Page 1

INSTRUCTION MANUAL

SPERIAN

AIR PURIFYING RESPIRATOR

SURVIVAIR SERIES 2000

SURVIVAIR BLUE 1

®

SURVIVAIR LOW MAINTENANCE

SURVIVAIR HALF MASK FACEPIECES

WARNING

Do not use your respirator until you read and understand this

instruction manual. You are required to inspect the respirator prior

to putting it into service. Please refer to the inspection procedures in

this manual. Failure to comply with this warning may result in personal

injury, illness, or death.

NIOSH APPROVED—SEE SEPARATE APPROVAL LABEL

AN ISO 9001

REGISTERED

COMPANY

SPERIAN Respiratory Protection USA, LLC

© Copyright SPERIAN Respiratory

Protection USA, LLC

MAY 1997 All Rights Reserved

P/N 230094 REV E 03/09

3001 South Susan St., Santa Ana, CA 92704

Toll-Free 888.APR.SCBA or 714.545.0410

Fax 714.850.0299

www.sperianprotection.com

Page 2

SAFETY PRECAUTIONS

The Warnings, Cautions, and Notes contained in this manual have the following

signicance.

WARNING

Maintenance or operating procedures and techniques that may result in

personal injury, illness, or death if not carefully followed.

CAUTION

Maintenance or operating procedures and techniques that may result in

damage to equipment if not carefully followed.

Maintenance or operating procedures and techniques or information

considered important enough to emphasize.

WARNINGS AND LIMITATIONS

• The employer is responsible for establishing that this respirator is

suitable for the user’s application.

• This respirator will reduce, but will not eliminate the inhalation of

contaminants. Some sensitive individuals may experience health

problems when exposed to even minute amounts of contaminants. This

respirator will not prevent health problems for those individuals. Where

suspected cancer-causing contaminants are present, positive-pressure

supplied air respirators will provide higher protection levels.

• SPERIAN cannot predict what will happen to this respirator in every

potential environment. Materials can be chemically attacked if exposed

to the wrong environment and may exhibit excessive corrosion or

other forms of damage. Permeation or penetration of gases, liquids,

or particles through the materials could be excessive. Extremes of

temperature might cause thermal degradation. Each of these things, or

a combination of them, could create conditions in which this SPERIAN

respirator would be dangerous to use.

• This respirator must be used in conjunction with a written respirator

program meeting the requirements of the OSHA Standard for

Respiratory Protection, 29 CFR 1910.134, available from the U.S.

Department of Labor, Occupational Safety and Health Administration.

The program must include procedures for evaluating air contaminants

and selecting appropriate respirators; procedures for proper use

of respirators; procedures for testing the facepiece-to-face t of

respirators; procedures for cleaning, disinfecting, inspecting,

maintaining, and storing respirators; procedures for determining if

workers are physically and medically capable of wearing respirators;

and procedures for training employees in the use

NOTE

2

Page 3

WARNINGS AND LIMITATIONS—Continued

and care of respirators and in recognizing the hazards associated with

contaminants in the work place.

• Do not use this respirator without the appropriate SPERIAN cartridges

and/or lters securely threaded onto the facepiece. Always read cartridge

labels prior to use and be certain that you have cartridges and/or lters

that will provide the required protection. This respirator must be used for

protection against only those air contaminants listed on the air purifying

cartridge, lter, and/or the NIOSH approval label. Respirators labeled for

protection against particulates only shall not be used for gases/vapors.

Respirators labeled for protection against gases/vapors only shall not

be used for particulates.

• Routinely used respirators must be inspected before and after each use.

Stored emergency respirators must be inspected after each use and at

least once every 30 days. A written record must be kept of inspections

of emergency respirators.

• Do not use this respirator in environments where the concentrations of

contaminants are unknown or are immediately dangerous to life or health

(IDLH). IDLH atmospheres are dened as those which the wearer could not

breathe for short periods, could not escape without the aid of a respirator,

or which have an immediate or delayed adverse effect on health.

