Sperian Panther Hip-Pac P9684 Series, Panther Hip-Pac P9686 Series, Panther Hip-Pac P9685 Series, Panther Hip-Pac 9649 Operation Manual

Page 1

PANTHER HIP-PAC

™

SUPPLIED-AIR RESPIRATOR, PRESSURE-DEMAND CLASS

AND

SELF-CONTAINED BREATHING APPARATUS

P9684 SERIES 5- and 10-Minute Escape

P9685 SERIES 15-Minute Escape

P9686 SERIES HP 10-Minute Escape

9649 SERIES HP 10-Minute Escape

OPERATION MANUAL

DO NOT USE this respirator until you completely read and understand this

instruction manual. You are required to inspect your respirator prior to put-

ting it into eld service. Please refer to the inspection procedures in this

manual. Failure to comply with this Warning may lead to serious personal

injury, serious illness, or death.

© Copyright SPERIAN May 2003

All Rights Reserved

P/N 963018 REV B 12/13

WARNING

AN ISO 9001

REGISTERED

COMPANY

Sperian Respiratory Protection USA, LLC

3001 South Susan St., Santa Ana, CA 92704

Toll Free (800) 873-5242

www.sperianprotection.com

Page 2

Page 3

Panther HIP-PAC

Table of Contents

I. INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

II. SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . 1

III. DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

IV. PARTS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

V. USE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

A. Air Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

B. Quick Coupler Assembly. . . . . . . . . . . . . . . . . . . . . . 6

C. Donning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

D. Fit Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

E. Emergency Exit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

F. Emergency Operation. . . . . . . . . . . . . . . . . . . . . . . . 11

G. Dofng. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

H. 21 Series Facepiece Drink Tube . . . . . . . . . . . . . . . 12

VI. MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

A. Conventional Facepiece Cleaning . . . . . . . . . . . . . 12

B. Hood-style Facepiece Cleaning . . . . . . . . . . . . . . . 13

C. Second Stage Regulator Cleaning . . . . . . . . . . . . . 14

D. Exterior Surfaces Cleaning . . . . . . . . . . . . . . . . . . . 14

E. Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

F. Repair. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

G. Functional Testing . . . . . . . . . . . . . . . . . . . . . . . . . . 14

H. Cylinder Maintenance and Recharging . . . . . . . . . 14

I. Cold Weather Operation and Maintenance . . . . . . . 17

J. Storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

K. Overhaul Frequency. . . . . . . . . . . . . . . . . . . . . . . . . 19

L. Additional Information . . . . . . . . . . . . . . . . . . . . . . . 19

VII. WARRANTY AND LIMITATION OF LIABILITY. . . . . . 20

VIII. INSPECTION TABLE . . . . . . . . . . . . . . . . . . . . . . . . . 21

IX. REPAIR TABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

X. FUNCTIONAL TESTING TABLE . . . . . . . . . . . . . . . . . 23

XI. CAUTIONS AND LIMITATIONS. . . . . . . . . . . . . . . . . . 24

I. INTRODUCTION

This manual provides instructions for the use and maintenance of the SPERIAN Panther HIP-PAC™ pressuredemand supplied-air respirator and self-contained

breathing apparatus, P968450 Series, P968470 Series,

P968500 Series, P9686 Series, and 9649 Series. The

Panther HIP-PAC is intended for supplied-air entry into

hazardous atmospheres, and emergency exit using the

ve/ten/fteen-minute cylinder in the event of a remote

air supply failure. You must read and understand this

manual and be trained in the proper use of the Panther HIP-PAC before wearing it in a hazardous envi-

ronment.

II. SAFETY PRECAUTIONS

The Warnings, Cautions, and Notes contained in this

manual have the following signicance:

WARNING

Maintenance or operating procedures

and techniques that may result in serious personal injury, serious illness, or

death if not carefully followed.

CAUTION

Maintenance or operating procedures

and techniques that may result in damage to equipment if not carefully followed.

NOTE

Maintenance or operating procedures

and techniques or information considered

important enough to emphasize.

III. DESCRIPTION

The SPERIAN Panther HIP-PAC consists of a rellable

cylinder, valve and pressure gauge assembly, rst stage

regulator, second stage regulator, facepiece, waist belt,

and regulator hose. The cylinder stores 8 cubic feet of

air at 2216 psig for the 5-minute apparatus, 15.2 cubic

feet of air at 3000 psig for the 10-minute apparatus, 17

cubic feet of air at 4500 psig for the 10-minute apparatus, and 24 cubic feet of air at 3000 psig for the 15-minute apparatus. The cylinder valve controls air pressure

to the regulator, and houses a safety relief device and

a cylinder pressure gauge. The regulators reduce the

cylinder pressure or remote air pressure and supply a

ow to the facepiece. A check valve in the low pressure

air line hose prevents inward leakage of contaminated

air when disconnected from the air supply.

WARNING

• The employer is responsible for establishing that these respirators are suit-

able for the user’s application.

• No respirator can provide complete

protection from all conditions. Use

extreme care for all emergency opera-

tions. Do not use the Panther HIP-PAC

for interior structural re ghting, abra-

sive blasting, or under water.

• The pressure within the Panther HIP-

PAC remains positive under most work-

ing conditions, but as with all respira-

tors, negative pressure excursions are

possible. Conditions when a respirator

can experience negative facepiece pres-

sures include, but are not limited to: 1)

the respirator is improperly worn, 2) the

respirator is not used in accordance

with the instructions, or 3) the respira-

tor is over-breathed during heavy work

rates. The HIP-PAC will provide reduced

protection when operated in a negative

pressure mode.

• Your SPERIAN respirator has been

constructed of materials selected for

their performance, safety, and durability. However, all materials have limita-

tions to exposure to extremes of heat

and cold or to the many chemicals in

use today, and could be degraded by

exposure beyond their limitations, cre-

ating conditions in which this SPERIAN

equipment would be dangerous to use.

• Before allowing anyone to enter a

hazardous environment while wear-

ing SPERIAN equipment, the employer

must conduct safe, scientic tests to

determine if the environment could ren-

der the equipment unsafe. Results of

1

Page 4

Panther HIP-PAC

WARNING─Continued

this testing should be well docu-

mented. Seek the help of a certified

safety professional or industrial hy-

gienist. DO NOT USE this equipment

if the user would be endangered in

any way through environmentally in-

duced degradation of the materials in

the apparatus.

• All persons using this SPERIAN respirator must be made aware of its limita-

tions. We cannot be responsible for any

damage to property, personal injury, or

death in which environmental exposure

is a contributing factor.

• SPERIAN cannot predict what will hap-

pen to this equipment in every potential

environment. Materials can be chemi-

cally attacked if exposed to the wrong

environment and may exhibit corrosion

or other forms of damage. Permeation

or penetration of gases, liquids, or par-

ticles through the materials could be

excessive. Extremes of temperature

might cause thermal degradation. Each

of these things, or a combination of

them, could create conditions in which

this SPERIAN equipment would be dangerous to use.

• This respirator must be used in conjunction with a written respirator pro-

gram meeting the requirements of the

OSHA Standard for Respiratory Protec-

tion 29 CFR 1910.134, available from the

U.S. Department of Labor, Occupational

Safety and Health Administration. The

program must include, but not be lim-

ited to, procedures for evaluating air

contaminants and selecting appropriate

respirators, procedures for proper use

of respirators, procedures for testing

the facepiece-to-face t of respirators,

procedures for cleaning, disinfecting,

inspecting, maintaining, and storing

respirators, procedures for determining

if workers are physically and medical-

ly capable of wearing respirators, and

procedures for training employees in

the use of respirators and in recognizing the hazards associated with con-

taminants in the workplace.

• The air supply must meet the guidelines of the Compressed Gas Associa-

tion (CGA) pamphlet G-7.1, Grade D Air,

as appropriate.

• DO not wear this respirator if a satisfactory t, as determined by a qualita-

tive or quantitative t test, cannot be

obtained. See ANSI Z88.2, latest edition,

and OSHA 1910.134. Beards and side-

burns will prevent good facepiece seal.

Do not use this respirator unless you

are clean shaven.

WARNING─Continued

• This respirator does not protect exposed areas of the body. Some contam-

inants can be absorbed directly through

the skin while others may irritate exposed areas. This respirator does not

provide protection from splash of hazardous liquids, ying objects, hazard-

ous rays, or harmful noise. Always wear

proper head, ear, and eye protection.

• This respirator is designed for use in

temperatures above -30°F.

• When using this respirator at temperatures of 0 to -30°F, the rst stage regu-

lator must be wrench tightened on the

cylinder valve, and anti-fog solution,

P/N 951015 or 951016, must be applied

to the inside of the facepiece lens.

• The Panther HIP-PAC has a rated ser-

vice time of 5, 10, or 15 minutes. Under

average conditions, you will have up to

5, 10, or 15 minutes in which to escape

from a toxic environment. Stress and

exertion may cause extra air consump-

tion and reduce the service time. Know

escape routes in advance and the time

required to travel them.

• Compressors, storage cylinders,

valves, regulators, ttings, and other

hardware must be large enough to de-

liver the air volume required by all us-

ers at peak demand.

• This respirator will reduce, but will

not eliminate the inhalation of con-

taminants. Some sensitive individuals

may experience health problems when

exposed to even minute amounts of

contaminants. This respirator will not

prevent health problems for those indi-

viduals.

• Do not modify this respirator in any

manner.

• This respirator must only be worn

and used as specied in SPERIAN’s in-

structions. Always read and follow the

instructions listed in the Material Safe-

ty Data Sheet for the chemicals that are

present in the work area. Selection and

use of these respirators must be done

in accordance with ANSI Z88.2, latest

edition, and the applicable OSHA statutes.

