Spellman XRV160P4000, XRV160P1800, XRV160N1800, XRV160P3000, XRV160N4000 Installation Manual

...Page 1

SPELLMAN HIGH VOLTAGE XRV SUBSYSTEM

INSTALLATION MANUAL

Page 2

Table of Contents

General Safety ............................................................................................................................................. 4

Personal Safety ......................................................................................................................................... 4

X-Ray Tube Overview

X-ray tube data sheet ................................................................................................................................ 7

XRV Sub-system Overview ........................................................................................................................... 8

XRV 160kV Overview ............................................................................................................................... 10

XRV 225kV Overview ............................................................................................................................... 14

XRV 320kV & XRV 350kV Overview ......................................................................................................... 18

XRV 450kV Overview ............................................................................................................................... 20

I/O System Interface Box Overview ....................................................................................................... 24

XRVC Controller Overview ..................................................................................................................... 27

Coolers & Chillers Overview .................................................................................................................. 29

R24 & R28 HV Cable Overview .............................................................................................................. 31

XRV Setup & Installation ............................................................................................................................ 33

Unipolar System Diagram ....................................................................................................................... 34

Bipolar System Diagram ......................................................................................................................... 36

.................................................................................................................................. 5

Unpacking Generator ............................................................................................................................. 38

System Grounding .................................................................................................................................. 40

High Voltage Cable Installation (non-spring loaded) ............................................................................. 42

High Voltage Cable Installation (spring loaded) ..................................................................................... 48

System Grounding Detail and HV Cable Connections ............................................................................. 51

Cooler/Chiller Connections .................................................................................................................... 52

Interlock & Communication Connections (unipolar basic) ................................................................... 55

Power Connections (unipolar basic) ...................................................................................................... 60

Power Source Connections (unipolar basic) .......................................................................................... 64

Power & Feedback Connections (bipolar basic) ..................................................................................... 69

Power Connections I/O System Interface Box ........................................................................................ 70

Main Input Power Connections I/O Interface Box ................................................................................. 75

XRVC Control Box Installation ................................................................................................................ 78

118157-001 Rev C

Page 2 of 98

Page 3

Table of Contents

GUI (Graphical User Interface) Installation ........................................................................................... 81

Software Communication ...................................................................................................................... 84

X-ray Tube Filament Calibration ............................................................................................................ 87

Accessory Test Kits ................................................................................................................................. 96

XRV Sub-system Nomenclature ............................................................................................................. 97

Drawing List ............................................................................................................................................ 98

118157-001 Rev C

Page 3 of 98

Page 4

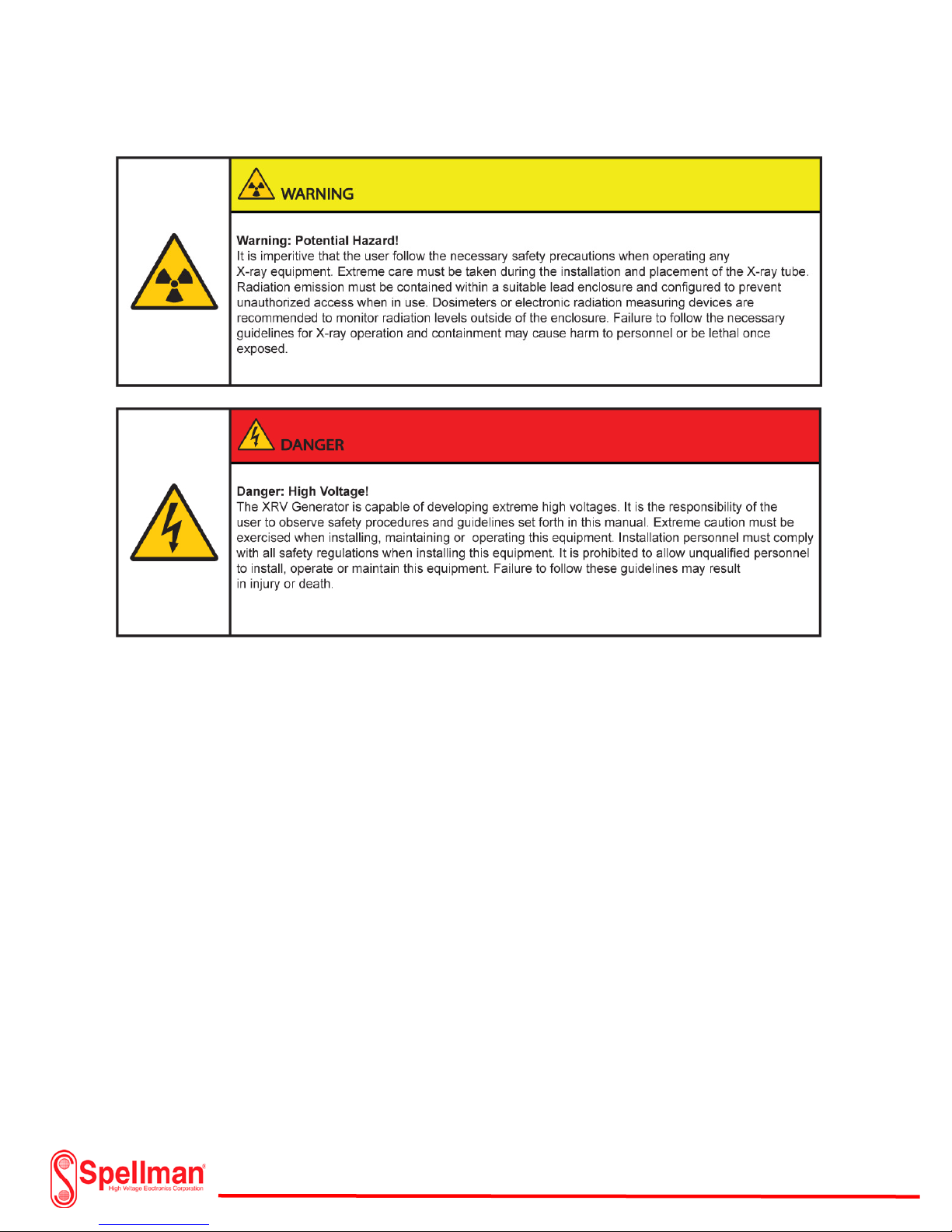

XRV Subsystem Installation Manual:

General Safety

It intent of this manual to identify and safely execute the installation of the XRV Generator and

subsystem components. “Caution” and “Warning” labels used throughout this manual to highlight

critical areas of the installation and operation of this equipment. Installation, maintenance and

operation should only be handled by qualified personnel. Failure to follow these guidelines may result in

hazardous operating conditions.

Personal Safety

It is the responsibility that the individual operating this equipment do so in a safe non-hazardous

manner. Training is required on a regular basis to prevent personal injury. It is extremely important to

monitor X-ray levels applying the use of dosimeters or alternate electronic measuring devices within

normal standard guidelines. Radiation measuring equipment requires calibration on a regular basis to

prevent personal injury. Do not use this equipment in an unsafe manner or for anything other than the

intended use. Contact Spellman High Voltage regarding questions about the safe operation or

installation of this equipment.

118157-001 Rev C

Page 4 of 98

Page 5

X-Ray Tube Overview:

There are numerous X-ray tubes available depending on the user application. The tube requirement is

normally the first component selected for a specific application before any of the other subsystem

requirements. There are two basic types of x-ray tubes. One type is called a single ended or “Unipolar”

while the other is a double ended or “Bipolar”. The single ended tube only requires one high voltage

source and a filament supply in order to emit X-rays. The source voltage is usually negative with respect

to earth ground.

External cooling may be required during operation of the tube depending on the level of power output.

Single ended tubes are cooled by water circulation systems specially designed to remove heat from the

anode during operation. The circulation system consists of a water reservoir tank, pump, hoses and a

fan circulating over a radiator that is very similar to an automobile cooling system. The hoses from the

cooling system connect to the grounded side of the tube. The tube may have special fittings and will

identify the water input and output side. The flow rate and capacity of the cooling system will generally

rely on the recommendations of the tube manufacturer and operating power level. On higher power

tubes, a chiller subsystem may be required. The chiller utilizes a compressor and pump to maintain

lower water temperatures for higher wattage tubes. Both systems measure the input temperature with

respect to output temperature of the water and employ an interlock system to remove high voltage on

the X-ray tube preventing damage. Various Coolers and Chillers are available with the XRV Sub-System

and are described later in this manual.

Standard single ended tube operating voltages range from 75kV to a maximum of 225kV and may be

purchased through Spellman as part of the XRV Sub-System.

Higher voltage tubes are double-ended or “Bipolar” meaning a negative and a positive high voltage

source is required for operation. The tube operates in a similar fashion as the single ended tube with the

exception that the anode is at high voltage potential in addition to the cathode instead of being at

ground potential. Ground potential is located in the center of the tube rather than at one end. Bipolar

tubes require two X-ray generators as opposed to one.

Bipolar X-ray tubes require oil cooling as opposed to water -cooled systems. The oil serves as an

electrical insulation medium internal to the tube in addition to cooling the anode. Oil cooled systems

use a heat exchanger (oil to water) that is isolated from the oil circulation flowing through the tube. As

with water-cooled systems, the manufacturer will specify the heat removal capacity and flow rates.

These can be compared with the recommendations for X-ray tube thermal management set by the tube

manufacturer. Like the water-cooled system, these systems employ the use of thermal interlocks

terminating high voltage if the tube begins to overheat.

118157-001 Rev C

Page 5 of 98

Page 6

X-Ray Tubes:

Various Unipolar or Bipolar metal ceramic X-ray tubes manufactured by Comet and Varian are available

for the XRV Subsystem. Contact Spellman High Voltage Corp. for more information.

Comet

Unipolar X-ray tube

Varian

Bipolar X-ray tube

118157-001 Rev C

Page 6 of 98

Page 7

X-Ray Tube Data Sheets:

kV

Comet

Varian

160

225

320

350

450

MXR-160HP/11 MXR-160/22

MXR-225HP/11 FB MXR-161

MXR-160HP/20 MXRP-160C

MXR-160/20 MXR-165

MXR-160/21

MXR-225HP/11 MXR-225/26

MXR-225HP/11 FB

MXR-225/21

MXR-225/22

MXR-226

MXR-320HP/11 MXR-321

MXR-320HP/11 FB

MXR-320/23 MXR-320/23AX

MXR-320/23-90 MXR-320/26AX

MXR-320/26 MXR-320HP/11AX

MXR-320/26-90

MXR-350/23

MXR-350/23-90

MXR-350/26

MXR-350/26-90

MXR-351

MXR-322

HPC-160FB NDI-160/21

HPX-160/20 NDI-160/22

HPX-160/11 NDI-161

NDI-160/01

NDI-160/20

HPC-225FB NDI-225/22

HPX-225-11 NDI-225/FB

NDI-225/01 NDI-226

NDI-225/20

NDI-225/21

HPX-320-11

NDI-320

NDI-320/23

NDI-320/26

NDI-321

NDI-350

NDI-350/23

NDI-350/26

MXR-451HP/11

MXR-451/26

MXR-452/Y

For Comet X-ray Tube Specifications: www.comet-xray.com

For Varian X-ray Tube Specifications: www.vareximaging.com

118157-001 Rev C

HPX-450-11

NDI-451

NDI-451 Be

NDI-452

Page 7 of 98

Page 8

XRV Subsystem Overview:

XRV Generator:

