Page 1

R

Instruction Manual

V6 SERIES

MODEL :

SERIAL# :

DATE :

SPELLMAN

HIGH VOLTAGE ELECTRONICS

CORPORATION

One Commerce Park

Valhalla, New York, 10595

+1(914) 686-3600* FAX: +1(914) 686-5424*

E-mail: sales@spellmanhv.com

Website: www.spellmanhv.com

High Voltage Power Supply

V6 MANUAL 118129-001 Rev B

Page 2

IMPORTANT SAFETY PRECAUTIONS

SAFETY

THIS POWER SUPPLY GENERATES VOLTAGES THAT ARE DANGEROUS AND MAY BE FATAL.

OBSERVE EXTREME CAUTION WHEN WORKING WITH THIS EQUIPMENT.

High voltage power supplies must always be grounded.

Do not touch connections unless the equipment is off and the

Capacitance of both the load and power supply is discharged.

Allow five minutes for discharge of internal capacitance of the power supply.

Do not ground yourself or work under wet or damp conditions.

SERVICING SAFETY

.

Maintenance may require removing the instrument cover with the power on.

Servicing should be done by qualified personnel aware of the electrical hazards.

WARNING note in the text call attention to hazards in operation of these units

that could lead to possible injury or death.

CAUTION notes in the text indicate procedures to be followed to avoid possible

damage to equipment.

Copyright © 2000, Spellman High Voltage Electronics Corporation. All Rights Reserved.

This information contained in this publication is derived in part from proprietary and patent data. This information has

been prepared for the express purpose of assisting operating and maintenance personnel in the efficient use of the

model described herein, and publication of this information does not convey any right to reproduce it or to use it for

any purpose other than in connection with installation, operation, and maintenance of the equipment described.

118004-001 REV. B

Page 3

WICHTIGE SICHERHEITSHINWEISE

SICHERHEIT

DIESES HOCHSPANNUNGSNETZTEIL ERZEUGT LEBENSGEFÄHRLICHE HOCHSPANNUNG.

SEIN SIE SEHR VORSICHTIG BEI DER ARBEIT MIT DIESEM GERÄT.

Das Hochspannungsnetzteil muß immer geerdet sein.

Berühren Sie die Stecker des Netzteiles nur, wenn das Gerät ausgeschaltet ist und die elektrischen

Kapazitäten des Netzteiles und der angeschlossenen Last entladen sind.

Die internen Kapazitäten des Hochspannungsnetzteiles benötigen ca. 5 Minuten, um sich zu entladen.

Erden Sie sich nicht, und arbeiten Sie nicht in feuchter oder nasser Umgebung.

SERVICESICHERHEIT

Notwendige Reparaturen können es erforderlich machen, den Gehäusedeckel während des Betriebes zu

entfernen.

Reparaturen dürfen nur von qualifiziertem, eingewiesenem Personal ausgeführt werden.

“WARNING” im folgenden Text weist auf gefährliche Operationen hin, die zu Verletzungen oder zum Tod

führen können.

“CAUTION” im folgenden Text weist auf Prozeduren hin, die genauestens befolgt werden müssen, um

eventuelle Beschädigungen des Gerätes zu vermeiden.

118004-001 REV. B

Page 4

PRECAUTIONS IMPORTANTES POUR VOTRE SECURITE

CONSIGNES DE SÉCURITÉ

CETTE ALIMENTATION GÉNÈRE DES TENSIONS QUI SONT DANGEUREUSES ET PEUVENT ÊTRE FATALES.

OYEZ EXTRÊMENT VIGILANTS LORSQUE VOUS UTILISEZ CET ÉQUIPEMENT.

S

Les alimentations haute tension doivent toujours être mises à la masse.

Ne touchez pas les connectiques sans que l’équipement soit éteint et que la capacité à la fois de la charge et de

l’alimentation soient déchargées.

Prévoyez 5 minutes pour la décharge de la capacité interne de l’alimentation.

Ne vous mettez pas à la masse, ou ne travaillez pas sous conditions mouillées ou humides.

CONSIGNES DE SÉCURITÉ EN CAS DE REPARATION

La maintenance peut nécessiter l’enlèvement du couvercle lorsque l’alimentation est encore allumée.

Les réparations doivent être effectuées par une personne qualifiée et connaissant les risques électriques.

Dans le manuel, les notes marquées « WARNING » attire l’attention sur les risques lors de la manipulation de ces

équipements, qui peuvent entrainer de possibles blessures voire la mort.

Dans le manuel, les notes marquées « CAUTION » indiquent les procédures qui doivent être suivies afin d’éviter

d’éventuels dommages sur l’équipement.

118004-001 REV. B

Page 5

IMPORTANTI PRECAUZIONI DI SICUREZZA

SICUREZZA

QUESTO ALIMENTATORE GENERA TENSIONI CHE SONO PERICOLOSE E

POTREBBERO ESSERE MORTALI.

PONI ESTREMA CAUTELA QUANDO OPERI CON QUESO APPARECCHIO.

Gli alimentatori ad alta tensione devono sempre essere collegati ad un impianto di terra.

Non toccare le connessioni a meno che l’apparecchio sia stato spento e la capacità interna

del carico e dell’alimentatore stesso siano scariche.

Attendere cinque minuti per permettere la scarica della capacità interna dell’alimentatore

ad alta tensione.

Non mettere a terra il proprio corpo oppure operare in ambienti bagnati o saturi d’umidità.

SICUREZZA NELLA MANUTENZIONE.

Manutenzione potrebbe essere richiesta, rimuovendo la copertura con apparecchio

acceso.

La manutenzione deve essere svolta da personale qualificato, coscio dei rischi elettrici.

Attenzione alle AVVERTENZE contenute nel manuale, che richiamano all’attenzione ai

rischi quando si opera con tali unità e che potrebbero causare possibili ferite o morte.

Le note di CAUTELA contenute nel manuale, indicano le procedure da seguire per evitare

possibili danni all’apparecchio.

