Page 1

R

PMX

Instruction Manual

MODEL :

SERIAL# :

DATE :

SPELLMAN

HIGH VOLTAGE ELECTRONICS

CORPORATION

475 Wireless Blvd.

Hauppauge, New York, 11788

+1(631) 630-3000*FAX: +1(631) 435-1620*

E-mail: sales@spellmanhv.com

Website: www.spellmanhv.com

High Voltage Power Supply

PMX MANUAL 118163-001 Rev A

Page 2

IMPORTANT SAFETY PRECAUTIONS

SAFETY

THIS POWER SUPPLY GENERATES VOLTAGES THAT ARE DANGEROUS AND MAY BE FATAL.

OBSERVE EXTREME CAUTION WHEN WORKING WITH THIS EQUIPMENT.

High voltage power supplies must always be grounded.

Do not touch connections unless the equipment is off and the

Capacitance of both the load and power supply is discharged.

Allow five minutes for discharge of internal capacitance of the power supply.

Do not ground yourself or work under wet or damp conditions.

SERVICING SAFETY

.

Maintenance may require removing the instrument cover with the power on.

Servicing should be done by qualified personnel aware of the electrical hazards.

WARNING note in the text call attention to hazards in operation of these units

that could lead to possible injury or death.

CAUTION notes in the text indicate procedures to be followed to avoid possible

damage to equipment.

Copyright © 2000, Spellman High Voltage Electronics Corporation. All Rights Reserved.

This information contained in this publication is derived in part from proprietary and patent data. This information has

been prepared for the express purpose of assisting operating and maintenance personnel in the efficient use of the

model described herein, and publication of this information does not convey any right to reproduce it or to use it for

any purpose other than in connection with installation, operation, and maintenance of the equipment described.

118004-001 REV. B

Page 3

WICHTIGE SICHERHEITSHINWEISE

SICHERHEIT

DIESES HOCHSPANNUNGSNETZTEIL ERZEUGT LEBENSGEFÄHRLICHE HOCHSPANNUNG.

SEIN SIE SEHR VORSICHTIG BEI DER ARBEIT MIT DIESEM GERÄT.

Das Hochspannungsnetzteil muß immer geerdet sein.

Berühren Sie die Stecker des Netzteiles nur, wenn das Gerät ausgeschaltet ist und die elektrischen

Kapazitäten des Netzteiles und der angeschlossenen Last entladen sind.

Die internen Kapazitäten des Hochspannungsnetzteiles benötigen ca. 5 Minuten, um sich zu entladen.

Erden Sie sich nicht, und arbeiten Sie nicht in feuchter oder nasser Umgebung.

SERVICESICHERHEIT

Notwendige Reparaturen können es erforderlich machen, den Gehäusedeckel während des Betriebes zu

entfernen.

Reparaturen dürfen nur von qualifiziertem, eingewiesenem Personal ausgeführt werden.

“WARNING” im folgenden Text weist auf gefährliche Operationen hin, die zu Verletzungen oder zum Tod

führen können.

“CAUTION” im folgenden Text weist auf Prozeduren hin, die genauestens befolgt werden müssen, um

eventuelle Beschädigungen des Gerätes zu vermeiden.

118004-001 REV. B

Page 4

PRECAUTIONS IMPORTANTES POUR VOTRE SECURITE

CONSIGNES DE SÉCURITÉ

CETTE ALIMENTATION GÉNÈRE DES TENSIONS QUI SONT DANGEUREUSES ET PEUVENT ÊTRE FATALES.

OYEZ EXTRÊMENT VIGILANTS LORSQUE VOUS UTILISEZ CET ÉQUIPEMENT.

S

Les alimentations haute tension doivent toujours être mises à la masse.

Ne touchez pas les connectiques sans que l’équipement soit éteint et que la capacité à la fois de la charge et de

l’alimentation soient déchargées.

Prévoyez 5 minutes pour la décharge de la capacité interne de l’alimentation.

Ne vous mettez pas à la masse, ou ne travaillez pas sous conditions mouillées ou humides.

CONSIGNES DE SÉCURITÉ EN CAS DE REPARATION

La maintenance peut nécessiter l’enlèvement du couvercle lorsque l’alimentation est encore allumée.

Les réparations doivent être effectuées par une personne qualifiée et connaissant les risques électriques.

Dans le manuel, les notes marquées « WARNING » attire l’attention sur les risques lors de la manipulation de ces

équipements, qui peuvent entrainer de possibles blessures voire la mort.

Dans le manuel, les notes marquées « CAUTION » indiquent les procédures qui doivent être suivies afin d’éviter

d’éventuels dommages sur l’équipement.

118004-001 REV. B

Page 5

IMPORTANTI PRECAUZIONI DI SICUREZZA

SICUREZZA

QUESTO ALIMENTATORE GENERA TENSIONI CHE SONO PERICOLOSE E

POTREBBERO ESSERE MORTALI.

PONI ESTREMA CAUTELA QUANDO OPERI CON QUESO APPARECCHIO.

Gli alimentatori ad alta tensione devono sempre essere collegati ad un impianto di terra.

Non toccare le connessioni a meno che l’apparecchio sia stato spento e la capacità interna

del carico e dell’alimentatore stesso siano scariche.

Attendere cinque minuti per permettere la scarica della capacità interna dell’alimentatore

ad alta tensione.

Non mettere a terra il proprio corpo oppure operare in ambienti bagnati o saturi d’umidità.

SICUREZZA NELLA MANUTENZIONE.

Manutenzione potrebbe essere richiesta, rimuovendo la copertura con apparecchio

acceso.

La manutenzione deve essere svolta da personale qualificato, coscio dei rischi elettrici.

Attenzione alle AVVERTENZE contenute nel manuale, che richiamano all’attenzione ai

rischi quando si opera con tali unità e che potrebbero causare possibili ferite o morte.

Le note di CAUTELA contenute nel manuale, indicano le procedure da seguire per evitare

possibili danni all’apparecchio.

118004-001 REV. B

Page 6

Contents

CHAPTER 1 INTRODUCTION ....................................................2

1.1 PMX DESCRIPTION...............................................2

1.1.1 Power Supply Requirements ................................3

1.1.2 Environment Requirements ..................................4

1.2 THEORY OF OPERATION ....................................4

1.2.1 Function Overview ...............................................4

1.2.2 Line Rectification and Filterin g ...........................4

1.2.3 Inverter .................................................................4

1.2.4 High Voltage Transformer ...................................4

1.2.5 High Voltage Assembly ........................................4

1.2.6 System Control PWB ............................................4

1.2.7 Filament Power Supply ........................................5

1.2.8 High Speed Starter ...............................................6

1.3 SAFETY ...................................................................7

1.3.1 Safety and Warning Symbols ................................7

CHAPTER 2 INSTALLATION .....................................................8

2.1 INTRODUCTION ....................................................8

2.2 UNPACKING ..........................................................8

2.3 OVERALL CONNECTIONS ............................................8

2.4 POWER LINE MAINS .......................................... 10

2.5 Cable connection illustration ............................. 10

2.5.1 HV Cable Connection ........................................ 10

2.5.2 Stator Cable Connection .................................... 11

2.5.3 Filament Driver Cable Connection .................... 11

2.6 MULTI INTERFACE CABLE CONNECTIONS .. 12

2.6.1 Pin Layout of the Multi interface ....................... 12

2.7 INTERLOCK CONNECTIONS ...................................... 14

2.8 TUBE CURRENT MONITOR CONNECTION................. 14

2.9 GROUND CONNECTION .................................... 14

2.9.1 X-Ray Tube Housing Ground ............................. 14

2.9.2 Chassis Ground .................................................. 15

2.10 FINAL CHECKS .................................................... 15

2.11 GUI SOFTWARE .................................................. 15

CHAPTER 3 ........................................................................... 17

INTERFACING ........................................................................ 17

3.2 MULTI INTERFACE............................................. 17

3.2.1 Connector Style and Pin Layout ........................ 17

3.2.2 Serial Communication Interface ........................ 18

3.2.3 Digital I/O Control Inte rface ............................. 19

3.2.4 Remote Status Interface ..................................... 20

3.2.5 Remote Monitoring Interface ............................. 22

3.3 ETHERNET INTE RFACE ............................................. 22

CHAPTER 4 CONFIGURATION, CAL IBRATION AND

OPERATION .......................................................................... 23

4.1 INTRODUCTION ........................................................ 23

4.2 TUBE PREHEAT TABLE CONFIGURATION .................. 23

4.3 FILAMENT AU TO -CALIBRATION ............................... 25

4.4 OPERATING X-RAY EXPOSURES ............................... 26

4.4.1 Normal Exposure ............................................... 26

4.4.2 AEC Exposure .................................................... 28

4.4.3 Smart AEC Exposure ......................................... 29

CHAPTER 5 ........................................................................... 32

TROUBLE SHOOTING ............................................................ 32

5.1 INTRODUCTION ................................................. 32

5.2 STATUS AND ERROR CODES ........................... 32

5.2.1 Status Messages ................................................. 32

5.2.2 Faults Messages ................................................ 33

CHAPTER 6 ....................................................................... 39

MAINTENANCE ............................................................... 39

6.1 INTRODUCTION ................................................. 39

6.2 PERFORMANCE TEST ............................................... 39

6.3 HIGH VOLTAGE D IVIDER S ........................................ 39

CHAPTER 7 ....................................................................... 40

REPLACEMENT PARTS .................................................. 40

CHAPTER 8 ....................................................................... 41

FACTORY SERVICE ........................................................ 41

PMX MANUAL 1 118164-001 REV. A

Page 7

CHAPTER 1

INTRODUCTION

1.1 PMX DESCRIPTION

Spellman’s PMX redefines the standard for high

performance Mam mography X-Ray generator s

including FFDM and DBT. It features 2 and 3

point exposure modes as well as smart AEC

with pre exposure.

The 50kV @ 5kW (peak) high voltage output

coupled with a dual focal spot, DC current

source filament power supply provides stable

and accurate X-Ray tube emission currents.

The solid encapsulated high voltage output

section eliminates oil concerns while reducing

effects of environmental humidity and

contamination.

PMX’s flexible interfacing and controlling

capabilities as well as powerful application

features represent a radically new advanced

approach to mammography X-Ray generators.

PMX MANUAL 2 118164-001 REV. A

Page 8

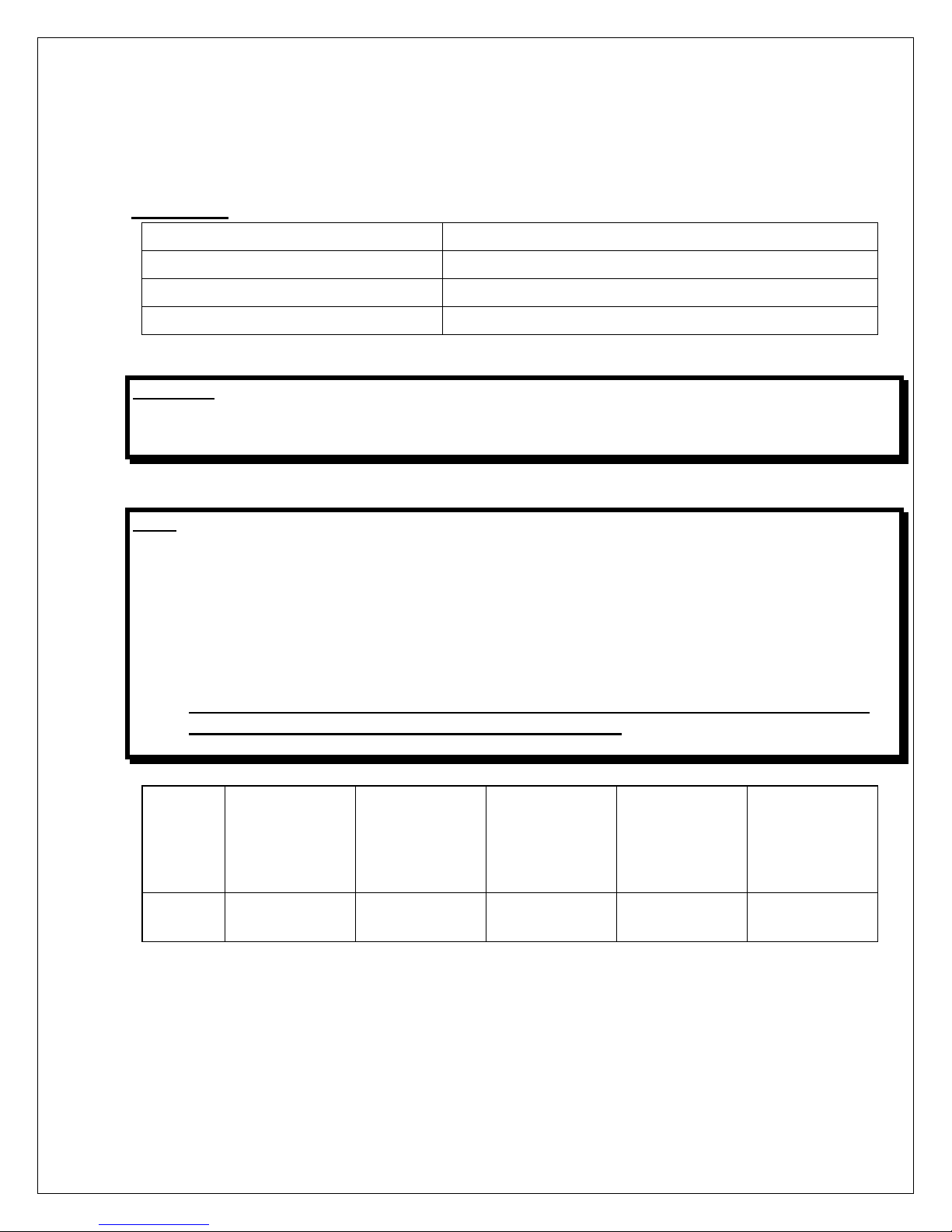

1.1.1 Power Supply Requirements

Single Phase

Line Voltage 200Vac-240Vac, +/-10%, 1 Phase, 35 Amps

Line Frequency 50/60 Hz.

In Rush Current 50 Amps, Maximum

Standby Current 1 Amp

WARNING: The PMX generator can provide power that can damage the X-Ray tube. The user is

responsible for limiting the maximum exposure values to within the ratings of the X-Ray

tube. Spellman is not liable for any damage to the X-Ray tube by the misuse of the PMX

X-Ray generator.

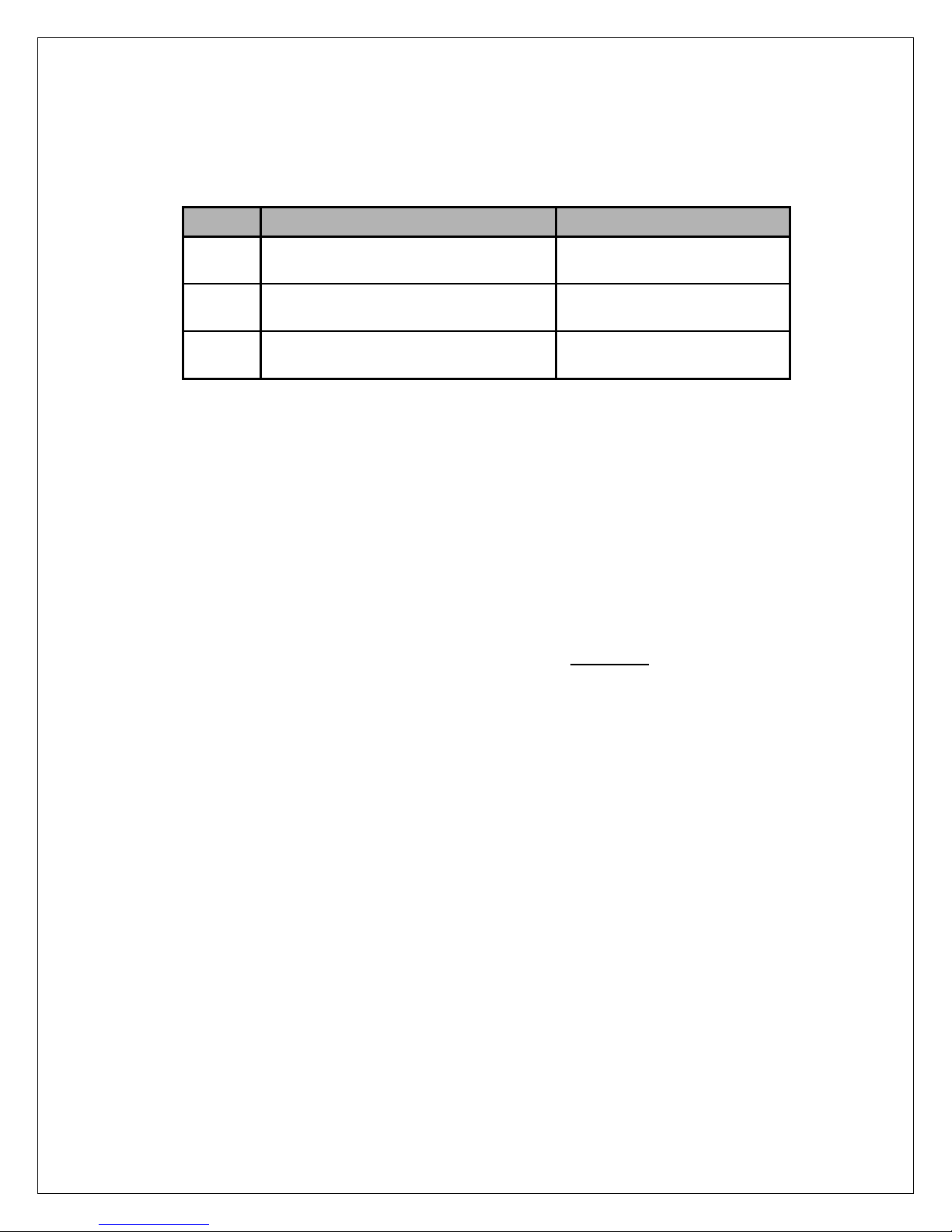

The following table defines the power line requirements for the generators.

NOTE: THE FOLLOWING TABLE CONTAINS RECOMMENDED VALUES FOR THE WIRE SIZES

BETWEEN THE MAINS DISCONNECT AND THE GENERATOR. THE ACTUAL VALUES USED AT

AN INSTALLATION ARE DEPENDENT ON THE QUALITY OF THE INPUT LINE (VOLTAGE

LEVEL) THE CURRENT REQUIREMENTS AND THE LENGTH OF THE CABLE RUN AND MUST

BE CONFIRMED BY THE INSTALLER.