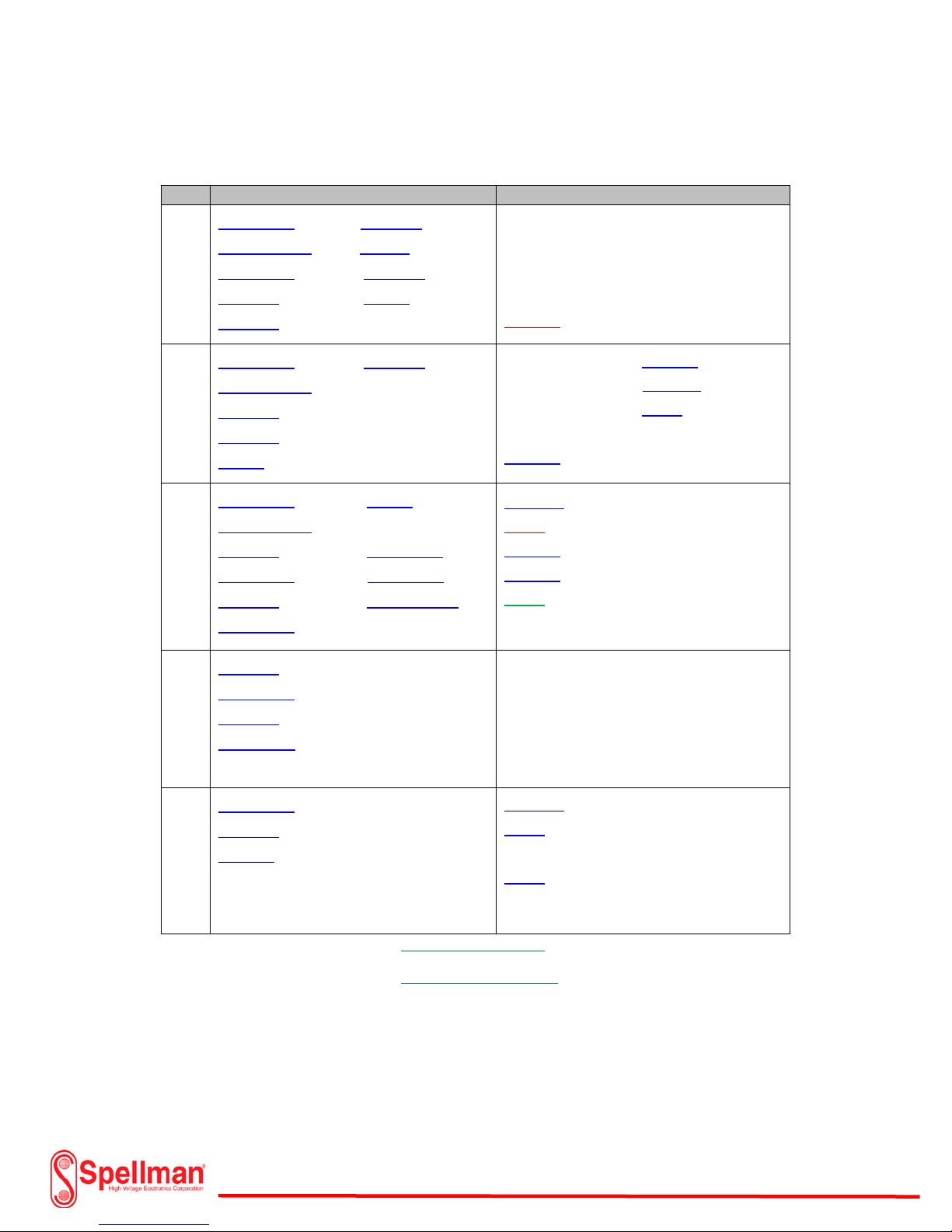

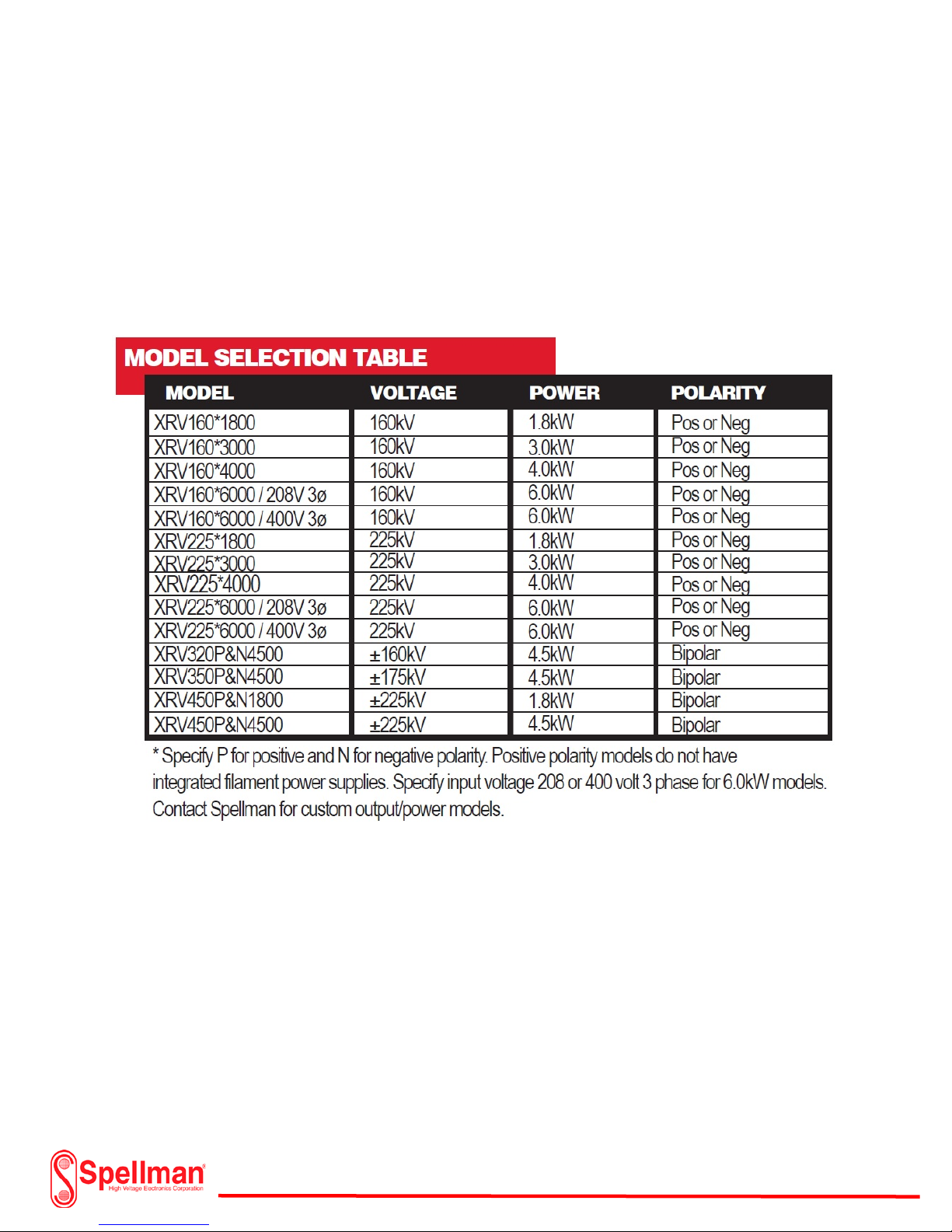

The XRV Generator is available in several configurations for various X-ray tube requirements. The

generators are assembled in a compact chassis allowing for a minimum amount of space required for

installation but providing for the utmost safety. Military style circular connectors for the main and

auxiliary power input offers integration flexibility and safety. Additionally, the user has the option of an

analog, com port, Ethernet or a USB connection for local or remote operation. The Ethernet connection

is extremely useful when operating the supply remotely or in the unlikely event the generator requires

evaluation by Spellman High Voltage personnel. Utilization of this feature can save the customer hours

of downtime especially when assistance is required from a long distance.

An integrated microprocessor and resistor feedback network constantly measure and adjust the output

voltage and current to provide a stable highly regulated source. Models range from 1800 watts to 6000

watts of output power. A simple to use Graphical User Interface (GUI) or selectable analog control

provides for safe operation and customer integration. The GUI software supplied with each model of the

XRV generator can be custom programmed when placing an order for specific applications. Likewise, the

analog interface allows the user to integrate unique controls and monitoring equipment. A 25 pin

subminiature “D” connector (supplied with each XRV) is standard for interlock connections and user

controls. The GUI software can also serve as a remote monitor during analog operation.

A single ended or “Unipolar” X-ray tube requires a single XRV Generator. The XRV model will depend on

the X-ray tube selected. For example, a 160kV “Unipolar” tube operating at 3 kilowatts or less would

most likely use a standard XRV model XRV-160N-3000. The output voltage of the generator would be

negative with respect to ground due to the operating specifications of the X-ray tube. Additionally, an

isolated DC supply is included to power a large or small filament connection within the X-ray tube. The

DC filament current is adjustable via the software provided or analog input selection. Specific filament

voltage and current requirements are available upon request.

Page 8 of 98

118157-001 Rev C

Page 9

XRV Generator:

A double ended or “Bipolar” X-ray tube requires two separate XRV Generators. One Generator has a

negative output with respect to ground while the other has a positive output with respect to ground.

The software provided or analog selection allows for the operation of both the positive and negative

outputs simultaneously with a minimal amount of imbalance. There are several models of the XRV

Generator available. These are listed below.

118157-001 Rev C

Page 9 of 98

Page 10

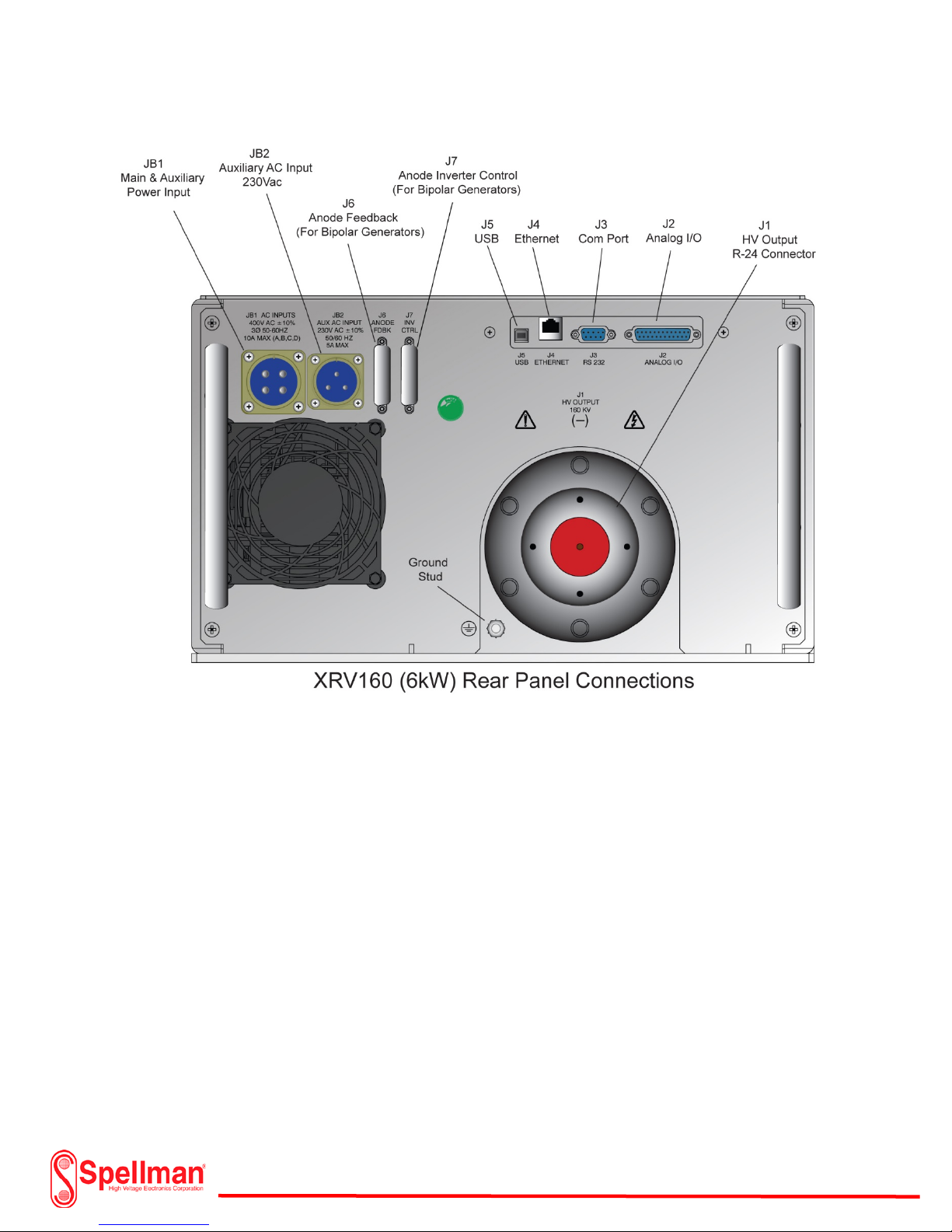

XRV 160kV Overview:

XRV160kV Rear Panel

The 160kV XRV Generator measures a compact

7.16” W x 10.09” x H 24” D (excluding handles).

