Page 1

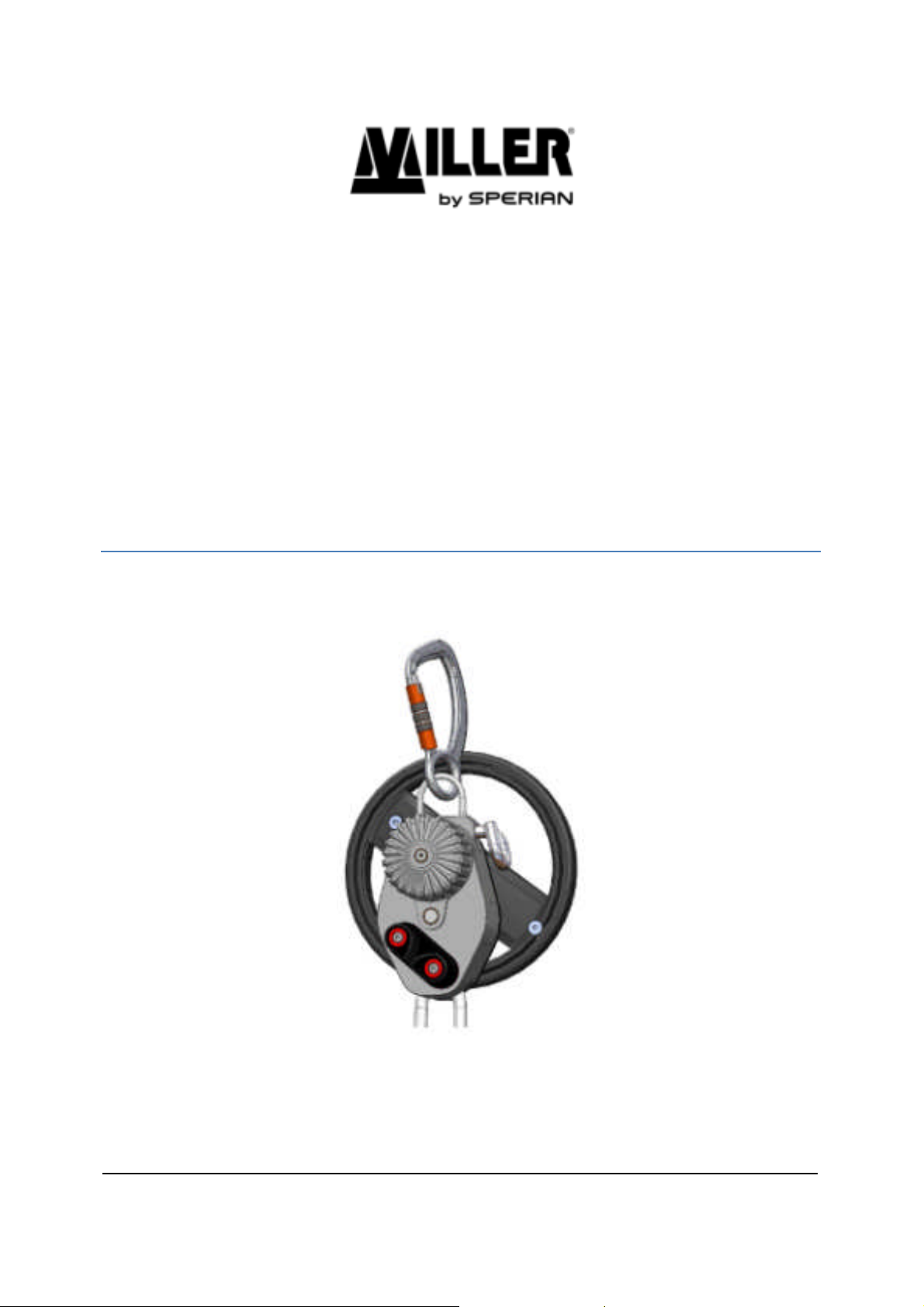

Operating manual

for descender and

rescue lifting device

™

SafEscape ELITE

SD 72

As on 28.05.09

Sperian Fall Protection Deutschland GmbH& Co. KG, Seligenweg 10, D-95028 Hof, Tel. +49 92818302-0, Fax+49 9281 3626,

soell@sperianprotection.com, www.fall-protection.com

Page 2

Contents

1. General inform ation ............................................................................................................ 3

2. Te chnical description.......................................................................................................... 3

2.1. Technical data........................................................................................................... 3

2.2. Assembly................................................................................................................... 5