• Do not use the respirator if you have health or respiratory problems

as identied by 29 CFR 1910.134, Appendix C, Medical Evaluation

Questionnaire (or by a medical professional). Persons sensitized can

have a severe reaction to chemicals at levels well below accepted

health levels such as the OSHA Permissible Exposure Limit (PEL),

ACGIH® Threshold Limit Value (TLV), or NIOSH Recommended Exposure

Limits (REL). Isocyanates are potent sensitizers. Use positive pressure

supplied air respirators to provide better protection against these

chemicals. Do not use this respirator if you have been sensitized from

previous exposure or believe that you may be sensitive or allergic to any

chemical (e.g., isocyanates, latex, etc.) until you obtain clearance from

a medical doctor.

• Use of components other than those listed on the NIOSH approval label

and in this manual, or as authorized by SPERIAN, or modication of this

respirator in any manner will void the NIOSH certication and invalidates

all SPERIAN’s warranties for the respirator. • This respirator must be

worn and used as specied in SPERIAN’s instructions. No respirator

can provide complete protection from all conditions. Use extreme care

for emergency conditions.

• Some individuals are sensitive to chemicals (e.g., isocyanates, latex,

oil mists, etc.) or may have some type of respiratory disorder (e.g.

asthma, chronic obstructive airway disease, etc.). If you are sensitive

to any chemical or have a respiratory disorder, you may have a severe

reaction at contaminant levels well below accepted health levels, such

as the OSHA Permissible Exposure Limit (PEL), ACGIH® Threshold Limit

Value (TLV), or the NIOSH Recommended Exposure Limits (REL). Many

chemicals (e.g., isocyanates, mercury, etc.) have no physical warning

3

Page 4

WARNINGS AND LIMITATIONS—Continued

properties and you cannot taste or smell the contaminants even though

they may be present in the respirator facepiece. This respirator will

reduce, but will not eliminate the possibility of contaminants entering

the facepiece and causing a severe reaction. Do not use this respirator

until you obtain clearance from a medical doctor. Always read and

follow the instructions listed in the Material Safety Data Sheet for the

chemicals that are present in the work area.

• Do not use if you have a preexisting skin condition (for example,

folliculitus or vitiligo) until you obtain clearance from a medical doctor.

• Users must clean and maintain this respirator only in accordance with

SPERIAN’s instructions.

• Before entering a hazardous environment while wearing this respirator,

you must conduct safe, scientic tests to determine if the environment

could render the equipment unsafe. Results of this testing should be

well documented. Seek the help of a certied safety professional or

industrial hygienist. Do not use this equipment if the user would be

endangered in any way through environmentally induced degradation

of the materials in the apparatus.

• Do not wear this respirator if a satisfactory t, as determined by a

qualitative or quantitative t test, cannot be obtained. See ANSI Z88.2,

latest issue, and OSHA CFR 1910.134, latest edition.

• If this respirator will be used during welding, it is the user’s responsibility to

obtain the proper equipment for protection against sparks, optical radiation,

and impact. This respirator will not protect you against these hazards.

• Do not use this respirator at temperatures above 130°F (55°C).

• This respirator does not protect exposed areas of the body. Some

contaminants can be absorbed directly through the skin while others

may irritate exposed areas.

• This respirator does not supply oxygen. Do not use the respirator in

atmospheres containing less than 19.5% oxygen by volume.

• Beards, stubble, or sideburns will prevent a good facepiece seal, and

facial hair may interfere with valve function. Do not use this respirator

unless you are clean shaven. Absence of one or both dentures can

seriously affect the t of the respirator.

• Immediately return to a non-contaminated area if you taste or smell

contaminants; your eyes, nose, or throat become irritated; breathing

becomes difcult; you feel nauseous or dizzy; the breathing air becomes

uncomfortably warm; the facepiece moves, slips, or leaks; or any of the

end-of-service-life indicators (ESLIs) on the mercury vapor cartridge

turns gray.

• Do not use respirators in environments where ying sparks or chips may

damage the speaking diaphragm. Do not use respirators with damaged

speaking diaphragms.