118004-001 REV. B

Page 6

Table of Contents

1. INTRODUCTION

1.1 Description of the V6 Series ................................................................................1

1.2 Standard Features .................................................................................................1

1.3 Remote Operating Features ..................................................................................1

1.4 Options .................................................................................................................2

1.5 Interpreting the Model Number ...........................................................................2

2. INSPECTION & INSTALLATION

2.1 Initial Inspection ..................................................................................................3

2.2 Mechanical Installation ........................................................................................3

2.3 Temperature Considerations ................................................................................3

3. OPERATING INSTRUCTIONS

3.1 Operation..............................................................................................................5

3.2 Standard Features .................................................................................................6

4. PRINCIPLES OF OPERATION

4.1 DC Input...............................................................................................................9

4.2 AC Input………………………………………………………….……………..9

4.3 Inverter .................................................................................................................9

4.4 High Voltage Transformer ...................................................................................9

4.5 High Voltage Output Section ...............................................................................9

4.6 Control Circuitry ..................................................................................................9

PAGE

5. OPTIONS

5.1 RS232 Interface ...................................................................................................11

6. MAINTENANCE

6.1 Periodic Servicing ................................................................................................12

6.2 Performance Tests ................................................................................................12

6.3 High Voltage Dividers .........................................................................................12

7. FACTORY SERVICE

7.1 Warranty Service .................................................................................................13

7.2 Factory Service Procedures ..................................................................................13

7.3 Shipping Instructions ...........................................................................................13

V6 Series MANUAL i 118130-001 REV C

Page 7

LIST OF FIGURES

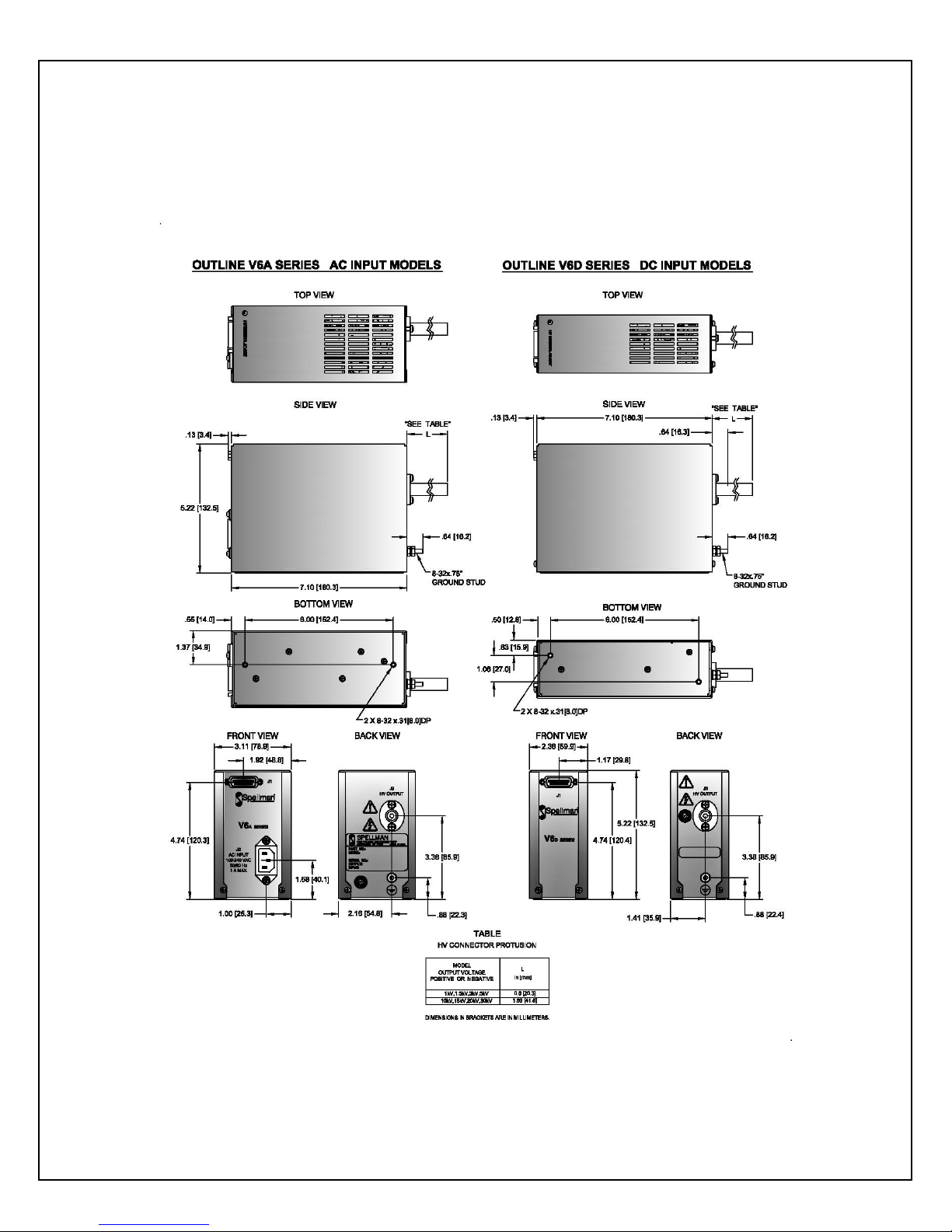

Figure 1 Outline Dimensions ....................................................................................4

Figure 2 Grounding DC Unit.....................................................................................7

Figure 3 Grounding AC Unit.....................................................................................7

Figure 4 Remote Programming with a Remote Voltage Source ...............................7

Figure 5 Programming using the +5V Reference ......................................................7

Figure 6 Local Programming using the internal multi turns potentiometer...………8

Figure 7 Remote Voltage and Current Monitoring ...................................................8

Figure 8 Enable Input ................................................................................................8

Figure 9 Block Diagram ............................................................................................10

