Sperian PANTHER, PUMA, COUGAR Operation Manual

PANTHER™/COUGAR™/PUMA

™

SELF-CONTAINED BREATHING APPARATUS (SCBA)

30 MINUTE LP SERIES

30/45/60 MINUTE HP SERIES

OPERATION MANUAL

DO NOT USE this SCBA until you completely read and understand this instruction

manual. You are required to inspect your SCBA prior to putting it into eld service.

Please refer to the inspection procedures in this manual. DO NOT USE this SCBA unless you are properly trained and this SCBA has been properly maintained. Failure to

comply with this Warning may lead to personal injury, illness, or death.

©

Copyright Sperian Respiratory Protection USA, LLC

April 2008 All Rights Reserved

P/N 968808 REV F 10/08

WARNING

AN ISO 9001

REGISTERED

COMPANY

Sperian Respiratory Protection USA, LLC

3001 South Susan St., Santa Ana, CA 92704

Toll-Free 888.APR.SCBA or 714.545.0410

Fax 714.850.0299

www.sperianprotection.com

WARRANTY AND LIMITATION OF LIABILITY

LIMITED WARRANTY: SPERIAN warrants this product to be free from defects in materials and workmanship for 12

years from the date of purchase, with the exception of the Puma hood, which is warranted for 2 years; the compressed

air cylinder, which is warranted for 15 years; and the rst stage regulator, which is warranted for the life of the product.

If the SCBA is equipped with a Heads-Up Display, the HUD electronics are warranted for 2 years. During these periods,

SPERIAN will repair or replace defective parts, at SPERIAN’s option.

Freight charges to and from the SPERIAN factory shall be paid by the purchaser.

EXCLUSIONS: NOTWITHSTANDING ANY CONTRARY TERM IN THE PURCHASER’S PURCHASE ORDER OR

OTHERWISE, THE ONLY WARRANTY EXTENDED BY SPERIAN IS THE EXPRESSED LIMITED WARRANTY DEFINED ABOVE. THIS WARRANTY IS EXCLUSIVE AND IN LIEU OF ANY IMPLIED WARRANTY OF MERCHANTABILITY, OR FITNESS FOR A PARTICULAR PURPOSE.

CONDITIONS: To maintain this warranty, this product must be used, maintained, and inspected as prescribed in the

owner’s instruction manual, including prompt replacement or repair of defective parts, mandatory ow tests and overhauls, and such other necessary maintenance and repair as may be required. Normal wear and tear; parts damaged

by abuse, misuse, negligence, or accidents; batteries; and installed accessories which have separate warranties are

specically excluded from this warranty.

LIMITATION OF LIABILITY: No other oral warranties, representations, or guarantees of any kind have been made by

SPERIAN, its distributors, or the agents of either of them, that in any way alter the terms of this warranty. EXCEPT AS

HEREIN PROVIDED, SPERIAN SHALL HAVE NO LIABILITY FOR ANY LOSS OR DAMAGE, WHETHER DIRECT,

INDIRECT, INCIDENTAL, OR CONSEQUENTIAL, TO ANY PURCHASER OR USER OF THIS PRODUCT ARISING

FROM THE SALE, USE, OR OPERATION OF THIS PRODUCT.

WARNING

The failure to use and maintain this equipment in strict conformance with the applicable instruction manual may result in personal injury, illness, or death. The equipment’s use in any manner that is not expressly authorized pursuant to the applicable

instruction manual may result in severe adverse impacts to human health.

Panther/Cougar/Puma SCBA Operation Manual

Table of Contents

I. INTRODUCTION ........................................................................... 1

II. SAFETY PRECAUTIONS ............................................................. 1

III. PARTS LIST ................................................................................ 4

IV. DESCRIPTION ............................................................................ 5

A. Backpack and Cylinder ........................................................... 5

B. First Stage Regulator .............................................................. 6

C. Gauge/Heads-Up Display (HUD) ............................................ 6

D. Chest-mounted Gauge ............................................................ 7

E. Second Stage Regulator ......................................................... 7

F. Facepiece ................................................................................ 8

G. Universal Air Connection (UAC) ............................................. 8

V. UNPACKAGING ........................................................................... 9

A. Warranty Card ......................................................................... 9

B. Remove the SCBA from the Packaging .................................. 9

VI. OPERATION ............................................................................... 9

A. Donning ................................................................................... 9

B. Leak Check—TwentyTwenty Plus Facepiece ....................... 12

C. Leak Check—Puma Hood .................................................... 12

D. Exhalation Valve Test—TwentyTwenty Plus

Facepiece and Hood ................................................................. 12

E. Pressurization ....................................................................... 12

F. Universal Air Connection (UAC) Operation ............................ 14

G. Emergency Operation ........................................................... 15

H. Dofng ................................................................................... 15

I. Cylinder Removal and Reinstallation ...................................... 16

J. Transportation ........................................................................ 17

K. Interface Considerations ....................................................... 17

VII. CYLINDER FILLING AND SAFETY ......................................... 17

A. Inspection .............................................................................. 18

B. Filling Procedure ................................................................... 19

VIII. MAINTENANCE ...................................................................... 20

A. Facepiece Cleaning .............................................................. 20

B. Second Stage Regulator Cleaning ........................................ 21

C. Exterior Surfaces Cleaning ................................................... 22

D. Inspection .............................................................................. 22

E. Repair .................................................................................... 22

F. Functional Testing .................................................................. 22

G. Cylinder Maintenance and Recharging ................................. 22

H. Cold Weather Operation and Maintenance ........................... 22

I. Storage ................................................................................... 26

J. Overhaul Frequency .............................................................. 26

K. Additional Information ............................................................ 27

IX. INSPECTION TABLE ................................................................ 28

X. REPAIR TABLE .......................................................................... 29

XI. FUNCTIONAL TESTING TABLE ............................................... 31

XII. CAUTIONS AND LIMITATIONS ............................................... 32

I. INTRODUCTION

This manual provides operating instructions as well

as cleaning, maintenance, and storage procedures for

the SPERIAN Panther™/Cougar™/Puma™ high and low

pressure SCBA. You must read and understand these

instructions and be properly trained before using the

SCBA in a hazardous atmosphere.

