Page 1

Biosystems

NXP

Fixed Gas

Detector Head

Reference

Manual

Sperian Instrumentation

651 South Main Street

Middletown, CT 06457

800-711-6776

860-344-1079

Fax 860-344-1068

Part Number 13-345

Version 1.01

10SEP2009

http://www.biosystems.com

Page 2

2

Page 3

THE BIOSYSTEMS NXP FIXED GAS DETECTOR HEAD HAS BEEN

DESIGNED FOR THE DETECTION AND MEASUREMENT OF

POTENTIALLY HAZARDOUS ATMOSPHERIC CONDITIONS.

IN ORDER TO ASSURE THAT THE USER IS PROPERLY WARNED

OF POTENTIALLY DANGEROUS ATMOSPHERIC CONDITIONS, IT

IS ESSENTIAL THAT THE INSTRUCTIONS IN THIS REFERENCE

MANUAL BE READ, FULLY UNDERSTOOD, AND FOLLOWED.

Biosystems NXP

Reference Manual

Sperian Instrumentation Part Number 13-345

Version 1.01

Copyright 2009

by

Sperian Protection Instrumentation, LLC

Middletown, Connecticut 06457

All rights reserved.

No page or part of this operation manual may be reproduced in any form without

written permission of the copyright owner shown above.

Sperian reserves the right to correct typographical errors.

Specifications are subject to change without notice.

1

Page 4

Table of Contents

Signal Words .......................................................................................................................5

Modification of Sperian Instrumentation Products ...............................................................5

Operating Temperature and Humidity Limits .......................................................................5

Warnings and Cautions .......................................................................................................6

1. Overview.......................................................................................................................7

1.1 Capabilities ..........................................................................................................7

1.2 Method of sampling..............................................................................................7

1.3 Sensor options .....................................................................................................7

1.4 Verification of accuracy........................................................................................7

1.5 Displays and controls...........................................................................................8

1.6 Power requirements.............................................................................................8

1.7 Alarms and Alarm Logic.......................................................................................8

1.7.1 Atmospheric Hazard Alarms ............................................................................8

1.7.2 Sensor Over-range Alarms ..............................................................................9

1.7.3 Alarm Relays ..................................................................................................10

1.8 Fault Conditions .................................................................................................10

1.9 Remote Sensors ................................................................................................10

1.10 4-20 mA Current Loop .......................................................................................11

1.11 Event Logger......................................................................................................11

1.12 Firmware Upgrades............................................................................................11

2. Installation ..................................................................................................................12

2.1 Installation overview...........................................................................................12

2.2 Cautions.............................................................................................................13

2.3 NXP Detector Head Environmental Ratings ......................................................13

2.4 Siting of detector heads .....................................................................................13

2.5 Wiring requirements...........................................................................................13

2.5.1 Grounding ......................................................................................................14

2.6 Output Specifications .........................................................................................14

2.7 External Wiring...................................................................................................14

2.8 Remote Sensor Installation ................................................................................16

2.8.1 Disconnecting the sensor ...............................................................................16

2.8.2 Connecting the sensor cable..........................................................................16

2.8.3 Mounting the remote sensor ..........................................................................16

2.8.4 Connecting the cable (non-explosion-proof sensor) ......................................16

2.8.5 Connecting the cable (explosion-proof sensor)..............................................16

3. Field Usage ................................................................................................................18

2

Page 5

3.1 Modes of operation ............................................................................................18

3.2 Clearing the MAX reading..................................................................................19

3.3 Effect of contaminants on NXP sensors.............................................................20

3.3.1 Effects of contaminants on oxygen sensors...................................................20

3.3.2 Effects of contaminants on combustible sensors ...........................................20

3.3.3 Effects of contaminants on toxic gas sensors ................................................20

3.4 Sensor Replacement .........................................................................................21

4. Verification of Accuracy (Calibration) .........................................................................22

4.1 Warnings and cautions concerning verification of accuracy ..............................22

4.2 Overview of verification of accuracy...................................................................22

4.2.1 Calibration Interval .........................................................................................22

4.2.2 Special Instructions for Fixed Gas Detectors .................................................22

4.2.3 Accuracy of Oxygen Sensors.........................................................................22

4.2.4 Accuracy of Toxic and LEL Sensors ..............................................................23

4.3 Fresh air calibration ...........................................................................................23

4.4 Span calibration of Toxic and LEL sensors........................................................24

4.5 Test Mode ..........................................................................................................25

4.6 Calibration Failures ............................................................................................26

4.6.1 Fresh Air Calibration Failure ..........................................................................26

4.6.2 Span Calibration Failure.................................................................................26

5. Configuration ..............................................................................................................28

5.1 Accessing the Setup menu and Submenus .......................................................28

5.2 Setup Submenu Flow Chart...............................................................................29

5.3 Set Date and Time .............................................................................................30

5.4 Set Loop Range .................................................................................................30

5.5 Set Alarm Levels................................................................................................30

5.6 Set Alarm Latch .................................................................................................31

5.7 Set Combustible Gas Sensor Display................................................................31

5.8 Set Cal Gas Concentration ................................................................................31

5.9 Set Cal Interval ..................................................................................................31

5.10 Set Bump Test Interval ......................................................................................31

6. Diagnostics .................................................................................................................32

6.1 Accessing the Diagnostics menu and Options...................................................32

6.2 Diagnostic Menu Flow Chart ..............................................................................33

6.3 Serial Number / Software Version......................................................................34

6.4 Sensor Count Display ........................................................................................34

6.5 Sensor Temperature Display .............................................................................34

3

Page 6

6.6 Current Loop Output Test ..................................................................................34

6.7 Relay Test..........................................................................................................34

6.8 12-Volt Output Test............................................................................................35

6.9 LCD and Backlight Test .....................................................................................35

6.10 LED Test ............................................................................................................35

6.11 Audible Alarm Test.............................................................................................35

7. Service........................................................................................................................36

Returning your NXP to Sperian Instrumentation for service or repair ............................36

Appendices ........................................................................................................................37

Appendix A: NXP Toxic Sensor Cross Sensitivity Data .................................................37

Appendix B: Fault Conditions.........................................................................................38

Appendix C: Calibration Frequency Recommendation ..................................................39

Appendix D: Sperian Instrumentation Warranty Gas Detection Products......................40

4

Page 7

Signal Words

The following signal words, as defined by ANSI Z535.4-1998, are used in the

NXP Reference Manual.

indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury.

indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

indicates a potentially hazardous situation, which if not avoided,

may result in moderate or minor injury.

CAUTION used without the safety alert symbol indicates a potentially

hazardous situation, which, if not avoided, may result in property damage.

The NXP MUST be installed in a non-hazardous area.

Modification of Sperian Instrumentation Products

Any unauthorized modification of any Sperian Instrumentation

product may compromise the certification and the safety of the product, and may

lead to serious personal injury or death. Modification of any part or component of a

Sperian Instrumentation product requires the express written approval of both the

appropriate certification agency and Sperian Instrumentation.

Operating Temperature and Humidity Limits

The Biosystems NXP’s operating temperature range is printed

on the label on the inside of the instrument. The Biosystems XPR’s operating

temperature range is printed on the housing. Use of Sperian Gas Detection

products outside of their specified operating temperature ranges may result in

inaccurate and potentially dangerous readings.

5

Page 8

Warnings and Cautions

1. The Biosystems NXP gas detector has been designed for

the detection of dangerous atmospheric conditions. An alarm condition

indicates the presence of a potentially life-threatening hazard and should be

taken very seriously.

2.

In the event of an alarm condition it is important to follow

established procedures. The safest course of action is to immediately leave the

affected area, and to return only after further testing determines that the area is

once again safe for entry. Failure to immediately leave the area may result in

serious injury or death.

3.

The accuracy of the NXP should be checked periodically

with known concentration calibration gas. Failure to check accuracy can lead to

inaccurate and potentially dangerous readings.

4.

Fresh air/zero calibrations may only be performed in an

atmosphere that is known to contain 20.9% oxygen, 0% LEL and 0 PPM toxic

gas. If fresh air is unavailable, a cylinder of “Zero Air” must be used during the

fresh air/zero calibration procedure. Calibration of the NXP in a contaminated

atmosphere may lead to inaccurate and potentially dangerous readings.

5.

The accuracy of the NXP should be checked immediately

following any known exposure to contaminants by testing with known

concentration test gas before further use. Failure to check accuracy can lead to

inaccurate and potentially dangerous readings.

6.

A sensor that cannot be calibrated or is found to be out of

tolerance should be replaced immediately. An instrument that fails calibration

may not be used until testing with known concentration test gas determines that

accuracy has been restored, and the instrument is once again fit for use.

7.

Do not reset the calibration gas concentration unless you

are using a calibration gas concentration that differs from the one that is normally

supplied by Sperian for use in calibrating the NXP. Customers are strongly urged

to use only Sperian calibration materials when calibrating the NXP. Use of nonstandard calibration gas and/or calibration kit components when calibrating the

NXP can lead to inaccurate and potentially dangerous readings and may void

the standard Sperian warranty.