V6 Series MANUAL ii 118130-001 REV C

Page 8

Chapter 1

INTRODUCTION

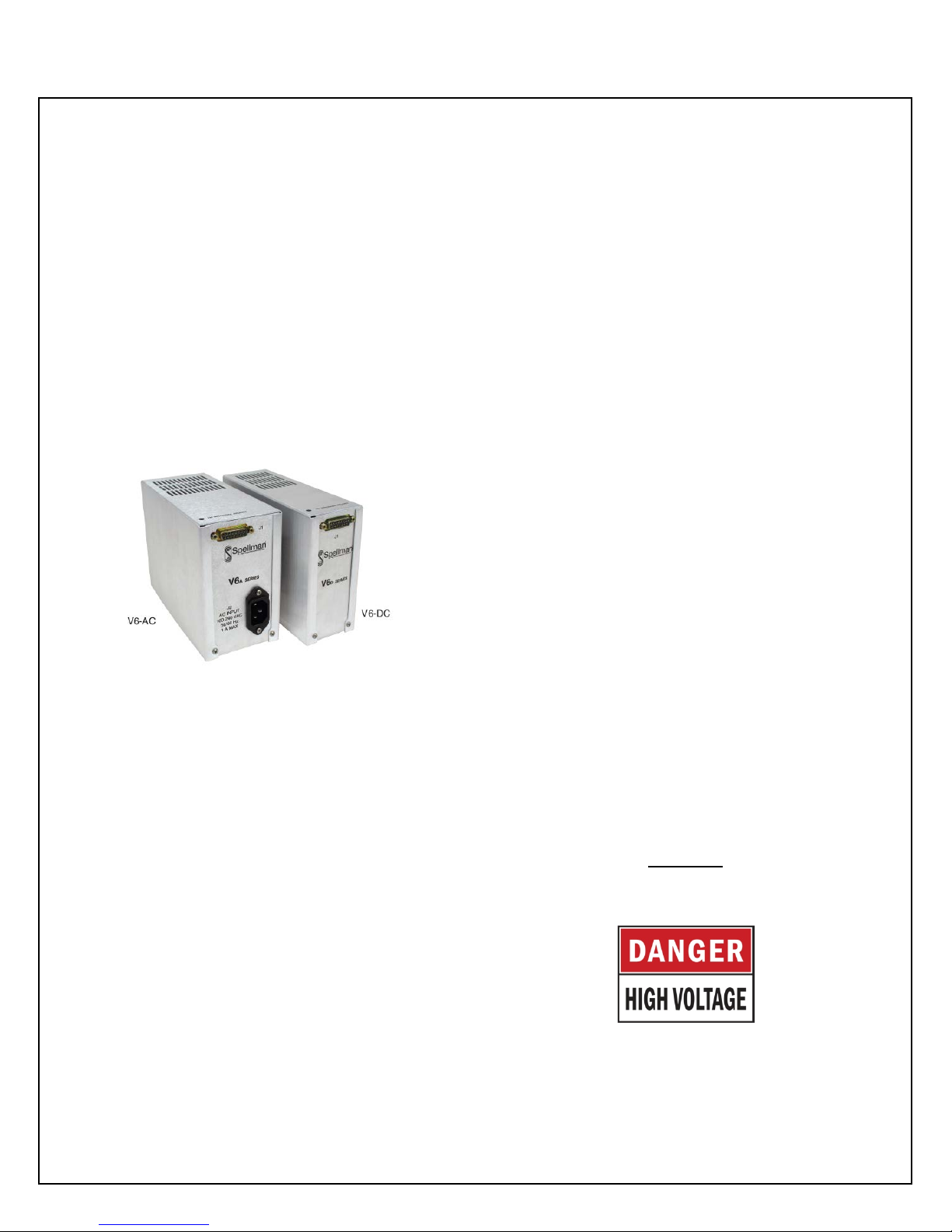

1.1 Description of the V6 Series

Spellman’s V6 Series is a family of regulated, fixed

output polarity module high voltage power supplies which

provide exceptional performance and value in many

applications. Utilizing proprietary power conversion

technology these SMT based high voltage modules

provide improved performance, reliability and easy

system integr ation. T he V6 series units are fully enclosed

and designed for system or bench top operation.

The V6 is rated at 30 watts with output voltages spanning

from 1kV to 30kV with fixed positive or negative

polarities. Voltage & Current loo ps with automatic cross

over control regulate the output into any load condition.

The output voltage is controlled locally by an internal

multi-turn potentiometer. Remote analog voltage and

current programming capability are included in all

models. Analog monitor outputs are also included for

remote monito ring of outp ut voltage and current. The V6

is a reliable and robust series that is arc a nd short circuit

protected. The comprehensive standard interface provides

interfacing flexibility and all V6 units are CE, UL and

RoHS compliant.

1.2 S t a nda rd Features

The V6 Series incorporates several standard features

designed to optimize user satisfaction and safety:

●Current Regulating Loop: Current programmability

allows the user to set where the unit will current limit,

anywhere from 0 to 100% of maximum rated current.

● 0 to +5Vdc Remote Programming Inputs: Positive

polarity, high impedance, ground referenced 0 to 5Vdc

voltage programming inputs correspond to 0 to 100%

rated voltage and current outputs.

● Local Control: Multi-turn potentiometer located on the

top of the unit is provided to control the output voltage

locally.

● 0 to +5Vdc Monitor Outputs: Positive polarity, low

impedance, ground referenced 0 to 5Vdc voltage monitor

outputs correspond to 0 to 100% rated output voltage and

current.

● Precision +5Vdc Reference Output: A precision

micro power band gap reference of +5Vdc, ±0.5%,

25ppm/°C is provided to simplify remote programming of

the power supply.

● Arc and Short Circuit Protected: Due to the fixed,

high frequency conversion rate the V6 series output

capacitance is small resulting in minimal stored energy.

Through the use of generously rated surge limiting

resistors and a fast acting c urrent loop, all units are fully

arc and short circuit protected.

1.3 Re m ot e Ope rating Features

● Enable Input: The Enable Input allows the user to

easily control the HV ON/OFF status o f t he power supply.

HCMOS compatible signals A low (<1.5Vdc) enable

input signal e quals HV ON, w hil e a high (open or >3 V d c)

enable signal equals HV OFF.

Warning!

The Enable Input should not be used as

protection against user injury or for a safety

interlock function.