• Do not use SPERIAN respirators, accessories, and associated equipment in

atmospheres which may contain con-

taminant concentrations above the low-

er explosive limit (LEL). Intrinsic safety

certication of electronic components

does not eliminate potential danger

from ignition in these atmospheres.

2

Page 5

WARNING─Continued

• Some individuals are sensitive to

chemicals (e.g., isocyanates or paint

hardeners, latex, oil mists, etc.) or may

have some type of respiratory disor-

der (e.g., asthma, chronic obstructive

airway disease, etc.). If you are sensitive to any chemical or have a respira-

tory disorder, you may have a severe

reaction at contaminant levels well

below accepted health levels, such as

the OSHA Permissible Exposure Lim-

it (PEL), AIHA Threshold Limit Value

(TLV), or the NIOSH Recommended Ex-

posure Limits (REL). Many chemicals

(e.g., isocyanates, mercury, etc.) have

no physical warning properties and you

cannot taste or smell the contaminants

even though they may be present in the

respirator facepiece. This respirator will

reduce, but will not eliminate the possi-

bility of contaminants entering the face-

piece and causing a severe reaction. Do

not use this respirator if you have been

sensitized from previous exposure or

believe that you may be sensitive or al-

lergic to any chemical until you obtain

clearance from a medical doctor.

• Users must clean and maintain this

respirator only in accordance with

SPERIAN’s instructions. Accessories

not offered by SPERIAN may degrade

performance, and will void NIOSH cer-

tication.

• The respirator facepiece assembly

contains natural rubber latex which

may cause allergic reactions in some

individuals. Discontinue use if you experience an allergic reaction.

• Discontinue use if you experience skin

irritation or discoloration.

• FAILURE TO OBSERVE ALL WARNINGS MAY RESULT IN SERIOUS PER-

SONAL INJURY, SERIOUS ILLNESS, OR

DEATH.

Panther HIP-PAC

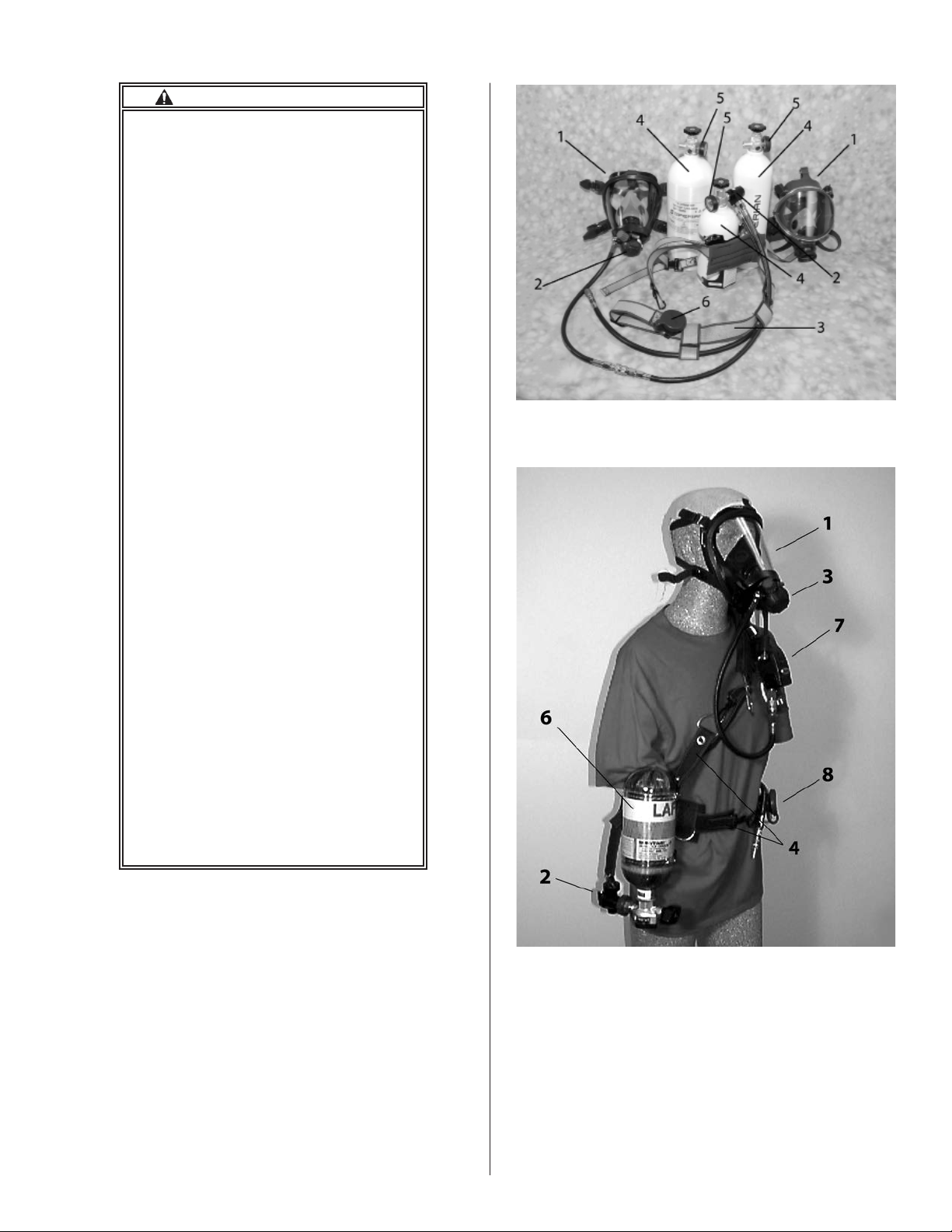

Figure 1A. Low Pressure HIP-PACs

2216 psig & 3000 psig

Figure 1B. High Pressure HIP-PAC, 4500 psig

IV. PARTS LIST (See Figure 1A for low pressure

2216 psig & 3000 psig HIP-PACs and Figure 1B for

high pressure 4500 psig HIP-PAC.)

3

Page 6

Panther HIP-PAC

LOW PRESSURE 2216 PSIG & 3000 PSIG HIP PAC PARTS LIST

Item P/N DESCRIPTION

1 968416 Classic Facepiece, Standard, Black

968417 Classic Facepiece, Small, Black

2120XX Series 21 SeriesFacepieces w/ Drink Tube**

2220XX Series TwentyTwenty Plus Facepieces*

2320XX Series TwentyTwenty Plus Facepieces**

2420XX Series TwentyTwenty Plus Facepieces**

2520XX Series TwentyTwenty Plus Facepieces**

2620XX Series TwentyTwenty Plus Facepieces**

2720XX Series TwentyTwenty Plus Facepieces**

968005 Puma Hood, Standard, Red, Small Nose Cup

968006 Puma Hood, Standard, Red, Medium Nose Cup

968007 Puma Hood, Standard, Red, Large Nose Cup

2 968443 Regulator Assy., First and Second Stages, without

Quick Disconnect

968441 First Stage Pressure Reducer with Quick

Disconnect

961793 Second Stage Regulator with Quick Disconnect

3 968510 Harness Assy., 5 and 10-min., Kevlar

968515 Harness Assy., 15-min., Kevlar

975230 Harness Assy., 5 and 10-min., Nylon

4 975081 5-minute, 2216 psig, All-Aluminum Cylinder and

Valve Assy.

975154 10-minute, 3000 psig, All-Aluminum Cylinder and

Valve Assy.

968512 15-minute, 3000 psig, Hoop-wrapped Cylinder and

Valve Assy.

5 975089 Gauge, 2216 psig

975189 Gauge, 3000 psig

6 961289 Regulator Reciever

* No longer available but still holds current approval. See Matrix for detailed part

numbers and descriptions.

** See Matrix for detailed part numbers and descriptions.

Air Supply Hoses and Air Line Coupling Kits

Lightweight 3/8" PVC Air Supply Hoses w/out Air Line Coupling Kit

930801 25 feet

930802 50 Feet

930804 100 Feet

High Performance 3/8" Neoprene Air Supply Hoses w/out Air Line Coupling Kit

930870 10 Feet

930861 25 feet

930862 50 Feet

930864 100 Feet

Air Line Coupling Kits - Female/Male quick disconnect for 3/8" hoses

930810 Foster

930820 Schrader

930830 Hansen

945007 Hansen Stainless Steel, Two-way Shutoff

930852 Snap-tite

Air Supply Hose Accessories

985237 Gasket for 3/8" hoses

985238 Fitting, Double Male

Accessories

980003 Spectacles Kit, Classic Facepiece, Wire Frame

964054 Spectacles Kit, Classic Facepiece, NexSpex

962260 Spectacles Kit, all 2020 Series Facepieces , Wire

Frame

964044 Spectacles Kit, all 2020 Series Facepieces ,

NexSpex

B140095 Lens Cover, Clear, Classic Facepiece

702019 Lens Cover, Tinted, TwentyTwenty Plus

702028 Lens Cover, Clear, TwentyTwenty Plus

951015 Anti-fog Solution, (1 oz.)

951016 Anti-fog Solution, (16 oz.)

981805 Anti-fog Wipes, (Box of 100)

B140096 Mask Wipes, (Box of 100)

