t is achieved. It

is difcult for the wearer to reinstall the cartridges

without disturbing the face seal and to determine

5. Dofng Instructions for APR Conguration

1. Loosen the two lower head straps completely

(for ve strap head harness or Headnet).

2. Grasp the nozzle rmly, and pull the facepiece

upward over the head.

6. Chemical and Particulate Filter Service Life

and Replacement

a. Chemical Cartridge Service Life and Replacement

13

Page 17

SURVIVAIR Opti-Fit™ Convertible Facepiece

WARNING

● OSHA allows the use of air purifying respirators for protection against

contaminants with poor warning

properties. You must replace cartridges when the end-of-service-life

indicator (ESLI) has changed color

or in accordance with an OSHA compliant cartridge change-out schedule

that is based on objective information

or data that ensures the cartridges

are changed before the end of their

service life.

● You must immediately leave the contaminated area if you taste or smell

contaminants, or if your eyes or

throat become irritated. Replace cartridges and/or filters before re-entering the contaminated area.

● Establishing the cartridge service

life for mixtures of contaminants is a

complex task, and one that requires

considerable professional judgment

to create a reasonable change-out

schedule. OSHA provides a “rule-ofthumb” method for determining the

cartridge service life for mixtures.

The method addresses two situations. The first is where the individual

compounds of the mixture have similar breakthrough times (i.e., within

one order of magnitude). In this case,

OSHA recommends adding the concentrations of all the components of

the mixture to determine a “total concentration,” then determine the mixture service life by applying the total

concentration to the component with

the shortest service life. The second

is where the individual compounds

have breakthrough times that vary

by two orders of magnitude or greater. In this case, OSHA recommends

the mixture service life be based

on the contaminant with the shortest breakthrough time. The OSHA

rule-of-thumb methods may not be

applicable for all mixtures. In some

cases, the actual mixture service life

may be much lower than the one calculated. For this reason, SPERIAN

recommends that the cartridge service life for mixtures be determined

using experimental methods. If you

are unsure of how to determine the

cartridge service life for mixtures,

please contact SPERIAN.

● Failure to comply with this warning

may lead to personal injury, illness,

or death.

The cartridge service life depends on the user’s

breathing rate, the characteristics of the contaminant, and the environmental conditions such as

temperature and humidity. Saturated cartridges will

leak trace amounts of contaminant to the wearer,

which may be detected by odor, taste, and/or irritation. Replace cartridges when the end-of-service-life indicator (ESLI) has changed color, at the

rst trace of the characteristic contaminant odor

or taste, at regularly scheduled intervals recommended by your safety professional, if they show

any signs of damage, or in accordance with an

OSHA compliant cartridge change-out schedule.

The service life of the cartridge can be estimated

using SPERIAN’s cartridge service life estimation

program, available from SPERIAN. Always replace

cartridges in pairs.

Replace cartridges as follows:

1. Return to fresh air.

2. Remove cartridges by turning counterclockwise. Dispose of used cartridges

in accordance with Federal, state, and

local guidelines.

3. Install new cartridges, taken only from

sealed packages, as described in Section VIII, Part A.1.C.

4. Perform a facepiece t check as described in Section VIII, Part A.3.

b. Particulate Filter Service Life and Replacement

WARNING

You must replace the lters when breathing becomes uncomfortable or difcult.

As particulates collect on the lter sur-

face, the breathing resistance of the

facepiece increases. If you wait too long

to replace the lters, the particulates

may leak past the face seal instead of

being collected on the lters. Therefore,

SPERIAN strongly recommends that the

lters be changed at least daily.

Failure to comply with this warning

may lead to personal injury, illness, or

death.

The service life of the lter depends on the lter

series, the way in which the lter captures the con-

taminant (either mechanically or by electrostatic

means), the characteristics of the contaminant,

the user’s breathing rate, and the environmental

conditions such as humidity, temperature, etc.

SPERIAN’s N95, N99, R95 and Slimline P100 lters use electrostatic charges to capture particles.

High humidity and temperatures, as well as contact with oil or non-oil based liquid aerosols, may

affect the capture of contaminants by these lters.

All new SPERIAN lters must be maintained in fac-

tory sealed bags and must only be removed when

14

Page 18

SURVIVAIR Opti-Fit™ Convertible Facepiece

they are to be used. Used lters must be stored in

a protective bag, and in a clean, dry environment.

Detailed guidelines for each lter series are provided below.

