Page 1

Instruction Manual

SPELLMAN

HIGH VOLTAGE ELECTRONICS

CORPORATION

One Commerce Park

Valhalla, New York, 10595

+1(914) 686-3600* FAX: +1(914) 686-5424*

E-mail: sales@spellmanhv.com

Website: www.spellmanhv.com

XRB011

R

XRB011 User’s Manual 118148-001 Rev A

Page 2

IMPORTANT SAFETY PRECAUTIONS

SAFETY

THIS POWER SUPPLY GENERATES VOLTAGES THAT ARE DANGEROUS AND MAY BE FATAL.

OBSERVE EXTREME CAUTION WHEN WORKING WITH THIS EQUIPMENT.

High voltage power supplies must always be grounded.

Do not touch connections unless the equipment is off and the

Capacitance of both the load and power supply is discharged.

Allow five minutes for discharge of internal capacitance of the power supply.

Do not ground yourself or work under wet or damp conditions.

SERVICING SAFETY

.

Maintenance may require removing the instrument cover with the power on.

Servicing should be done by qualified personnel aware of the electrical hazards.

WARNING note in the text call attention to hazards in operation of these units

that could lead to possible injury or death.

CAUTION notes in the text indicate procedures to be followed to avoid possible

damage to equipment.

Copyright 2000, Spellman High Voltage Electronics Corporation. All Rights Reserved.

This information contained in this publication is derived in part from proprietary and patent data. This information has

been prepared for the express purpose of assisting operating and maintenance personnel in the efficient use of the

model described herein, and publication of this information does not convey any right to reproduce it or to use it for

any purpose other than in connection with installation, operation, and maintenance of the equipment described.

118091-001 REV. B

Page 3

WICHTIGE SICHERHEITSHINWEISE

SICHERHEIT

DIESES HOCHSPANNUNGSNETZTEIL ERZEUGT LEBENSGEFÄHRLICHE HOCHSPANNUNG.

SEIN SIE SEHR VORSICHTIG BEI DER ARBEIT MIT DIESEM GERÄT.

Das Hochspannungsnetzteil muß immer geerdet sein.

Berühren Sie die Stecker des Netzteiles nur, wenn das Gerät ausgeschaltet ist und die elektrischen

Kapazitäten des Netzteiles und der angeschlossenen Last entladen sind.

Die internen Kapazitäten des Hochspannungsnetzteiles benötigen ca. 5 Minuten, um sich zu entladen.

Erden Sie sich nicht, und arbeiten Sie nicht in feuchter oder nasser Umgebung.

SERVICESICHERHEIT

Notwendige Reparaturen können es erforderlich machen, den Gehäusedeckel während des Betriebes zu

entfernen.

Reparaturen dürfen nur von qualifiziertem, eingewiesenem Personal ausgeführt werden.

“WARNING” im folgenden Text weist auf gefährliche Operationen hin, die zu Verletzungen oder zum Tod

führen können.

“CAUTION” im folgenden Text weist auf Prozeduren hin, die genauestens befolgt werden müssen, um

eventuelle Beschädigungen des Gerätes zu vermeiden.

118091-001 REV. B

Page 4

PRECAUTIONS IMPORTANTES POUR VOTRE SECURITE

CONSIGNES DE SÉCURITÉ

CETTE ALIMENTATION GÉNÈRE DES TENSIONS QUI SONT DANGEUREUSES ET PEUVENT ÊTRE FATALES.

OYEZ EXTRÊMENT VIGILANTS LORSQUE VOUS UTILISEZ CET ÉQUIPEMENT.

S

Les alimentations haute tension doivent toujours être mises à la masse.

Ne touchez pas les connectiques sans que l’équipement soit éteint et que la capacité à la fois de la charge et de

l’alimentation soient déchargées.

Prévoyez 5 minutes pour la décharge de la capacité interne de l’alimentation.

Ne vous mettez pas à la masse, ou ne travaillez pas sous conditions mouillées ou humides.

CONSIGNES DE SÉCURITÉ EN CAS DE REPARATION

La maintenance peut nécessiter l’enlèvement du couvercle lorsque l’alimentation est encore allumée.

Les réparations doivent être effectuées par une personne qualifiée et connaissant les risques électriques.

Dans le manuel, les notes marquées « WARNING » attire l’attention sur les risques lors de la manipulation de ces

équipements, qui peuvent entrainer de possibles blessures voire la mort.

Dans le manuel, les notes marquées « CAUTION » indiquent les procédures qui doivent être suivies afin d’éviter

d’éventuels dommages sur l’équipement.

118091-001 REV. B

Page 5

IMPORTANTI PRECAUZIONI DI SICUREZZA

SICUREZZA

QUESTO ALIMENTATORE GENERA TENSIONI CHE SONO PERICOLOSE E

POTREBBERO ESSERE MORTALI.

PONI ESTREMA CAUTELA QUANDO OPERI CON QUESO APPARECCHIO.

Gli alimentatori ad alta tensione devono sempre essere collegati ad un impianto di terra.

Non toccare le connessioni a meno che l’apparecchio sia stato spento e la capacità interna

del carico e dell’alimentatore stesso siano scariche.

Attendere cinque minuti per permettere la scarica della capacità interna dell’alimentatore

ad alta tensione.

Non mettere a terra il proprio corpo oppure operare in ambienti bagnati o saturi d’umidità.

SICUREZZA NELLA MANUTENZIONE.

Manutenzione potrebbe essere richiesta, rimuovendo la copertura con apparecchio

acceso.

La manutenzione deve essere svolta da personale qualificato, coscio dei rischi elettrici.

Attenzione alle AVVERTENZE contenute nel manuale, che richiamano all’attenzione ai

rischi quando si opera con tali unità e che potrebbero causare possibili ferite o morte.

Le note di CAUTELA contenute nel manuale, indicano le procedure da seguire per evitare

possibili danni all’apparecchio.

118091-001 REV. B

Page 6

SPELLMAN HIGH VOLTAGE Introduction 1

Installation and Operating Manual Page1-1 118149-001 REV F

XRB011 INTRODUCTION

1

XRB011

SERVICE

AND

INSTALLATION

MANUAL

INSTALLATION

2

INTERFACING

3

TROUBLESHOOTING

4

SCHEMATICS (Simplified Diagram)

5

Page 7

SPELLMAN HIGH VOLTAGE Introduction 1

Installation and Operating Manual Page1-2 118149-001 REV F

CHAPTER 1

XRB011 INTRODUCTION

CONTENTS:

Section

1.1 XRB011 DESCRIPTION ............................................................................................................................................... 3

1.2 TECHNICAL SPECIFICATIONS ........................................................................................................................................... 3

1.2.1 Generator Hardware Specifications .......................................................................................................................... 3

1.2.2 Generator Control Modes / Application Features ..................................................................................................... 3

1.2.3 Power Supply Requirements ...................................................................................................................................... 3

1.2.4 Environment Requirements ........................................................................................................................................ 4

1.2.5 Mechanical ................................................................................................................................................................. 5

1.3 THEORY OF OPERATION .......................................................................................................................................... 7

1.3.1 Function Overview ................................ ................................................................................................ ..................... 7

1.3.2 Input Line Power ........................................................................................................................................................ 7

1.3.3 HV Inverter ................................................................................................................................................................ 7

1.3.4 High Voltage Transformer ......................................................................................................................................... 7

1.3.5 High Voltage Assembly .............................................................................................................................................. 7

1.3.6 System Control PWB .................................................................................................................................................. 7

1.3.7 Filament Power .......................................................................................................................................................... 8

1.3.8 High Voltage Interlock ............................................................................................................................................... 8

1.4 SAFETY ......................................................................................................................................................................... 9

1.4.1 Safety and Warning Symbols ...................................................................................................................................... 9

Page 8

SPELLMAN HIGH VOLTAGE Introduction 1

Installation and Operating Manual Page1-3 118149-001 REV F

1.1 XRB011 DESCRIPTION

The XRB011 MONOBLOCK is a complete integrated system consisting of a high voltage power supply

(HVPS), filament supply, X-ray tube and oil encapsulant which provide the required high voltage insulation in

one compact enclosure. The combination of proprietary control system and protection circuitry enables the

supplies to operate under arcing and extreme transient conditions without damage or interruptions. Additional

advantages are the elimination of high voltage cables and extremely low leakage X-ray radiation.

The XRB011 incorporates local and remote programming, monitoring, and fault indicators including safety

interlock. The X-ray source is a sealed unit containing a HVPS and an X-ray tube. The insulating oil provides

electrical insulation for the high voltage sections of the power supply and the X-ray tube in a sealed tank. The

oil also functions as a coolant to carry heat away from the tube. Convection cooling augmented by customer

provided minimum 50cfm external fan is required for the 50W option. A rubber bellows in the tank of the X-ray

source compensates for the expansion of the oil as the oil temperature varies with operating conditions thereby

eliminating the need for bulky overflow tank.

.

1.2 TECHNICAL SPECIFICATIONS

1.2.1 Generator Hardware Specifications

kVp range:

35 to 80 kVp output capability

kVp steps:

Continuous with 12 bits resolution

kVp accuracy:

<=1% (measured after kVp rises to the

peak level)

Ripple (kV):

<= 1% Peak to Peak

Settling time:

< 10ms to within 95% of the

programmed voltage

Reproducibility:

<0.5%

Stability:

<=0.01% per 8 hours after a ½ hour

warm up

Temperature Coefficient:

<=100ppm/ ℃

Time range:

XRB011 is specified as a Continuous

operation.

mA :

250µA maximum for 20W option

700µA maximum for 50W option

mA accuracy:

<2.5% (measured after mA rises to

stable DC level)

mA range

0 to 250 µA for 20W option

0 to 700 µA for 50W option

Reproducibility:

<0.5%

1.2.2 Generator Control Modes / Application Features

Manual Operating Mode – 2 Parameters Mode (kV, mA)

System Communication Protocol / Fault & Error Management

See details in the Serial Communication Protocol Specifications

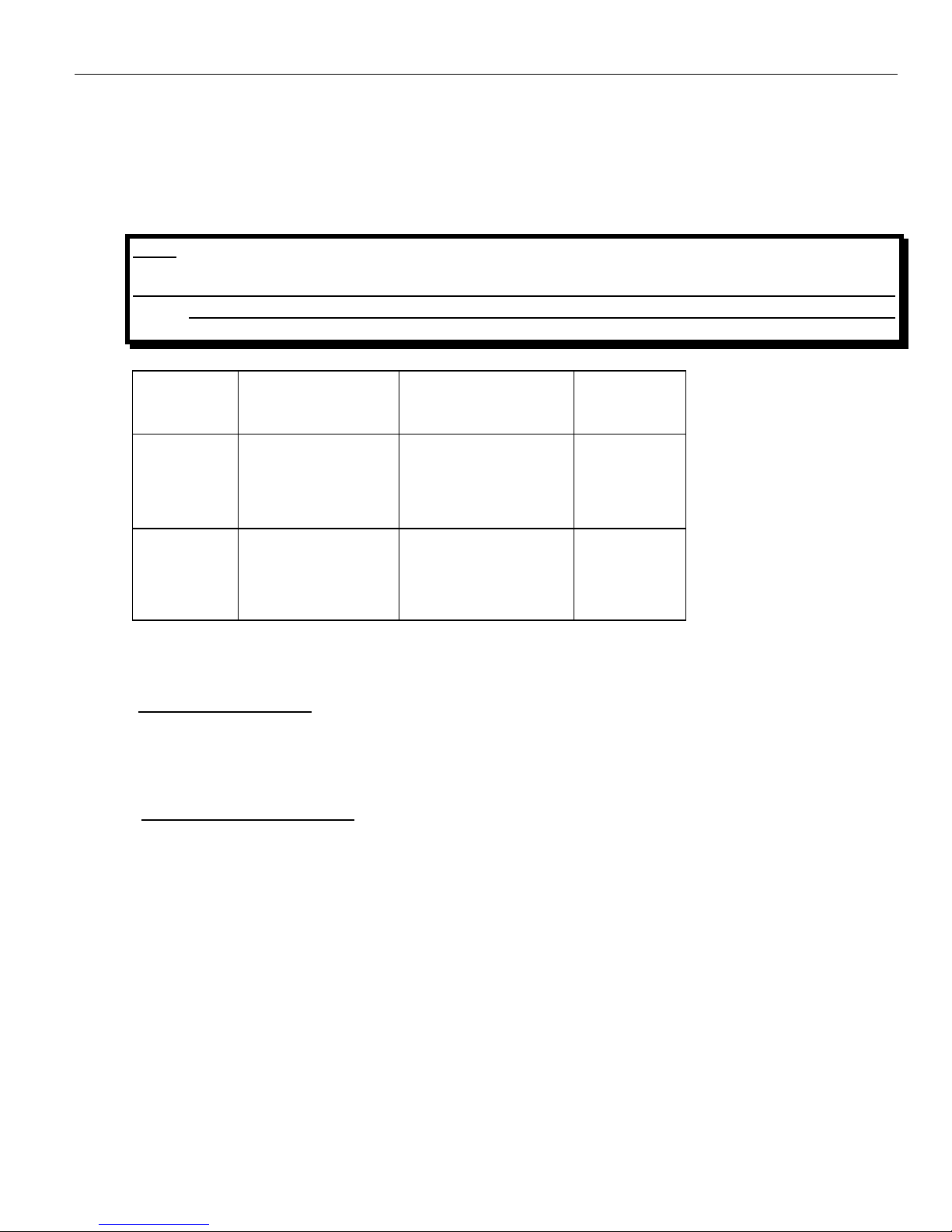

1.2.3 Power Supply Requirements

Single Phase

Page 9

SPELLMAN HIGH VOLTAGE Introduction 1

Installation and Operating Manual Page1-4 118149-001 REV F

Line Voltage

24VDC±1VDC, 2.5A (20W option). 4A (50W option)

The following table defines the power line requirements for the generators.

