Page 1

AIR-PURIFYING RESPIRATOR

Series 4000

FULL FACEPIECE

WARNING

DO NOT USE this respirator until you completely read and understand this instruction manual. You are

required to inspect your respirator prior to putting it into eld service. Please refer to the inspection

procedures in this manual.

I. INTRODUCTION

This manual provides instruction in the use and maintenance of the SPERIAN Series 4000 Full Facepiece AirPurifying Respirator. You must read and understand

this manual and be trained in the proper use of this

respirator before wearing it in a contaminated at-

mosphere.

The following table lists the current models available.

Model Description

410010 Small Facepiece, Blue, 4-Strap

410015 Small Facepiece, Blue, 5-Strap

410071 Small Facepiece, Blue, 4-Strap with Nose Cup

410075 Small Facepiece, Blue, 5-Strap with Nose Cup

410079 Small Facepiece, Black, 5-Strap with Nose Cup

410090 Small Facepiece, Black, 5-Strap

420010 Standard Facepiece, Blue, 4-Strap

420015 Standard Facepiece, Blue, 5-Strap

420071 Standard Facepiece, Blue, 4-Strap with Nose Cup

420075 Standard Facepiece, Blue, 5-Strap with Nose Cup

420079 Standard Facepiece, Black, 5-Strap with Nose Cup

420090 Standard Facepiece, Black, 5-Strap

II. SAFETY PRECAUTIONS

The Warnings, Cautions, and Notes contained in this

manual have the following signicance:

WARNING

Maintenance or operating procedures

and techniques that will result in personal injury or death if not carefully followed.

NOTE

Maintenance or operating procedures and techniques or information considered important enough

to emphasize.

III. DESCRIPTION

This SPERIAN air purifying respirator consists of a

full facepiece made of pliable silicone rubber with two

threaded connectors for attaching particulate lters, gas

and vapor cartridges, and cartridge/lter combinations

as required for specic contaminant protection.

WARNING

• The employer is responsible for establishing that this

respirator is suitable for the user’s applications.

• This facepiece must be worn and used as specied in

SPERIAN’s instructions.

• Your SPERIAN respirator has been constructed of

materials selected for their performance, safety,

and durability. However, all materials have exposure

limitations to extremes of heat and cold or to the many

chemicals in use today, and could be degraded by

exposure beyond their limitations, creating conditions

in which this SPERIAN equipment would be dangerous

to use.

• Before entering an environment while wearing SPERIAN

equipment, you must conduct safe, scientic tests

to determine if the environment could render the

equipment unsafe. Results of this testing should be

well documented. Seek the help of a certied safety

professional or industrial hygienist. DO NOT USE this

equipment if the user would be endangered in any way

through environmentally induced degradation of the

materials

CAUTION

Maintenance or operating procedures and

techniques that will result in damage to

equipment if not carefully followed.

©

Copyright Sperian Respiratory Protection USA, LLC

April 2008 All Rights Reserved

P/N 420094 REV C 03/09

AN ISO 9001

REGISTERED

COMPANY

Sperian Respiratory Protection USA, LLC

3001 South Susan St., Santa Ana, CA 92704

Toll-Free 888.APR.SCBA or 714.545.0410

Fax 714.850.0299

www.sperianprotection.com

Page 2

in the apparatus. SPERIAN cannot be responsible for

damage to property, personal injury, or death in which

environmental exposure is a contributing factor.

• Do not use this respirator in environments where the

concentrations of contaminants are unknown, or where

the atmosphere is immediately dangerous to life or

health (IDLH). IDLH atmospheres are dened as:

1. Those which the wearer could not breathe for short

periods.

2. Those from which the wearer could not escape

without the aide of the respirator.

3. Those which have an immediate or delayed adverse

effect on health.

• Never use this respirator without appropriate SPERIAN

cartridges/lters identied on the NIOSH approval label

securely threaded onto the face piece.

• This respirator does not supply oxygen and must not be

used in the atmospheres containing less than 19.5%

oxygen by volume.

• Our engineers cannot predict what will happen to this

equipment in every potential environment. Materials

can be chemically attacked if exposed to the wrong

environment and may exhibit excessive corrosion or

other forms of damage. Permeation of gases and liquids

through the materials could be excessive. Extreme of

temperature might cause thermal degradation. Each of

these things, or a combination of them, could crated

conditioning with this SPERIAN equipment would be

dangerous to use.