1.4 Option

RS232 interface is available

V6 Series MANUAL 1 118130-001 REV C

Page 9

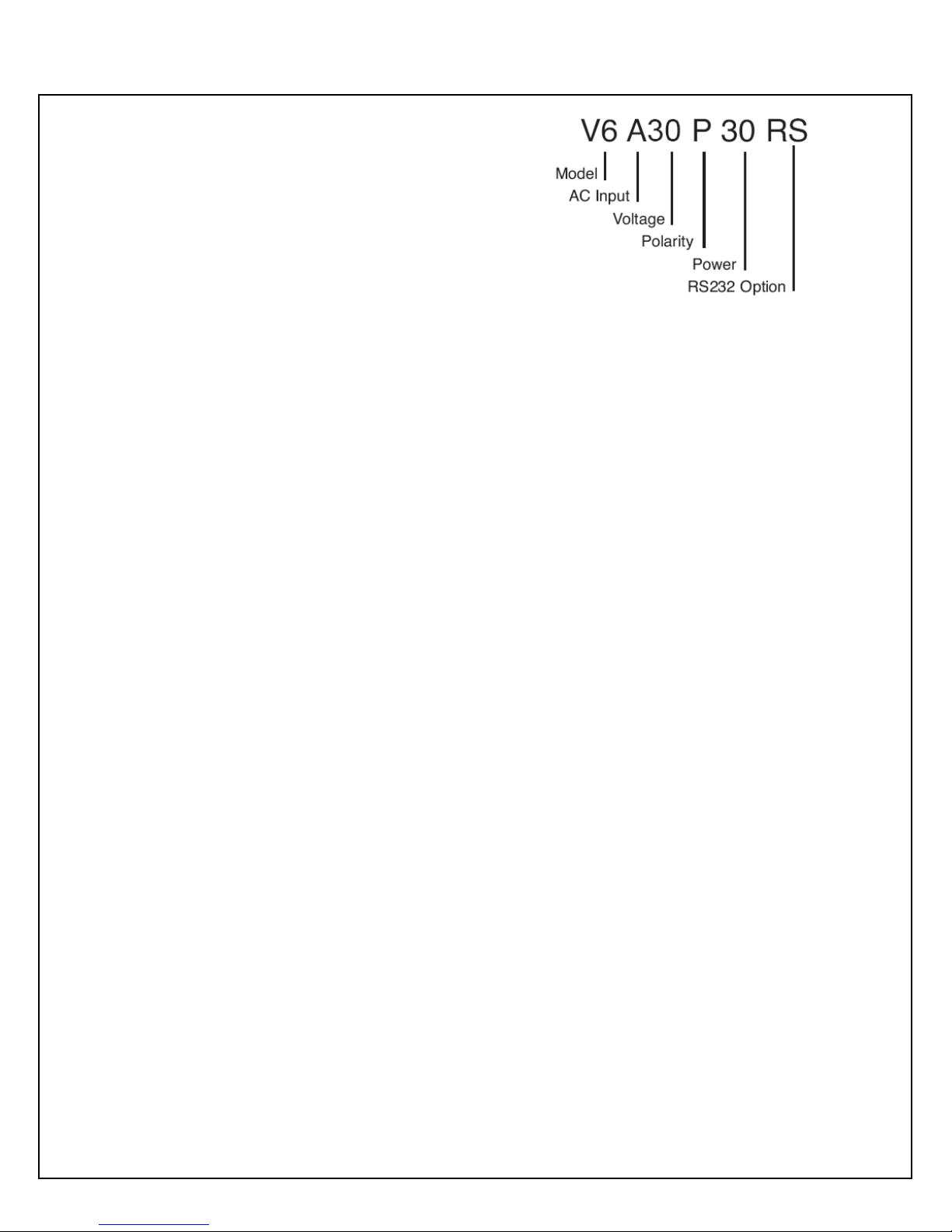

1.5 Interpreting the Model

Number

The power supplies model number describes its

capabilities. Model numbers are configured as follows:

U6A30P30RS where:

V6 is the product series name

A is for AC input voltage and D for DC input voltage

30 is the maximum output voltage in kV

P is the output polarity

30 is the output power in watts

RS is for RS-232 interface (omit RS for analog interface)

Interface

X numbered units are unique units custom developed for

specific application requirements above and beyond the

scope of the available standard options. Each 4 digit X

number corresponds to an applicable specification control

drawing.

V6 Series MANUAL 2 118130-001 REV C

Page 10

Chapter 2

INSPECTION & INSTALLATION

Initial inspection and preliminary checkout procedures are

recommended. For safe operation, please follow the

procedures described in Chapter 3, Operating Instructions.

2.1 Initial In spection

Inspect the packaging exterior for evidence of damage

due to improper handling in tr ansit. Notify the car rier and

Spellman High Voltage immediatel y if damage is evident.

Do not destroy or remove any of the packing material

used in a da maged shipme nt.

After unpacking inspect the power supply for any visible

signs of damage.

2.2 Mechanical Installation

V6 units ca n be mounted in any position using the tapped

holes in the base plate. 8-32 screws are required for

mounting. Please see the V6 series data s heet for a more

detailed dimensional drawing.

2.3 Temperature Consideration

It is the user’s responsibility to maintain the case

temperature below 50°C. Damage to the power supply

due to inadequate cooling is considered misuse and

repairs will not be covered under warranty

.

V6 Series MANUAL 3 118130-001 REV C

Page 11

.

Figure 1 Outline Dimensions

V6 Series MANUAL 4 118130-001 REV C

Page 12

Chapter 3

Operating In structions

3.1 Operation

WARNING!

This equipment generates dangerous voltages

that may be fatal.

Proper grounding of all high voltage equi p ment

is essential.

It is highly recommended that all testing comply

with IEEE Standard 510-1983 IEEE

Recommended Practices for Safety in High

Voltage and High Power Testing. A copy of this

standard can be downloaded from the Spell m an

High Voltage website

INPUT VOLTAGE

Check the identification label on the power supply and

confirm it matches the input voltage of the so urce suppl y

that will be used to power the V6 module. T he DC units

operate with +24Vdc ± 10%, 2Amp. The AC units

operate from 90Vac to 264Vac 50/60 Herts, 1Amp

HIGH VOLTAGE CONNECTION

Insure that high voltage connection is properly terminated

to the load. Co nfirm that adequate air isolatio ns spacings

exist for the maximum voltage of the power supply, using

the guideline of 10kV per inch (25.4mm) to any points

that will be elevated to high voltage. All acce ssible high

voltage points should be enclosed in a protective Faraday

enclosure. Any access panels on the safety enclosure

should be interlocked.

V6 Series MANUAL 5 118130-001 REV C

here.

GROUNDING

Proper grounding of the unit is essential for reliable

operation. Power Ground, Signal Ground and HV Ground

Return are connected internally.

The Power Ground connection (J1 Pin 13) carries the

+24Vdc current that powers the unit. Make this

connection adequate enough to handle 2 amps, minimum.

Additionally it is recommended that this connection be

used to tie the power supply to whatever potential is used

as the local “system ground”.

Signal grounds relating to programming and monitor

functions should be referenced to the V6’s Signal Ground

(J1 Pin 6).

A physical load return connection must be made from the

bottom of the load to the power supplies HV Ground stud

(chassis).

See Figure 2 for DC modules details.

See Figure 3 for AC modules details.

OPTIONS

See Section 5 of this manual for RS-232 Communication

Protocol. Custom X numbers units may also require

special test requirements; con sult the unit’s specification

control drawing for details.

SIGNAL CONNECTIONS

Connect the appropriate programming and monitoring

signals to the unit as detailed in the figures in this chapter.

INITIAL TURN ON

A) Set t he voltage and current p rogramming inputs

for zero output (J1-4 and J1-9 respectively).

Open t he Enable Input (J1-8), to a ssure the unit

is in HV OFF mode.

B) The DC or AC input power can now be

connected.

C) Enable the power supply by grounding the

Enable Input (J1-8).

Page 13

D) Set the cur rent programming level (J1-9) to just

above the current anticipated that will be drawn

from the power supply.

E) Slo wly increase the voltage p rogramming (J1-4)

while monitoring the voltage and current

monitors (J1-10 and J1-11 respectively).

Carefully note proper equipment operation and

that the load is behaving as predicted.

F) To turn the H V OFF , open th e Enable Input ( J1-

8). If the equipment is to be left off for an

extended period of time or service of the unit or

load is required, turn off the input power.