940172 Neck Strap Kit, Classic Facepiece

962232 Neck Strap Kit, TwentyTwenty Facepiece

962869 Neck Strap Kit, TwentyTwenty Plus Facepiece

961710 Headnet Kit, Classic Facepiece, Standard

961730 Headnet Kit, Classic Facepiece, Small

969019 Headnet Kit, TwentyTwenty and TwentyTwenty Plus

Facepieces

962264 Nosecup Kit, TwentyTwenty, Twenty Twenty Plus

Facepiece, Small, Clear

962265 Nosecup Kit, TwentyTwenty, Twenty Twenty Plus

Facepiece, Medium, Clear

Item P/N DESCRIPTION

962266 Nosecup Kit, TwentyTwenty, Twenty Twenty Plus

Facepiece, Large, Clear

702064 Nosecup Kit, TwentyTwenty, Twenty Twenty Plus

Facepiece, Small, Black

702065 Nosecup Kit, TwentyTwenty, Twenty Twenty Plus

Facepiece, Medium, Black

702066 Nosecup Kit, TwentyTwenty, Twenty Twenty Plus

Facepiece, Large, Black

968469 Utility "D" Ring Kit

Communications

964331 TwentyTwenty Plus Radio Communication System

964332 SmallTalk Plus Voice Amplier Kit

964333 TwentyTwenty Plus Radio Communication/SmallTalk Plus

Voice Amplifer Kit

969083 Remote Push-to-Talk Kit

Upgrade and Conversion Kits

P968453 SAR Upgrade Kit, 5 Minute

P968473 SAR Upgrade Kit, 10 Minute

P968535 SAR Upgrade Kit, 15 Minute

P968453 SCBA Conversion Kit, 5 Minute

P968472 SCBA Conversion Kit, 10 Minute

P968540 SCBA Conversion Kit, 15 Minute

Welding Accessories

430000 Welding Shield, Classic Facepiece

430005 Lower Welding Bib, Classic Facepiece

430010 Upper Welding Bib, Classic Facepiece

Tools

962244 Air Klic Removal Tool, TwentyTwenty Plus Facepiece

Fit Testing Accessories

962900 APR Adapter/Qualitative Fit Test Adapter

962920 Quantitative Fit Test Adapter (For use with 962900)

Rebuild Kits (You must be a Certied Technician to rebuild these systems)

975245 First Stage Pressure Reducer Rebuild Kit

961572 Panther Second Stage Regulator Rebuild Kit

4

Page 7

Panther HIP-PAC

HIGH PRESSURE 4500 PSIG HIP PAC PARTS LIST

Item P/N DESCRIPTION

1 968416 Classic Facepiece, Standard, Black

968417 Classic Facepiece, Small, Black

2120XX Series 21 Series Facepieces w/ Drink Tube**

2220XX Series TwentyTwenty Plus Facepieces*

2320XX Series TwentyTwenty Plus Facepieces**

2420XX Series TwentyTwenty Plus Facepieces**

2520XX Series TwentyTwenty Plus Facepieces**

2620XX Series TwentyTwenty Plus Facepieces**

2720XX Series TwentyTwenty Plus Facepieces**

968005 Puma Hood, Standard, Red, Small Nose Cup

968006 Puma Hood, Standard, Red, Medium Nose Cup

968007 Puma Hood, Standard, Red, Large Nose Cup

2 964683 First Stage Regulator

3 961793 Second Stage Regulator

4 968686 Harness Assy.

968680 Harness Assy. For use with COMPASS

5 968713 Intermediate Pressure (IP) Hose

6 917250 Cylinder/Valve

917212 Cylinder/Valve, LAFD, Red

917215 Cylinder/Valve, LAFD, Blue

917218 Cylinder/Valve, LAFD, Black

7 964912 COMPASS Kit, LAFD

964914 COMPASS Kit

964916 COMPASS Kit with Auxiliary Coupler

8 961289 Regulator Reciever

* No longer available but still holds current approval. See Matrix for detailed part

numbers and descriptions.

** See Matrix for detailed part numbers and descriptions.

Air Supply Hoses and Air Line Coupling Kits

Lightweight 3/8" PVC Air Supply Hoses w/out Air Line Coupling Kit

930801 25 feet

930802 50 Feet

930804 100 Feet

High Performance 3/8" Neoprene Air Supply Hoses w/out Air Line Coupling Kit

930870 10 Feet

930861 25 feet

930862 50 Feet

930864 100 Feet

Air Line Coupling Kits - Female/Male quick disconnect for 3/8" hoses

930810 Foster

Air Supply Hose Accessories

985237 Gasket for 3/8" hoses

985238 Fitting, Double Male

Accessories

980003 Spectacles Kit, Classic Facepiece, Wire Frame

964054 Spectacles Kit, Classic Facepiece, NexSpex

962260 Spectacles Kit, all 2020 Series Facepieces , Wire

Frame

964044 Spectacles Kit, all 2020 Series Facepieces ,

NexSpex

B140095 Lens Cover, Clear, Classic Facepiece

702019 Lens Cover, Tinted, TwentyTwenty Plus

702028 Lens Cover, Clear, TwentyTwenty Plus

951015 Anti-fog Solution, (1 oz.)

951016 Anti-fog Solution, (16 oz.)

981805 Anti-fog Wipes, (Box of 100)

B140096 Mask Wipes, (Box of 100)

940172 Neck Strap Kit, Classic Facepiece

962232 Neck Strap Kit, TwentyTwenty Facepiece

962869 Neck Strap Kit, TwentyTwenty Plus Facepiece

961710 Headnet Kit, Classic Facepiece, Standard

961730 Headnet Kit, Classic Facepiece, Small

969019 Headnet Kit, TwentyTwenty and TwentyTwenty

Plus Facepieces

962264 Nosecup Kit, TwentyTwenty, Twenty Twenty Plus

Facepiece, Small, Clear

962265 Nosecup Kit, TwentyTwenty, Twenty Twenty Plus

Facepiece, Medium, Clear

962266 Nosecup Kit, TwentyTwenty, Twenty Twenty Plus

Facepiece, Large, Clear

702064 Nosecup Kit, TwentyTwenty, Twenty Twenty Plus

Facepiece, Small, Black

702065 Nosecup Kit, TwentyTwenty, Twenty Twenty Plus

Facepiece, Medium, Black

702066 Nosecup Kit, TwentyTwenty, Twenty Twenty Plus

Facepiece, Large, Black

968469 Utility "D" Ring Kit

Item P/N DESCRIPTION

Communications

964331 TwentyTwenty Plus Radio Communication System

964332 SmallTalk Plus Voice Amplier Kit

964333 TwentyTwenty Plus Radio Communication/SmallTalk Plus

Voice Amplifer Kit

969083 Remote Push-to-Talk Kit

Welding Accessories

430000 Welding Shield, Classic Facepiece

430005 Lower Welding Bib, Classic Facepiece

430010 Upper Welding Bib, Classic Facepiece

Tools

962244 Air Klic Removal Tool, TwentyTwenty Plus Facepiece

Fit Testing Accessories

962900 APR Adapter/Qualitative Fit Test Adapter

962920 Quantitative Fit Test Adapter (For use with 962900)

Rebuild Kits (You must be a Certied Technician to rebuild these systems)

975245 First Stage Pressure Reducer Rebuild Kit

961572 Panther Second Stage Regulator Rebuild Kit

NOTE

The respirator and hose assemblies are

supplied without quick couplers. The desired

quick coupler assemblies must be purchased

separately. Instructions for assembling quick

couplers and hoses are provided below in

paragraph V, B, “Quick Coupler Assembly.”

5

Page 8

Panther HIP-PAC

V. USE INSTRUCTIONS

A. Air Supply

WARNING

• Compressors, storage cylinders,

valves, regulators, ttings, and other

hardware must be large enough to de-

liver the air volume required by all users at peak demand.

You are responsible for air quality and

compliance with safety and health

codes applicable to your area.

• No more than three (3) lengths of air

supply hose shall be used for the 9308

and 93080 series hose, and no more

than six (6) lengths for the 9649 series

hose.

• The air supply hose inlet must be supplied with 80 to 125 psig air pressure.

• The length of air supply hose must be

10 to 300 feet for the 9308 series hose,

25 to 300 feet for the 93080 series hose,

and 50 to 150 feet for the 9649 series

hose. Do not combine different series of

hoses or coupler assemblies.

• The NIOSH approval applies to the

use of the splitter (suit bypass) only

as speci ed in the “Special or Critical

User’s Instructions.”

• Failure to comply with this Warning

may lead to serious personal injury, serious illness, or death.

1. Ensure that the air supply is Type 1, Grade D, or

better, as described in the Compressed Gas Associa-

tion Commodity Speci cation for Air, G-7.1. Moisture

content, expressed as dewpoint, shall be maintained

at -65°F (-53.9°C) or lower, or less than 24.0 ppm by

volume.

2. Set relief valves at a maximum pressure of 150

psig (1.03 MPa).

B. Quick Coupler Assembly

A male coupler from one of the air line coupler kits listed

in the parts list, paragraph IV, must be assembled to the

open end of the respirator hose. This operation requires

a torque wrench.

1. Respirator Hose

a. Remove the shipping cap plug from the respira-

tor hose.

b. Hold the female threaded tting with a wrench

or vise.

c. Apply thread sealant completely around the male

threads of the coupler.

WARNING

Do not allow the thread sealant to ex-

tend past the last thread of the coupler.

Thread sealant that extends past the

coupler threads can restrict or block air

ow to the user. Failure to comply with

this Warning may lead to serious personal injury, serious illness, or death.

d. Thread the male coupling into the female tting

on the respirator hose. Torque to 90 5 in-lb.

e. Pressurize and check for leaks with a bubbletype leak detector.

f. If leaks are detected, disassemble and repeat

steps a through e.

g. If the leaks persist, remove the hose from service and have repairs made by a SPERIAN-certi ed

technician.