• All persons using this SPERIAN breathing apparatus

must be amde aware of its limitations.

We cannot be responsible for any damage to property,

personal injury, or dath in which environmental

exposure is a contributing factor.

• Always read cartridge labels prior to use to be certain

that you have cartridges and/or lters that will provide

the required protection. Cartridges/lters labeled for

protection against particulate only shall not be used

for gases/vapors, and cartridges/lters labeled for

protection against gases/vapor only shall not be used

for particulates:

• Immediately return to a non-contaminated area if:

a. You taste or smell contaminates , or if your eyes,

nose, or throat become irritated. blasting, underwater

diving, or interior structural re ghting.

b. Breathing becomes difcult.

c. The air you are breathing becomes uncomfortably

warm.

d. You feel nauseous or dizzy.

• This respirator does not protect exposed areas of the

body. Some contaminates can be absorbed directly

through the skin while other may irritate exposed area.

• This respirator must not be used for abrasive blasting,

underwater diving, or interior structural re ghting.

WARNING

• Do not use this respirator at temperatures below -30°F

(-1°C) or above 130°F (71°C). Do not wear this respirator

if a satisfactory t, as determined by a qualitative or

quantitative t test, cannot be obtained. See ANSI

Z88.2 1992 and OSHA Standards for Asbestos and

Lead. Beards, stubble, or sideburns will prevent a good

facepiece seal. Do not use this respirator unless you

are clean shaven. Absence of one or both dentures can

seriously affect the t of the facepiece.

• No respirator can provide complete protection from all

conditions. Use extreme care for emergency operations.

Do not use this respirator for applications involving

exposure to high heat or direct ame.

• Accessories not offered by SPERIAN may degrade

performance, and will void NIOSH certication.

• NEVER use this respirator without SPERIAN cartridges

or lters securely threaded onto the facepiece. This

respirator must be used in conjunction with a written

respirator program meeting the requirements of the

OSHA Standard for Respiratory Protection, 29 CFR

1910.134, available from the U.S. Department of Labor,

Occupational Safety and Health Administration. The

program must include procedures for evaluating air

contaminants and selecting appropriate respirators,

procedures for proper use of respirators, procedures

for testing the facepiece-to-face t of respirators,

procedures for cleaning, disinfecting, inspecting,

maintaining, and storing respirators, procedures for

determining if workers are physically and medically

capable of wearing respirators, and procedures for

training employees in the use of respirators and in

recognizing the hazards associated with contaminants

in the work place. When used with a written respirator

program, this respirator will reduce, but not eliminate

the inhalation of contaminants.

• SPERIAN respirators, accessories, and associated

equipment should not be used in atmospheres which

may contain contaminant concentrations above the

lower explosive level (LEL). Intrinsic safety certication

of electronic components does not eliminate potential

danger from ignition in these atmospheres.

• FAILURE TO OBSERVE ALL WARNINGS MAY RESULT IN

PERSONAL INJURY, SERIOUS ILLNESS, OR DEATH.