WARNING!

After turn

been connected to the output of the power

supply. Wait a minimum of 5 minutes, and then

discharge any remaining stored energy by

connecting the high voltage output to ground.

Failure to follow these safety warnings can result

off, do not touch anything that has

in injury or death.

3.2 S t a nda rd Features

Programming and monitoring of the V6 Series is

accomplished via the use of conventional positive

polarity, gro und referenced signals. All signa l inputs and

outputs are noise filtered, impedance protected and diode

clamped providing an easy to use, robust analog customer

interface. Excellent results have been obtained via the use

of standard engineering design guidelines like twisted

pair, shielded cables, the prudent dressing of interface

wiring away from possible noise sources, short cable runs

and adhering to a well thought out and executed

grounding topology.

REMOTE PROGRAMMING

The V6’s programming and monitor signals are based

upon a universal, positive polarity, ground referenced

signal such that 0 to 5Vdc corresponds to 0 to 100% rated

output.

Programming can be accomplished via the use of an

applicable customer provided ground referenced voltage

source that meets the mentioned requirements. See Figure

4 for details.

If such a source is not available a precision +5Vdc

reference is provided on J1-7. A simple adjustable voltage

divider can be created using this reference and an external

potentiometer(s) which will provide full control of the

voltage and current loops.

See Figure 5 for details.

LOCAL PROGRAMMING

Local programming can be accomplished via the use the

multi turn potentiometer on the top of the unit.

Continuous multi-turn precision potentiometers directly

dial the output voltage . T he re so lutio n o f the pot is 0.05%

of maximum. The potentiometers are screwdriver

adjustable and easily accessed. For local voltage control

the following pins must be shorted: J1-1 to J1-5, J1-7 to

J1-9. See Figure 6 for details.

REMOTE MONITORING

The voltage and current monitor signals have adequate

bandwidth capability to accurately represent the actual

respective output within t he dynamic limits o f the power

supply. See Figure 7 for details.

ENABLE INPUT

The enable input signal provides simple control of the

ON/OFF functionality of the high voltage output. See

Figure 8 for deta ils.

WARNING!

It is extremely dangerous to use this cir cuit to

inhibit high voltage generation for the purpose of

servicing or approaching any area considered

unsafe during normal usage.

V6 Series MANUAL 6 118130-001 REV C

Page 14

V6D Unit

High Voltage Connection

Load Return Connection

System Ground

Customer

Load

HV

Out

GND

Stud

J1-13

Power Ground Return

Power Input

J1-15

J1-6

Signal Ground

V6A Unit

High Voltage Connection

Load Return Connection

System Ground

Customer

Load

HV

Out

GND

Stud

J2-L

J2-G

J2-N

Line

Ground

J1-6

Signal Ground

Neutral

AC Input

Power

V6 Unit

High Voltage Connection

Load Return Connection

System Ground

Customer

Load

HV

Out

GND

Stud

J1-9

I Program

V Program

J1-6

Signal Ground

DC

+

DC

+

-

J1-4

V6 Unit

High Voltage Connection

Load Return Connection

System Ground

Customer

Load

HV

Out

GND

Stud

J1-7

+5V REF

I Pgm

J1-9

J1-6

Signal Ground

J1-4

V Pgm

I Pgm

10KΩ

10KΩ

Figure 2

Grounding DC Unit

Figure 3

Grounding AC Unit

Figure 4

Remote Programming with a Remote Voltage Source

Vprg / Iprg: 0 to 5Vdc = 0 to 100% Rated Output

If one pot is not used connect the other programing input directly to +5V Reference J1-7

V6 Series MANUAL 7 118130-001 REV C

Figure 5

Programming using the +5V Reference

Page 15

Figure 6

V6 Unit

High Voltage Connection

Load Return Connection

System Ground

Customer

Load

HV

Out

GND

Stud

J1-1

Local Voltage Program

Voltage Program Input

J1-4

J1-9

Current Program Input

J1-7

+5V Reference Out

V6 Unit

High Volt age Con nection

Load Return Connection

Sy s te m Gro un d

Cust o mer

Load

HV

Out

GND

St ud

J1-10

Imon

Vm on

J1-6

Signal Ground

Meter

J1-11

Meter

V6 Unit

High Voltage Connection

Load Return Connection

System Ground

Customer

Load

HV

Out

GND

Stud

J1-8

Enable Input

J1-6

Signal Ground

HV OFF – High (>3Vdc)

or switch open

HV ON – Low (<1.5Vdc)

or switch closed

Local Programming using the internal multi turns potentiometer

Figure 7

Remote Voltage and Current Monitoring

Vmon / Imon: 0 to 5Vdc = 0 to 100% Rated Output

Figure 8

Enable Input

V6 Series MANUAL 8 118130-001 REV C

Page 16

Chapter 4

Principles of Ope ration

Warning!

The energy levels used and generated by the

power supply can be lethal! Do not attempt to

operate the power supply unless the user has

sufficient knowledge of the dangers and hazards

of working with high voltage. Do not attempt to

approach or touch any circuits that are

connected to or have been connected to the

power supply. Be certain to discharge any stored

energy that may be present before and after the

power supply is used. Consult IEEE

recommended practices for safety in high

voltage testing document number 510-1983.

4.1 DC/AC Input

The V6 Series is a DC to DC converter. Within the power

supply conve rsions fro m low voltage DC, to low voltage

AC, to high voltage AC and finally to high voltage DC

takes place. The DC input +24Vdc powers the power

conversion circuitry that creates the high voltage output

along with the low voltage DC housekeeping vo l tages that

provide power to the affiliated support control circuitry.

The AC units use an off the shelf universal input 24V

switching power supply.

4.2 Inverter

The DC input voltage is fed to the Inverter circuitry. Here

the low voltage DC is converted to a low voltage, high

frequency AC signal. T his power conversion step allows

for all subs equent power processing to take advanta ge of

component miniaturization due to the high operational

frequency. T he Inverte r functi onality is c ontrolled via the

power supply’s regulating loops which allows for

complete command of the desired output voltage and

current.

4.3 High Voltage Transformer

The high voltage transformer is a ferrite core step up type

in which the primary is driven from the output of the

Inverter circuit. The secondary of the high voltage

transformer feeds the High Voltage Output Section.

4.4 High Voltage Output Section

The High Voltage O utput Section utilizes an arrangement

of half wave Cockcroft-Walton voltage multiplier stages

to obtain the necessary output voltage.

The actual output voltage is sampled via a high

impedance divider to create a voltage feedback signal. A

current feedback signal is created via a current sense

resistor in t he low end return of the Hig h Voltage O utput

Circuitry. These two accurate ground referenced feedback

signals are used to precisely regulate and control the unit,

in addition to providing external monitoring.