• Do not alter or modify any respirator product.

• This respirator facepiece assembly contains natural rubber latex, which

may cause allergic reactions in some individuals. Discontinue use if you

experience an allergic reaction.

4

Page 5

WARNINGS AND LIMITATIONS—Continued

• Discontinue use if you experience skin irritation or discoloration.

• For use by trained, qualied personnel only.

• This product may provide less than adequate protection if improperly

used, resulting in personal injury, illness, or death.

• Following is a list of contaminants for which these respirators must

not be used. This list is far from complete. Please contact SPERIAN for

information on other contaminants.

• FAILURE TO COMPLY WITH THESE WARNINGS MAY RESULT IN

PERSONAL INJURY, ILLNESS, OR DEATH.

Acrolein Carbonyls Hydrogen

Aniline Cyanogen Methanol Phosphine

Arsine Dimethylaniline Methylene

Boron Hydrides Dimethyl Sulfate Nitrogen

Bromine Ethyl Cyanide Nitroglycerin Sulfur Chloride

Carbon Dioxide Fluorine Nitromethane Vinyl Chloride

Carbon Monoxide Hydrogen Cyanide Ozone

Selenide

Chloride

Oxides

Phosgene

Phosphorous Trichloride

Stibine

A. HOW TO INSTALL CHEMICAL CARTRIDGES AND PARTICULATE FILTERS

1. Particulate Filters

Before using a particulate lter, you must conrm the atmosphere is non-IDLH

and not oxygen decient, the contaminant is a particulate hazard, and you must

determine the hazard ratio (hazard concentration/exposure limit). If the hazard

ratio is less than 10, you may use a half mask respirator with a lter efciency of

95% or higher. If the hazard ratio is less than 20, you may use a full facepiece

respirator with a lter efciency of 95% or higher. If the hazard ratio is less than

100, you may use a full facepiece respirator with a lter efciency of 99% or

higher. If the hazard ratio is greater than 100, you must use another type of

respirator.

N-series lters must only be used for non-oil containing aerosols or particulates.

R or P-series lters can be used if the atmosphere contains oil (e.g., lubricants,

cutting uids, glycerin, etc.). An R-series lter used in an oil containing atmosphere

must be replaced after each 8-hour work shift. A P-series lter can be used for

more than one 8-hour work shift.

Refer to NIOSH Guide to the Selection and Use of Particulate Respirators

Certied Under 42CFR84 for additional guidelines on use limitations for lters.

5

Page 6

WARNING

Filters improperly used or improperly assembled to the facepiece could

cause leakage, which could lead to personal injury, illness, or death.

2. Mercury Vapor Cartridges

Special or Critical User’s Instructions: The mercury vapor cartridges incorporate

4 (four) end-of-service-life indicators (ESLIs). Each ESLI, yellow in color when

new, turns to gray when exposed to mercury vapor. Do not use these cartridges

unless you can distinguish between the safe and discard colors of the ESLI. The

indicators must be visible when wearing the respirator without having to manipulate

either the facepiece or the indicator. If the indicator cannot be seen, do not wear

the respirator. The cartridges must be replaced when the ESLIs change color from

yellow to gray, when the ESLIs become dirty or damaged, after 30 days of use, or

if removed from their original packaging and not used within 30 days. Never enter

or remain in a hazardous atmosphere if one or more of the ESLIs is gray.

3. Cartridge/Filter Installation

a) Ensure that you have the correct cartridge and/or lter type for the contaminants

in your work area. If you are not sure, consult your supervisor or safety

professional. See paragraph A.2. for special user’s instructions if you are using

Mercury Vapor Cartridges.

b) Install cartridges or P100 lters by threading them onto the facepiece

connectors. Hand-tighten to ensure a good seal against the facepiece. Do not

overtighten.

c) If using lter pads, insert the appropriate pad into the lter retainers so that the

side stamped with the part number will face toward the facepiece when installed.

Completely snap the lter retainers onto the cartridges or lter holders.

d) Inspect the lter through the retainer to ensure that the entire edge of the

lter is making contact with the retainer and the lter is not bunched or folded.