NOTE: THE FOLLOWING TABLE CONTAINS RECOMMENDED VALUES FOR THE 24V INPUT POWER.

A POOR QUALITY INPUT LINE MAY RESULT IN THE INSTALLER HAVING TO

DERATE THE GENERATOR'S MAXIMUM POWER

Mains

Voltage

Minimum

Recommended

Minimum

Recommended

Ground Wire Size

Apparent

Mains

Resistance

24VDC

J1-1

J1-2

J1-3

#20 AWG (0.52 mm

2

)

#20 AWG (0.52 mm

2

)

#20 AWG (0.52 mm

2

)

0.033

0.033

0.033

24V RETURN

J1-5

J1-6

J1-7

#20 AWG (0.52 mm2)

#20 AWG (0.52 mm2)

#20 AWG (0.52 mm2)

0.033

0.033

0.033

1.2.4 Environment Requirements

Operating Environment

Operating Temperature

0 to 40 C (32 to 104 F).

Relative Humidity

10 to 95%, non-condensing.

Atmospheric pressure range

500 to 1060 hPa (375 to 795 mm Hg).

TRANSPORT AND STORAGE

Ambient temperature range

-20 to 70 C (-4 to 158 F).

Relative humidity

5 to 95%, non-condensing.

Atmospheric pressure range

500 to 1060 hPa (375 to 795 mm Hg).

Page 10

SPELLMAN HIGH VOLTAGE Introduction 1

Installation and Operating Manual Page1-5 118149-001 REV F

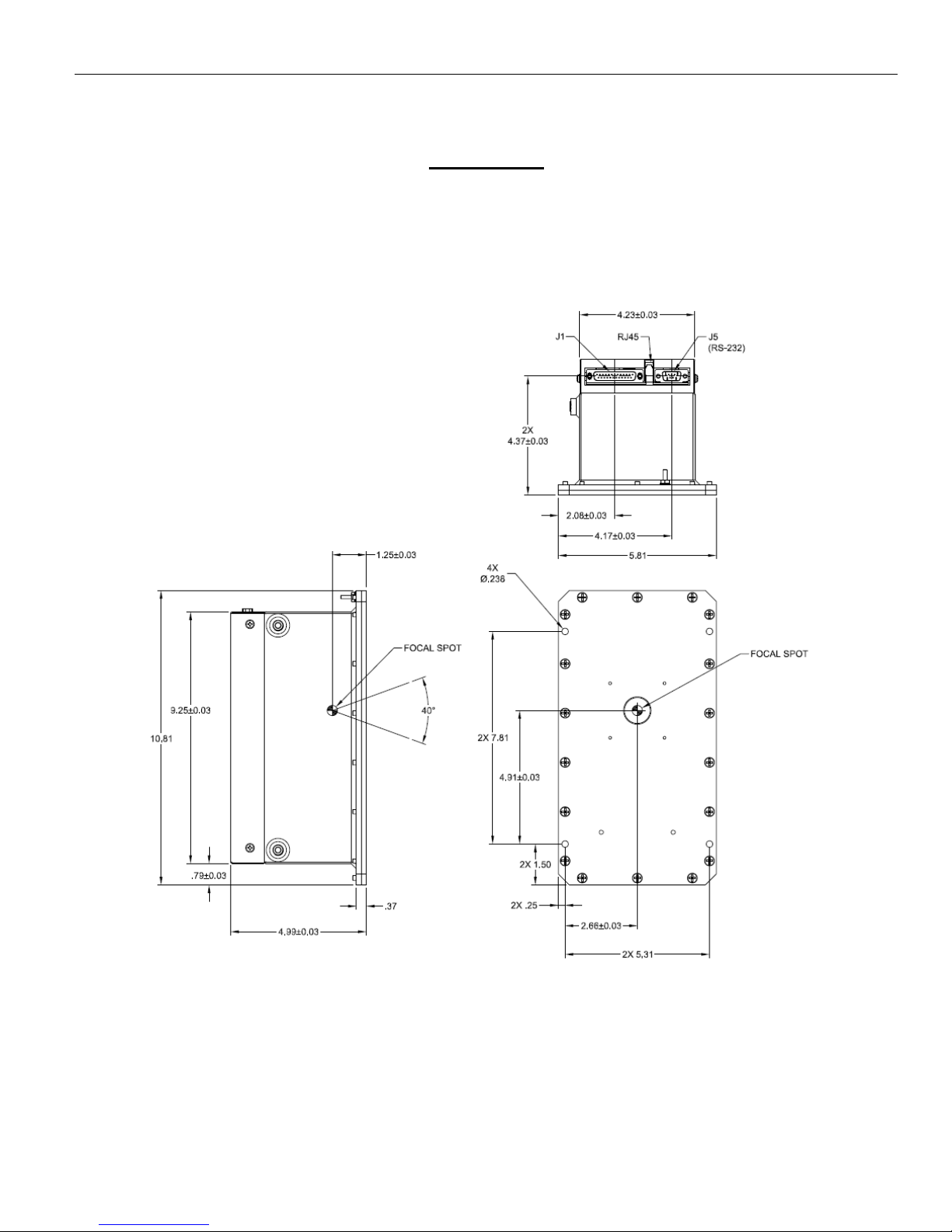

1.2.5 Mechanical

20W OPTION

Page 11

SPELLMAN HIGH VOLTAGE Introduction 1

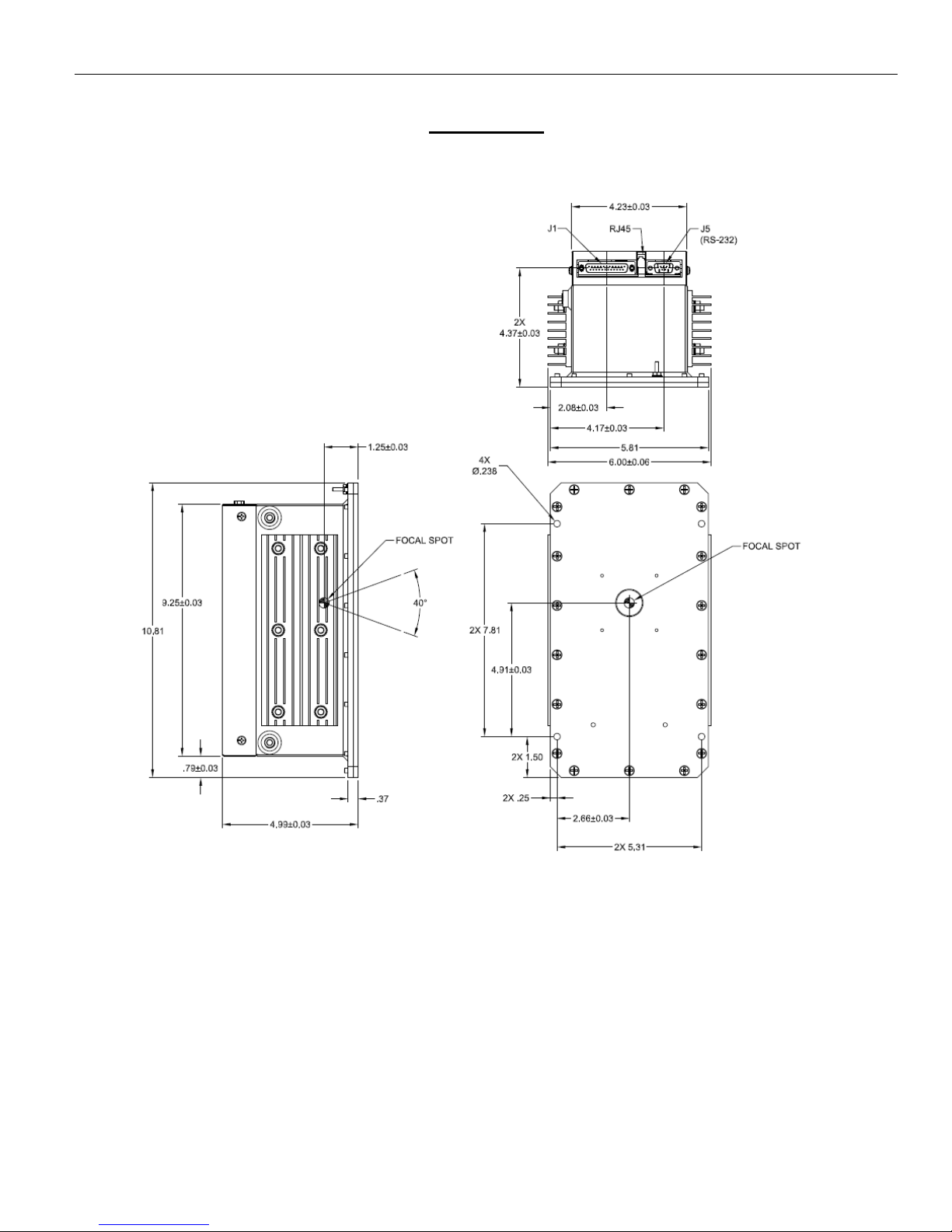

Installation and Operating Manual Page1-6 118149-001 REV F

50W OPTION

Page 12

SPELLMAN HIGH VOLTAGE Introduction 1

Installation and Operating Manual Page1-7 118149-001 REV F

1.3 THEORY OF OPERATION

1.3.1 Function Overview

The XRB011 MONOBLOCK Series is a complete integrated system consisting of a high voltage power

supply (HVPS), filament supply, X-ray tube and oil encapsulant which provide the required high voltage

insulation in one compact enclosure. The combination of proprietary control system and protection circuitry

enables the supplies to operate under arcing and extreme transient conditions without damage or interruptions.

Additional advantages are the elimination of high voltage cables and extremely low leakage X-ray radiation.

The XRB011 MONOBLOCK Series incorporates local and remote programming, monitoring, and fault

indicators including safety interlock. The X-ray source is a sealed unit containing a HVPS and an X-ray tube.

The insulating oil provides electrical insulation for the high voltage sections of the power supply and the X-ray

tube in a sealed tank. The oil also functions as a coolant to carry heat away from the tube. Convection cooling

augmented by customer provided minimum 50cfm external fan is required for the 50W option. A rubber

bellows in the tank of the X-ray source compensates for the expansion of the oil as the oil temperature varies

with operating conditions thereby eliminating the need for bulky overflow tank.

The XRB011 MONOBLOCK is basically a DC to DC power converter. Within the generator, conversions of DC

to DC, then to high frequency AC, then to high voltage DC take place. By reviewing further the subassemblies, a basic understanding of the process can be gained.

1.3.2 Input Line Power

The Input DC voltage provides the voltage for the high voltage inverter and the filament supply.

The line input voltage can vary from 23V up to 25V within the series.

1.3.3 HV Inverter

The inverter is a “Push-Pull” topology. Voltage mode control is used for driving the inverter. Two MOSFET

transistors are used as switches in the HV inverter. These MOSFET provide high frequency switching to

control the primary current flow in the high voltage transformer.

Circuits on the Control board provide the gate control of the switches. The PWM IC generates gate drive

control signals.

1.3.4 High Voltage Transformer

The output of the High Frequency Quasi-resonant Inverter is connected to the primary of the High Voltage

Transformer. The High Voltage Transformer is a step up type. Typical secondary voltage is in the range of

5.7kV depending upon output voltage ratings.

1.3.5 High Voltage Assembly

The High Voltage Assembly circuitry typically consists of two high voltage multipliers to generate ±40kV. The

high voltage section is a bipolar ground-referenced supply. The multiplier is a standard diode-capacitor

multiplier with seven stages of voltage multiplication and the divider is a precision resistance divider string.

Each supply is capable of generating 40 kV.

A high bandwidth resistive/capacitive divider provides voltage feedback for regulation and monitoring. A sense

resistor connected at the low voltage end of the High Voltage Rectifier provides current feedback for regulation

and monitoring.

1.3.6 System Control PWB

Control of the generator utilizes sophisticated analog and digital circuitry resulting in fast and accurate control,

protection and signaling to the user.

This generator is based on advanced PWM control utilizing the specific integrated circuit. Analog signals are

digitized in A/D converter and processed within DSP circuits to provide maximum accuracy and reliability.

All feedback signals are sent to the user interface through digital and D/A circuits where switching is possible

between feedback and program signals. This allows the user to preset the desired output before energizing

high voltage.

All program voltages are typically ramped up to set level by the digital ramp generator.

Page 13

SPELLMAN HIGH VOLTAGE Introduction 1

Installation and Operating Manual Page1-8 118149-001 REV F

A-D and D-A converters and drivers provide system Fault Control and Indication. User interface is processed

on this PWB as well, providing isolated relay coils, opt couplers and open collectors contact.

1.3.7 Filament Power

The filament inverter provides the filament power for the X-ray tube. The filament inverter is a high frequency,

series resonant inverter. The inverter provides ac current to the primary of the filament isolation transformer.

The filament isolation transformer secondary is connected to the filament tube. The filament power is

2.25Vac/1.7Aac.