4.5 Cont rol Circuitry

Various SMT based control circuitry is used for all

interfacing, monitoring and re gulation functionalit y of the

V6 modular power supply.

The voltage and current feedback signals generated in the

High Voltage Output Section are compared to the

requested voltage and current commands from the remote

interface. The voltage or current loop error amplifier

creates the appropriate error signal which is then provided

to the Pulse Width Modulation (P WM) circuitry.

The output of the PWM circuitry drives the Inverter

circuit to provide the required output in a continuous

closed loop control process, regulating in either voltage

mode or current mode as required.

V6 Series MANUAL 9 118130-001 REV C

Page 17

The internally generated voltage and current feedback

signals are processed and provided to the remote interface

for monitoring purposes.

The Enable Input from the remote interface controls the

HV ON and HV OFF status of the power supply by

interfacing with the PWM circuitry.

A precision +5Vdc, ±0.5%, 25ppm/°C micro power band

gap reference output is provided for user programming

convenience .

Figure 9 - Block Diagram

V6 Series MANUAL 10 118130-001 REV C

Page 18

Chapter 5

PIN

SIGNAL PARAMETERS

1

Not Used

2

RS232 Receive Data

3

RS232 Transmit Data

4

Not Used

5

RS232 Ground

6

Ground

7

Not Used

8

Not Used

9

Not Used

10

0 to 5V=0 to 100% Rated Output, Zout=10kΩ (Analog)

11

0 to 5V=0 to 100% Rated Output, Zout=10kΩ (Analog)

12

Not Used

13

Input Voltage Return used for DC

14

Input Voltage 24V ±10%, 2A used for DC

15

Input Voltage 24V ±10%, 2A used for DC

OPTION

5.1 RS-232 Interface

See attached document 118109-001

for Communication Protocol

RS-232 interface options, see table below

V6 AC/DC Analog/Digital Interface J1 15 pin D-connector Table

V6 Series MANUAL 11 118130-001 REV C

Page 19

Chapter 6

MAINTENANCE

WARNING!

This power supply generates voltages tha t

are dangerous and may be fatal.

Observe extreme caution when working with

high voltage.

6.1 Periodic Servicing

The V6 product family does not require any periodic

maintenance or servicing.

6.2 Per f ormance Testing

WARNING!

High Voltage is dangerous.

Only qualified personnel should perform

these tests.

It is highly recommended that all testing

comply with IEEE Standard 510-1983 IEEE

Recommended Practices for Safety in High

Voltage and High Power Testing. A copy of

this standard can be downloaded from the

Spellman High Voltage website

here.

Test equipment includes, but is not limited to: an

oscilloscope, a high impedance digital volt meter, a

current meter, a ripple checker, a high voltage load, a

high voltage d ivider (such as the Sp ellman H VD-100

or HVD-200) an insulated load stick and insulated

short circuit stick and a safety interlocked Faraday

test cage to safety conduct the tests inside of. All

equipment must be properly rated for the power

supply to be tested. If you do not possess the required

equipment and skills necessary to safety conduct

these tests do not attempt to perform these

performance tests.

6.3 High Voltage Dividers

High voltage dividers for precise measurements of

output voltage with accuracy up to 0.1% are available

from Spellman. The HVD-100 is used for voltages up

to 100KV, the HVD-200 measures up to 200KV.

The HVD Series of high voltage dividers are

designed for use with differential volt meters or high

impedance digital voltmeters. The high input

impedance of the HVD Series is ideal for measuring

high voltage low current sources, which would be

overloaded by traditional lower impedance dividers.

Generalized high voltage test procedures are

described in Bulletin STP-783, Standard Test

Procedures for High Voltage Power Supplies.

A copy of this bulletin can be downloaded from the

Spellman High Voltage website here

V6 Series MANUAL 12 118130-001 REV C

The HVD Series data sheet can be downloaded from

the Spellman High Voltage website here

Spellman Sales Department for information on price

and availability.

.

HVD Dividers

. Contact the

Page 20

Chapter 7

FACTORY SERVICE

7.1 Warranty Repairs

During the Warranty period, Spell man will repair all units

free of charge. The Warranty is void if the unit is worked

on by anyone other than Spellman personnel. See the

Warranty in the rear of this manual for more information.

Follow the return procedures described in Section 7.2.

The customer shall pay for shipping to and from

Spellman.

7.2 Factory Service Procedures

Spellman has a well-equipped factory repair department.

If a unit is returned to the factory for calibration or repair,

a detailed description of the specific problem should be

attached.

For all units returned for repair, please obtain an

authorization to ship from the Customer Service

Department, either by phone or mail prior to shipping.

When you call, please state the model and serial numbers,

which are on the plate on the rear of the power supply,

and the purchase order number for the repair. A Return

Material Authorization Code Number (RMA Number) is

needed for all returns. This RMA Number should be

marked clearly on the outside of the shipping container.

Packages received without an RMA Number will be

returned to the customer. The Customer shall pay for

shipping to and from Spellman.

7.3 Shipping Instructions

All power supplies returned to Spellman must be sent

shipping prepaid. Pack the units carefully and securely in

a suitable container, preferably in the original container, if

available. The power supply should be surrounded by at

least four inches of shock absorbing material. Please

return all associated materials, i.e. high voltage output

cables, interconnection cables, etc., so that we can

examine and test the entire system.

All correspondence and phone calls should be directed to:

Spellman High Voltage Electronics Corp.

One Commerce Park

Valhalla, New York 10595

TEL: (914) 686-3600

FAX: (914) 686-5424

E-Mail: sales@Spellmanhv.com

A preliminary estimate for repairs will be given by phone

by Customer Service. A purchase order for this amount is

requested upon issuance of the RMA Number. A more

detailed estimate will be made when the power supply is

received at the Spellman Repai r Center. In the eve nt that

repair work is extensive, Spellman will call to seek

additional authorization from your company before

completing the repairs.

V6 Series MANUAL 13 118130-001 REV C

Page 21

To obtain information on Spellman’s product warranty please visit our website at:

http://www.spellmanhv.com/en/About/Warranty.aspx

Page 22

V6 Series Power Supply Communication

Protocol

Serial – RS-232

Copyright 2011, Spellman High Voltage Electronics Corporation. All Rights Reserved.

This information contained in this publication is derived in part from proprietary and patent data. This information has

been prepared for the express purpose of assisting operating and maintenance personnel in the efficient use of the

model described herein, and publication of this information does not convey any right to reproduce it or to use it for

any purpose other than in connection with installation, operation, and maintenance of the equipment described.