The outer diameter of the pad must be compressed between the top lip of the

cartridge or lter holder and the inner sealing ledge of the retainer. Install the

lter holders in the same manner as the cartridges.

6

Page 7

B. HOW TO DON THE RESPIRATOR

WARNING

Always read cartridge labels prior to use to be certain that you have

cartridges and/or lters that will provide the required protection. Filters

labeled for protection against particulates only shall not be used for

gases/vapors, and cartridges labeled for protection against gases/vapors

only shall not be used for particulates. Both cartridges/lters must be

of the same type. The failure to comply with this warning may lead to

personal injury, illness, or death.

1. Inspect the respirator as described in section G.

2. Install cartridges/lters onto the inlet ports. Hand tighten, but do not

overtighten. See inset 1.

3. Position the bottom of the facepiece as low as possible under the chin while

positioning the narrow portion of the facepiece on the bridge of the nose.

Position the cradle headband above the ears so that it straddles the crown

of the head. See inset 2.

4. Hook the lower headband straps below the ears and around the back of

the neck. Adjust the upper headband by pulling both straps at the same

time. Adjust the lower headband straps in the same manner. Adjust the

headbands for a leak-tight t, but do not overtighten the straps. See

inset 3. For the Blue 1 respirator, you must remove the respirator to

adjust the headband strap slides as necessary for a leak-tight t, but do

not overtighten the straps.

5. Perform a t check before using the respirator.

7

Page 8

C. HOW TO FIT CHECK THE RESPIRATOR

You must perform the following t check each time the respirator is worn.

WARNING

If you cannot obtain a leak-tight t, do not use the respirator. Consult

your supervisor or safety professional. Failure to comply with this warning may lead to personal injury, illness, or death.

1. Positive Pressure Fit Check: Hold the palm of your

hand gently over the exhalation valve outlet. Do not

distort the natural shape of the facepiece. Exhale

gently and hold your breath to create and maintain a

slight positive pressure inside the facepiece. See inset

1. If air leakage occurs, readjust the facepiece and

headbands, then retest.

2. Negative Pressure Fit Check: Cover the inlet of

the cartridges and/or lters with the palms of your

hands or another suitable item, such as a thin sheet

of plastic or rubber. When the respirator is equipped

with cartridges, lter retainers may be used as an

aid. Alternatively, the cartridges may be removed

to perform the t check. If removed, SPERIAN

recommends someone other than yourself reinstall

them after a leak-tight t is achieved. It is difcult for

the user to reinstall the cartridges without disturbing

the facepiece-to-face seal and to determine whether

the cartridges are correctly seated against the

facepiece. It is your responsibility to ensure that

the facepiece-to-face seal is not disturbed when

reinstalling the cartridges and that each cartridge is

sealed against the facepiece. Inhale gently and hold

your breath to slightly collapse the facepiece. See

inset 2. If air leakage occurs, readjust the facepiece

and headbands, then retest. If lter retainers are used,

do not remove them after the t check is completed.

Removing the lter retainers may shift the facepiece

and break the facepiece-to-face seal.

8

Page 9

D. HOW TO USE THE RESPIRATOR

To receive the maximum protection available from the respirator, you must read,

understand, and follow all the warnings, limitations, and instructions contained in

this manual and follow your employer’s instructions on the use and maintenance

of this respirator. Read and understand the following warning prior to using the

respirator.

WARNING

• Never remove the respirator for any reason while you are in the work

area.

• You must leave the work area immediately if the facepiece-to-face seal is

disturbed for any reason, such as:

a. Slipping due to excessive sweating or excessive head movement.

b. The facepiece becomes dislodged as a result of being knocked.

c. You sneeze or cough while wearing the facepiece.

d. You need to blow your nose or scratch covered areas of your

face.

e. For any other reason that would cause the facepiece seal to be

disturbed.

• You must restore the facepiece-to-face seal and perform a t check in a

non-hazardous environment before reentering the work area.