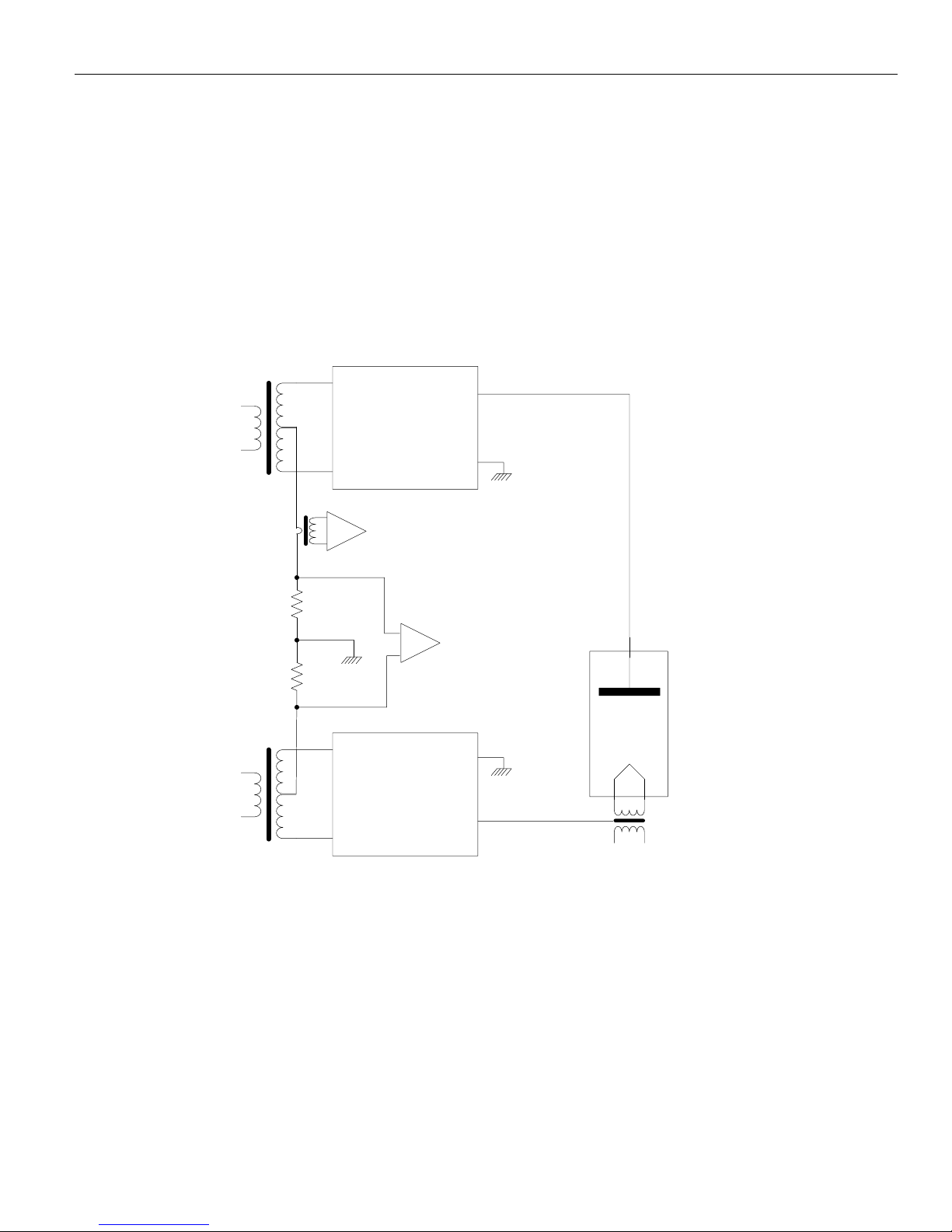

See Figure 1.2 for a simplified diagram of the X-RAY tube connection and current sensing circuits. The

filament circuitry also provides a variety of control, diagnostic and protection functions.

If any abnormal condition appears, monitoring circuitry will shut down the unit.

Figure 1.2 Simplified schematic of X-RAY tube connection

1.3.8 High Voltage Interlock

The XRB011 is equipped with safety interlocks for user personnel and equipment protection. An open interlock

circuit inhibits operation of the XRB011 MONOBLOCK.

POS HV MULT

NEG HV MULT

GND

+

-kV

+kV

FILAMENT

XFMR

X-RAY TUBE

ARC DETECT

mA Monitor

-

GND

GND

HV XFMR

HV XFMR

Page 14

SPELLMAN HIGH VOLTAGE Introduction 1

Installation and Operating Manual Page1-9 118149-001 REV F

1.4 SAFETY

1.4.1 Safety and Warning Symbols

WARNING: THIS X-RAY UNIT MAY BE DANGEROUS TO OPERATOR UNLESS SAFE EXPOSURE

FACTORS AND OPERATING INSTRUCTIONS ARE OBSERVED.

The following advisory symbols are used on the safety warning labels, and/or on circuit boards.

“CAUTION” symbol used to indicate a potential

hazard to operators, service personnel or to the

equipment.

“CAUTION” symbol used to indicate an X-RAY

RADIATION EXPOSURE, is hazard to operators,

service personnel or to the equipment.

Protective Earth

IEC 60417-5017

Page 15

SPELLMAN HIGH VOLTAGE Installation 2

Installation and Operating Manual – XRB011 Page 2-10 118149-001 REV F

CHAPTER 2

INSTALLATION

CONTENTS:

2.1 INTRODUCTION ........................................................................................................................................................ 11

2.2 UNPACKING .............................................................................................................................................................. 11

2.3 OVERALL CONNECTIONS ................................................................................................................................ ................ 12

2.4 INPUT POWER VOLTAGE ........................................................................................................................................ 13

2.5 CABLE CONNECTION ILLUSTRATION .............................................................................................................................. 13

2.5.1 MULTI INTERFACE CABLE CONNECTIONS ....................................................................................................... 13

2.5.1 Pin Layout of the Multi interface ............................................................................................................................. 14

2.5.2 GROUND CONNECTION .......................................................................................................................................... 14

2.5.3 CHASSIS GROUND ......................................................................................................................................................... 15

2.5.4 X-RAY PORT ............................................................................................................................................................ 15

2.6 FINAL CHECKS .......................................................................................................................................................... 15

Page 16

SPELLMAN HIGH VOLTAGE Installation 2

Installation and Operating Manual – XRB011 Page 2-11 118149-001 REV F

2.1 INTRODUCTION

This Chapter contains instructions for unpacking the XRB011 MONOBLOCK, allowing for initial power-up

and exposures.

2.2 UNPACKING

WARNING: THE XRB011MONOBLOK WEIGHS APPROXIMATELY 20 POUNDS (9.07 KG) IN ITS

SHIPPING CONTAINER.

1. Inspect the package exterior for evidence of damage due to handling in transit. Notify the carrier

and Spellman immediately if damage is evident. Do not destroy or remove any of the packing

material used in a damaged shipment.

2. Remove the cardboard outer pack. See the cautionary note below before removing the pack.

CAUTION: OPEN THE CARDBOARD PACK CAREFULLY. SHARP TOOLS MAY DAMAGE THE

CONTENTS.

3. Set aside the cardboard pack(s).

4. After unpacking, inspect the panel and chassis for visible damage.

5. Keep the shipping containers. In case of shipping damage, place the unit(s) back in its shipping

pack and notify the carrier and the Customer Support Department as shown on the inside cover

page of this manual.

6. Fill out and mail the Warranty Registration card accompanying the unit. Spellman XRB011

MONOBLOCK is covered by warranty.

Page 17

SPELLMAN HIGH VOLTAGE Installation 2

Installation and Operating Manual – XRB011 Page 2-12 118149-001 REV F

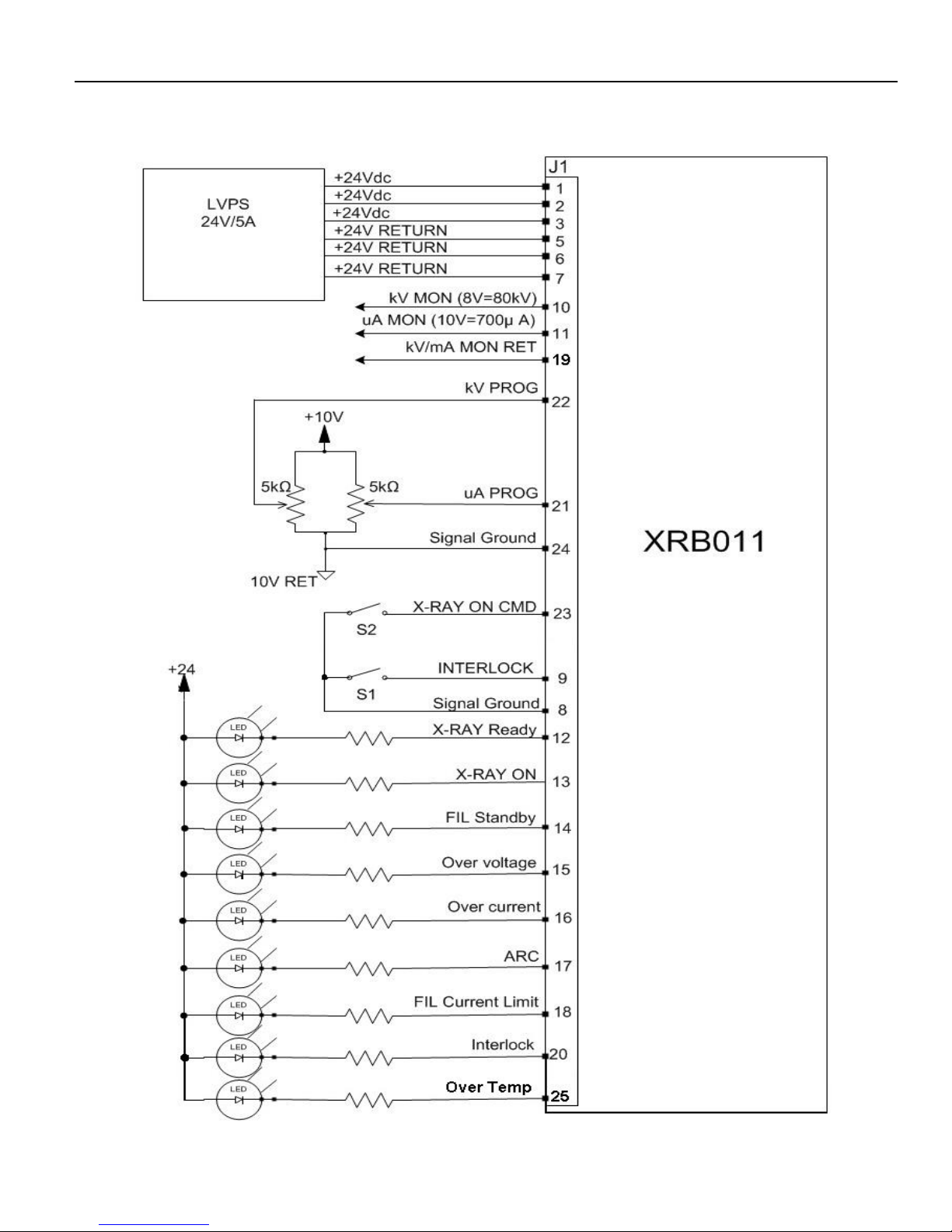

2.3 OVERALL CONNECTIONS

NOTE: THIS IS BASIC CONNECTION ILLUSTRATION FOR TESTING. MORE COMPLEX AND

DEDICATED CIRCUITRY IS NEEDED IN ULTIMATE APPLICATION.

All cables should be routed away from the X-Ray port, and dressed and secured neatly in place. Cables

should be cut to the correct length if possible as excess cabling may contribute to EMI/RFI problems. For

those cables that cannot be cut to the correct length, try to minimize the area inside any loops of excess

cable, as these loops are in effect an antenna.