ALL THE RATINGS LISTED CONSIDER THE GENERATOR REQUIREMENTS ONLY. THE

INSTALLER MUST MAKE THE NECESSARY COMPENSATION FOR ADDITIONAL LOAD

REQUIREMENTS

A POOR QUALITY INPUT LINE MAY RESULT IN THE INSTALLER HAVING TO

DERATE THE GENERATOR'S MAXIMUM POWER

Mains

Voltage

220 Vac

Minimum

Recommended

Mains

Disconnect

to Generator

15 ft./5 m max)

#10

2

(6 mm

)

• External EMC Filter (required to meet

CE/EMC specifications) – Not provided with

the generator. Custom er is responsible f or

providing the external filter as needed;

Schaffner FN2070-08-36A type EMI filter or

equivalent one recommended.

PMX MANUAL 3 118164-001 REV. A

Generator

In Rush Line

Current

50 A 35 A #10

Minimum

Recommended

Generator

Service Rating

• Mains Contactor - Not provided within the

generator. Customer is responsible for

mains safety disconnection.

Minimum

Recommended

Ground

Wire

Size

2

(6 mm

)

Apparent

Mains

Resistance

0.06 Ω

Page 9

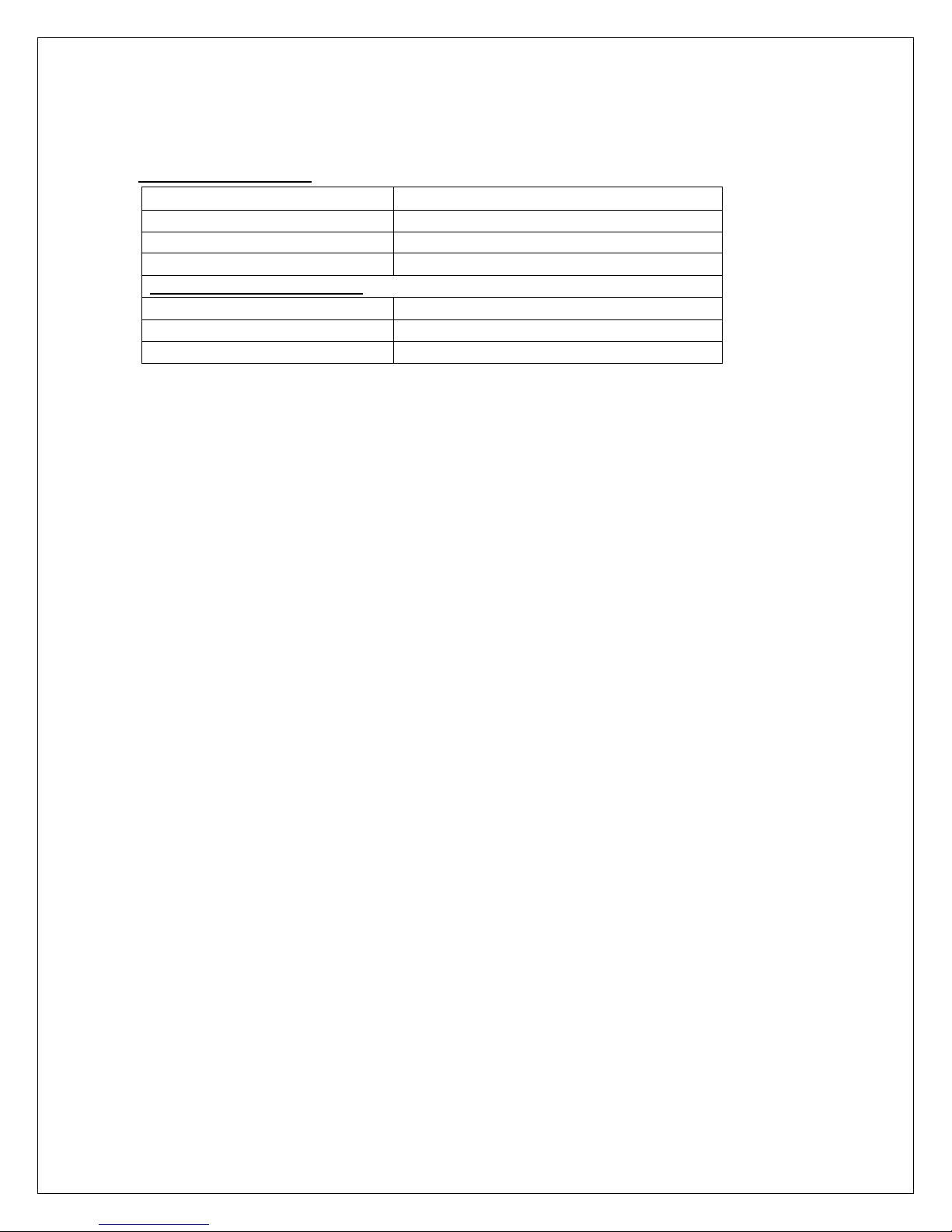

Operating Temperature

10 to 40 °C (50 to 104 °F).

Relative Humidity

20 to 85%, non-condensing.

Atmospheric pressure range

500 to 1060 hPa (375 to 795 mm Hg).

TRANSPORT AND STORAGE

Ambient temperature range

-40 to 85 °C (-40 to 185 °F).

Relative humidity

5 to 95%, non-condensing.

Atmospheric pressure range

500 to 1060 hPa (375 to 795 mm Hg).

1.1.2 Environment Requirements

Operating Environment

1.2 THEORY OF OPERATION

1.2.1 Function Overview

The PMX X-Ray generator utilizes sophisticated

power conversion technology. A variety of

analog, digital and switching pow er conversion

techniques are used throughout.

The PMX generator is basically an AC to DC

power converter. Within the generator,

conversions of AC to DC, then to high frequency

AC, then to high voltage DC take place. By

reviewing further the sub-assemblies, a basic

understanding of the process can be gained.

1.2.2 Line Rectification and Filtering

Basic AC line rectification provides the DC buss

voltage for the high voltage inverter, Anode

rotor drive, and the filament supply.

The input line voltage can vary from 180V up to

264V within the series.

The line voltage is connected directly to the EMI

filter. The EMI filter reduces conducted HF noise

on the AC mains. The output of the EMI f ilter is

connected to an off line auxiliary power inverter

circuit that provides 2 4V power for gener ating

other auxiliary supply DC voltages.

1.2.3 Inverter

The inverter is a “half -bridg e” topolog y. Cur rent

mode control is used for driving the inverter. An

IGBT power module employed. The IGBT

provides high frequency switching to control the

primary current flow to the high voltage

transformer.

Circuits on the Power PCB board provide the

gate control of the IGBT switches. The system

control board generates gate drive control

signals. The circuits on t he Po wer PC B pro vi de

the required gate voltages and off s ets .

1.2.4 High Voltage Transformer

The output of the High Frequency Quasiresonant Inverter is connected to the primary of

the High Voltage Transformer. The High

Voltage Transform er is a step up type. T ypical

secondary output voltage is in the range of

12.5kV depending upon output voltage ratings.

1.2.5 High Voltage Assembly

The High Voltage Assembly will vary depending

upon the model ord ered. The circu itry typically

consists of an arrangement of half wave voltage

doubler.

A high bandwidth resistive/capacitive divider

provides voltage feedback for regulation and

monitoring. A sense resistor connected at the

low voltage end of the High Voltage Multiplier

circuit pro vides current feedback for regulation

and monitoring.

1.2.6 System Control PWB

Auxiliary DC voltages are generated in the low

voltage power supply section of the System

Control PWB.

PMX MANUAL 4 118164-001 REV. A

Page 10

LEDs provide status diagnostics needed for

recognizing the operation/shutdown mode of

the generator.

A precision +10Vdc reference is generated on

the control PCB for programming kV, mA and

other references.

Control of the generator utilizes sophisticated

analog and digital circuitr y resulting in fast and

accurate control, protection and communication

interfacing.

This generator is based on advanced quasiresonant PWM control. Analog signals are

digitized in A/D conver ter and pr ocess ed with in

FPGA and DSP circuits to provide maximum

accuracy and reliability.

All feedback signals are sent to the user

interface through digital an d D/A circ uits where

switching is possible between feedback and

program signals. This allows the us er to pres et

the desired output before energizing high

voltage.

All program voltages ar e typically ramped up to

set level by the digital ramp generator.

FPGA and accompanying A-D and D-A

converters and drivers provide system Fault

Control Indicat ion. User interface is proces sed

on this PWB as well, providing isolated relay

coils, opto couplers and open collector contacts.

1.2.7 Filament Power Supply

The filament inverter provides the power to drive

the filament winding of the X-Ray tube. The

filament inverter is a high frequency, series

resonant inverter. The inverter provides high

frequency ac current to the primary of the

filament isolation transformer. The filament

isolation transformer secondary is connected to

a full wave rectifier and capacitor f ilter creating

a DC filament. Rela y K4 connects the f ilament

output to TB3 terminals 1 or 3 for small or large

filament respectively as required by the

operator. The filam ent circuitry also provides a

variety of control, diagnostic and protection

functions.

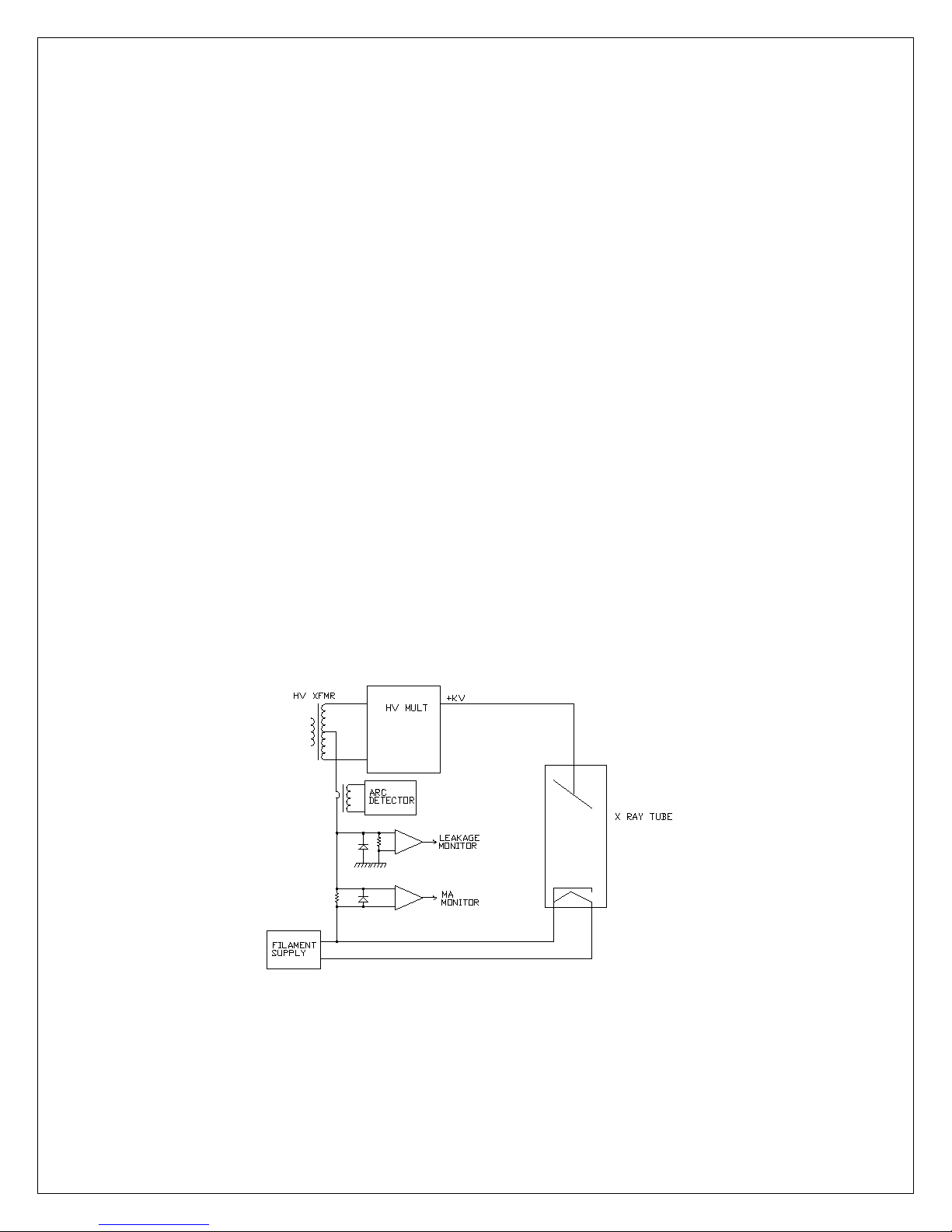

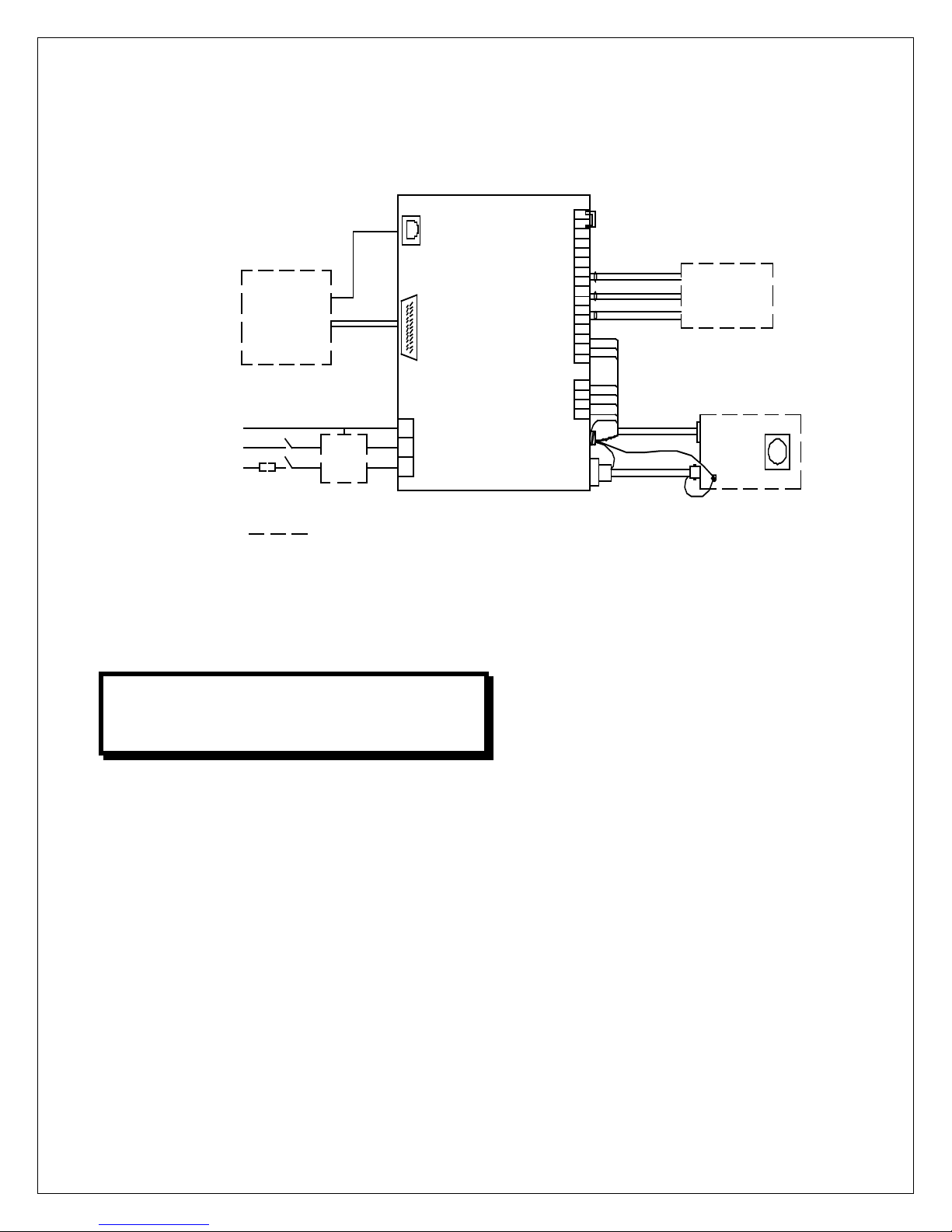

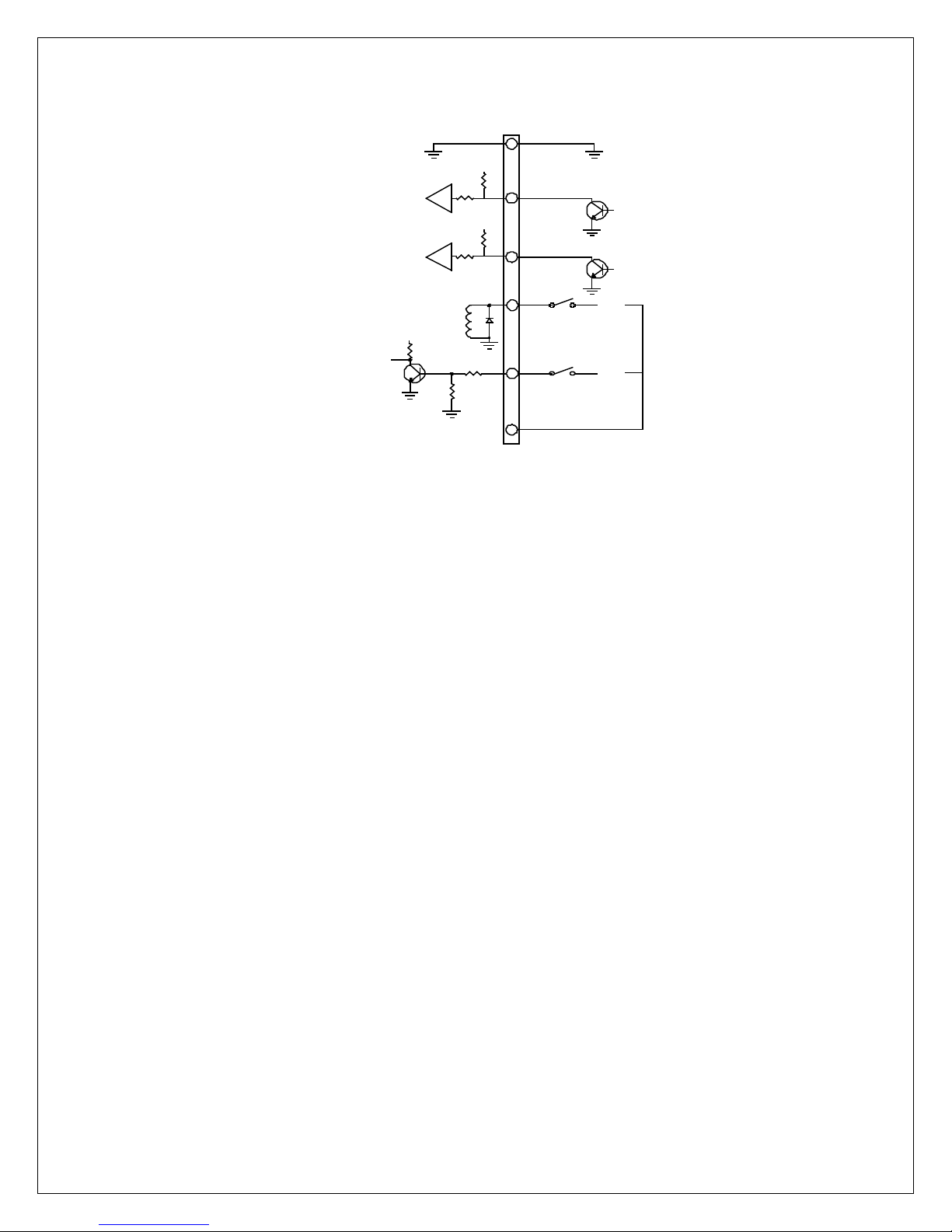

See Figure 1.2 for a simplified diagram of the XRay tube connection and current sensing

circuits. The filament circuitry also provides a

variety of control, diagnostic and protection

functions.