2.3. Intended use ............................................................................................................. 5

3. Preparation........................................................................................................................... 6

4. Use......................................................................................................................................... 7

4.1. Re scuing accide nt victims...................................................................................... 7

Lifting function......................................................................................................................... 7

De scent function...................................................................................................................... 8

4.2. Options for moving the res cuing person.............................................................. 9

5. Safety instructions ............................................................................................................ 11

5.1. Storage and transport............................................................................................ 11

5.2. Servicing and cle aning.......................................................................................... 11

5.3. Period of wear......................................................................................................... 11

5.4. Re gular inspections............................................................................................... 11

6. Ins tructions for the visual inspection of the de scender and rescue lifting devices. 14

6.1. Testing the device hous ing................................................................................... 14

6.2. Checking the cam cle at ......................................................................................... 14

6.3. Checking the karabine r and the round steel shackle........................................ 14

6.4. Checking the kernmantel rope ............................................................................. 15

6.5. Checking the handw heel....................................................................................... 16

7. Logbook.............................................................................................................................. 17

8. Lis t for the documentation of the available desce nt energy ....................................... 18

Sperian Fall Protection Deutschland GmbH& Co. KG, Seligenweg 10, D-95028 Hof, Tel. +49 92818302-0, Fax+49 9281 3626,

soell@sperianprotection.com, www.fall-protection.com

2

Page 3

1. General information

The descender and rescue lifting device is used to rescue persons who have met

with an accident when working at a height or underground.

The descender and rescue lifting device is not a fall arrester!

Everyuser of the descender and rescue lifting device must read and understand this

manual before using the system.

The descender and rescue lifting device should be used only by qualified and/or

competent persons who have the required knowledge of what is to be done in case

of emergencies.

The area of application of the descender and rescue lifting device is between

ambient temperatures of –30°C and +60°C. In case of temperatures below freezing

point, it must be noted that the brake of the descender and rescue lifting device can

freeze as a result of the moisture.

2. Technical description

2.1. Technical data

Manufacturer: Sperian Fall Protection Deutschland GmbH & Co. KG

Type: SafEscape ELITE™…….

Device class: EN341 Class A,EN1496 Class B

Serial number: ……………………………..

Year of manufacture: ……………………………..

Length of the rope: …………………………

Device weight (without rope):1.65 kg withouthandwheel

2.3 kg with handwheel

Rope weight: 6.7 kg / 100 m

Test standards: prEN 341:2008 type 1 Class A

EN1496:2007 Class B

Testing agency: TÜVSÜD Product Service GmbH

Ridlerstrasse 65

80339 Munich

Germany

CE 0123

Sperian Fall Protection Deutschland GmbH& Co. KG, Seligenweg10, D-95028 Hof,Tel. +49 9281 8302-0, Fax +49 9281 3626,

soell@sperianprotection.com, www.fall-protection.com

3

Page 4

The device has been type examination-tested with the following rated outputs

as per EN341 / EN1496:

Descent loads / heights: 100 kg / 16 x500 m = 8000 m (1 heftyperson)

Minimum descent load: 30 kg

Ø Descentvelocity: ≈1 m/s

Lifting power: 100 kg

Lift: 3.5 m

Additional functional tests can be used to test the maximum power values of

the devices:

The device maybe used in these conditions onlyin case of an emergency!Increased

descent velocities and severe wearmust also be taken into account if necessary!

Descent loads / heights: 150 kg / max2 x500 m

250 kg / max2 x200 m (2 heftypersons)

max possible lifting power: 280 kg

max possible lift: 10 m and above

Exercises are not termed as emergencies! Certain safety equipment must be

kept as reserves. Here, we recommend the following power values:

Descent loads / heights: 75 kg / 20 x 500 m = 10,000 m (1 heftyperson)

100 kg / 15 x500 m = 7,500m (1 heftyperson)

150 kg / max4 x150 m = 600 m

250 kg / max2 x150m = 300m (2 heftypersons)

Minimum descent load: 30 kg

Lifting power: 100 kg

Lift: 3.5 m

The rope and the device should be checked for wear after amaximum of 50 descents

or 10 liftings.

Sperian Fall Protection Deutschland GmbH& Co. KG, Seligenweg10, D-95028 Hof,Tel. +49 9281 8302-0, Fax +49 9281 3626,

soell@sperianprotection.com, www.fall-protection.com

4

Page 5

2.2. Assembly

Carabiner

Round steelshackle

Rope turning device

Descender and

Handwheel

Cam cleat

Moving rope

rescue lifting device

2.3. Intended use

The descender and rescue lifting device is used to rescue persons who have met

with an accident when working at a height or underground.