• Failure to comply with this warning may lead to personal injury, illness,

or death.

E. CHEMICAL CARTRIDGE SERVICE LIFE AND REPLACEMENT

• OSHA allows the use of respirators for protection against contaminants

with poor warning properties such as isocyanates. To maximize

protection against isocyanates and other chemicals with poor

warning properties, it is important to replace the cartridges when the

end-of-service-life indicator (if so equipped) has changed color, or in

accordance with an OSHA compliant cartridge change-out schedule

based on objective information or data that ensures the cartridges are

changed before the end of their service life.

• You must immediately leave the contaminated area if you taste or smell

contaminants, or if your eyes or throat become irritated. Replace the

cartridges before reentering the contaminated area.

• You must replace the combination cartridges when breathing becomes

uncomfortable or difcult. As particulates collect on the lter surface,

the breathing resistance of the respirator increases. If you wait too long

to replace the cartridges, particulates may leak past the face seal instead

of being collected on the lter; therefore, SPERIAN recommends that

the cartridges be changed at least daily.

WARNING

9

Page 10

WARNING—Continued

• Establishing the cartridge service life for mixtures of contaminants

is a complex task, and one that requires considerable professional

judgment to create a reasonable change-out schedule. OSHA provides

a “rule-of-thumb” method for determining the cartridge service life for

mixtures. The method addresses two situations. The rst is where the

individual compounds of the mixture have similar breakthrough times

(i.e., within one order of magnitude). In this case, OSHA recommends

adding the concentrations of all the components of the mixture to

determine a “total concentration,” then determine the mixture service

life by applying the total concentration to the component with the

shortest service life. The second is where individual compounds have

breakthrough times that vary by two orders of magnitude or greater.

In this case, OSHA recommends the mixture service life be based on

the contaminant with the shortest breakthrough time. The OSHA ruleof-thumb methods may no be applicable for all mixtures. In some

cases, the actual mixture service life may be much lower than the one

calculated. For this reason, SPERIAN recommends that the cartridge

service life for mixtures be determined using experimental methods. If

you are unsure how to determine the cartridge service life for mixtures,

please contact SPERIAN.

• Failure to comply with this warning may lead to personal injury, illness,

or death.

The gas/vapor service life depends on the user’s breathing rate, the characteristics of the contaminant, and environmental conditions such as temperature and

humidity. Saturated cartridges will leak trace amounts of contaminants to the

wearer, which may be detected by odor, taste, and/or irritation. Replace the cartridges when the end-of-service-life indicator (if so equipped) has changed color,

or in accordance with an OSHA-compliant cartridge change-out schedule that is

based on objective information or data that ensures that cartridges are changed

before the end of their service life. Replace the cartridges earlier if you detect the

contaminant by smell, taste, or irritation, or if either cartridge shows any signs of

damage. SPERIAN recommends cartridges be replaced daily even if the end-ofservice-life indicator has not changed color, or the change-out schedule is determined to be greater than 1 day. Always replace cartridges in pairs. Replace

cartridges as follows:

1. Return to fresh air.

2. Unscrew and remove the used cartridges from the facepiece and dispose of the used cartridges in accordance with Federal, state, and local

guidelines.

3. Install new cartridges, taken only from sealed packages, as described in

section A.

4. Perform a facepiece t check as described in section C.

10

Page 11

F. PARTICULATE FILTER SERVICE LIFE AND REPLACEMENT

The lter service life depends on the lter series type used, the user’s breathing

rate, the characteristics of the contaminant, and environmental conditions such as

humidity. All N- and R-series lters should be replaced whenever they are damaged, soiled, contaminated with water, or cause increased breathing resistance

such that the respirator becomes uncomfortable to wear. In addition, when an

R-series lter is used in an oil-containing atmosphere, the lter must be replaced

after each 8-hour work shift. SPERIAN recommends, due to considerations of

hygiene, that all lters be replaced at least daily, and more often if necessary.