If any abnormal c ondition appears, monitoring

circuitry will shut down the unit indicating the

fault.

Figure 1.2 Simplified schematic of X-Ray tube connection

PMX 5 118164-001 REV. A

Page 11

1.2.8 High Speed Starter

The rotating anode is powered and controlled

by the action of a split-phase t ype of induction

motor circuits in the PMX generator. The

rotating anode has considerable mass to

dissipate the heat generated by the beam

current, and subse quently requires some tim e

to accelerate to its norm al operat ing sp eed. T o

reduce this time, the “h igh s peed s tart er ” cir cuit

in the PMX applies a series of “boost” steps

consisting of different frequencies and

increased voltage during the boost cycle to

increase the accelerati on of the anode rotat ion

to operating speed within several seconds.

Following the boost cycle, the applied voltage is

reduced to proper vo ltage to maintain ro tation.

There are two operati ng modes for the anode

rotor: low speed (60Hz stator voltage), and high

speed (180Hz stator voltage). These are

selected by the operator depending on the

requirements of the application.

The PMX is equipped with safety interlock s for

user personnel and equipment protection. An

open interlock circuit inhibits operation of the

PMX generator.

PMX MANUAL 6 118164-001 REV. A

Page 12

High voltage symbol use d to indic ate the pres ence of

Warning symbol used to indicate a potential hazard to

1.3 SAFETY

1.3.1 Safety and Warning Symbols

WARNING: THIS X-Ray UNIT MAY BE DANGEROUS TO OPERATOR UNLESS SAFE EXPOSURE

FACTORS AND OPERATING INSTRUCTIONS ARE OBSERVED.

The following advisory symbols are used on the safety warning labels, and/or on circuit boards.

high voltage.

operators, service personnel or to the equipment.

PMX MANUAL 7 118164-001 REV. A

Page 13

CHAPTER 2

INSTALLATION

2.1 INTRODUCTION

This chapter contains instructions for

unpacking, positionin g, and cabl ing the PMX

generator, allowing for initial power-up and

exposures.

2.2 UNPACKING

WARNING: THE GENERATOR

WEIGHS APPROXIMATELY

23 POUNDS (10.5KG).

1. Inspect the package exterior for

evidence of dam age du e to handling

in transit. Notify the carrier and

Spellman immediately if damage is

evident. Do not destroy or remove

any of the packing material used in a

damaged shipment.

2. Remove the cardboard outer

packaging. See the cautionary note

below before removing the

packaging.

CAUTION: OPEN THE CARDBOARD

PACKAGING CAREFULLY. SHARP TOOLS MAY

DAMAGE THE CONTENTS.

3. Set aside the cardboard packaging.

4. After unpacking, inspect for visible

damage.

5. Keep the shipping containers. In

case of shipping dam age, place the

unit(s) back in its s hipping pack and

notify the carrier and the Customer

Support Department as indicated in

this manual.

2.3 OVERALL CONNECTIONS

NOTE: THIS IS BASIC CONNECTION

ILLUSTRATION FOR TESTING. MORE

COMPLEX AND DEDICATED CIRCUITRY

IS NEEDED IN THE FINAL APPLICATION.

All cables should be route d away from high

voltage areas, and dressed and secured

neatly in place. Cables s hould be cut to the

correct length if possible as excess cabling

may contribute to EMI/RFI problems. For

those cables that cannot be cut to the correct

length (HV cables and console cables for

example), try to minimize the area inside any

loops of excess cable, as t hese loops are in

effect an antenna.

PMX MANUAL 8 118164-001 REV. A

Page 14

PMX MANUAL 9 118164-001 REV. A

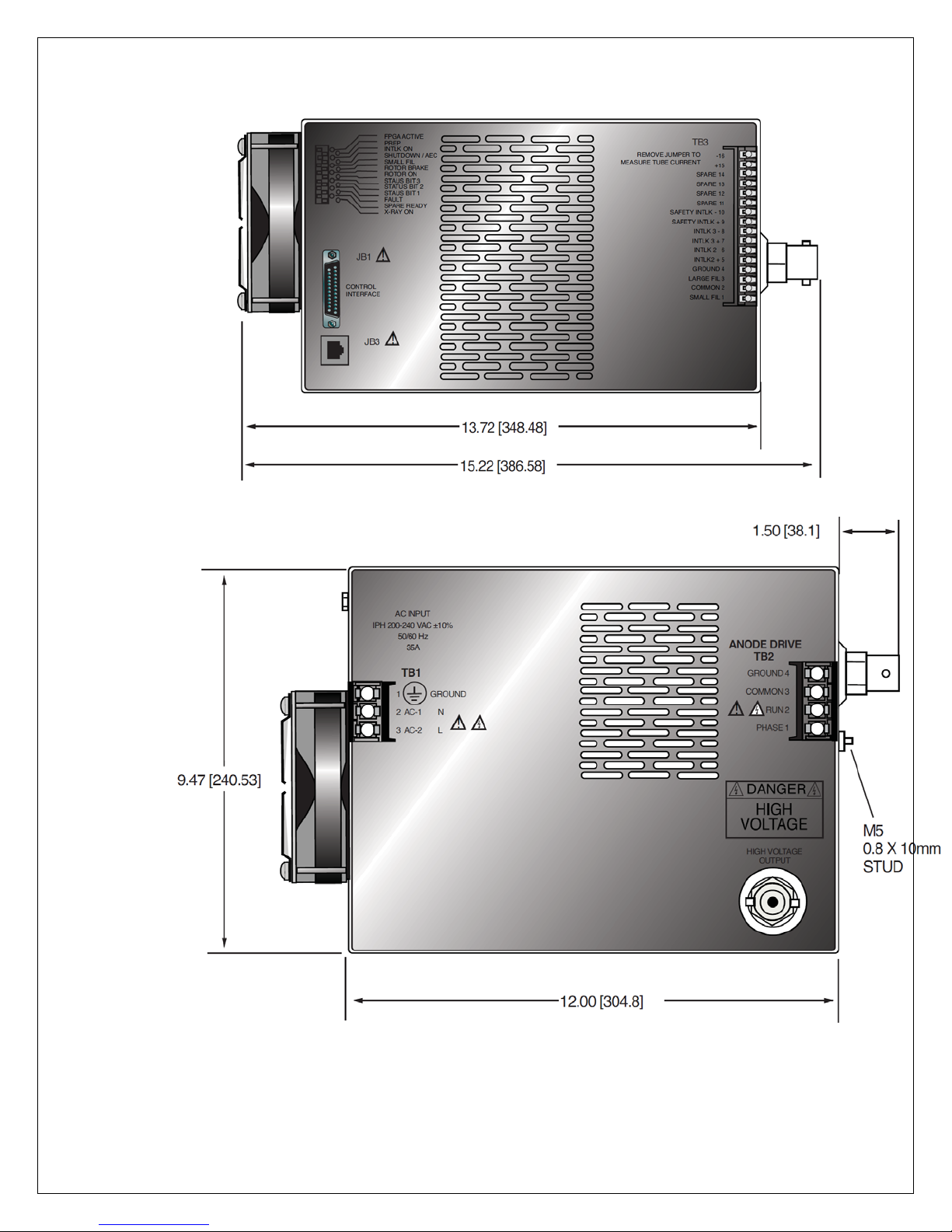

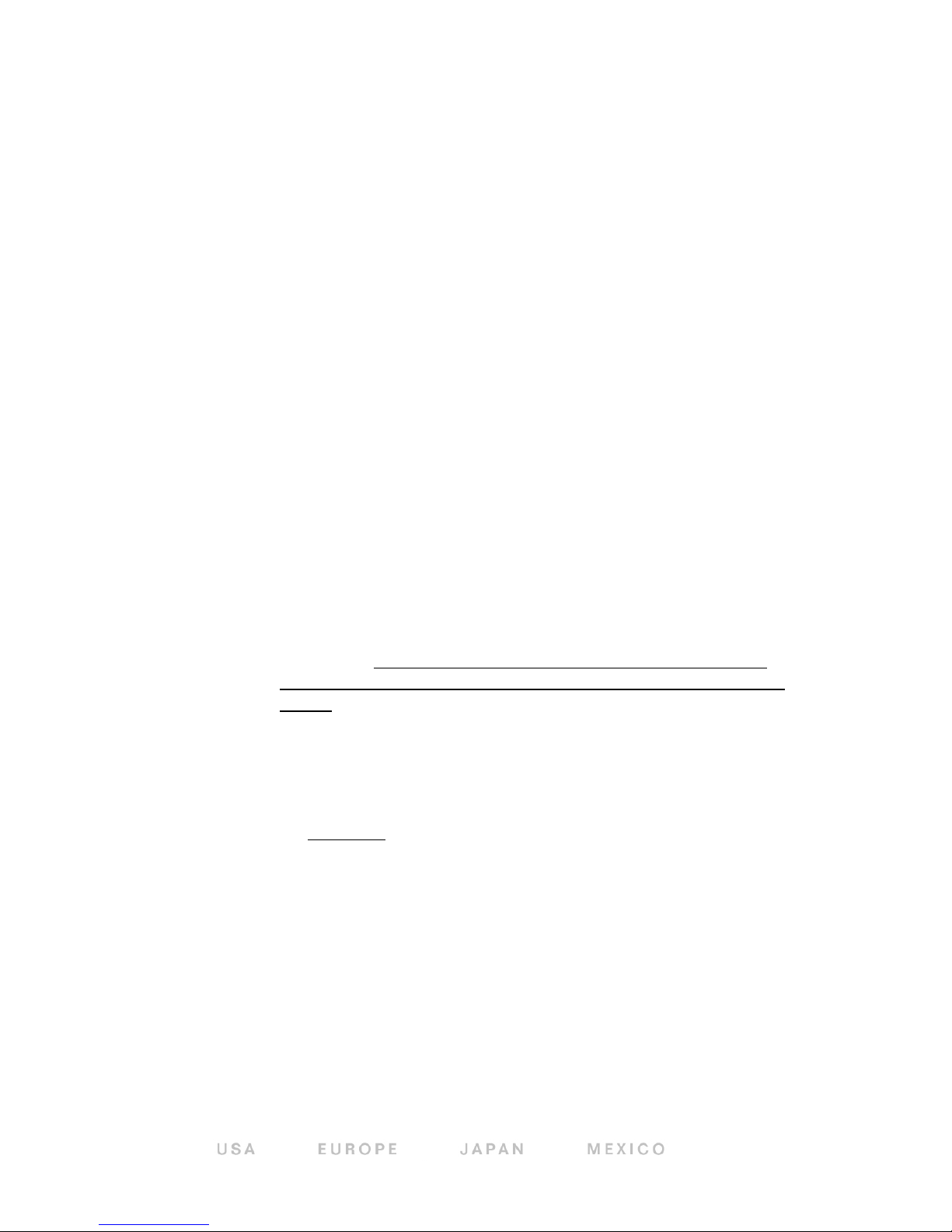

Figure 2-1: PMX I/O and indicator locations

Page 15

TB1

1.GROUND

2.AC-1

3.AC-2

JB1

CONTROL

INTERFACE

TB3

TB2

ANODE DRIVE

FILAMENT DRIVE

HIGH VOLTAGE

OUTPUT

JB3

ETHERNET

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

1

2

3

4

GROUND STUD

SYSTEM INTERLOCK

FILTER

N

L

PE

mA TEST PINS

FUSE CONTACTOR

INTERFACE

CABLE

SYSTEM INTERFACE

(OPTIONAL)

X-RAY TUBE

HV CABLE

VMX GENERATOR

POWER LINE

LV CABLE

INTERLOCK

SHORT THE WIREPAIR IF

SYSTEM INTERLOCK NOT

AVAILABLE

INTERLOCK WIRE

USER SUPPLIED COMPONENT

NOTE:

2.4 POWER LINE MAINS

WARNING: MAIN CONTACTOR IS NOT

PROVIDED WITHI N TH E G EN ER A TO R ,

CUSTOMER IS RESPONSIBLE FOR MAINS

SAFETY DISCONNECTION.

PMX MANUAL 10 118164-001 REV. A

Figure 2-2: Overall connection

The PMX supply does not contain power

line current limiting or fuses. It is strongly

recommended that the user provide fuses

or circuit breaker protection on the input

power lines to limit fault current that may

occur due to component failure, or

operator error. Fuses or circuit breake rs

with current rating of 35 Amps are

recommended

Refer to Chapter 1 for generator po wer and

generator power line requirements.

1. Check the input voltage rating on the

nameplate of the supply and make

certain that this is the rating of the

power source to be connected.

2. Units operate on 200V-240VAC, +/-

3. A three-wire terminal block (TB1) is

4. DO NOT SWITCH ON MAINS

2.5 Cable connection illustration

2.5.1 HV Cable Connection

The X-Ray tube should be mounted in its

1. Verify that the HV cable terminations

2. Be sure that the rubber expansion

10%, 50/60Hz, single phase 35A.

provided for connecting to the AC

supply (refer to Figure 2-2).

POWER AT THIS TIME.

normal fixture i.e. tube stand or other

device.

are clean and in good condition.

ring is located at the bottom of the HV

cable plug.

Page 16

3. Connect HV cable to the CA3 type

high voltage output terminal at rear of

the unit.

4. Connect the other side of HV c able

to the corresponding HV te rminal on

tube housing.

5. Connect the cable shield wire

accompanying HV c able to the PMX

ground stud and tube housing

separately.

2.5.2 Stator Cable Connection

Refer to Table 2-1 for the X-Ray tube stator

connections.

1. Tube low voltage cable is a hybrid

one with filament and stator drive

wire bundled together. Tube side

should be standard terminal style,

while generator side is unterminated.

Customer should term inate the wire

with suitable terminal.

2. Connect wires from the X-Ray tube

housing low voltage connector stator

pins to PMX terminal block TB2

terminals 1 (stator PHASE), 2 (stator

RUN), 3 (stator COM), and 4

(GROUND).

3. Connect tube thermal switch wires to

TB3-5 and TB3-6 if present. If not,

short the two pins. Normally, there

are no such separate wires for

MAMMO tubes; it is always

integrated into the three phase line.

Refer to tube hous ing dat a sheet for

specific information.

2.5.3 Filament Driver Cable Connection

1. Filament driver cable has three wires

and bundled together with stator

wires within same cable. Customer

should terminate the wire with

suitable terminals and lea ve enough

length to reach the terminal TB3.

2. Connect wires from the X-Ray tube

housing low voltage connector

filament pins to PMX terminal block

TB3 terminals 1 (FIL Small), 2 (FIL

COM), and 3 (FIL Large).