1. N-Series Filters

These lters are only NIOSH approved for use

against solid and water-based particulates

and must not be used in any area that contains oil aerosols. N-series lters capture particles using electrostatic charges, and these

types of lters may be subject to some loss of

efciency if they are exposed to certain liquid

aerosols. The N-series (N95 and N99) lters

must be replaced immediately whenever:

● they are damaged, soiled, soaked with

liquids such as water or alcohol, or appear to be suspect or damaged in any

manner, or

● the user notices an increase in breathing

resistance such that the respirator becomes uncomfortable to wear.

If none of the above occurs and there is a

respiratory protection program per OSHA

29 CFR 1910.134 in place, then these lters

may be used continually, but only for a maximum of 30 days or 40 total hours, whichever

comes rst. However, SPERIAN recommends

that all lters be replaced daily because the

user may be unable to detect small defects

resulting in a loss of lter efciency, and the

determination of when breathing resistance

becomes too uncomfortable is subjective.

Further, SPERIAN recommends that these

lters be replaced daily when there are any

liquid aerosols present and there is no respirator program in place.

2. R-Series Filters

These lters are NIOSH approved for use

against any type of particulate, except that

for atmospheres that contain oil. The lters

can only be used for 8 hours or a single shift,

whichever comes rst. When used in either

oil-containing or non-oil containing atmo-

spheres, these lters must be replaced immediately whenever:

● they are damaged, soiled, soaked with liq-

uids such as water or alcohol, or appear to

be suspect or damaged in any manner, or

● the user notices an increase in breathing resistance such that the respirator becomes

uncomfortable to wear.

If none of the above occurs, the lter is used

in an area that does not contain oil, and there

is a respiratory protection program per OSHA

29 CFR 1910.134 in place, then these lters

may be used continually, but only for a maximum of 30 days or 40 total hours, whichever

comes rst. Even when used in non-oil containing atmospheres, SPERIAN recommends

that all lters be replaced daily because the

user may be unable to detect small defects

resulting in a loss of lter efciency, and the

determination of when breathing resistance

becomes too uncomfortable is subjective.

3. P-Series Filters

These lters are NIOSH approved for long

duration use against any type of particulate.

When used in either oil-containing or non-oil

containing atmospheres, these lters must be

replaced immediately whenever:

● they are damaged, soiled, soaked with

liquids such as water or alcohol, or appear to be suspect or damaged in any

manner, or

● the user notices an increase in breathing

resistance such that the respirator becomes uncomfortable to wear.

If none of the above occurs and there is a

respiratory protection program per OSHA

29 CFR 1910.134 in place, then these lters

may be used continually, but only for a maximum of 30 days or 40 total hours, whichever

comes rst. However, service time for the

Model 1050 P100 lter can be extended if l-

ter performance to 42 CFR Part 84 can be

demonstrated. Whether used in oil-containing

or non-oil containing atmospheres, SPERIAN

recommends that all lters be replaced daily

because the user may be unable to detect

small defects resulting in a loss of lter efciency, and the determination of when breathing resistance becomes too uncomfortable is

subjective.

WARNING

Failure to properly assemble lter pads

to cartridges or lter holders can cause

leakage, which could lead to personal

injury, illness or death.

1. Return to fresh air.

2. Remove cartridges or P100 lters by

turning them counterclockwise. Dispose

of used cartridges and lters in accordance with Federal, state, and local

guidelines.

3. If using lter pads, remove the lter retainers from the cartridges or lter holders. Remove the used lter pads and

dispose of them in accordance with Federal, state, and local guidelines. Clean

the lter retainer and cartridge or holder

if necessary.

4. Install new P100 lters or lter pads,

taken only from sealed packages, as

described in Section VIII, Part A.1.C.

5. Perform a facepiece t check as described in Section VIII, Part A.3.

15

Page 19

SURVIVAIR Opti-Fit™ Convertible Facepiece

B. Supplied Air Respirator (CF-SAR) Congurations

In addition to the General Warnings listed in Section IV,

the following warnings apply to supplied air respirator

(CF-SAR) congurations:

WARNING

● SPERIAN respirators, accessories,

and associated equipment should

not be used in atmospheres that

may contain contaminant concentrations above the lower explosive level

(LEL). Intrinsic safety certification

of electronic components does not

eliminate potential danger from ignition in these atmospheres.

● Do not exceed maximum use concentrations established by regulatory standards.

● Air line respirators can be used only

when the respirators are supplied

with respirable air meeting the requirements of CGA-7.1, Grade D or

higher quality.

● Use only the pressure ranges and

hose lengths specified in these user

instructions.

● Do not use this respirator in confined

spaces.

● For the P100 escape configuration:

Never use this respirator without two

SPERIAN Model 1050 P100 filters securely threaded onto the facepiece.