The rear of the chassis has all of the necessary

connectors for power input, controls, monitoring,

and kV output. Each connector on the rear panel

is clearly marked for installation purposes. The

main and auxiliary input includes an Amphenol

style mating connector with an additional DB-25

pin connector for the I/O analog connection. The

high voltage output mates with a standard R-24

type connector. These are available from Spellman

High Voltage Corp. in different lengths and configurations for installation of the X-ray tube. Standard

Graphical User Interface (GUI) software is included with the XRV 160 Generator. A personal PC is

required for installation. The user has the option of connection to a USB, Ethernet or Com Port. The

control and monitoring of the XRV160 also includes an analog I/O connector for custom configurations.

An additional optional touch screen controller (XRVC) is also available from Spellman High Voltage Corp..

118157-001 Rev C

4kW Units

Page 10 of 98

Page 11

XRV 160kV Overview : XRV160 (Front Panel)

The XRV160 front panel uses LED Indicators that

show the status of the Generator. Green

Indicators signify normal operational mode

while red indicators signify a fault condition. A

fault or red indication prevents high voltage

operation. Fault conditions are “latched”

meaning that a reset must be employed before

re-starting the generator. Once the fault clears,

the red indicator will extinguish. Additionally,

fault status and ready conditions are monitored

from the I/O connector on the rear panel and

the GUI Interface software. A removable air

filter keeps dust and dirt from entering the

chassis.

XRV160 Front Panel Indicators

118157-001 Rev C

Page 11 of 98

Page 12

XRV 160kV Overview:

The 160kV XRV is additionally available in a 6kW version. The 6kW version uses a 208 Vac 3Ø power

input or a 400Vac 3Ø power input. The chassis overall size is the same as the 4kW version. The only

difference between the 6kW version and the 4kW version is the power input connections. Two

connectors separate the Mains from the auxiliary power input. Amphenol style power mating

connectors are included with all XRV models.

208Vac 3Ø Input

118157-001 Rev C

Page 12 of 98

Page 13

XRV 160kV Overview:

400Vac 3Ø Input

Page 13 of 98

118157-001 Rev C

Page 14

XRV225kV Overview: XRV225 (Front Panel)

The XRV225 front panel uses the same LED Indicators

as the XRV160 showing the status of the Generator.

Green Indicators signify normal operational mode

while red indicators signify a fault condition. A fault

or red indication prevents high voltage operation.

Fault conditions are “latched” meaning that a reset

must be employed before re-starting the generator.

Once the fault clears, the red indicator will

extinguish. Additionally, fault status and ready

conditions are monitored from the I/O connector on

the rear panel and the GUI Interface software. A

removable air filter keeps dust and dirt from entering

the chassis.

118157-001 Rev C

XRV225 Front Panel Indicators

Page 14 of 98

Page 15

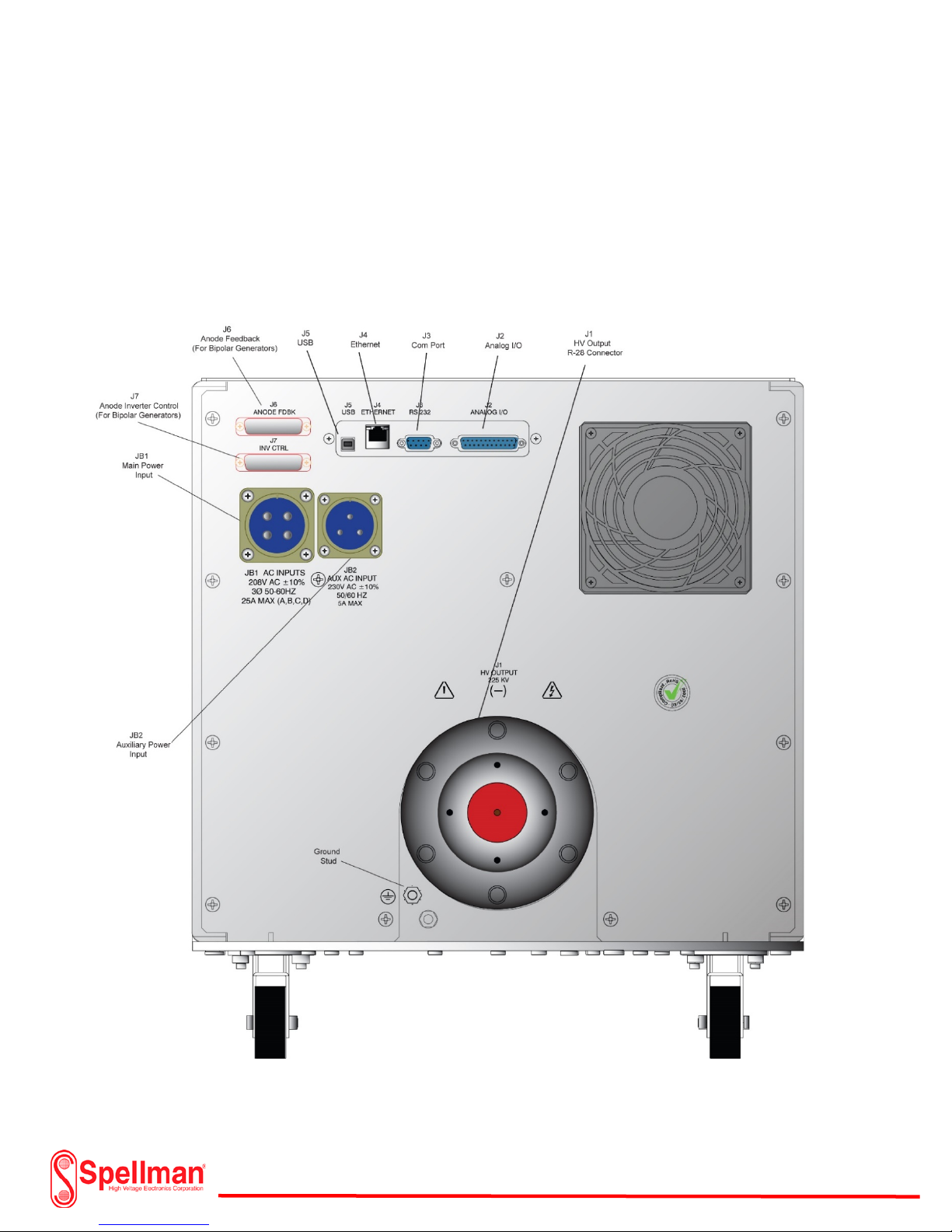

XRV225kV Overview:

XRV225kV (Rear Panel)

The 225kV XRV Generator measures a compact 17” W x

18.90” (including castors) x H 30.72” D (excluding cable

well). The assembly includes lockable castors for easy

moving. The rear of the chassis has all of the necessary

connectors for power input, controls, monitoring, and kV

output. Each connector on the rear panel clearly marked

for installation purposes. The main and auxiliary input

includes an Amphenol style mating connector with an

additional DB-25 pin connector for the I/O analog

connection. The high voltage output mates with a

standard R-28 type connector. These are available from

Spellman High Voltage Corp. in different lengths and

configurations for installation of the X-ray tube. Standard Graphical User Interface (GUI) software is

included with the XRV 225 Generator. A personal PC is required for installation. The user has the option

of connection to a USB, Ethernet or Com Port. The control and monitoring of the XRV225 also includes

an analog I/O connector for custom configurations. An additional optional touch screen controller

(XRVC) is also available from Spellman High Voltage Corp..

118157-001 Rev C

Page 15 of 98

Page 16

XRV225kV Overview:

The 225kV XRV is additionally available in a 6kW version. The 6kW version uses a 208 Vac 3Ø power

input or a 400Vac 3Ø power input. The chassis overall size is the same as the 4kW version. The only

difference between the 6kW version and the 4kW version is the power input connections. Two

connectors separate the Mains from the auxiliary power input. Amphenol style power mating

connectors are included with all XRV models.

XRV225kV 208Vac 3Ø 6kW Unit

118157-001 Rev C

Page 16 of 98

Page 17

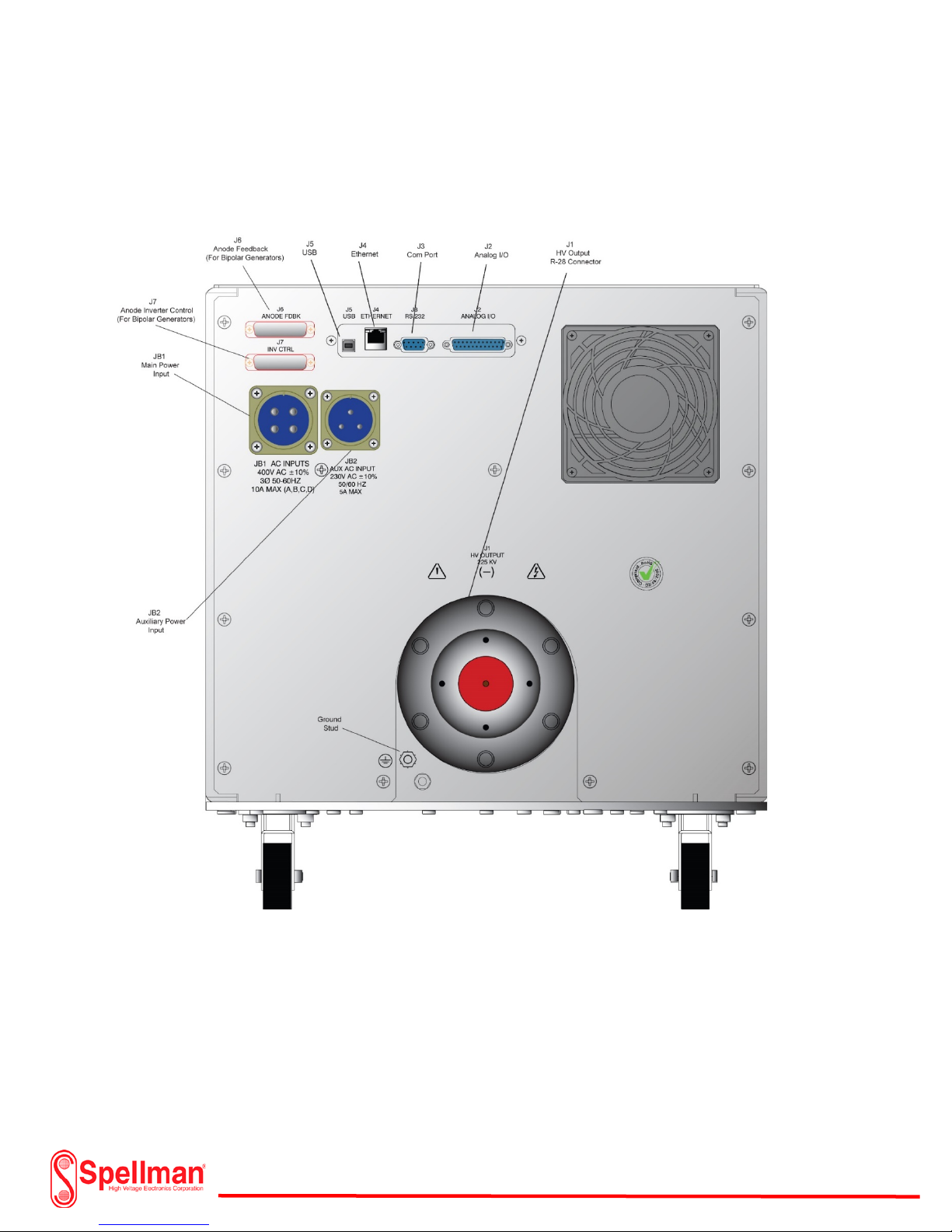

XRV225kV Overview:

118157-001 Rev C

XRV225 400Vac 3Ø 6kW Unit

Page 17 of 98

Page 18

XRV320 and XRV350 Overview:

XRV320 and XRV350 (Rear Panels)

The 320kV and 350kV XRV Generators are

specifically designed to operate bipolar x-ray tubes. The

X-ray tube requires a negative kV generator (cathode)

which includes a filament supply and a positive kV

output (anode) generator. Each generator on the

320kV system has a maximum voltage of 160kV. One is

positive 160kV with respect to ground while the other is

negative 160kV with respect to ground. Likewise, the

350kV model has a maximum of 175kV each with

respect to ground. Each generator measures 7.16” W x

10.09” x H 24” D (excluding handles). The rear of the

chassis has all of the necessary connectors for power

input, controls, monitoring, and kV output. Each

connector on the rear panel is clearly marked for

installation purposes. An interconnect cable on the cathode side supplies auxiliary power to the anode

generator. Two additional 25 pin DB style cables interface the anode generator feedback and inverter

signals to the main control board residing in the cathode generator supply. The mains input on the

cathode generator includes an Amphenol style mating connector and an additional DB-25 pin connector

for the user I/O analog control. Both the cathode and anode kV outputs mate with a standard R-24 type

connector. These are available from Spellman High Voltage Corp. in different lengths and configurations

for installation of the X-ray tube. Standard Graphical User Interface (GUI) software is included with the

XRV 320 or XRV350 Generator. A personal PC is required for installation. The user has the option of

connection to a USB, Ethernet or Com Port. The control and monitoring of the XRV320 and XRV350 also

includes an analog I/O connector for custom configurations. An additional optional touch screen

controller (XRVC) is also available from Spellman High Voltage Corp

118157-001 Rev C

Page 18 of 98

Page 19

XRV320 and XRV350 Overview : XRV320 and XRV350 (Front Panels)

The cathode (negative) generator front panel of the

XRV320 and XRV350 models use the same LED

Indicators as the unipolar XRV160 showing the status

of the Generator. Green Indicators signify normal

operational mode while red indicators signify a fault

condition. A fault or red indication prevents high

voltage operation. Fault conditions are “latched”

meaning that a reset must be employed before restarting the generator. Once the fault clears, the red

indicator will extinguish. The anode (positive)

generator does not have any indicators since all of

the monitoring and fault status indicators originate

from the control board within the cathode (negative)

generator. Additionally, fault status and ready conditions are monitored from the I/O connector on the

rear panel and the GUI Interface software. A removable air filter keeps dust and dirt from entering the

chassis.

Front Panel Detail

XRV320 and XRV350 Cathode XRV320 and XRV350 Anode

118157-001 Rev C

Page 19 of 98

Page 20

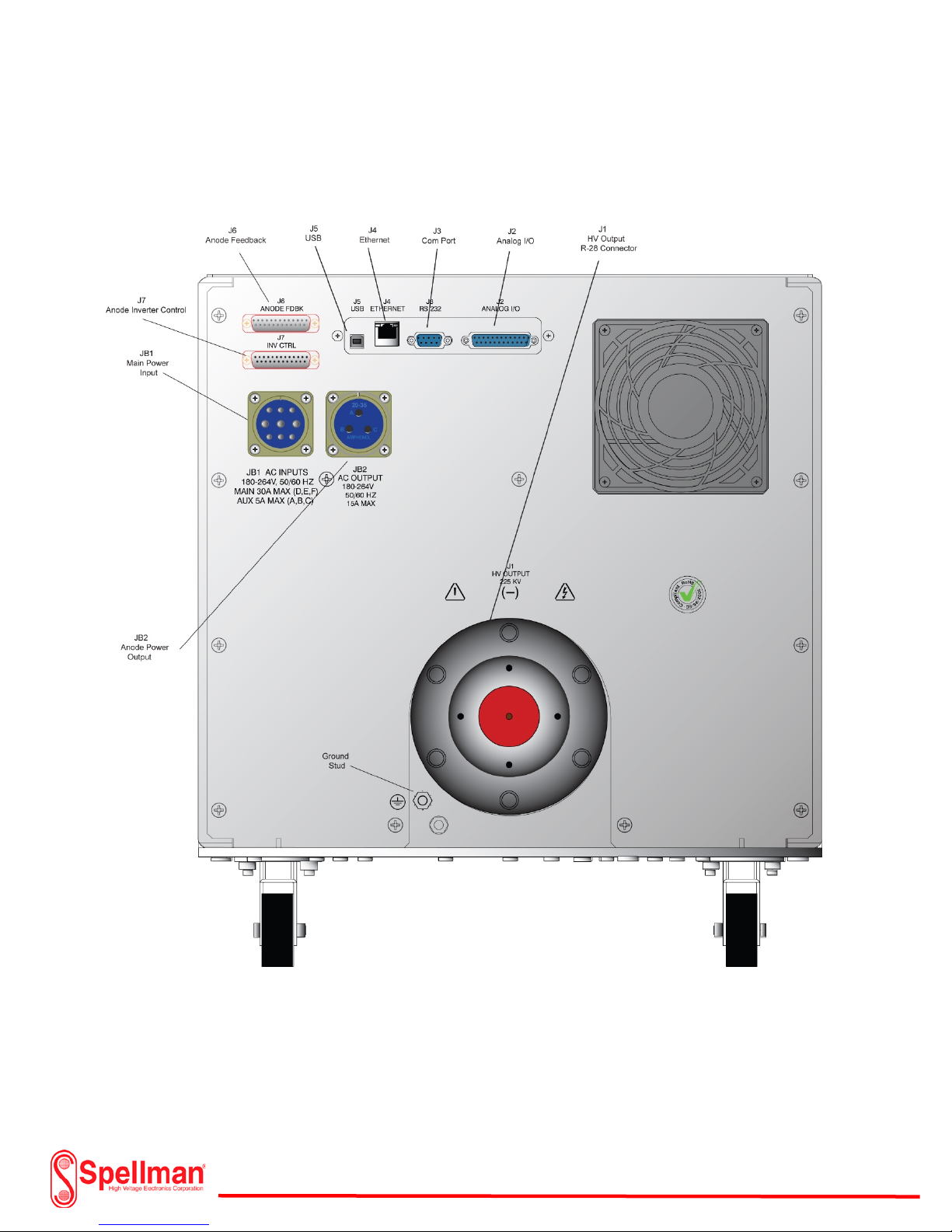

XRV450 Overview :

XRV450 (Rear Panels)

The 450kV Generator is specifically designed to operate with

bipolar x-ray tubes. The X-ray tube requires a negative kV

generator (cathode) which includes a filament supply and a

positive kV output (anode) generator. Each generator on the

450kV system has a maximum voltage of 225kV. One is

positive 225kV with respect to ground while the other is

negative 225kV with respect to ground. Each generator

measures 17” W x 18.90” (including castors) x H 30.72” D

(excluding cable well). The rear of each chassis has all of the

necessary connectors for power input, controls, monitoring,

and kV output. Each connector on the rear panel is clearly marked for installation purposes. An

interconnect cable on the cathode side supplies auxiliary power to the anode generator. Two additional

25 pin DB style cables interface the anode generator feedback and inverter signals to the main control

board residing in the cathode generator supply. The mains input on the cathode generator includes an

Amphenol style mating connector and an additional DB-25 pin connector for the user I/O analog control.

Both the cathode and anode kV outputs mate with a standard R-28 type connector. These are available

from Spellman High Voltage Corp. in different lengths and configurations for installation of the X-ray

tube. Standard Graphical User Interface (GUI) software is included with the XRV 450 Generator. A

personal PC is required for installation. The user has the option of connection to a USB, Ethernet or Com

Port. The control and monitoring of the XRV450 also includes an analog I/O connector for custom

configurations. An additional optional touch screen controller (XRVC) is also available from Spellman

High Voltage Corp..

Page 20 of 98

118157-001 Rev C

Page 21

XRV450 Overview :

118157-001 Rev C

XRV450 Bipolar Cathode Generator

Page 21 of 98

Page 22

XRV450 Overview :

118157-001 Rev C

XRV450 Bipolar Anode Generator

Page 22 of 98

Page 23

XRV450 Overview :

XRV450 (Front Panels)

The cathode (negative) generator front panel of the

XRV450 model uses the same LED Indicators as the

unipolar XRV225 showing the status of the

Generator. Green Indicators signify normal

operational mode while red indicators signify a fault

condition. A fault or red indication prevents high

voltage operation. Fault conditions are “latched”

meaning that a reset must be employed before restarting the generator. Once the fault clears, the red indicator will extinguish. The anode (positive)

generator does not have any indicators since all of the monitoring and fault status indicators originate

from the control board within the cathode (negative) generator. Additionally, fault status and ready

conditions are monitored from the I/O connector on the rear panel and the GUI Interface software. A

removable air filter keeps dust and dirt from entering the chassis.

Front Panel Detail

XRV450 Cathode XRV450 Anode

118157-001 Rev C

Page 23 of 98

Page 24

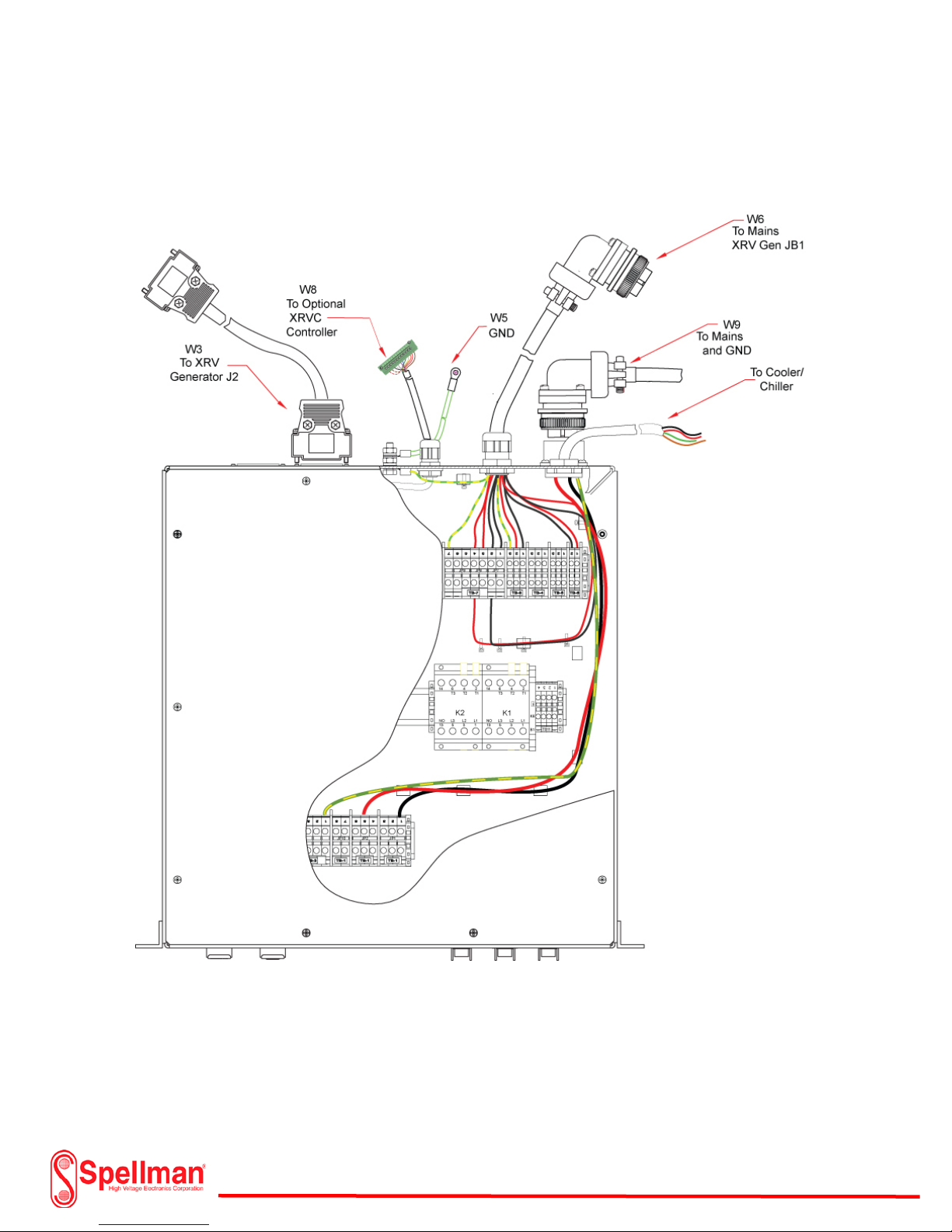

I/O System Interface Box Overview:

The XRV I/O System Interface Box provides easy

integration of the XRV Generator, XRV Touch Screen

Controller and Cooler/Chiller unit. The interface box

is enclosed in a 19” x 5.21” x 18” deep rack

mountable chassis and includes all the necessary

cables for a complete system setup and operation.

Power distribution includes a maximum 230Vac @

4kW XRV High Voltage Generator and encompasses

all the necessary X-ray safety requirements meeting

international standards. The XRV I/O Box

accommodates a variety of interface options that

are best suited for user requirements and mounting

configurations.

There are several models of the XRV I/O Box. These are capable of integrating different optional

accessories ranging from an XRV Touch Screen Controller to a “bare bones” setup allowing the user to

operate the XRV High Voltage Generator via connection to a personal PC. The user may also choose the

analog I/O interface control and monitoring as without the use of a personal PC. There are several

models of the I/O Interface Box for use with the 230Vac, 4kW XRV Generators. Other models for use

with high power Generators will be available in the near future.

XRV I/O Box Models:

118157-001 Rev C

Page 24 of 98

Page 25

I/O System Interface Box Overview:

I/O System Interface Box Front Panel Detail

118157-001 Rev C

Page 25 of 98

Page 26

I/O System Interface Box Overview:

I/O System Interface Box Rear Panel Connections Detail

118157-001 Rev C

Page 26 of 98

Page 27

XRVC Controller Overview:

The XRVC Controller uses an embedded computing

system that runs a custom graphical use (GUI) interface

and allows the user to configure custom X-ray tube

profiles for any of the Spellman XRV series. The unit,

housed in a 19”W x 5.25” H x 13” D (ex. connectors)

features a 7” touch screen, RS-232 serial ports,

10/100/1000Mbit Ethernet and a 160GB hard drive. The

Intel Atom N270 CPU processor runs at an impressive

1.6GHz and includes 1GB of static Ram. The user has the

ability to create, save and load customized profiles for

use within the operating capabilities of the XRV

Generators. The intuitive, touch-centric, menu driven system allows ease of use with little or no learning

curve. Communication settings are stored after only one system configuration session. Parameter

settings on supported X-ray tubes may be automatically uploaded to the XRVC within the recommended

manufacturer guidelines. A comprehensive status and control screen continuously monitors

information on all critical operation parameters. An integrated on screen keyboard eliminates the need

for an external keyboard. The input voltage is 180-264Vac, 50/60Hz easily integrating with the Spellman

I/O System Interface Box.

XRVC Controller Front Panel Detail

118157-001 Rev C

Page 27 of 98

Page 28

XRVC Controller Overview:

XRVC Controller Rear Panel Detail

Page 28 of 98

118157-001 Rev C

Page 29

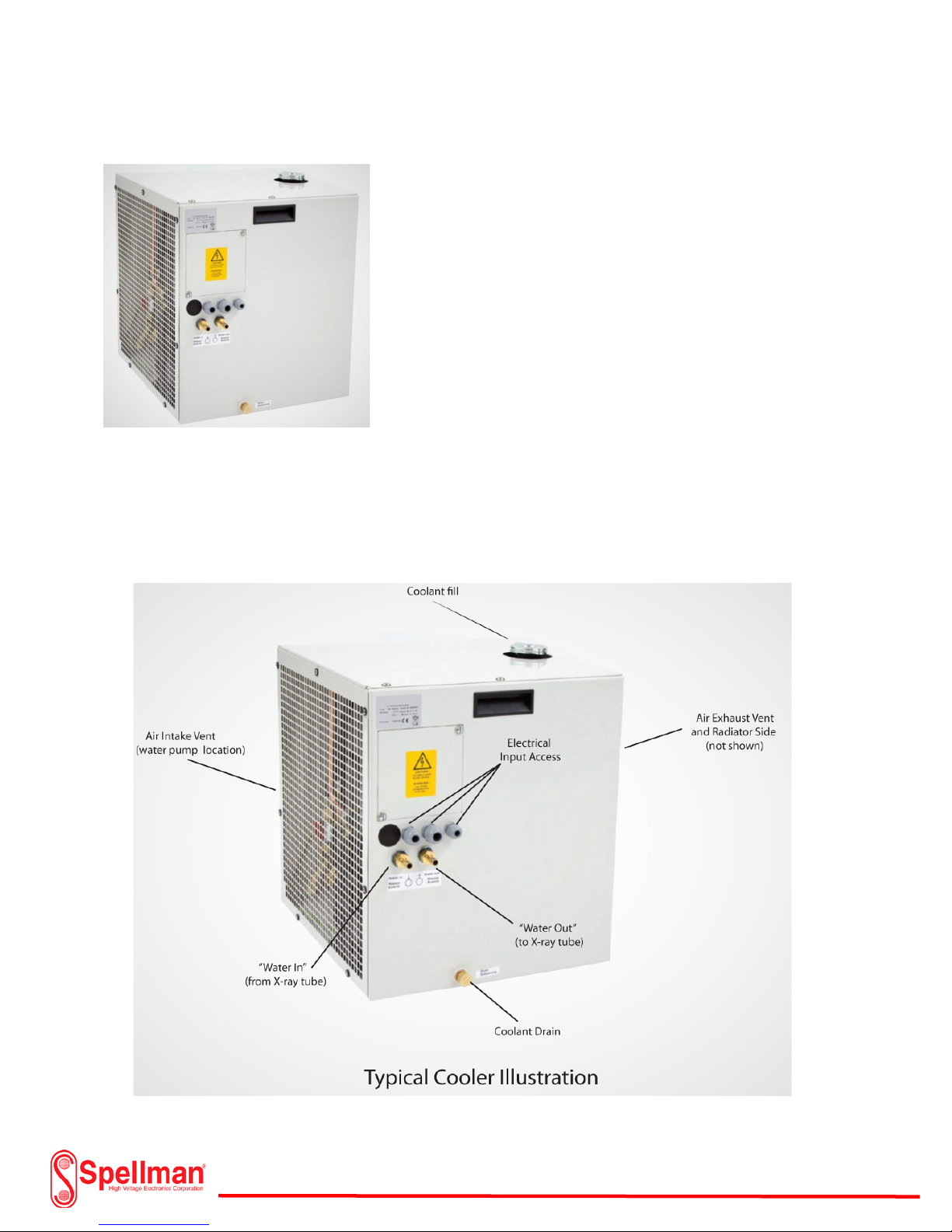

XRV Coolers and Chillers Overview:

The X-ray tube will generate a substantial amount of heat during

operation. It is important to remove as much heat as possible to

avoid damage to the X-ray tube. Various coolers remove heat

from a closed circulated water system flowing through the X-ray

tube at ground potential. The unipolar X-ray tube normally

specifies the water flow rate and ambient conditions required to

prevent damage to the tube. The capacity of the cooler to

remove heat through a water to air heat exchanger depends on

the difference between the ambient temperature and the water

outlet temperature. The coolant used could be either plain water

or a mixture of water and glycol usually specified by the

manufacturer. The inlet and outlet hose connections are specifically marked for correct flow through the

tube. A thermal switch monitors the outlet water temperature. If the outlet temperature exceeds the

recommended operating temperature, the switch will activate opening an interlock chain removing

power from the Generator. For optimal performance of the cooler, it is important not to obstruct or

restrict the air flowing through the vents. The ambient air temperature should be maintained according

to the manufacturers’ recommendations.

118157-001 Rev C

Page 29 of 98

Page 30

XRV Coolers and Chillers Overview:

Chillers may be used with either Unipolar or Bipolar X-ray tubes. The

tube power and ambient temperature will determine if a chiller is

required in order to cool the X-ray tube. Chillers are much like air

conditioners whereas a compressor lowers the temperature of the

water or oil within a closed loop system. Oil coolant is used with a

Bipolar tube since the Anode section of the X-ray tube “Floats” at

high voltage potential and an insulation medium must be used to

cool it and provide isolation to ground. An internal thermostat

maintains the temperature. It constantly compares the water/oil

that returns from the X-ray tube to the water/oil supplied to the Xray tube. If the difference is too great, the chiller will provide an

interlock signal (usually a dry contact switch) to shut down the high

voltage generator and prevent any damage to the X-ray tube.

Adequate clearance is necessary when installing a chiller to allow the

flow of air through the venting system.

118157-001 Rev C

Page 30 of 98

Page 31

XRV R24 and R28 HV Cables Overview:

The X-ray tube and the XRV Generator uses a specific type of

receptacle for the high voltage connection. The receptacles

mate with an R24 or R28 high voltage cable. The R24 Cable is for

systems with an output voltage of 160kV or less while the R28

Cable are designed for systems with voltages as high as 225kV.

The conical shaped cable plugs ,designed to reduce voltage

stress on the connections use silicone grease to fill any air voids

and avoid high voltage arcing. The cables are available in

various lengths, straight or right angle spring and non-spring

loaded connectors. Flanges are specially designed to apply the

right amount of contact force and keep the connector securely in place. A special gapping tool adjusts

the flange to cable well spacing making sure the male conical connector is the correct length for the

cable well depth. Typical Cables and Flanges are shown below.

Spring Loaded R24 and R28 Type Cables

118157-001 Rev C

Page 31 of 98

Page 32

XRV R24 and R28 HV Cables Overview:

Standard Type R24 and R28 Type Cables

R24 and R28 Type Cable Flanges

118157-001 Rev C

Page 32 of 98

Page 33

XRV Setup and Installation:

There are several installation configurations available for the XRV Subsystem. The most economical

system employs the use of a single ended X-ray tube, the XRV Generator, Personal PC, X-ray Cable, Input

Power / Communication Cables and Water Cooler/ Chiller. The XRV Generator includes ready to install

software that can be loaded into the user’s personal PC. A minimal setup for a standard Unipolar

subsystem is illustrated on the following page. The user must provide a personal PC for installing the

included software or elect to interface their own controls via the I/O from J2 (25 Pin subminiature D

connector) on the rear of the XRV Generator. Information regarding the I/O connector will be covered

later in this manual. It is imperative the installer follow all safety regulations and codes for installing this

equipment. Details such as input power requirements, wire sizing, and physical placement of each

component is critical for safe and trouble free operation. Do not install power wires or high voltage

cables in high traffic areas where they could be damaged by heavy equipment. Wire lengths should be

considered for voltage drops and thermal management. The X-ray tube

118157-001 Rev C

Page 33 of 98

Page 34

XRV Unipolar System Diagram

Typical Unipolar System (Minimal Requirements)

118157-001 Rev C

Page 34 of 98

Page 35

XRV Unipolar System Diagram

Typical Unipolar System with Additional Controller and I/O Box

118157-001 Rev C

Page 35 of 98

Page 36

XRV Bipolar System Diagram

Typical Bipolar System (Minimal Requirements)

Page 36 of 98

118157-001 Rev C

Page 37

XRV Bipolar System Diagram

Typical Bipolar System with Additional Controller and I/O Box

118157-001 Rev C

Page 37 of 98

Page 38

Unpacking Generator:

Loosen 6 Bolts on Bottom

of Generator Crate

XRV 160

Generator Crate

XRV 160 Generator

Lift Generator

from Handles

The XRV Generator and subsystem components are shipped in padded containers to avoid damage

during shipment. All of the containers will have an indication that shows the correct orientation for

shipment and unpacking. The XRV Generator is surrounded within a foam padding to protect it from

shock and vibration during shipment. There are 6 bolts on the surrounding bottom of the crate that

need to be loosened in order to remove the XRV Generator. Do not remove the 4 bolts from the top of

the crate. Once the bolts are loosened, the top can be removed. Two people can lift the top of the crate

evenly from either end or a hoist and strap may be used instead. Visually inspect the XRV Generator for

any signs of damage once the top is removed. Report any damage to Spellman High Voltage. Include any

photos and a verbal description. The crate should not be exposed to moisture or extreme temperatures.

118157-001 Rev C

Page 38 of 98

Page 39

P/N 105808-434 Conn.

P/N 105808-654 (4) Pin Conn. (6kW)

P/N 203373-001 25 Pin

Subminiature D

P/N SWD0026-009

Software

P/N 304747-001

(Bipolar XRV Only)

P/N PNC4002A

(Bipolar XRV Only)

P/N PNC4002A

(Bipolar XRV Only)

Unpacking Generator:

In addition to the XRV Generator, there will be several accessories. The 4kw unipolar models include a

CD/DVD program setup, Interlock bypass subminiature D connector and a Main Power Connector. The

6kW unipolar generator includes an additional Auxiliary Power Connector. The 4kW bipolar generator

includes an interconnect power cable and 2 additional subminiature D cables for the feedback and

inverter control for the additional positive polarity generator. Additional subsystem components such as

the X-ray tube, Cooler/Chiller

P/N 105808-440 Clamp

P/N 105808-440 Clamp

P/N 105808-441 (3) Pin Conn. (6Kw)

P/N 105808-440 Clamp

118157-001 Rev C

Page 39 of 98

Page 40

XRV Generator Installation:

General:

Locate the XRV Generator in an area where there is limited access and in close proximity to the X-ray

tube load. The Generator must have adequate clearance for the intake air filter and exhaust fan. Make

sure the area is a dry and dust free location. The X-ray tube load must be located within an interlocked

secure lead shielded enclosure that prevents unauthorized access when in use. Typical distances from

the X-ray tube to the Generator range from 5 meters to 20 meters depending on the length of the high

voltage cable. Installation and maintenance of the high voltage cable is extremely important to prevent

damage to both the X-ray tube and XRV Generator cable sockets. Locate the high voltage cables away

from high traffic areas and the input power cables. Use a minimum of #10 copper grounding wire and

#10 ring lugs when grounding any of the subsystem components. Make sure to use the proper crimping

tool for the ring lug used. Keep the ground distances as short as possible from the XRV Generator and

earth ground. Review the label on the rear of the XRV Generator to for the correct installation of the

input voltage. Incorrect input voltage will damage the XRV Generator.

System Grounding:

All of the subsystem components are required to be connected earth ground. Install all of the

system components in the desired location. Cabling should be as short as possible Use a minimum of

#10 AWG insulated copper stranded wire for the XRV Generator, X-ray tube, cooler/chiller, I/O Box and

Controller. Strip and crimp the wire on to a #10 Ring Lug using the proper crimping tool. Ensure that the

crimp is tight and does not pull out of the lug. Remove the ground connection nut from the X-ray tube

and place the ring lug over the threaded connection. Replace the nut and torque to the manufacturer’s

specification. Connect the opposite end of the wire to the rear panel ground of the XRV Generator

118157-001 Rev C

Page 40 of 98

Page 41

System Grounding:

ground. Strip and crimp #10 ring lugs on another #10 AWG wire to connect from the XRV generator to

earth ground. Keep this wire as short as possible.

If the Generator is a bipolar model, a ground wire with lugs (supplied) connect between the Anode

(Positive Generator) and the Cathode (Negative Generator) chassis ground. If the system includes the

I/O Subsystem Box and the Controller, connect the Controller ground using #10 AWG wire and

appropriate ring lugs to the I/O Subsystem. Run another ground from the I/O Subsystem Box ground lug

to earth ground. The grounding system should look like the following diagram for a unipolar system.

Page 41 of 98

118157-001 Rev C

Page 42

High Voltage Cable Installation:

General:

Two types of high voltage cable connectors used for connecting the XRV Generator to the X-ray tube.

They are either spring-loaded or non-spring loaded. The maximum high voltage for the XRV generator

and X-ray tube dictates either an R-24 or R-28 type cable. An R-24 high voltage cable is used on the

160kV XRV Generator while the R-28 is used on the 225kV models. The X-ray tube specifies what type of

cable plug it requires. Spring-loaded connectors are the preferred choice since they are adjusted for the

right amount of force when connecting to the receptacle. Gapping tools measure the correct spacing of

the flange when inserting the plug into the high voltage receptacle. Non-spring loaded cables are still

used but require increased maintenance and special attention when installing.

Non-spring loaded cable installation:

Several steps are required when installing a non-spring loaded high voltage cable.

The first step is to ensure that the cable plugs and receptacles are free from dirt

or damage that could cause high voltage breakdown. It is important to clean

both the cable plug and receptacle prior to installation. While wearing nitrile

powder free examination gloves, use a clean lint free cloth such as Kimtech Science Delicate Task Wipes,

remove any dust or dirt from the cable plug and cable receptacle.

Lint Free Wipes Nitrile Gloves Dow Corning #4 Silicone Compound

118157-001 Rev C

Page 42 of 98

Page 43

Cleaning Cable Plug:

Wipe cable end with

Apply 2 beads of

Spread compound

Remove compound

While supporting the cable with one hand, apply a small bead of the Dow Corning #4 silicone compound

to opposite sides of the cable plug to opposite sides of the cable plug. Spread the compound with your

finger evenly over the entire rubber cone surface of the plug. Using another clean lint free wipe, remove

the applied silicone from the cable plug. Do not use alcohol to clean the cable plug, as this will dry out

the rubber cone. Repeat for the opposite side and place in a clean area.

dry lint free cloth

evenly with finger

silicone compound

with new cloth

118157-001 Rev C

Page 43 of 98

Page 44

Cable Receptacle Cleaning:

Obtain a foam

Wrap a lint free clean

Insert into HV

Remove and

Inspect the cable receptacle in both the XRV Generator and X-ray tube for any dirt or foreign debris.

Wrap a lint free cloth around a “foam” glass cleaning brush and insert gently into the cable receptacle.

The foam brush should have 1/8” clearance on the inner circumference of the cable receptacle. While

holding the cloth, rotate the foam brush several times and remove from the receptacle. Inspect the

receptacle for debris. Repeat if necessary.

glass cleaning brush

cloth around foam brush

receptacle and rotate

discard cloth

118157-001 Rev C

Page 44 of 98

Page 45

Non-spring loaded HV cable installation:

Obtain flange

Place flange over

Thread flange on

Gapping tool for

Insert dry HV cable

Measure distance

High Voltage Cable Installation (X-ray Tube):

Wear nitrile gloves and obtain an X-ray tube cable flange. Wipe the flange with a lint free cloth and place

over a clean high voltage cable plug. (One cable flange will fit the X-ray tube and the other will fit the

XRV Generator). Rotate the flange counter clockwise on to the cable threads until it stops. Do not cross

thread the assembly. Insert the clean dry connector into the high voltage cable receptacle of the X-ray

tube with a small amount of force. Adjust the cable flange by rotating it clockwise until the flange is

approximately 1/2 inch from the X-ray tube mounting surface. Insert the gapping tool (5.5m – 6mm)

between the tube mounting surface and the flange. Rotate the flange until it is snug against the gapping

tool. Remove the gapping tool and rotate the flange slightly to align the mounting holes with the x-ray

tube holes. Tighten the grub screws of the cable flange to prevent any further rotation and remove the

plug from the receptacle. Apply 2 thin beads on opposite sides of the rubber cone. Distribute a thin coat

of silicone evenly on the entire cone. Finish the distribution by spreading in a circular fashion around the

circumference of the cone. Do not apply any silicone to the metal tip. If the silicone gets on the metal

tip, use a clean dry lint free cloth to remove it. Insert the HV cable plug into the receptacle until it seats

properly. Use the correct hardware and torque as per manufacturer specifications to tighten the cable

flange screws, alternating between the opposite placed screws.

and HV cable

R24 & R28 Cable

118157-001 Rev C

cable plug

plug into X-ray tube

Page 45 of 98

cable plug

with gapping tool

Page 46

High Voltage Cable Installation (X-ray Tube):

Apply 2 beads of

Spread compound

Insert HV cable plug

Tighten grub

Tighten cable flange

screws

in tube receptacle

silicone compound

screws

evenly with finger

118157-001 Rev C

Page 46 of 98

Page 47

High Voltage Cable Installation (XRV Generator):

Insert dry HV cable

plug in XRV receptacle

Adjust flange with

gapping tool

Tighten grub

screws

Apply 2 beads of

silicone compound

Spread compound

evenly with finger

Insert HV plug in XRV &

Repeat the assembly procedure as previously described on the opposite end of the high voltage cable

plug. The only notable difference is that the gapping tool will sit flush against the high voltage cable

receptacle when adjusting the flange. The tube receptacle has a collar that the flange fits over, while the

XRV Generator flange will sit flush against the receptacle.

tighten flange screws

High Voltage

Cable Gapping

Distances:

118157-001 Rev C

Page 47 of 98

Page 48

Standard High Voltage Cable Installation Problems:

High voltage arcing and failures can result from improperly gapped standard cables. Too much force on

a cable will cause the cone to bulge and deform creating voids within the receptacle. Another issue

involves stressing the filament and common connections resulting in breakdown. Never try to reuse a

kinked or bulging cable. Over application of silicone grease will also create voids and high voltage arcing.

Spring Loaded High Voltage Cable Installation:

Clean the spring-loaded cables and high voltage receptacles prior to insertion. Refer to the cleaning

procedures in the non-spring loaded section of this manual.

Wear nitrile gloves and obtain an X-ray tube cable flange. Wipe the flange with a lint free cloth and place

over a clean spring-loaded high voltage cable plug. (One cable flange will fit the X-ray tube and the other

will fit the XRV Generator). Rotate the flange counter clockwise on to the cable threads until it stops. Do

not cross thread the assembly. Insert the clean dry connector into the high voltage cable receptacle of

the X-ray tube with a small amount of force. Make sure the contact head of the cable filly inserts while

checking the gap. Refer to the “High Voltage Cable Gapping Distances” table for the correct gap

measurement. Use a gapping tool if available. When the desired gap has been set, rotate the cable

flange slightly so that the holes line up with the receptacle holes. Tighten the grub screws on the cable

flange so that it restricts it from rotating. Remove the cable plug and apply 2 thin beads on opposite

sides of the rubber cone. Distribute a thin coat of silicone evenly on the entire cone. Finish the

distribution by spreading in a circular fashion around the circumference of the cone. Do not apply any

silicone to the metal tip. If the silicone gets on the metal tip, use a clean dry lint free cloth to remove it.

Page 48 of 98

118157-001 Rev C

Page 49

Place the connector carefully into the X-ray tube receptacle without scraping any of the silicone from

Insert dry HV cable

plug into X-ray tube

Adjust flange for

Tighten grub

screws

Tighten cable flange screws

Apply 2 beads of

silicone

Spread compound

Insert HV cable plug

Correct Gapping

the cone. Tighten the cable flange screws, alternating between the opposing placed screws.

Spring Loaded High Voltage Cable Installation:

If a cable flange with a window is used, verify the correct compression was achieved by verifying 2 rings

are visible through the cable flange window. If not, reset the gapping distance until 2 rings are visible

(approx. 5.5mm displacement). Repeat this installation for the XRV Generator side of the cable.

proper gapping

in tube receptacle

evenly with finger

118157-001 Rev C

Page 49 of 98

Page 50

Under gapped

Over gapped

Typical gapping tool for

Spring Loaded High Voltage Cable Installation:

spring loaded cables

118157-001 Rev C

Page 50 of 98

Page 51

System Grounding Detail and HV Cable Connections:

118157-001 Rev C

Page 51 of 98

Page 52

Cooler/Chiller Connections:

The X-ray tube requires cooling to prevent damage. Single ended or unipolar tubes require a water

circulation system in order to cool the tube while a double ended or bipolar x-ray tube requires a chiller

and oil cooling. Depending on the power rating for the X-ray tube, the manufacturer will recommend a

specific flow rate and the cooling medium for the tube. A typical cooler will have a water fill cap, water

drain plug, water inlet and outlet flow connections, power input connections and interlock connections.

A typical cooler is illustrated below.

In some environments it may be necessary to mix glycol with the water in order to prevent freezing

should the ambient temperature drop. Allow sufficient space for the unit when installing for air

circulation. The manufacturer normally recommends the minimum distance required and the mixture

for glycol to water for specific temperature ranges. The water outlet connection is water that flows to

the x-ray tube anode while the water inlet connection returns from the X-ray tube anode. Although the

cooler may provide temperature indicators and over temperature switches, it is important for the

correct water flow configuration from the tube to the cooler. Failure to do so may result in overheating

and tube damage. Below is a typical symbol for inlet and outlet water connections.

Various hose connections may be used for the water connections. Some are quick disconnecting while

others either use threads or hose clamps. Consult Spellman High Voltage when ordering the cooler for

more information regarding connectors. If the I/O Box is purchased with the sub-system, a circuit

breaker will be provided for the cooler. If the I/O Box is not a part of the sub-system, then the user will

be responsible for the correct breaker installation. Typically a cooler will require a 7.5 Amp. double pole

breaker. Consult Spellman High Voltage for sizing the breaker.

118157-001 Rev C

Page 52 of 98

Page 53

Ball Type

Internal Cooler

Internal Cooler

Cooler/Chiller Connections:

The cooler may or may not include a water flow indicator. Typically, water flow may be rated in liters

per minute or gallons per minute depending on the tube size and specifications. It is important to check

the water flow with a meter to ensure the tube has adequate cooling. Digital or traditional ball type

meters may be permanently installed for verification. An internal flow and over temperature switch is

provided with a dry set of contacts that can be integrated with the XRV Generator that will turn off the

high voltage if the water flow is insufficient or temperature is too high.

Flow Meter

Flow Switch

Temperature Switch

The bipolar tube uses oil since the anode is at high voltage potential and must be isolated from ground.

Oil is circulated by a pump and cooled using a refrigerant compressor. Oil flow rates and chiller sizing is

dictated by the power dissipated by the tube. The manufacturer of the tube generally recommends flow

rates and compressor size. If the I/O Box interface is used, a circuit breaker is included for the chiller. If

the user chooses not to include the I/O Box assembly, the circuit breaker needs to be sized to handle the

in-rush current when the compressor turns on.

Generally a 20 Amp. breaker for motors will

suffice. Consult Spellman High Voltage

when selecting a breaker size for the chiller

used. Leave enough space surrounding the

chiller for air flow.