PMX MANUAL 11 118164-001 REV. A

Page 17

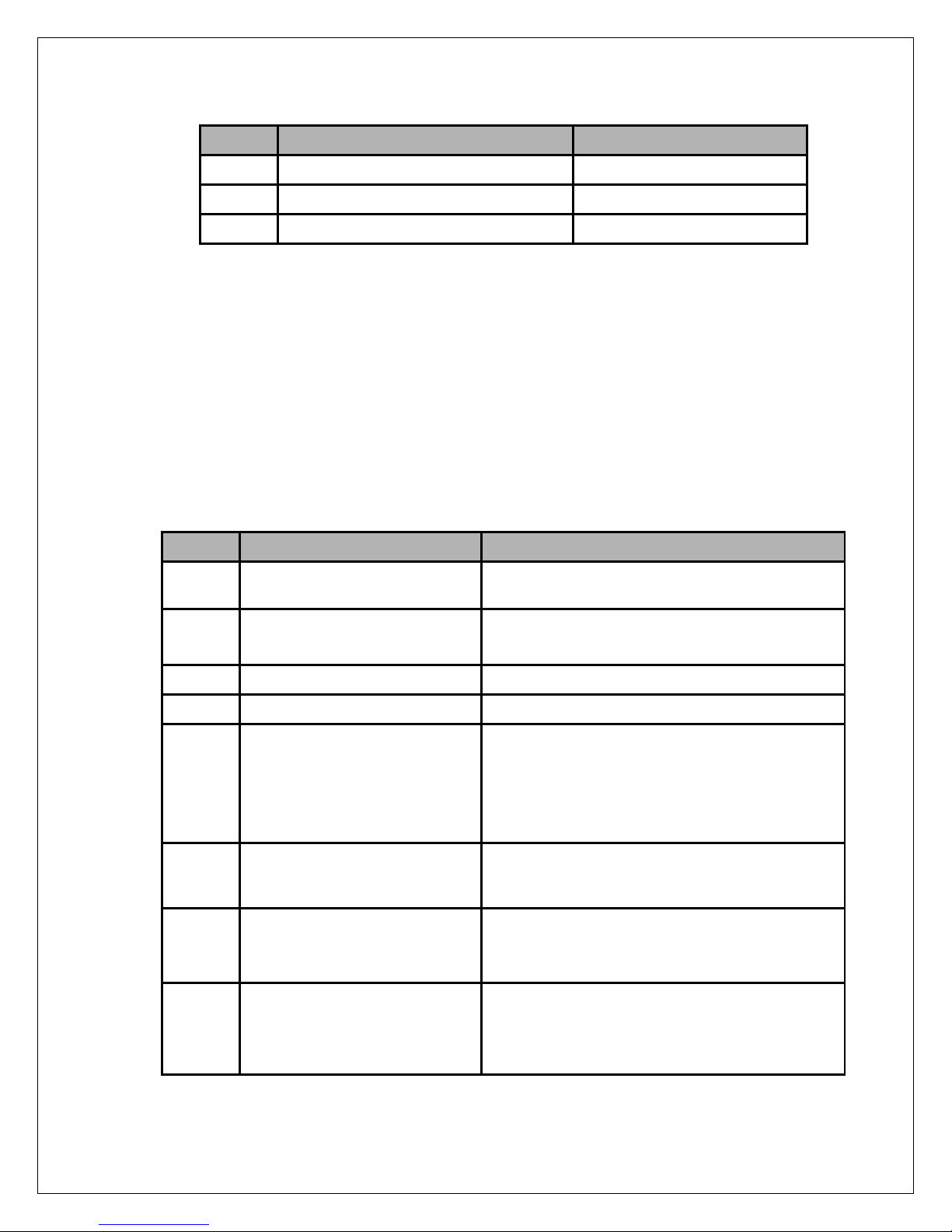

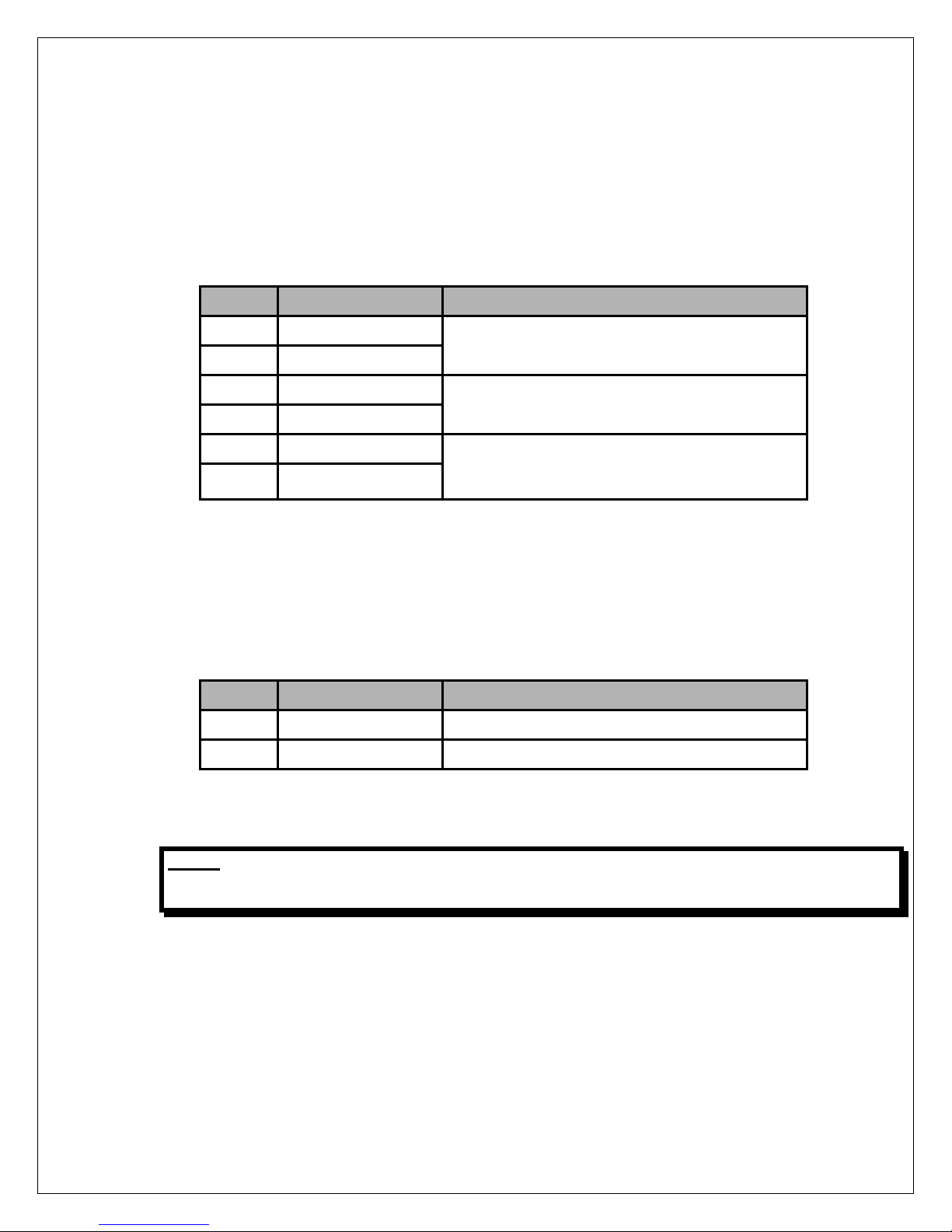

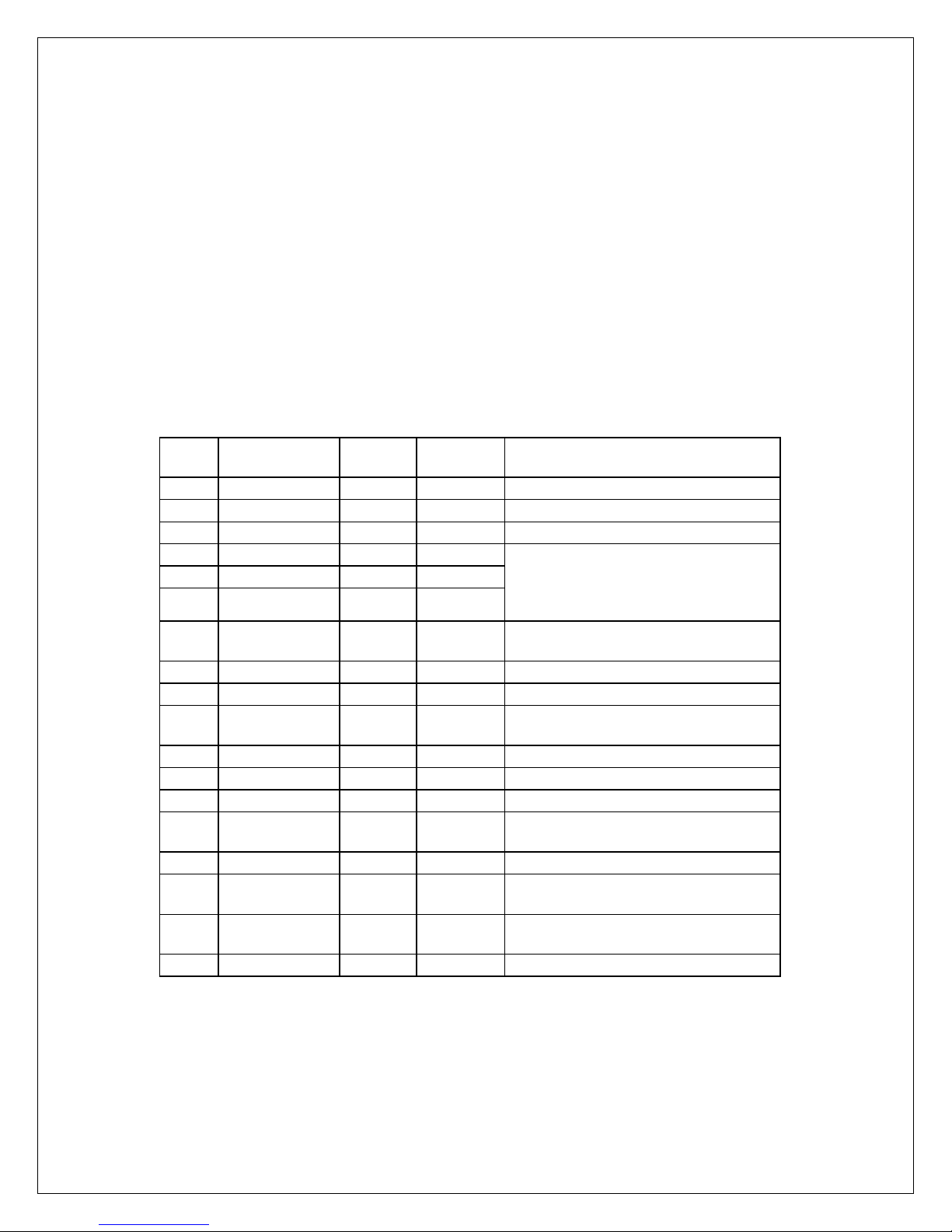

Pin #

Definition

Description

TB3-1

SMALL FIL

To tube small filament.

TB3-2

COMMON

To tube filament common.

TB3-3

LARGE FIL

To tube large filament.

Pin #

Definition

Description

JB1-1

GND

Generator signal groun d for referenc e of interface

JB1-2

(+) 5VDC Out

5 volts DC from generator for use in powering

such as optocouplers. 100mA

maximum.

JB1-3

RS232 Tx Out

RS232 Transmit (out) from generator

JB1-4

RS232 Rx In

RS232 Receive (in) to generator

JB1-5

PREP

User Signal (Contact Closure) to alert the

this signal is active, exposure parameters are

enables the starter to boost the rotor. Contact

JB1-6

READY

Generator Signal to user to indicate the rotor r uns

JB1-7

ROTOR SHUTDOWN

User Signal to generator to brake the rotor drive off.

JB1-8

EXPOSURE

User Signal (Contact Closure) to generator to

Voltage is generated after the boost time.

pin 24. Closed=Exposure.

Table 2-2. Pin layout of filament driver connector.

2.6 MULTI INTERFACE CABLE

CONNECTIONS

The PMX has multi interface connections

include digital I/O, serial communication, and

interlock. Operator m ust verify and connect

every signal properly though some of them

are optional, before initiating power-up and

basic test.

The interlock, serial communication and

exposure buttons interface shall be made

available via a multi signal cable. Refer to *-*

for a schematic of isolation and signal

direction.

2.6.1 Pin Layout of the Multi interface

The multi signal interface shall have a female

25 pin D-Sub (JB1) on the PMX. Twisted

pairs shall be used where applicable. The pin

layout is giv en in Table 2-3.

circuits

interface circuitry

generator that exposure sequence will begin. Once

locked in and cann ot be changed. The gener ator

connection to pin 24. Closed = PREP.

to speed and the generator is ready for X-Ray

exposure. Transistor output. Low/Active=Ready

Low brakes Rotor. (Open wil l not restart rot or until

a new PREP cycle is started). Reference to GND.

generate X-Rays. Filament is boosted, and High

PMX MANUAL 12 118164-001 REV. A

(Approximately 1 second). Contact connection to

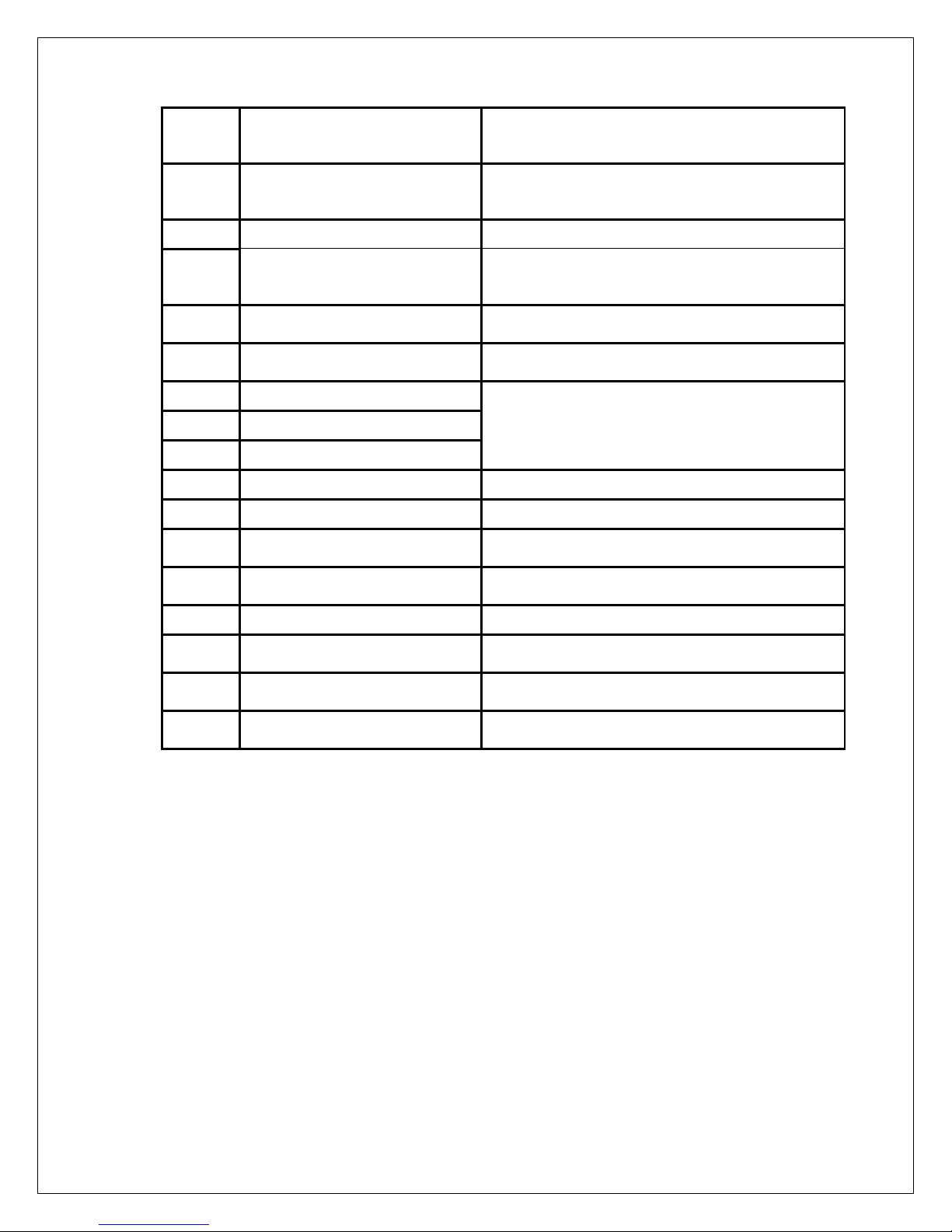

Page 18

JB1-9

X-Ray ON 75% Status

Transistor output to indicate X-Ray ON status.

Status Synchronize with 75% kV setting point.

JB1-10

X-Ray ON Status

Transistor output to indicate HV ON status.

Synchronize with HV start-up.

JB1-11

N/C

Not Used

JB1-12

X-Ray SHUTDOWN/AEC

User Signal to generator to rapidly turn HV OFF

Reference to

GND. LOW Shuts down HV.

JB1-13

RS232 ISO Ground

Isolated ground from the isolated RS232

transceiver I.C.

JB1-14

HVG FAULT Status

Generator signal indicating generator fault. Open

collector transistor output. Lo w/Ac ti ve =Fau lt

JB1-15

Status Bit 1

3 bit status lines f or up to 6 status m essages . See

functionality. Open Collector transistor output.

JB1-16

Status Bit 2

JB1-17

Status Bit 3

JB1-18

N/C

N/C

JB1-19

N/C

N/C

JB1-20

kV Monitor

Signal from generator. 0-10V=0-50kV. Zout=1K

ohm

JB1-21

Emission Monitor

Signal from generator. 0-10V=0-200m A. Zout=1K

ohm

JB1-22

Filament Current Monitor

Signal from generator. 0-10V=0-6A. Zout=1K ohm

JB1-23

Program/Monitor Return

Ground for reference of program and monitor

signals

JB1-24

+24VDC Out

For connection to P REP and EXPOSURE control

relay coils.

JB1-25

SHIELD/GND

For connection of interface cable shield to

generator chassis ground.

(Reference to GND). High/Active=X-Ray ON

(Reference to GND). High/Active=HV ON Status.

and ON during Exposure. (AEC).

separate matrix (Table 2-4) describing

Low/Active=Message.

Table 2-3 Pin layout of multi signal connector

Refer to chapter 3 for detailed requirements and function descriptions.

PMX MANUAL 13 118164-001 REV. A

Page 19

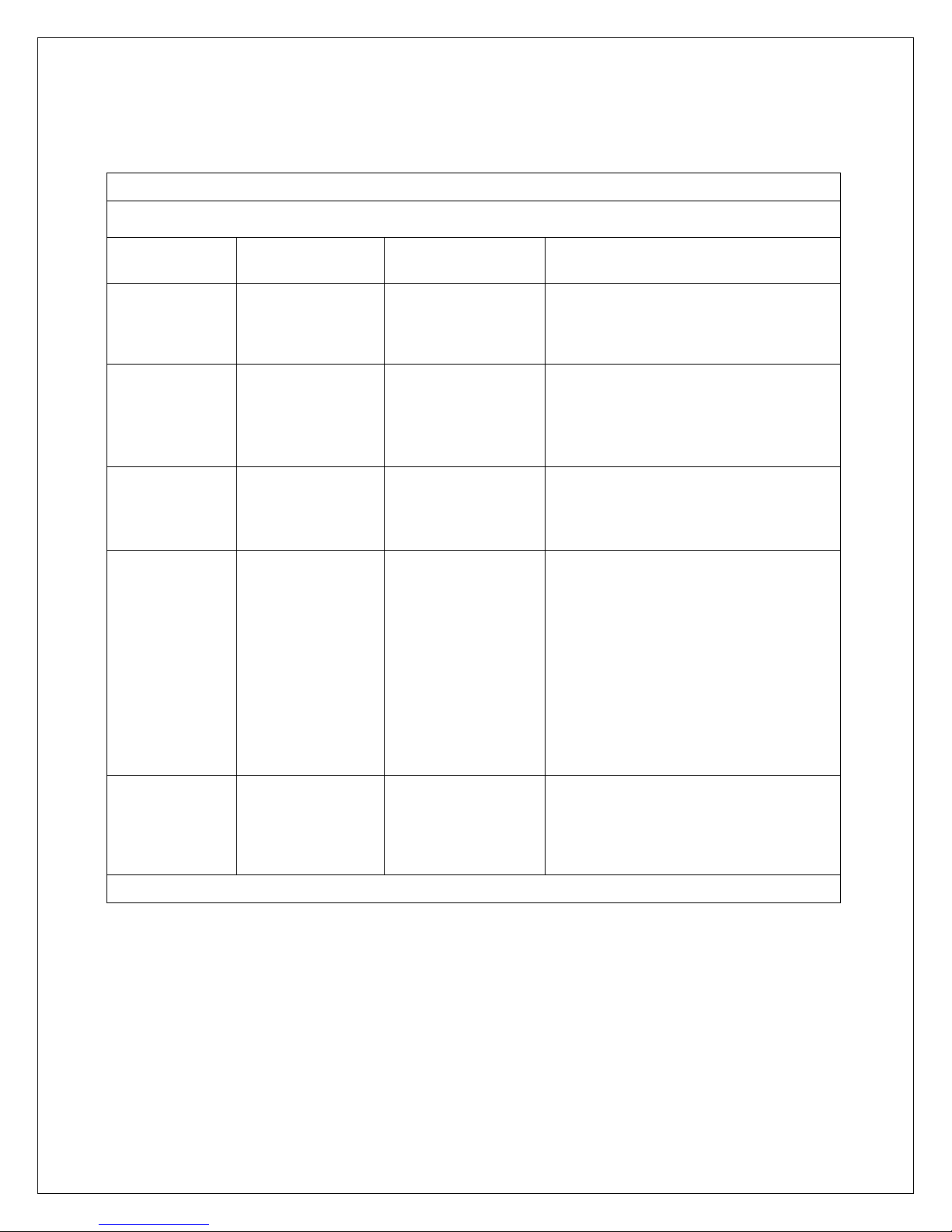

Pin #

Definition

Description

TB3-5

Interlock 2 +

Used if tube has separate thermostat switch.