DOC. 118109-001 REV B

475 Wireless Boulevard • Hauppauge, New York 11788, USA • www.spellmanhv.com • T:+1 631.630.3000 • F:+1 631.435.1620

Page 23

Table Of Contents

1.0 SCOPE ............................................................................................................................... 3

2.0 FUNCTIONAL DESCRIPTION ..................................................................................... 3

3.0 GETTING STARTED – HARDWARE SETUP ............................................................ 3

3.1 RS232 INTERFACE ...................................................................................................... 3

3.2 RS-232 CABLING ......................................................................................................... 3

4.0 GETTING STARTED – SOFTWARE ........................................................................... 4

4.1 RS-232 ............................................................................................................................ 4

5.0- SERIAL INTERFACE PROTOCOL ............................................................................. 4

5.1 COMMAND ARGUMENTS ......................................................................................... 5

5.2 CHECKSUMS ................................................................................................................ 5

5.3 COMMAND OVERVIEW ............................................................................................ 8

5.4 RESPONSE OVERVIEW .............................................................................................. 8

5.5 COMMAND STRUCTURE .......................................................................................... 9

5.5.1 Program KV ................................................................................................................... 9

5.5.2 Program Output Current ............................................................................................... 10

5.5.3 Request ADC Data ....................................................................................................... 11

5.5.4 Request Status .............................................................................................................. 12

5.5.5 Request Software Version ........................................................................................... 13

5.5.6 Request Hardware Version ........................................................................................... 14

5.5.7 Request Model Number ................................................................................................ 15

5.5.8 Set H.V. OffOn ............................................................................................................. 16

Standard V6 Series Communication Protocol 2 118109-001 REV B

Page 24

1.0 SCOPE

This document applies to the communication interface on the V6 Series Power

Supply.

2.0 FUNCTIONAL DESCRIPTION

The V6 Series power supply provides a serial communications interface:

RS-232 on J1 I/O Connector

.

Data acquisition and control capabilities are provided by:

14 channels of 12-bit analog-to-digital converters

2 additional analog channels that monitor the house-keeping power supply

and ambient temperature

5 digital output bits

8 digital inputs bits

3 relays/interlocks

3.0 GETTING STARTED – HARDWARE SETUP

The digital hardware includes a 40MIPS digital signal processor

processor/controller

3.1 RS232 INTERFACE

The RS232C interface has the following attributes:

115.2K bits per second

No Parity

8 Data Bits

1 Stop Bit

No handshaking

3.2 RS-232 CABLING

An RS-232 cable where one end is a DB9 connector and the other end is

a DB15 male connector. Line 2 is connected straight through to pin 2 and

3 line is conncected straight through to line 3. Please refer to the following

chart.

Standard V6 Series Communication Protocol 3 118109-001 REV B

Page 25

PC Connector (DB-9 Female)

PC to SIC Board Cable Details

Pin 2: RX In Pin 2: RX Out

Pin 3: TX Out Pin 3: TX In

Pin 5: Ground Pin 5: Ground

4.0 GETTING STARTED – SOFTWARE

The following sections detail how to create software to interface to the V6 Series

communications interfaces.

4.1 RS-232

The RS-232 interface makes use of a standard ‘command/response’

communications protocol. See section 6.0 for the syntax of the serial

interface protocol.

All software that addresses the RS-232 interface must adhere to the

following parameters:

115K.2 bits per second

No Parity

8 Data Bits

1 Stop Bit

No handshaking

5.0- SERIAL INTERFACE PROTOCOL

J1 Connector (DB-15

Female)

Serial communications will use the following protocol:

<STX><CMD><,>ARG><,><CSUM><ETX>

Where:

<STX> = 1 ASCII 0x02 Start of Text character

<CMD> = 2 ASCII characters representing the command ID

<,> = 1 ASCII 0x2C character

Standard V6 Series Communication Protocol 4 118109-001 REV B

Page 26

<ARG> = Command Argument

<,> = 1 ASCII 0x2C character

<CSUM> = Checksum (see section 5.2 for details)

<ETX> = 1 ASCII 0x03 End of Text character

5.1 COMMAND ARGUMENTS

The format of the numbers is a variable length string. To represent the number

42, the string ‘42’, ‘042’, or ‘0042’ can be used. This being the case, commands

and responses that carry data are variable in length.

5.2 CHECKSUMS

The checksum is computed as follows:

Add the <CMD>, <,>, and <ARG>, and <,> bytes into a 16 bit (or larger)

word. The bytes are added as unsigned integers.

Take the 2’s compliment (negate it).

Truncate the result down to the eight least significant bits.

Clear the most significant bit (bit 7) of the resultant byte, (bitwise AND with

0x7F).

Set the next most significant bit (bit 6) of the resultant byte (bitwise OR

with 0x40).

Using this method, the checksum is always a number between 0x40 and 0x7F.

The checksum can never be confused with the <STX> or <ETX> control

characters, since these have non-overlapping ASCII values.

If the DSP detects a checksum error, the received message is ignored – no

acknowledge or data is sent back to the host. A timeout will act as an implied

NACK.

Standard V6 Series Communication Protocol 5 118109-001 REV B

Page 27

The following is sample code, written in Visual Basic, for the generation of

checksums:

Public Function ProcessOutputString(outputString As String) As String

Dim i As Integer

Dim CSb1 As Integer

Dim CSb2 As Integer

Dim CSb3 As Integer

Dim CSb$

Dim X

X = 0

For i = 1 To (Len(outputString)) 'Starting with the CMD character

X = X + Asc(Mid(outputString, i, 1)) 'adds ascii values together

Next i

CSb1 = 256 - X 'Twos Complement

CSb2 = 63 And (CSb1)

CSb3 = 64 Or (CSb2) 'OR 0x40

CSb$ = Chr(Val("&H" & (Hex(CSb3))))

ProcessOutputString = Chr(2) & outputString & CSb$ & Chr(3)

End Function

Here is an example of an actual Checksum calculation for command 10

(Program kV setpoint)

The original message with a placeholder for the checksum is

<STX>10,4095,<CSUM><ETX>

First, you add up all the characters starting with the ‘1’ in the command

number, to the comma before the checksum with their ASCII values (in

hexadecimal):

0x31 + 0x30 + 0x2C + 0x34 + 0x30 + 0x39 + 0x35 + 0x2C = 0x18B

Next, you then take the two’s complement of that number by negating it,

by subtracting it from 0x100 (decimal 256), and only retain the lowest 7

bits by bitwise ANDing the results with 0x7F. :

NOTE: This combines the steps of getting the twos complement,

truncating the result to 8 bits and clearing the 8th bit.