● For the P100 escape configuration:

The P100 escape filter functionality

of the P100 escape CF-CF-SAR configuration is not to be used in atmospheres containing less than 19.5%

oxygen.

● FAILURE TO COMPLY WITH THIS

WARNING MAY LEAD TO PERSONAL

INJURY, ILLNESS, OR DEATH.

1. Air Supply (applicable to side-mounted tube, front-

mounted tube and P100 escape congurations)

The following warnings regarding air supply are ap-

plicable to all continuous ow supplied air respirator

(CF-SAR) congurations (side-mounted tube, front-

mounted tube, P100 escape), and should be followed for safe operation of a supplied air respirator.

WARNING

● Compressors, storage cylinders,

valves, regulators, fittings, and other hardware must be large enough

to deliver the air volume required by

all users at peak demand.

● You are responsible for air quality and

compliance with safety and health

codes applicable to your area.

● See the tables in Section VIII, Part B.8

for hose length, air supply pressure,

and quick coupler requirements.

● Do not mix hose types or coupler assemblies except as specified in the

tables in Section VIII, Part B.8.

● Be sure that all respirable air system

piping, tubing, fittings, and couplings

are incompatible with non-respirable

gas systems.

● If an air pump or compressor is used

to supply breathing air, the following

precautions must be taken:

The air pump or compressor in-1.

take must not be located in an area

that could possibly contain contaminants, such as but not limited

to engine exhaust, spray booth

exhaust, or other toxic gases.

The air pump or compressor must 2.

have intake and exhaust filters

capable of removing dirt, carbon

dust, oil, oil vapor, and excess

water mist that may be present in

the area of the intake or may be

generated within the air pump or

compressor itself. Carbon monoxide alarms should be installed on

oil lubricated compressors and in

any other situation where carbon

monoxide may be present.

Frequently test the purity of the air 3.

delivered by the air pump or compressor. Air pumps and compressors deteriorate with age, as does

the quality of the air they deliver.

Set the pressure regulator and/or 4.

relief valve to maintain the pressure within the range specified in

the tables in Section VIII, Part B.8.

● FAILURE TO COMPLY WITH THIS

WARNING MAY LEAD TO PERSONAL

INJURY, ILLNESS, OR DEATH.

Ensure that the air supply is type 1, Grade D or better, as described in the Compressed Gas Association

Commodity Specication for Air, G-7.1.

Set relief valves at a maximum pressure of 150 psig

(1.03 Mpa).

16

Page 20

SURVIVAIR Opti-Fit™ Convertible Facepiece

2. Quick Coupler Assembly (applicable to sidemounted tube, front-mounted tube and P100 es-

cape congurations)

A male plug from one of the air line coupler kits

listed in the Parts List, Section VI, must be assembled to the open end of the breathing tube. This

operation requires a torque wrench.

WARNING

Do not use pipe thread sealing tape

on the quick coupler or air line hose

threads. The tape could restrict air-

ow or tape fragments could enter the

air system. Failure to comply with this

warning may lead to personal injury, illness, or death.

The steps and considerations required for com-

pleting the Quick Coupler assembly are as follow:

1. Breathing Tube

a. Apply Loctite No. 567 PST pipe sealant

or equivalent to the ¼ NPT threads of the

male quick coupler plug. Ensure that no

sealant enters the quick coupler or air line

hose.

b. Thread the male plug into the female t-

ting on the breathing tube. Torque to 150

±5 in-lb.

NOTE

The Vortex air cooler is not approved for use

with the low pressure ambient air pump.

2. Air Supply Hose

Each length of hose is equipped with a ¼ inch

female NPT swivel nut at each end and a male

to male ¼ inch NPT adapter. The male to male

adapter may be used to connect two lengths of

hose or connect the hose to the air supply. Four

approved methods of connecting hose lengths

and air supply are illustrated in Figure 10.

WARNING

● The full facepiece is NIOSH approved

only when supplied with respirable

breathing air through no more than

three (3) lengths of 9308 Series hose,

or two (2) lengths of 9852 Series air

line hose at the pressures listed in

Tables I and II, located in Section VIII,

Part B.8. Do not mix hose types from

different columns.

● The third pressure column in Table

I should be used when using a low

pressure ambient air pump. No more

than two (2) lengths of 9852 Series

air line hose may be used. The air

supply must be coupled to the air

source and the breathing tube with

the OBAC couplers and plugs.

● FAILURE TO COMPLY WITH THIS

WARNING MAY LEAD TO PERSONAL

INJURY, ILLNESS, OR DEATH.

CAUTION

Do not exceed the maximum continuous

duty or maximum intermittent duty operating pressure of the low pressure ambient air

pump. Refer to your pump user manual.