TB3-6

Interlock 2 -

TB3-7

Interlock 3 +

Used if tube has cooling circulator flow switch.

TB3-8

Interlock 3 -

TB3-9

Safety Interlock+

User signal (Contact Closure) f or safety interlock s

HV OFF, or

TB3-10

Safety Interlock-

Pin #

Definition

Description

TB3-15

Tube current +

Tube current flows out from this pin.

TB3-16

Tube current -

Tube current flows into this pin.

2.7 Interlock Connections

Interlock connections are provided for a

variety of safety functions such as room door

interlock, separate thermal switch interlock,

tube flow switch interlock. The unit will not

operate unless the interlocks are closed.

2.8 Tube Current Monitor Connection

Tube current test pins are provided for

monitoring the actual tube current (mA) if

needed. Normally, a jumper is installed to

short the two pins (refer to Figure 2-2).

The pin definition shows below:

Opening the interlock circuit will cause the

unit to shut off.

Three safety interlocks are located in TB3 for

system interlock purpose. Short the terminals

if not used.

The pin definition shows below:

Open=over temp. (Short terminals if not used).

Open=no flow. (Short terminals if not used).

such as door interlocks. Open turns

inhibits HV from being generated.

Remove the jumper and install the current

meter in series to monitor the actual tube

current.

Two test pins are located in TB3 (TB3-15,

TB3-16). Short the two pins if not used.

2.9 GROUND CONNECTION

NOTE: THE INSTALLER SHOULD ENSURE THAT ALL CABLE CONNECTIONS TO THE GENERATOR

ARE SECURE, AND ALL CABLES EXTERNAL TO THE GENERATOR ARE

ADEQUATELY PROTECTED AGAINST ACCIDENTAL DISCONNECTION.

2.9.1 X-Ray Tube Housing Ground

A separate ground wire (10 AWG, 6mm

must be connected from the X-Ray tube

housing to the ground stud on the r ear of the

PMX chassis. These ground locations may

have other ground wires already connected;

PMX MANUAL 14 118164-001 REV. A

ensure that these existing ground wires are

not disconnected when making the X-Ray

2

)

tube ground connection.

Failure to make this groun d connection may

result in intermittent operation and/or

exposure errors or even worse IGBT failure.

Page 20

2.9.2 Chassis Ground

The chassis of the P MX generator m ust be

grounded to the local earth grou nd and also

to the tube housing groun d. See Figure 2-2

for typical operating setup. A three-wire

terminal block is provided for connecting to

the AC supply.

2.10 FINAL CHECKS

NOTE: THE INSTALLER SHOULD ENSURE THAT ALL CABLE CONNECTIONS TO THE

GENERATOR ARE SECURE, AND ALL CABLES EXTERNAL TO THE GENERATOR ARE

ADEQUATELY PROTECTED AGAINST ACCIDENTAL DISCONNECTION.

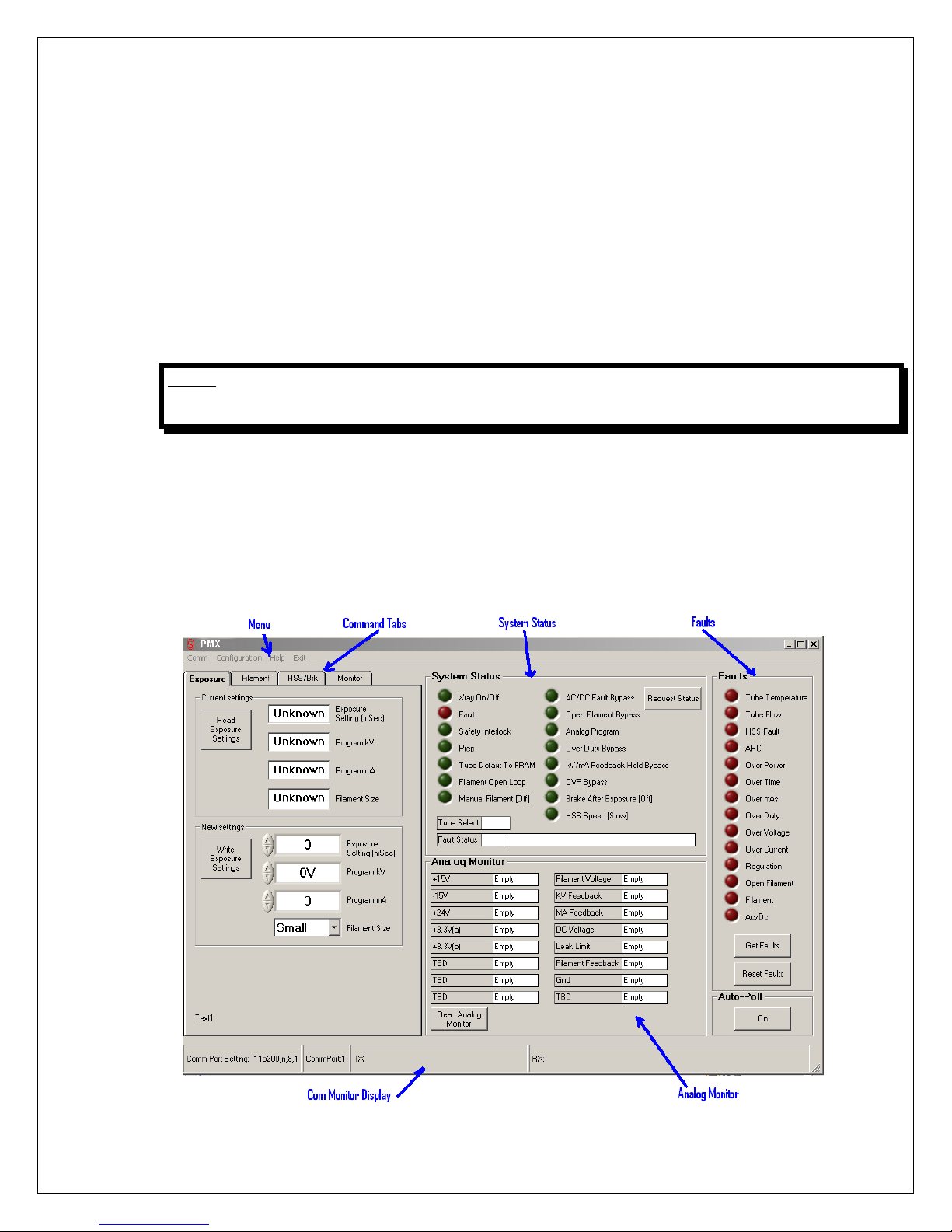

2.11 GUI SOFTWARE

The optional GUI utility software allows for

data communication between the generator

and an external computer. This provides a

“virtual console” with which user can release

all the command defined in the protocol and

verifies all the functions independently before

The room interface c onnect ions m ay now be

completed. Before power on, user needs to

check the items as below finally.

• When finished all wiring, check that all

connections are tight and secure.

• Double check the breaker, EMC filter,

fuses, etc. User is res ponsible f or on t he

main input power lines.

• Check that all cables are dressed neatl y

outside the cabinet, and secured as

necessary.

• Check the ground connection again.

integrating the generator into their ultimate

system.

The GUI consists of the Analog Monitor

Section, the System Status Section, the Fault

Section, the Command Tab Section, the Com

Monitor Display, and the Menu.

PMX MANUAL 15 118164-001 REV. A

Page 21

The Command Tab section, along with the

Monitor / Status / Fault sections provide

access to the various com mands defined in

the PMX Protocol Spec. The Analog Monitor,

System Status, and Fault sections are always

visible and can be accessed at any time. The

Command Tab section provides access to

function. Clicking on the tabs at the top of the

Command Tab section selects a particular

group of commands. Only one group (tab)

can be selected at any one time.

See separate docum ent for t he detaile d GUI

instruction.

other commands grouped together by

PMX MANUAL 16 118164-001 REV. A

Page 22

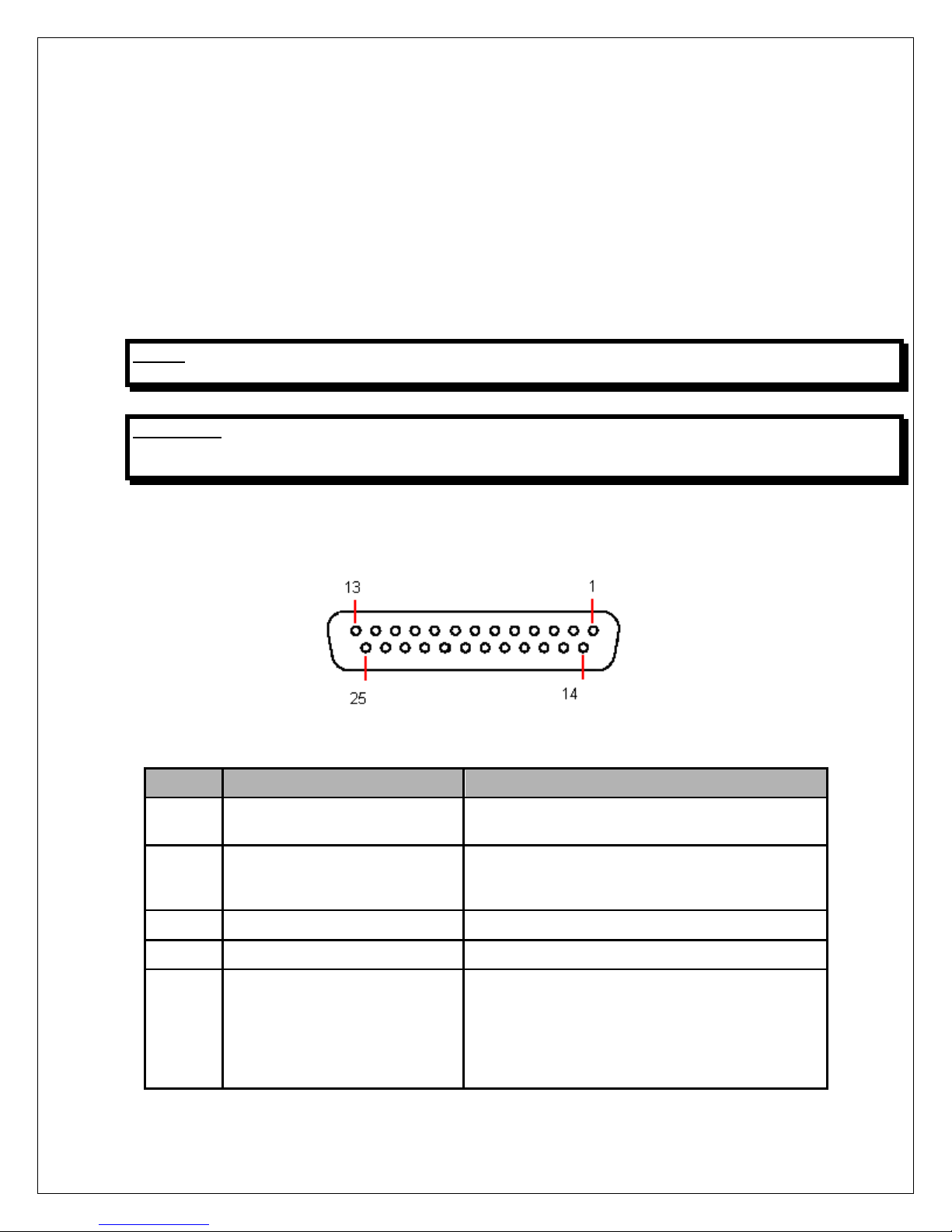

Pin #

Definition

Description

JB1-1

GND

Generator signal groun d for referenc e of interface

JB1-2

+5VDC Out

5 volts DC from generator for use in powering

. 100mA

JB1-3

RS232 Tx Out

RS232 Transmit (out) from generator

JB1-4

RS232 Rx In

RS232 Receive (in) to generator

JB1-5

PREP

User Signal (Contact Closure) to alert the

this signal is active, exposure parameters are

enables the starter to boost the rotor. Contact

CHAPTER 3

INTERFACING

3.1 introduction

This chapter describes the interfacing of the

PMX generator to the customer s ystem control

side, especially with th e serial communication,

3.2 MULTI INTERFACE

NOTE: THE INSTALLER MUST PROVIDE THE NECESSARY INTERFACING CABLES FOR WIRING TO THE

GENERATOR INPUTS AND OUTPUTS DESCRIBED IN THIS SECTION.

WARNING: LINE VOLTAGE IS PRESENT INSIDE THE GENERATOR AT ALL TIMES THAT THE MAIN

DISCONNECT IS SWITCHED ON. FOR SAFETY, THE MAIN DISCONNECT SHOULD BE

SWITCHED OFF AND LOCKED OUT WHILE CONNECTING ROOM EQUIPMENT.

3.2.1 Connector Style and Pin Layout

exposure control switch. Also, exposure mode

is introduced with the timing sequence

described as well.

Figure 3-1 multi signal interface connector

PMX MANUAL 17 118164-001 REV. A

circuits

interface circuitry such as opto couplers

maximum.

generator that exposure sequence will begin. Once

locked in and cann ot be changed. The gener ator

connection to pin 24. Closed = PREP.

Page 23

JB1-6

READY

Generator Signal to user to indicate the rotor r uns

JB1-7

ROTOR SHUTDOWN

User Signal to generator to brake the rotor drive off.

JB1-8

EXPOSURE

User Signal (Contact Closure) to generator to

pin 24. Closed=Exposure.

JB1-9

X-Ray ON 75% Status

Transistor output to indicate X-Ray ON status.

Ray ON

Status Synchronize with 75% kV setting point.

JB1-10

X-Ray ON Status

Transistor output to indicate HV ON status.

Synchronize with HV start-up.

JB1-11

N/C

Not Used

JB1-12

X-Ray SHUTDOWN/AEC

User Signal to generator to rapidly turn HV OFF

Reference to

GND. LOW Shuts down HV.

JB1-13

RS232 ISO Ground

Isolated ground from the isolated RS232

transceiver I.C.

JB1-14

HVG FAULT Status

Generator signal indicating generator fault. Open

collector transistor output. Lo w/Ac ti ve =Fau lt

JB1-15

Status Bit 1

3 bit status lines f or up to 6 status m essages . See

functionality. Open Collector transistor output.

JB1-16

Status Bit 2

JB1-17

Status Bit 3

JB1-18

N/C

N/C

JB1-19

N/C

N/C

JB1-20

kV Monitor

Signal from generator. 0-10V=0-50kV. Zout=1K

ohm

JB1-21

Emission Monitor

Signal from generator. 0-10V=0-200m A. Zout=1K

ohm

JB1-22

Filament Current Monitor

Signal from generator. 0-10V=0-6A. Zout=1K ohm

JB1-23

Program/Monitor return

Ground for reference of program and monitor

signals.

JB1-24

+24Vdc Out

For connection to P REP and EXPOSURE control

relay coils.

JB1-25

SHIELD/GND

For connection of interface cable shield to

generator chassis ground

to speed and the generator is ready for X-Ray

exposure. Transistor output. Low/Active=Ready

Low brakes Rotor. (Open wil l not restart rot or until

a new PREP cycle is started). Reference to GND.

generate X-Rays. Filament is boosted, and High

Voltage is generated after the boost time.

(Approximately 1 second). Contact connection to

(Reference to GND). High/Active=X-

(Reference to GND). High/Active=HV ON Status.

and ON during Exposure. (AEC).

Table 3-2 Pin layout of multi signal interface

3.2.2 Serial Communication Interface

separate matrix (Table 2-4) describing

Low/Active=Message.

PMX MANUAL 18 118164-001 REV. A

Page 24

Pin #

Definition

Description

JB1-3

RS232 Tx

RS232 Transmit (out) from

JB1-4

RS232 Rx

RS232 Receive (in) to

JB1-13

RS232 ISO Ground

Isolated ground from the

The serial communication is part of the Multi

Signal Interface (JB1).

The pin definition shows below:

User should connect the R S232 cable properl y

with system side such as PC. Twisted wires are

preferable to enhance the EMC performance.

GUI software can be used temporarily to test the

PMX provided installed on the user PC. (Ref er

to separate document for detailed information of

GUI). But user need to develop their own

ultimate software based on open protocol

(Refer to separate document) and design

system control board to integrated PMX into

their system with proper method (Refer to 2.6.1

NOTE the isolation requirement).