NOTE

All SPERIAN-certied technicians are required to remain current on new procedures

and parts through SPERIAN’s published

Technical Bulletins, technical manual revi-

sions, and certication seminars.

II. SAFETY PRECAUTIONS

WARNING

Maintenance or operating procedures

and techniques that may result in personal injury, illness, or death if not

carefully followed.

CAUTION

Maintenance or operating procedures

and techniques that may result in

damage to equipment if not carefully

followed.

The Warnings, Cautions, and Notes contained in this

manual have the following signicance:

NOTE

Maintenance or operating procedures and

techniques or information considered important enough to emphasize.

WARNING

The user is responsible for establishing •

that this equipment is suitable for the

user’s application.

For respiratory protection, this SCBA •

must be worn and used as specied in

SPERIAN’s instructions. No protective

equipment can provide complete pro-

tection from all conditions. Use extreme

care for all emergency operations. DO

NOT USE THE COUGAR OR PUMA

SCBA FOR INTERIOR STRUCTURAL

FIRE FIGHTING OR IN OTHER APPLICATIONS INVOLVING EXPOSURE TO

HIGH HEAT OR DIRECT FLAME. Do not

use the Panther SCBA alone for any re

ghting or hazardous materials operations; additional protective clothing and

equipment are required for protection.

This SCBA may cease to provide protection if used during excessive heat or

ashover conditions harsher than those

in which it has been tested. This SCBA

must be utilized under suitable thermal

protective garments during exposure

to excessive heat or ashovers. Users

must clean and maintain this SCBA

only in accordance with SPERIAN’s instructions. Accessories or replacement

components not certied for use with

this SCBA may degrade performance or

make this SCBA unsafe, or void NIOSH

certication, and must not be used

without SPERIAN’s written

1

Panther/Cougar/Puma SCBA Operation Manual

WARNING—Continued

consent. The user must read, understand, and follow the accessory installation and operation instructions

before using this SCBA in a hazardous environment. Only SPERIAN components shall be used with this SCBA.

Failure to comply shall void the warranty and NIOSH approval.

Your SPERIAN respirator has been •

constructed of materials selected after

careful consideration for their perfor-

mance, safety, and durability. However,

all materials have exposure limitations

to ame, extremes of heat and cold, or

to the many chemicals in use today. No

materials exist that can be used safely

in all of these environments.

Our engineers cannot predict what will •

happen to this equipment in every potential environment. Materials can be

chemically attacked if exposed to the

wrong environment and may exhibit

excessive corrosion or other forms of

damage. Permeation of gases and liquids through the materials could be excessive. Flame or extremes of temperature might cause thermal degradation.

Each of these things, or a combination

of them, could create conditions in

which this SPERIAN equipment would

be dangerous to use.

This respirator will reduce, but will •

not eliminate the inhalation of contaminants. Before allowing anyone to

enter a hazardous environment while

wearing SPERIAN equipment, you

must conduct safe, scientic tests to

determine if the environment could

render the equipment unsafe. Results

of this testing should be well docu-

mented. Seek the help of a certied

safety professional or industrial hygienist. DO NOT USE this equipment

if the user would be endangered in

any way through environmentally induced degradation of the materials in

the apparatus.

All persons using this SPERIAN •

breathing apparatus must be made

aware of its limitations. We cannot be

responsible for any damage to property, personal injury, or death in which

environmental exposure is a contributing factor.

This respirator does not protect ex-•

posed areas of the body. Some contaminants can be absorbed directly

through the skin while others may irritate exposed areas.

WARNING—Continued

Visual indications of material degra-•

dation may be identied by charring,

blistering, cracking, crazing, pitting,

chalking, rust, and signicant color

changes, all of which can result in a

weakened structure, prohibiting ex-

tended useful service life.

Do not wear this respirator if a satis-•

factory t, as determined by a qualitative or quantitative t test, cannot be

obtained. See ANSI Z88.2 latest edition and OSHA Respirator Standard

(29 CFR 1910.134).

Beards and sideburns will prevent •

a good facepiece seal. Do not use

this respirator unless you are clean

shaven.

This respirator must be used in con-•

junction with a written respirator program meeting the requirements of

the OSHA Standard for Respiratory

Protection, 29 CFR 1910.134, available from the U.S. Department of Labor, Occupational Safety and Health

Administration. The program must

include, but not be limited to proce-

dures for evaluating air contaminants

and selecting appropriate respirators,

procedures for testing the facepiece-

to-face t of respirators, procedures

for cleaning, disinfecting, inspecting,

maintaining, and storing respirators,

procedures for determining if workers

are physically and medically capable

of wearing respirators, and procedures for training employees in the

use of respirators and in recognizing

the hazards associated with contaminants in the workplace.

Do not use this respirator underwater •

or for abrasive blasting.

Before use in welding operations, the •

SCBA must be equipped with a black

facepiece, a welding shield, and upper

and lower bibs.