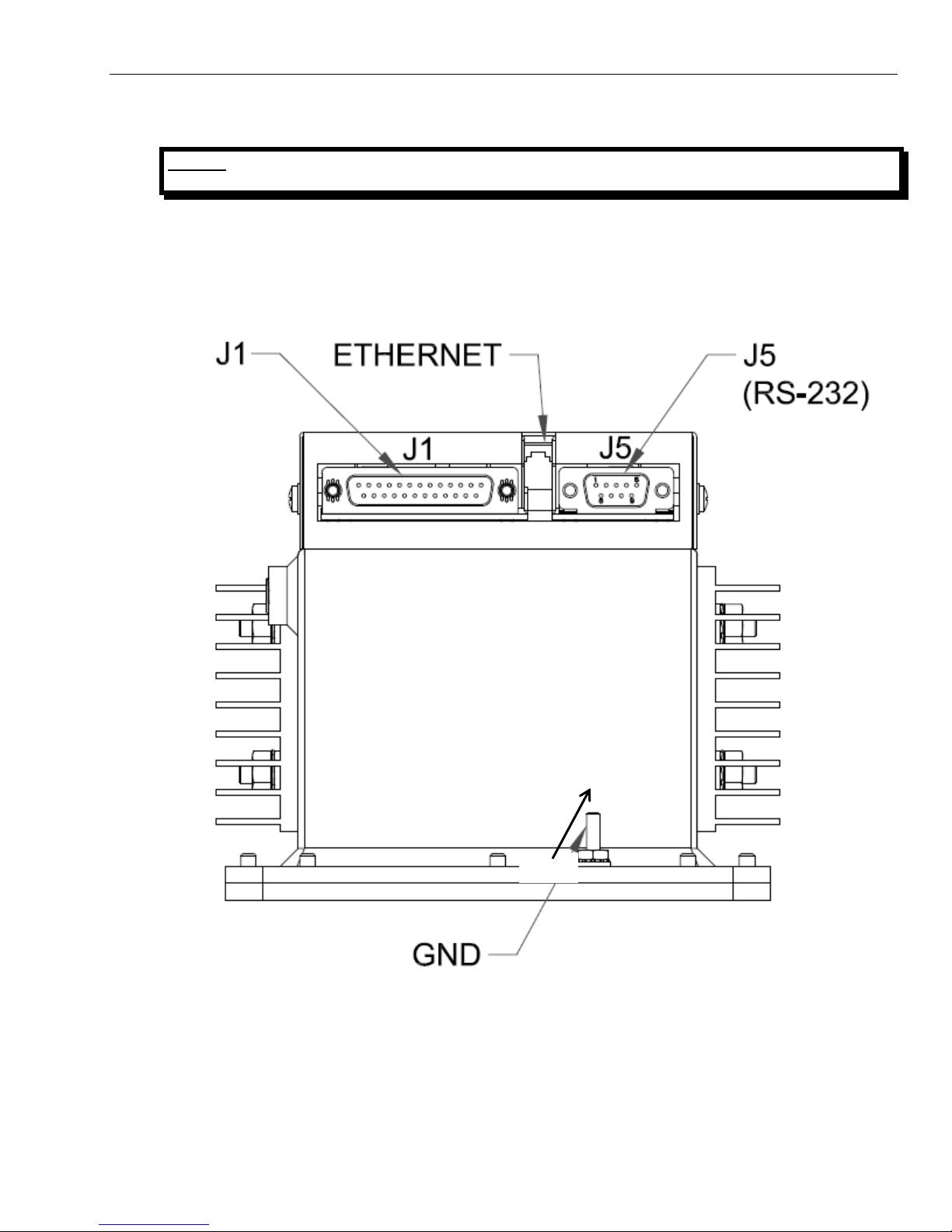

Figure 2-1: XRB011 I/O location

GND

RJ45

Page 18

SPELLMAN HIGH VOLTAGE Installation 2

Installation and Operating Manual – XRB011 Page 2-13 118149-001 REV F

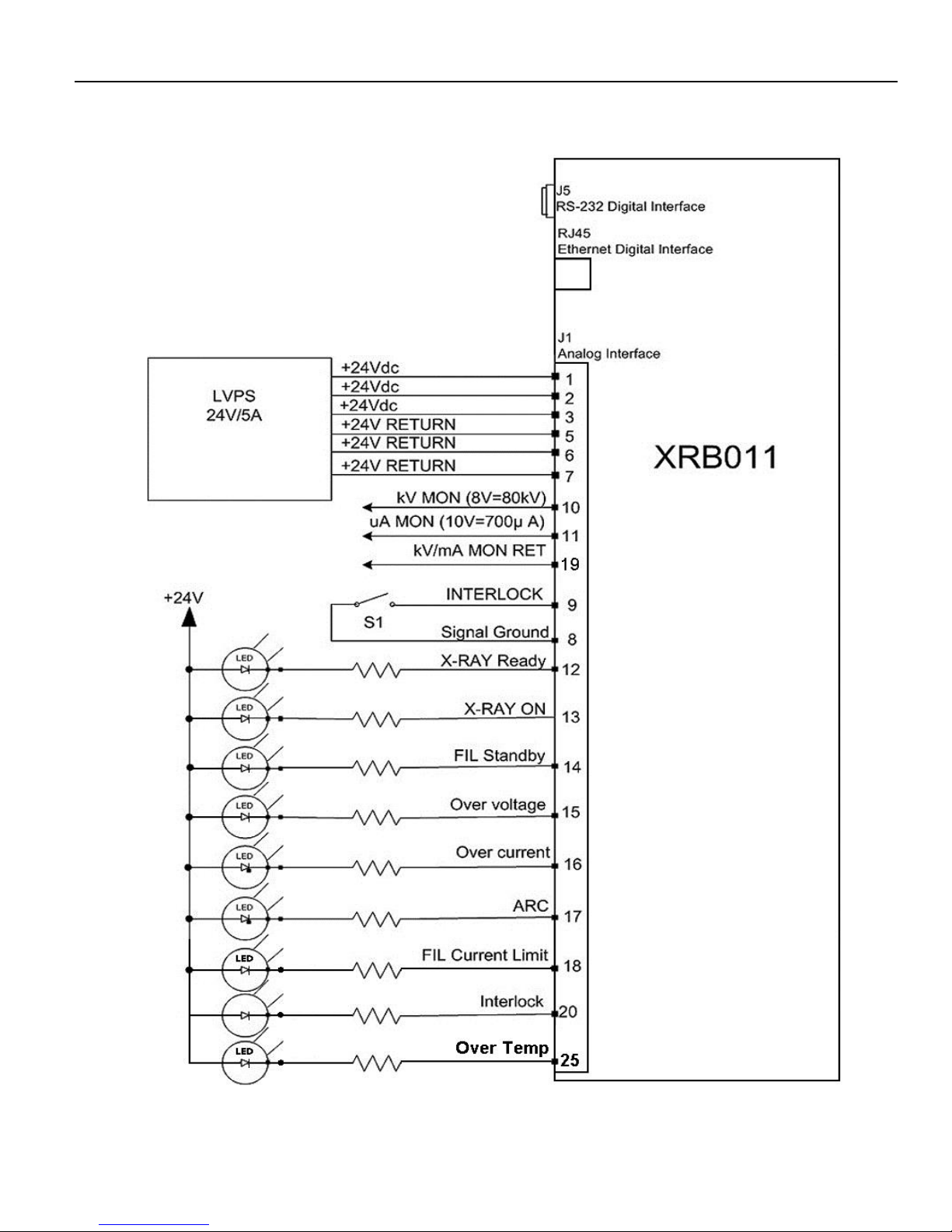

Figure 2-2: Overall connection

2.4 INPUT POWER VOLTAGE

1. Check the input voltage rating on the nameplate of the supply and make certain that this is the

rating of the power source to be connected.

2. Units operate on 24VDC, 2.5A (20W option), 4A (50W option).

3. DO NOT SWITCH ON MAINS POWER AT THIS TIME.

2.5 CABLE CONNECTION ILLUSTRATION

2.5.1 MULTI INTERFACE CABLE CONNECTIONS

Multi Interface connections include digital I/O, serial communication, and interlock. Operator must verify

and connect every signal properly though some of them are optional, before initiating power-up and basic

test.

Page 19

SPELLMAN HIGH VOLTAGE Installation 2

Installation and Operating Manual – XRB011 Page 2-14 118149-001 REV F

The interlock, serial communication and exposure buttons interface shall be made available via a multi

signal cable. Refer to *-* for a schematic of isolation and signal direction.

2.5.1 Pin Layout of the Multi interface

The multi signal interface shall have a female 25 pin D-Sub (J1). Twisted pairs shall be used where

applicable. The pin layout is given in Table 2-3.

PIN

SIGNAL

PARAMETERS

1

+24V

+24Vdc±1Vdc @ 4A

2

+24V

+24Vdc±1Vdc @ 4A

3

+24V

+24Vdc±1Vdc @ 4A

4

NC

No connection

5

+24V RETURN

+24V RETURN

6

+24V RETURN

+24V RETURN

7

+24V RETURN

+24V RETURN

8

Signal Ground

Signal Ground

9

Interlock Input

Input, Active low, Interlock is low safe to enable high

voltage. Connect to +24V Return

10

kV Monitor

Output, 0 to 8V = 0 to rated output voltage. Zout=100Ω

11

µA Monitor

Output, 0 to 10V = 0 to rated output current. Zout=100Ω

12

X-Ray Ready status

Output, Active Low,

Open Collector, 24Vdc @ 10mA max

13

X-Ray ON status

Output, Active Low,

Open Collector, 24Vdc @ 10mA max

14

Filament Standby status

Output, Active Low,

Open Collector, 24Vdc @ 10mA max

15

Over Voltage Fault

Output, Active Low,

Open Collector, 24Vdc @ 10mA max

16

Over Current Fault

Output, Active Low,

Open Collector, 24Vdc @ 10mA max

17

ARC Fault

Output, Active Low,

Open Collector, 24Vdc @ 10mA max

18

Filament Current Limit

Fault

Output, Active Low,

Open Collector, 24Vdc @ 10mA max

19

Signal Ground

Signal Ground

20

Interlock Output

Output, Active Low,

Open Collector, 24Vdc @ 10mA max

21

µA Program

Input, 0 to 10V = 0 to rated output current. Zin=10kΩ

22

kV Program

Input, 0 to 8V = 0 to rated output voltage. Zin=10kΩ

23

X-Ray ON Command

Input, Active low,

Low (short)=X-Ray ON

High (open)=X-Ray OFF

Internal pull up resistor to +15V

24

Signal Ground

Signal Ground

25

Over Temp.

Output, Active Low,

Open Collector, 24Vdc @ 10mA max

Table 2-3 Pin layout of multi signal connector

Refer to chapter 3 for detailed requirements and function descriptions.

2.5.2 GROUND CONNECTION

NOTE: THE INSTALLER SHOULD ENSURE THAT ALL CABLE CONNECTIONS TO THE

GENERATOR ARE SECURE, AND ALL CABLES EXTERNAL TO THE GENERATOR

ARE ADEQUATELY PROTECTED AGAINST ACCIDENTAL DISCONNECTION.

Page 20

SPELLMAN HIGH VOLTAGE Installation 2

Installation and Operating Manual – XRB011 Page 2-15 118149-001 REV F

2.5.3 CHASSIS GROUND

The chassis of the XRB011 MONOBLOCK must be grounded to the local earth ground and also to the

tube housing ground.

2.5.4 X-RAY PORT

ENSURE THAT THE EXIT PORT IS PROPERLY MATED TO COLLIMATOR OR SATISFACTORILY

SHIELDED WITH LEAD PLUG TO LIMIT EXPOSURE TO LEAKAGE RADIATION.

X-ray Safety Procedures must be followed when testing this unit. The XRB011 is capable of producing

Lethal Voltages and X-ray Radiation. Only proceed with operation of the HVPS after

Consulting with the Manufacturer and verification of X-Ray setup for the proper precautions.

Reading this entire document.

NEVER OPERATE THIS UNIT WITH AN OPEN X-RAY EXIT PORT.

It is recommended not to allow leakage radiation exceeding 0.5mR/hr at 5cm from any surface of the

MONOBLOCK.

2.6 FINAL CHECKS

The room interface connections may now be completed. Before power on, user needs to check the items

as below finally.

When finished all wiring, check that all connections are tight and secure.

Check that all cables are dressed neatly outside the cabinet, and secured as necessary.

Check the ground connection again.

THIS EQUIPMENT GENERATES DANGEROUS VOLTAGES THAT MAY BE FATAL.

PROPER GROUNDING OF ALL HIGH VOLTAGE EQUIPMENT IS ESSENTIAL.

WARNING X-RAY RADIATION EXPOSURE IS HAZARDOUS

Failure to follow these procedures may void the warranty.

Check the input voltage rating on the nameplate of the supply and make certain that this is the rating of the available

power source. Spellman MONOBLOCK XRB011 operates on 24VDC±1VDC

WARNING

WARNING

Page 21

SPELLMAN HIGH VOLTAGE Installation 2

Installation and Operating Manual – XRB011 Page 2-16 118149-001 REV F

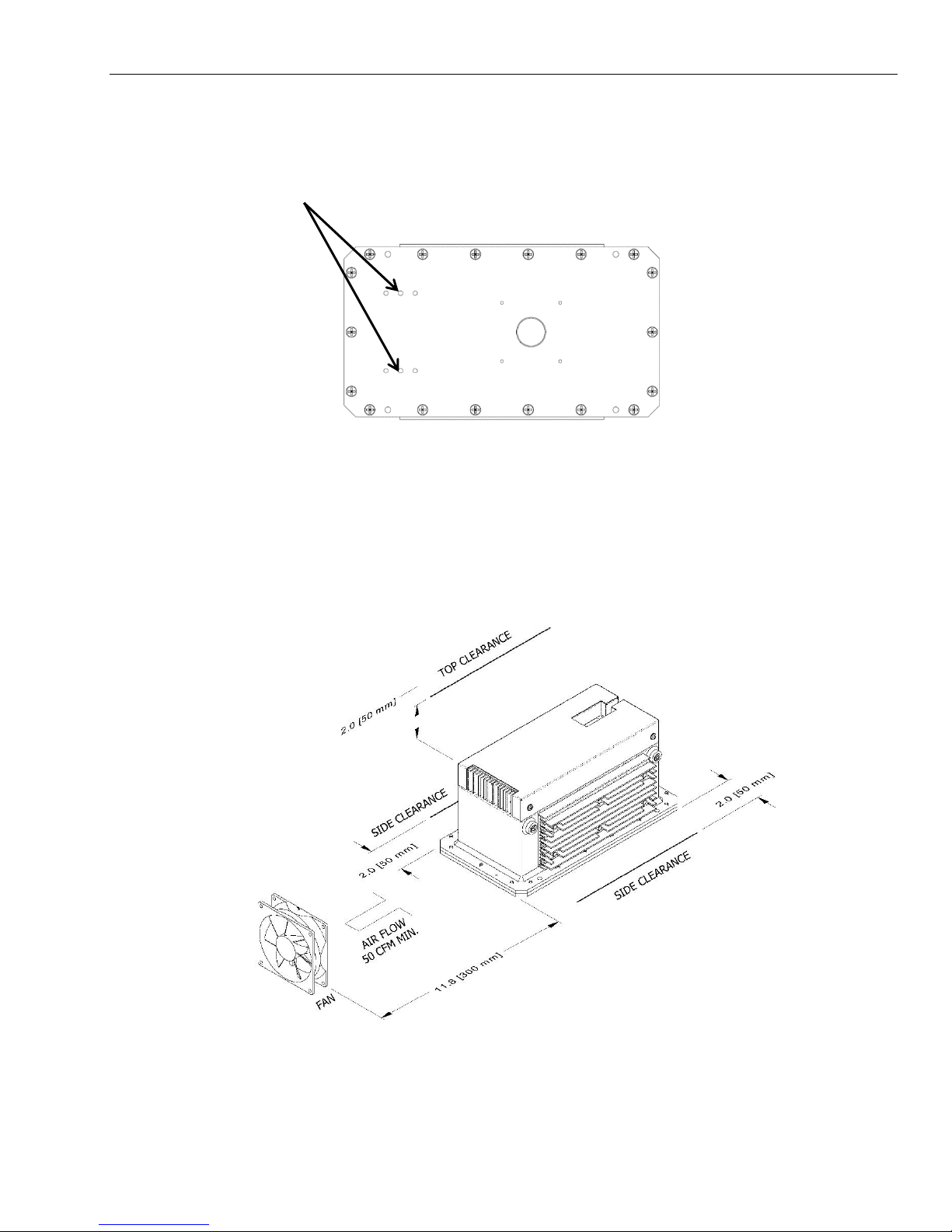

Bellows Vent holes:

Do not block or insert anything into the vent holes located on top cover as shown. These two holes provide venting

for the internal bellows that is used to compensate for the expansion of the oil as the oil temperature varies.