The descender and rescue lifting device is not a fall arrester!

The descender and rescue lifting device has not been designed for lifting and

lowering loads.

Sperian Fall Protection Deutschland GmbH& Co. KG, Seligenweg10, D-95028 Hof,Tel. +49 9281 8302-0, Fax +49 9281 3626,

5

soell@sperianprotection.com, www.fall-protection.com

Page 6

3. Preparation

The user must conduct a visual inspection of the descender and rescue lifting device

each time before using it to ensure that all its equipmentis operational. The rope, the

device housing, the safety karabiner, the rope turning point and the handwheel must

be free of damage and smooth run-in and run-out of the rope should be possible at

the point where it enters and leaves the descender and rescue lifting device. If any

type of damage is detected or if there is a doubt regarding the safety of the system,

the use of the device must be stopped immediatelyand the device should be handed

over to the manufacturer or one of the experts specified by the manufacturer for

checking.

The anchor point for the descender and rescue lifting device must withstand at least

11 kN. Connection to the anchor point can be established using lanyards as per EN

354, holding ropes as per EN 358, karabiners as per EN 362, guided-type fall

arresters on a flexible anchor line as per EN 353-2 or tape slings and anchor slings

as per EN 795.

If possible, the anchor point should be at such a point on the structure that allows a

free descent without obstacles. Descent over sharp edges and sharp-edged objects

must be avoided and sufficient distance (approximately 0.5 m) should be maintained

from the stonework in order to facilitate descent. If it is not possible to maintain a

sufficient distance, the rope must be protected by underlaying it with a suitable edge

protection.

During the entire rescue process, ensure that the persons involved are always

secured at the base. This means that if there are no railings, the persons must be

secured using a full body harness as per EN 361 or lanyards as per EN 354 or

energy absorbers as per EN 355.

The operator at the location must ensure the availability of a rescue measures plan

which takes into account all possible accidents that mayoccur.

Sperian Fall Protection Deutschland GmbH& Co. KG, Seligenweg10, D-95028 Hof,Tel. +49 9281 8302-0, Fax +49 9281 3626,

soell@sperianprotection.com, www.fall-protection.com

6

Page 7

4. Use

4.1. Rescuing accident victims

Lifting function

After the accident victim who has been secured using lanyards as per EN 354 has

fastened the descender and rescue lifting device to a suitable anchor point, the rope

end joint at the rope exit must be attached to the chest or back element on the full

bodyharness of the accident victim using the provided karabiner.

The rope between the descender and

rescue lifting device and the person to

be descended should not beslack. The

free rope at the other side is pulled

down or tautened using the handwheel.

The free rope is led through the turning

device, looped through and fixed into

the cam cleat.

The handwheel can be rotated to

elevate the accident victim till he/she

can either be lifted to a secure base or

the securing lanyard of the person to

be rescued can be detached. When

doing so, the slack rope between the

turning device and the cam cleat is

pulled downward and tightened over

and over again. This helps in

minimising the distance over which the

person to be rescued may slip in case

the handwheel is inadvertently

released.

Sperian Fall Protection Deutschland GmbH& Co. KG, Seligenweg10, D-95028 Hof,Tel. +49 9281 8302-0, Fax +49 9281 3626,

soell@sperianprotection.com, www.fall-protection.com

7

Page 8

Descent function

Always put the handle back into the

handwheel; else, there can be extreme

vibrations during automatic descent

due to the lack of balance. Pull the

rope in the cam cleat out of the cam

cleat from behind and lower the

accident victim. Here, the rope is also

anchored using the turning device. The

released rope easily slides into the

hand during descent.

The movement velocity is automatically controlled via a centrifugal brake. In addition,

the person on the base (the rescuing person) also has the option of holding onto the

rope in his/her hands, thus stopping the descent.

Ensure that the rope which goes up during descent does not get caught in or

entangled with the structure, thus interrupting the descent. Also ensure that there are

no obstacles during descent.

The rope must always be looped around the turning point during the descent in order

to minimise the force to be applied whenstopping the descent.

Alternating descent of persons

The descender and rescue lifting device allows several people to abseil one after the

other.

When the first person who abseils reaches the ground, he/she unhooks the karabiner

of the descender and rescue lifting device from his/her full body harness. The next

person to abseil hooks himself/herself to the karabiner on the other rope at the top

and abseils or is abseiled.