2

Page 3

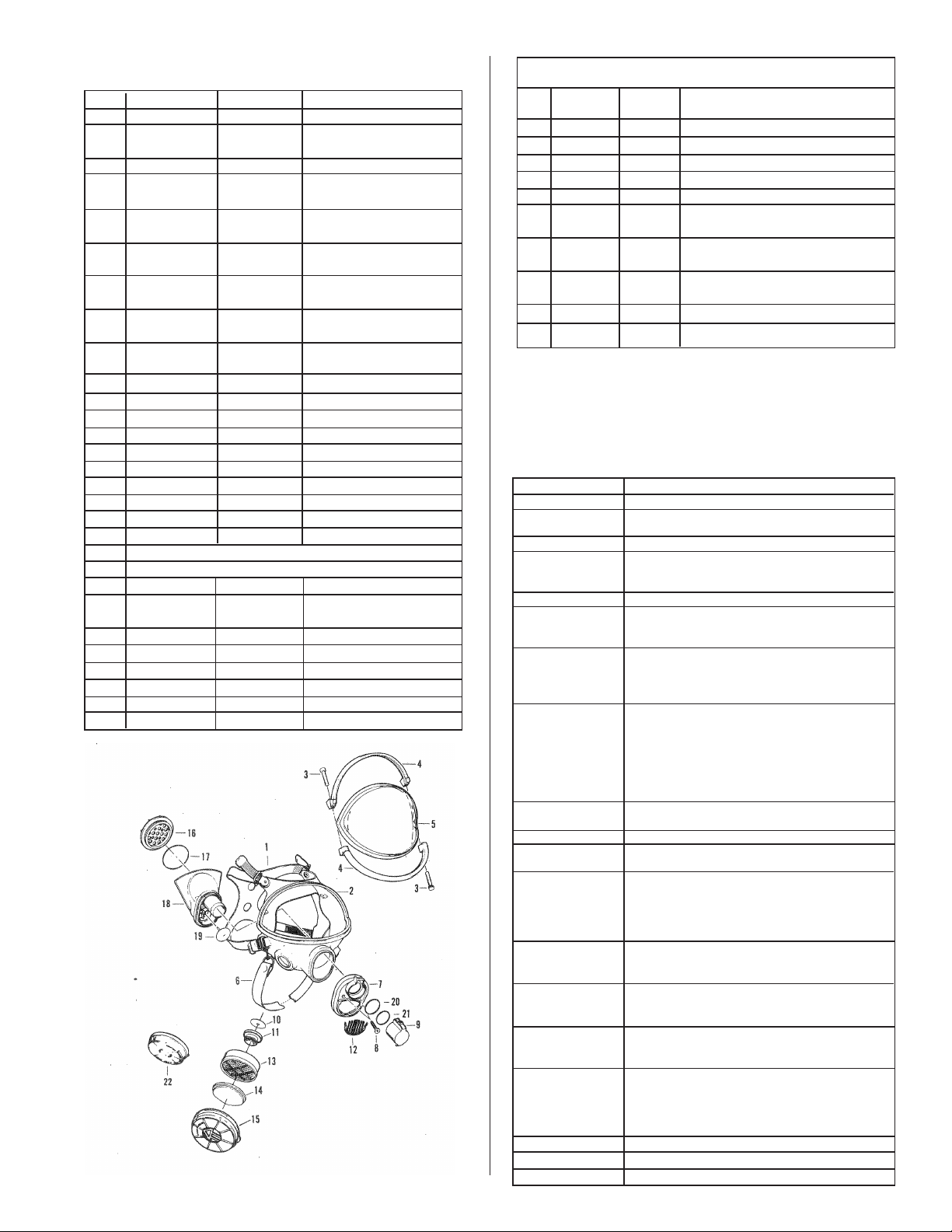

IV. PARTS LIST

ITEM QTY. (Ea.) P/N DESCRIPTION

1 1 941723 Headstrap, 4-Strap, Blue

968424 Headstrap, 5-Strap,

Black

961094 Headstrap, 5-Strap, Blue

2 1 420002 Standard Skirt, 4-Strap,

Blue

420003 Standard Skirt, 5-Strap,

Black

420081 Standard Skirt, 5-Strap,

Blue

1 410002 Small Skirt, 4-Strap,

Blue

410003 Small Skirt, 5-Strap,

Black

410081 Small Skirt, 5-Strap,

Blue

3 2 839102 Screw

4 2 941280 Rim

5 1 941712 Lens

6 1 940135 Strap Assy.

7 1 520039 Cover

8 2 955805 Screw

9 1 420020 Cap

10 1 pkg. of 6 140001 Inhalation Valve

11 1 pkg. of 2 140002 Threaded Connector

12 1 420008 Grill

13 Cartridges —See Table 1

14 Filters — See Table 1

15 1 140079 Filter Retainer

16 1 941759 Speaking Diaphragm

Assy.