Do not block any vents holes on the cover

Cooling:

A customer supplied minimum 50 CFM fan should be used for the 50W option to maintain safe operating

temperature for MONOBLOCK X-ray generator. The air flow should be direct at the heat sink on the side of the

unit and at the side of the control board compartment. During operation the internal oil temperature should be below

60C and should not exceed 65C. See below Figure for fan location.

FAN

Page 22

SPELLMAN HIGH VOLTAGE Interfacing 3

Installation and Operating Manual – XRB011 Page 3-17 118149-001 REV F

CHAPTER 3

INTERFACING

3.1 INTRODUCTION .............................................................................................................................................................. 18

3.2 LOCAL PROGRAMMING MODE ............................................................................................................................... 18

3.3 LOCAL MONITORS ......................................................................................................................................................... 18

3.5 REMOTE PROGRAMMING MODE ............................................................................................................................ 18

3.6 REMOTE MONITORS ................................................................................................................................................ 18

3.7 XRAY ON COMMAND .............................................................................................................................................. 18

3.8 EXTERNAL INTERLOCK ......................................................................................................................................... 18

3.9 SYSTEM STATUS AND FAULT DIAGNOSTIC DISPLAY ..................................................................................................... 18

3.10 REMOTE MODE (DIGITAL CONTROL) ............................................................................................................................. 19

3.11 CONNECTOR STYLE AND PIN LAYOUT .......................................................................................................................... 20

3.12 SERIAL COMMUNICATION INTERFACE ........................................................................................................................... 21

3.13 RECOMMENDED INTERFACE CIRCUITS (LOCAL MODE, ANALOG INTERFACE) .................................................... 22

3.14 RECOMMENDED INTERFACE CIRCUITS (REMODE MODE, DIGITAL INTERFACE) ........................................... 23

Page 23

SPELLMAN HIGH VOLTAGE Interfacing 3

Installation and Operating Manual – XRB011 Page 3-18 118149-001 REV F

3.1 INTRODUCTION

This Chapter describes the interfacing of the XRB011 MONOBLOCK to the customer system control side,

especially with the serial communication, exposure control switch. Also, exposure mode is introduced with the

timing sequence described as well.

3.2 LOCAL PROGRAMMING MODE

Allows Local adjustment of the output voltage and current via analog voltage inputs on J1 analog interface.

To operate in Local mode, position jumpers for JP11 in the 1-2. JP11 is located on the control board. Remove

the cover to access JP11.

Program kV output value by providing 0-8.00V (0-80kV) to J1-22(reference to signal ground J1-24 or 25).

Program µA output value by providing 0-10.00V (0-250µA for 20W option), (0-700µA for 50W option) to J1-21

(reference to signal ground J1-24 or 25).

All program values default to zero upon power up except kV program to 3.5V (35kV)

3.3 LOCAL MONITORS

Provides local analog monitors for the output voltage and current via analog voltage outputs on J1 analog

interface.

Monitor kV output by measuring J1-10(reference to signal ground J1-24), 0-8.00v (0-80kV).

Monitor µA output by measuring J1-11 (reference to signal ground J1-24 or 25),

0-10.00V (0-250µA,20W option), (0-700µA, 50W option)

3.5 REMOTE PROGRAMMING MODE

Allows remote adjustment of the output voltage and current via RS- 232 digital interface at J5 or Ethernet digital

interface RJ45

To operate in Remote mode, position jumper JP11 in the 2-3 position on the control board. Remove the cover to

access JP11.

All program values default to zero upon power up except kV program to 35kV.

3.6 REMOTE MONITORS

Provides remote monitors of the output voltage and output current via RS- 232 digital interface at J5 or

Ethernet digital interface RJ45

3.7 XRAY ON COMMAND

Provides control of X-ray ON and X-ray OFF either via a dry contact connection from J1-23 to J1-19 when operating

in Local Mode (analog control). In remote Mode J1-23 is not active and X-ray ON and OFF is controlled through

RS- 232 or Ethernet communication.

The external interlock must also be close for the X-ray to enable.

3.8 EXTERNAL INTERLOCK

The X-ray cannot be enabled unless the external interlock is closed by connecting J1-9 to J1-8. During high voltage

operation, opening the interlock circuit will cause the High Voltage to be disabled.

3.9 SYSTEM STATUS AND FAULT DIAGNOSTIC DISPLAY

If a fault occurs, the power supply will revert to the POWER DOWN mode indicated by X-RAY READY STATUS (J1-

12), RS-232 or Ethernet as HV OFF. In local mode to reset all faults, the X-RAY ON Command (J1-23) must be

toggled OFF and ON. In Remote mode; to reset all faults a host command sent via RS-232 or Ethernet, Reset Faults <52>

.

All fault and status outputs are open collector (Normally off), and are intended to drive an LED or diode of an optocoupler with 24V@10mA max

EXTERNAL INTERLOCK FAULT: Indicates the EXTERNAL INTERLOCK connection is not in closed

position. The fault is indicated by INTLK OPEN via RS-232 or Ethernet as (ARG 9). Analog output signal (J1-20)

is active low (Low = interlock is closed, High = interlock is open)

Page 24

SPELLMAN HIGH VOLTAGE Interfacing 3

Installation and Operating Manual – XRB011 Page 3-19 118149-001 REV F

X-RAY READY STATUS: Indicates that there are no faults and the interlock is closed. The status is

indicated by NO FAULT (X-RAY READY) via RS-232 or Ethernet as (ARG 0). Analog output signal (J1-12) is

active low.

X-RAY ON STATUS: Indicates that the X-RAY is ON or OFF. This status is indicated by via RS-232or

Ethernet as X-RAY ON (ARG 1), X-RAY OFF (ARG 0). Analog output signal (J1-13) is active low (Low X-

RAY is on, High=X-RAY is off).

OVERVOLTAGE FAULT: Indicates the over voltage protection circuitry has caused the high voltage to turn off.

Over voltage protection is internally set to 82kV. This fault is indicated by High kV via RS-232 or Ethernet as (ARG

6), Over Voltage. Analog output signal (J1-15) is active low.

OVER CURRENT FAULT: Indicates the output current has exceeded 275µA (20W option), 710µA (50W option)

or if the allowable percentage of error between actual and programmed emission currents is exceeded resulting in the

HV to be turned off. This fault is indicated by High mA via RS-232or Ethernet as (ARG 3). Analog output signal

(J1-16) is active low.

ARC FAULT: Indicates that an arc has occurred. Occurrences of one arc will shutdown the high voltage and

latched. This fault is indicated by ARC FAULT via RS-232 or Ethernet as (ARG 2). Analog output signal (J1-17)

active low.

UNDER VOLTAGE FAULT: Indicates a failure in the voltage regulation circuitry less than <35kV. This fault

occurs when there is a lack of output power to maintain regulation and will result in shutdown of the HV. This fault is

indicated by via RS-232 or Ethernet as (ARG 4). There is no analog output signal.

FILAMENT CURRENT LIMIT FAULT: Indicates the filament current exceeded the safe operating current of the

X-Ray tube. This fault is indicated by FILAMENT LIMIT via RS-232 or Ethernet as (ARG 10). Analog output

signal (J1- 18) is active low.

FILAMENT STANDBY STATUS: Indicates the X-RAY is off and the filament current is in standby mode. This

status is indicated by FILAMENT STANDBY via RS-232 or Ethernet as (ARG 11). Analog output signal (J1-14) is

active low.

WATCHDOG TIMER: Indicates the host computer has lost communication and with the HVPS system for a period

greater than ten second. This feature is enabled via RS-232 host command. This fault is indicated via RS-232 as

(ARG 7) Watchdog Time- out. See digital manual for details.

OVER TEMPERATURE: Indicates that the internal oil temperature has exceeded 65 degree C.

3.10 REMOTE MODE (DIGITAL CONTROL)

G.U.I Installation software will be provided up on request.

Start the G.U.I.

Read agreement then click AGREES...