Whether used in oil-containing or non-oil-containing atmospheres, SPERIAN rec-

ommends the lters be replaced daily because the user may be unable to detect

small defects in the lter, resulting in a loss of lter efciency, and the determina-

tion of when breathing resistance becomes too uncomfortable is subjective. Filters

should also be replaced in accordance with schedules established by regulatory

agencies.

WARNING

Failure to properly assemble lter pads to cartridges or lter holders can

cause leakage. Failure to comply with this warning may lead to personal

injury, illness, or death.

Replace lters as follows:

1. Return to fresh air.

2. If using P100 lters, unscrew and remove the used lters from the facepiece and dispose of the used lters in accordance with Federal, state, and

local guidelines.

3. If using lter pads, remove the lter retainers from the cartridges or lter

holders. Remove the used lter pads and dispose of them in accordance

with Federal, state, and local guidelines. Clean the lter retainer and car-

tridge or holder if necessary.

4. Install new P100 lters or lter pads (taken only from sealed packages) as

described in section A.

5. Perform a facepiece t check as described in section C.

11

Page 12

G. INSPECTION

Inspect this respirator for defects as described below before and after each use

and at least monthly if not used. Repair as necessary, clean and disinfect after

each use, and store properly to assure that the respirator is maintained in satisfactory working condition. See section H for repair instructions. Keep a record of

inspection and repair dates, and results.

WARNING

• Do not use the respirator with damaged or improperly operating valves.

• Failure to comply with this warning may lead to personal injury, illness,

or death.

If the respirator is equipped with a speaking diaphragm, do not remove it from

the facepiece for inspection.

1. Inspect the facepiece skirt for cuts, gouges, punctures, tears, nicks, and

deterioration from age, heat, or contamination, and the face seal area for

distortion.

2. Inspect the headbands for abrasions, cuts, nicks, loss of elasticity, or deterioration from age, heat, or contamination.

3. Inspect the inhalation and exhalation valves for nicks, cracks, tears, or

creases, and the exhalation valve seat for nicks, cracks, or dents.

4. Check the exhalation valve for proper operation by exhaling through the

respirator and pausing before inhaling. The exhalation valve must close by

itself before inhaling. Replace valves which fail to close.

5. If the respirator is equipped with a speaking diaphragm, inspect it for

holes or tears by holding it up to a light and verifying that no light shines

through.

NOTE

12

Page 13

H. MAINTENANCE

Respirators should be cleaned after each day’s use by washing with mild soap and

warm water. Then disinfect the respirators with a suitable sanitizing solution. ANSI

Z88.2, latest edition, also provides information and guidelines on the cleaning and

sanitizing of respirators.

1. Cleaning

WARNING

• Specialized processes are required to disinfect and decontaminate a

respirator. You must follow the instructions of the manufacturer of the

equipment and chemicals.

• It is the user’s responsibility to ensure that the processes chosen provide adequate cleaning, disinfection, and decontamination, and do not

damage the respirator in any way.

• In the absence of a commercial sanitizing product, the hypochlorite solution described below will eliminate many, but not all biohazards.

• Failure to comply with this warning may lead to personal injury, illness,

or death.

CAUTION

• Do not use solvent type cleaners to clean any part of the respirator.

• Do not use sonic cleaners on respirators equipped with a speaking dia-

phragm.

a) Remove the cartridges and/or lters.

b) Immerse the facepiece in warm, soapy water and gently scrub with a soft

brush.

c) Rinse thoroughly in fresh water to remove all traces of soap, especially

from the exhalation valve.

d) Disinfect the facepiece in a warm, 120°F (48°C) maximum, suitable sanitiz-

ing solution, such as “hypochlorite” for 2 to 3 minutes. A hypochlorite solution can be prepared by mixing 2 tablespoons of chlorine bleach per each

gallon of water. Rinse thoroughly with fresh warm, 120°F (48°C) maximum

water.

e) Dry with a clean, lint-free cloth or allow to air dry. Warm air may be used.

f) Carefully inspect the respirator as described in section G. Reinstall the car-

tridges and/or lters before use.