This SCBA is designed for storage in •

temperatures from -30°F to +160°F.

SPERIAN respirators, accessories, •

and associated equipment should not

be used in atmospheres which may

contain contaminant concentrations

above the lower explosive level (LEL).

Intrinsic safety certication of elec-

tronic components does not eliminate

potential danger from ignition in these

atmospheres.

2

Panther/Cougar/Puma SCBA Operation Manual

WARNING—Continued

The pressure within the SPERIAN •

facepiece remains positive under

most working conditions, but as with

all SCBAs, negative pressure excursions are possible. Conditions when

an SCBA can experience negative

facepiece pressures include, but are

not limited to: 1) the SCBA is improperly worn, 2) the SCBA is not used in

accordance with the instructions, 3)

the SCBA is improperly maintained, or

4) the SCBA is over-breathed during

heavy work rates. The SCBA will provide reduced protection when operated in a negative pressure mode.

Some sensitive individuals may ex-•

perience health problems when ex-

posed to even minute amounts of contaminants. This SCBA will not prevent

health problems for those individuals.

Persons sensitized can have a se-•

vere reaction to chemicals at levels

well below accepted health levels

such as the OSHA Permissible Exposure Limit (PEL), ACGIH® Threshold

Limit Value (TLV®), or NIOSH Recommended Exposure Limits (REL). Do

not use this SCBA if you have been

sensitized from previous exposure or

believe that you may be sensitive or

allergic to any chemical (e.g., isocyanates, latex, etc.).

Do not alter or modify this SCBA in any •

manner. Modifying this SCBA will void

NIOSH certication and may create a

condition in which the SCBA would

not provide the intended protection.

Some individuals are sensitive to •

chemicals (e.g., isocyanates, latex,

oil mists, etc.) or may have some

type of respiratory disorder (e.g.,

asthma, chronic obstructive airway

disease, etc.). If you are sensitive to

any chemical or have a respiratory

disorder, you may have a severe reaction at contaminant levels well below

accepted health levels, such as the

OSHA Permissible Exposure Limit

(PEL), ACGIH® Threshold Limit Value

(TLV®), or the NIOSH Recommended

Exposure Limits (REL). Many chemicals (e.g., isocyanates, mercury, etc.)

have no physical warning properties

and you cannot taste or smell the con-

taminants even though they may be

present in the facepiece. This SCBA

will reduce, but will not eliminate, the

possibility of contaminants entering

the facepiece and causing a severe

reaction. Do not use this respirator

under these conditions.

WARNING—Continued

Discontinue use if you experience •

skin irritation or discoloration.

You must read, understand, and fol-•

low all warnings, instructions, labels,

Material Safety Data Sheets (MSDS),

etc., for the materials you are using

(e.g., paints, hardeners, insecticides,

varnishes, etc.). You must also read,

understand, and follow all warnings,

instructions, etc., listed in the MSDS

for any contaminants that may be or

are present in the work area.

An impact to the second stage regu-•

lator when the cylinder valve is open

may inadvertently activate the First-

Breath-On mechanism, causing air to

ow from the regulator and diminishing the air in the cylinder.

ONLY grasp the cylinder valve hand-•

wheel to open or close the valve; DO

NOT pick up or carry a cylinder by

the handwheel, drop a cylinder on the

handwheel, or bump the handwheel,

as this may cause the cylinder valve

to inadvertently open, which may lead

to the cylinder becoming airborne

under the thrust of air released from

the valve, causing injury or death. ALWAYS pick up and carry an air cylinder by the cylinder body.

DO NOT over-torque the air cylinder •

valves. ALWAYS verify that the hydro-

static test facility performing your cyl-

inder testing DOES NOT over-torque

the cylinder valves when they rein-

stall them. SPERIAN SCBA air cylin-

der valves must be tightened with a

torque wrench to a torque value of 70

ft-lb. The torque wrench must have a

range of no more than 0 to 175 ft-lb

and an accuracy of at least ±4 ft-lb (a

variation of no more than 6%).

FAILURE TO COMPLY WITH THESE •

WARNINGS MAY LEAD TO PERSONAL INJURY, ILLNESS, OR DEATH.