Sperian offers calibration kits and long-lasting cylinders of test gas

specifically developed for easy NXP calibration. Customers are strongly urged

to use only Sperian calibration materials when calibrating the NXP.

8.

For safety reasons this equipment must be operated and

serviced by qualified personnel only. Read and understand this reference

manual before operating or servicing the NXP.

9.

A rapid up-scale reading followed by a declining or erratic

reading may indicate a hazardous combustible gas concentration that exceeds

the XPR’s zero to 100 percent LEL detection range.

6

Page 9

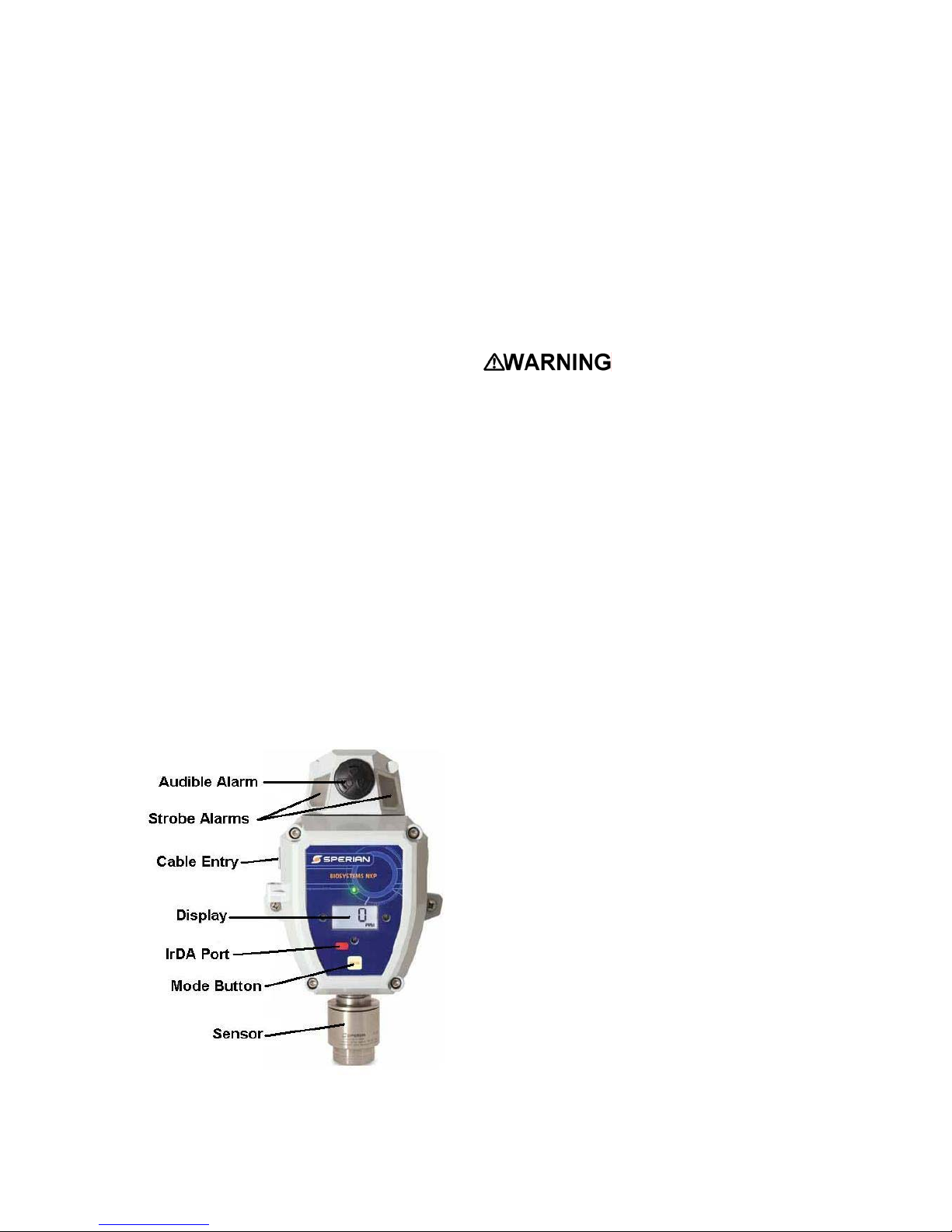

1. Overview

1.1 Capabilities

The NXP Gas Detector Head is a fixed

gas detection system from Sperian

Instrumentation. The NXP can function

on its own as a stand-alone unit, and can

also be used as part of a 4-20 mA current

loop system with a PLC or other type of

controller.

Standard features include user interface,

built-in digital readout to allow for direct

calibration at the head, and relays to allow

for additional alarms and control.

Each NXP Gas Detector Head includes a

sensor housing and gas-specific sensor.

Sensor housings are available in nonexplosion-proof and remote explosionproof (XPR) versions. Sensors can be

mounted directly to the NXP housing, or

can be placed remotely (up to 50 feet

away) using a special remote sensor

cable.

Note: Conduit, wire and other

components necessary to connect the

NXP Gas Detector Head to a controller

are not included and must be ordered

separately.

Installation of

explosion-proof housings must be

performed in accordance with local

regulations.

1.2 Method of sampling

The atmosphere being measured reaches

the sensor in the NXP/XPR by diffusing

through a protective filter directly into the

sensor. Normal air movements are

usually enough to carry the sample to the

sensor. The sensor reacts to changes in

the concentration of the hazard being

measured. Values are constantly updated

and displayed on the NXP Gas Detector

head’s LCD readout. If the head is

connected to a controller, the appropriate

level 4-20 mA signal is simultaneously

sent to the controller.

The NXP Gas Detector head may be

installed at a substantial distance from the

controller. The maximum distance

between the head and the controller is

2000 feet when using the proper cable.

Wiring requirements are discussed in detail

in section 2.5.