If every person to be rescued does not have a full body harness, the full body

harness or the rescue triangle is taken off by the abseiled person on reaching the

ground and left on the rope so that the full body harness again reaches the top with

the end of the rope that is now free and can thus be used by the next person who

abseils.

Sperian Fall Protection Deutschland GmbH& Co. KG, Seligenweg10, D-95028 Hof,Tel. +49 9281 8302-0, Fax +49 9281 3626,

soell@sperianprotection.com, www.fall-protection.com

Page 9

4.2. Options for moving the rescuing person

Moving the rescuing person and person to be rescued simultaneously

The process of simultaneously moving two people is permissible only up to a

maximum descent height of 200 m.

Both the persons must put on or wear a full body harness as per EN 361 or a rescue

harness as per EN 1497 (follow the relevant operating manual).

After the accident victim has been lifted to a secure base, the rescuing person can

hook the karabiner at the end of the rope which is already in the chest or back

element of the accident victim to the chest element of his own full body or rescue

harness.

The rope between the descender and rescue lifting device and the person to be

abseiled should not be slack. The free rope at the other side must be pulled

downward and fastened in order to tauten the rope. It is also anchored using the

turning device.

The persons can now abseil from the base byletting go the fastened rope.

The movement velocity is automatically controlled via a centrifugal brake. In addition,

the person who remains on the base can interrupt the movement of the rope moving

upwards bybraking manually(holding on to the rope).

If there is nobody on the base anymore, the option of stopping the movement

manually is no longer available for the entire stretch depending on the rope length

(rope supplies), because after half the stretch, the rope coming up is above the

abseiling person.

Simultaneous abseiling of two persons provides the option of abseiling a person

needingmedical aid undersupervision.

When moving two persons (max 250 kg) simultaneously, it must be taken into

account that the descent velocities will be more as compared to a one-person

operation.

Moving the rescuing person after the rescue process

After the rescue process is complete, the descender and rescue lifting device is

unhooked from the anchor point by the rescuer and the karabiner on the rope end

joint of the free rope is hooked at the anchor point.

The karabiner on the descender and rescue lifting device is hooked at the chest

element of the full bodyharness such that the person with the descender and rescue

lifting device canmove away.

Tighten and hold the rope below the descender and rescue lifting device (starting

point of the rope) if necessary; the rope should not be slack. Here, the rope is also

anchored using the turning device.

Sperian Fall Protection Deutschland GmbH& Co. KG, Seligenweg10, D-95028 Hof,Tel. +49 9281 8302-0, Fax +49 9281 3626,

soell@sperianprotection.com, www.fall-protection.com

9

Page 10

The person can now abseil from the base by letting go of the rope. The movement

velocityis automaticallycontrolled via a centrifugal brake. The movement can also be

interrupted by means of manual braking. For that, the rope below the descender and

rescue lifting device must be held such that further downward gliding of the device on

the rope is not possible.

Note:

Additional safety is always necessary during exercises!

Sperian Fall Protection Deutschland GmbH& Co. KG, Seligenweg10, D-95028 Hof,Tel. +49 9281 8302-0, Fax +49 9281 3626,

soell@sperianprotection.com, www.fall-protection.com

10

Page 11

5. Safety instructions

5.1. Storage and transport

The rescue equipment should be stored in dryand cool rooms and protected against

UV irradiation. Avoid contact with acids, corrosive liquids and oils. In case the

unavoidablemoisture penetration of the rope, these should be dried naturallyand not

using heat sources.

A stable device bag or device case should always be used to transport the rescue

equipment in order to avoid damage due to external effects.

5.2. Servicing and cleaning

A visual inspection of the rescue equipment must be conducted before every use in

order to ensure that the device is operational.

If damage to the rope, karabiner or descender device is detected, the use of the

rescue equipment must be stopped and the device must be checked by the

manufacturer or a bodyauthorised byhim/her.

Note : No changes or additions must be made to the descender and rescue lifting

device; else, the type examination is no longer valid.

Use a dry cloth or brush to clean the housing. The rope can be cleaned with

lukewarm water and mild soap followed by rinsing with plain water. Ensure that it is

completelydry before packaging. Do not use heatsources!

5.3. Period of wear

The period of wear depends on the relevant operating conditions. Based on the

present experiences, a period of wear for textile ropes could be 4 to 7 years under

normal operating conditions. The device can be used for many more years

depending on thestorage and operating conditions.