3

Panther/Cougar/Puma SCBA Operation Manual

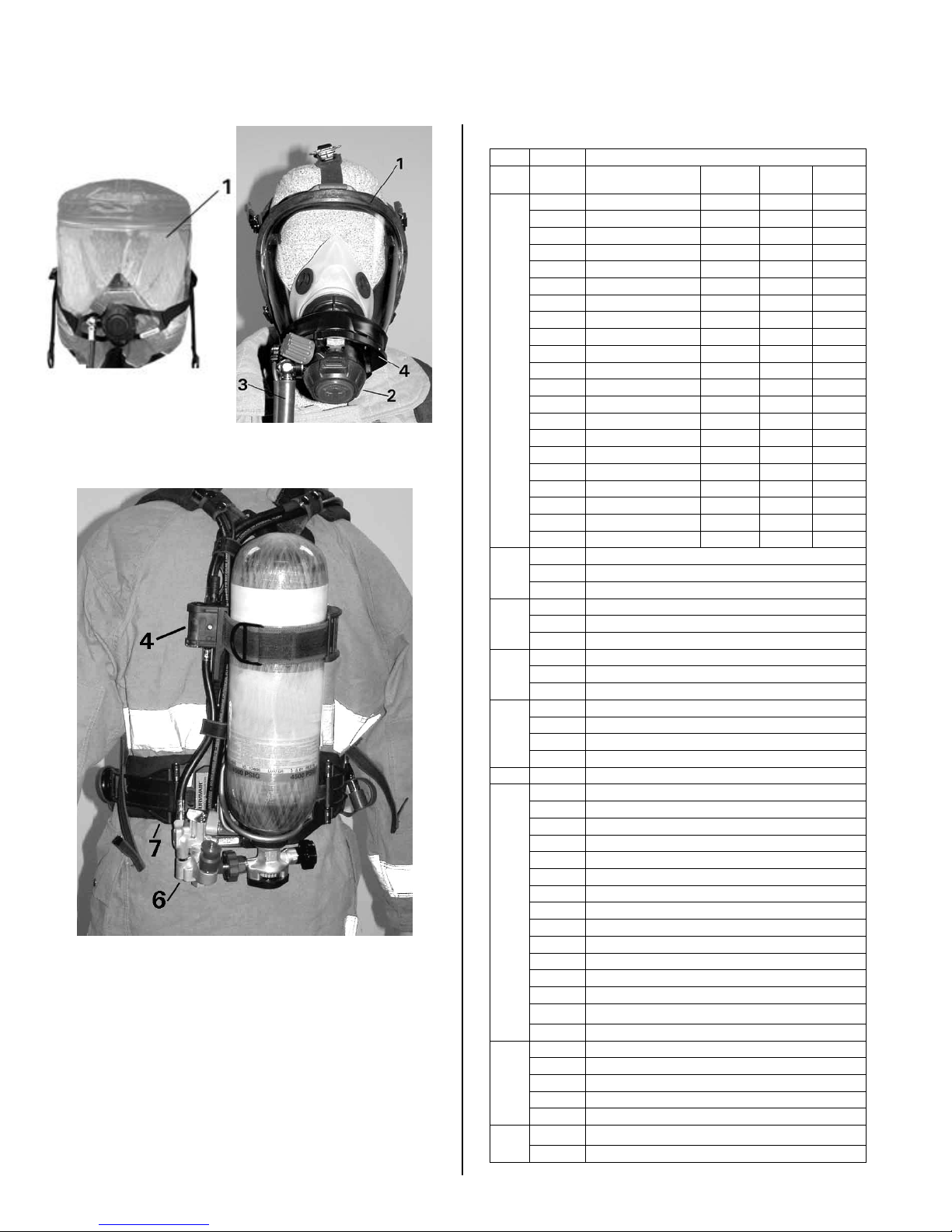

Puma Hood TwentyTwenty Plus

Facepiece Kit

Figure 1. Panther/Cougar SCBA

III. PARTS LIST (See Figure 1)

ITEM P/N DESCRIPTION

Facepiece Size Color

1 252021 TwentyTwenty Plus Medium Blue Large

252023 TwentyTwenty Plus Medium Black Large

252010 TwentyTwenty Plus Small Blue Medium

252011 TwentyTwenty Plus Small Blue Large

252012 TwentyTwenty Plus Small Black Medium

252013 TwentyTwenty Plus Small Black Large

252020 TwentyTwenty Plus Medium Blue Medium

252022* TwentyTwenty Plus Medium Black Medium

252030 TwentyTwenty Plus Large D. Gray Medium

252031 TwentyTwenty Plus Large D. Gray Large

252032 TwentyTwenty Plus Large Black Medium

252033 TwentyTwenty Plus Large Black Large

252038 TwentyTwenty Plus Small Blue Small

252053 TwentyTwenty Plus Small Black Small

252040 TwentyTwenty Plus Medium Blue Small

252041 TwentyTwenty Plus Medium Black Small

252042 TwentyTwenty Plus Large D. Gray Small

252043 TwentyTwenty Plus Large Black Small

968005 Hood-style (Puma) Standard Orange Small

968006* Hood-style (Puma) Standard Orange Medium

968007 Hood-style (Puma) Standard Orange Large

2 961709 Cougar/Puma Second Stage Regulator, Standard

961793 Cougar/Puma Second Stage Regulator, Buddy Breather

968801* Panther Second Stage Regulator, HUD

3 968802* Intermediate Pressure Line, HUD

961494 Buddy Breather Hose Assembly, Cougar/Puma

965110 Over-the-Shoulder Buddy Breather Kit

4 968800 Heads-Up Display (HUD), 2216 psig

968877 Heads-Up Display (HUD), 3000 psig

968888* Heads-Up Display (HUD), 4500 psig

5 980642 Gauge, L.P. (2216 psig) (Not Shown)