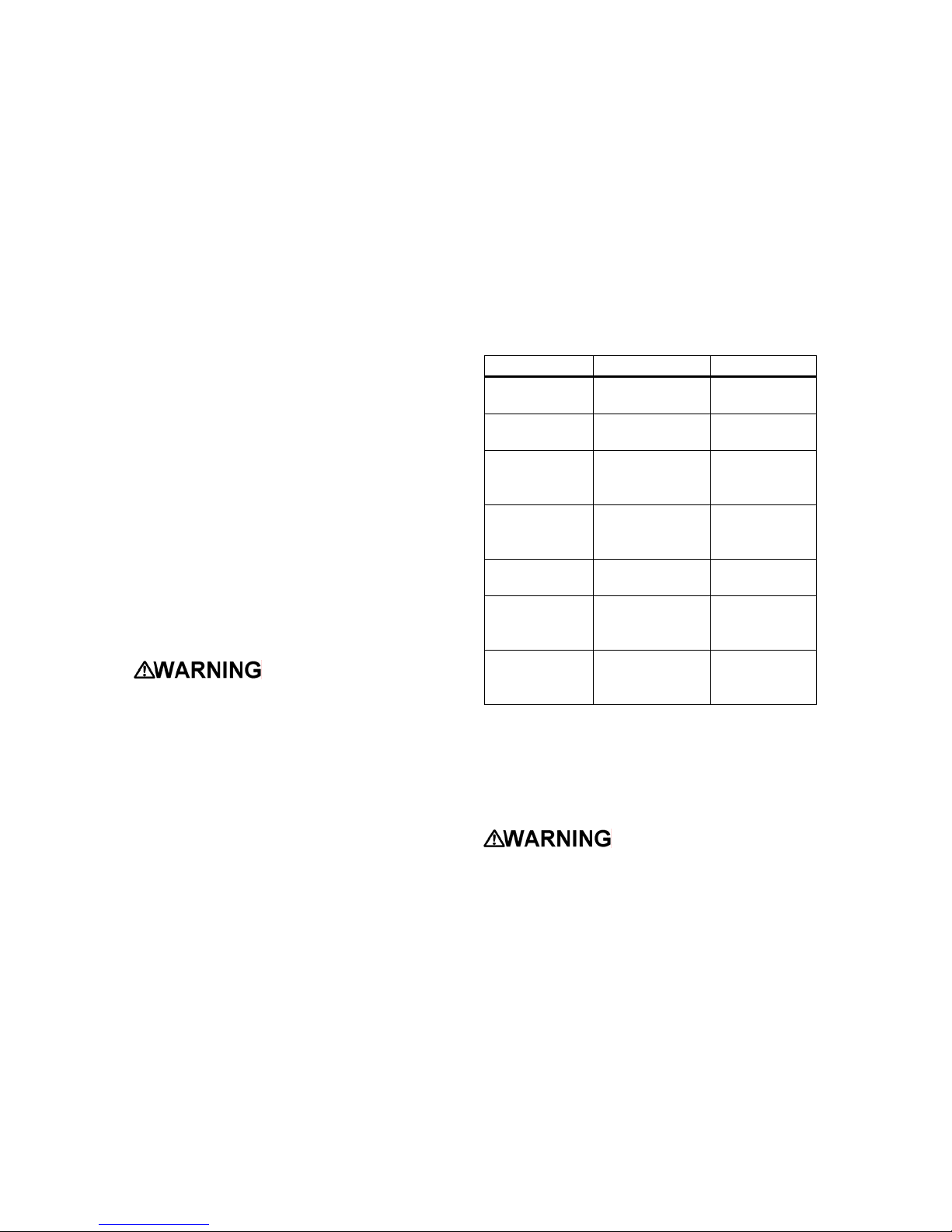

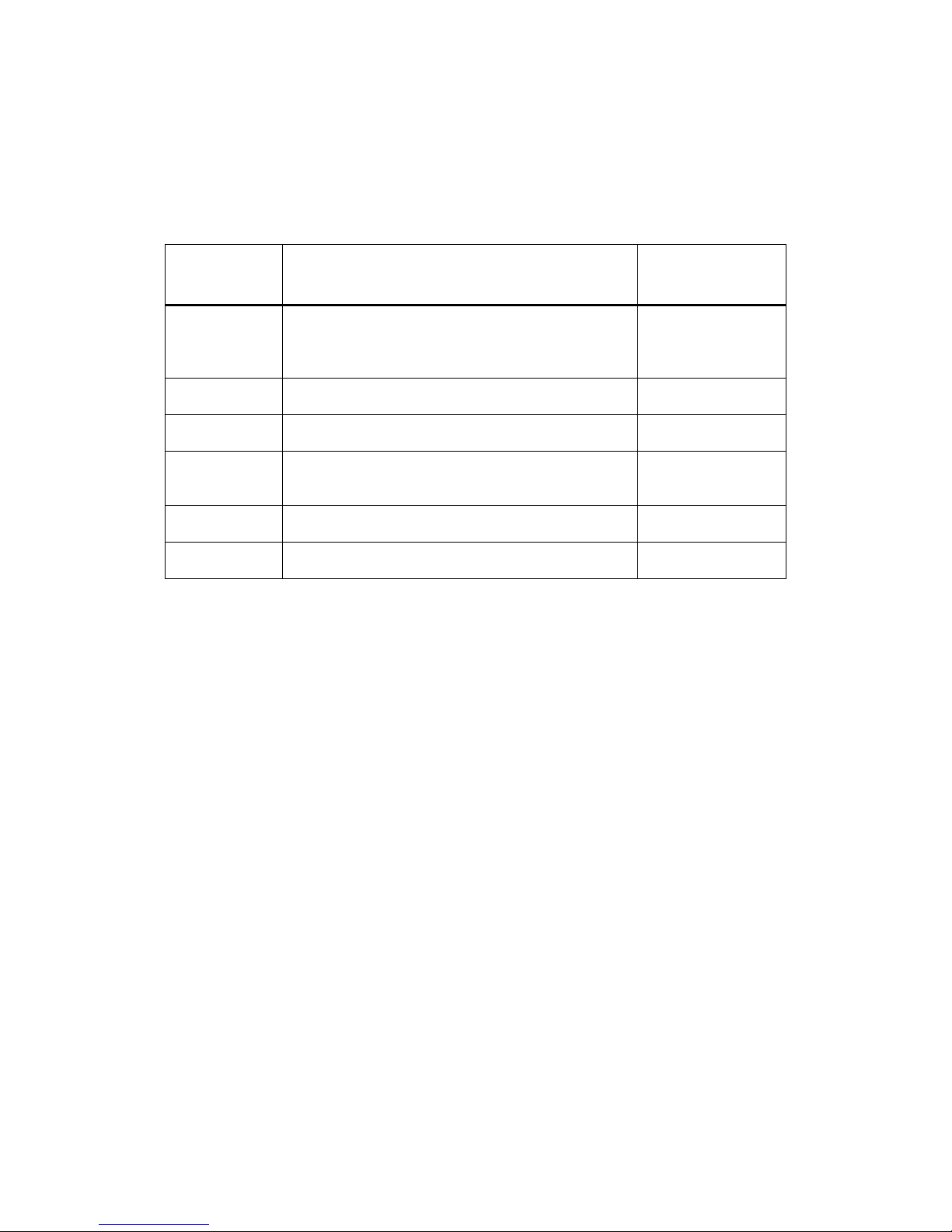

1.3 Sensor options

NXP Gas Detector Heads can be

configured to detect a number of different

atmospheric hazards. Each NXP uses a

single substance-specific sensor that

determines the hazard that the system is

configured to detect. The sensors that are

currently available, along with their ranges

and resolutions, are shown in table 1.3.

Note: Changing the sensor range will

require calibration of the instrument.

Sensor Range Resolution

Oxygen (O2)

Combustible

(LEL sensor)

Carbon

Monoxide

(CO)

Carbon

Monoxide

(CO-H)

Hydrogen

Sulfide (H

Hydrogen

Sulfide (H

Sulfur

Dioxide

(SO

)

2

0-25%/Vol.

0-30%/Vol.

0-100% LEL

0-5.0% CH

0-100 PPM

0-500 PPM

0-1000 PPM

0-100 PPM

0-500 PPM

0-1000 PPM

0-10 PPM 0.1 PPM

S)

2

0-50 PPM

0-100 PPM

S)

2

0-250 PPM

0-25 PPM

0-50 PPM

4

0.1% Vol

1% LEL

0.05% CH

1 PPM

1 PPM

1 PPM

0.1 PPM

Table 1.3 – Sensor Ranges

1.4 Verification of accuracy

NXP Gas Detector Heads have been

designed for easy verification of accuracy.

The accuracy of the NXP

should be checked periodically with

known concentration calibration gas.

Failure to check accuracy can lead to

inaccurate and potentially dangerous

readings.

Please see Sperian’s calibration

recommendations in Appendix C.

Verification of detector accuracy is a twostep procedure for toxic and LEL (XPR

only) sensor-equipped detectors, and a

one-step procedure for oxygen sensorequipped detectors.

Verification normally begins by exposing

the NXP’s sensor to known “fresh air” and

7

4

Page 10

checking the readings. If the readings

differ from those expected in fresh air

(20.9% oxygen, 0 PPM toxic gas, 0% LEL

combustible gas), a "fresh air zero"

adjustment must be made. For most fixed

applications, where the freshness of the

ambient air is in question, a cylinder of

“Zero Air” must be used during the fresh

air/zero calibration.

The second step, which only applies to

toxic and LEL sensors, is to verify sensor

accuracy by exposing it to known

concentration test gas and noting the

response. Toxic and LEL readings are

considered accurate if the readings are

between 90% and 120% of the expected

value as given on the gas cylinder. If the

reading is accurate, then the instrument

requires no further adjustment. Toxic and

LEL readings that fall outside of this range

are considered inaccurate and indicate

that the sensor must be calibrated before

further use.

Calibration procedures are discussed

in detail in Chapter 4.

1.5 Displays and controls

NXP Gas Detector Heads include a 3-digit

LCD located on the face of the detector

housing. The heads also include a MODE

button that allows the user to initiate and

control the calibration of the detector.

1.6 Power requirements

Power to the NXP can be provided either

from a controller or via a standard wall cube

available from Sperian.

The NXP requires a power supply of 13-30

VDC. Power is applied to connector J1 (see

Figure 2.5). Once powered up and running,

the NXP is intended for continuous

monitoring. If it is necessary to power down

the NXP, power should be removed from

the wall cube or controller that is supplying

power to the NXP.

1.7 Alarms and Alarm Logic

NXP Gas Detector

Heads have been designed for the

detection of dangerous atmospheric

conditions. An alarm condition

indicates the presence of a potentially

life-threatening hazard and should be

taken very seriously.

In the event of an alarm condition it is

important to follow established

procedures. The safest course of action

is to immediately leave the affected area,

and return only after further testing

together with other appropriate safety

procedures determine that the area is

once again safe for entry.

1.7.1 Atmospheric Hazard Alarms

NXP Fixed Gas Detectors with toxic or

combustible gas sensors include two levels

of alarms. One alarm serves as the

warning alarm; the second alarm serves as

the danger alarm. Detectors with oxygen

sensors have four alarm levels, as

described below.

Figure 1.5 – Main NXP Components

Toxic and combustible gas sensors have

“ascending” alarms, meaning that the

alarms are activated when gas readings

rise above a pre-set alarm threshold.

Oxygen sensors have both “ascending” and

“descending” alarms, meaning that the

alarms activate when gas readings rise

above a pre-set alarm threshold or fall

below a pre-set alarm threshold. There is a

warning alarm and a danger alarm in each

direction.

Table 1.7 lists the available alarm levels

and span gas values for each sensor type.

Custom alarm levels and calibration gas

values may be set using BioTrak II

8

Page 11

software. Please see the BioTrak II

operation manual for instructions. The

alarm levels apply to both warning and

danger alarms, with the following

restrictions:

• Alarms can not be set to a value

above the full-scale range. If a range

is selected that is below current alarm

levels, the alarms will be adjusted to

default values for that range.

• The warning alarm can not be set

beyond the danger alarm setting.