2. Air Supply Hose - Each length of hose is equipped

with a 1/4 inch female NPT swivel nut at each end

and a male-to-male 1/4 inch NPT adapter. The maleto-male adapter may be used to connect two lengths

of hose or connect the hose to the air supply. Four

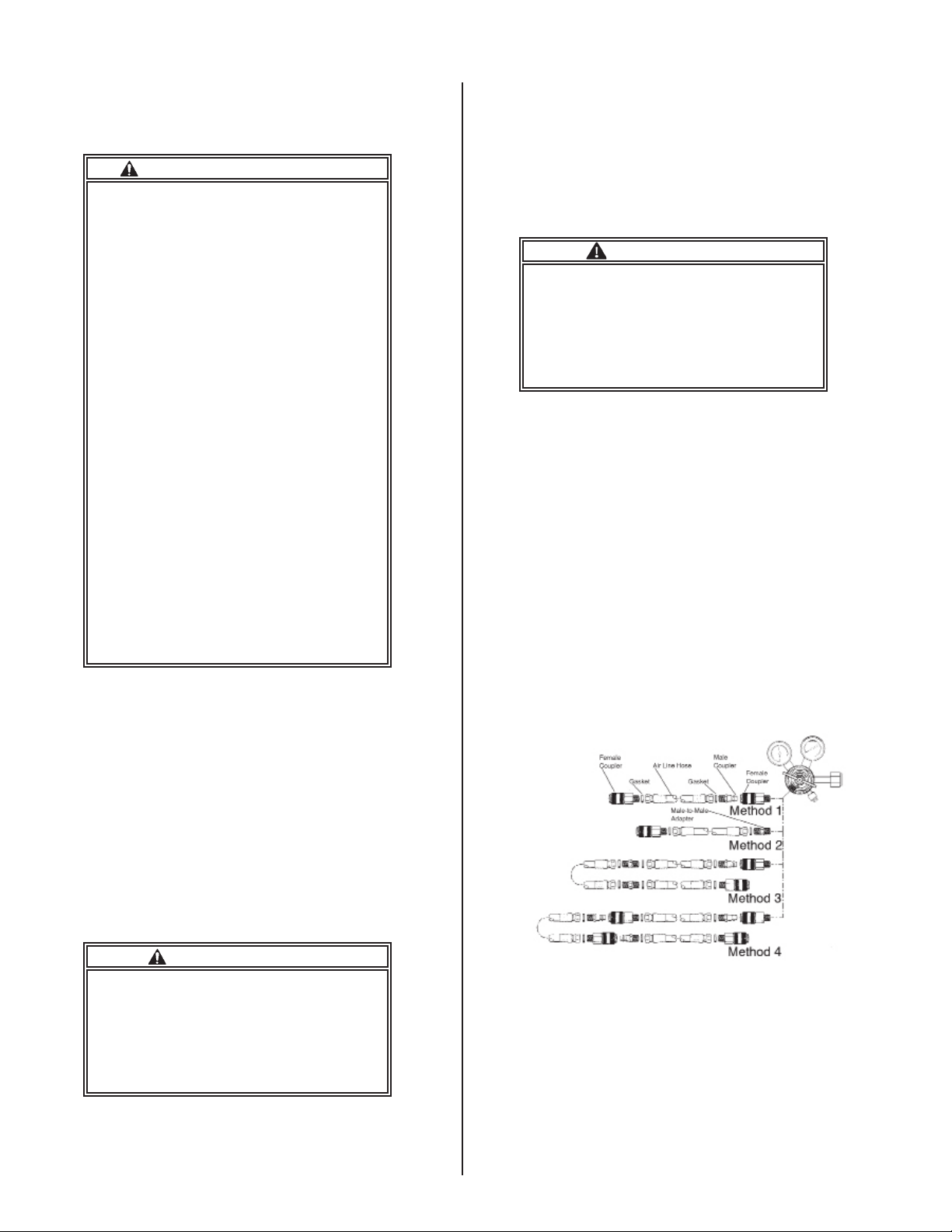

approved methods of connecting hose lengths and air

supply are illustrated in Figure 2.

WARNING

Carefully inspect and clean all threads

to remove foreign material. Foreign ma-

terial entering the air line can restrict

or block air ow to the user. Failure to

comply with this Warning may lead to

serious personal injury, serious illness,

or death.

Figure 2. Hose Connections

3. When assembling the quick disconnect ttings of

the coupler or the male-to-male adapters to the hose,

verify that the hose gaskets are in place and torque to

90 5 in-lb. Thread sealant is not required.

6

Page 9

Panther HIP-PAC

4. The air supply connection using the 1/4 inch maleto-male adapter illustrated in Method 2 is also approved for use with Methods 3 and 4.

a. Method 1 is preferred when only one length of

hose is required, since it allows the hose to be disconnected from the air supply.

b. Method 3 is preferred when multiple lengths of

hose (maximum of three) are required, eliminating

the cost of quick-disconnect couplers at the hose

junctions.

5. Pressurize and check for leaks with a bubble-type

leak detector. If leaks are detected:

a. Disassemble and repeat steps 3 through 5.

b. If the leaks persist, remove the hose from ser-

vice and have repairs made by a SPERIAN-certied

technician.

WARNING

Always verify that the swivel nut gas-

kets are in place and undamaged before

assembly. Missing or damaged swivel

nut gaskets may allow contaminants to

leak into the system causing illness or

death.

1. Verify that the air cylinder valve is turned off.

2. Verify that the bypass is in the OFF position and

that the cylinder gauge reads full.

3. Depress the shutoff button on the second stage

regulator.

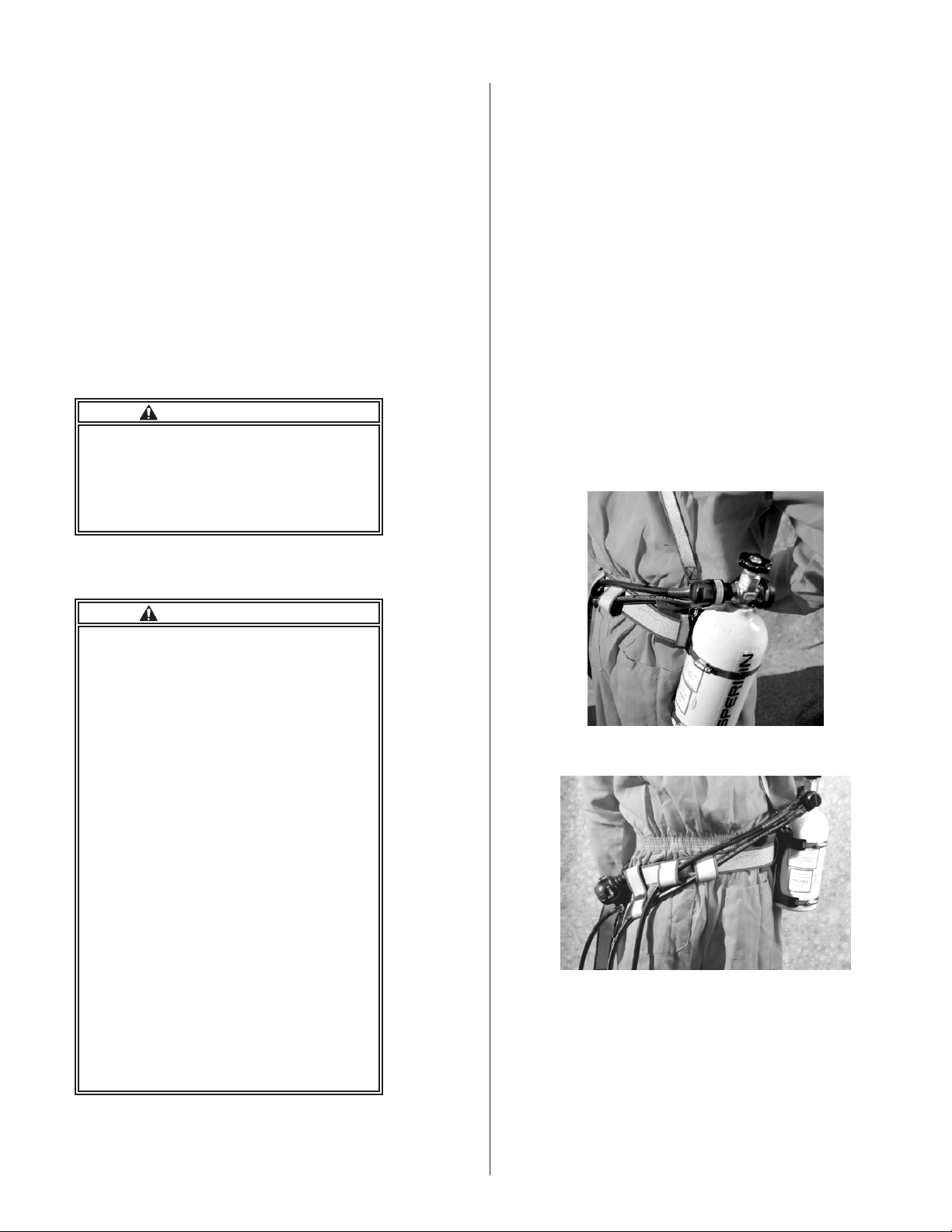

4. Ensure that the waist belt and hip pad (if used) are

properly positioned on the tank mounting bracket belt

loop. See Figure 3.

5. Insert the air line hose through the rst waist belt

loop on the back of the waist belt and the restraint

sleeve located on the waist belt. See Figure 4.

6. Route the second stage hose through the second

loop on the back of the waist belt. Position the second

stage hose so that it routes under your left arm. (If the

hose is too tight, adjust the cylinder nearer the small

of your back.)

NOTE

The following steps 7-10 do not apply to

the 5-minute and 10-minute nylon harness

assembly, P/N 975230.

C. Donning

WARNING

• Always don, remove, and t check the

respirator in a safe, uncontaminated

area.

• The regulator must be attached to the

Panther HIP-PAC air cylinder before

connecting the air line hose to the air

supply. Using the supplied air line without the regulator being attached to the

cylinder could result in loss of air, causing illness or death.

• Verify that the air cylinder valve is

turned off before connecting to the air

supply. Using the Panther HIP-PAC with

the air cylinder turned on while connect-

ed to the air supply will cause loss of air

in the cylinder, resulting in reduced es-

cape time in case of an emergency.