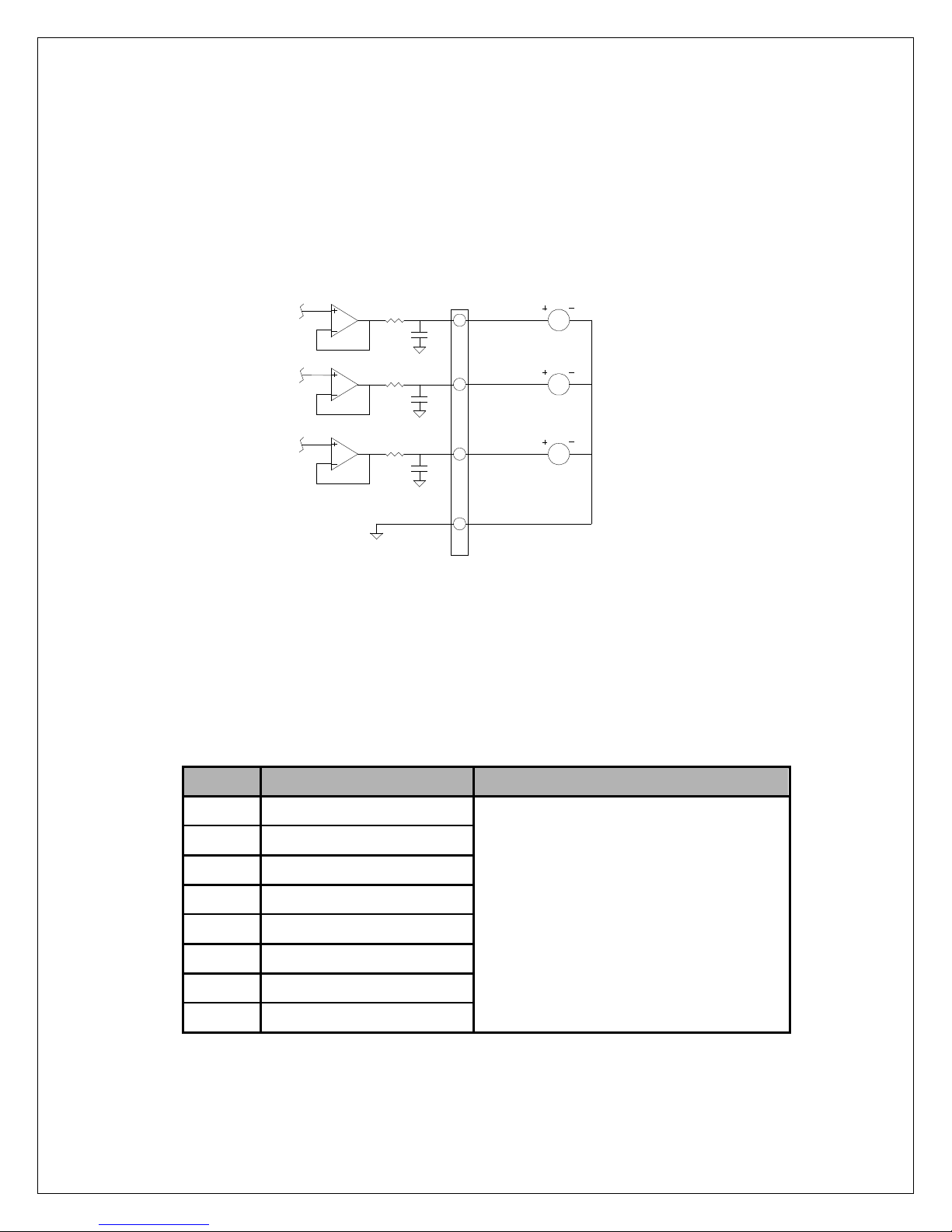

3.2.3 Digital I/O Control Interface

Remote digital control of the PREP, ROTOR

SHUTDOWN, EXPOSURE, X-Ray

SHUTDOWN, are available on the 25-pin I/O

connector for maintenance. All of these controls

except PREP and EXPOSURE are toggle on/off

type signals. PREP and EXPOSURE are

The RS232 communic ation interface has been

isolated inside t he HVG with specific IC.

generator

generator

isolated RS232 transceiver I.C .

controlled by a momentary normally open

contact. If remote control is required, the remote

interface dummy plug must be removed and

replaced with the appropriate remote circuits.

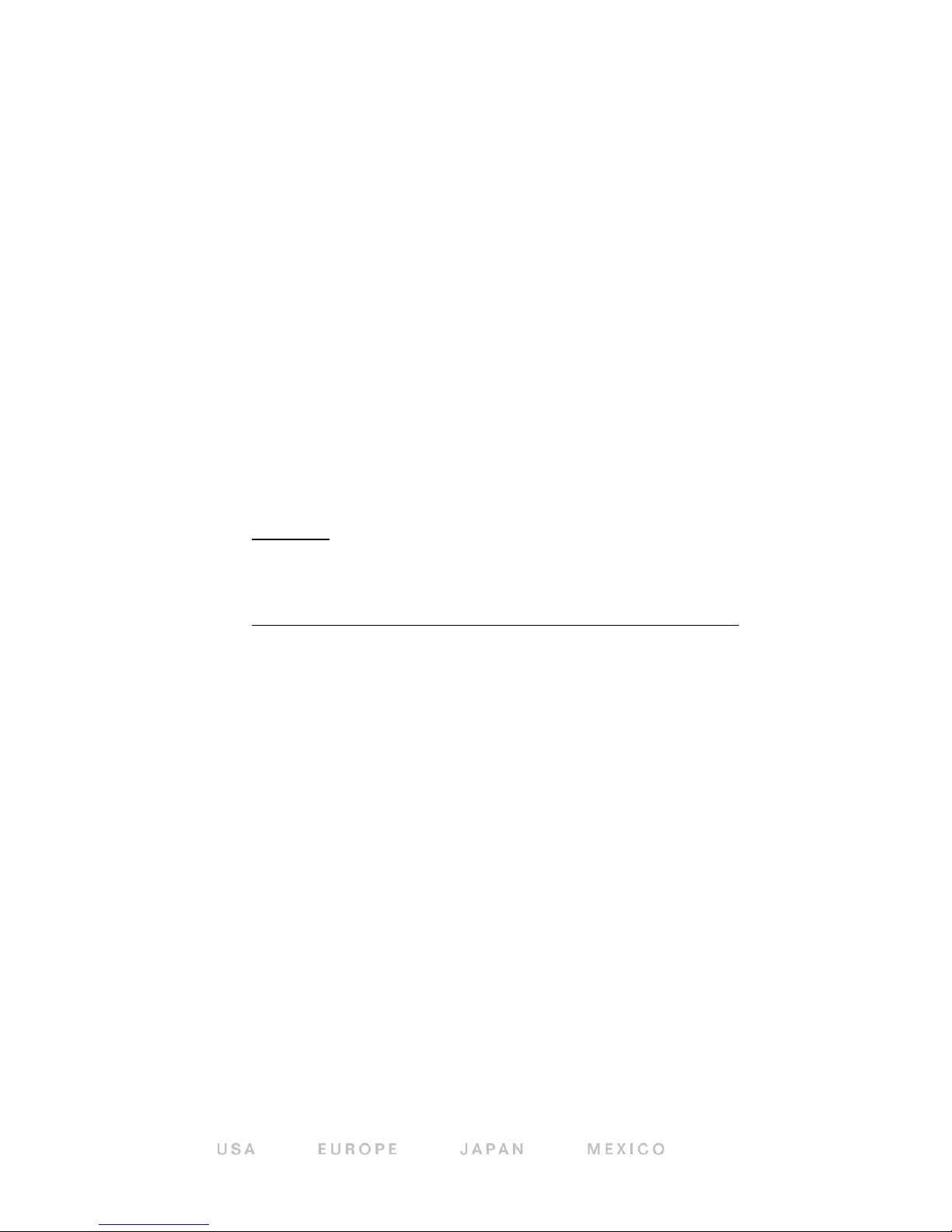

See Figure 3-2 for recommended interface

circuits.

In order to eliminate sig nal bounce caused

by mechanical contact, an el ectron ic sw itch

such as opto coupler device is

recommended for these signals.

Warning: Max current that the +24Vdc

supply can provide is 100mA.

PMX MANUAL 19 118164-001 REV. A

Page 25

JB1

Customer Interface

High Voltage

power supply

1

7

12

5

8

+5V

10K

Transistor On =

Rotor shutdown

+5V

10K

Transistor On =

X-ray OFF

+24V

Switch closed

for PREP

+24V

Switch closed

for EXPOSURE

NOTES:

Relay coil Z=178

Ω

+5V

24

+24V

3.2.4 Remote Status Interface

Remote status signals f or KV MIN tube curren t

limit, tube power limit, overvoltage, and filament

Figure 3-3 for recommended interface circuits.

Figure 3-2 Digital I/O Control Interface

Current limit, over temperature, and power

supply fault is provided.

These signals are open collector type.

(Normally off), and are intended to drive the

diode of an opto-coupler.

PMX MANUAL 20 118141-002 REV

Page 26

JB1

Customer Interface

Generator interface

6

9

NOTES:

50mA max collector current on internal power supply transistors

+5V

330

100

+5V

1K

100

+5V

1K

100

10

+5V

330

100

+5V

330

100

+5V

330

100

+5V

330

100

READY

X-RAY ON Status

HV ON Status

14

HVG FAULT Status

15

BIT1 Status

16

BIT2 Status

17

BIT3 Status

LOW=READY

HIGH=X-RAY 75% ON

HIGH=X-RAY ON

HIGH=FAULT

LOW=ACTIVE

LOW=ACTIVE

LOW=ACTIVE

BIT1

BIT2

BIT3

MESSAGE

high

high

high

No Messages

low

high

high

Tube Temp/Flow Fault/HSS Fault

high

low

high

Arc Detected/Shutdown

high

high

low

Over Load: Power/MAS/Time/Duty

low

low

high

Over Voltage/Over Current/Regulation error

low

low

low

Open Filament/Filament Fault

Figure 3-3 Remote status interface

If a fault occurs, the power supply will shut down

and a 3 bit binary code will be gen erate d at the

user interface connector J B1. T o res et, use the

reset function on remote user interface.

Table 3-3 status messages matrix

The fault inf orm ation is provided with three bits

code. Below is the information list.

More than one fault is defined with one code

combination. Use can get specific fault

information by serial command.

PMX MANUAL 21 118164-001 REV. A

Page 27

JB1

Generator side

22

Customer side

20

21

1K

0.1

1K

0.1

1K

0.1

23

M

M

M

kV monitor

mA monitor

Filament

monitor

Monitor return

NOTES:

1) Metering circuit should be high Z type(>10Meg)for accurat e measurement.

2) All signals 0-10Vdc = 0-100 % of specified maximum outputs .

Pin #

Definition

Description

JB3-1

TX+ White/Orange

JB3-2

TX- Orange

JB3-3

RX+ White/Green

JB3-4

POE V+ blue

JB3-5

POE V+ blue/white

JB3-6

RX- Green

JB3-7

POE V- brown/white

JB3-8

POE V- brown

3.2.5 Rem ote Monitoring Interface

Test points are made available at the 25-pin I/O

connector from monitoring tube voltage, tube

current and tube filament current. The test

Figure 3-4 for wiring diagram and specifications for remote monitor interface.

points are always positive regardless of the

output polarity, where 0 to 10V = 0-100% of

output. Accuracy is within ±0.5%. All test points

have output impedance of 1Kohm.

Figure 3-4 Remote monitoring interface

3.3 ETHERNET INTERFACE

Ethernet is an optional serial communication

interface with separate standard RJ45 style

RJ45 pin definition shows below:

connector. JB3 is terminal number.

10/100 Base-T Ethernet Interface

PMX MANUAL 22 118164-001 REV. A

Page 28

CHAPTER 4 CONFIGURATION,

CALIBRATION AND OPERATION

4.1 INTRODUCTION

This chapter describes the procedure for

configuring the tube type, configuring user

WARNING: USE EXTREME CARE IN MEASURING HIGH VOLTAGES. ACCIDENTAL CO NTACT

MAY CAUSE SERIOUS INJURY OR DEATH.

MAINS VOLTAGE WILL BE PRESENT INS IDE THE GENERATOR CHASSIS, EVEN

WITH THE POWER SWITCHED OFF. THIS VOLTAGE IS EXTREMELY DANGEROUS,

USE EXTREME CAUTION.

THE DC BUS CAPACITORS, LOCATED ON THE DC BUS ASSEMBLY, PRE SENT A

HAZARD FOR A MINIMUM OF 5 MINUTES AFTER THE GENERATOR HAS BEEN

SWITCHED OFF. CHECK THAT THESE CAPACITORS ARE DISCHARGED BEFORE

TOUCHING ANY PARTS IN THE GENERATOR.

allowed dual speed starter data and

operating filament auto-calibration.

WARNING: THE PROCEDURES IN THIS CHAPTER REQUIRE THE PRODUCTION OF X-Rays.

TAKE ALL APPROPRIATE SAFETY PRECAUTIONS TO PROTECT PERSONNEL

FROM X-Ray RADIATION.

WARNING: ALWAYS ENSURE THAT THE EQUIPMENT UNDER TEST AND ALL ASSOCIATED

TEST EQUIPMENT IS PROPERLY GROUNDED

ENSURE THAT THE HIGH VOLTAGE C ABLES ARE INTACT / UNDAMAGED AND

PROPERLY CONNECTED BEFORE ATTEMPTING EXPOSURES

ENSURE THAT THE PMX IS PROPERLY

INSTALLED AS PER CHAPTER 2 AND

CHAPTER 3 BEFO RE OPER AT I NG W H AT

THIS CHAPTER DESCRIBES.

4.2 TUBE PREHEAT TABLE

CONFIGURATION

The PMX contains up to 2 tube types power

limitation an d filament value tables. Consult

Spellman representati ves when ordering for

available tube tables pre-installed or tube

type field configuration possibility.

Reloading the default preheat tables in the

PMX u nit requires use of the DIP switc hes.

The DIP switches are located near the edge

of the board, to the right of the connector. The

DIP switch identifiers are stenciled on the PC

Board just above the switches, and the

individual switches are numbered at the

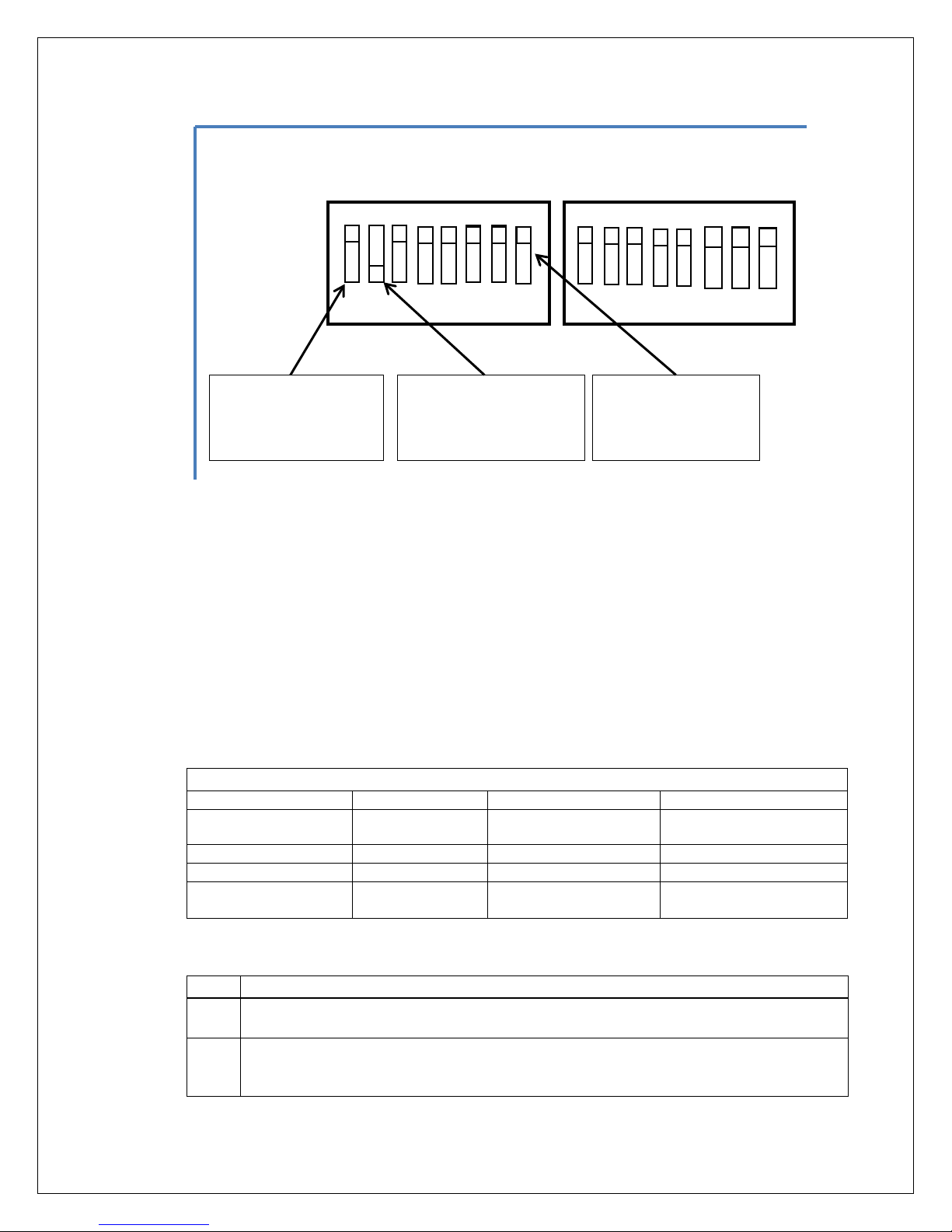

bottom of the DIP switch. The figure below

illustrates the DIP switch placement.

PMX MANUAL 23 118164-001 REV. A

Page 29

Table 1 -Tube Table Selection Matrix

Tube Selected

Tube number

Switch #1 Position

Switch #2 position

0

(Varian) M113T

3

Down

Up

Invalid Setting (do

not use)

Step

Action

1.

Power down the system, if it is not already powered down. Switch #8 on DIP Switch 1

should be in the up position as show above. This is the normal working position.

2.

Set Switch #8 on Dip Switc h 1 to the down position, th is is with the switch s et toward

#2 on DIP SW1 to the desired tube table as specified in Table 1 above.

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

SW1

SW2

DIP SW1 – Switch

DIP SW1 – Switch #1

DIP SW1 – Switch #2

(Up Position Shown)

Figure 4-1: DIP Switches for Configuration

Switch 8 on DIP SW 1 controls the loading of

the default Tube Table in to FRAM. When the

unit is powered up with this switch in the

down position the sel ected tube def ault data

is loaded in to FRAM, overwriting any current

data, including learned pr eheat values. This

switch only causes tab le up date when it is in

the down position at power up. Setting the

switch to the down position after power up

does not change the tube table.