Figure 10. Methods of Hose Connection

3. When assembling the quick disconnect ttings

of the coupler or the male to male adapters to

the hose, verify that the hose gaskets are in

place and torque to 90 ±5 in-lb. Thread sealant

is not required.

4. The air supply connection using the ¼ inch male

to male adapter illustrated in Method 2 is also

approved for use with Methods 3 and 4.

● Method 1 is preferred when only one length

of hose is required since it allows the hose to

be disconnected from the air supply.

● Method 3 is preferred when multiple lengths

of hose (maximum of three) are required,

eliminating the cost of quick disconnect couplers at the hose junctions.

5. Pressurize and check for leaks with a bubble

type leak detector. If leaks are detected:

● Disassemble and repeat steps 3 through 5.

● If the leaks persist, remove the hose from ser-

vice and have repairs made by a SPERIAN

certied technician.

● Disassemble and repeat steps 3 through 5.

● If the leaks persist, remove the hose from ser-

vice and have repairs made by a SPERIAN

certied technician.

17

Page 21

SURVIVAIR Opti-Fit™ Convertible Facepiece

WARNING

Always verify that the swivel nut gaskets

are in place and undamaged before assembly. Missing or damaged swivel nut

gaskets may allow contaminants to leak

into the system, causing illness or death.

3. Breathing Tube Setup (applicable to side-mounted tube, front-mounted tube and P100 escape

congurations)

1. Inspect the equipment as described in Section

IX, Part B.

2. Verify that the O-ring is installed at the base of

the nozzle inlet. See Figure 11.

5. Attach the breathing tube to the facepiece.

● For side-mounted tube CF-SAR conguration:

Thread one end of breathing tube onto one

side connector of the facepiece. Verify that

the other side connector is securely capped

with a screw cap.

● For front-mounted tube and P100 escape CFSAR congurations: An audible click should

be heard when attaching the breathing tube

to the front adapter port on the facepiece

nozzle. See Figure 13.

Figure 13. Front Adapter Port and Screw Caps

Figure 11. Inlet O-ring

3. Verify that unused ports are capped as detailed

in Section VII for the applicable CF-SAR opera-

tional conguration.

4. Verify that the o-ring is installed into the end of

the breathing tube as shown in Figure 12.

6. Connect the air line hose to the air supply.

7. Adjust the regulator at the air supply to the proper pressure. Refer to the tables in Section VIII,

Part B.8 for determining the required pressure.

8. Don the waist belt, positioning the snap hook

over the left hip. Tighten snugly.

9. Attach the waist belt snap hook to the breathing

tube clip.

10. Plug the male quick coupler of the breathing

tube into the air line quick coupler, and verify

that breathing air ows into the facepiece. From

the inside of the facepiece, you can verify air-

ow by placing your hand near the back side of

the nozzle inlet.

11. With the air owing, verify that the air supply

pressure is within the appropriate pressure

range listed in the tables in Section VIII, Part

B.8. Adjust if necessary.

12. Disconnect the breathing tube quick coupler

from the air line and proceed with donning the

facepiece.

4. Donning Instructions for CF-SAR Congurations

Figure 12. Breathing Tube O-ring

WARNING

Always don, remove, and t check the

respirator in a safe, uncontaminated

area. Failure to comply with this warning may lead to personal injury, illness,

or death.

18

Page 22

SURVIVAIR Opti-Fit™ Convertible Facepiece

1. Inspect the respirator as described in Section

IX, Part B.

NOTE

If the waist belt was not previously donned

during the Breathing Tube Setup procedure

of Section VIII, Part B.3, don the waist belt

now. Position the snap hook over the left hip

and attach it to the breathing tube.

2. Verify that unused ports are capped as detailed

in Section VII for the applicable CF-SAR operational conguration. (See Figure 14 for a representation of the side-mounted tube CF-SAR

conguration).

Figure 15a. Adjust Lower Straps

Figure 14. Place Chin in Chin Cup

3. Adjust the top straps until one inch of strap extends through each buckle. Fully loosen the

lower straps. For respirators featuring a Headnet, fully loosen all straps.

4. Place the neck strap (if installed) over your

head.

5. Place your chin against the chin cup and center

the facepiece on your face. See Figure 14.

6. Hold the facepiece against your face and pull

the straps over your head.

7. Tighten the two lower straps, temple straps,

then the top straps until a good seal is obtained

and all straps lie at on your head. Do not overtighten the straps. See Figure 15a. For respirators with a Headnet, tighten the two lower

straps and the temple straps until a good seal

is obtained and all straps lie at on your head.