980643 Gauge, L.P. (3000 psig) (Not Shown)

980641 Gauge, H.P. (4500 psig) (Not Shown)

968818 Accessory Gauge Hose, HUD (Not Shown)

ITEM P/N DESCRIPTION

6 961366 Cougar/Puma First Stage, Whistle, 2216 psig

961372 Cougar/Puma First Stage, Warbling Whistle, 2216 psig

961371 Cougar/Puma First Stage, Panther Bell, 2216 psig

961359 Cougar/Puma First Stage, Whistle, 3000 psig

961364 Cougar/Puma First Stage, Warbling Whistle, 3000 psig

961363 Cougar/Puma First Stage, Panther Bell, 3000 psig

961356 Cougar/Puma First Stage, Whistle, 4500 psig

961358 Cougar/Puma First Stage, Warbling Whistle, 4500 psig

961357 Cougar/Puma First Stage, Panther Bell, 4500 psig

910099 Cougar/Puma First Stage, MARK 2 Bell, 2216 psig

910071 Cougar/Puma First Stage, MARK 2 Bell, 3000 psig

910001 Cougar/Puma First Stage, MARK 2 Bell, 4500 psig

968830 Panther First Stage, Whistle, 4500 psig

968831 Panther First Stage, Panther Bell, 4500 psig

968832* Panther First Stage, Warbling Whistle, 4500 psig

968836 Panther First Stage, Whistle, 2216 psig

968837 Panther First Stage, Panther Bell, 2216 psig

968838 Panther First Stage, Warbling Whistle, 2216 psig

968821 First Stage, Mark 2, 4500 psig

968822 First Stage, Mark 2, 2216 psig

7 965801 Cougar/Puma Backpack

965800* Panther Backpack

Nose

Cup

4

Panther/Cougar/Puma SCBA Operation Manual

ITEM P/N DESCRIPTION

CYLINDER/VALVE ASSEMBLY

Pressure (psig) Duration

916103 2216 30 Hoop Glass

915140 2216 30 none Aluminum

915170 2216 30 Full Glass

915165 4500 30 Hoop Glass

916173 4500 30 Full Glass

916140 4500 45 Full Glass

915182 4500 60 Full Glass

916123 3000 30 Full Carbon

917130 2216 30 Full Carbon

917131 4500 30 Full Carbon

917145 4500 45 Full Carbon

917160 4500 60 Full Carbon

TwentyTwenty Plus Facepiece Accessories

962869 Neck Strap Kit

962900 Kit, APR Adapter

962260 Spectacles Kit

962266 Large Nose Cup Kit

962265 Medium Nose Cup Kit

962264 Small Nose Cup Kit

960038 Headnet

964171 Radio Communication System

964172 SmallTalk

964173 Radio Communication/SmallTalk Plus Voice Amplication

964165 Remote Push-to-Talk Kit

940118 Protective Mask Bag

140096 Mask Wipes (100 ea.)

951015 Anti-fog Solution (1 oz.)

951016 Anti-fog Solution (16 oz.)

981806 Anti-fog Wipe

980200 Suit Pass-through Kit

946935 Cylinder Sleeve for LP Hoop-wrapped Cylinder

946937 Cylinder Sleeve for HP Hoop-wrapped Cylinder

941256 Cylinder Sleeve for LP Carbon Cylinder

941257 Cylinder Sleeve for 3000 psig Carbon Cylinder

941258 Cylinder Sleeve for HP 30 Minute Carbon Cylinder

941259 Cylinder Sleeve for HP 45 Minute Carbon Cylinder

941261 Cylinder Sleeve for HP 60 Minute Carbon Cylinder

968670 Chest Strap Kit

964867 Utility D-ring

930801/

02/04/

61/62/

64/70

930810 Foster Coupler Kit

930820 Schrader Coupler Kit

930830 Hansen Coupler Kit

945007 Hansen Coupler Kit, Stainless Steel

961438 SuperCharge Fill Hose, Handwheel and Nipple, 2216

961546 SuperCharge Fill Hose, Handwheel and Nipple, 2216

961549 SuperCharge Fill Hose, Handwheel and Nipple, 2216

961439 SuperCharge Fill Hose, Handwheel and Nipple, 3000

961547 SuperCharge Fill Hose, Handwheel and Nipple, 3000

961562 SuperCharge Fill Hose, Handwheel and Nipple, 3000

961441 SuperCharge Fill Hose, Handwheel and Nipple, 4500

961548 SuperCharge Fill Hose, Handwheel and Nipple, 4500

961563 SuperCharge Fill Hose, Handwheel and Nipple, 4500

965110 Over-the-Shoulder Buddy Breather Kit

965119 Over-the-Shoulder Buddy Breather Kit with Check Valve

965122 Air Line Adapter Kit

™

System

General Accessories

Air Supply Hoses,3/8 inch

psig, 4 foot

psig, 10 foot

psig, 20 foot

psig, 4 foot

psig, 10 foot

psig, 20 foot

psig, 4 foot

psig, 10 foot

psig, 20 foot

(for use with P/N 965122 Kit)

(minutes)

Kit

®

Plus Voice Amplication System

Wrap Material

ITEM P/N DESCRIPTION

962600 COMPASS Integrated PASS Device

963820 COMPASS Buddy Breather Kit

963850 COMPASS SAR Attachment Kit

963702 COMPASS and Buddy Breather Kit

963703 COMPASS and Buddy Breather with SAR Attachment Kit

962700 DoublePASS Remote Alarm Module

ITEM P/N DESCRIPTION

Fit Testing Accessories, Qualitative (Cougar and Puma)

193140 IAA/Banana Oil Fit Test Kit

100100 Organic Vapor Cartridge, Box of 6 (For Use with P/N

193138 Replacement IAA Solution, 1 oz.

962920 Fit Test Kit, SCBA/APR Adapter (Requires the P/N

962925 Fit Test Kit, Rell

105005 P100 Filters, Box of 10

962848 Probed Lens, TwentyTwenty Plus Facepiece

193140 Fit Test Kit)

Fit Testing Accessories, Quantitative (Cougar Only)

962900 Kit, APR Adapter)

* Shown in Figure 1

IV. DESCRIPTION

The Panther/Cougar/Puma SCBA provides the wearer

with respiratory protection in hazardous environments,

and may be used for entrance into and escape from

atmospheres that are immediately dangerous to life

or health (IDLH). The Panther is an NFPA-compliant

SCBA and may be used for re ghting. The Cougar

and Puma are industrial SCBAs and must not be used

in the presence of high heat or open ames.