Page 53 of 98

118157-001 Rev C

Page 54

Cooler

Application

Chiller

Cooler/Chiller Connections:

Application

Cooler/Chiller Connections: (Complete System)

118157-001 Rev C

Page 54 of 98

Page 55

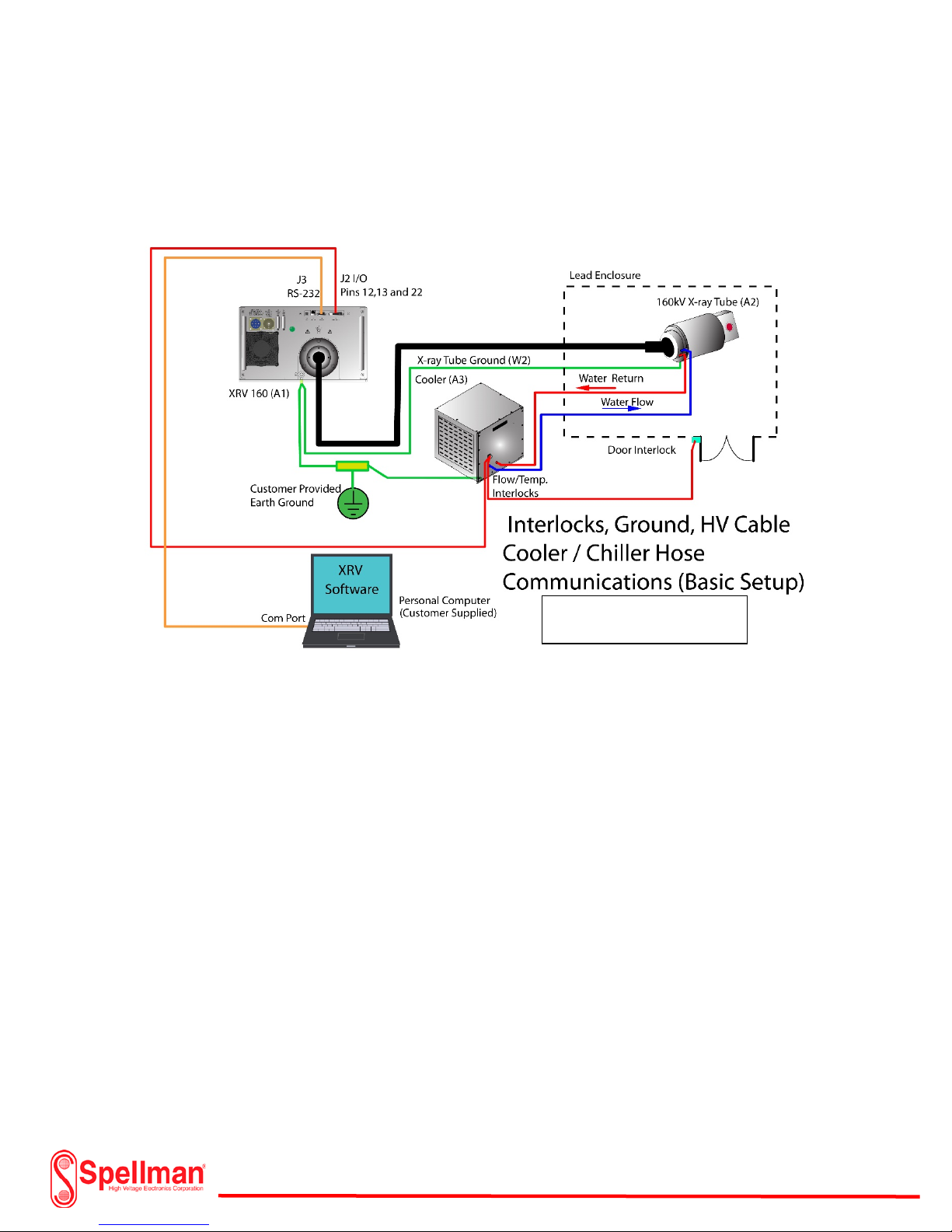

Cooler/Chiller Connections: (Complete System)

Interlock, Communication Connections (Unipolar Basic):

The minimal requirements for the user include the XRV Generator/s, High Voltage Cable and Flanges,

Cooling or Chiller, Personal Computer and the X-ray tube. All other requirements such as a lead

enclosure, circuit breakers, grounding equipment, interlock switches, safety monitoring and grounding

devices are the responsibility of the user. The input power cables should be the last connections

installed.

The XRV Generator I/O connector has provisions for safety interlock circuitry that will terminate high

voltage. A safety interlock chain is comprised of normally pen switches or contacts that close in a series

circuit in order to enable high voltage operation. If the user wishes to enable high voltage but one or

more safety interlocks are open, the high voltage is inhibited until the interlock is satisfied. Interlocks

may be latching or non-latched. Latched interlocks occur after high voltage is on and the user must

Page 55 of 98

118157-001 Rev C

Page 56

Interlock, Communication Connections (Unipolar Basic):

initiate a “fault reset” to clear the condition. If the fault condition still exists, the high voltage is unable

to be enabled until the fault is cleared and a reset is initiated. Some common interlocks include x-ray

chamber access, chiller/cooler water flow, chiller / cooler water temperature and ambient temperature.

118157-001 Rev C

Typical Interlock Connections

Page 56 of 98

Page 57

RS-232 Cable

Ethernet Cable

USB Cable

Interlock, Communication Connections (Unipolar Basic):

The cooler or chiller will normally provide a thermal switch and a flow switch having a dry set of

contacts. This can be used to remove high voltage from the tube. An access interlock switch must be

used on the lead enclosure door to prevent high voltage operation when opened.

The next step is to choose the type of communication used for the control of the XRV Generator. There

are there are 3 communication interface options including a Com Port RS-232, Ethernet Connection, and

USB connection. The most commonly used is the RS-232 Com Port Connection. The connection consists

of a customer supplied cable and the XRV Generator communication software selection.

Page 57 of 98

118157-001 Rev C

Page 58

RS-232 Cable

Interlock, Communication Connections (Unipolar Basic):

118157-001 Rev C

Page 58 of 98

Page 59

Ethernet Cable

USB Cable

Interlock, Communication Connections (Unipolar Basic):

118157-001 Rev C

Page 59 of 98

Page 60

Power Connections (Unipolar Basic):

MS-3106A-24-11S

Connector & Clamp

Amphenol style connectors are included with the XRV Generator for connecting power to the unit.

There are two types of connectors. Up to 4 kilowatt generators use an Amphenol MS3106A-24-11S

straight connector for connecting input power. The 6 kilowatt generator requires a 3 phase input and

uses two separate connectors. One connector is for the Mains Input and the remaining is for the

Auxiliary Input.

118157-001 Rev C

Page 60 of 98

Page 61

Power Connections (Unipolar Basic):

6kW Input Power Connectors

Use stranded copper wire #8 AWG for the Input power Mains and Ground connection. Use stranded

copper wire #12 AWG for the Auxiliary Line, Neutral and Ground connection. Input power requirements

for the 4kW Generators are 180Vac to 264Vac ± 10%, 30A maximum for Mains and 5A maximum for

Auxiliary.

The 6 kilowatt generator uses an MS3106A-24-22S style connector for the Mains Input and an

MS3106-20-3S style connector for the Auxiliary Power Input. The 6kW generators require 3 Phase

208Vac ±10%, 30A maximum input or 400Vac ±10%, 15A Max. Input. The input power is selected when

placing the order for the XRV Generator . The Auxiliary Power Input requires a separate 230 Vac ±10%,

5A maximum source. Use #10 AWG copper stranded wire for each phase and ground on the Input Power

Mains JB-1. Use #12 AWG copper stranded wire for each line and ground on the Input Power Auxiliary

JB-2.

Page 61 of 98

118157-001 Rev C

Page 62

Power Connections (Unipolar Basic):

4kW Input Power

Connector

6kW Input Power

Connectors

The input power connectors are required to have soldered connections. Avoid shorts or loose wiring

when assembling. Use an ohmmeter to check for shorted connections. Use the appropriate size wire for

each connection. Input power wires should be run neat and as short as possible. Avoid high traffic areas

or places where they are easily damaged by other equipment. When assembling, remove the clamp and

shell to expose the pin cups. Remove the insulation from one end of the wire (approximately 3/8”) so

the bare wire will touch the bottom of the solder cup and be level with the top. Use the appropriate

wire size according to the connector specification. Slide a 1-1/4 inch piece of shrink tubing over the wire

insulation for the final step. Using a soldering iron, tin the stranded wire from the tip up to the

insulation. Place the wire straight into the pin cup so that the tip rests on the bottom and apply the

soldering iron to the outside of the cup. Insert the solder into the cup and apply until it almost fills to the

top. Let the connection and wire cool. Check for cold solder joints or solder bridges. Slide the shrink

tubing down over the cup pin and heat the tubing with a heat gun so that it fits snugly over the wire and

cup. Repeat the procedure for the remaining connections. Check each connection so that it is secure and

not touching any other connections. Slide down the cover and ring clamp with the rubber shroud

toward the connector and tighten. Secure the wire clamp by tightening the two screws.

118157-001 Rev C

Page 62 of 98

Page 63

Strip and Tin

Insert Wire into Pin Cup

and Apply Solder

Slide Shrink Tubing Over

Solder Cup and Apply Heat

Shrink Tubing Over

Completed XRV Cable, Clamp

Power Connections (Unipolar Basic):

Appropriate Size Wire

Soldered Connections

and Rubber Shroud

The input power connections for the 6 kilowatt XRV Generator is the same procedure as above with the

exception of the additional connector and different wire size. Check all power connections to the XRV

Generator before any connections to the mains and auxiliary power source.

Note: The cooler / chiller system will have instructions on cable sizing for power connections and

interlock connections.

118157-001 Rev C

Page 63 of 98

Page 64

Power Connections (Unipolar Basic):

Power Source Connections (Unipolar Basic):

A single phase 208 Vac, 60 Ampere power source is required for the 4 kilowatt XRV Generator. Use a

circuit breaker rated for 30 amperes for protection on the mains input and a circuit breaker rated for 10

amperes on the auxiliary input. Typically a 7.5 amp. breaker is used for the cooler and a 20 amp. breaker

for a chiller. Consult the cooler or chiller manual for circcuit breaker sizing. Consult Spellman High

Voltage for input voltage options.

118157-001 Rev C

Page 64 of 98

Page 65

Emergency Stop

Switch

Typical 208 Vac 3Ø

Power Source Connections (Unipolar Basic):

The circuit breakers should be located on a panel in an accessible area. It is recommended but not

necessary to have an emergency stop switch that will interrupt all the input power sources to the

generator and subsystem.

Verify that the ground buss bar in the main breaker panel connects to earth ground. Connect the mains

and auxiliary cable from the XRV generator and the cooler or chiller to the load side of the circuit

breakers.

Breaker Box

118157-001 Rev C

Page 65 of 98

Page 66

118157-001 Rev C

Page 66 of 98

Page 67

Power Source Connections (Unipolar Basic):

118157-001 Rev C

Page 67 of 98

Page 68

Power Source Connections (Unipolar Basic):

118157-001 Rev C

Page 68 of 98

Page 69

JB1 to JB2 Anode to

J2 to J6 Anode to Cathode

J3 to J7 Anode to Cathode

Anode Power & Feedback Connections

Power & Feedback Connections (Bipolar Basic):

The power connections for bipolar XRV Generators are identically the same as the unipolar XRV

Generators with the exception of an added chassis and three interconnect cables. Follow the procedure

for the unipolar generators but include the following cables and additional chassis ground. See page 35

for system diagram.

Cathode Power Cable

Feedback Cable

Inverter Control Cable

118157-001 Rev C

Page 69 of 98

Page 70

Power Connections (I/O System Interface Box):

I/O Box Configuration without

I/O Box Configuration with

The I/O Box offers a convenient method to connect the input power, the XRVC Controller, XRV

Generator and Cooler/Chiller and associated interlock circuits. If the I/O System Interface Box is used

without the XRVC Controller, it will include a key switch and 3 status indicators on the left side of the

front panel. If the XRVC Controller is used, then the left side of the panel will be blank.

Optional XRVC Controller

Both I/O Boxes include an Amphenol style connector on the rear panel for input power connections. The

circular connector can be either supplied as a separate piece or with the user specified cable length. If

the user decides to install the cable, use #8 AWG copper stranded wire soldered to the Amphenol

mating connector.