Sensor

Available Alarm Levels

Type

(Process) High: OFF, 1.0, 2.0, 2.5, 5%

Oxygen (O2)

Combustible

(LEL display)

Combustible

display)

(CH

4

Carbon

monoxide

(CO, CO-H)

Hydrogen

sulfide (H

Sulfur Dioxide

(SO

S)

2

)

2

(Safety) High: 22.0, 22.5, 23.0, 23.5%

(Safety) Low: 20.0, 19.5, 19.0, 18.5, 18.0%

OFF, 0.25, 0.5, 0.75, 1.0, 1.25, 2.5% CH

OFF, 10, 25, 35, 50, 100, 150, 200 PPM

(Process) Low: OFF

OFF, 5, 10, 15, 20, 25, 50% LEL

OFF, 2, 5, 10, 15, 20 PPM

OFF, 2, 5, 10, 15, 20 PPM

Table 1.7 – Available alarm levels and calibration span gas settings

When an alarm set point is exceeded the

LEDs on the front panel and in the strobe

housing will flash (Yellow for Warning, Red

for Danger), and the audible alarm will

sound. Any external devices controlled by

means of the NXP’s alarm relay contacts

will also be activated.

Latching Alarms

NXP alarms are normally self-resetting.

When readings drop back below the preset alarm levels, the instrument returns to

normal operation, and the alarms and relay

contacts are turned off.

It is possible to set NXP’s alarms so that

they "latch". During latched operation,

once an alarm condition occurs, the visual

and audible alarms and relays will remain

active even after the atmospheric hazard

has cleared. They must be manually reset

using the MODE button. See section 5.6

for information on setting latching alarms.

Available

Span Gas

Settings

N/A

25, 30, 40, 50,

60% LEL

4

1.25, 1.5, 2.0, 2.5,

3.0% CH

35, 50, 75, 100,

150, 200 PPM

10, 20, 25, 30

PPM

10, 20, 25, 30

PPM

4

Alarm Acknowledgement

During an alarm condition, the audible

alarm and the strobe LEDs can be

acknowledged (temporarily deactivated) by

pressing the MODE button. The LEDs on

the display board and the alarm relays will

remain active. Once acknowledged, the

audible alarm and strobe LEDs will be

reactivated under the following conditions:

• Gas level remains above the alarm

level for 5 minutes

• Gas level decreases below the alarm

level, and then rises above it again

• Warning alarm was acknowledged, and

the gas level then rises above the

Danger alarm level

1.7.2 Sensor Over-range Alarms

If the concentration of the gas being

detected goes above the selected sensor

range, a sensor over-range occurs.

9

Page 12

The instrument will act as if a danger alarm

condition exists, even if the alarms have

been disabled.

• Oxygen and Toxic Gas Over-range

When the gas concentration falls back

within the sensor’s range, the over-range

alarm will be reset, unless latching alarms

have been selected.

• Combustible Gas Over-range

In the case of an LEL over-range condition

(LEL over 100%), power to the LEL sensor

will be disconnected to protect the sensor

from overheating and premature failure.

The instrument will remain in alarm with

the sensor powered down until the MODE

button is pressed or the instrument’s power

is cycled.

If the MODE button is pressed during this

time, power to the sensor will be turned on

briefly. If the gas level is below 100% LEL,

the sensor will remain on and the

instrument will resume gas detection

mode, along with any applicable alarms. If

the gas level is still over 100% LEL, the

sensor will be shut off again and the

instrument will remain in over-range alarm.

1.7.3 Alarm Relays

The NXP incorporates relays that are

activated during alarm conditions. There

are separate relays for Warning and

Danger alarms, as well as a Fault condition

relay (see section 1.8).

The Warning and Danger relays are

activated any time that the gas level

exceeds the current alarm levels. Each

relay has a normally-open and a normallyclosed contact. Normally-open contacts

close (make contact) during an alarm

condition, while normally-closed contacts

open (break contact).

These contacts can be used to operate

external alarms or larger relays that drive

other equipment, such as ventilation

systems. See Figure 2.5 for relay

connection locations.

The relay contacts in the NXP do not

supply power to the external accessories.

They act as switch contacts only. External

alarms, relays and contactors require their

own power supplies.

The maximum rating of the NXP’s relay

contacts is 30 VDC at 5 amps.

Under no

circumstances should AC line voltage

be connected directly to the relay

contacts.

1.8 Fault Conditions

The NXP is capable of detecting certain

internal fault conditions. During one of

these conditions the loop current will fall to

2 mA, the Fault relay will be activated, and

the red LEDs will flash every 5 seconds to

alert the user to the problem. Fault codes

are listed below. See Appendix B for

explanations of fault codes.

F1 - Sensor Fault

F2 – EEPROM Read Fault

F5 – EEPROM Write Fault

F11 – Power Low Fault

F12 – Power High Fault

Power Failure Fault

The Fault relay is normally energized. This

is called Fail-Safe mode. In the case of a

total loss of power to the instrument, the

Fault relay will trip, and any external

devices connected to it will be activated.

Loop current will fall to 0 mA.

Note: The Fault relay does not supply

power to the device(s) connected to it. It

acts as a switch contact only. External

power must be supplied to any devices

connected to this relay.

Under no

circumstances should AC line voltage

be connected directly to the relay

contacts.

1.9 Remote Sensors

The NXP normally comes with the sensor

housing attached to the instrument. When

necessary, the sensor can be installed

remotely, up to 50 feet from the instrument.

10

Page 13

The standard sensor can be used for nonhazardous (non-explosive) environments.

For use in hazardous locations, the XPR

explosion-proof sensor housing must be

used. The XPR is built into a heavy-duty

stainless steel explosion-proof housing. See

section 2.8 for remote sensor installation.

The XPR remote

sensor housing must not

be opened in

a hazardous location unless power to

the NXP has been disconnected. Power

must not be restored to the NXP until

the XPR housing has been completely

closed.

Installation of

explosion-proof housings must be

performed in accordance with local

regulations.

1.10 4-20 mA Current Loop

The NXP incorporates a connection for an

industry-standard 4-20 mA current loop.

This circuit generates a current based on

the gas level detected. The NXP is

normally set to “Source” mode, meaning

that it generates a current output. It can

also be set to “Sink” mode if needed,

meaning that it sinks (inputs) the current

from an external source.

A 4 mA signal indicates a reading of zero,

and a 20 mA signal indicates a full-scale

reading. Full-scale is determined by the

Loop Range setting in the Setup menu.

See Table 1.3 for available ranges and

section 5.4 for instructions on setting the

Loop Range. See Figure 2.5 for wiring of

the loop signal.

1.11 Event Logger

The event logger in the NXP stores data

associated with alarm conditions. Each

event (alarm) includes the following data:

• Event Start time

• Event End time

• Duration of the event.

• Minimum reading during event

• Maximum reading during event

• Average reading during event

• Temperature at end of event

• Sensor type

• Flags for ‘In calibration’, warning alarm,

danger alarm and temperature alarm

during event

• Time event was acknowledged

The NXP stores the data from the 128

most recent alarm events. Once 128

events have been stored, the NXP will

begin to overwrite the data from the oldest

event in memory with data from new

events. One event may be a combination

of different alarms occurring

simultaneously or in immediate

succession.

The event logger may be downloaded

using BioTrak II software. The PC must be

equipped with an IrDA port to provide a

connection.

While the NXP is

communicating through its IrDA

connection, it IS NOT

sensing the gas

level of the atmosphere, and WILL NOT

activate any alarms. The area must be

made safe or another form of

atmospheric monitoring must be used

during IrDA communication.

1.12 Firmware Upgrades

As improvements are made and features

are added to the NXP’s firmware, new

versions of the firmware will be made

available to customers. Normally, this

firmware can be downloaded and installed

by the customer using a computer with

IrDA communication capability and the

FX2 Flash Upgrade utility software.

Instrument firmware and upgrade utility

software can be downloaded from

http://www.biodownloads.com

in the

Download Section.

11

Page 14

2. Installation

2.1 Installation overview

Sperian Instrumentation’s gas detection

systems are fully tested and calibrated

before they leave the factory. Following

installation, Sperian strongly

recommends that full testing and

verification of proper operation be

carried out before the system is placed

in service.

Repair of system components damaged

as a result of improper installation can

be expensive. NXP Gas Detector Head

installation, initial setup, and/or system

modification should only be undertaken

by individuals who are qualified and

authorized to do so. Call Sperian’s

Instrument Service Department at (860)

344-1079 or 800-711-6776 if you need

help or have any questions.

Case and Mounting Dimensions (inches [mm])

Oxygen detector assemblies are available

in both standard (non-explosion-proof) and

remote explosion-proof (XPR) housings.

Toxic gas sensors are available in standard

(non-explosion-proof) housings, and certain

toxic sensors are also available in remote

explosion-proof (XPR) housings.

Remote detector assemblies for

combustible gas are only available in

explosion-proof (XPR) housings.

NXP Gas Detector Heads are equipped to

provide a 4-20 mA output that is used to

communicate with a remotely located

controller or PLC system. Each detector

head also has a built-in LCD readout for

local display of gas type and concentration.