• Always disengage the regulator from

the facepiece and return it to the waist

belt-mounted receiver when not in use.

This will prevent contaminants from

entering the regulator outlet port. Dirt,

dust, and water may enter the regulator,

causing it to malfunction.

• Failure to comply with this Warning

may lead to serious personal injury, serious illness, or death.

Figure 3. Waist Belt and Hip Pad Position

Figure 4. Routing of Hoses

7. Ensure that the regulator receiver is attached to the

waist belt just behind the snap hook.

8. Ensure that the waist belt is laced properly through

the D-ring slide and the snap hook. See Figure 5.

7

Page 10

Panther HIP-PAC

Figure 5. Waist Belt D-ring

9. Insert the second stage regulator into the regulator

receiver on the waist belt.

10. Open the (optional) shoulder strap to its maximum

position. Place the shoulder strap over the left shoulder and position the shoulder pad on the top of the left

shoulder. Adjust the shoulder strap to raise the cylinder, and to raise the waist belt into position around

the waist.

11. Position the cylinder so that the cylinder is located

slightly behind the right hip, latch the belt buckle, and

adjust both the waist and shoulder straps (if used)

for comfort. Pull the loose end of the waist strap to

tighten.

12. Connect the air line hose to the remote air

supply.

NOTE

When using Foster ttings, always ensure that the

locking sleeves are rotated to the locked position.

13. When donning the respirator without the optional

shoulder strap, follow the same procedures except

omit step 10.

14. Tighten the AIR KLIC on the facepiece by turning

it clockwise.

15. Verify that the AIR KLIC is secured by trying to

turn it counterclockwise.

ii. If your SCBA is equipped with a neck strap,

place the neck strap over your head.

iii. Grasp the lower headstraps as shown in

Figure 6.

Figure 6. Grasp Lower

Headstraps

iv. Place your chin in the chin cup and pull the

straps over your head.

v. Center the facepiece and atten the head-

strap hub on the back of your head.

vi. Tighten the two lower straps. Do not overtighten.

vii. Tighten the temple straps (Figure 7), then

the top strap, until all the headstraps lie at on

your head.

Figure 7. Tighten Upper Straps

WARNING

The AIR KLIC must be held securely

in the nozzle by the ratchet-and-pawl

mechanism. If it is necessary to use a

respirator that has been stored at a tem-

perature below freezing (32°F or 0°C)

prior to using, then DO NOT exhale into

the facepiece until the facepiece has

been properly donned with the nose

cup situated properly on the face and

the regulator installed and activated.

Failure to comply with this Warning

may lead to serious personal injury, serious illness, or death.

16. There are two methods, depending upon which

head harness is used, to secure the Classic™ or

TwentyTwenty Plus facepiece to the user. Both methods are described below.

a. Standard silicone headstrap:

i. Fully loosen the headstraps.

viii. Perform a leak check as described below.

NOTE

When properly adjusted, the headstrap

hub should be centered on the back of

your head, and the lower straps should be

below your ears. Make sure that your chin

is properly recessed in the chin cup.

b. Optional Headnet

i. Inspection

• Classic Facepiece—Ensure that the three

locking fabric straps located across the forehead

are positioned so that they do not slip out from

under the buckles.

• TwentyTwenty Plus Facepiece and 21 Series

Facepiece—Ensure that the three locking fab-

ric straps located across the forehead are fully

inserted into their slots in the rims and that the

locking aps prevent the straps from pulling out

of the slots.

8

Page 11

All Facepieces

ii. Place your chin in the chin cup, pull the

elastic adjustment strap over your head, and

tighten by pulling evenly on both sides. See

Figure 8.

Figure 8. Adjust Headnet

iii. Center the facepiece and fasten the Head-

net with a wiping motion toward the back of

your head.

iv. Retighten the elastic adjustment straps. Do

not overtighten.

v. Perform a leak check as described below.

CAUTION

Do not adjust the t of the facepiece

with the three locking straps at the top

of the headnet. Use the two bottom

straps only.

NOTE

When properly adjusted, the headnet

should be centered on the back of your

head, and the lower straps should be below

your ears.

c. Hood-Style Facepiece

Panther HIP-PAC

WARNING—Continued

cleaning and disinfecting, anti-fog solution

(SPERIAN P/N 951015, 951016, OR 981805)

must be applied to the inside of the lens.

• The Challenge® NXT, PVC lens, neoprene

neck seal, and adhesive all may react

in a different manner when exposed to

chemicals or chemical mixtures. You must

verify that none of the components of the

hood will degrade against the chemicals or

mixtures to which it may be exposed.

• It is vital to ensure that you have objective

evidence that the hood will be able to

maintain its integrity against the expected

chemical exposure during operations. This

can be accomplished by tests you conduct

or by contacting SPERIAN for further

information. Listed below are a few, but not

necessarily all, chemicals that are known

to degrade or destroy the PVC material.

Do not use the hood in environments

containing these chemicals:

• Acetone

• Bleach

• Carbon tetrachloride

• Methanol

• Methyl ethyl ketone

• Nitric acid

• Toluene

• Trichloroethylene

• Failure to comply with this warning may

lead to serious personal injury, serious

illness, or death.

i. Fully loosen the suspension straps.

ii. Grasp the hood-style facepiece by the neck

seal and pull the neck seal over your head.

WARNING

The SPERIAN hood-style facepiece:

• Must be worn in conjunction with an SAR

and/or SCBA and used as specied in

SPERIAN’s instructions.

• When donned and used with its SAR/

SCBA, will reduce, but not eliminate the

inhalation of contaminants.

• Does not protect against falling objects or

projectiles.

• Must not be worn around open ames. It

must not be used for structural re ghting,

underwater activities, or abrasive blasting.

• Must not be used unless a satisfactory t

is obtained.

• Must not be reused if contaminated.

• Must not be altered or modied in any

manner.

• Requires that the wearer must assure

that the neck seal is not compromised by

hair or clothing when in use.

• Requires that after each use and/or

iii. Position the nose cup on your face, then

simultaneously tighten the two suspension

straps.

D. Fit Check

WARNING

• Conduct t checks only in a safe, un-

contaminated environment.

• Do not use this respirator in a con-

taminated atmosphere if you do not

obtain a satisfactory seal during the t

check. If a seal was not obtained, repo-

sition the facepiece, check the straps,

and perform the t check again. Failure

to obtain a satisfactory seal could allow contaminants to leak into the face-

piece, causing illness or death. Failure

to comply with this Warning may lead to

serious personal injury, serious illness,

or death.

9

Page 12

Panther HIP-PAC

NOTE

Steps 1-3 apply to conventional facepieces

only.

1. Place the palm of your hand over the AIR KLIC as

shown in Figure 9.

2. Inhale and hold your breath for a few seconds.

The facepiece should collapse on your face without

leaking.

Figure 9. Fit Check for Conventional Facepiece

3. If the facepiece leaks, reposition it, check the

straps, and repeat the t check.

NOTE

Steps 4-5 apply to Puma hood-style

facepieces only.

4. Don and pressurize the hood-style facepiece as

shown in Figure 10.

NOTE

The second stage regulator release buttons

must be pressed simultaneously to remove

the regulator from the holder.

8. Insert the regulator into the AIR KLIC on the facepiece and press rmly until you hear both release but-

tons snap into place.

NOTE

• A CLICK will be heard when each AIR

KLIC button is properly engaged.

• Do not press the release buttons when

installing the regulator.

WARNING

Rotate and tug the regulator to ensure

that both release buttons are properly

engaged in the AIR KLIC. Do not push

the release buttons while verifying the

engagement of the regulator. Do not

press the release buttons unless you

intend to remove the regulator from the

facepiece. Pressing both release but-

tons during or after installation onto the

facepiece could result in inadvertent

regulator disengagement, causing serious injury or death.

9. Take a sharp, deep breath to activate the regulator.

10. Take several breaths to check the ow of air.

11. Press the black rubber override button on the

second stage regulator to ensure that it is operating

properly.

12. Quickly open and close the bypass valve to ensure that it is operating properly.

13. The Panther HIP-PAC is now ready for use.

Figure 10. Fit Check for Hood-style Facepiece

5. Hold your breath for several seconds and listen for

audible leaks.

6. When a satisfactory t is obtained, verify that the

respirator hose is connected to the air line hose and

the air line hose is connected to an air source set for

the correct pressure.

7. Remove the second stage regulator from the waist

strap regulator holder by pressing the two release

buttons.

WARNING

Always close the regulator receiver

cover to prevent contaminants from

collecting in the receiver. Failure to

comply with this Warning may lead to

serious personal injury, serious illness,

or death.

WARNING

• Entry into hazardous atmospheres with

the Panther HIP-PAC must be done while

connected to the air line. Do not use the

escape cylinder air supply for entry.

• Ensure that the escape cylinder is full.

• The Panther HIP-PAC has a rated service

time of 5, 10, or 15 minutes.Under average

conditions, you will have up to 5, 10, or 15

minutes in which to escape from a toxic

environment. Stress and exertion may

consume extra air and reduce service time.

Know escape routes in advance and the

time required to travel them.

• Always follow established safety

procedures when exposed to atmospheres

that are hazardous or immediately

dangerous to life or health.

• Failure to comply with this Warning may

lead to serious personal injury, serious

illness, or death.

10

Page 13

Panther HIP-PAC

E. Emergency Exit

1. If the air line supply is cut off while the user is in a

hazardous atmosphere, turn the cylinder valve of the

Panther HIP-PAC counterclockwise at least one full

turn to start the ow of air from the cylinder.

2. If required for escape, disconnect the air line hose

from the Panther HIP-PAC respirator hose.

3. Proceed immediately to fresh air.

4. When in a safe environment, remove the facepiece

and turn the cylinder valve clockwise to shut off air

from the cylinder.