2. Repair (See the Table at the End of this Manual for Replacement Parts)

a. Threaded Connector Replacement

1) Remove cartridges, P100 lters, or lter holders from the facepiece.

2) Remove the damaged threaded connector from the facepiece by pressing

it inward.

13

Page 14

3) Insert a new connector, threaded end rst, from inside the facepiece.

Push the connector until the threads are clear and the connector ange is

securely seated.

b. Exhalation Valve Seat and Cover Replacement

1) Remove the exhalation valve cover using the small tab on the cover.

2) Remove the exhalation valve.

3) Remove the valve seat by pushing inward to disengage the seat from the

facepiece.

4) Insert a new valve seat from inside the facepiece. Securely seat the smaller

diameter ange by exing the facepiece material while pressing the seat,

working the facepiece into the seat groove.

5) Install a new valve by pulling the stem through the seat until it snaps into

place.

6) Reinstall the exhalation valve cover.

7) Test the new valve by performing a negative pressure t check as described

in section C.

I. STORAGE

WARNING

This SPERIAN respirator does not have a dened storage life. Carefully

inspect the respirator before each use. Failure to comply with this warn-

ing may lead to personal injury, illness, or death.

CAUTION

The maxim um stora ge temperature for the respi rator is 140°F (6 0°C).

Lon g-ter m stor age at elevate d temp eratu res may cause premature

deterioration.

After inspection and cleaning, store the respirator to protect it against dust,

sunlight, extreme heat and cold, excessive moisture, or damaging chemicals.

J. SHIPMENT

All products returned to SPERIAN’s factory, distributors, or repairs centers must

be decontaminated before shipment.

14

Page 15

K. ADDITIONAL INFORMATION

If you need assistance or additional information on any SPERIAN product, consult

your local distributor or contact:

SPERIAN

3001 S. Susan Street

Santa Ana, CA 92704 U.S.A.

(714) 545-0410 or (888) APR-SCBA

FAX (714) 850-0299

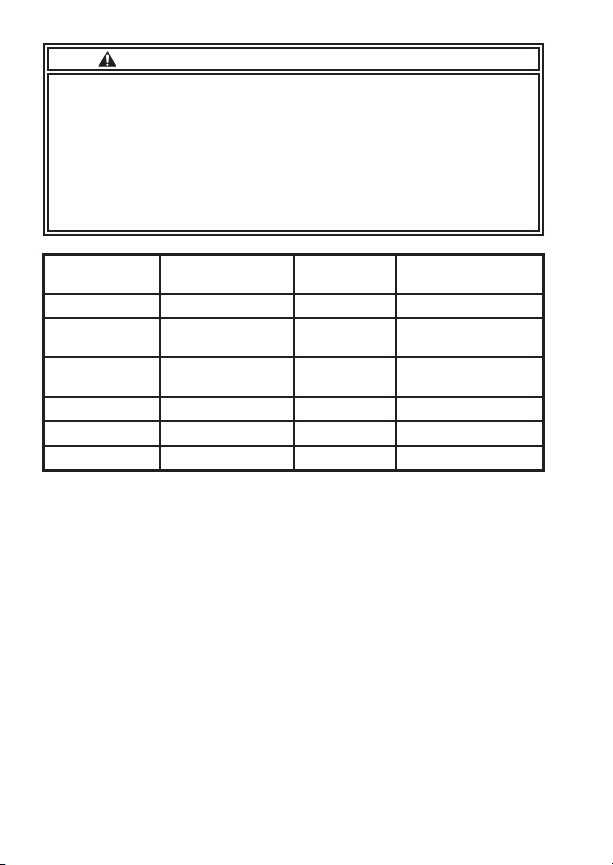

L. REPLACEMENT PARTS

REPLACEMENT PARTS TABLE (See Figure on page 17)