Standard V6 Series Communication Protocol 6 118109-001 REV B

Page 28

(0x100 – 0x18B) & 0x7F = 0x75

Finally, bitwise OR the result with 0x40:

0x75 | 0x40 = 0x75

The checksum byte is 0x75 (Decimal 117, ASCII: u)

Here is another example, this time for command 22 (Request Status) which has

no arguments.

The original message with a placeholder for checksum is:

<STX>22,<CSUM><ETX>

First, you add up all the characters starting with the ‘2’ in the command

number to the comma before the checksum with their ASCII values (in

hexadecimal):

0x32 + 0x32 + 0x2C = 0x90

Next, you then take the two’s complement of that number by negating it,

by subtracting it from 0x100 (decimal 256), and only retain the lowest 7

bits by bitwise ANDing the results with 0x7F:

NOTE: This combines the steps of getting the twos complement,

truncating the result to 8 bits and clearing the 8th bit.

(0x100 – 0x90) & 0x7F = 0x70

Finally, bitwise OR the result with 0x40:

0x70 | 0x40 = 0x70

The checksum byte is 0x70 (Decimal 112, ASCII: p)

Standard V6 Series Communication Protocol 7 118109-001 REV B

Page 29

5.3 COMMAND OVERVIEW

Command Name <CMD> <ARG> RANGE

Program KV (DAC

10 1-4 ASCII 0-4095

A)

Program Output

11 1-4 ASCII 0-4095

Current (DAC B)

Request ADC Data 20 None Request Status 22 None Request Software

23 None Version

Request Hardware

24 None Version

Request Model

26 None Number

Set H.V. OnOff 99 1 or 0 -

5.4 RESPONSE OVERVIEW

The command responses will follow the same format as outlined above in

section 5.3. This list is comprised of Commands with complex responses

only. Commands using a simple response will use the <$> character

(ASCII 0x24) as a “Success” response or a single character error code.

These responses will be eight ASCII characters in length.

Response Name <CMD> Response

Request Analog

Readbacks – KV &

20 20-41

ASCII

MA

Request Status 22 12 ASCII

Request DSP

23 18 ASCII

Software Version

Request Hardware

24 10 ASCII

Version

Request Model

26 12 ASCII

number

Standard V6 Series Communication Protocol 8 118109-001 REV B

Page 30

5.5 COMMAND STRUCTURE

5.5.1 Program KV

Description:

The host requests that the firmware change the setpoint of DAC

Channel A.

Direction:

Host to supply

Syntax:

<STX><10><,><ARG><,><CSUM><ETX>

Where:

<ARG> = 0 - 4095 in ASCII format

Example:

<STX>10,4095,<CSUM><ETX>

Detailed Example:

02 31 30 2C 34 30 39 35 2C 75 03

Response:

<STX><10><,><$><,><CSUM><ETX>

Standard V6 Series Communication Protocol 9 118109-001 REV B

Page 31

5.5.2 Program Output Current

Description:

The host requests that the firmware change the setpoint of DAC Channel

B.

Direction:

Host to supply

Syntax:

<STX><11><,><ARG><,><CSUM><ETX>

Where:

<ARG> = 0 - 4095 in ASCII format

Example:

<STX>11,4095,<CSUM><ETX>

Response:

<STX><11><,><$><,><CSUM><ETX>

Standard V6 Series Communication Protocol 10 118109-001 REV B

Page 32

5.5.3 Request ADC Data

Description:

The host requests that the firmware report the current ADC Channel KV

monitor, and Channel MA monitor.

Direction:

Host to supply

Syntax:

<STX><20><,><CSUM><ETX>

Response:

<STX><20><,><ARG1><,><ARG2><,><CSUM><ETX>

Where:

<ARG1> KV: 0 - 4095 in ASCII format

<ARG2> MA: 0 - 4095 in ASCII format

Example:

<STX>20,4095,4095,<CSUM><ETX>

Standard V6 Series Communication Protocol 11 118109-001 REV B

Page 33

5.5.4 Request Status

Description:

The host requests that the firmware report the current DAC Channel D

setpoint.

Direction:

Host to supply

Syntax:

<STX><22><,><CSUM><ETX>

Response:

<STX><22><,><ARG1><,><ARG2><,><ARG3><,><CSUM><ETX>

Where:

<ARG1> 1 = Over Voltage, 0 = Normal

<ARG2> 1 = Over Current, 0 = Normal

<ARG3> 1 = Enable, 0 = Disable

Example:

<STX>22,0,0,0,<CSUM><ETX>

Standard V6 Series Communication Protocol 12 118109-001 REV B

Page 34

5.5.5 Request Software Version

Description:

The host requests that the firmware sends the DSP firmware part

number/version.

Direction:

Host to supply

Syntax:

<STX><23><,><CSUM><ETX>

Example:

<STX>23,<CSUM><ETX>

Response:

<STX><23><,><ARG><,><CSUM><ETX>

Where:

<ARG> consists of eleven ASCII characters representing the current

firmware part number/version. The format is SWM9999-999

Example:

<STX>23,SWM9999-999,<CSUM><ETX>

Standard V6 Series Communication Protocol 13 118109-001 REV B

Page 35

5.5.6 Request Hardware Version

Description:

The host requests that the firmware sends the hardware version.

Direction:

Host to supply

Syntax:

<STX><24><,><CSUM><ETX>

Example:

<STX>24,<CSUM><ETX>

Response:

<STX><24><,>< ARG><,><CSUM><ETX>

Where:

<ARG> consists of 3 ASCII characters representing the hardware version.

The format is ANN, where A is an alpha character and N is a numeric

character

Example:

<STX>24,A01,<CSUM><ETX>

Standard V6 Series Communication Protocol 14 118109-001 REV B

Page 36

5.5.7 Request Model Number

Description:

The host requests that the firmware sends the unit model number

Direction:

Host to supply

Syntax:

<STX><26><,><CSUM><ETX>

Example:

<STX>26,<CSUM><ETX>

Response:

<STX><26><,><ARG><,><CSUM><ETX>

Where:

<ARG> consists of five ASCII characters representing the model number.

The format is XNNNN, where N is a numeric character.

Example:

<STX>26,X9999,<CSUM><ETX>

Standard V6 Series Communication Protocol 15 118109-001 REV B

Page 37

5.5.8 Set H.V. OffOn

Description:

The host requests that the firmware set H.V. Off or On

Direction:

Host to supply

Syntax:

<STX><99><,><ARG><,><CSUM><ETX>

Where:

<ARG> = 0 = HV Off, 1 = HV On.

Example:

<STX>10,1,<CSUM><ETX>

Response:

<STX><10><,><$><,><CSUM><ETX>

Standard V6 Series Communication Protocol 16 118109-001 REV B

Loading...

Loading...