5.4. Regular inspections

The rescue equipmentmust be tested at least once a year by the manufacturer or an

expert, even if it is not in use. If damage is detected during this inspection or there

are doubts regarding the usability of the equipment, the device must be sent to the

manufacturer or aservice centre authorised byhim.

This expert testing must be conducted at least every 7 years either by the

manufacturer himself/herself or byan expert authorised byhim/her.

Sperian Fall Protection Deutschland GmbH& Co. KG, Seligenweg10, D-95028 Hof,Tel. +49 9281 8302-0, Fax +49 9281 3626,

soell@sperianprotection.com, www.fall-protection.com

11

Page 12

Normal use

In case of stronger loads (e.g. ambient or industrial factors having an effect on the

material), the complete rescue equipment should be tested more often if required.

After a 3000 m descent with a maximum of 100 kg descent load, the descender and

rescue lifting device must be inspected by the manufacturer or an expert authorised

bythe manufacturer and the rope must also be tested.

This inspectionmust be conducted well in advance in case of higher descent loads.

Inspections in case of use in training operations / exercises

A visual inspection must be conducted on the descender and rescue lifting device by

an expert before every training session since the device is often used in training

operation or exercises. The information sheet of the manufacturer must be adhered

to when conducting the visual inspection for descender and rescue lifting devices.

In addition, an expert (e.g. skilled trainer) must conduct a revision inspection after the

intervals specified below in case of training devices or devices which are often used

in exercises.

Test intervals specified bythe manufacturer for a revision inspection:

Movement / descent

Device usage Test interval

Revision inspection

Movement onlywith individual

persons,

Maximum descent load 100 kg

Maximum descent height 500

m

After 300 mtrs. or

whenever damages are

assessed during the

inspection or anydoubts

arise regarding the good

Test interval

Rope

After 1000 m free

movement,i.e., the rope

does not run over an

edge, etc.

functionalityof the

equipment, the device

shall sesent to the

manufacturer or to an

authorizedservice point.

Constantmovement with 2

After every2ndmovement After every2ndmovement

persons

Maximum descent load 250 kg

Maximum descent height 200

m

Sperian Fall Protection Deutschland GmbH& Co. KG, Seligenweg10, D-95028 Hof,Tel. +49 9281 8302-0, Fax +49 9281 3626,

soell@sperianprotection.com, www.fall-protection.com

12

Page 13

Lifting

Device usage Test interval

Revision inspection

Maximum lifting power 280 kg

10 m 10 m

Test interval

Rope

Maximum lift 3.5 m

All the limit values specified for test cycles are applicable only for devices and ropes

which do not have any signs of wear. If there are visible / noticeable signs of wear on

the rope or the device which do not necessarily lead to absolute retraction of the

device, the test intervals must be shortened or the device must be inspected

immediatelyand repaired orscrapped if necessary.

The device must be tested after every training session and one day before the next

usage, irrespective of whether or not the above-mentioned limit values for the test

cycle have been reached during the previous training session.

The test lists of the manufacturer for conducting the inspection as well as the

corresponding operating manuals must be adhered to.

The instructions and the test instructions of themanufacturer must be adhered to.

The available descent energy and the conducted revision inspections must be

entered in the attached list for documentation. Descent and lift should be

differentiated between in this case.

Authorisation f or conducting trainings and exercises.

Application trainings must be conducted only by persons who have been trained

(having a certificate / training certificate) by the manufacturer or a direct

representative to become a trainer.

Exercises must be conducted only under the supervision of competent persons who

have participated (having a certificate / training certificate) in at least one training

application bythe manufacturer or an authorised person.

The manufacturer or a direct representative of the manufacturer trains the trainers.

The training to become a trainer also includes the training to become an expert. The

trained trainer is authorised to conduct application trainings as well as expert

trainings. Only the trainers authorised by the manufacturer may conduct trainings for

trainers.

13

Sperian Fall Protection Deutschland GmbH& Co. KG, Seligenweg10, D-95028 Hof,Tel. +49 9281 8302-0, Fax +49 9281 3626,

soell@sperianprotection.com, www.fall-protection.com

Page 14

6. Instructions f or the visual inspection of the descender and rescue lifting

devices

During the visual inspection of the descender device, ensure that the housings and

housing covers have a quality seal which is intact. If it is not, it might mean that the

device has been opened byunauthorised persons.