NOTE

The Panther SCBA meets all requirements •

of the NFPA 1981 Standard, 2002 Edition,

Open-Circuit Self-Contained Breathing Apparatus for Fire and Emergency Services.

See NFPA 1500, Standard on Fire Depart-•

ment Occupational Safety and Health Program for proper use of SCBAs in the work

environment.

A. Backpack and Cylinder

The backpack consists of a lightweight contoured 1.

polymer frame with a built-in carrying handle. The

cylinder is attached by a lightweight webbing-style

band. The Panther harness is made of Kevlar/Nomex straps. The Cougar/Puma harness is made of

nylon straps. The chest-mounted pressure gauge

is mounted on the right shoulder strap, and the

intermediate pressure hose is routed over the left

shoulder. The gauge indicates the cylinder pressure once the cylinder valve has been opened.

The chest-mounted pressure gauge is optional

for the Panther SCBA. It is included with the Cougar and Puma SCBAs, but is optional for the Cougar if a Heads-Up Display is installed.

The air cylinder is a composite construction with 2.

an aluminum inner liner overwrapped by a nonme-

tallic ber, and has a maximum working pressure

of 2216 or 3000 psig (low pressure) in 30-minute

duration, or 4500 psig (high pressure) in 30-, 45-,

5

Panther/Cougar/Puma SCBA Operation Manual

and 60-minute durations. An all-aluminum cylinder is available with a maximum working pressure of 2216 psig only.

WARNING

The backpack must never be used as a •

rescue device attachment point.

ONLY grasp the cylinder valve hand-•

wheel to open or close the valve; DO

NOT pick up or carry a cylinder by

the handwheel, drop a cylinder on the

handwheel, or bump the handwheel,

as this may cause the cylinder valve

to inadvertently open, which may lead

to the cylinder becoming airborne under the thrust of air released from the

valve, causing injury or death. ALWAYS

pick up and carry an air cylinder by the

cylinder body.

Failure to comply with this Warning may •

lead to personal injury, illness, or death.

B. First Stage Regulator

The rst stage regulator contains a pressure reducer,

audible alarm, and intermediate pressure hose.

Panther-style First Stage with Alarm3.

The rst stage lowers cylinder air pressure to a.

approximately 100 psig. The relief valve activates to protect the system when the regulated pressure exceeds 200 to 225 psig.

The Panther-style rst stage regulator is b.

equipped with either a whistle, warbling whistle, or bell audible alarm. The low pressure

SCBA audible alarm activates at 510 to 598

psig (2216 psig system) or 690 to 810 psig

(3000 psig system); the high pressure SCBA

audible alarm activates at 1035 to 1215 psig

(4500 psig system). The audible alarm will

continue to sound until air pressure drops below 200 psig.

MARK 2-style Bell Alarm4.

The rst stage regulator lowers cylinder air a.

pressure to an intermediate pressure of approximately 120 psig. An automatic backup

system maintains a safe ow of air in case of

a malfunction.

The audible alarm operates in two modes, b.

ringing at a slow rate when the quantity of air

in the cylinder has dropped to approximately

25% of capacity, and ringing rapidly when a

failure occurs in the rst stage system. The

low pressure SCBA bell alarm rings at 510

to 598 psig (2216 psig system) or 690 to 810

psig (3000 psig system); the high pressure

SCBA bell alarm rings at 1035 to 1215 psig

(4500 psig system); the bell alarm will continue ringing until air pressure drops below

200 psig.

C. Gauge/Heads-Up Display (HUD)

WARNING

The Heads-Up Display (HUD) may only •

be used with the 2520XX series TwentyTwenty Plus facepiece.

If the low battery alert activates (am-•

ber LED on the backpack- mounted

transducer module ashes every two

seconds) during storage, or if the amber LED on the backpack-mounted

transducer module does not ash at all

during storage, the battery must be replaced before using the SCBA.

Activation of the visual alarm (ash-•

ing red LED) portion of the HUD may

or may not coincide with the audible

alarm (i.e., bell, whistle, etc.) on the

SCBA. As soon as the rst alarm activates, PROCEED IMMEDIATELY TO A

SAFE AREA.

You must have binocular vision (vision •

from both eyes) to see and interpret

the display correctly. Your visual acuity while wearing the facepiece must

meet the requirements set forth by the

authority having jurisdiction over your

operation and/or work place.

Failure to comply with this Warning may •

lead to personal injury, illness, or death.

NOTE

The Panther SCBA comes equipped with •

the Heads-Up Display (HUD).

The HUD is optional on the Cougar SCBA, •

but may only be used with the 2520XX series TwentyTwenty Plus facepiece.

The Puma SCBA cannot be equipped with •

a HUD.

The HUD is mounted on the second stage regulator.

When the second stage regulator is installed in the Panther TwentyTwenty Plus facepiece, the display can be

seen through openings in the facepiece nozzle cover.