CAUTION

Do not overtighten the cylinder valve.

Damage to the valve seat could result.

F. Emergency Operation

1. PROBLEM: Restricted or interrupted air ow

a. Open the bypass valve by turning the red knob

on the second stage regulator counterclockwise un-

til the desired constant air ow is achieved.

WARNING

Activating the bypass valve rapidly depletes your air supply. Immediately exit

to a safe area. Failure to comply with

this Warning may lead to serious personal injury, serious illness, or death.

G. Dofng

WARNING

• Follow all appropriate decontamination procedures before dofng the Pan-

ther HIP-PAC.

• Doff the Panther HIP-PAC only in a

safe area.

• Failure to comply with this Warning

may lead to serious personal injury, serious illness, or death.

1. Press the second stage regulator shutoff button.

2. Press the two release buttons and remove the regulator from the facepiece.

WARNING

Always disengage the regulator from

the facepiece and return it to the waist

belt-mounted receiver when not in use.

This will prevent contaminants from en-

tering the regulator outlet port. Dirt and

dust may enter the regulator, causing it

to malfunction. Failure to comply with

this Warning may lead to serious personal injury, serious illness, or death.

3. Disconnect from the remote air source, or close the

cylinder valve.

b. IMMEDIATELY exit to a safe area.

c. Have the HIP-PAC inspected and/or repaired by

a certied repair technician before reuse.

2. PROBLEM: First-Breath-On failure

a. Press the black rubber manual override button on

the front of the regulator to start air ow.

b. IMMEDIATELY exit to a safe area.

c. Have the second stage regulator inspected and/

or repaired by a certied repair technician before

reuse.

3. PROBLEM: Free ow

a. If the regulator will not shut off (free ows) during

extremely heavy breathing, exhale forcefully. The

regulator should return to normal ow.

b. If the free ow continues, open and close the by-

pass once, or depress the manual override button

once.

c. If the problem persists, IMMEDIATELY exit to a

safe area.

d. Have the HIP-PAC inspected and/or repaired by

a SPERIAN-certied repair technician before reuse.

4. Press the override button on the second stage regulator to vent air from the Panther HIP-PAC.

5. Push the second stage regulator into the waist

strap-mounted regulator holder until it clicks.

6. Place your thumbs under the headstrap buckles,

loosen the lower straps, and remove the facepiece.

7. Unsnap the waist strap buckle and remove the

Panther HIP-PAC.

8. Prepare the Panther HIP-PAC for storage.

CAUTION

If the Panther HIP-PAC is to be trans-

ported unsecured for long periods of

time, the rst stage connection to the

cylinder valve must be wrench-tight.

11

Page 14

Panther HIP-PAC

H. Use of the 21 Series Drink Tube

The drink tube allows the user to consume uids

while wearing the 21 Series facepiece and is compatible with a MIL-C-51278 water canteen cap.

WARNING

• Using the drink tube in a contaminated

area or after leaving a contaminated

area may expose you to contaminants.

Use the drink tube in accordance with

instructions provided by the IC or ICS.

• Failure to comply with this warning

may lead to personal injury, illness, or

death.

1. While wearing the 21 Series facepiece, remove

the drink tube coupling from the retainer and insert

it into a MIL-C-51278 canteen cap.

2. Use mouth movements to insert the drink tube

mouthpiece inside the nose cup into your mouth.

3. Hold the canteen upside down higher than the

mouthiece and suck the uid into your mouth as

shown in Figure 11.

4. When through drinking, turn the canteen right

side up and remove the mouthpiece from your

mouth.

5. Remove the coupling from the canteen cap and

return the coupling to the drink tube retainer.

VI. MAINTENANCE

WARNING

Specialized processes are required to

disinfect and decontaminate a respira-

tor. You MUST follow the instructions

of the manufacturer who supplies the

disinfecting or decontamination equip-

ment or chemicals. Failure to comply

with this Warning may lead to serious personal injury, serious illness, or

death.

CAUTION

• DO NOT clean the facepiece with the

regulator attached.

• You must ensure that this respirator is

not damaged when using disinfecting or

decontamination equipment or chemicals.

• The facepiece lens can be scratched

through careless or abusive handling.

DO NOT use abrasive cleaners or pads.

DO NOT towel dry.

NOTE

Inspect the Panther HIP-PAC for defects

before and after each use, and at least once

monthly if not used. Repair as necessary,

clean and disinfect after each use, and store

properly to assure that the Panther HIP-

PAC is maintained in satisfactory working

condition. Keep a record of inspection

and repair dates and results. Refer to the

inspection table in the back of this manual.

Figure 11. 21 Series Drink Tube

A. Conventional Facepiece Cleaning

NOTE

Silicone and rubber parts of the facepiece

may be cleaned between washings with

SPERIAN Mask Wipes, P/N 140096.

1. Make a cleaning solution of warm water and a

mild detergent.

2. Fully immerse the facepiece in the solution.

3. Agitate the facepiece and gently clean with a soft

brush.

4. Thoroughly rinse the facepiece in fresh water,

paying particular attention to removal of all soap

residue from the exhalation valve. If possible, direct

running water onto the exhalation valve.

5. Allow the facepiece to drip dry. Warm air may be

used to speed up drying.

12

Page 15

Panther HIP-PAC

NOTE

Repeated cleaning may require

reapplication of anti-fog coating to the

facepiece lens. Use only SPERIAN AntiFog Solution, P/N 951015 (1 oz.), or P/N

951016 (16 oz.).

6. After cleaning, three drops of anti-fog solution may

be applied to the inner surface of the lens with a lintfree cloth. Allow the coating to dry for 15 minutes

before using the facepiece. The 2720 series of the

Twenty-Twenty Plus facepiece has a permanent antifog coating. Anti-fog solution does not need to be applied.

7. Hold the facepiece rmly against your face and exhale several times to ensure that the exhalation valve

functions smoothly.

8. Cleaning the 2120 Series Facepiece Drink Tube

a. Remove the retainer, internal & external drink

tube from the facepiece. The internal drink tube is

removed by pulling the drink tube from inside the

nosecup until the tube comes off the plastic barb.

The external drink tube is removed by using a 1

inch spanner wrench to unscrew the connector cap

and pulling the drink tube off of the plastic barb.

The retainer can be pulled off of the left side connector.

b. Rinse the insides of the retainer, internal & ex-

ternal drink tubes with warm water, removing any

residue. Rinse thoroughly and allow the components to air dry.

c. Re-install the external drink tube over the barb

of the at side of the plastic connector. Place the

adapter into the connector slot, and tighten on the

o-ring seal and screw connector cap with the 1

inch spanner wrench. Do not overtighten. Place

the retainer over the connector cap and place the

external drink tube/valve inside the retainer. Re-

install the internal drink tube by placing the con-

necting end of the tube through the nosecup hole

and over the adapter’s internal plastic barb. Orient

internal tube to the user’s preference by rotating

drink tube around barb.

B. Hood-style facepiece cleaning

WARNING

• It is the user’s responsibility to ensure

that the cleaning process chosen provides

adequate disinfection or decontamination.

• Specialized processes are required to

disinfect and decontaminate a respirator.

You MUST follow the instructions of

the manufacturer who supplies the

disinfecting or decontamination equipment

or chemicals. Use ONLY the sanitizing

products listed in this manual to disinfect

WARNING—Continued

and decontaminate the full facepiece hood.

• After each use and/or after cleaning and

disinfecting, SPERIAN anti-fog solution,

(P/N 951015, 951006, or 981805) must be

applied to the inside of the lens.

• Failure to comply with this warning may

lead to serious personal injury, serious

illness, or death.

CAUTION

• DO NOT clean the hood-style facepiece

with the regulator attached.

• You must ensure that this respirator

is not damaged by disinfecting

or decontamination equipment or

chemicals.

• The hood-style facepiece lens can be

scratched through careless or abusive

handling. DO NOT use abrasive cleaners

or pads. DO NOT towel dry.

• Sanitizing solutions containing

chloride bleach (such as a “hypochlorite

solution”) may damage the hood-style

facepiece lens.

NOTE

• ANSI Z88.2 1992 also provides

information and guidelines on the cleaning

of respirators.

• After each use, prior to cleaning and

disinfecting, inspect the inside of the lens

for an anti-fog appliqué. If an appliqué is

present, inspect it to verify that it is still

adhering to the lens properly. If the antifog appliqué is delaminating from the lens,

remove it from the inside of the lens by

lifting one edge of the appliqué and gently

peeling it away, being careful not to damage

the lens.

• Once the appliqué has been removed, it

is not necessary to replace it with another

appliqué. Application of SPERIAN Anti-fog

Solution, P/N 951015, 951016, or 981806,

to the inside of the lens is adequate.

1. Make a cleaning solution of warm water (120° F

or 48° C maximum) and a mild detergent.

2. Immerse the hood-style facepiece in the solution

until the exhalation valve is covered.

3. Agitate it and gently clean it with a soft brush.

4. Thoroughly rinse the hood in fresh water, paying

particular attention to removal of all soap residue

from the exhalation valve. If possible, direct running

water onto the exhalation valve.

5. Disinfect the hood using one of the following

sanitizing products: ARI Sanitizer Deodorizer–ARI,

Orchard Hill, GA; Lysol Disinfectant; or Simple

13

Page 16

Panther HIP-PAC

Green All Purpose Cleaner.

6. Allow the hood to drip dry. Warm air may be used

to speed up drying.

7. Hold the hood facepiece inner mask rmly

against your face and exhale several times to ensure that the exhalation valve functions smoothly.

8. After cleaning and disinfecting the hood, liberally apply SPERIAN anti-fog solution, P/N 951015,

951016, or 981805 to the inside of the lens and

allow it to dry thoroughly.