Flatten the Headnet with a wiping motion toward the back of your head. Retighten straps

as necessary. Do not overtighten the straps.

See Figure 15b.

Figure 15b. Flatten Headnet with a Wiping Motion

NOTE

When properly adjusted, the head strap hub

should be centered on the back of your head

and the lower straps should be below your

ears. See Figure 16a. For the Headnet version, the backstrap should be at the nape of

the neck. The Headnet should lie at on the

head and not bunch up. See Figure 16b.

Figure 16a. Properly Center Head Strap Hub

19

Page 23

SURVIVAIR Opti-Fit™ Convertible Facepiece

Figure 16b. Properly Fitted Headnet

5. Fit Check Instructions for CF-SAR Congurations

You must perform the following t checks appropriate for the CF-SAR conguration you are using

each time the respirator is worn or before entering

the contaminated area.

WARNING

If a leak-tight seal is not obtained during

the following t check, do not wear the

respirator. Ask your supervisor or safety

professional for assistance. The failure

to comply with this warning may lead to

personal injury, illness, or death.

A. Positive Pressure Fit Check for Side-mounted

Tube CF-SAR Conguration

Hold the palm of your hand gently over the exhalation valve outlet of the nozzle cover as shown in

Figure 17 and cover the open end of the breathing

tube with your other hand. Do not distort the natural shape of the facepiece. Exhale gently and hold

your breath to create and maintain a slight positive

pressure inside the facepiece. If air leakage occurs, readjust the facepiece and head straps, then

retest.

NOTE

The negative pressure t check detailed below can be performed as an alternate (or ad-

ditional) t check method for the side-mounted tube CF-SAR conguration.

B. Negative Pressure Fit Check for Side-mounted

Tube, Front-mounted Tube, and P100 escape CF-

SAR Congurations

● For all CF-SAR congurations: Plug the end of

the breathing tube with a suitable plug.

● For P100 escape CF-SAR congurations:

Cover the inlets of the lters with the palms of

your hands or another suitable item such as a

thin sheet of plastic or rubber.

NOTE

Alternatively, the P100 lters may be removed to perform the t check. If removed,

SPERIAN recommends someone other

than you reinstall them after a leak-tight t is

achieved. It is difcult for the user to reinstall

the lters without disturbing the face seal and

to determine whether the lters are correctly

installed. It is your responsibility to ensure

that the face seal is not disturbed when reinstalling the lters and that each lter is installed correctly.

Inhale gently and hold your breath to slightly collapse the facepiece. The facepiece should remain

collapsed on your face without leaking. If the facepiece leaks, reposition, check the straps, and repeat

the t check.

If a good t was achieved, remove the plug from the

breathing tube. If using the P100 escape CF-CF-

SAR conguration, reinstall the P100 lters.

Attach the breathing tube to the air line hose. The

continuous ow supplied air respirator (CF-SAR) is

now ready for use.

WARNING

Never use this respirator unless the

quick connect is fully engaged in the

locked position. Failure to comply with

this warning may lead to personal injury, illness, or death.

Figure 17. Positive Pressure Fit Check

If a good t was achieved, attach the breathing tube

to the air line hose. The continuous ow supplied

air respirator (CF-SAR) is now ready for use.

6. How to Use the Respirator

Before entering the work area for the rst time, or

for re-entry, you must verify proper operation of the

respirator in accordance with Section VIII, Parts B.1,

B.2, and B.3, and follow the donning and t checking procedures described in Section VIII, Parts B.4

and B.5.

To receive the maximum protection available from

your respirator, you must read, understand, and

follow all the warnings, limitations, and instructions

contained in this manual and follow your employ-

20

Page 24

SURVIVAIR Opti-Fit™ Convertible Facepiece

er’s instructions on the use and maintenance of

the respirator. Read and understand the following

warnings prior to using the respirator.

If you are using an ambient air pump, turn off the

pump when the respirator is not in use. Operating the

pump without a connected supply hose and respirator will cause the pump to overheat. Turn the pump

on before reentering the work area and verify that the

pump outlet pressure is correct (See Tables I and II),

and that the respirator is providing air as described in

Section VIII, Part B.8.

WARNING

● The respirator consists of a full facepiece constructed of silicone with a

polycarbonate lens, EPDM or EVA

breathing tube, and PVC or rubber

air line hoses. It is the user’s responsibility to verify the respirator materials are acceptable for their intended

use. If you are unsure, consult your

local safety professional to verify

that no possible contaminants and/

or liquids will permeate through any

of the respirator materials.

● Do not don, doff, or store the respirator in an area where contaminants

can contact or accumulate inside