Ifthe seal is missing or damaged, the use of the device must be stopped immediately

and the device must be handed over to the manufacturer or one of the experts

specified bythe manufacturer

6.1. Testing the device housing

Checking thestarting point / end point of the rope:

The wear / abrasion of the starting and end point of the rope must be checked. The

abrasion at the start and end point of the rope should not be more than 2 mm; if it is,

the use of the device must be stopped.

The material in the wear area has a polished scrubbed, smooth and shining surface.

The abrasion / wear creates a strong valleyin the material.

Checking the device housing:

The housing must be tested for corrosion, mechanical damage, deformation and

crack formation.

A visual inspection must be conducted. If there are cracks, deformations, corrosions

or mechanical damage, the use of the device must be stopped and it must be sent to

the manufacturer for testing.

The bolts must be checked for completeness and fixed seat.

The availability of all bolts must be visually checked. Unfastened bolts must be

tightened using an appropriate spanner. Ifthe bolts are no longer completelypresent,

the use of the device must be stopped.

6.2. Checking t he cam cleat

The cam cleat must be checked for crack formation, fixed seat and operability.

6.3. Checking t he karabiner and the round steel shackle

The karabiners and the round steel shackles must be visually checked for corrosion,

mechanical damage, deformation and crack formation. The use of the equipment

must be stopped in case of damage.

Sperian Fall Protection Deutschland GmbH& Co. KG, Seligenweg10, D-95028 Hof,Tel. +49 9281 8302-0, Fax +49 9281 3626,

soell@sperianprotection.com, www.fall-protection.com

14

Page 15

Independentlocking of the karabinermust also be checked.

6.4. Checking t he kernmantel rope

The entire length of the rope must be checked visually and manually for cuts, fibre

fractures, thickening, kinks, knots, fire areas, strong wear, abrasion, open, released

terminations (saturations) and case displacement.

Tear in the saturation and heat shrink

tube

Torn open saturation

Strong rope abrasion

Sperian Fall Protection Deutschland GmbH& Co. KG, Seligenweg10, D-95028 Hof,Tel. +49 9281 8302-0, Fax +49 9281 3626,

soell@sperianprotection.com, www.fall-protection.com

15

Page 16

Attention must be paid to the properties of the rope (above-mentioned points) during

the manual sliding of the rope.

If the rope has one of the above-mentioned properties, the use of the device must be

stopped. The rope must be replaced by the manufacturer or a person authorised by

the manufacturer.

The material abrasion and brake dust resulting from the use of the device gets

partially transferred from the device on to the rope. This results in discolouration of

the rope (grey-black), but it does not have an adverse effect on the properties of the

rope.

6.5. Checking t he handwheel

The handwheelshould be checked for fixed sit and operability.

If the handwheel cannot be rotated anymore or if it shakes or rotates without

resistance, the use of the devicemust be stopped.

Sperian Fall Protection Deutschland GmbH& Co. KG, Seligenweg10, D-95028 Hof,Tel. +49 9281 8302-0, Fax +49 9281 3626,

soell@sperianprotection.com, www.fall-protection.com

16

Page 17

7. Logbook

The following is a record sheet for conducting the revision inspection of the

equipment and must be maintained in the form of a logbook.

After 300 mtrs. or whenever damages are assessed during the inspection or any

doubts arise regarding the good functionality of the equipment, the device shall se

sent to the manufacturer or to an authorized service point.

Product: SafEscape ELITE™ descender and rescue lifting device

Serial number of the manufacturer:

Owner / user:

Date of purchase: First used on:

Date of

inspection

Result of the inspection

Details about the detected defects

Stamp / Signature

of the expert

Sperian Fall Protection Deutschland GmbH& Co. KG, Seligenweg10, D-95028 Hof,Tel. +49 9281 8302-0, Fax +49 9281 3626,

soell@sperianprotection.com, www.fall-protection.com

17

Page 18

8. List for the documentation of the available descent energy

Product: SafEscape ELITE™descender and rescue lifting device

Serial number of the manufacturer:

Owner / user:

Date of use

Re sult of vis ual

inspection before

using the device

Trainer /

user

Available

descent

energy in m

w ith the

specification

of the

descent load

Available

descent

energy when

lifting in m

w ith the

specification

of the descent

load

Signature

of the

trainer

Sperian Fall Protection Deutschland GmbH& Co. KG, Seligenweg10, D-95028 Hof,Tel. +49 9281 8302-0, Fax +49 9281 3626,

soell@sperianprotection.com, www.fall-protection.com

18

Loading...

Loading...