When used in this type of configuration,

power is supplied to the detector by the

controller.

When used as a stand-alone detector,

power can be supplied to the detector

from a standard wall cube that is included

with the detector, or from an external

power supply with an output of 13-30

12

Page 15

VDC. In this configuration, the NXP must

be set to Source mode (see Figure 2.5).

ducts in which gases that are heavier than

air may collect.

2.2 Cautions

The NXP MUST be

installed in a non-hazardous area. Only

the XPR explosion-proof sensor

housing, if used, may be installed in a

hazardous location.

Disconnect the NXP Gas Detector Head

from any external power source and

from any battery backup power supply

before installing, replacing, or handling

system components.

Both the Gas Detector head and any

connected controller unit should be

calibrated and alarm levels tested at

the time of initial installation before the

system is first put into service.

2.3 NXP Detector Head

Environmental Ratings

The NXP housing has an environmental

rating of NEMA 4X and an ingress

protection rating of IP66. These ratings

apply to the NXP only, and do not extend

to the wall cube power supply. If the NXP

is to be installed in an area where it could

be exposed to pressurized jets of water,

wind-blown sand or dust, or other adverse

environmental conditions, it is

recommended that power be connected

through weather-proof cabling or conduit.

See section 2.7 for instructions on

removing the wall cube and connecting

external wiring.

2.4 Siting of detector heads

The specific placement of gas detector

heads should be determined by the type

of area being monitored, the type and

source of the atmospheric hazard being

measured, prevailing wind patterns, and

other information.

Call Biosystems Technical Service

Department at (860) 344-1079 or 800711-6776 for additional advice.

In general, for gases lighter than air the

detector heads should be placed at a level

slightly above the area where leaks are

likely to occur. For gases that are heavier

than air the detectors should be located

close to floor level or in inspection pits or

There are many circumstances that may

modify this general advice. It is beyond

the scope of this manual to attempt to

describe all of the potential situations that

could cause this advice to be modified,

but a single example follows:

The molecular weight of nitrogen (MW ≅

28) is very close to that of air (MW ≅ 29).

When nitrogen is at the same temperature

as the air into which it is introduced, it

mixes readily, and tends to spread evenly

throughout the affected atmosphere. On

the other hand, if the nitrogen is under

pressure, and then suddenly released into

the atmosphere, as the gas expands

(going from higher pressure to a lower

pressure) it cools. The cooler gas is

denser than the air into which it is being

introduced, so it no longer mixes as

readily. Instead, the nitrogen tends to sink

to floor level and spread laterally. In this

case remote detectors being used to

monitor for oxygen deficiency should be

located near floor level in order to detect

the deficiency as quickly as possible.

The nearer in density to air a gas is, the

more easily it will flow with air due to

drafts, ventilation etc. A compromise

approach for placement of detectors used

to measure gases which are only slighter

lighter (such as carbon monoxide) or

heavier (such as hydrogen sulfide) than

air is to mount the detectors at a height as

close as possible to the breathing area of

personnel being protected.

When installing detector heads it is

important to ensure that the sensor is not

exposed to liquid or dust contamination

that would interfere with the passage of

gas through the protective filter into the

sensor. Detector assemblies should be

placed so that the sensor points straight

downward. A splash deflector should be

used when water or other liquids are

chronically present in the area where the

detector is located.

2.5 Wiring requirements

Recommendations for wire used to

connect NXP detector assemblies to a

standard controller unit with a 24 VDC

power supply are listed in Table 2.5.

13

Page 16

Lower power supply voltages may require

larger size wire.

scale reading (100% LEL or a full-scale

oxygen or toxic gas reading).

Conductor

Size (AWG)

22 3 500

20 3 800

18 3 1200

16 3 2000

Number of

Conductors

Maximum

length (ft)

Table 2.5 NXP system wiring

recommendations

“Maximum length” indicates the maximum

distance a detector head may be located

from the controller when using the

indicated gauge of conductor. For all

types of detector assemblies, use 3conductor shielded cable with drain.

Due to the relatively low signal levels

carried by wiring between gas detectors

and the control unit, it is essential not to

run wire near high power electrical

equipment. When NXP heads are

installed in environments that contain high

power electrical equipment it is usually

best to install the wire in conduit.

The NXP wiring diagram is given below in

figure 2.5.

Remote Sensor Cable

The sensor can be placed remotely up to

50 feet away from the NXP (See section

2.8). Cable for connecting a remote

sensor to the NXP must be specified

when placing the order.

2.5.1 Grounding

Cable used to connect NXP gas detector

heads to a controller should always have

a shield and drain lead. In order to reduce

electromagnetic interference (EMI), the

screen (drain) of the cable should be

connected to the ground connection of the

detector head. Ground loops must be

avoided. Grounding is done through the

normal safety earth of the system.

2.6 Output Specifications

When the NXP is used with a controller,

the controller should be configured to

respond to an industry-standard 4-20 mA

current loop signal, with 4 mA indicating a

reading of zero (0% LEL, 0% O

or 0 PPM

2

toxic gas), and 20 mA indicating a full-

The NXP is shipped in Source Mode,

meaning it acts as the source of the loop

current. It can be switched to Sink Mode if

necessary by moving the jumper from J10

to J9 on the communication board, and

connecting the signal wire to pin 2 instead

of pin 3 on J1 (see Figure 2.5).

When used as a stand-alone instrument,

whether powered by a wall cube or

external power supply, the NXP must be

in Source mode.

2.7 External Wiring

The NXP is shipped with a wall cube

attached for ease of installation. In some

cases it may be desirable to use external

wiring instead, such as when connecting

the NXP to a controller or other power

supply, or when it is to be mounted in an

area where it could be exposed to water,

dust, or other harsh environments. To

install external wiring, follow the

instructions below.

1. Make sure that there is no power

applied to the NXP. Unscrew the four

screws on the cover. Pull the cover

straight out, and then swing it to the left.

2. Grasp the electronics assembly and

carefully pull it straight out from the

housing, being careful not to pull on the

attached wiring.

3. Unplug the 4-pin connector that is

plugged into J1 on the rear PCB. Using a

small screwdriver, loosen the wire contact

screws on the connector and remove the

wires.

4. Pull the wall cube wires out through the

back of the unit. From inside the housing,

screw the supplied #8 self-tapping screw

(with washer) into the hole where the wall

cube wires were removed.

5. Remove one of the plastic plugs from

either side of the housing. Depending on

the desired wiring, install either a 1/2”

NPT cable strain relief or a 1/2” NPT

conduit fitting, using Teflon tape on the

threads. Tighten firmly but do not

overtighten.

6. Route the wiring through the strain

relief or fitting and connect the wires to the

14

Page 17

connector. Refer to Figure 2.5 for the

correct connections.

7. Plug the connector into J1 on the PCB.

Reinstall the electronics assembly and

push until it is fully seated against the

standoffs to which it mounts.

8. Apply power to the NXP and ensure

correct operation. Make sure the cover

gasket is seated, close the cover and

tighten the cover screws securely.

Figure 2.5 NXP detector wiring diagram

15

Page 18

2.8 Remote Sensor Installation

The NXP normally comes with the sensor

housing attached to the instrument. When

necessary, the sensor can be installed

remotely, up to 50 feet from the instrument.

Follow the procedure below to connect the

sensor using a separately supplied remote

connector cable. Cables are available in

lengths of 5, 10 and 50 feet.

2.8.1 Disconnecting the sensor

Be sure that power is

removed from the NXP.

Unscrew the four cover screws on the

front of the NXP housing, then pull the

cover slightly away from the housing and

swing it open.

Grip the circular electronics assembly and

gently pull the assembly from its mounting

points. Disconnect the sensor cable from

the PCB connector.

Using a 1-1/8” wrench on the flat surfaces

just below the threads, unscrew the entire

sensor housing from the instrument

housing. There is no need to remove the

sensor housing cover.

2.8.2 Connecting the sensor cable

Apply Teflon sealing tape to the threads of

the metal thread adapter and install it in

the hole where the sensor housing was

removed. Tighten snugly, but do not

overtighten.

Apply Teflon sealing tape to the threads of

the strain relief, which can now be

installed into the metal thread adapter or

into one of the other ports near the top of

the unit. Close off any unused ports

(including the thread adapter, if not used)

with the plugs provided in order to

maintain the environmental integrity of the

enclosure.

Insert the female end of the sensor cable

into the strain relief outer nut, making sure

that the internal rubber grommet is in

place. Push several inches of the cable

into the instrument housing. Do not tighten

the nut yet.

Connect the cable to the PCB connector

where the sensor cable was removed. Be

sure to observe the correct polarity when

connecting the cable. When it is

connected, replace the electronics

assembly in the housing, pushing firmly

so that it seats on its mounting points.

Make sure that there are a few inches of

slack in the cable inside the housing, and

then tighten the strain relief nut until the

cable is grasped firmly.

2.8.3 Mounting the remote sensor

Thread the sensor housing into the

sensor connection box supplied with the

remote cable kit and tighten securely.

Mount the box in the chosen location with

the sensor housing facing downward.