C. Second Stage Regulator Cleaning

WARNING

• Do not allow water or cleaning solutions to enter the breathing system or

the regulator. Dirt, dust, or soap residue

could degrade regulator performance

causing it to fail, possibly resulting in

injury or death.

• Do not submerge the regulator in water or cleaning solutions. It may be partially submerged only as instructed in

step 6 below.

• Failure to comply with this Warning

may lead to serious personal injury, serious illness, or death.

NOTE

• Always hold the regulator with the outlet

facing downward during washing and

rinsing.

• The Protective Cleaning Cap, P/N 873004,

may be used to seal the Panther second

stage regulator to prevent contaminants

from entering the regulator outlet. See

Figure 12.

1. Make a cleaning solution of warm water and a mild

detergent.

2. Have a bucket of fresh water available for rinsing.

3. With the regulator facing downward, clean the exterior surfaces and the interior of the outlet tube with

a soft brush.

4. With the regulator facing downward, immediately

rinse the exterior surfaces and the interior of the outlet

tube with fresh water. Scrub excess soap away with

the brush.

5. Dry with a clean cloth or with low pressure (15 psig

maximum) clean (breathing grade) air.

6. If dirt or debris interferes with the First-Breath-On

mechanism, clean it as follows:

a. Lift the edge of the rubber manual override button

with a small, at-blade screwdriver, and peel it off.

b. Place the protective cap over the outlet tube.

c. Hold the regulator with the cover facing down-

ward and rinse in a shallow bucket of fresh water.

d. Allow the water to drain, and dry with low pressure air (15 psig maximum).

e. Replace the manual override button.

D. Exterior Surfaces Cleaning

CAUTION

The hoses, backpack harness, frame,

and cylinder and valve assembly may

be cleaned with a damp cloth or a mild

soap and warm water solution. Rinse

thoroughly and air dry or wipe with a

clean cloth.

E. Inspection (see page 21)

F. Repair (see page 22)

WARNING

Before disassembly, make sure that all

air is bled from the lines. Shut off or

deplete the air supply to prevent equip-

ment damage or personal injury. Failure

to comply with this Warning may lead to

serious personal injury, serious illness,

or death.

Figure 12. Protective Cleaning Cap

14

CAUTION

User repair of the Panther HIP-PAC is

limited to replacement of components

listed on the NIOSH approval label and

repairs described in this section. Disassembly should be performed only to the

extent necessary to replace the components. To protect your warranty and the

NIOSH certication on the equipment,

all other repairs must be done only by

SPERIAN-certied technicians. If there

are none at your facility, consult your

SPERIAN distributor for the repair facility nearest you.

.

Page 17

Panther HIP-PAC

NOTE

All SPERIAN-certied Technicians

are required to remain current on new

procedures and parts through SPERIAN’s

published Technical Bulletins, technical

manual revisions, and certication

seminars.

G. Functional Testing (see page 23)

Perform functional tests after cleaning or repair. After

testing, ll the cylinder and store the Panther HIP-PAC.

H. Cylinder Maintenance and Recharging

WARNING

• You must read and understand all warnings

and instructions provided on the cylinder

DOT warning label and in instruction

manuals before using the cylinder/valve

assembly.

• Only trained personnel may store, ll,

service, maintain, handle, use, or dispose

of cylinders used with this HIP-PAC. Follow

the guidelines of the Compressed Gas

Association (CGA) pamphlets P-1, C-1,

C-2, C-6, C-6.1, C-6.2, G-7, and G-7.1, as

appropriate. Always follow established

safety precautions when recharging

cylinders.

• Do not alter cylinders used with this HIPPAC.

• Fill only to the stamped service pressure.

Do not overll.

• Do not ll a leaking cylinder. Depressurize

immediately.

• Do not tamper with the safety pressure

relief device. Rapid depressurization when

the safety pressure relief device activates

will cause excessive noise. During rapid

depressurization, cylinders may become

ballistic and cause injury. Stay clear of

cylinders when the safety relief device is

activated.

• Do not ll the cylinder if unraveling or

charring of composite bers occurs.

• Do not ll or use the cylinder if you have

any doubt about its suitability for recharge.

Return it to a certied hydrostatic test

facility.

• Do not expose cylinders used with this

HIP-PAC to open ame or heat sources

which may heat the cylinder to 350°F.

Cylinders damaged by re or exposed to

heat of 350°F must be destroyed.

• Repainted or renished cylinders must be

hydrostatically tested before reuse.

WARNING—Continued

• Do not ll a composite cylinder if it

is not marked as being hydrostatically

tested within three (3) years. Do not ll an

aluminum cylinder if it is not marked as

being hydrostatically tested within ve (5)

years.

• Do not ll or use composite cylinders

older than 15 years. Depressurize and

destroy these cylinders.

• Inspect cylinders before each lling.

Remove cylinders from service which have

cuts, gouges, dings, bulges, corrosion,

etc. A special internal and external visual

inspection of cylinders must be completed

at least every hydrostatic test. Follow the

guidelines of CGA 6.2.

• Do not use caustic paint strippers or

corrosive cleaners.

• Do not ll with oxygen.

• Do not remove, obscure, or alter any

labels on HIP-PAC cylinders.

• Failure to comply with this Warning may

lead toserious personal injury, serious

illness, or death.

1. Inspection

After each use and prior to recharging, each air

cylinder shall be subjected to a thorough visual

inspection.

WARNING

Do not ll any cylinders that are damaged,

you suspect may be damaged or unsafe,

or are out of conformance with applicable

hydrostatic test dates. Damaged cylinders

must be inspected by an approved

hydrostatic test facility and repaired as

required before being lled. Failure to

comply with this warning may lead to

serious personal injury, serious illness, or

death.

a. Aluminum Cylinders

Ensure that no more than ve years have elapsed

since the last hydrostatic test has been performed,

as indicated by the most recent date stamped into

the cylinder shoulder. Inspect the exterior of the

cylinder for dents, gouges, or rusted areas, and

evidence of exposure to high temperature such as

darkened or blistered paint, charred decals, melted

or distorted gauge lens, etc.

15

Page 18

Panther HIP-PAC

b. Composite Cylinders

Ensure that no more than three years have elapsed

since the last hydrostatic test has been performed

for the 3000 psig, hoop wrapped cylinder and ve

years for the 4500 psig fully wrapped ber cylinder,

and that the cylinder is less than 15 years old. Inspect the exterior of the cylinder for dents, gouges,

or cuts which have penetrated and caused separation or unraveling of the composite overwrap. Watch

for evidence of exposure to high temperature, such

as darkened or blistered paint, charred overwrap or

decals, melted or distorted gauge lens, etc.

c. Cylinder Valve

The cylinder valve should also be examined for ob-

vious external damage such as a deformed handwheel, inaccurate or inoperative pressure indicator,

damaged threads on the outlet connection, or other

evidence of impact or exposure to extreme heat.

If internal contamination is suspected, remove the

cylinder valve and inspect the interior of the cylinder. The cylinder valve overhaul cycle should be as

follows. For steel, all aluminum, or fully wrapped

carbon ber cylinders, overhaul the valve at every

hydrostatic retest (5 year cycle). For hoop wrapped

cylinders, overhaul the valve at every other hydrostatic retest (6 year cycle).

d. Additional Information

i. Additional information on cylinder inspection

and maintenance can be found in CGA pamphlet

C-6, “Standards for Visual Inspection of Com-

pressed Gas Cylinders,” CGA pamphlet C-6.1,

“Visual Inspection of High Pressure Aluminum

Cylinders,” or CGA pamphlet C-6.2, “Guidelines

for Visual Inspection and Requalication of Fiber

Reinforced High Pressure Cylinders,” available

from the Compressed Gas Association, Inc. If

there is any doubt about the suitability of a cylinder to recharge, it should be returned to a certied hydrostatic retest facility for expert examination and retesting.

ii. A comprehensive listing of all licensed hydrostatic test stations is available from the Department of Transportation.

2. Filling Procedure

a. Air Purity

Unless safety and health codes in your area specify

otherwise, air cylinders should be relled with compressed air meeting the purity requirements for

Type 1, Grade D Gaseous Air as specied by the

Compressed Gas Association Commodity Speci-

cation for Air, publication G-7.1. The moisture content, expressed as dewpoint, shall be maintained

at -65°F (-53.9°C) or lower, or less than 24.0 ppm

by volume moisture content. UNDER NO CIRCUMSTANCES SHALL AN AIR CYLINDER BE FILLED

OR PARTIALLY FILLED WITH OXYGEN.

b. Maximum Fill Pressure

Determine the service pressure of the cylinder prior

to lling. Composite and aluminum cylinders may

be lled only to the service pressure indicated on

the cylinder label. Composite and aluminum cylin-

ders must never be lled to a pressure greater than

the marked service pressure.

c. Filling Procedure

i. The ll station must be constructed and

equipped in accordance with applicable state industrial safety codes.

ii. The cylinder may be partially immersed (DO

NOT submerge the cylinder valve) in a water

bath to minimize the temperature rise that oc-

curs as the cylinder is lled. The ll hose should

be equipped with a restraining cable to prevent

uncontrolled “whipping” in case of hose failure.

iii. After connecting the ll hose, open the cylin-

der valve fully. A separate metering valve must

be used to control the ll rate. Fill the cylinder

slowly, at a rate not exceeding 500 psig per minute. (Use caution if faster recharging rates are

used.) After the initial lling, allow the cylinder

to cool to room temperature, then “top off” the

cylinder to achieve full service pressure.

iv. Use particular care to ensure that an air cyl-

inder is never connected to a source capable

of supplying air at a pressure greater than the

maximum service pressure of that cylinder.

v. Close the cylinder valve when the cylinder is

full.

vi. Slowly bleed pressure from the lling lines.

vii. Disconnect the lling line.

viii. Let the cylinder cool and check the gauge

reading. Top off if necessary.

d. Storage

Air cylinders should be recharged as soon as prac-

tical after use. Cylinders should not be stored par-

tially charged, for two reasons:

i. If used without recharge, the service duration

of the apparatus is reduced.

ii. The safety relief device is designed speci-

cally to protect a fully charged cylinder from the

effects of a re.