17 1 820031 O-ring

18 1 980081 Nozzle

19 1 pkg. of 4 140003 Exhalation Valve

20 1 824014 Leak Check O-ring

21 1 824014 Cap O-ring

22 1 981177 Filter Shower Cap

Figure 1. Series 4000 APR

ACCESSORIES

P/N DESCRIPTION

980003 Spectacles Kit

980017 Nose Cup Kit

140095 Lens Cover

951015 Anti-fog Solution (1 oz.)

951016 Anti-fog Solution (16 oz.)

430000 Welding Shield, Standard Weld

ing Plate

430030 Welding Shield, Auto-Dark, Vari

able 9-12 Shade

430040 Welding Shield, Auto-Dark, Fixed

10 Shade

430005 Welding Bib, Lower

430010 Welding Bib, Upper

NOTE

Use only components with the part numbers listed on the

NIOSH approval label. Use of any other components will

void the approval.

TABLE 1. CARTRIDGES AND FILTERS

MODEL NO. CARTRIDGES

100100 Organic Vapors

100200 Acid Gases: Sulfur Dioxide, Chlorine, Hy

drogen Chloride, Formaldehyde

100300 Organic Vapors and Acid Gases: Organic

Vapors; Sulfur Dioxide, Chlorine, Hydrogen

Chloride, Chlorine Dioxide, Hydrogen Fluo

ride, Hydrogen Sulde (Escape Only)

100400 Ammonia and Methylamine

109100 Combination Organic Vapors; HEPA;

Dusts, Fumes, and Mists; Pesticides; and

Mists of Paint, Lacquer, and Enamel

109200 Combination Acid Gases; HEPA; and

Dusts, Fumes, and Mists: Sulfur Dioxide,

Chlorine, Hydrogen Chloride; HEPA; Dusts,

Fumes, and Mists

109300 Combination Organic Vapors; Acid Gases;

HEPA; Dusts, Fumes, and Mists; and

Pesticides: Organic Vapors; Sulfur Dioxide,

Chlorine, Hydrogen Chloride, Chlorine

Dioxide, Hydrogen Fluoride, Hydrogen

Sulde (Escape Only); HEPA; Dusts,

Fumes, and Mists; Pesticides

109400 Combination Ammonia; Methylamine; HEPA;

and Dusts, Fumes, and Mists

1091 Combination Organic Vapors and P100

1092 Combination Acid Gases and P100: Sulfur Diox

ide, Chlorine, Hydrogen Chloride; and P100

1093 Combination Organic Vapors; Acid Gases;

and P100: Organic Vapors; Sulfur Dioxide,

Chlorine, Hydrogen Chloride, Chlorine Dioxide,

Hydrogen Fluoride, Hydrogen Sulde (Escape

Only); and P100

1094 Combination Ammonia; Methylamine; and

P100

FILTERS

101000 Dusts and Mists when used with 100100,

100200, 100300, or 100400 cartridge, and

140079 retainer.

102000 Paint, Lacquer, and Enamel Mists, and Dusts

& Mists when used with 100100 cartridge and

140079 retainer.

104000 Pesticides; Paint, Lacquer, and Enamel

Mists; and Dusts, Fumes, and Mists when

used with 100100 cartridge and 140079 retainer.

Dusts, Fumes, and Mists when used with

100300 cartridge and 140079 retainer.

109000 HEPA; and Dusts, Fumes, and Mists

1090 P100

1195 P100 Disk

3

Page 4

WARNING

Following is a partial list of materials for which these respirators

MUST NOT be used. This list is far

from complete. Contact SPERIAN

for information on other materials.

Acroline Hydrogen Selenide

Aniline Isocyanates: TDI, HDI, MDI

Arsine Methanol

Boron Hydrides Methylene Chloride, Methyl

Bromine Nitro Compounds:

Carbon Dioxide

Carbon Monoxide

Carbonyls

Cyanogen

Dimethylaniline Ozone

Dimethyl Sulfate Phosgene

Ethyl Cyanide Phosphine

Fluorine Phosphorous Trichloride

Hydrogen Cyanide Stibine

Sulfur Chloride Vinyl Chloride

V. USE INSTRUCTIONS

Bromide, Methyl Chloride

Nitrogen Oxides

Nitroglycerin

Nitrobenzene

Nitromethane

A. Filter/Cartridge Installation

Ensure that you have the correct lter and/or 1.

chemical cartridge for the specic contaminants in

your work area. If you are not sure, consult your

supervisor or safety professional.

Thread the P100 or HEPA lters or correct chemi-2.

cal cartridges onto the facepiece connectors.