Page 25

SPELLMAN HIGH VOLTAGE Interfacing 3

Installation and Operating Manual – XRB011 Page 3-20 118149-001 REV F

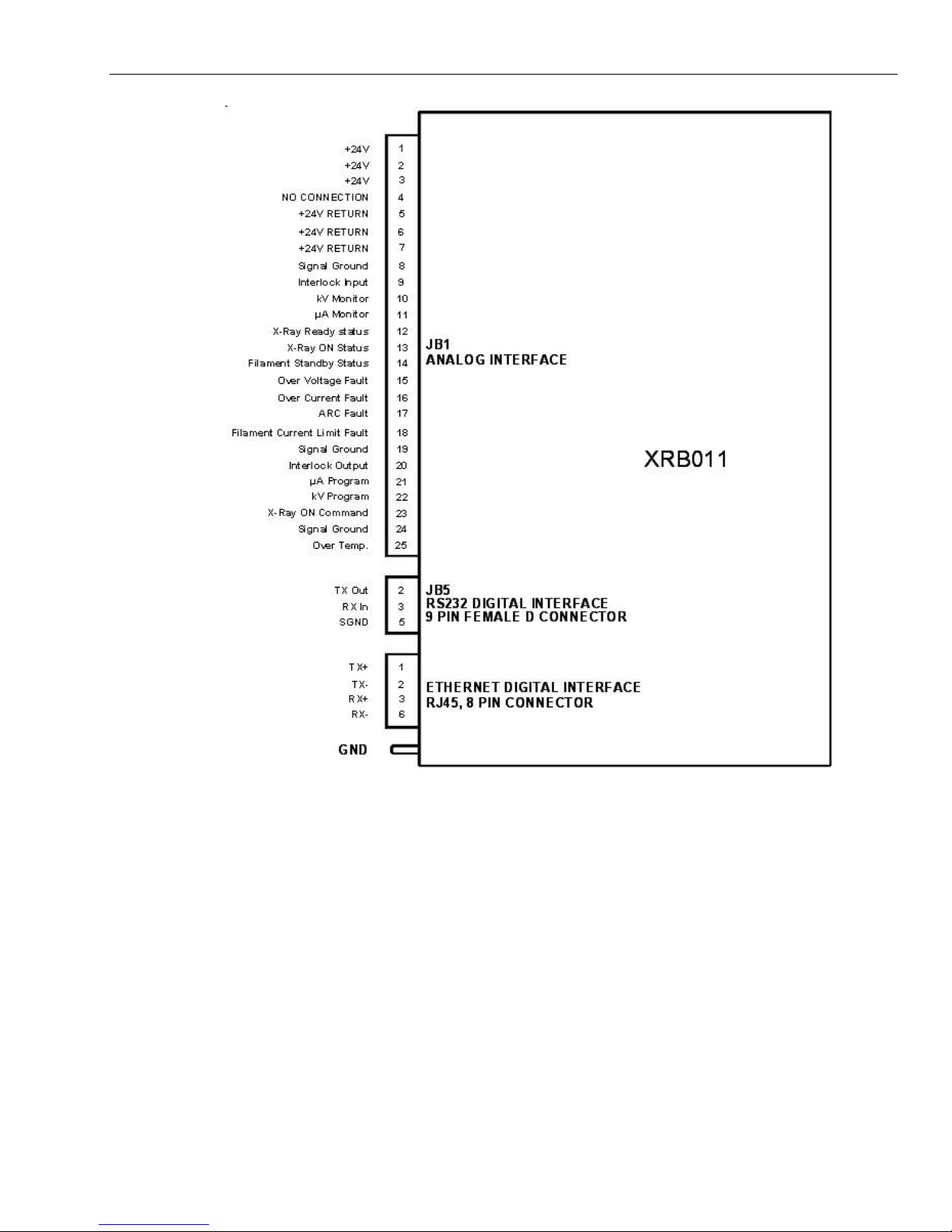

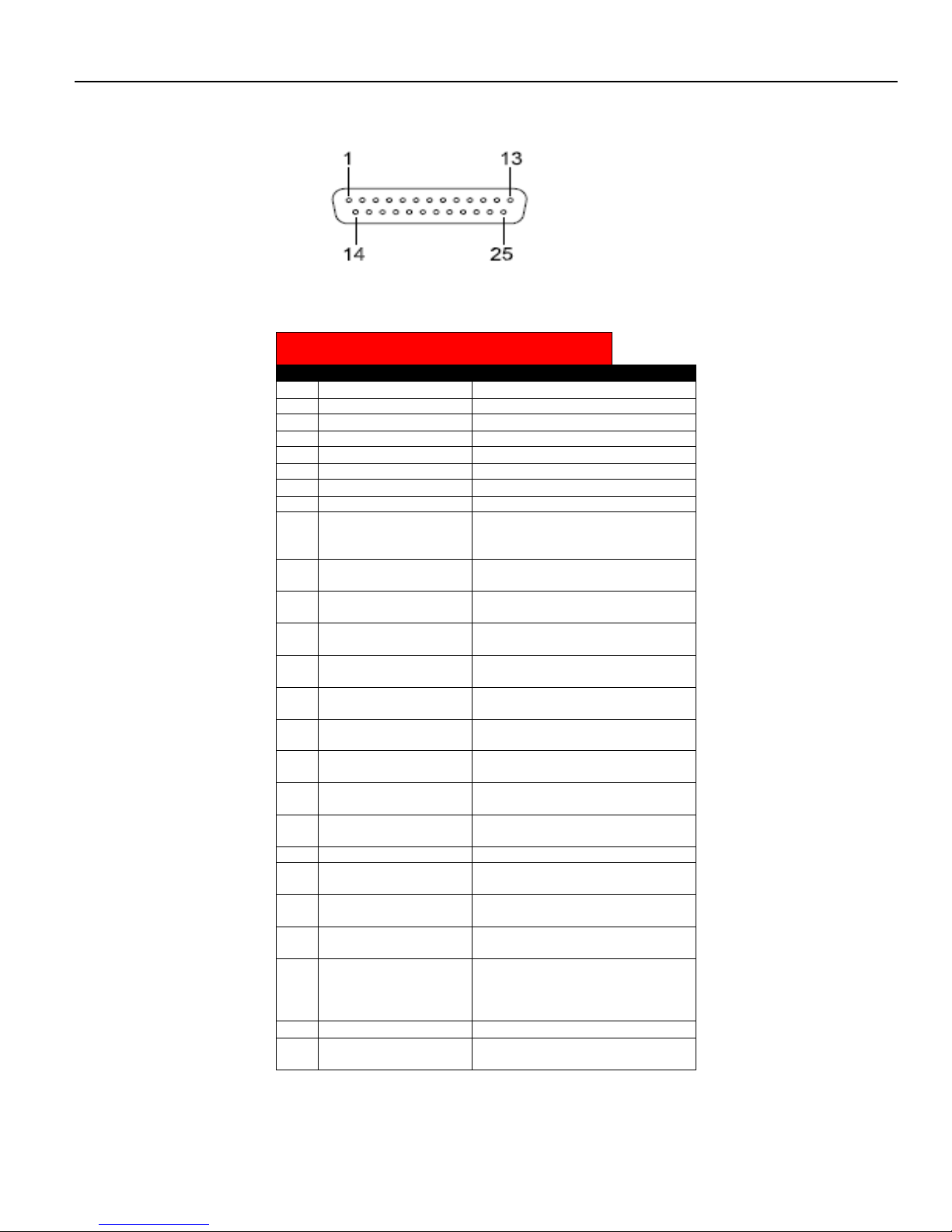

3.11 J1 CONNECTOR STYLE AND PIN LAYOUT

Figure 3-1 multi signal interface connector

Table 3-2 Pin layout of multi signal interface

PIN

SIGNAL

PARAMETERS

1

+24V

+24Vdc±1Vdc @ 4A

2

+24V

+24Vdc±1Vdc @ 4A

3

+24V

+24Vdc±1Vdc @ 4A

4

NC

No connection

5

+24V RETURN

+24V RETURN

6

+24V RETURN

+24V RETURN

7

+24V RETURN

+24V RETURN

8

Signal Ground

Signal Ground

9

Interlock Input

Input, Active low, Interlock is low safe

to enable high voltage. Connect to

+24V Return

10

kV Monitor

Output, 0 to 8V = 0 to rated output

voltage. Zout=100Ω

11

µA Monitor

Output, 0 to 10V = 0 to rated output

current. Zout=100Ω

12

X-Ray Ready status

Output, Active Low,

Open Collector, 24Vdc @ 10mA max

13

X-Ray ON status

Output, Active Low,

Open Collector, 24Vdc @ 10mA max

14

Filament Standby status

Output, Active Low,

Open Collector, 24Vdc @ 10mA max

15

Over Voltage Fault

Output, Active Low,

Open Collector, 24Vdc @ 10mA max

16

Over Current Fault

Output, Active Low,

Open Collector, 24Vdc @ 10mA max

17

ARC Fault

Output, Active Low,

Open Collector, 24Vdc @ 10mA max

18

Filament Current Limit

Fault

Output, Active Low,

Open Collector, 24Vdc @ 10mA max

19

Signal Ground

Signal Ground

20

Interlock Output

Output, Active Low,

Open Collector, 24Vdc @ 10mA max

21

µA Program

Input, 0 to 10V = 0 to rated output

current. Zin=10kΩ

22

kV Program

Input, 0 to 8V = 0 to rated output

voltage. Zin=10kΩ

23

X-Ray ON Command

Input, Active low,

Low (short)=X-Ray ON

High (open)=X-Ray OFF

Internal pull up resistor to +15V

24

Signal Ground

Signal Ground

25

Over Temp.

Output, Active Low,

Open Collector, 24Vdc @ 10mA max

Page 26

SPELLMAN HIGH VOLTAGE Interfacing 3

Installation and Operating Manual – XRB011 Page 3-21 118149-001 REV F

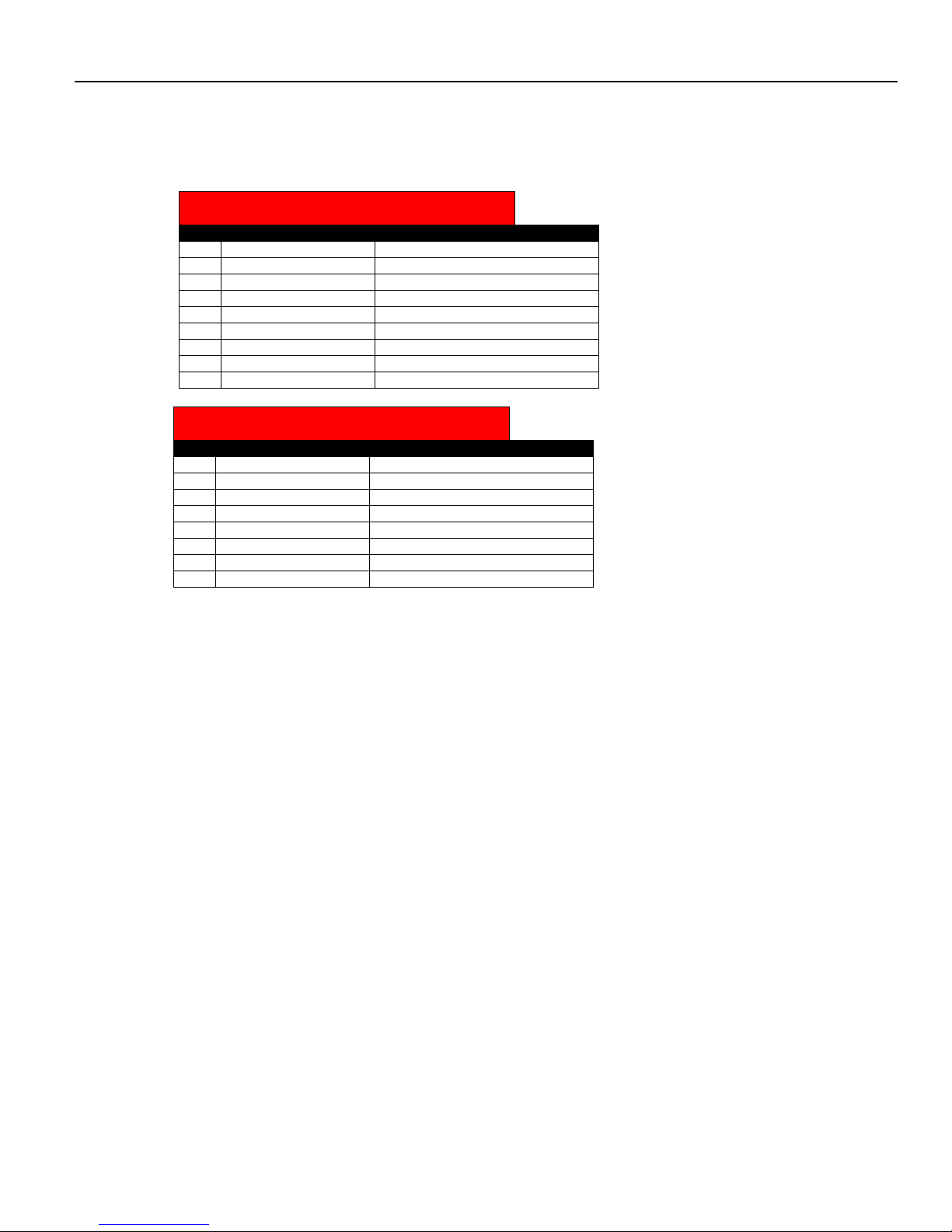

3.12 SERIAL COMMUNICATION INTERFACE

The serial communication is part of the Multi Signal Interface

The pin definition shows below:

PIN

SIGNAL

PARAMETERS

1

NC

No connection

2

TX Out

Transmit Data

3

RX In

Receive Data

4

NC

No connection

5

SGND

Signal Ground

6

NC

No connection

7

NC

No connection

8

NC

No connection

9

NC

No connection

PIN

SIGNAL

PARAMETERS

1

TX+

Transmit Data +

2

TX -t

Transmit Data -

3

RX +

Receive Data +

4

NC

No connection

5

NC

No connection

6

RX-

Receive Data -

7

NC

No connection

8

NC

No connection

User should connect a straight type RS232 cable properly with system side such as PC. Twisted wires are

preferable to enhance the EMC performance.

GUI software can be used temporarily to test the XRB011 provided per request installed on the user PC.

(Refer to separate document for detailed information of GUI). But user need to develop their own ultimate

software based on open protocol (Refer to separate document) and design system control board to integrated

XRB011 into their system with proper method (Refer to 2.6.1 NOTE the isolation requirement).

Page 27

SPELLMAN HIGH VOLTAGE Interfacing 3

Installation and Operating Manual – XRB011 Page 3-22 118149-001 REV F

3.13 RECOMMENDED INTERFACE CIRCUITS (LOCAL MODE, ANALOG INTERFACE)

Page 28

SPELLMAN HIGH VOLTAGE Interfacing 3

Installation and Operating Manual – XRB011 Page 3-23 118149-001 REV F

3.14 RECOMMENDED INTERFACE CIRCUITS (REMODE MODE, DIGITAL INTERFACE)

Monitors and Fault LED’s are optional

Page 29

SPELLMAN HIGH VOLTAGE Trouble Shooting 4

Installation and Operating Manual – XRB011 Page 4-24 118149-001 REV F

CHAPTER 4

TROUBLE SHOOTING

CONTENTS:

Section Title

4.1 INTRODUCTION ........................................................................................................................................................ 25

4.2 STATUS AND ERROR CODES.................................................................................................................................. 25

4.2.1 Status Messages ....................................................................................................................................................... 25

TABLE 1 – GUIDANCE AND MANUFACTURER’S DECLARATION ............................................................................................ 25

ELECTROMAGNETIC EMISSIONS – FOR ALL ME EQUIPMENT AND ME SYSTEMS ...................................................... 25

TABLE 2 – GUIDANCE AND MANUFACTURER’S DECLARATION

ELECTROMAGNETIC EMISSIONS – FOR ALL ME EQUIPMENT AND ME SYSTEMS ...................................................... 26

TABLE 3 – GUIDANCE AND MANUFACTURER’S DECLARATION

ELECTROMAGNETIC IMMUNITY – FOR ME EQUIPMENT AND ME SYSTEMS THAT ARE NOT LIFE-SUPPORING ........... 26

TABLE 4 – RECOMMENDED SEPARATION DISTANCES BETWEEN PORTABLE AND MOBILE RF COMMUNICATIONS EQUIPMENT

AND THE ME EQUIPMENT OR ME SYSTEM – FOR ME EQUIPMENT AND ME SYSTEMS THAT ARE NOT LIFE- ............... 27

Page 30

SPELLMAN HIGH VOLTAGE Trouble Shooting 4

Installation and Operating Manual – XRB011 Page 4-25 118149-001 REV F

4.1 INTRODUCTION

Fault or error message will be indicated via system status indicator or serial message during abnormal

operation. This Chapter contains tables of those messages and suggests actions to be taken by service

personnel to correct any malfunctions that may occur.

4.2 STATUS AND ERROR CODES

4.2.1 Status Messages

Fault/Symptom

Possible Cause

OV led illuminated and Over voltage fault at RS-232

resulting in HV Status Off.

kV programming set greater than 82kV.

UV led illuminated and Under Voltage fault at RS-232

resulting in HV Status Off.

kV programming set less than 35kV.

OC led illuminated and Over Current fault at RS-232

resulting in HV Status Off.

mA programming greater than 275µA (20W option)

710µA (50W option)

UC led illuminated and Under Current fault at RS-232

resulting in no emission, HV Status Off.

Occurrence of filament of the tube breaks open.

ARC FLT led illuminated and Arc fault at RS-232

resulting in HV Status OFF

Occurrence of tube arc causing shutdown. Clear fault

and send X-ray command. Refer to tube re-seasoning

procedure Table 2 and idle times. If problem continues

contact Spellman service department.