118157-001 Rev C

Optional XRVC Controller

Page 70 of 98

Page 71

Power Connections (I/O System Interface Box):

Note: Included cables with the I/O Box not shown for the

Generator Power, or XRVC Controller

Connect the ground lug on the rear panel to earth ground. Use a minimum of #10 AWG copper stranded

wire. Remove the top cover of the I/O Box for the Chiller or Cooler Interlock and power cable

installation. The Chiller or Cooler includes instructions for sizing the input power wire and detailing

water or oil flow and thermal interlock connections. Remove the top of the I/O Box and locate TB-4 and

TB-5. Route the input power wires from the Cooler or Chiller through the “Cooler” wire grommet and

connect to TB-4 Terminals 1, 2 and 3. Make sure that #3 is the ground connection from the Cooler or

Chiller. The Cooler or Chiller voltage is normally 230Vac single phase. Consult the manufacturer for

additional information. Connect the interlock switches for temperature and coolant flow from the

Cooler or Chiller through the “Cooler “grommet to TB-5, Terminals 1 and 3. Refer to cutout of I/O Box

diagram for connection locations.

Interlock Switches Cooler/Chiller

118157-001 Rev C

Page 71 of 98

Page 72

Power Connections (I/O System Interface Box):

118157-001 Rev C

Page 72 of 98

Page 73

Power Connections (I/O System Interface Box):

The I/O Box also includes an additional door interlock that may be used to interrupt power to the XRV

Generator in the event of unauthorized access to the X-ray chamber or other restricted areas. The

interlock connection is located on TB6 terminals 1 and 2. Use #16 AWG copper wire for the connections.

118157-001 Rev C

Page 73 of 98

Page 74

Power Connections (I/O System Interface Box):

C.D.R.H. Bridge Jumper Location TB-7

If a Door Power Interlock is used, remove the bridge jumper on TB7 terminals 1 and 2 and terminals 3

and 4. The Power Interlock is designed for use with C.D.R.H. requirements that are mounted to an x-ray

cabinet and door to provide the required disconnection of the input voltage independent of any moving

parts other than the door.

118157-001 Rev C

Page 74 of 98

Page 75

Main Input Power Connections (I/O System Interface Box):

The main input power connections will depend on the power rating of the XRV Generator. A 4kW XRV

Generator will require a single phase 180Vac to 264Vac source while the 6kW XRV Generator requires a

3 phase 208Vac +/-10% Input. The input voltage requirement for the 6kW units must be specified by the

user when purchased. If the user installs the input power cables, the appropriate wire size must be used.

Recommended wire for the 4kW generators and below is copper stranded #8 AWG. The wire size for the

6kW 3 phase systems is #10AWG due to the higher current draw on the input line. With the exception of

the Cooler/Chiller and Power Door Interlock connections, all of the cabling and connectors are provided

with the I/O System Interface Box to easily connect all of the subsystem components.

Note: Although a 3 phase 400Vac system can be selected, the I/O Subsystem Box for that voltage is

not available at this time.

118157-001 Rev C

Page 75 of 98

Page 76

Main Input Power Connections (I/O System Interface Box):

118157-001 Rev C

Page 76 of 98

Page 77

I/O Subsystem Interface Box (System Diagram):

118157-001 Rev C

Page 77 of 98

Page 78

XRVC Control Box:

The XRVC Control Box eliminates the need of having a personal PC to run and monitor the XRV

Generator and subsystem components. It employs an embedded computing system that runs a custom

graphical use (GUI) interface and allows the user to configure custom X-ray tube profiles for any of the

Spellman XRV series. Although it can be used without the I/O System Interface Box, it is more readily

integrated with it. The I/O Box includes the cables and connectors that intuitively connects to the XRVC

Controller. The placement and setup is relatively quick and allows the user a plug and play system.

Instructions on setting up the XRVC controller and operation are covered in the XRVC manual.

118157-001 Rev C

Page 78 of 98

Page 79

XRVC Controller, I/O System Interface Box, Cooler/Chiller,

XRVC Control Box and I/O System Box Setup:

XRV Generator and X-Ray Tube Setup for 4kW System

Page 79 of 98

118157-001 Rev C

Page 80

XRVC Controller, I/O System Interface Box, Cooler/Chiller,

XRVC Control Box and I/O System Box Setup:

118157-001 Rev C

XRV Generator and X-Ray Tube Setup for 6kW System

Page 80 of 98

Page 81

GUI Installation:

The GUI is designed to control the XRV series x ray generator. It allows users to control all necessary

functions of the x-ray generator from a user-friendly windows base menu. Functionality is organized into

nine screens that appear as tabs within the GUI. The “Main Control” screen will generally be the used

most frequently. Additional screens for seasoning, communication, user configuration and filament

control provide functionality necessary to control and monitor all aspects of the XRV series power

supplies.

1.1 System Requirements

• A computer with a male RS232 D 9 pin connector

• Windows XP, Windows 7, or Windows 10

• CD-ROM drive, USB or from Spellman website

• Color Monitor with display resolution of 1024 X 768

2.2 Installation via CD

1. Insert the XRV disk in the CD Drive

2. Click “Start” Button on screen

3. Click on “My Computer icon”

4. Click CD drive icon

5. Double-click on the XRV setup icon

6. Follow the instructions displayed on screen

2.3 Installation via USB Flash Drive

1. Insert the XRV flash drive in the USB port of the computer

2. Open the GUI 1.8kW to 6kW folder

3. Open the GUI X4867 folder

4. Open the GUI X4867 subfolder

5. Open D0204001_V15038 folder

6. Double Click Setup 1 Icon

7. Follow instructions displayed on screen

118157-001 Rev C

Page 81 of 98

Page 82

Flash Drive USB installation Step 1

Flash Drive USB installation Step 2

118157-001 Rev C

Page 82 of 98

Page 83

Flash Drive USB installation Step 3

Flash Drive USB installation Step 4

118157-001 Rev C

Page 83 of 98

Page 84

Flash Drive USB installation Step 5

XRV Generator Rear Panel

Software Communication:

After the GUI is installed, shut down the computer. Select which type of communication cable will be

used to control the XRV Generator. Connect a 9 pin com port (RS-232), Ethernet or USB from the

computer to the XRV Generator J3, J4 or J5 input connector. Make sure that the appropriate interface

cable is plugged in before power is applied to the computer or XRV Generator.

118157-001 Rev C

Page 84 of 98

Page 85

Software Communication:

When the appropriate cable is connected, power up the computer and ONLY the auxiliary power on the

XRV Generator. Do NOT apply power to the Mains on the generator. Launch the GUI from the computer

and click on the “Coms” Tab. Select the desired communication setup as illustrated in the diagram.

Note: When using the XRVC control subsystem option, no software installation is necessary.

Note: When using the RS232 method of communication, the user must select a Com

port, Baud Rate, Data Bits, Parity, and Stop Bits. When using the Ethernet method of

communication, the user must select a port number and IP address. Be sure to press

the “Click here to save these settings” button when finished.

118157-001 Rev C

Page 85 of 98

Page 86

Software Communication:

Once communication has been set up, click on the “Main Control” tab to verify the data transmission

information is transferred from the XRV Generator to the computer as shown above. For additional

information regarding software installation and control, refer to Spellman High Voltage “XRV Controller

Reference Guide Manual (Classic)”.

118157-001 Rev C

Page 86 of 98

Page 87

X-Ray Tube Filament Calibration:

The X-ray tube filament current is required to be calibrated once the initial installation is completed

or if the X-ray tube was replaced. The calibration is required for both the large and small filaments. If

the tube only has one filament, only the large filament will require calibration. The tube

manufacturer will recommend the maximum setting for each filament. In most cases, the filament

current supplied will be DC unless the user has specified an AC filament source when procuring the

XRV Generator. If an AC filament source was selected, then an appropriate meter having an

adequate frequency response of 25kHz or more should be used to measure the RMS current.

Current measurements are made directly in the high voltage cable that is connected to the X-ray

tube. Refer to the current limit data for small and large found in the Tube Specification Data Sheet.

The filament measuring and calibration adapter is available as an accessory kit from Spellman High

Voltage.

118157-001 Rev C

Page 87 of 98

Page 88

X-Ray Tube Filament Calibration:

Test equipment required:

1=Measuring Adapter for high voltage socket

2= Measuring Adapter for high voltage cable plug

3= Digital Multimeter (Customer Supplied)

C=Com m on Connection, L= Large Filament Connection, S= Small Filament Connection

118157-001 Rev C

Page 88 of 98

Page 89

X-Ray Tube Filament Calibration Setup:

118157-001 Rev C

Page 89 of 98

Page 90

X-Ray Tube Filament Calibration Using GUI:

1) Connect the filament calibration for the large or small filament as shown in the diagram. Make

sure the common is connected to earth ground.

2) Energize the Auxiliary circuit breaker to the XRV Generator.

Do Not Energize the Main Circuit Breaker!

3) Launch the supplied XRV software and verify the XRV Generator is communicating with the GUI.

4) Refer to the manufacturer’s X-ray tube specification and verify the maximum current for the

filament.

118157-001 Rev C

Page 90 of 98

Page 91

5) Click on the “User Config” tab and enter “useraccess” for the password.

6) Enter the “Large Filament Limit” current and Click to send.

Note: In this example, the tube only has a large filament. The “Small Filament Limit”

setting can be ignored.

118157-001 Rev C

Page 91 of 98

Page 92

7) Click on the “Fil/Local Cntrl” tab and select “Large” Filament.

8) Select Filament “On”

118157-001 Rev C

Page 92 of 98

Page 93

9) Return to “UserConfigs” tab and enter password.

10) Starting from 0 current, slowly increase the Large Filament current Pre-heat setting while

monitoring the digital multimeter. Increase the current until the multimeter reads 10% below

the maximum current setting on the tube. Do not exceed the maximum tube current!

118157-001 Rev C

Page 93 of 98

Page 94

11) The actual filament current and the monitored current monitored by the GUI should be within

1% tolerance. If the reading is not at spec, adjust R53 (LARGE FIL I CAL) on Filament/Feedback

board XRV (Part # 460158-XXX).

12) Select the “Fil/Local Cntrl” tab and select Filament Control “Off”. The Small Filament Calibration

follows the same procedure as the Large Filament Calibration. Ensure the multi-meter current

connections are through the small filament as referred to in the diagram. For additional

information, see Filament Calibration Procedure in the XRV Generator Manual.

118157-001 Rev C

Page 94 of 98

Page 95

13) Return to “User Configs” and enter password.

14) Return “Preheat Settings” to original filament current settings or recommended manufacturer

recommended settings. Click to save and set the preheat limit.

118157-001 Rev C

Page 95 of 98

Page 96

Accessory Test Kits for XRV Generators:

XRV-14-1 (R24 Dummy/Blanking Plug)

R24 test plug useful for evaluating or troubleshooting

XRV160 model generators or X-ray tube functionality. The

plug is inserted into the high voltage receptical and allows

for operation of the XRV Generator without the X-ray tube

load.

XRV-14-2 (R28 Dummy/Blanking Plug)

R28 test plug useful for evaluating or troubleshooting

XRV225 model generators or X-ray tube functionality. The

plug is inserted into the high voltage receptical and allows

for operation of the XRV Generator without the X-ray tube

load.

XRV-14-3 (Filament Adapter with Resistor)

XRV filament power supply calibration tool utilizing a

resistive load for filament current calibration and

verification. For use with both the XRV160 and XRV225

models. Customer supplied voltmeter is required.

118157-001 Rev C

Page 96 of 98

Page 97

XRV-1-(x)

High Voltage Power Supply (A1)

XRV-2-(x)

X-Ray Tube (A2)

XRV-3-(x)

HV Cable & GND Cable Kit (W1 & W2)

XRV-4-(x)

HV Cable Flange (Power Supply Side) (FL1)

XRV-5-(x)

HV Cable Flange (X-ray Tube Side) (FL2)

XRV-6-(x)

Cooler/Chiller (A3)

XRV-7-(x)

Cooling Hose (Item 3 & 4)

XRV-8-(x)

Controllers & Cable Kit (A4, W3, W4, W5)

XRV-9-(x)

I/O Box (A5)

XRV-10-(x)

Mains/Aux & GND Cable Kit (W6 & W10)

XRV-11-(x)

I/O Box to Door Interlock Cable (W7)

XRV-12-(x)

I/O Box to Controller Cable (W8)

XRV-13-(x)

I/O Box Input Power Cable (W9)

XRV-14-(x)

Test Kits for XRV

Accessory Test Kits for XRV Generators:

XRV-14-4 (Filament Measuring Adapter)

XRV X-ray tube filament calibration tool utilizing a unique