Carefully hand-tighten, ensuring a good seal 3.

against the facepiece. Do not over tighten.

To install lter pads, insert the correct lter pad 4.

into the lter retainer with the side stamped with

the part number facing the wearer.

Snap the lter retainer onto the chemical car-5.

tridge.

When using the transparent lter retainer, P/N 6.

140079, inspect the assembly through the re-

tainer and ensure that:

The edge of the lter makes contact with the a.

entire retainer wall.

The lter is not bunched or folded.b.

The lter completely covers the top of the c.

cartridge.

B. Donning

WARNING

Always read cartridge labels prior to use to

be certain that you have cartridges and/or

lters that will provide the required protection. Cartridges/lters labeled for protection

against particulates only shall not be used

for gases/vapors, and cartridges/lters labeled for protection against gases/vapors

only shall not be used for particulates. Both

cartridges/lters must be of the same type.

Inspect the respirator as described in section VI, 1.

paragraph B.

Adjust the top facepiece straps until one inch of 2.

strap extends through each buckle. Fully loosen

the lower straps.

Place the neck strap around the back of your 3.

neck.

Place your chin against the chin cup and center 4.

the facepiece.

Grasp the facepiece with your hand, and pull the 5.

straps over your head.

Tighten the bottom straps until a good seal is ob-6.

tained. Adjust the top straps if required.

For the 5-strap facepiece, tighten the lower straps, 7.

the temple straps, then the top strap, until all the

headstraps lie at on your head.

NOTE

When properly adjusted, the headstrap hub should

be centered on the back of your head, and the lower

straps should be below your ears.

C. Facepiece Fit Check

WARNING

If a leak-tight seal is not obtained during the

following t checks, do not wear the respirator. Ask your supervisor or safety professional for assistance.

1. Positive Pressure Fit Check

a. Hold your palm over the exhalation valve grill.

b. Exhale gently to create a positive pressure

inside the facepiece.

c. If leakage occurs, readjust facepiece and

straps until leak-tight. If you are unable

to obtain a proper fit, consult your safety

professional.

2. Negative Pressure Fit Check

a. Remove the lters and cover the lter inlets

with your hands and inhale gently. Hold your

breath for a few seconds. The facepiece

should collapse on your face without leaking.

b. If the facepiece leaks, reposition, check straps,

and repeat the leak check.

c. If a good t was achieved, reinstall the lters.

D. Using the Respirator

To receive the maximum protection available from your

respirator, you must follow your employer’s instructions

on the use and maintenance of the respirator. Read and

understand the following warnings prior to using the

respirator.

WARNING

● Never remove your respirator for any reason while you are in the work area.

● You must leave the work area immediately

if the face piece seal is disturbed for any

reason, such as:

4

Page 5

Warning —Continued

a. Slipping due to excessive sweating or

excessive head movement.

b. The facepiece becomes dislodged as a result

of being knocked.

c. You sneeze or cough while wearing the

facepiece.

d. You need to blow your nose, scratch covered

areas of your face, or need to adjust your

spectacles kit.

e. For any other reason that would cause the

facepiece seal to be disturbed.

You must restore the facepiece seal and perform

a t check before reentering the work area.

G. Cartridge Replacement

The cartridges must be replaced whenever you smell

or taste contaminants, or if your eyes, nose, or throat

become irritated. Cartridges must also be replaced

if they show any sign of damage. Dispose of used

cartridges in accordance with applicable local, state,

and federal guidelines.

Return to an area with clean air.1.

Unscrew the used cartridges from the facepiece 2.

connectors and discard.

Securely install new cartridges onto threaded 3.

facepiece connectors as described in section V,

paragraph A.

E. Dofng

CAUTION

Always loosen the two lower headstraps completely prior to removing the facepiece.

Loosen the two lower headstraps completely.1.

CAUTION

Do not twist the nozzle when removing the facepiece

Grasp the nozzle rmly and pull the facepiece upward 2.

over your head.

Remove the neck strap from around your neck3. .

F. Filter Replacement

SPERIAN recommends that the lters be changed at

least daily, and more often if necessary. The lters must

be replaced whenever they become contaminated with

dust or water; if you smell or taste contaminants; if your

eyes, nose, or throat become irritated; or if breathing

becomes difcult. Filters must also be replaced if they

show any sign of damage. Dispose of used lters in

accordance with applicable local, state, and federal

guidelines.

Return to an area with clean air.1.

Remove the lter retainer from the chemical 2.

cartridge. If using a P100 or HEPA lter, unscrew

the used lters from the facepiece connectors

and discard them.

Remove and discard the lter pad.3.

Clean the lter retainer if required.4.

Insert the correct lter pad into the lter retainer 5.

with the side stamped with the part number

facing up.

Snap the lter retainer onto the chemical cartridge. 6.

If using a P100 or HEPA lter, securely install new

lters onto the threaded facepiece connectors as

described in section V, paragraph A.

Perform a t check.7.

VI. MAINTENANCE

NOTE

Inspect this respirator for defects before and after

each use, and at least once monthly if not used.

Repair as necessary, clean and disinfect after each

use, and store properly to assure that the respirator is

maintained in satisfactory working condition. Keep a

record of inspection and repair dates and results. Refer

to the inspection table in the back of this manual.

A. Cleaning

WARNING

Specialized processes are required to disinfect and decontaminate a respirator. You

MUST follow the instructions of the manufacturer who supplies the disinfecting or de-

contamination equipment or chemicals.

NOTE

Silicone and rubber parts of the facepiece may be

cleaned between washings with SPERIAN Mask

Wipes, P/N 140096.

1. Make a cleaning solution of warm water and a mild

detergent.

2. Remove the cartridges/lters from the facepiece.

3. Immerse the facepiece top rst in the solution until

the exhalation valve is covered.

4. Agitate the facepiece and gently clean with a soft

brush.

5. Thoroughly rinse the facepiece in fresh water,

paying particular attention to removal of all soap

residue from the exhalation valve. If possible, direct

running water onto the exhalation valve.

6. Disinfect the facepiece in a warm (48°C or 120°F

maximum) suitable sanitizing solution such as

a “hypochlorite solution” for 2 to 3 minutes. A

hypochlorite solution can be made by mixing two

(2) tablespoons of chlorine bleach per each gallon

of water. Rinse thoroughly with fresh warm (48°C

or 120°F maximum) water.

7. Allow the facepiece to drip dry. Warm air may be

used to speed up drying.

5

Page 6

NOTE

Cleaning solutions containing ammonia or repeated

washing will remove the lens anti-fog coating. Recoat

with SPERIAN Anti-Fog Solution, P/N 951015 (1 oz.),

or 951016 (16 oz.).

8. After cleaning, apply three drops of anti-fog

solution as required to the inner surface of the

lens and spread with a lint-free cloth. Allow to dry

for 15 minutes.

9. Hold the facepiece rmly against your face and

exhale several times to ensure that the exhalation

valve functions smoothly.

B. Inspection (See the Inspection Table in the Back

of this Manual)

WARNING

Ensure that the o-ring, P/N 824014, is in the cap plug,

P/N 420020, and that the cap plug is securely seated

on the nozzle. Using the APR without the cap plug oring or without the cap plug securely seated could allow contaminants to leak into the facepiece, resulting

in illness or death.

NOTE

The leak check o-ring, item 20 of Figure 1, located

between the cap plug (item 9) and the cover (item 7)

is to allow the positive pressure t check only.

E. Shipment

All products returned to SPERIAN’s factory, distributors, or repair centers must be decontaminated prior

to shipment.

F. Overhaul Frequency

This SPERIAN respirator does not have an overhaul

requirement other than that required in Section VI,

Maintenance.

G. Additional Information

If you need assistance or additional information on

any SPERIAN product, consult your local distributor

or contact:

SPERIAN

3001 South Susan Street

Santa Ana, CA 92704

(714) 545-0410 or toll free 888-APR-SCBA

FAX (714) 850-0299

ALL RETURNED PRODUCTS MUST BE

DECONTAMINATED PRIOR TO SHIPMENT. PRODUCTS CONTAMINATED

WITH DANGEROUS SUBSTANCES WILL

BE REFUSED AND RETURNED FREIGHT

COLLECT.

C. Repair (See the Repair Table in the Back of this

Manual)

Repair by the user is limited to replacement of

components as listed on the NIOSH approval label.

Disassembly should be performed only to the extent

necessary to replace the components. To protect your

warranty and the NIOSH certication of the equipment,

all other repairs must be done only by authorized

SPERIAN technicians and repair centers. Consult your

SPERIAN distributor for the one nearest you.

D. Storage

WARNING

This SPERIAN respirator does not have

a dened storage life. Carefully inspect it

before each use.

CAUTION

The maximum storage temperature for this device is 140°F (60°C). Long term exposure to elevated storage temperatures could cause premature deterioration.

After inspection and cleaning, store your SPERIAN

APR to protect it against dust, sunlight, extreme heat

and cold, excessive moisture, or damaging chemicals.

6

Page 7

VII. INSPECTION TABLE

IF ANY OF THE DEFECTS LISTED BELOW ARE FOUND, HAVE THE RESPIRATOR REPAIRED BEFORE USE.

COMPONENT LOOK FOR

FACEPIECE LENS Nicks, scratches, or abrasions which could impair visibility.

FACEPIECE RIMS Deformed, cracked, or broken.1.

FACEPIECE SKIRT Cuts, gouges, or punctures.1.

FACEPIECE HEADSTRAP Abrasions or nicks.1.

FACEPIECE BUCKLES Crushed, bent, or corroded.1.

FACEPIECE INLET NOZZLE Loose cover screws.1.

SPEAKING DIAPHRAGM Holes or tears. Do not remove to inspect.

1.

Deep gouges or cracks which could reduce impact resistance.2.

Anti-fog coating in need of replacement.3.

Loose screws. Do not overtighten.2.

Tears or nicks in the sealing area.2.

Deterioration from age, heat, or contamination.3.

Deterioration from age, heat, or contamination.2.

Damaged or loose rivets.2.

Heat or impact damage.2.

Nicks, cracks, or dents in the exhalation valve seat.3.

Nicks, cracks, tears, or creases in the exhalation valve.4.

Sticking exhalation valve. Exhale a few times to test. The valve must close after 5.

each exhalation. Valves that fail to close must be replaced.

VIII. REPAIR TABLE

COMPONENT INSTRUCTIONS

HEADSTRAP REPLACEMENT Remove the old headstrap from the facepiece, noting the routing of the straps.

NOSE CUP Unscrew the speaking diaphragm ring counterclockwise and remove it, along with 1.

FACEPIECE LENS REPLACEMENT Use a 5/32 inch Allen wrench to remove the two rim screws.1.

EXHALATION VALVE Remove the valve grill cover form the nozzle.1.

ACCESSORIES Each modication kit and acessory purchased from SPERIAN has installation

1.

Install new headstrap.2.

the o-ring from the nozzle. NOTE: If the speaking diaphragm ring is too tight to

remove by hand, use the Speaking Diaphragm Tool, P/N 980019.

Discard the old nose cup.

2.

If removed, reinstall the o-ring on the speaking diaphragm ring.3.

Fit the speaking diaphragm ring into the nose cup.4.

Position the nose cup inside the facepiece with the locating pins seated in the 5.

exhalation valve hole.

Tighten the speaking diaphragm ring.

6.

Perform a facepiece t check as described in section V, paragraph C.7.

Gently sepearte the rims from the facepiece.2.

Pull the facepiece skirt away from the lens.3.

Remove the old lens.4.

Match one corner of the new olens with the corner of the skirt.5.

Place the edge of the lens inside the lens channel fo the skirt.6.

Knead the skirt until it ts evenly around the edge of the lends, and the corners of 7.

the skirt match the corners of the lens.

Install the two rims. Start both scrws but do not tighten. CAUTION-Do not pinch

8.

the skirt between the rims.

Alternatley tighten each screw until rmly tightened.

9.

NOTE ─ The corners of the skirt should be centered between each rim when installation is complete.

Perform a facepiece t check as described in section V, paragraph C.

10.

Remove and discard teh old exhalation valve.2.

Insert a new valve and pull the valve stem until it snaps into place.3.

Replace teh valve grill cover.4.

Perform a facepiece t check as described in section V, paragraph C.5.

instructions. Use these instructions for removing and replacing any accessory.

www.sperianprotection.com

7

Loading...

Loading...