When the cylinder valve is opened, the HUD will activate automatically, and will indicate the air pressure

remaining in the cylinder. The display consists of four

green LEDs, representing Full, ¾, ½, and ¼. At full cylinder pressure, all four LEDs are lit. As the air pressure

in the cylinder decreases, the LEDs turn off one at a

time, thereby indicating the air pressure status. When

the pressure drops below 50% of cylinder capacity, the

LED representing ½ cylinder capacity starts to ash,

and continues to ash for a short time (approximately

20 seconds) before returning to continuously lit. When

the pressure drops to ¼ (25%) of cylinder capacity, the

last green LED turns red and begins to ash, thereby

giving the user a visual alarm of low air pressure in ad-

6

Panther/Cougar/Puma SCBA Operation Manual

dition to the audible alarm located on the rst stage regulator. On a 2216 psig SCBA, the ¼ LED will turn red

and begin to ash between 510 and 598 psig; on a 3000

psig SCBA, the ¼ LED will turn red and begin to ash

between 690 and 810 psig; on a 4500 psig SCBA, the ¼

LED will turn red and begin to ash between 1035 and

1215 psig. When the pressure drops to 10% of cylinder

capacity, the red LED begins to ash noticeably faster

and continues ashing in this manner until air pressure

drops below approximately 200 psig, at which time the

display will turn off. No lighted LEDs represents zero air

pressure.

An external red LED, mounted on the front of the HUD

module, warns others of the user’s low air status by

ashing at the same time the ¼ LED is ashing inside

the HUD module. The external red LED ashes notice-

ably faster when the pressure drops to 10% of cylinder

capacity.

A photodiode is mounted externally on the top of the

HUD module. It senses ambient light conditions and

adjusts the intensity of the green HUD LEDs to match

these conditions. If the ambient light is bright, the LEDs

are in bright mode. In no-light or low-light conditions,

the LEDs are in dim mode so that they are not distracting to the user.

The transducer module on the backpack has a red LED

that acts as a battery status indicator. When the SCBA is

in storage (the cylinder valve is not opened), the amber

LED will ash once every 10 seconds to indicate a usable battery condition. The amber LED ashes every two

seconds to indicate a low battery condition, and it will

cease ashing altogether to indicate a dead battery.

WARNING

A Duracell Ultra 123 or Eveready En-•

ergizer EL 123A PBP must be used in

the HUD transducer module in order to

maintain the intrinsic safety certication of this product.

Failure to comply with this Warning •

may lead to personal injury, illness, or

death.

To replace the battery, remove the slotted battery cap

located on the top of the transducer module (located on

the side of the cylinder band) using a coin or a large,

at-blade screwdriver. Remove the old battery, install a

new battery in the orientation shown on the side of the

case, and replace the battery cap.

WARNING

If the low battery alert activates (am-•

ber LED on the backpack-mounted

transducer module ashes every two

seconds) during storage, or if the amber LED on the backpack-mounted

transducer module does not ash at all

during storage, the battery must be replaced before using the SCBA.

If the low battery alert in the HUD ac-•

tivates during actual use (amber LED

at the lower right of the display ashes

once every second), the SCBA may

continue to be used. The battery must

be replaced before the next usage.

Failure to comply with this Warning •

may lead to personal injury, illness, or

death.

D. Chest-mounted Gauge

(Optional for Panther SCBA, and Optional for Cougar

SCBA if a HUD Is Installed)

The chest-mounted pressure gauge is mounted on the

right shoulder strap and may be swiveled 360° for easy

viewing. When the cylinder valve is opened, the gauge

indicates the air pressure remaining in the cylinder.

E. Second Stage Regulator

WARNING

An impact to the second stage regula-

tor when the cylinder valve is open may

inadvertently activate the First-BreathOn mechanism, causing air to ow from

the regulator and diminishing the air in

the cylinder. Failure to comply with this

Warning may lead to personal injury, illness, or death.

The pressure-demand second stage regulator is

mounted on the facepiece by the SPERIAN AIR KLIC™

system. The mechanism automatically locks in place

when the regulator is pushed into the AIR KLIC, and

is detached when the release buttons are pressed. To

prevent inadvertent air ow, the regulator will not operate until the First-Breath-On mechanism is activated or

the manual override button on the front of the regulator

is pressed. The ow of air can be stopped by pressing

the shutoff button. A large red knob on the right side of

the regulator controls an adjustable bypass valve. Turn-

ing this knob counterclockwise provides a constant ow

of air.

7

Panther/Cougar/Puma SCBA Operation Manual

F. Facepiece

WARNING

The SPERIAN Puma hood-style face-•

piece :

Must be worn in conjunction with an •

SCBA and used as specied in SPERIAN’s instructions.

When donned and used with its SCBA, •

will reduce, but not eliminate, the inhalation of contaminants.

Does not protect against falling objects •

or projectiles.

Does not protect exposed areas of the •

body.

Must not be worn around open ames. •

It must not be used for structural re

ghting, underwater activities, or abrasive blasting.

Must not be used unless a satisfactory •

t is obtained.

Must not be reused if contaminated.•

Must not be altered or modied in any •

manner.

Requires that the wearer must assure •

that the neck seal is not compromised

by hair or clothing when in use.

Requires that after each use and/or •

cleaning and disinfecting, anti-fog solu-

tion (SPERIAN P/N 951015, 951016, or

981805) must be applied to the inside

of the lens. Failure to comply with this

Warning may lead to personal injury, illness, or death.

The Panther/Cougar SCBA will include a “hard” TwentyTwenty® Plus facepiece. The Puma SCBA will include

a “soft” hood-style facepiece. The silicone TwentyTwenty Plus facepiece has a special wide lip sealing

surface and ve point silicone headstrap harness or

optional Headnet™ harness. The lens is treated with

an abrasion-resistant coating on the inside and outside

surfaces of the lens. The nozzle houses a removable

nose cup, speaking diaphragm, and exhalation valve.

The AIR KLIC is threaded into the nozzle by a ratchet

mechanism to prevent leakage and provide a secure

mount for the second stage regulator.