(Down Position Shown)

#8

(Up Position Shown)

Switch 1 and Switch 2 o n DIP SW 1 select

which tube table wi ll be loaded in to FRAM

and become the active T ube. The setting of

these switches only matters when Switch 8 is

in the Down position at power u p. Changing

the Switch 1 and/or Switch 2 does not change

or reload the tube table if the unit is po wer ed

up with Switch 8 in the up position.

(IAE)XM1016T

Follow the below steps to select the desired table from the pre-installed tube table:

the center of the board (opposite to the above illustration). Also set switch #1 and switch

PMX MANUAL 24 118164-001 REV. A

Up Up

Down Down

Page 30

3.

Turn on the power to the PMX unit, and wait for 10 seconds. This will reload the selected

default table in to the FRAM.

4.

After the 10 seconds has elapsed, turn the power off, and return Switch 8 t o the Up

leave Switch 8 in the Up position.

Step

Action

1.

Entering calibration mode

2.

Enable Prep and Exposure to start calibration

filament will be affected. For example if small filament is calibrated and you attempt to

position. The tables have been reloaded and the system is ready to use. Make sure to

4.3 FILAMENT AUTO-CALIBRATION

The calibration function automatically

establishes calibration curves relating

filament current to tub e cur r ent (mA) at three

or four kV settings, dep ending on generator

type. This allows the g enerator to predic t t he

filament temperature (filament current) that

will be required for any mA value over the full

kV operating range.

It is recommended that the X-Ray tube be

seasoned before att empting auto cal ibrat ion ,

particularly if the tube has not been used for

Sending a “Set Calibration Mode” command (command number 28) with an argument of

1 or 2 or 3 with Prep and Exposure control in the OFF state. Gener ator w ill enter

calibration mode but in ‘pause’ state as the Prep and Exposure is inactive.

Calibration will be starting if both Prep and Exposure are activated. Once the sequence

has started the generator will automatically cycle through the exposure settings as long

as the Prep and Exposure control are ON until it either finishes calibration or there is an

exposure fault.

An exposure fault will cause the calibration routine to abort, and the unit to exit

calibration mode. If the user removes Prep and / or Exposure control during the

sequence, the calibration routine will enter a “Paused” state. It will not exit calibration

mode, but it will stop doing exposures and wait until Prep and Exposure control are both

returned to the ON state. If the user returns Prep and Exposure control ON, the PMX will

continue the calibration. Usually it will continue from where it was when the sequence

was paused, but depending on what it was doing when the calibration sequence was

interrupted it may go back and repeat a previous step.

The user may cancel calibration at any time by first setting Prep and / or exposure

control off, and then sending a “Set Calibration Mode” Command with an argument of 0.

Sending this command resets the calibration sequence. The next time calibration is

started it will go back to the beginning. Once calibration is started previous values for

preheat will be overwritten. Stopping calibration in the middle will result in some points

being calibrated and others not being calibrated. This may result in poor or inconsistent

preheat adjustment.

If user chooses to calibrate large and small filaments separately, only the chosen

some time. Refer to tube datasheet for

seasoning operation.

There are two different modes for user

selection to calibrate filament. User can

calibrate the large filament and small filament

separately or calibrate both large filament

and small filam ent at one t im e. Sendi ng “Set

Calibration Mode” command (command

number 28) with different argument will enter

different calibratio n mode (Refer to protoc ol

specification document for details).

Use these steps to per form the X-Ray tube

auto calibration function:

PMX MANUAL 25 118164-001 REV. A

Page 31

calibrate the large filament, but the calibration fails, it does not affect the small filament

3.

Exiting calibration mode

Step

operation

Action

2.

Presetting

Using the computer interface, select ROTOR SPEED, and

EXPOSURE time (0.5 seconds suggested).

2.

PREP

After presetting desired levels, initiate a PREP command.

PMX internal memory.

3.

READY

After approximatel y 2 seconds, a READ Y status signal will

reset.

4.

EXPOSURE

When READY status is retur ned from the power supp ly, an

set for the

will return to 0 volts until the next PREP/EXPOS URE cycle.

calibration. In this case you would have to rerun the large filament calibration, but not the

small filament calibration.

When calibration pr ocess is finished, Prep and Exposure should be released, and then

sending a “Set Calibr ation Mode” Comm and with an argument of 0 will let the PMX exit

calibration mode.

4.4 OPERATING X-RAY EXPOSURES

4.4.1 Normal Exposure

WARNING: AFTER TURN OFF, DO NOT UNPLUG TH E OUPUT CABLE UNTIL THE INTERNAL

CAPACITANCE IS DISCHARGED (APPROXIMATELY 3 MINUTES).

Use these steps to initiate a normal exposure:

SMALL or LARGE FILAMENT. Set KV (initial setting of

20kV is suggested), mA (10mA suggested), and

This will cause the X-Ray tube anode rotor to start, and apply

filament pre-heat cur rent to the t ube per value s tored in the

be returned to the computer indicating that the anode rotor is

up to speed, and the t ube i s read y to gen erate X -Rays. T h e

READY signal wil l remain for 30 seconds and aut omaticall y

exposure can then be ini tiated. When exposure is i nitiated,

HV is applied to the X -Ray tube and the power supp ly loop

control automaticall y adjusts the filament current to provide

the mA tube current that was previously preduration of the exposure time. Following an exposure, the HV

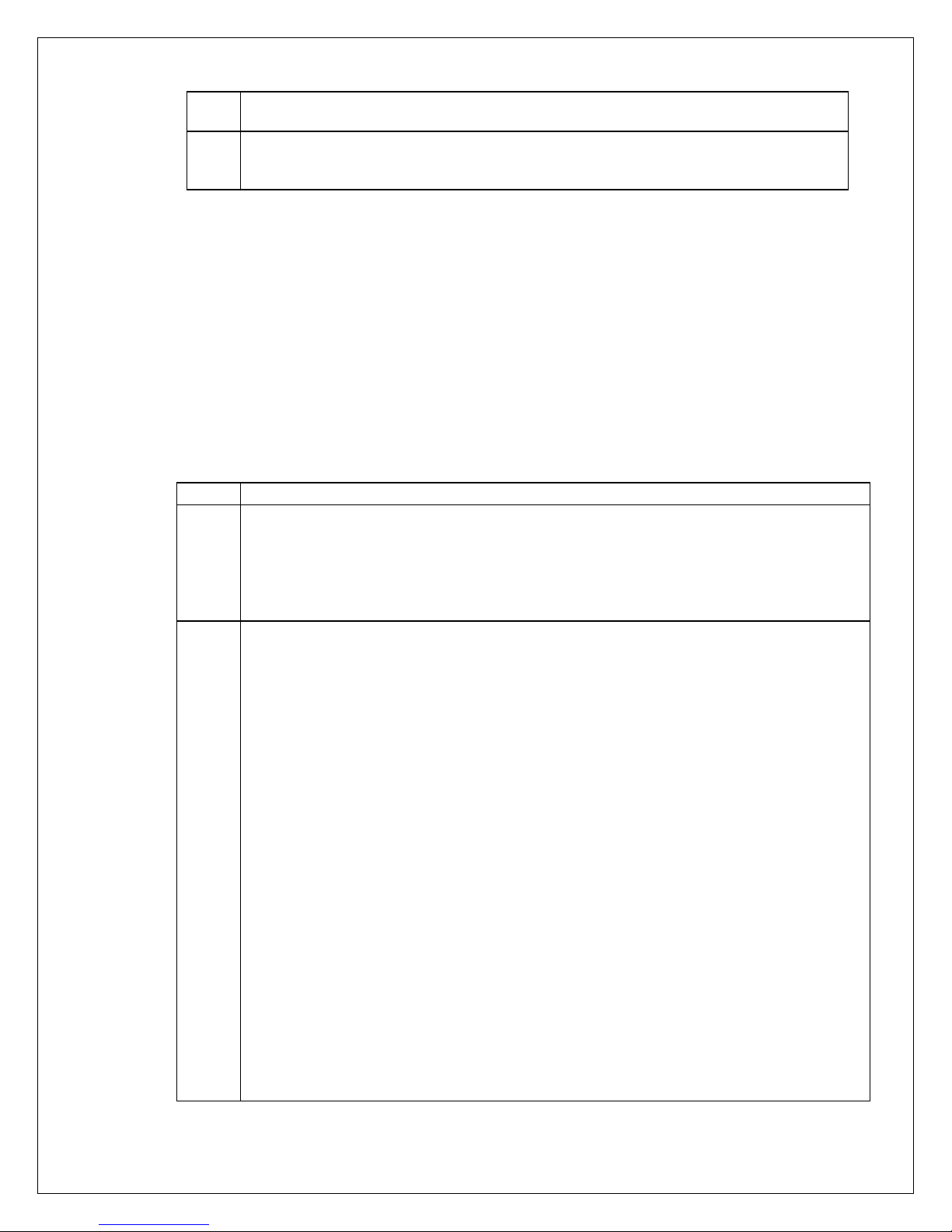

Below is timing sequence for a typical normal exposure.

PMX MANUAL 26 118164-001 REV. A

Page 32

Exposure

kV

T1

T2

kV设定值的

75%

T

Xray_ON

Prep

Exposure

Ready

Filament Inhibit

Enable MA Program

Enable KV Program

DSP Inhibit

Xray On

Ma Servo

HSS Low

Speed States

HSS High

Speed States

STOP

STOP

BOOST

BOOST RUN

STOPRUN

RUN

Hang

Time

RUN

Hang

Time

BRAKE STOP

BOOST

BOOST RUN

STOPRUN

BRAKE STOP

Prep then Exposure

Prep & Exposure

Together

75% kV setting value

There are still other signals reflecting tim ing

relations with exposur e sequence, which are

provided for synchronizing purpose for user

system application.

See below the timing:

X-Ray On

75% Status:

Open collector output signal. High level is

active; indicate that the kV reach to 75%

setting value, and the exposure time begin to

accumulate.

PMX MANUAL 27 118164-001 REV. A

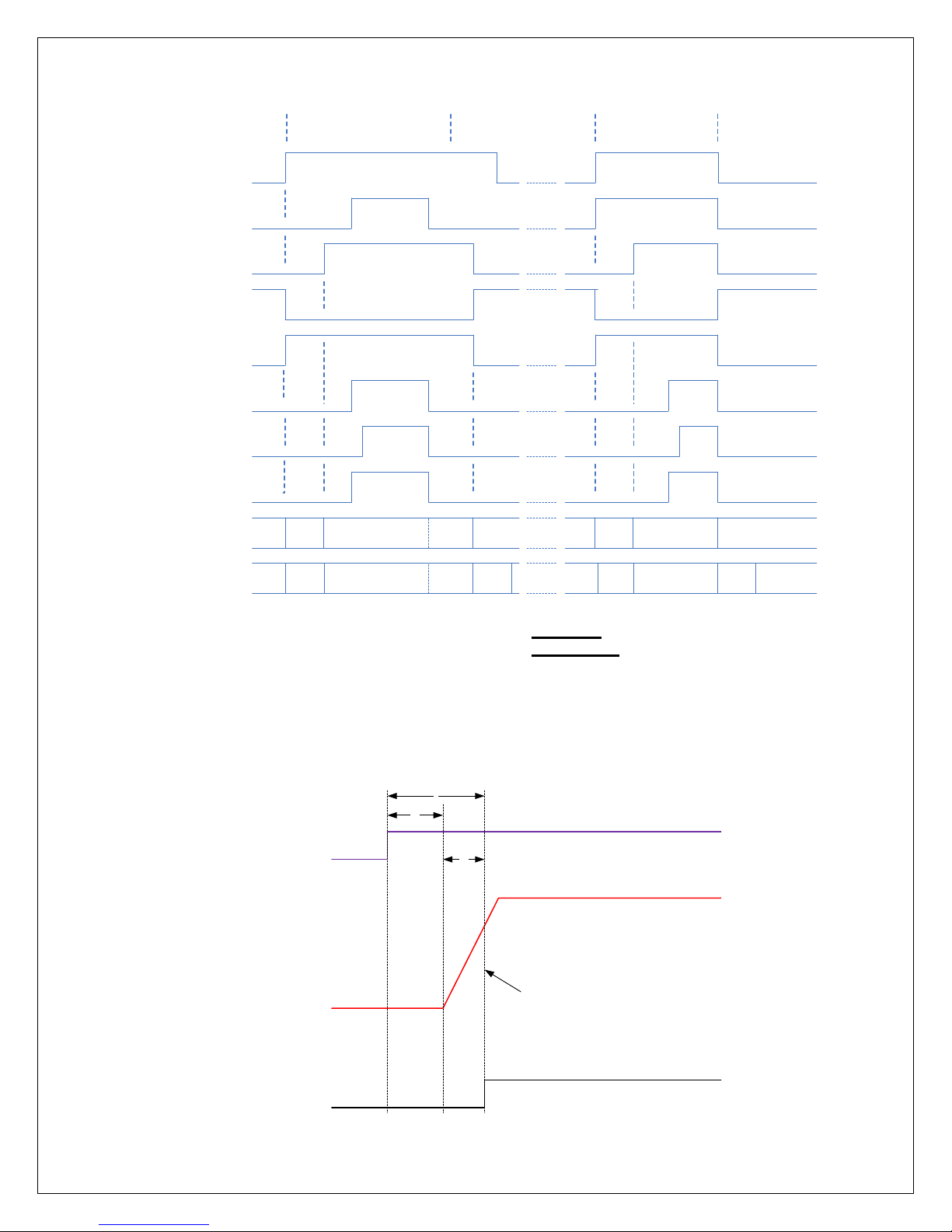

Page 33

X-ray On

KV

Exposure

X-Ray On Status:

Open collector output signal. High level is

active; indicate that the HV output is

beginning.

See below the timing:

4.4.2 AEC Exposu re

In AEC Mode the external AEC control inp ut,

also called “X-Ray SHUTDOWN/AEC”, is

allowed to gate the high voltage on and off. In

order to generate X-Rays Prep, Exposure

Control and AEC must all be in the “ON”

state, which is High (Log ic 1). In ad ditio n the

unit must be in the ready state. When running

in AEC mode the exposure control timer only

runs when the AEC signal is high. The

exposure sequence term inates when any of

the following are true:

1. Prep goes inactive (low)

2. Exposure control goes in ac tive (lo w)

3. The exposure timer times out. (Timer is set

as part of exposure command)

4. The 30 second Prep time is exceeded.

When in AEC Mode it is assumed that the

AEC signal will be in the off state when the

exposure sequence terminates. If the AEC

signal is ON, an under -time fault will occur.

The rotor continues to run when the X-Ray is

shut off by the AEC signal. An example of

AEC timing is show below for the case of

Prep & Exposure together + HSS slow speed.

Also note, in AEC mode Break after

Exposure is automatic ally disabled, and will

not occur even if it is set. In addition the Break

after exposure hang time will be 30 seconds,

regardless of the current setting.

PMX MANUAL 28 118164-001 REV. A

Page 34

Prep

Exposure

Ready

AEC

(X-Ray Disable)

X-

Ray Enabled

X-Ray Disabled

HSS

STOP

BOOST

RUN

STOP

X

-Ray On

See below the Timing.

4.4.3 Smart AEC Expo sure

The main character of this mode is that preexposure is followed by the main exposure at

different parameter settings defined by the

system.

This mode has the ability to change

parameters during a n “exposure sequence”.

Exposure sequence is d efined a number of

Exposures whereby the System gates the

generator ON and OFF by the AEC

Shutdown signal input. The end of each

individual exposure would be normally

terminated by seconds or mAs programming.

In Smart AEC Mode (S-MAC) the exposure is

split into two parts. Both parts of the exposure

are required to use the same filament and

HSS speed, but the k V / mA / ex posure tim e

are allowed to change bet ween the first part

of the exposure and the second part. The

Prep, Exposure Control, X -Ray On (status),

and AEC signals, along with the serial

command port are all involved with Smart

AEC mode. The sequence of events for doing

a Smart AEC exposure is as follows:

1. The host sends the required commands

to set up the exposure. These are HSS

Speed, Filament, kV, mA, and exposure

time for 3 point mode, or Filament, kV

and mAs for 2 point mode. (Note that in

Fig 16 - AEC Timing

smart AEC, 2 point mode HSS Speed is

automatically set to Fast).

2. The host sets Prep “On”. The unit will go

into the Boost / Preheat phase on the

filament. (See Note 1).

3. The host sets exposure control ON and

AEC control ON to enable X-Rays. AEC

may be set ON before or simultaneous

with exposure control ON.

4. The unit will turn High voltage ON. High

voltage will remain ON until the

programmed exposure time has

elapsed. The host should monitor the XRay On status.

5. After the X-Ray On status transitions

from ON to OFF the Host should set the

AEC control to the X-Ray disabled state

(Low). The host must also leave the

exposure control ON during this time.

6. The host must now send the settings for

nd

part of the exposure over the

the 2

serial interface. Any combination of kV,

mA, exposure time if in 3-point mode, or

kV and mAs if in 2-point mode may be

changed. HSS Speed and Filament may

not be changed.

PMX MANUAL 29 118164-001 REV. A

Page 35

7. The host must wait a minimum of 20

milliseconds after the end of the last

command for the PMX unit to process

the commands. By the end of the 20

nd

millisecond period the 2

part of the

exposure will be set up and a new value

of preheat current applied to the

filament. (See Note 2).

8. The host sets the AEC signal High to

nd

indicate the 2

part of the exposure can

begin.

9. The PMX unit will turn High voltage ON.

High voltage will remain ON until the

programmed exposure time has

elapsed. The host should monitor the XRay On status.

10. When the X-Ray transitions to OFF the

exposure sequence is complete. The

Host can set Prep and Exposure Control

including the 2 second time to ready, can’t be

longer than 30 seconds.

Note 5: The AEC control signal M UST be in

the X-Ray disabled state (low) during the

nd

exposure settings upd ate for the 2

par t of

the exposure. The state of the AEC control

signal does not matter when setting up the 1

st

part of the exposure because Exposure

Control and Prep are low.

Note 6: In Smart AEC Mode, Commands,

request last exposure kV monitor and request

last exposure mA m onitor treat the first and

second part of the exposure as separate

exposures. For exam ple if the kV monitor is

requested after the f irst part of the exposure

has finished, but bef ore the sec ond part has

started, the average kV of the first part is

reported. If the k V m onitor is then requeste d

after the second part of the exposure has

finished, the averag e will be for the second

part of the exposure only.

to OFF.