For maximum safety, the cylinders should be stored

fully charged.

If the cylinder is stored empty and the valve is inadvertently left open, humid atmospheric air may

enter the cylinder and result in interior corrosion.

If a HIP-PAC is to be maintained in “standby” mode,

i.e., available for immediate emergency usage, the

cylinder pressure gauge should be checked at least

once a month to assure that the cylinder is charged

to full service pressure. Place the cylinder in a suit-

able safety sleeve or lling area.

16

Page 19

Panther HIP-PAC

I. Cold Weather Operation and Maintenance

Operation of the Panther HIP-PAC in cold weather, 32°F

(0°C) or colder, requires the user to be aware of the potential problems caused by the combination of moisture

and low temperatures.

WARNING

• Moisture entering the regulator sys-

tem, either from moisture in the cylinder

air or by external means, e.g., overspray

during operations or inclement weather

conditions, may cause regulator sys-

tem freezeup, restricting or stopping air

ow to the user. This could result in se-

rious injury or death to the user.

• Recharge the cylinders with Grade

D or better air conforming to Com-

pressed Gas Association Specication

G-7.1. Moisture content, expressed as

dewpoint, shall be maintained at -65°F

(-53.9°C) or lower, or less than 24.0 ppm

by volume. Air exceeding this moisture

content may cause regulator system

freezeup, restricting or stopping air

ow to the user. This could result in se-

rious injury or death to the user.

NOTE

• Moisture can cause regulator system

freezing problems even if the ambient air

temperature is above freezing. The air

owing from the HIP-PAC cylinder through

the regulator system decreases from

cylinder pressure to near atmospheric

pressure very rapidly. As this pressure

decreases, the air rapidly expands, causing

the air and therefore the regulator to cool.

• Although the ambient temperature may be

above 32°F (0°C), the temperature inside

the regulator system may be considerably

lower (below freezing).

• SPERIAN recommends that HIP-PACs

used on a routine basis or HIP-PACs

kept for emergency use be stored at

temperatures above 32°F (0°C). HIP-PACs

stored at temperatures below 32°F (0°C)

may need to be warmed to at least 32°F

(0°C) prior to use if ice has formed on the

facepiece exhalation valve, AIR KLIC, and/

or quick-disconnects.

SPERIAN recommends a “change of season” inspection

and increased attention to your preventive maintenance

during cold weather conditions. The following recommended inspections and procedures will help prevent

cold weather problems; however, cold weather conditions may also cause other problems not listed below.

1. Air Supply

NOTE

Cold weather conditions require very dry

air. Moisture entering the HIP-PAC may

cause icing and equipment malfunction.

a. Test compressor(s) for air quality and dewpoint

prior to the cold season.

b. Recharge the cylinders with Grade D or better

air conforming to Compressed Gas Association

Specication G-7.1. Moisture content, expressed

as dewpoint, shall be maintained at -65°F (-53.9°C)

or lower, or less than 24.0 ppm by volume.

c. Prevent any moisture from entering the HIPPAC.

d. Remove ice and water from cylinder valve threads

prior to lling in cold weather conditions.

2. Facepiece and Exhalation Valve

a. The facepiece must be protected from moisture

during cold weather conditions to reduce ice formation on the facepiece lens, in the AIR KLIC, and in

the exhalation valve.

b. Prior to donning the facepiece in cold weather,

visually inspect the lens, AIR KLIC, and exhalation

valve for ice.

c. If ice is present, warm the facepiece to melt the

ice. Ice may be melted by placing the facepiece inside outerwear near the body to warm.

d. Ice in the exhalation valve may be melted by at

least six to eight exhalations onto the exhalation

valve.

e. Verify the proper function of the exhalation valve

by performing a positive pressure exhalation test

and negative pressure leak check as follows.

f. Don the facepiece as specied in the Donning

section of this manual.

g. Perform a positive pressure exhalation test:

i. Take a deep breath, and place your hand over

the AIR KLIC.

ii. Exhale normally. The exhalation valve must

function normally.

iii. If the exhalation valve does not function or it is

difcult to exhale, remove the facepiece.

iv. Exhale on the exhalation valve at least six to

eight more times to melt the ice.

v. Reposition the facepiece, check the straps,

and repeat the test.

vi. If the exhalation valve continues to malfunc-

tion, remove the facepiece from service.

vii. Have the facepiece inspected and/or repaired

by a SPERIAN-certied repair technician before

reuse.

h. Perform a negative pressure leak check:

i. Place your hand over the AIR KLIC.

ii. Inhale and hold your breath for a few seconds.

17

Page 20

Panther HIP-PAC

The facepiece should collapse on your face and

remain collapsed for several seconds without

leaking.

iii. If the facepiece leaks, exhale onto the ex-

halation valve at least six to eight more times.

Reposition the facepiece, check the straps, and

repeat the leak check.

iv. If the facepiece continues to leak, remove it

from service.

v. Have the facepiece inspected and/or repaired

by a SPERIAN-certied repair technician before

reuse.

i. Again, visually check to verify that the facepiece,

lens, AIR KLIC, and exhalation valve are ice-free.

WARNING

If it becomes necessary to remove the

facepiece when using the HIP-PAC,

move to a non-hazardous area rst.

Failure to comply with this Warning

may lead to serious personal injury, serious illness, or death.

j. If the ambient temperature is near or below freezing, place the facepiece and regulator under outer-

wear to keep it warm in case reuse is necessary.

3. Second Stage Regulator

WARNING

• Ice on the second stage regulator AIR

KLIC buttons or the facepiece AIR KLIC

adapter may prevent proper engage-

ment of the regulator.

• The user must ensure that the regula-

tor is properly engaged by rotating and

tugging the regulator to verify that both

release buttons are properly engaged in

the AIR KLIC.

• Failure to comply with this Warning

may lead to serious personal injury, serious illness, or death

a. The second stage regulator must be protected

from moisture during cold weather conditions to

avoid ice buildup on its exterior surfaces. Ice can

interfere with emergency bypass operation or AIR

KLIC button function, which can hinder regulator

removal from the facepiece or from the regulator

receiver.

b. Visually inspect the external surfaces of the regulator for ice prior to use.

c. If ice is present, it may be melted by placing the

regulator inside outerwear near the body to warm.

d. Again, visually inspect the regulator for ice, then

check the red bypass knob and the AIR KLIC buttons for proper function.

te. Should ice form on the regulator while the regulator is in the facepiece, it will continue to function

properly. When it becomes necessary to remove

the regulator, rotate the regulator to break off the

ice, then remove the regulator from the facepiece.

f. If the AIR KLIC buttons are frozen and the regula-

tor cannot be removed, do not force the buttons.

Move to a non-hazardous area, depress the regulator shutoff button, and remove the facepiece and

regulator as a unit.

g. If the shutoff button is nonfunctional, turn off the

air supply at the cylinder valve.

h. Remove the facepiece and regulator as a unit.

i. Warm the facepiece and regulator until the normal

function of the AIR KLIC button and/or the shutoff

button returns.

j. Should ice form on the regulator while the regulator is in the regulator receiver, rotate the regulator

to break off the ice, then remove the regulator from

the regulator receiver.

k. If the AIR KLIC buttons are frozen and the regu-

lator cannot be removed from the receiver, do not

force the buttons. Unbuckle the waist belt, and

place the belt, regulator receiver and regulator under outerwear next to your body to warm it until the

AIR KLIC button functions properly.

4. Regulator Receiver

a. During cold weather operation, keep the regula-

tor receiver cover in place on the regulator receiver

to keep out moisture and debris.

b. Visually inspect the regulator receiver for ice prior

to use.

c. Remove ice by warming the regulator receiver,

placing it under outerwear near the body to warm.

5. Cylinder Valve

a. During cold weather conditions, ice can form on

the cylinder valve.

b. Warm the cylinder valve to melt the ice.

WARNING

Do not use heat above 160°F (71°C) or

direct ame to melt ice. Failure to com-

ply with this Warning may lead to serious personal injury, serious illness, or

death.

NOTE

Remove ice and water from cylinder valve threads

prior to lling in cold conditions.

6. Optional Quick-disconnect Fitting or Male Coupling

a. During cold weather conditions, ice may form

on the optional quick-disconnect tting or the male

coupling.

b. If the quick-disconnect tting and the male cou-

pling are connected prior to ice buildup, they will

continue to function properly.

18

Page 21

Panther HIP-PAC

c. If the second stage regulator is not connected at

the quick-disconnect tting, ice formation on either

the quick-disconnect tting or the male coupling can

make connection impossible.

d. Prior to use, visually inspect the quick-disconnect

tting and male coupling for ice.

e. Remove or melt the ice, then dry the quick-disconnect tting and male coupling to avoid water en-

tering the regulator.

7. Training and Use

a. Conduct training sessions for cold weather op-

erations using all equipment and accessories which

may be used during actual operations.

NOTE

A program for use, training, inspection,

record keeping, and maintenance is given

in National Fire Protection Association

Standard 1404, Fire Department SelfContained Breathing Apparatus Program.

b. During cold weather operations, do not place cylinders or HIP-PACs into wet or snowy areas.

c. Visually inspect the cylinder to remove ice; clean

the threads; and take care to prevent water from

entering the cylinder or accumulating on connecting

surfaces.

d. Icing will be accelerated by high air ow condi-

tions. Examples may include, but are not limited to:

• Bypass usage

• Facepiece leakage due to improper sealing

• Allowing the regulator to free-ow when the

facepiece is off

• Improperly maintained equipment