ITEM PART NO. DESCRIPTION

1 260023 Headband and Yoke, Series 2000

1 860030 Headband and Yoke, Low Maintenance

1a 140080 Upper Cradle, Blue 1

1b 140022 Lower Headband, Blue 1

1c 140024 Lower Headband, Blue 1

140040 Lower Headband and Upper Cradle Set, Blue 1

2 See Note Facepiece Skirt, Series 2000

2a See Note Facepiece Skirt, Blue 1, w/Speaking Diaphragm

2b See Note Facepiece Skirt, Blue 1, w/o Speaking Diaphragm

3 260019 Exhalation Valve Seat

4 140005 Exhalation Valve

5 260018 Exhalation Valve Cover

6 140001 Inhalation Valve

7 140002 Threaded Connector, Series 2000 and Blue 1

7 360008 Threaded Connector, Low Maintenance

8 140074 Filter Holder

9 140079 Filter Retainer

10 220054 Speaking Diaphragm

11 - 13 Filters-See Cartridge and Filter Table

14 and 15 Cartridges-See Cartridge and Filter Table

NOTE: Contact your local distributor for the appropriate skirt part number.

15

Page 16

CARTRIDGE AND FILTER TABLE (See Figure on page 17)

ITEM MODEL FILTERS

11 1060 Filter Pad, N95

11 1070 Filter Pad, N99/R95

12 1050 P100, Micro

13 1190 P100 Slimline

1195 P100 Disk

ITEM MODEL CARTRIDGES

14 100100 Organic Vapors

14 100200 Acid Gases

14 100300 Organic Vapors and Acid Gases

14 100400 Ammonia and Methlyamine

14 100600 Mercury Vapor and Chlorine

14 100800 Multi-Contaminant

15 1051 Combination Organic Vapors and P100

15 1052 Combination Acid Gases and P100

15 1053 Combination Organic Vapors, Acid Gases, and P100

15 1054 Combination Ammonia, Methylamine, and P100

15 1056 Combination Mercury Vapor, Chlorine, and P100

16

Page 17

Figure 1. Half Mask Facepiece

17

Page 18

M. WARRANTY AND LIMITATION OF LIABILITY

LIMITED WARRANTY: SPERIAN warrants this product to be free from defects

in materials and workmanship for 5 years (1 year for plastic parts) from the date

of purchase. During this period, SPERIAN will repair or replace defective parts,

at SPERIAN’s option. Freight charges to and from the SPERIAN factory shall be

paid by the purchaser.

EXCLUSIONS: NOTWITHSTANDING ANY CONTRARY TERM IN THE PURCHASER’S PURCHASE ORDER OR OTHERWISE, THE ONLY WARRANTY

EXTENDED BY SPERIAN IS THE EXPRESSED LIMITED WARRANTY DEFINED ABOVE. THIS WARRANTY IS EXCLUSIVE AND IN LIEU OF ANY IMPLIED WARRANTY OF MERCHANTABILITY, OR FITNESS FOR A PARTICULAR PURPOSE.

CONDITIONS: To maintain this warranty, this product must be used, maintained,

and inspected as prescribed in the owner’s instruction manual, including prompt

replacement or repair of defective parts and such other necessary maintenance

and repair as may be required. Normal wear and tear; parts damaged by abuse,

misuse, negligence, or accidents; and inhalation and exhalation valves are specically excluded from this warranty.

LIMITATION OF LIABILITY: No other oral warranties, representations, or guarantees of any kind have been made by SPERIAN, its distributors, or the agents of either of them, that in any way alter the terms of this warranty. EXCEPT AS HEREIN

PROVIDED, SPERIAN SHALL HAVE NO LIABILITY FOR ANY LOSS OR DAMAGE, WHETHER DIRECT, INDIRECT, INCIDENTAL, OR CONSEQUENTIAL, TO

ANY PURCHASER OR USER OF THIS PRODUCT ARISING FROM THE SALE,

USE, OR OPERATION OF THIS PRODUCT.

WARNING

The failure to use and maintain this equipment in strict conformance with

the applicable instruction manual may result in personal injury, illness,

or death. The equipment’s use in any manner that is not expressly authorized pursuant to the applicable instruction manual may result in severe

adverse impacts to human health.

www.sperianprotection.com

18

Loading...

Loading...