Note 1: The time to read y is 2 seconds. The

exposure control signa l can be set ON prior

to the end of the 2 sec on d t ime, but the High

Voltage will not actuall y turn ON until the 2

seconds have elapsed from Prep active.

Note 2: Even though the new exposure

settings will be programmed and the new

nd

preheat set for the 2

par t of the exposure

within 20 milliseconds of receiving the last

setup command, the filament temperature

will not change ins tantaneously. Turning on

the high voltage immediately after the 20

millisecond period ends will not allow enough

time for the filament to reach the desired

temperature. This may result in large mA

nd

variations at the start of the 2

part of the

exposure.

Note 3: In Smart AEC mode, Break after

exposure is forced to “OFF”, and the Break

after exposure hang tim e set to 30 s econds,

regardless of the previously programmed

values. (This is the same as in standard AEC

mode).

Note 4: There is no specified m axim um tim e

between the first part a nd s econd part of th e

exposure. The limiting f actor is that the unit

can have Prep activ e for a maximum of 30

seconds, so the entire exposure sequence,

PMX MANUAL 30 118164-001 REV. A

Page 36

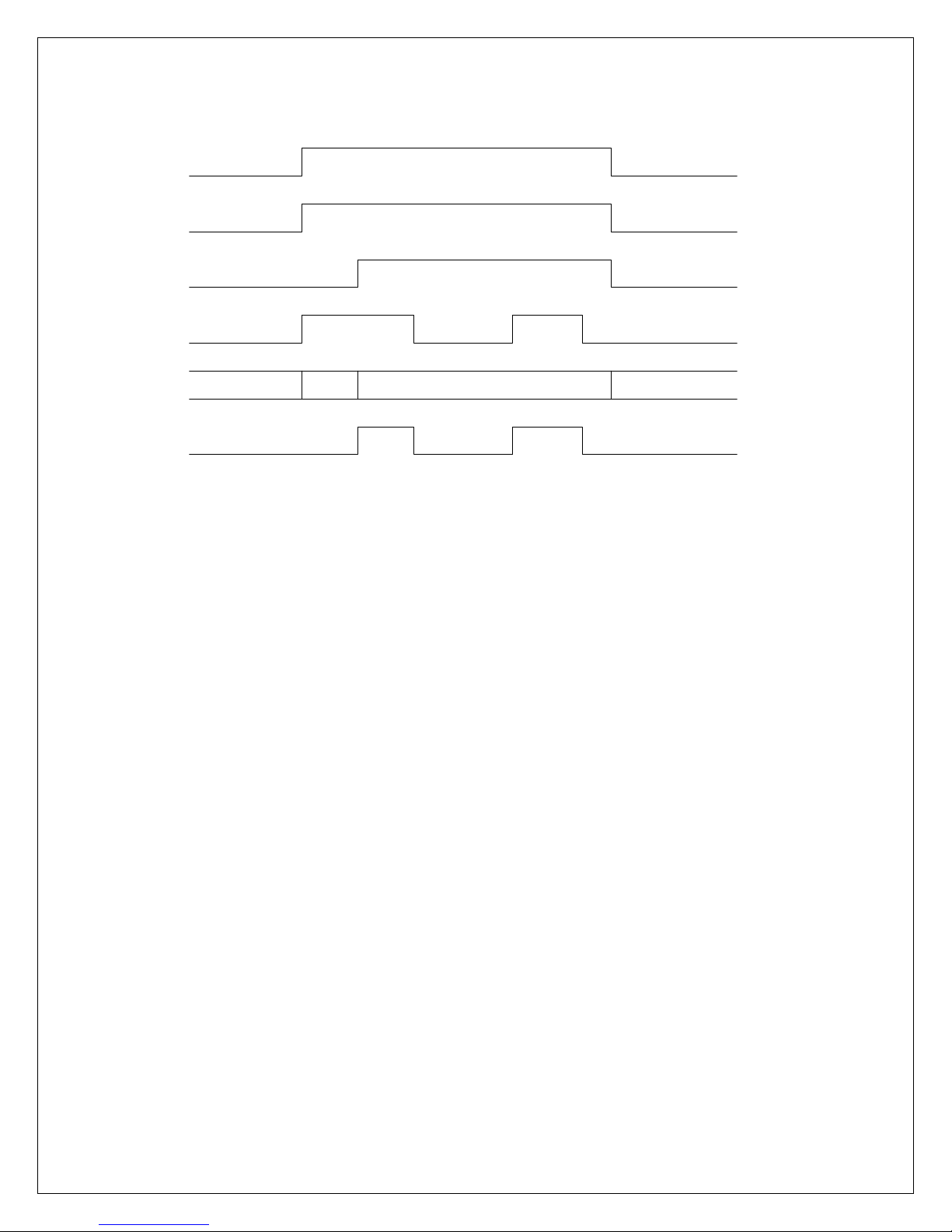

Prep

Ready

Exposure

Control

`

X-Ray On terminated by

exposure timer

X-Ray ON (Status)

X-Ray On terminated by

exposure timer

AEC

(X-Ray Disabled

when low)

Host sends new exposure

settings over Serial Link

20 millisecond

Delay after receiving new exposure

settings for VMX command processing

Exposure part 1 settings used Exposure part 2 settings used

Standby Boost / Preheat 1 MA-Servo 1 Preheat 1

Preheat 2

MA-Servo 2 Preheat 2

Standby

Filament

Host sets AEC Low prior to sending new

exposure settings

Host sets AEC High to

start 2

nd

part of

exposure

2 seconds

Fig 18 – Smart AEC Mode

Previous

Exposure

Value

Previous discarded

kV & mA report

Current values

Exposure Part 1

kV & mA

Being averaged

Exposure Part 1 average

kV and mA held

Exposure Part 2

kV & mA

Being Averaged

Exposure Part 2 average

kV and mA held

Value Returned using Request Last Exposure kV / mA Monitor

See below the timing sequence:

Notes:

Setting the AEC signal low before X-Ray On

status goes low (X-Ray Off) will cause an undertime fault.

Exposure commands sent at an illegal time

such as when AEC is high or X-Ray i s ON will

be ignored and will return a “State Error” code.

Exposure commands used to set up the 2nd

part of the exposure m ust be sent at the time

indicated in the diagram.

Aborting the Sm art AEC sequence by bring ing

Prep and/or Exposure control low in after the

part 1 exposure is finished but before the part 2

exposure is started will not generate a fault.

It is not allowed to change from 2-Point Mode to

It is required to se nd a new s etup between t he

part 1 exposure and part 2 exposure, even if the

new setup is exactly the s ame as the old. This

can be done using the “ Set Exposur e Settings”

command, or Individ ua l set c ommands such as

“Set Exposure kV”, “Set Exposure mA” and “Set

Exposure Time” if in 3 point mode, or “Set

Exposure kV”, and “Set Exposure mAs” in 2

point mode. It is allowed but not required to

send a Set Filament or Set HSS Speed

command, provided t he setting is the sam e as

in the part 1 exposure.

3-Point mode or the revers e in the middle of a

Smart AEC exposure.

PMX MANUAL 31 118164-001 REV. A

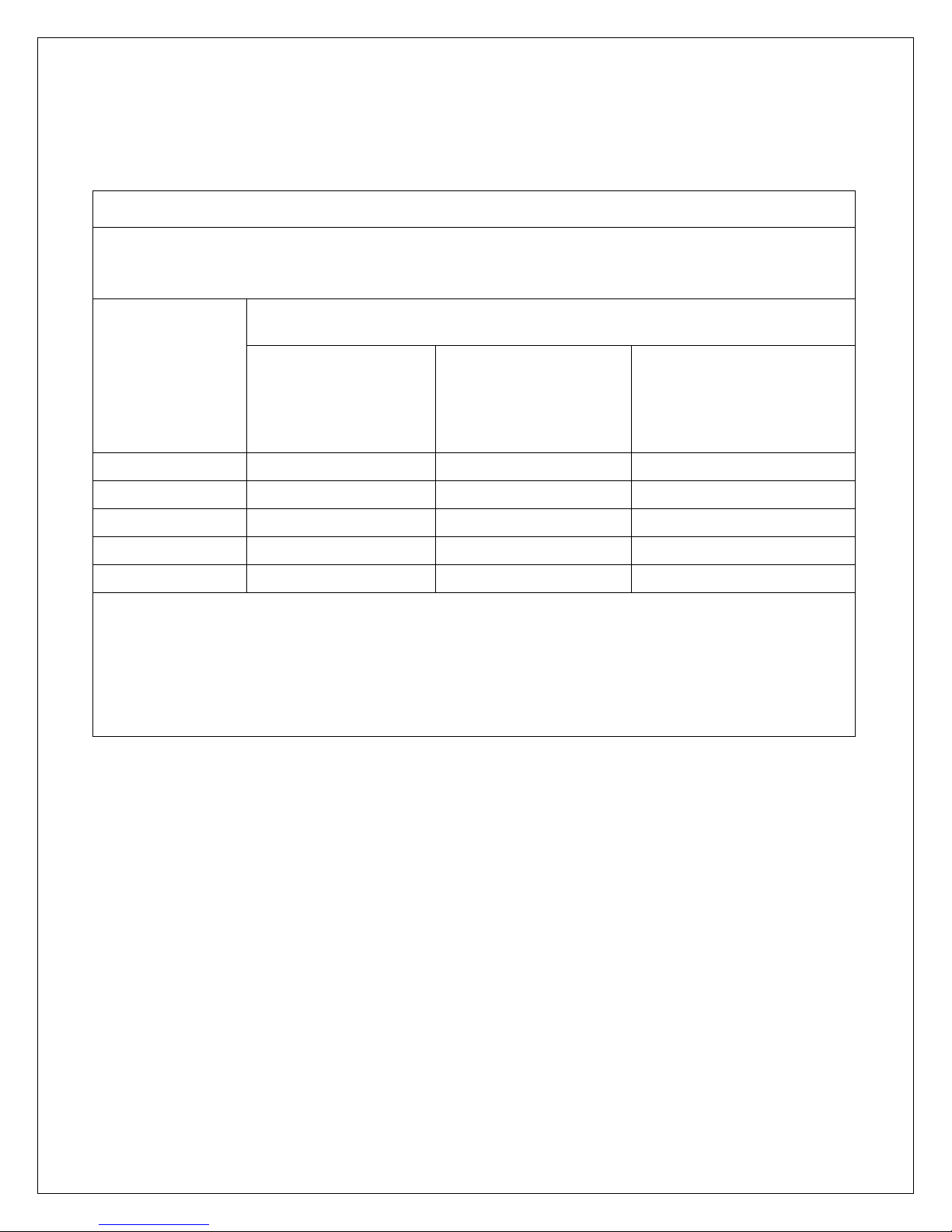

Page 37

LED

DEFINITION

COLOR

NORMAL

STATE

FUNCTION

DS1

Not used

DS2

+24V

GREEN

Lit

Indicate +24V power supply is acti ve.

DS3

DSP Alive

RED

Lit DS4

STATUS BIT1

YEL

Lit

3 bit status lines for status

messages matrix.

DS5

STATUS BIT2

YEL

Lit

DS6

STATUS BIT3

YEL

Lit

DS7

READY

YEL

Lit

Indicate the generator is ready for XRay exposure.

DS8

SPARE

YEL

Lit

DS9

FAULT

RED

Lit

Indicate generator fault.

DS10

X-Ray

shutdown/AEC

YEL

Lit

Indicate the status of the s ignal ( JB1-

12).

DS11

SF

YEL

Lit

Filament selection indicator.

DS12

Rotor on

GREEN

Lit

Starter status indicator.

DS13

HSS fault

RED

Lit

Indicate high speed starter fault.

DS14

Prep

GREEN

Lit

Synchronizing indication of Prep

signal.

DS15

Safety Int’lk

GREEN

Lit

Safety interlocks status indication.

DS16

X ray ON

RED

Lit

Synchronizing indication of X-Ray On

signal.

DS17

FPGA HEART

BEAT

YEL

Lit

Indicate FPGA is working.

DS18

Rotor brake

YEL

Lit

Indicate brake status of starter.

CHAPTER 5

TROUBLE SHOOTING

5.1 INTRODUCTION

Fault or error message will be indicated via

system status indicator or serial message

during abnormal operation. This Chapter

contains tables of those messages and

suggests actions to be taken by service

personnel to correct an y malfunctio ns that m ay

occur.

System Control Board 460220-001

5.2 STATUS AND ERROR CODES

5.2.1 Status Messages

LEDs provide status indication of the necessary

diagnostics needed for recognizing the

operation/shutdown mode of the generator.

LEDs display the following information:

messages.

Refer to chapter 3 the status

PMX MANUAL 32 118164-001 REV. A

Page 38

NAME

Arg. #

DESCRIPTION

ACTION

Interlock 1

1

General Purpose Interlock Input 1

(Originally called Tube

the input pin results in a fault

condition. This was originally

for other purposes.

Check the short connection.

Interlock 2

2

General Purpose Interlock Input 2

(Originally called Tube Flow). An

open/logic high on the input pin

faulted condition. This was

for other purposes.

Check the short connection

HSS Fault

3

High Speed Starter Fault – Any Fault

1. Check the AC line voltage.

times boost within 1 minute.

ARC

4

ARC Fault – T he un it sh utdo wn high

voltage because an electric arc

occurred.

1. Check HV cable connections.

3. Replace the X-ray tube.

Over Power

5

An attempt was m ade to tu rn on the

a power output of greater than 5kW.

Over Time

6

This fault is possible only in AEC

because of the expiration of the

timer with AEC active)

Ensure that the cumulative time in

one exposure sequence not

Over mAs

7

The mAs of the current exposure has

value * then set exposure time.

Over Duty

8

The unit requires 20 seconds inbeing defined as entering prep,

Ensure that the exposure

operation within the duty cycle

limitation.

5.2.2 Faults Messages

Temperature). An open/logic high on

condition. A Logic low / Short to GND

is the “Good” or non-faulted

intended for connection to a tube

temperature switch, bu t can be used

results in a fault condition. A Logic

low / Short to GND is the “ Good” or

nonoriginally intended f or connection to

a tube flow switch, but can be used

related to operation of the high speed

starter.

generator with sett ings that result in

Mode. It indicates the unit shut-down

exposure timer, rather than the AEC

control signal. (Tim eout of exposure

exceeded the set value by 25%. This

is calculated by taking the average

current and multipl ying by exposure

time. The unit will fault immediately

when this happens, and shut down

the high voltage. Note that when in 2

point mode the limit is set to 125% of

the value programmed using the “Set

mAs” command. In 3 point mode it is

calculated by multi plying the set mA

2. Check the low voltage cable

connections.

3. Ensure that no more than 2

2. Season X-ray tube.

exceed the exposure timer (ms).

In AEC mode, expos ur e ti mer acts

as back up timer.

PMX MANUAL 33 118164-001 REV. A

between exposure cycles. A cycle

Page 39

exposure control on, high voltage on,

if the cumulative

AOP mode.

Over

9

This fault occurs if the output voltage

more).

Consult product support.

Over Current

10

If the output current exceeds 213.8

this fault will occur.

Consult product support.

Regulation

11

This fault occurs if the actual kV is

25% of the set

mA regulation.

1. Chec k the line volta ge in g ood

Open

12

Tube filament shows open (zero

applied to

1. Check the LV cable

3. Consult product support.

Filament

13

The filament current has exceeded

ubes, but as additional

tubes are added, this value may

change for the new tubes.

1. Check the preheat value.

hange setting value and

Ac/Dc

14

The rectified input v olt age t o th e uni t

more.

Check input line voltage

high voltage off, exit prep. The unit is

also limited to 5 seconds of exposure

time in any 2 minute period. If an

attempt is made before to turn on

high voltage in less the 20 seconds

after the last expos ure this fault will

occur. Also,

exposure time over the last 2 minutes

exceeds 5 seconds and an attempt is

made to turn high voltage on this fault

will occur.

Note: The 20 second lim it does not

apply to high voltage o n / off cycles

that are part of a sequence in AEC or

Voltage

Filament

(overcurrent)

exceeded 60kV for 1 mill isecond (or

mA for 100 milliseconds (or more)

exceeded by +/-10% or mA output

has exceeded +/value.

Note: There is a delay from high

voltage on to when the k V and mA

are checked to allow tim e for the kV

and mA to stabilize so false faults are

not generated. This time is 30 msec .

for kV regulation and 250 msec. for

current despite voltage

filament) for more than 2 seconds.

the set maximum limit of for more

than 200 msec.

The set lim it is 5.2A for all currentl y

supported t

condition.

2. Replace the X–ray tube

3. Consult product support.

connection

2. Measure filament resistance to

verify filament condition.

2. C

verify again.

3. Change to another X-ray tube.

4. Consult product support.

PMX MANUAL 34 118164-001 REV. A

is less than 255V DC for 1 second or

Page 40

Under Time

15

In manual or sm art AEC m ode, the

e to the

removal of the Prep or exposure

of the exposure Timer. (Exposure

was shorter then programmed).

Verify the control timing in

accordance with the function

Safety

Fault

16

An attempt was made to start an

exposure with the safety interlock

open. High voltage will not go on.

Check the safety interlock

Setup Fault

17

An attempt was made to start an

unit. High voltage will not go on.

Verify the setting value.

low and are not likely to cause any

is suitable for use in all

exposure terminated du

protocol.

control signals prior to th e expiration

Cannot occur in AEC mode.

Interlock

exposure (turn high voltag e on) with

connection.

an illegal setup progr am med into the

Notes:

If high voltage is on when a particular fault

occurs the high voltage will immediately be shut

off.

Over Time and Under Time faults can only

occur at the end of an ex posure (immediately

after high voltage is turned off). These faults

indicate an error in how the control signals were

the mode the unit was set up in, rather than a

fault in the PMX supp l y ope ration .

Over Duty faults can only occur at the transition

of exposure control fr om off to on. That is, r ight

at the start of an expos ure. Once an exposure

is started it will be al lowed to continue even if

after it is finished the on time exceeds 5

seconds over the previous 2 minutes.

applied as com pared to what was expected for

Table 1 – Guidance and MANUFACTURER’S declaration – ELECTROMAGNETIC EMISSIONS – for all ME

EQUIPMENT and ME SYSTEMS

Guidance and manufacturer’s declaration – electromagnetic emissions

The PMX is intended for use in the electromagnetic environment specified below. The customer or the

user of the PMX should assure that it is used in such an environment.

Emissions test Compliance Electromagnetic environment – guidance

RF emissions

CISPR 11

RF emissions

CISPR 11

Harmonic

emissions