Unit will not Enable

Interlock open

OT led illuminated and Over Temp fault at RS-232

resulting in HV Status Off.

Tank oil temperature has exceeded 65 degrees C

TABLE 1 – GUIDANCE AND MANUFACTURER’S DECLARATION

ELECTROMAGNETIC EMISSIONS – FOR ALL ME EQUIPMENT AND ME SYSTEMS

Guidance and manufacturer’s declaration – electromagnetic emissions

The XRB011 is intended for use in the electromagnetic environment specified below. The customer or the

user of the XRB011 should assure that it is used in such an environment.

Emissions test

Compliance

Electromagnetic environment – guidance

RF emissions

CISPR 11

Group 2

The XRB011 uses RF energy only for its internal

function. Therefore, its RF emissions are very low

and are not likely to cause any interference in nearby

electronic equipment.

RF emissions

CISPR 11

Class B

The XRB011 is suitable for use in all establishments

other than domestic and those directly connected to

the public low-voltage power supply network that

supplies buildings used for domestic purposes.

Harmonic emissions

IEC 61000-3-2

Not applicable

Voltage fluctuations/

flicker emissions

IEC 61000-3-3

Not applicable

Page 31

SPELLMAN HIGH VOLTAGE Trouble Shooting 4

Installation and Operating Manual – XRB011 Page 4-26 118149-001 REV F

TABLE 2 – GUIDANCE AND MANUFACTURER’S DECLARATION – ELECTROMAGNETIC EMISSIONS – FOR

ALL ME EQUIPMENT AND ME SYSTEMS

Guidance and manufacturer’s declaration – electromagnetic immunity

The XRB011 is intended for use in the electromagnetic environment specified below. The customer or the

user of the XRB011 should assure that it is used in such an environment.

Immunity test

IEC 60601 test level

Compliance level

Electromagnetic environment – guidance

Electrostatic

discharge

(ESD)

IEC 61000-4-2

±6 kV contact

±8 kV air

±6 kV contact

±8 kV air

Floors should be wood, concrete or ceramic

tile. If floors are covered with synthetic

material, the relative humidity should be at

least 30 %.

Electrical fast

transient/burst

IEC 61000-4-4

±2 kV for power

supply lines

±1 kV for input/output

lines

±2 kV for power

supply lines

±1kV for

input/output

lines

Mains power quality should be that of a

typical commercial or hospital environment.

Surge

IEC 61000-4-5

Not applicable

Not applicable

Mains power quality should be that of a

typical commercial or hospital environment.

Voltage dips,

short

interruptions

and

voltage

variations

on power

supply

input lines

IEC 61000-4-11

Not applicable

Not applicable

Mains power quality should be that of a

typical commercial or hospital environment.

If the user of the XRB011 requires

continued operation during power mains

interruptions, it is recommended that the

XRB011 be powered from an uninterruptible

power supply or a battery.

Power

frequency

(50/60 Hz)

magnetic field

IEC 61000-4-8

3 A/m

3 A/m

Power frequency magnetic fields should be

at levels characteristic of a typical location

in a typical commercial or hospital

environment.

NOTE UT is the A.C. mains voltage prior to application of the test level.

TABLE 3 – GUIDANCE AND MANUFACTURER’S DECLARATION – ELECTROMAGNETIC IMMUNITY – FOR ME

EQUIPMENT AND ME SYSTEMS THAT ARE NOT LIFE-SUPPORING

Guidance and manufacturer’s declaration – electromagnetic immunity

The XRB011 is intended for use in the electromagnetic environment specified below. The customer or the user of the

XRB011 should assure that it is used in such an environment.

Immunity test

IEC 60601 test level

Compliance level

Electromagnetic environment – guidance

Portable and mobile RF communications equipment

should be used no closer to any part of the XRB011,

including cables, than the recommended separation

distance calculated from the equation applicable to

the frequency of the transmitter.

Page 32

SPELLMAN HIGH VOLTAGE Trouble Shooting 4

Installation and Operating Manual – XRB011 Page 4-27 118149-001 REV F

Recommended separation distance

Conducted RF

IEC 61000-4-6

3 Vrms

150 kHz to 80 MHz

3 Vrms

d = 1.17 √P

Radiated RF

IEC 61000-4-3

3 V/m

80 MHz to 2.5 GHz

3 V/m

d = 1.17 √P 80 MHz to 800 MHz

d = 2.33 √P 800 MHz to 2.5 GHz

Where P is the maximum output power rating of the

transmitter in watts (W) according to the transmitter

manufacturer and d is the recommended separation

distance in meters (m).

Field strengths from fixed RF transmitters, as

determined by an electromagnetic site survey,a

should be less than the compliance level in each

frequency range.b

Interference may occur in the vicinity of equipment

marked with the following symbol:

NOTE 1 At 80 MHz and 800 MHz, the higher frequency range applies.

NOTE 2 These guidelines may not apply in all situations. Electromagnetic propagation is affected by absorption and

reflection from structures, objects and people.

a Field strengths from fixed transmitters, such as base stations for radio (cellular/cordless) telephones and land mobile

radios, amateur radio, AM and FM radio broadcast and TV broadcast cannot be predicted theoretically with accuracy. To

assess the electromagnetic environment due to fixed RF transmitters, an electromagnetic site survey should be

considered. If the measured field strength in the location in which the XRB011 is used exceeds the applicable RF

compliance level above, the XRB011 should be observed to verify normal operation. If abnormal performance is observed,

additional measures may be necessary, such as re-orienting or relocating the XRB011.

b Over the frequency range 150 kHz to 80 MHz, field strengths should be less than 3 V/m.

TABLE 4 – RECOMMENDED SEPARATION DISTANCES BETWEEN PORTABLE AND MOBILE RF

COMMUNICATIONS EQUIPMENT AND THE ME EQUIPMENT OR ME SYSTEM – FOR ME

EQUIPMENT AND ME SYSTEMS THAT ARE NOT LIFE-SUPPORTING

Recommended separation distances between portable and mobile RF communications equipment

and the XRB011

The XRB011 is intended for use in an electromagnetic environment in which radiated RF disturbances are

controlled. The customer or the user of the XRB011 can help prevent electromagnetic interference by

maintaining a minimum distance between portable and mobile RF communications equipment (transmitters)

and the XRB011 as recommended below, according to the maximum output power of the communications

equipment.

Rated maximum

output

power of

transmitter

W

Separation distance according to frequency of transmitter

m

150 kHz to 80 MHz

d = 1.17 √P

80 MHz to 800 MHz

d = 1.17 √P

800 MHz to 2,5 GHz

d = 2.33 √P

0.01

0.117

0.117

0.233

0.1

0.370

0.370

0.737

Page 33

SPELLMAN HIGH VOLTAGE Trouble Shooting 4

Installation and Operating Manual – XRB011 Page 4-28 118149-001 REV F

1

1.17

1.17

2.33

10

3.70

3.70

7.37

100

11.7

11.7

23.3

For transmitters rated at a maximum output power not listed above, the recommended separation distance d

in meters (m) can be determined using the equation applicable to the frequency of the transmitter, where P

is the maximum output power rating of the transmitter in watts (W) according to the transmitter

manufacturer.

NOTE 1 At 80 MHz and 800 MHz, the separation distance for the higher frequency range applies.

NOTE 2 These guidelines may not apply in all situations. Electromagnetic propagation is affected by

absorption and reflection from structures, objects and people.

Page 34

SPELLMAN HIGH VOLTAGE Schematics 5

Installation and Operating Manual – XRB011 Page 5-29 118149-001 REV F

CHAPTER 5

SCHEMATICS

CONTENTS:

5.1 INTRODUCTION ........................................................................................................................................................ 30

5.2 FUNCTIONAL SCHEMATIC INDEX ........................................................................................................................ 30

Page 35

SPELLMAN HIGH VOLTAGE Schematics 5

Installation and Operating Manual – XRB011 Page 5-30 118149-001 REV F

5.1 INTRODUCTION

This chapter contains the functional schematics for XRB011 MONOBLOCK. Each schematic represents a

major function in the generator; the 2 functional schematics in this chapter represent all of the major

functional blocks in this generator.

5.2 FUNCTIONAL SCHEMATIC INDEX

The following functional schematics are not included in this manual.

DESCRIPTION

DRAWING NUMBER #

Block diagram Schematic

441431-001

Control Board Schematic

441434-001

Page 36

To obtain information on Spellman’s product warranty please visit our website at:

http://www.spellmanhv.com/en/About/Warranty.aspx

Page 37

XRB011 Digital Interface

Serial RS-232 - Ethernet

Copyright 2014, Spellman High Voltage Electronics Corporation. All Rights Reserved.

This information contained in this publication is derived in part from proprietary and patent data. This information has

been prepared for the express purpose of assisting operating and maintenance personnel in the efficient use of the

model described herein, and publication of this information does not convey any right to reproduce it or to use it for

any purpose other than in connection with installation, operation, and maintenance of the equipment described.

118150-001 REV. B

Page 38

Changes

REVISION DATE DESCRIPTION

1 09/18/13 Draft version

2 04/18/14 Added Ramp Time command description

Added User Configuration command.

3 05/14/14 Deleted mA Low fault, changed HV to X-RAY,

Update status table.

4 03/28/16 Added Over temperature fault to command 22.

118150-001 REV. B Page 2 of 66

Page 39

Table Of Contents

1.0 SCOPE ................................................................................................................. 5

2.0 FUNCTIONAL DESCRIPTION ............................................................................. 5

3.0 RS232 .................................................................................................................. 5

3.1 RS232 INTERFACE ....................................................................................................... 5

3.2 RS-232 CABLING .......................................................................................................... 6

3.3 Programming the RS-232 Interface ...................................................................................... 7

3.3.1 Enabling Communications Objects in Visual Basic for RS-232 ........................... 7

3.3.2 Configuring Communications in Visual Basic for RS-232 .................................... 7

3.4 SERIAL INTERFACE PROTOCOL .............................................................................. 8

3.4.1 COMMAND ARGUMENTS ................................................................................... 8

3.4.2 CHECKSUMS ........................................................................................................... 8

3.4.3 COMMAND OVERVIEW ..................................................................................... 11

3.4.4 RESPONSE OVERVIEW ...................................................................................... 12

3.4.5 COMMANDS DESCRIPTION ............................................................................. 13

3.4.6 SERIAL COMMAND HANDLING ................................................................. 29

4.0 ETHERNET ........................................................................................................ 30

4.1 ETHERNET INTERFACE .......................................................................................... 30

4.2 ETHERNET CABLING ............................................................................................... 30

4.3 ETHERNET WEB SERVER ........................................................................................ 32

4.3.1 Diagnostic Web Server ........................................................................................... 32

4.3.2 Web Pages ................................................................................................................ 32

4.4 Direct Connection between the DXM and a Computer ................................................ 39

4.5 Configuring the Computer for Direct Ethernet Connection .......................................... 39

4.6 Testing a Direct Connection ......................................................................................... 42

4.7 Configuring the XRB011 For a Local Area Network (LAN) ...................................... 43

4.8 Configuring the Network Settings from the Monitor and Configure Applet ................ 43

4.9 Enabling Communications Objects in Visual Basic for Ethernet Communications ..... 45

4.10 Configuring Communications in Visual Basic for Ethernet ......................................... 45

4.11 TCP/IP FORMAT ......................................................................................................... 47

4.12 COMMAND ARGUMENTS ....................................................................................... 48

4.13 COMMAND OVERVIEW ........................................................................................... 49

4.14 RESPONSE OVERVIEW ............................................................................................ 50

4.15 COMMANDS DESCRIPTION .................................................................................... 51

4.15.1 Set KV <10> .............................................................................................................. 51

4.15.2 Set MA <11> ............................................................................................................. 52

4.15.3 Request KV Set point <14> ..................................................................................... 53

4.15.4 Request MA Set point <15> .................................................................................... 54

4.15.5 Request Status <22>................................................................................................. 55

4.15.6 Request Firmware Version <23> ............................................................................ 56

4.15.7 Request Model Number <26> ................................................................................ 57

4.15.8 Tickle Watchdog <27> ............................................................................................. 58

4.15.9 Enable Watchdog <28> .......................................................................................... 59

118150-001 REV. B Page 3 of 66

Page 40

4.15.12 Reset Faults <52> .................................................................................................. 62

4.15.13 Get KV Monitor <60> ............................................................................................ 63

4.15.14 Get MA monitor <61> ........................................................................................... 64

4.15.15 Get X-RAY Status <98> ........................................................................................ 65

4.15.16 Turn High X-RAY On/Off <99> ......................................................................... 66

118150-001 REV. B Page 4 of 66

Page 41

WARNING

THIS EQUIPMENT GENERATES DANGEROUS VOLTAGES THAT MAY BE FATAL.

PROPER GROUNDING OF ALL HIGH VOLTAGE EQUIPMENT IS ESSENTIAL.SEE 80kv

MONOBlOCK OWNERS MANUAL FOR PROPER GROUNDING TECHNIQUE AND SAFETY

PRECAUTIONS BEFORE APPLING AC INPUT POWER TO THE XRB UNIT.

TO PREVENT DAMAGE TO THE HOST COMPUTER THE COMPUTER SHOULD BE

GROUNDED TO THE SAME GROUND AS THE UUT.

This unit is capable of producing X-ray radiation, please proceed only after

proper precautions have been taken to prevent X-ray exposure.

1.0 SCOPE

This document applies to the communications interfaces on the XRB, assembly

460162.