Mounting the sensor in any other

orientation could allow water or debris to

collect on the sensor face, impairing

operation.

For explosionproof sensors in hazardous locations,

conduit is required from the sensor

connection box to the safe area. Check

local electrical requirements for proper

conduit and conduit seals.

2.8.4 Connecting the cable (non-

explosion-proof sensor)

Route the cable through any necessary

wire trays, conduit, etc., to the location of

the remote sensor. If using conduit,

remove the strain relief from the

connection box and connect the conduit

to the box. Otherwise, run the male end of

the cable through the strain relief and into

the box, using the procedure outlined in

section 2.8.2. See figure 2.8 for an

exploded view of the assembly.

Connect the cable to the sensor

connector, observing the polarity of the

connectors. Provide some slack inside

the box, and then tighten the strain relief

nut until the cable is grasped firmly.

Install the connection box cover, apply

power to the instrument and check for

proper operation.

2.8.5 Connecting the cable

(explosion-proof sensor)

For explosionproof sensors in hazardous locations,

16

Page 19

explosion-proof conduit is required

from the sensor connection box to the

safe area. Check local electrical

requirements for proper conduit and

conduit seals.

Route the cable through the conduit to the

location of the remote sensor.

Inside the sensor connection box, connect

the cable to the sensor connector,

observing the polarity of the connectors.

Close the connection box and tighten the

cover securely. Make sure any required

conduit seals are in place.

Apply power to the instrument and check

for proper operation.

Figure 2.8 Non-explosion-proof

remote sensor assembly

17

Page 20

3. Field Usage

Once the NXP has been installed and

connected to a power source, it will run

through a boot-up process, and then be in

continuous operation. During the boot-up

process, the following information will be

shown on the display:

• Power supply voltage

• LCD Test (All Segments On)

• Firmware Version

• “NEP” (Indicates Non-Explosion-

Proof Instrument)

3.1 Modes of operation

Press the MODE button to scroll through

the screens. The current gas reading

screen is shown during normal operation.

Detector heads equipped with toxic gas

sensors will display gas readings in partsper-million (PPM). Some sensors will

resolve readings to tenths of a part per

million.

• Sensor Type

• Loop Range (See Section 5.4)

• Instrument Serial Number

• Warning and Danger Alarm Levels

• Calibration reminder (if set)

• Bump Test reminder (if set)

• 10-second countdown

Gas readings are shown on the display on

the front of the detector. Toxic gas

readings are normally displayed in partsper-million (PPM), oxygen readings are

given in terms of percent volume (%Vol),

and combustible gas readings are given in

either percent LEL (LEL), or percent

volume methane (CH

).

4

Detector heads equipped with oxygen

sensors display readings in percent-byvolume. Fresh air contains 20.9% oxygen

by volume.

Detector heads equipped with

combustible gas sensors can display

readings in terms of either percentage of

the Lower Explosive Limit (%LEL) or

percent methane by volume (%CH4).

A reading of 100%

LEL or 5% CH4 indicates a potentially

explosive environment.

From the current gas readings screen,

press the MODE button once to view the

MAX reading screen. The MAX readings

screen displays the highest reading that

has been recorded by the instrument in

the past 24 hours.

18

Page 21

If the Calibration Interval has been set,

pressing the MODE button again within 8

seconds will display the number of days

until calibration is due.

↓

↓

↕

In addition, every 30 seconds the “CAL

dUE” reminder will appear on the display

and the red LEDs will flash.

↓

Similarly, if the Bump Interval has been

set, pressing the MODE button again

within 8 seconds will display the number

of days until a bump test is due.

See chapter 4 for instructions on

verifying sensor accuracy.

3.1.1 Calibration Due Warnings

When the NXP is due for calibration, the

triangular warning symbol is shown in the

current gas readings screen and the

calibration icon and green LED will blink.

3.2 Clearing the MAX reading

If it becomes necessary to clear the MAX

reading, press and hold the MODE button

for 4 seconds. The “MAX CLr” screen will

appear. Release the button within 4

seconds and a countdown will start. Press

the MODE button during the countdown

to reset the MAX reading to zero.

19

Page 22

3.3 Effect of contaminants on NXP

sensors

The atmosphere in which the NXP gas

detector head is located can have a

lasting effect on sensor accuracy.

Sensors may be poisoned or suffer

degraded performance if exposed to

certain substances.

There are three basic types of sensors

that may be installed in NXP detector

assemblies; galvanic oxygen, catalytic

hot-bead combustible gas (LEL), and

electrochemical toxic. Each type of

sensor uses a slightly different detection

principle, so the conditions that affect the

accuracy of the sensors vary from one

type of sensor to the next.

The accuracy of the

NXP should be checked immediately

following any known exposure to

contaminants by testing sensor

response with known concentration

test gas before further use. Failure to

check accuracy after a known sensor

exposure can lead to inaccurate and

potentially dangerous readings.

3.3.1 Effects of contaminants on

oxygen sensors

Oxygen sensors may be affected by

prolonged exposure to "acid" gases such

as carbon dioxide. The oxygen sensors

used in Sperian instruments are not

recommended for use in atmospheres

which continuously contain more than

25% CO

.

2

3.3.2 Effects of contaminants on

combustible sensors

Combustible sensors may be affected by

exposure to substances containing

silicone. For a complete list of known LEL

sensor contaminants, see the sensor

section of the Sperian Standard Warranty

in Appendix D.

Note: If sensitivity of the combustible

sensor is lost due to poisoning, it

tends to be lost first with regards to

methane.

A partially poisoned LEL sensor might still

respond accurately to propane while

showing a dangerously reduced response

to methane.

Sperian’s “Propane Equivalent”

calibration gas mixtures have been

developed to eliminate this potentially

dangerous source of calibration error.

Sperian’s “Propane Equivalent” mixtures

are based on methane so any loss of

sensitivity to methane is detected (and

can be corrected) immediately.

The combustible

sensor used in the NXP/XPR requires a

minimum of 10% oxygen by volume in

order to generate accurate

combustible gas readings.

Combustible sensor accuracy may be

diminished if the instrument is used in

oxygen-deficient atmospheres.

A rapid up-scale

reading may indicate a hazardous

combustible gas concentration that

exceeds the NXP’s detection range.

3.3.3 Effects of contaminants on

toxic gas sensors

Sperian uses “substance-specific”

electrochemical sensors that have been

carefully designed to minimize the effects

of common interfering gases.

“Substance-specific” sensors are

designed to respond only to the gases

that they are intended to measure. The

higher the specificity of the sensor the

less likely the sensor will be affected by

exposure to other gases which may also

be present. For instance, a “substancespecific” carbon monoxide sensor is

deliberately designed not to respond to

other gases that may be present at the

same time, such as hydrogen sulfide and

methane.

Even though care has been taken to

reduce cross-sensitivity, some interfering

gases may still have an effect on toxic

sensor readings. In some cases the

interfering effect may be “positive” and

result in readings that are higher than

actual. In other cases the interference

may be negative and result in readings

that are lower than actual.

20

Page 23

Cross sensitivity figures for toxic

sensors and common interfering gases

are listed in Appendix A.

3.4 Sensor Replacement

The sensor in the NXP is located inside

the sensor housing located on the bottom

of the instrument (see figure 1.5), or at the

remote sensor location.

If a remote XPR

(explosion-proof) sensor housing is

being used with the NXP, do not open

any part of the XPR’s housing in a

hazardous location unless power to the

NXP has been disconnected. Power

must not be restored to the NXP until

the XPR housing has been completely

closed.

To replace a sensor:

1. Remove power to the NXP.

Once the stabilization period has passed,

perform the Fresh Air Zero and the Gas

Calibration procedures as discussed in

sections 4.3 and 4.4.

2. Loosen the setscrew on the cover of

the sensor housing. Unscrew and remove

the cover.

3. Remove the metal collar around the

sensor by pulling it straight out of the

housing (do not twist). If the sensor did

not come out with the collar, remove it

separately.

4. Notice the small hole on the end

surface of the collar. Re-insert the collar,

lining up the hole with the pin on the

sensor adapter board. Make sure the

collar is fully inserted.

5. Line up the key on the new sensor with

the slot in the collar and push the sensor

into the collar until it mates with the

connector on the adapter board.

6. Install the sensor cover and screw it on

until it is fully seated against the sensor

housing base. Re-tighten the setscrew.

7. Apply power to the NXP. New sensors

must be allowed to stabilize prior to use,

according to the following schedule.

Sensor Stabilization

Period

Oxygen (O2) 1 hour

LEL 5 minutes

Toxic Sensors 15 minutes

21

Page 24

4. Verification of

Accuracy (Calibration)

4.1 Warnings and cautions concerning

verification of accuracy

The accuracy of the

NXP should be checked immediately

following any known exposure to

contaminants by testing with known

concentration test gas before further

use. Failure to check accuracy after a

known sensor exposure can lead to

inaccurate and potentially dangerous

readings.

A sensor that cannot

be calibrated or is found to be out of

tolerance should be replaced

immediately. An instrument that fails

calibration may not be used until

testing with known concentration test

gas determines that accuracy has been

restored, and the instrument is once

again fit for use.

Use of non-standard

calibration materials may lead to

dangerous error and may void

Biosystems standard warranty for gas

detection products. Customers are

strongly urged to use only Biosystems

calibration materials when calibrating

the NXP detector.

For detector heads that are used as part

of a detection system with a controller, it

is necessary to calibrate both the

controller and the gas detector head

when the system is first put into use.

Once the system has been properly

calibrated, the accuracy of the gas

detector head should be regularly verified

by exposure of the sensor to known

concentration test gas.

4.2.1 Calibration Interval

A regular schedule for ongoing

verification of gas detector head accuracy

should be set up. See Appendix C for

Sperian’s position on calibration

frequency.

The NXP has the ability to alert the user

when calibration is required. See section

5 for instructions regarding setting the

Calibration Interval.

When the calibration interval is reached,

the instrument will alert the user by

flashing “CAL dUE” and the gas bottle

icon on the display once every 30

seconds. The red alarm LEDs will also

flash.

→

The accuracy of

the NXP should be checked

periodically with known concentration

calibration gas. Failure to check

accuracy can lead to inaccurate and

potentially dangerous readings. See

Appendix C for Sperian’s position on

calibration frequency.

4.2 Overview of verification of

accuracy

NXP Gas Detector Heads have been

designed for easy single-person

calibration. The MODE button is located

on the display board and is used to enter

the Calibration and Test modes. The LCD

readout provides ongoing readings and

messages at the detector head during

calibrations and bump tests.

4.2.2 Special Instructions for Fixed

Gas Detectors

Fixed detectors are commonly located in

environments in which the purity of the

ambient air is unknown. In this case, a

cylinder of “Zero Air”, which contains

20.9% oxygen and no contaminants, must

be used to verify that the detector is

displaying the correct readings for a fresh

air atmosphere, and to perform a fresh air

calibration when necessary. “Zero Air” is

available from Sperian.

A second cylinder of gas is also required

for instruments equipped with toxic and

combustible gas sensors, so it is not

unusual to use two cylinders of calibration

gas to calibrate a fixed gas detector.

4.2.3 Accuracy of Oxygen Sensors

Oxygen detectors should read 20.9% in a

fresh air environment.

22

Page 25

If the oxygen detector is reading anything

except 20.9% when exposed to fresh air,

it should be fresh air calibrated as

discussed in section 4.3.

As discussed in section 4.2.2, a cylinder

of “Zero Air” must be used during the

fresh air calibration if there is any reason

to question the purity or composition of

the ambient atmosphere.

If a cylinder of “Zero Air” is to be used to

provide the fresh air source during the

fresh air calibration, connect the cylinder

to the detector and flow gas to the sensor

for 30 seconds before beginning this

procedure.

To initiate the fresh air calibration, press

the MODE button three times quickly in

succession.

4.2.4 Accuracy of Toxic and LEL

Sensors

In a fresh air environment, toxic gas

detectors should read 0 PPM and LEL

detectors should read 0% LEL.

If the toxic or LEL detector reads anything

other than zero when exposed to a known

source of fresh air, it should be fresh air

calibrated as discussed in section 4.3.

As discussed in section 4.2.2, a cylinder

of “Zero Air” must be used during the

fresh air calibration if there is any reason

to question the purity or composition of

the ambient atmosphere.

The second step (for toxic and LEL

sensors only) is to expose the sensor to

known concentration test gas and note the

sensor response. To test sensor

response in the NXP, place the detector in

Test Mode as discussed in section 4.5

and apply calibration gas.

During the sensor response test, toxic and

LEL readings are considered accurate if

the readings are between 90% and 120%

of the expected value as given on the gas

cylinder. If readings are accurate, then

the instrument requires no further

adjustment. Toxic and LEL readings that

do not fall between 90% and 120% of the

value on the cylinder are considered

inaccurate and indicate that the sensor

must be calibrated before further use as

discussed in sections 4.3 and 4.4.

4.3 Fresh air calibration

As discussed in section 4.2.2, fixed

systems are often used in locations where

the ambient air may not be fresh. In these

situations it is necessary to use a cylinder

of “Zero Air” to provide a known source of

contaminant-free air with 20.9% oxygen

for the fresh air calibration.

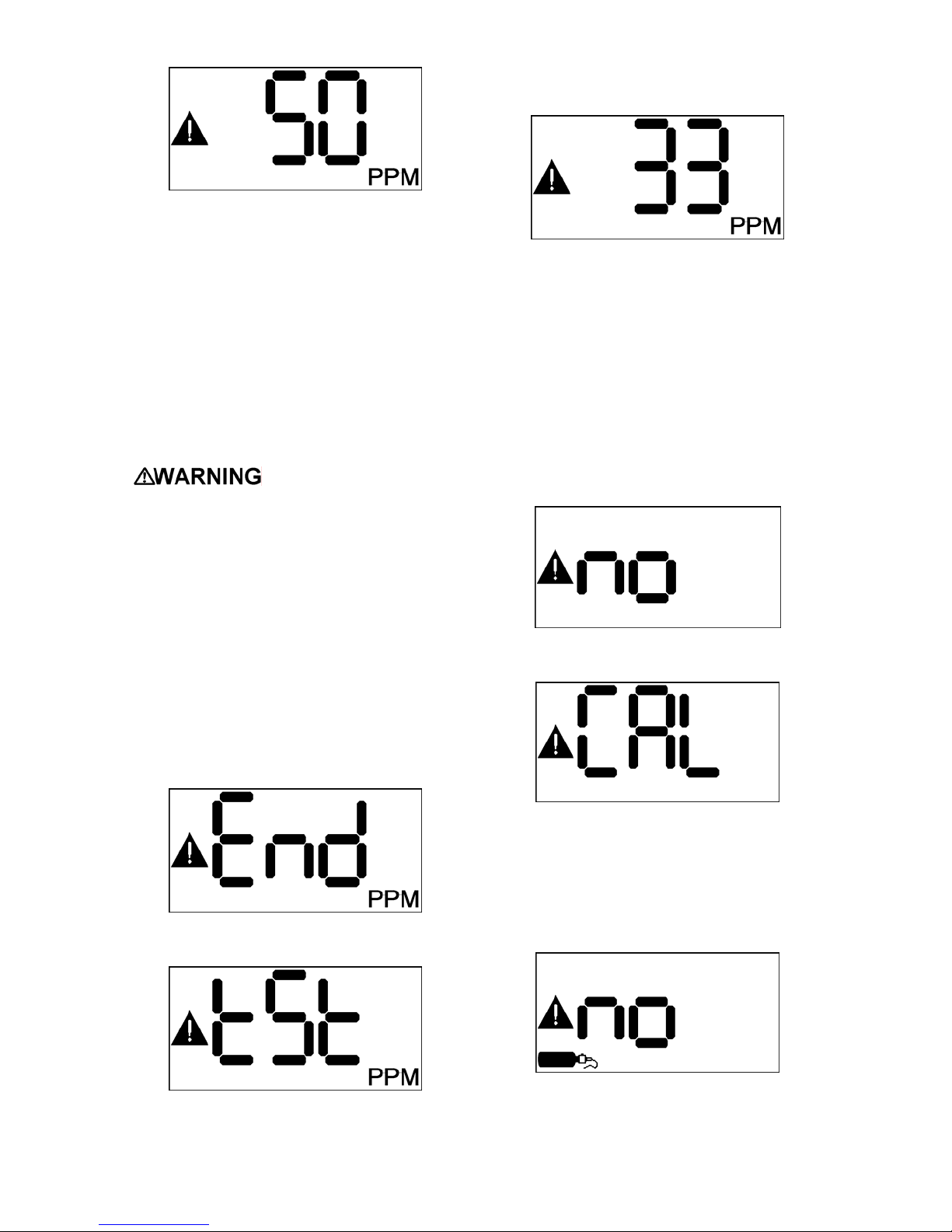

The detector head will show “CAL” with

the triangular warning symbol and

proceed to a 5-second countdown. The

triangular warning symbol is lit in this

case to let the user know that the gas

alarms will be disabled for the duration of

the fresh air calibration procedure.

↓

Press the MODE button prior to the end

of the countdown to initiate the fresh air

calibration. The screen will show

alternating left and right zeroes during the

process with the warning icon lit to show

that the alarms are disabled.

↕

23

Page 26

Following successful zero calibration,

NXP detectors with toxic or combustible

gas sensors will proceed to the span

calibration routine and will begin another

5-second countdown with the calibration

bottle icon lit.

To conclude the fresh air calibration

without performing a span calibration,

allow the countdown to reach zero without

pressing the MODE button. The NXP will

then return to the current gas reading

screen.

Connect the cylinder with the span

calibration gas to the detector and flow

gas to the sensor.

Customers are

strongly urged to use only Sperian

calibration materials when calibrating

the NXP. Use of non-standard

calibration gas and/or calibration kit

components when calibrating the NXP

can lead to inaccurate and potentially

dangerous readings and may void the

standard Sperian warranty.

4.4 Span calibration of Toxic and

LEL sensors

To initiate the span calibration routine for

toxic and LEL sensors, first complete the

fresh air calibration as detailed in section

4.3. A second 5-second countdown will

begin. The calibration cylinder icon will be

lit to let the user know that this countdown

is for the span calibration routine.

Press the MODE button before the

countdown concludes to initiate the span

calibration. If a cylinder of “Zero Air” was

used to provide fresh air during the fresh

air calibration, the cylinder should be

disconnected from the detector now.

The screen will alternate between GAS

and the expected calibration gas level.

The expected

calibration gas values should match the

applied gas values from the calibration

tank. Failure to ensure that these

numbers match can lead to inaccurate

and potentially dangerous readings

which could result in serious injury or

death.

Sperian Instrumentation offers calibration

kits and long-lasting cylinders of test gas

specifically developed for easy NXP

calibration.

Once gas is detected, the current reading

is shown with the bottle icon to show that

the detector is in calibration mode.

Once the instrument successfully

completes the span calibration, it will

display the maximum span calibration

adjustment value for two seconds. The

calibration gas should be removed at this

time.

↕

Following the Max Span screen the

instrument will continue to show the

current gas reading without the alarms in

order to allow the readings to drop back

below alarm levels. The triangular

24

Page 27

warning symbol will remain on to remind

the user that alarms are currently

disabled.

Once the readings drop below the alarm

level threshold the detector will return to

normal operation. However, alarms will be

enabled again in 60 seconds regardless of

the gas level.

↓

The span calibration mode can be

canceled at any time by pressing the

MODE button. If the sensor has not

detected the presence of calibration gas,

the detector returns immediately to normal

operation. If calibration gas was detected,

the “alarms off” settling time described

above will occur.

4.5 Test Mode

The Test Mode is used to verify accuracy

without performing a full calibration. This

type of test is commonly referred to as a

bump test. While the instrument is in Test

Mode, it will not go into alarm despite the

fact that the instrument may detect levels

of gas that exceed the alarm threshold.

For detectors that are used with a

controller, during Test Mode the detector

will send a signal to the controller that

mimics a fresh air reading to keep the

controller from registering an alarm

condition.

While in test mode, the green and yellow

LEDs will blink once every 10 seconds to

remind the user that alarms have been

disabled.

Allow the countdown to reach zero. The

test countdown will then be shown.

↓

Press MODE before the end of the

countdown to enter Test Mode. The

screen will alternate between “tSt” and

the gas reading for the duration of the

test.

To enter the Test Mode, press the MODE

button three times quickly in succession

as if to enter the Fresh Air Calibration

routine. The screen will show CAL and

begin a 5-second countdown.

↕

25

Page 28

Apply a known concentration calibration

gas to the sensor. Toxic and LEL readings

are considered accurate if the readings

are between 90% and 120% of the

expected value as given on the gas

cylinder. If readings are accurate, then

the instrument requires no further

adjustment. Toxic and LEL readings that

do not fall between 90% and 120% of the

value on the cylinder are considered

inaccurate and indicate that the sensor

must be calibrated before further use as

discussed in sections 4.3 and 4.4.

Customers are

strongly urged to use only Sperian

calibration materials when calibrating

the NXP. Use of non-standard

calibration gas and/or calibration kit

components when calibrating the NXP

can lead to inaccurate and potentially

dangerous readings and may void the

standard Sperian warranty.

be lit to show that the alarms are off until

the readings fall below the alarm levels.

The instrument will automatically exit Test

Mode if the MODE button is not pressed

within 5 minutes.

4.6 Calibration Failures

4.6.1 Fresh Air Calibration Failure

If the NXP is unable to complete the fresh

air calibration, the instrument will show

“no CAL” and then the countdown for Test

Mode before returning to the current gas

reading screen.

Sperian Instrumentation offers calibration

kits and long-lasting cylinders of test gas

specifically developed for easy NXP

calibration.

Press MODE to end the test and resume

normal gas reading mode.

↓

The detector will then return to the current

gas reading screen. The warning icon will

↕

4.6.2 Span Calibration Failure

If the NXP is unable to complete the span

calibration, the instrument will show “no

CAL” with the calibration cylinder icon

before returning to the current gas

reading screen.

↕

26

Page 29

If the NXP is unable to complete the span

calibration because it completely fails to

detect gas, it will show “no GAS” before

returning to the current gas reading

screen.

↕

5. LEL only: Wrong type of combustible

calibration gas. LEL calibration gas may

be based on several different response

standards; methane, propane and

pentane are the most common. If using a

new cylinder of calibration gas, make sure

that the type and concentration of

combustible gas is identical to that of the

previous bottle. Sperian Instrumentation

offers calibration gases in Methane,

Propane Equivalent and Pentane

Equivalent.

6. Inoperative sensor. Contact Sperian

Instrumentation for a replacement sensor.

7. Instrument problem. Contact Sperian

Instrumentation’s Instrument Service

department at the phone number on the

front of this manual.

Possible causes of span calibration

failure and remedies:

1. Empty calibration gas cylinder. Verify

that there is calibration gas in the cylinder.

2. Expired calibration gas cylinder. Verify

that the expiration date on the cylinder

has not passed.

3. Calibration equipment not connected

correctly. Check all connections between

cylinder, regulator, tubing, calibration

adapter and sensor.

4. Calibration gas setting does not

correspond to calibration gas

concentration. The default calibration gas

concentration is stored in the instrument’s

memory. If the value on the calibration

cylinder is different from the instrument’s

calibration gas setting, the calibration gas

setting must be changed to match the new

value, or the correct value calibration gas

must be obtained. Calibration gas value

can be changed by accessing the setup

menu with the MODE button as discussed

in section 5.

27

Page 30

5. Configuration

The following section explains how to set

up the NXP using the setup menu and

MODE button. All of the features in the

setup menu are also available through

IrDA communication using Sperian’s

BioTrak II software. Please see the

BioTrak II manual for instructions.

The NXP includes a setup menu that

allows the user to set up various

parameters and functions. The menu is

accessed though the MODE button.

5.1 Accessing the Setup menu and

Submenus

To access the Setup Menu, press and

hold the MODE button. The current gas

reading screen will be replaced with the

MAX Clr screen after about 3 seconds.

Continue to hold the button. In a few more

seconds, “SEt” will be shown.

The Setup menu and all of the submenus

are on a 5-second clock. To enter one of

the submenus, press the MODE button

while the submenu item is shown. To skip

over a submenu, do nothing. Once 5

seconds have passed the NXP will

automatically move to the next submenu.

This will continue until the final submenu

is reached. At the end of the 5-second

countdown for the final submenu, if the

MODE button is not pressed, the NXP will

return to the current gas reading screen.

The operating logic in the submenus is the

same as the operating logic in the main

menu. In each of the submenus, press

the MODE button to go deeper into the

submenu, or to make changes. Do

nothing to move on to the next submenu

item without making changes. Once the

final item in a submenu is reached, the

NXP will return to the next higher

submenu.

Release the MODE button. “UP” will be

shown, then a 5-second countdown will

start. To enter the setup menu, press the

MODE button before the countdown

reaches zero. To return to the gas

reading screen, do nothing. Once 5

seconds have passed, the NXP will

display the current gas reading.

Once in the setup menu, the NXP will

display “Set dAt”.

↔

The instrument will automatically scroll

through all of the menu choices. See the

flow chart in section 5.2 for details.

28

Page 31

5.2 Setup Submenu Flow Chart

Depending on the installed sensor, some of the following menu choices may be

unavailable. See individual sections for more information.

= Back to gas reading

+ = Enter Setup Menu

+ = Set Date, Time (see 5.3)

+ = Set Loop Range (see 5.4)

+ =

Set Alarm Levels (see 5.5)

+ = Set Alarm Latch (see 5.6)

+ = Set Combustible Sensor Display (see 5.7)

+ = Set Calibration Gas Level (see 5.8)

+ = Set Calibration Interval (see 5.9)

After the Bump Interval menu, the display will return to the current gas reading.

+ = Set Bump Test Interval (see 5.10)

29

Page 32

5.3 Set Date and Time

The first submenu controls date and time

functions. “SEt” “dAt” will be shown.

↔

Press MODE again within 5 seconds to

set date and time. “Set” Yr” will be shown.

attached 4-20 mA controller. Range

adjustment or recalibration of the

controller may be necessary.

5.5 Set Alarm Levels

↔

5.5.1 Setting alarms for Toxic and

Combustible gas sensors

↔

Press MODE again within 5 seconds to

view and/or change the year setting.

↔

Hold the MODE button to change the

year. Once the year is set, release the

MODE button and wait 5 seconds. The

display will cycle through month (Mo), day

(dAY), hour (Hr), and minute (Mn). For

each of these, press the MODE button to

view the curent value. Hold the MODE

button to change as necessary, or wait 5

seconds to keep the current value.

5.4 Set Loop Range

Press the MODE button within 5 seconds

to view the loop range setting. This setting

determines the value that corresponds to