The Puma hood-style facepiece is constructed of several different components. The hood material is a multi-

layered specialty material specically designed for its

resistance to a wide range of chemicals. The hood

contains a exible lens made of clear, non-porous vinyl. The primary neck seal of the hood-style facepiece

is constructed of neoprene rubber, a material used for

many conventional type facepieces. A secondary seal

is made inside the hood-style facepiece with a silicone

nose cup. The nose cup is available in small, medium,

or large size. The suspension system secures the hoodstyle facepiece in place on the user. Anti-fog solution

(SPERIAN P/N 951015, 951016, or 981805) may be

applied to the inside of the lens. An AIR KLIC provides

a secure mount for the SCBA second stage regulator.

WARNING

The hood material, vinyl lens, neoprene

neck seal, and adhesive all may react

in a different manner when exposed to

chemicals or chemical mixtures. You

must verify that none of the components of the hood will degrade against

the chemicals or mixtures to which it

may be exposed. Failure to comply with

this Warning may lead to personal injury, illness, or death.

The hood-style facepiece is made of several components, each having different reactions to chemical environments. It is vital to ensure that you have objective

evidence that the hood will be able to maintain its integrity against the expected chemical exposure during

operations. This can be accomplished by tests you conduct or by contacting SPERIAN for further information.

G. Universal Air Connection (UAC)

NOTE

The Panther SCBA comes equipped with the •

Universal Air Connection (UAC).

The UAC is optional on the Cougar and Puma •

SCBAs.

The Universal Air Connection (UAC) and ll hose (purchased separately in the P/N 968950 Rapid Intervention

Kit) or SuperCharge ll hose (See Parts List, General Accessories, on page 5.) provide a means for lling SCBA

cylinders during a rescue. An attendant/rescue crew

member must assist with the cylinder lling.

The Universal Air Connection (UAC) is located on the

rst stage regulator body. The UAC is accompanied by

a relief valve located on the back of the rst stage regulator, designed to vent air to atmosphere when the ll

pressure exceeds the cylinder service pressure in order

to prevent cylinder overpressurization. The UAC has a

dust plug which must be installed over the coupling at

all times before and after lling operations. The UAC

ll hose has the mating ll coupling. A directional ow

control piston is located in the quick disconnect coupling to prevent air loss and hose whipping if the hose

is installed incorrectly. The quick disconnect coupling is

supplied with dust plugs which must be installed when

the ll hose is not in use.

8

Panther/Cougar/Puma SCBA Operation Manual

WARNING

The UAC has a dust plug which must be •

installed over the coupling at all times

before and after lling operations.

DO NOT allow oil, grease, or other con-•

taminants to come in contact with the

quick disconnect couplings.

DO NOT use air other than breathing air, •

Grade D or better, conforming to CGA

G-7.1 Commodity Specication for Air.

The moisture content, expressed as

dewpoint, shall be maintained at -65°F

(-53.9°C) or lower, or less than 24.0

ppm by volume moisture content.

The SPERIAN UAC or UAC ll hose •

must ONLY be used to ll compressed

air cylinders. The SPERIAN UAC or

UAC ll hose must NEVER be used:

As a buddy breathing device.1.

For SCBA-to-SCBA lling.2.

To provide a continuous air supply.3.

Failure to comply with this Warning •

may lead to personal injury, illness, or

death.

V. UNPACKAGING

IMPORTANT—READ CAREFULLY

A. Warranty Card

NOTE

The warranty is void unless the warranty

card is returned to the factory within 30 days

of purchase.

Fill in the form with the required information.1.

Mail back the completed warranty registration 2.

card immediately.

To comply with NIOSH, SPERIAN is required to 3.

retain the completed warranty registration card.

Always refer to the equipment serial number if a 4.

claim is made.

Cut both of the locking straps that secure the c.

SCBA to the transportation cradle.

Lift the SCBA from the cradle.d.

CAUTION

Exercise extreme care when identifying

SCBA components. Engraving may induce stresses in materials that, over time,

could propagate cracks. Plastic labels,

dyno-labels, and stickers may burn.

VI. OPERATION

WARNING

Wear gloves when handling SCBAs that

have been stored in extreme tempera-

tures. Failure to comply with this Warning may lead to personal injury, illness,

or death.

NOTE

See NFPA 1500, Standard on Fire

Department Occupational Safety and Health

Program for proper use of SCBAs in the

work environment.

A. Donning

Remove the SCBA from its carrying case or 1.

stored location.

Hand tighten the rst stage handwheel to the cyl-2.

inder valve outlet.

Ensure that the cylinder valve gauge reads in the 3.

green (FULL) zone.

WARNING

Check the cylinder band latch each time;

set the cylinder band or strap to match

the cylinder. Failure to comply with this

Warning may lead to personal injury, illness, or death.

B. Remove the SCBA from the Packaging

Carrying case1.

Remove the carrying case from the box.a.

Lift both locking tabs on the case and open it.b.

Remove the facepiece from the case.c.

Unfasten the Velcro transportation fasteners.d.

Lift the SCBA from the case.e.

Carton packaging2.

Remove the facepiece from the box.a.

Remove the plastic transportation cradle from b.

the box with the SCBA connected to it.

Check the latch on the cylinder band and ensure 4.

that the cylinder is secure in the backpack.

Lay the harness out and straighten each strap. 5.

All adjustable straps should be extended to maximum length.

There are two methods of donning the SCBA: 6.

coat-style, one arm at a time; and over the head.

Choice of the method of donning is a matter of

individual choice or organizational policy. Both

methods are described below.

9

Loading...

Loading...