2.0 FUNCTIONAL DESCRIPTION

The XRB provides 2 types of digital communications interface:

RS-232 on J3

Ethernet

3.0 RS232

3.1 RS232 INTERFACE

The RS232C interface has the following attributes:

115K bits per second

No Parity

8 Data Bits

1 Stop Bit

No handshaking

DB-9 connector as shown

Figure 1 – J3, RS-232 DB-9M pinout (front view)

118150-001 REV. B Page 5 of 66

Page 42

PIN

DESCRIPTION

1 - 2

Tx Out

3

Rx In 4 -

5

Ground

6 - 7 - 8 - 9

-

PC to XRB Board Cable Details

PC Connector (DB-9 Female)

XRB Connector (DB-9 Male)

Pin 2: RX In

Pin 2: TX Out

Pin 3: TX Out

Pin 3: RX In

Pin 5: Ground

Pin 5: Ground

3.2 RS-232 CABLING

A standard shielded RS-232 cable is used to connect the XRB serial port

to the serial port on a standard personal computer. Please refer to the

following chart.

118150-001 REV. B Page 6 of 66

Page 43

3.3 Programming the RS-232 Interface

This section details how to create software to control the XRB011 serial

interface.

The RS-232 interface makes use of a standard ‘command/response’

communications protocol. See section 3.4 for a description of the serial

interface protocol.

All software that addresses the RS-232 interface must adhere to the

following parameters:

A default Baud rate of 115.2K bps

No Parity

8 Data Bits

1 Stop Bit

No handshaking

3.3.1 Enabling Communications Objects in Visual Basic for RS-232

Communications in Microsoft Visual Basic 6.0 are directed to a control

that abstracts the port. In the case of serial interface we need

Microsoft Comm Control 6.0. To enable this in your VB 6 project, go to:

Project -> Components

Then in the list make sure that Microsoft Comm Control 6.0 has a

check next to it. The Comm Control Object should then appear in your

toolbox. It will have an icon of a telephone and will be named:

MSComm. This can be dragged and dropped into your application.

You will then need to set the object’s properties.

3.3.2 Configuring Communications in Visual Basic for RS-232

In order to configure the MSComm Object, first you must initialize it

in the Object properties:

Settings 115200,n,8,1

Handshaking 0 – comNone

The application can be set to either default to a specific COM Port

or the End User can be allowed to choose one for the particular

PC. For the “Default” scenario, include the following commands in

the Form_Load() routine:

118150-001 REV. B Page 7 of 66

Page 44

MSComm1.CommPort = portNumber

MSComm1.PortOpen = True

3.4 SERIAL INTERFACE PROTOCOL

Serial communications will use the following data format::

<STX><CMD><,>ARG><,><CS><ETX>

Where:

<STX> = 1 ASCII 0x02 Start of Text character

<CMD> = 2 ASCII characters representing the command ID

<,> = 1 ASCII 0x2C character

<ARG> = Command Argument

<,> = 1 ASCII 0x2C character

<CS> = Checksum

<ETX> = 1 ASCII 0x03 End of Text character

3.4.1 COMMAND ARGUMENTS

The format of the numbers is a variable length string. To represent the

number 42, the string ‘42’, ‘042’, or ‘0042’ can be used. This being the

case, commands and responses that carry data are variable in length.

3.4.2 CHECKSUMS

The checksum is computed as follows:

Add the <CMD>, <,>, and <ARG>, and <,> bytes into a 16 bit (or larger)

word. The bytes are added as unsigned integers.

Take the 2’s complement (negate it).

Truncate the result down to the eight least significant bits.

Clear the most significant bit (bit 7) of the resultant byte, (bitwise AND with

0x7F).

Set the next most significant bit (bit 6) of the resultant byte (bitwise OR

with 0x40).

Using this method, the checksum is always a number between 0x40 and 0x7F.

The checksum can never be confused with the <STX> or <ETX> control

characters, since these have non-overlapping ASCII values.

118150-001 REV. B Page 8 of 66

Page 45

If the DSP detects a checksum error, the received message is ignored – no

acknowledge or data is sent back to the host. A timeout will act as an implied

NACK.

Here is another example, this time for command 22 (Request Status) which has

no arguments.

The original message with a placeholder for checksum is:

<STX>22,<CS><ETX>

First, you add up all the characters starting with the ‘2’ in the command number

to the comma before the checksum with their ASCII values (in hexadecimal):

0x32 + 0x32 + 0x2C = 0x90

Next, you then take the two’s complement of that number by negating it, by

subtracting it from 0x100 (decimal 256), and only retain the lowest 7 bits by

bitwise ANDing the results with 0x7F:

This combines the steps of getting the twos complement, truncating the result to

8 bits and clearing the 8th bit.

(0x100 – 0x90) & 0x7F = 0x70

Finally, bitwise OR the result with 0x40:

0x70 | 0x40 = 0x70

The checksum byte is 0x70 (Decimal 112, ASCII: p)

The following is sample code, written in Visual Basic, for the generation of

checksums:

Public Function ProcessOutputString(outputString As String) As String

Dim i As Integer

Dim CSb1 As Integer

Dim CSb2 As Integer

Dim CSb3 As Integer

Dim CSb$

Dim X

X = 0

For i = 1 To (Len(outputString)) 'Starting with the CMD character

X = X + Asc(Mid(outputString, i, 1)) 'adds ascii values together

Next i

CSb1 = 256 - X 'Twos Complement

CSb2 = 63 And (CSb1)

CSb3 = 64 Or (CSb2) 'OR 0x40

CSb$ = Chr(Val("&H" & (Hex(CSb3))))

118150-001 REV. B Page 9 of 66

Page 46

ProcessOutputString = Chr(2) & outputString & CSb$ & Chr(3)

End Function

Here is an example of an actual Checksum calculation for command 10

(Program kV set point)

The original message with a placeholder for the checksum is

<STX>10,4095,<CS><ETX>

First, you add up all the characters starting with the ‘1’ in the command number,

to the comma before the checksum with their ASCII values (in hexadecimal):

0x31 + 0x30 + 0x2C + 0x34 + 0x30 + 0x39 + 0x35 + 0x2C = 0x18B

Next, you then take the two’s complement of that number by negating it, by

subtracting it from 0x100 (decimal 256), and only retain the lowest 7 bits by

bitwise ANDing the results with 0x7F. :

This combines the steps of getting the twos complement, truncating the result to

8 bits and clearing the 8th bit.

(0x100 – 0x18B) & 0x7F = 0x75

Finally, bitwise OR the result with 0x40:

0x75 | 0x40 = 0x75

The checksum byte is 0x75 (Decimal 117, ASCII: u)

118150-001 REV. B Page 10 of 66

Page 47

Command Name

<CMD>

<ARG>

RANGE

Set KV

10

1-4 ASCII

0-Max KV

Set MA

11

1-4 ASCII

0-Max mA

Request KV Setpoint

14

None

Request MA Setpoint

15

None

-

Request Status

22

None

-

Request Software

Version

23

None

-

Request Model

Number

26

None

-

Tickle Watchdog

27

None

-

Enable Watchdog

28

1-2 ASCII

1-10

Ramp Time

29

1-4 ASCII

1 - 1000

User Configuration

31

4 ASCII

-

Reset Faults

52

None

-

Get KV monitor

60

None

-

Get MA monitor

61

None

-

Get X-RAY Status

98

None

-

Turn X-RAY

ON/OFF

99

1 ASCII

0 or 1

3.4.3 COMMAND OVERVIEW

118150-001 REV. B Page 11 of 66

Page 48

Response Name

<CMD>

<ARG>

Request KV

Setpoint

14

1-3 ASCII

Request MA

Setpoint

15

1-3 ASCII

Request Status

22

3 ASCII

Request DSP

Software Version

23

11 ASCII

Request Model

number

26

5 ASCII

Get KV monitor

60

1-3 ASCII

Get MA monitor

61

1-3 ASCII

Get X-RAY Status

98

1 ASCII

3.4.4 RESPONSE OVERVIEW

The command responses will follow the same format as outlined above in

section 2.1. This list is comprised of Commands with complex responses

only. Commands using a simple response will use the <$> character

(ASCII 0x24) as a “Success” response or a single character error code.

These responses will be eight ASCII characters in length.

118150-001 REV. B Page 12 of 66

Page 49

3.4.5 COMMANDS DESCRIPTION

3.4.5.1 Set KV <10>

Description:

The host requests that the firmware change the KV set point.

Direction:

Host to supply

Syntax:

<STX><10><,><ARG><,><CS><ETX>

Where:

<ARG> = Value of KV in ASCII format. Units are tenths of KV. Example,

for 80KV, enter 800.

Example:

<STX>10,800,<CS><ETX>

Response:

<STX><10><,><$><,><CS><ETX> or

<STX><10><,><ARG><,><CS><ETX>

where <ARG> = error code

Error Codes: 1 = receive error, 2 = unrecognized command

118150-001 REV. B Page 13 of 66

Page 50

3.4.5.2 Set MA <11>

Description:

The host requests that the firmware change the MA set point.

Direction:

Host to supply

Syntax:

<STX><11><,><ARG><,><CS><ETX>

Where:

<ARG> = Value of mA in ASCII format. Units are micro amps. Example,

For 0.2 mA, enter 200.

Example:

<STX>11,200,<CS><ETX>

Response:

<STX><11><,><$><,><CS><ETX>

<STX><11><,><ARG><,><CS><ETX>

where <ARG> = error code

Error Codes: 1 = receive error, 2 = unrecognized command

118150-001 REV. B Page 14 of 66

Page 51

3.4.5.3 Request KV Set point <14>

Description:

The host requests the KV set point.

Direction:

Host to supply

Syntax:

<STX><14><,><ETX>

Example:

<STX>14,<ETX>

Response:

<STX><14><,><ARG><,><ETX>

Where <ARG> = number in ASCII format representing un-scaled KV set

point. Units are tenths of KV.

118150-001 REV. B Page 15 of 66

Page 52

3.4.5.4 Request MA Set point <15>

Description:

The host requests that the firmware send the MA set point.

Direction:

Host to supply

Syntax:

<STX><15><,><ETX>

Example:

<STX>15,<ETX>

Response:

<STX><15><,><ARG><,><ETX>

Where <ARG> = = number in ASCII format representing un-scaled mA

set point. Units are micro amps.

118150-001 REV. B Page 16 of 66

Page 53

Arg

Name

Description

000

No Fault (X-RAY Ready)

It indicates thet the Monoblock is ready to produce X-RAY

001

Over Temperature

It indicates oil tank over temperature

002

Arc Fault

It indicates that an arc event was detected

003

High mA

The mA output is higher than allowed threshold

005

Low kV

The kV output is lower than threshold

006

High kV

The kV output is higher than allowed theshold

007

Watchdog

Watchdog timer expired while X-Rays were on

009

Interlock Open

Interlock is not satisfied

010

Filament Limit

Indicates filament overcurrent

011

Filament Standby

Filament status

3.4.5.5 Request Status <22>

Description:

The host requests that the firmware sends the power supply status. The

power supply sends a three digits code representing a specific status

condition. A description of these characters is shown in the table below.

Direction:

Host to supply

Syntax:

<STX><22><,><CS><ETX>

Example:

<STX>22,<CS><ETX>

Response:

<STX><22><,><ARG><,><CS><ETX>

Example:

<STX>22,000,<CS><ETX>

118150-001 REV. B Page 17 of 66

Page 54

3.4.5.6 Request Firmware Version <23>

Description:

The host requests that the firmware sends the DSP firmware version.

Direction:

Host to supply

Syntax:

<STX><23><,><CS><ETX>

Example:

<STX>23,<CS><STX>

Response:

<STX><23><,>< ARG><,><CS><ETX>

Where:

<ARG> consists of eleven ASCII characters representing the current

firmware part number/version. The format is SWMNNNN-NNN, where N is

a numeric character.

Example:

<STX>23,SWM0584-001,<CS><ETX>

118150-001 REV. B Page 18 of 66

Page 55

3.4.5.7 Request Model Number <26>

Description:

The host requests that the firmware sends the unit model number

Direction:

Host to supply

Syntax:

<STX><26><,><CS><ETX>

Example:

<STX>26,<CS><ETX>

Response:

<STX><26><,><ARG><,><CS><ETX>

Where:

<ARG> consists of five ASCII characters representing the model number.

The format is XNNNN, where N is a numeric character.

Example:

<STX>26,X4618,<CS><ETX>

118150-001 REV. B Page 19 of 66

Page 56

3.4.5.8 Tickle Watchdog <27>

Description:

This command is used to reset the Watchdog timer to prevent a watchdog

time out fault condition.

Direction:

Host to supply

Syntax:

<STX><27><,><CS><ETX>

Response:

<STX><27><,><ARG><,><CS><ETX>

Where:

<ARG>= $ or error code.

Error Codes: 1 = receive error, 2 = unrecognized command

118150-001 REV. B Page 20 of 66

Page 57

3.4.5.9 Enable Watchdog <28>

Description:

It enables the communication watchdog and sets the timeout delay. If no

message is received during the timeout period, high voltage will be shut

down and a watchdog fault will be declared. Enter timeout delays from 1

to 10 seconds. A value of zero disables the watchdog operation.

The default timeout is 5 seconds. This command is password protected

and the userconfig command must be sent first.

Direction:

Host to supply

Syntax:

<STX><28><,><ARG><,><CS><ETX>

Where <ARG> = 1-10 seconds

Response:

<STX><28><,><ARG><,><CS><ETX>

Where:

<ARG>= $ or error code.

Error Codes: 1 = receive error, 2 = unrecognized command

118150-001 REV. B Page 21 of 66

Page 58

3.4.5.10 Set Ramp Time <29>

Description: